Equipment House Thrives With Expansive, Solution-Based Lineup

Able Tool & Equipment was founded by Derek Bauer in 2005 at its original location in a one-bay garage in East Windsor, Conn. Within a few years, they moved to 410 Burnham Street, South Windsor, Conn., and shortly after a second location at 120 Interstate Drive, West Springfield, Mass.

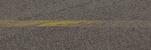

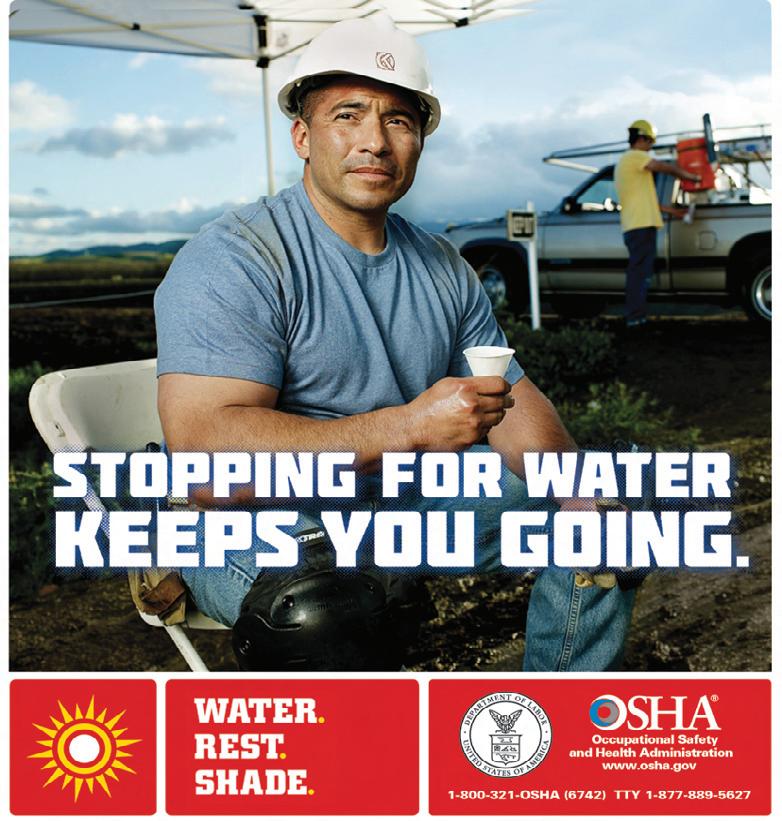

If asked to describe Able Tool & Equipment, Bauer would say that it is the distributor of light and compact equipment for the construction industry with an extremely diverse list of suppliers with the focus being on the heavy highway, concrete, excavating and utilities industries. The company offers all standard items, such as light towers, compressors, excavators, compactors, concrete buggies and more.

But Able Tool & Equipment also takes pride in identifying highly specialized items to help its customers satisfy challenges on the job site — items that not just any equipment house would have on hand.

Some of the companies that it represents are household names within the equipment industry, such as Wacker Neuson, Sullair, Gorman Rupp, EZ Drill, Chicago Pneumatic and Husqvarna. Because of its efforts to fill niche markets, there also are names that might not be as familiar, such as Weber, Hoffman Diamond, Michigan Pneumatic, Corecut, Kenco, Garbro, Miller Spreader and many more.

The equipment that Able offers is available for sale, but like every other equipment house in the industry today, rental is what the business is all about, and the company has rental programs to fit the needs of any customer.

“It was April the year of the COVID breakout, in fact just one month after COVID

Bauer has an extensive knowledge in the equipment rental business, partially because he had an extensive training period working for two of the major national equipment rental chains before starting his own company. Once he made up his mind to get Able Tool & Equipment started, he worked long hours seven days a week with the support of some really good employees and a wife who shared his vision to build a strong, successful dealership, only to have the main facility in South Windsor, Conn., completely destroyed by fire. (See Recovering From Disaster, below.)

The rebuild process took two years to complete. At times it was an unpleasant two years, as they were working in an incomplete building

THE NEW ENGLAND EDITION A Supplement to: Your New England States Connection • Kent Hogeboom 315-866-1423 ® “The Nation’s Best Read Construction Newspaper… Founded in 1957.” January 18 2023 Vol. LXI • No. 2

Derek Bauer, president of Able Tool and Equipment.

hit the U.S. in 2020,” said Able Tool & Equipment Founder, Derek Bauer. “As if things weren’t bad enough. We were busy working on an expansion on a property next door, building a significant warehouse to get more of our equipment under roof. We were really in the early phases of construction; the building was see ABLE page 4 Recovering From Disaster see FIRE page 4 In April of 2020 a massive fire destroyed Able Tool and Equipment’s South Windsor, Conn., facility. Specializing in: Demolition, Portable Crushing, Material Sales, C & D Recycling, Land Clearing, Heavy Hauling & Trucking Call for Pricing 2208 Plainfield Pike • Johnston, RI 02919 401-943-7100 • Fax: 401-647-5041 www.jrvinagrocorp.com info@jrvinagrocorp.com LEED Accredited in Waste Management m O DI G DE T E DRAC U 978-454 . P T T, , MA -3320 BROCKTON, MA 508-484-5567 OW B W, , N H 603-410-5540 omDoosanCorp underlicensef used s TheDoosantrademark Group ries sIndu avy a He Hyund e of at l an affi s acore an Inf s a Doo Hyund eserved rights acore.A undaiDoosanInfHy 2023 © poration. CALL 800-367-4937 *On approved credit Financing Available SHIP WITHIN 48 HOURS SAME DAY PARTS AVAILABILITY 24 HOUR TECHNICAL SUPPORT BACKED BY A 75 YEAR BUSINESS State Supplement sponsored by: Affordable Price. Premium Service. Thousands in Service! CALL YOUR ONE-STOP HAMMER SHOP™ TODAY!!! CALL 888-81-GORILLA(46745) • Largest hammer repair facility in North America • Demolition tools and parts for ALL makes and models • Hammer-equipped excavator rentals • Backed by a 75 year family owned business Tibbits Equipment Services, Inc. www.tibbitseq.com 802-479-9696 Specialty Construction Equipment SALES • RENTALS • HAMMERS Since 1989 KWIK KLEET® Traction Cleats www.foleyengines.com • Exhaust Scrubbers • Perkins Engines • Deutz Engines • Twin Disc/Rockford Clutches ‘05 Caterpillar 928G $36,800 Phil (413) 427-7171 This space available for annual contract. For pricing contact Kent Hogeboom (315) 866-1423

Page 2 • January 18, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide See Our Complete Inventory at www.wiclark.com stk# 26327, 653 Hrs, ROPS, Deutz diesel, single drum vibratory, good rubber, like new condition..............................................$64,500 2018 HAMM H7I 2014 DEERE 60G stk# 27845, 1400 hrs, hyd thumb, 24" bucket.. ............................................................$66,500 2018 DEERE 50G Cat power, 6'5" 15mm drum, rigid conveyor, 60% bottoms, good belting with grade, stk# 26377................................................$125.000 2010 WIRTGEN 2100 2019 JOHN DEERE 333G stk# 27812, 3300 hrs, skid steer cplr, coupler, 1yd bucket............................................$63,500 2015 DEERE 204K 2300 hours, push blade, hyd thumb, 80% tracks, Stk#27970................................$42,500 2012 DEERE 35D 2018 GENESIS GSD170 stk# 27786, mount plate and stiff arm. Minimal usage on grapple. Fits Deere/ Hitachi 850 class excavators..................................$35,000 C/air, angle blade, hyd thumb, 24" bucket, new tracks, Stk#27764................................$67,500 Call Mark Doty @ 203-823-2316 stk# 24340, 1493 hours, 78” drums, dealer maintained since new, very good condition...... $84,500 2014 HAMM HD+120IVVH stk# 27123, c/air, hi flow hyds, 2 speed, forestry package, new tracks, 84” bucket........ $79,500

OPRROOVVEN U

WITH UPTI

SENNEBOGEN, in kee philosophy to maxim created UPTIME Kits

m and

eping with their mize uptime, has Whether you are a service technician i road, these kits have need for every service and PM task in one p created to save you t Managing hundreds o parts, from belts and and special tools bec single part number to 2-6351 ) 29 (800 ongmead ast L E oa er R 1 Shak 25 yle t.ww our to commitment our

more in

n-house or on the everything you e, maintenance place. They were ime and money. of related service d nuts to O-Rings omes easy with a o order and stock w bout

C (800 Berli 1980 28 A 010 , M ow d om omers

and ready to built to match 52-4473 ) 3 0 7 in, CT 0603 urnpike 0 Berlin T sennebogeen-na.com/beyond-the--machine

the best thing is in requipment.c cust

th s that

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • January 18, 2023 • Page 3

BEYOND E H HE HIN D T MA virtual I ntime losellyt They are: • Easy to order and ea t d t stock asy to s l dow NO North our in parts com with customers maxim commitment h about more Read ontract Demolition C st in parts repair the have virtu and I machine another in If back. to front every come t a have They echnician machine, wntim warehouse. American ready-to-ship of inventories plete for uptime izes aftersale Machine” he “Beyond our ow , Bloomfield Hills, MI or quickly. back unit the g I k they Since do no lose ally bring just [they] situation, a have I over go to month a once through wntime… ock. get theSENNEBOGEN y-t t act OGEN f tor ained technicians tr ned tec cians components and too • Ideal for stocking se and trucks Choose from the follo • Central lubrication • Preventive mainte • O-Ring kits • Electrical service k Hydraulic service k :kits shops ols ervice owing kits system kits nance service kits its kits rain e • T ervic ts • S Par e for (TCO) Ownership of thinki We’re equipment. par ing • Application Special customer very to machine” the “beyond ng NEBOGENNN BOGEN SEN ctor suppor xible Financing lists • Fle a uptime dependable deliver througho t ttachments • A Cost Total lower and its of life the out • Hydraulic service k And

stock

your

series. Count on in-house. For

UPTIME Kits, scan

these kits, go, are custommachine model SENNEBOGEN nformation

QR

PTIME IME KITS a more Learn

on he

code.

Able Tool & Equipment Succeeds By Staying ‘Super Focused’ On Offerings

Recovering From Disaster

with no heat in the winter and no air-conditioning in the summer.

“My wife did everything she could to help relieve a lot of the stress that was going on during this difficult period. She has always been very supportive from the start. She doesn’t come into the office every day, but she is always there if we need her. It might be running to the bank; it might be organizing a company Christmas party, or taking care of gifts for customers … she’s there when I need her, so I can stay focused on running the business.”

When asked how he would describe his business today, Bauer replied, “I tell people we are a boutique business. We really are focused. The analogy I use all the time is a gun comparison. You can go buy your guns at Walmart or Dicks Sporting Goods or you can choose to go to a gun store and deal with people who are experts in firearms to discuss your needs.

“We fancy ourselves as the experts in what we do. We are super focused on the product lines that we offer and on the type of contractors we serve. I have employees and customers that will ask why we don’t move into larger earthmoving machines or other areas of the construction industry outside of what we do, and my answer is ‘we are really focused on what we’ve got, and we can’t be everything to everybody. We have had the opportunity to cherry pick

FIRE from page 1

basically a metal shell.

“It was a Wednesday morning at 8:15. You could smell smoke. Our first thought was that maybe one of the motors on a fan inside the building had burned up. We were trying to identify it, but we weren’t overly concerned. So, we started to open up all the doors to the building to try to ventilate and identify what was going on and it had just the opposite of the desired effect. There was a fire inside and we managed to feed it lots of oxygen and fan the flames.

“The next thing I knew, one of my employees was running to my office telling me to get out of the office right away because the building was on fire. I ran out to the shop and saw three of my guys up on the mezzanine trying to fight a fire that was now climbing up the sides of the walls. It was obvious the fire was now out of control, and it was time to call 911. We evacuated the building and waited and watched.

“When the fire department got there, we still thought it was not going to be a huge deal, they will knock the fire down, we’ll do some repairs, we’ll be OK. But the fire had made its way up into the ceiling and when the doors opened, the insulation caught fire and started to drop down into the main building spreading the fire everywhere. Unfortunately, we had some flammable products in the shop, including a product called Tanner gas, which is an alcohol-based product and is used as a de-icer in air systems and air tool applications.

“The firemen came to me and said something is going on in a part of that building; we add water and the fire gets bigger. Those chemicals were literally turning into bombs. The fire got so hot that the steel beams of the building literally turned red and melted. The building became a total loss.

“As I stood back and looked at it, it reminded me of pictures that I have seen of the Dresden fire bombings. Even as the fire was still burning strong, one of my employees [Andy], who thank goodness was thinking ahead, suggested that he take his laptop and head out to the Springfield, Mass., store, to let Springfield know what’s going on, coordinate with our software provider and the phone company so that calls and leads are being routed to Springfield. That was a fast process and thanks to his quick thinking we were able to take care of customers in a relatively short period of time.

“The next day we started to piece things together. We put planks over sawhorses and that became our counter. We did have heat in the partially completed warehouse, but it was a shell of a building and had

Page 4 • January 18, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

The fire got so hot that the steel beams of the building literally turned red and melted. The building became a total loss.

see

page 8

FIRE

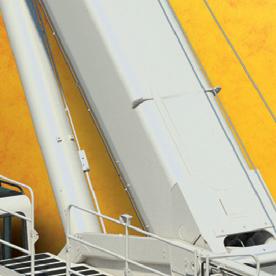

Able Tool and Equipment’s new shop area.

see ABLE page 8

ABLE from page 1

Able Tool and Equipment offers one of the largest inventories of Wacker earthmoving equipment in the Northeast.

The rebuild process took two years to complete.

DRACUT 978-454-3320 61 Silva Lane Dracut, MA 01826

BROCKTO 508-484-55 196 Manley Brockton, M

ON 567 y St. MA 02301 a om Doosan Corpor , is used under license fr TheDoosantrademark, oup yundai Heavy Industries Gr acoreisanaffiliateofH yundai Doosan Infr H ved. eser ll rights r e. A acor yundai Doosan Infr 2021 H ©

BOW 603-410-5540 1474 Rte 3A Bow, NH 03304 y. Schedule a demo today ation.

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • January 18, 2023 • Page 5 AUTHORIZED DOOSAN DEALER

www.equipmenteast.com

Page 6 • January 18, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • January 18, 2023 • Page 7 oven world r P ele-craw e d-class T MERICA! H WLER wlers MEERRIICCAA! NOORTTH R WLEER L#1T L#1T AM TELECRA LINE-UP W A N E-UP -C -U IN A ELLEE-CRAW etts 508-499-1950 02-658-1700 | 68m main boom | 223 ft Massachus mont 8 erVe TELESCOPIC CRAWLER 230 mt | 250 t 4 cameras! Vision packageUltra-wide winch design Superior capacities with full attachment 105m max tip height 348 ft , U entucky exington, K L www.woods ork 3 o New Y Pennsylvani .linkbelt.com SA | www w.com scr 315-676-2008 a 717-795-0700 THE MARKET! IN ABLE AILAVA ACITY A HIGHEST CAP BUY • LEASE • RENT

Able Founder Credits Experienced, Strong Service, Sales Teams for Success

what we do and what we don’t do. That makes sense for us, and it’s become our strength in the marketplace.’

“We certainly have some items that you can get anywhere, that honestly no one is really an expert in. Mini-excavators, skid steers would be examples. But then there are categories like compaction or more specifically, light compaction. Nobody in New England does light compaction like we do. You will not see more light compaction equipment in a yard anywhere than what we carry in inventory.

“When you talk about air tools, particularly mid-size and small air tools, and the compressors that go with them, the guys that are using a lot of air hammers, that’s an area that we really focus on and have invested in a massive inventory. With these specialty tools we not only sell and rent them, we also service them, which not just anyone can do.

Through the design and construction process, overhead cranes were incorporated in the shop to assist in the work on larger pieces of equipment; larger doors were incorporated to make access easier; a mezzanine was incorporated for parts storage.

“It’s no longer possible to do this all the time, but we try very hard to buy American anytime we can and with that comes dealing with suppliers that you really believe in, that you can develop a relationship with, that have specialists on their staff who can come help you when you need them. I particularly enjoy my relationship with some of the smaller American companies that we work with. Companies like Miller Curber, Garbro, Allen Engineering, Michigan Pneumatic, EZ Drill and some others. These companies are very flexible and when you get into a unique project, they will work with you to solve the specialized needs and challenges of the customer.

“We work with a company called Gar-Bro who makes concrete buckets. We are his distributor for New England. The owner of the company comes up and calls on us in person. We understand concrete buckets like nobody else in New England. What we do here is different than a heavy equipment or earthmoving shop. We solve very specific problems such as what size generator to match up with a particular product or what plate compactor is going to work best

in this particular application. Very few people work with bridge deck screeds like we do. We are experts in that area.”

Bauer takes great pride in the service and support after the sale or rental that Able Tool and Equipment is able to give to its customers.

“It starts with the sales team … with a group of just really good people, some have more experience than others, but these are the guys that ‘hook’ our customers.’ Both the inside and outside sales staff is largely a very experienced group. This has been one of the keys to our success — really strong employees. And add to that the strength of our service department. The experience runs deep on this side of the business, as well, including our Lead Technician Peter Davis, who has been nationally recognized by Wacker Neuson as one of their best in North America.

“We have very good service techs who have been with us a long time and are extremely knowledgeable. That’s hard to find, particularly when you are working with some of the see ABLE page 14

Recovering From Disaster

no phones. We started sending e-mails out to customers letting them know that we were still open for business.

“My thoughts turned to the insurance company and what was the cause of the fire and will everything be covered. We never did find what the cause of the fire was. The fire inspector starts asking you scary questions like ‘do you have any disgruntled employees,’ and all of this was going on in the first week of April, a key period of business for us. We knew we had to stay open and keep moving forward.

“It turned out the insurance company worked wonderfully with us. Our claims adjuster was very fair, he took good care of us. There’s just so much to try to piece together as far as what was inside the building. You know about your whole goods inventory, but parts can be tricky, and your employees have their tools. Do they know the inventory of their tools? Some of our mechanics have nearly $100,000 invested in their own tools. It turned out the insurance company had a very limited coverage for employees’ tools so to be fair I reimbursed our employees for those losses. Verifying what was lost was certainly a challenge because many items simply melted from the heat. But, again, the adjuster was fair. If we gave him an accurate description of the items that could be identified, he assumed that our description of the rest of the items was also accurate.

“We immediately started working with a contractor making plans for and building our new facility. It was tough losing the building we had, but it was not a purpose-built facility for what we do, and this new facility was certainly going to be an opportunity for us to design something from the ground up to meet our needs.”

Bauer then contacted a contractor who had previously done some interior work on the old facility. He immediately got an office trailer into the site to help relieve some of the pressure. Through the design and construction process, overhead cranes were incorporated in the shop to assist in the work on larger pieces of equipment; larger doors were incorporated to make access easier; a mezzanine was incorporated for parts storage.

“The contractor was wonderful to work with and we had some very heartwarming experiences in the process. Our neighbors and our customers started to blow up my phone offering help. Items like desks and chairs started to show up along with office supplies. Some people sent us in lunch or coffee … Really too many items to list, but it really made me realize that a focus that we’ve had for years on taking care of our customers wasn’t missed by the people we serve.”

And the people who take care of the customers, Able’s employees, were an integral part of the business successfully recovering from the fire.

“Without all of our team members coming together, working together and all striving to overcome this disaster, we could not have done it,” said Bauer. “I continue to be extremely appreciative and grateful for their efforts. Achieving loyalty from your team members during good times is easy, but during very difficult time is when you really find out how much people care about you. We’re truly fortunate to have such dedicated people working at Able.”

Page 8 • January 18, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

Able Tool and Equipment has one of the largest inventories of mini-hammers in the area.

Able Tool and Equipment’s new showroom.

CEG

FIRE

4

from page

ABLE from page 4

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • January 18, 2023 • Page 9 O Y NTHE R OUR O ELINE PUT E R VE EE NATIO Y Y IS YDA olu s S Sale engineered p y ee t k tha . T t t i e e g W d t ee u n o Yo eep s k Job Y unni d r n p a u u p yo ee t k ha s t tion P y entalit ” m one t d t i ge h a “ wit t n u g o ollin . R ward or g f ovin u m o h g t akin n m ee e b ’v y we h s w hat’ fi f e e or d m n r a aste e f on t d t i e o g eep s k imeline . T ougher g t tin get . ng. ter f Af rovidin achines w m e oves g m i e b ciently ter hor g s tin get g A tach u onstr C i h tac i H e y Becaus hi cm.us c n as c r me A y r ne h ac M on t c t e i v eser s d ustomer r c u d yo n . A t d i ne ar e e ou’v i Milford, NH 603.673.2640 Brentwood, NH 603.642.5666 Concord, NH 603.225.3361 chappelltractor.com Now Your Hitachi Dealer for Vermont, New Hampshire and Massachusetts

Connecticut’s Gold Star Memorial Bridge, spanning the Thames River to link the cities of New London and Groton, is receiving a much needed $158 million from the Biden Administration to help in its rehabilitation.

WTNH.com, a New Haven TV station, reported that U.S. Secretary of Transportation Pete Buttigieg made a stop in New London Jan. 4 to officially announced the Bipartisan Infrastructure Law funding for the northbound portion of the bridge.

The project is now expected to be completed a year ahead of schedule.

The Federal Highway Administration (FHWA) had noted earlier in the week that the grant was coming and would be part of the first round of large bridge grants from President Biden’s competitive Bridge Investment Program.

The funding will now go to the Connecticut Department of Transportation (CTDOT) to pay for the bridge’s improvements. The structure is part of the Interstate 95 corridor and is a vital connection for people and goods traveling between New York and New England.

The Gold Star Memorial Bridge is made up of a pair of steel truss bridges, totaling 11 highway lanes, which carry both I-95 and

U.S. Highway 1 across the river. The bridge’s south span opened in 1943, while the northbound span was completed 30 years later. It is the largest structure in the state with more than 1 million sq. ft. of deck area, and the longest bridge in Connecticut at 5,031 ft.

The five-lane northbound span carries 60,000 vehicles a day between New London and Groton.

“As everybody here knows, the bridge is not in good enough shape,” Buttigieg said. “It’s about to turn 80 years old. Parts [of it] have been given a rating of poor.”

In fact, WTNH.com noted that the bridge has only a 40-ton weight limit, forcing many trucks with heavy loads to travel the long way around.

“Every day, as was mentioned, we have to make the decision of taking that 17-mile loop around or loading our trucks underweight,” said Carolina Cavalcante, president of Tilcon Connecticut, a leading supplier of stone, hot mix asphalt and concrete in the state.

Federal Grant Allows CTDOT to Complete Rehab

With the funds in hand, CTDOT plans to rehabilitate the bridge in two phases. The initial work began last spring to replace more than 160,000 rivets with high strength bolts and will continue until June 2025.

A month after that, the second phase of the contract is slated to begin and is likely to last for another four years, according to CTDOT.

“The rehabilitation will address structural repairs, increase load capacity and eliminate a load restriction for overweight vehicles,”

FHWA noted in a news release.

In addition to alleviating congestion and safety issues for communities in southeastern Connecticut, upgrades to the Gold Star Bridge will mitigate delays in the movement of freight that currently raise costs for American families, according to Hartford’s WFSB-TV.

“Safe, modern bridges ensure that first responders can get to calls more quickly, shipments reach businesses on time, and drivers can get to where they need to go,” explained Buttigieg. “The Biden-Harris Administration is proud to award this historic funding to modernize large bridges that are not only pillars of our economy, but also iconic symbols of their states’ past and future.”

WFSB-TV reported that CTDOT also will add a new multi-use path to the northbound Gold Star Bridge span to foster bikesharing and pedestrian access to transit services.

As part of the selection process for this first round of the federal Bridge Investment Program grants, priority consideration was given to projects ready for construction, as well as those that need pre-construction funding, and would benefit from a multiyear grant agreement.

Page 10 • January 18, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide The Nice Company, Inc Equipment Sales and Rentals 9 Rosenfeld Drive, Hopedale, MA Toll Free# 508-381-3939 • www.theniceco.com We sell NICE machines! 2021 Hamm H11i, 5 hours, Heat/AC/Radio, 84" Drum, Work Lights, 24K lbs., Immaculate Condition! $124,500 2018 CAT 336FL, 2500 hours, Single Grouser Pads, 54" bucket, QC, AC/Heat/Radio, Rear Camera, Long Undercarriage $259,000 2016 Hamm H7i, 850 hours, AC/Heat/Radio,66" Drum, Work Lights, Kubota Engine $79,000 2003 CAT D8R, New Engine!, 375 hours, 80% UC, Recent Equalizer Bar, Work Ready! $149,000 2014 CAT 730C, 600 Hours, 6x6, Rubber front 50% rear 25-30%, Tailgate, Runs Great!.......... $235,000 2018 Deere 210G LC, 4000 hours, 36” bucket, QC, Hyd. Thumb, Aux hydraulics, Long undercarriage, Heat/AC, Clean Cab, Work ready $164,500 2016 CASE CX145CSR,3300 Hours, JRB Coupler, Hydraulic thumb, Auxiliary hydraulics, Road liner pads, Great condition! ..........$99,000 2017 Cat 450F, Front Aux. Hydraulics, Heat/AC/ Stereo, Auto-Shift, Ride Control, Pilot Controls, X-Tend-A-Hoe, 36” Rear Bkt, 96” Cat 4-in-One Front Bkt, In Perfect Condition! $99,000

The five-lane northbound span carries 60,000 vehicles a day between New London and Groton. One Span of Gold Star Bridge Receives $158M From Feds

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • January 18, 2023 • Page 11 G - 0 0 8 .c aEquipNE lt A • 82) 5 62-2 4 - 0 0 (8 A -2-ALTTA Go LT com

CityPlace to Be Burlington’s Largest Housing Project

Concrete is being poured at CityPlace, downtown Burlington, Vt.’s largest housing project, where preparations are under way to build hundreds of units. For some, the project evokes memories of what this part of the city was like decades ago. Now, it is undergoing yet another transformation.

The latest project will include 427 units of housing and tens of thousands of square footage of business space. Once complete, CityPlace will consist of two buildings of about 10 stories. Affordable units managed by the Champlain Housing Trust also are part of the plan, along with ground-level retail, 422 parking spaces, and a rooftop restaurant and observation deck, according to Seven Days, a Burlington news service.

The construction will replace the old Town Center Mall that was demolished a few years ago. But before the mall and other commercial buildings were there, the area was part of a large, residential neighborhood. With this latest project, the city hopes this will again become a place to live, work and shop downtown.

“Everything from that neighborhood is gone, so if I name a landmark, you aren’t going to know where it is because it’s all gone,” Monica Farrington said in speaking with Burlington’s WCAX-TV.

She grew up living in a house in the city’s old Italian neighborhood near the site. In addition, her grandmother owned a 20-room house that stood on South Champlain Street.

“It was a wonderful neighborhood,” Farrington continued. “Everybody was friendly, everybody knew one another. If you walked up or down the street, you knew the names of the people you ran into or walked by [while they were] sitting out on their porches. It was safe.”

But the neighborhood was aging, some of the properties were rundown, and it eventually became a target for urban renewal. With a nationwide program aimed to revitalize

blighted neighborhoods and spur the development of modern commercial buildings, a local vote was taken to demolish every home in the neighborhood, WCAX-TV noted in its Jan. 2 report.

“The news of the urban renewal was devastating to my family and to everybody else,” Farrington recalled. “They all started worrying about where they were going to go to, [and] how much money they were going to be given for their [properties].”

More than 150 families on 27 acres ended up having to move. Their homes were replaced by the mall, a bank, a hotel and other large commercial buildings that went up over the next few decades. Sections of Pine and St. Paul streets also were severed to make way for the mall.

Brian Pine, Burlington’s director of its Community & Economic Development Office (CEDO), told WCAX-TV that urban renewal did, indeed, bring economic vitality to the city.

“There’s no way to bring back what was [here before] or to make up for what was done 50 years ago, but the redevelopment and the reconnecting of those two streets — Pine and St. Paul — is a significant benefit and hopefully a way to make amends,” he explained.

What Was Old is New Again

Now, Burlington’s downtown is undergoing a new metamorphosis for the third time in approximately 50 years. Last fall, construction began on “The Pit,” the nickname given to the land after the mall was torn down.

Ironically, one of the CityPlace partners behind the development is Dave Farrington, the nephew of Monica Farrington, who saw her family home bulldozed here a half-century ago.

“It’s nice that it’s kind of coming full circle, that the area is going to get the roads back,” Dave Farrington told WCAX-TV. “We are standing in Pine Street and Bank off Cherry over there. [Eventually, this will] become a neighborhood of 600 or 700 people.”

With increased urban renewal, protections such as the rehabilitation tax credit were created to ensure that families are better supported if they are forced from their homes, he noted.

Pine also believes that where urban renewal failed in protecting the cultural memories of that area of the city in the past, it helped strengthen the resolve to protect historic places and buildings moving forward.

Page 12 • January 18, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide CONNECTICUT 410 Burnham St., South Windsor, CT 06074 860-289-2020 MASSACHUSETTS 120 Interstate Dr, West Springfield, MA 01089 413-363-0780 WHY CHOOSE ABLE TOOL and EQUIPMENT... • Local Ownership with flexible approach • Trained staff for repairs and maintenance • Dedicated Parts personnel on site • Focused on the Heavy Construction Industry • Providing the BEST support equipment available • Experienced outside sales staff Sales • Service • Parts • Rentals abletool.net Coring Equipment, Bits and Vacuum Widest Range of Coring Equipment and Accessories Available! Weka DK12 Hand Held Drill Motor Assortment of Core Bits CC150XL-EE FIRST-CUT™ Saw M-1 Core Bore Rigs Proud to be your Full Service Dealer NEW Inventory In Stock! CORE VAC CVG1 Vacuum

The latest project will include 427 units of housing and tens of thousands of square footage of business space.

True Poowwer components.

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • January 18, 2023 • Page 13

Able Tool & Equipment Provides Wide Array of Equipment

ABLE from page 8

smaller equipment. There are plenty of guys out there who can work on big machines, but small machine technicians are another whole story. That’s why people don’t just rent from us, they will buy from us because we’ve got the guys to keep it running.

“When a customer goes down, we know how to fix it, a service tech or a replacement machine is on the way. We understand the urgency within this business. Another attraction to doing business with us is our size. We’re a small house. If you come in here and do business with us, we’re going to know you. I’m going to know you. My service manager is going to know you. Our doors will always be open to you. Customers have my cell phone number, and my employees have my cell phone number. If I need to get involved, I get involved.

“The products that we sell each are a piece of the puzzle that completes the picture of the offerings we are trying to fill to the industry. Wacker is certainly one of our key lines and everyone immediately equates the name Wacker with high-end compaction equipment. Their earthmoving equipment is quickly making a name for itself. But I get excited about their niche items from that lineup. They have compact wheel excavators that aren’t really available from anyone else, which makes it a great niche rental item for us. We keep a high variety of attachments

available for the wheeled excavator and it has become a popular with utility contractors.

“Currently we are seeing a growing demand for battery-powered equipment and more and more manufacturers entering that market. The technology is there, battery powered equipment has plenty of horsepower. The challenge becomes how long will it run on a charge and how long does it take to recharge.

“In the battery-operated category, we have Kato electric excavators up to 4-ton, full-size skid steers as well as stand on skid steers. We have battery-operated compactors and vibrators. It’s early in the development of this technology and run time seems to be the biggest challenge but we want to be involved from the ground floor so that we grow with the technology. The run time is certainly a challenge, but it also varies a great deal with the application of the equipment. A big part of it is managing the customer’s expectations, but if emission regulations continue to get more and more stringent it’s a challenge all of us are going to have to deal with.

“Weber is an important line to us. They work extremely well with us as a manufacturer, and they give us compaction equipment that we can be very competitive with. It’s another case of a company who works closely with us and we’ve built a great relationship with them, and we inventory a great deal of their products. One of our primary

suppliers for concrete equipment is Allen Engineering. Again, they are Americanmade and they make some of our primary products for concrete contractors. Products like concrete vibrators, trowels, screeds, buggies, and in each one of these categories, Allen is an industry leader. Because they are a relatively small company and Americanmade, we are able to have a really strong relationship with them, which goes a long way for us when we really need to get something done.

“Chicago Pneumatic is a great brand for us and a very old and respected name in the industry. Michigan Pneumatic is another one of our suppliers that is all American-made and another company that we can have a relationship directly with the owner. They demonstrated early on in our relationship that they would be willing to do whatever it takes to get our business and that made a lasting impression.

“Michigan Pneumatic is making some very high-quality air tools in an industry segment where most of their competitors have moved their manufacturing overseas. They even do tool rebuilds. They also create some innovative products that nobody else does. For instance, they manufacture some concrete busters with T handles that have been so popular for us we have sold them all over New England for bridge deck demolition. They’ve built some very lightweight busters that are ideal for doing overhead breaking.

“Another company we’re proud to represent is Epiroc hammers. They manufacture the old Atlas Copco hammers, and we do a significant amount of small hammer business. I don’t know of anyone who does as much small hammer business as we do. We know the hammer business very well. But it’s a very tight niche of the hydraulic hammer market for us.”

A significant part of Able’s customer base is heavy highway contractors or, in other words, road and bridge builders.

“We feel that a significant portion of our product line is specifically targeting that audience and we go after that market very hard. Particularly our high-quality American-made products are niche items that are specifically used in that industry. The utility market also is a great market for us. We’ve got the compaction equipment they need, the saws and pumps that they are looking for, our compact excavating equipment is in high demand in that industry.

“Another important market to us is the concrete flat work specialists, or for that matter, anyone in the concrete business. We have all the items that anyone else serving concrete contractors would have and, like I mentioned earlier, we have specialized concrete items that no one else carries. We also get involved in excavation, demolition and municipalities.”

For more information about Able Tool & Equipment, visit https://abletool.net/

As they come to age and meet reasonable standards, Able Tool and Equipment is investing in the electric machine market, such as this Green Machine compact excavator.

Page 14 • January 18, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

CEG

Buggies of all types and sizes are labor savers that are in high demand.

Air compressors and generators are a critical part of any rental fleet.

Able Tool and Equipment has a significant inventory of Wacker light towers.

Kenco manufactures highly specialized attachments typically used by heavy highway and bridge contractors.

Concrete trowels manufactured by Allen Engineering, one of several products specifically for the concrete industry offered by Allen Engineering.

Gar-Bro concrete buckets is just one of many specialized concrete products available at Able Tool and Equipment.

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • January 18, 2023 • Page 15 THE MOST MATERIAL HANDLING MACHINES IN NEW ENGLAND SCREENING CRUSHING CONES IMPACTORS CONVEYORS TROMMELS WASHING RECYCLING USED AND NEW MACHINERY RENTALS AND FINANCING AVAILABLE CALL TODAY! 1-800-53-CRUSH Over 100 Machines in Stock Family Owned and Operated for over 20 years Call for Parts Today 140 Nutmeg Road South South Windsor, CT 06074 51 Veterans Drive Loudon, NH 03307 SCREENING CRUSHING CONVEYORS IMPACTORS TROMMELS 1-800-53 CRUSH WWW.POWERSCREEN-NE.COM LARGEST DEALER IN NEW ENGLAND ROCK SOLID SERVICE WE CRUSH YOUR ROCKS ROCK SOLID SERVICE WE CRUSH YOUR ROCKS

Maine OKs $104M Expansion of Sugarloaf Ski Resort

The Maine Department of Environmental Protection (DEP) has approved a plan for Sugarloaf, one of New England’s top ski resorts, to expand to its adjacent West Mountain property in Franklin County’s Carrabassett Valley.

The resort’s parent company, Michiganbased Boyne USA Inc., has outlined the multi-year, $104 million project as part of its 2030 primary plan for Sugarloaf. The blueprints include new trails to accommodate skiers of all abilities, adding and upgrading lifts, skier services infrastructure, roads, bridges, parking lots, condominiums, duplex-style townhomes and single-family lots.

In early December, the Carrabassett Valley Planning Board gave its conditional approval to the plan, the Lewiston Sun Journal reported Dec. 28.

“DEP approval of the West Mountain Expansion plan is a significant and meaningful step towards beginning construction on what will be a transformative project for Sugarloaf,” Karl Strand, Sugarloaf’s general manager, said in a statement. “We are grateful for the diligent work of everyone involved in this process over the past two years and look forward to moving forward with this exciting project as soon as we receive the remaining approvals.”

The U.S. Army Corps of Engineers and the Maine Department of Transportation still need to sign off on the project before construction can begin, the Sun Journal added. If that happens soon, timber clearing will begin this winter.

According to Mainebiz, the housing developments would include 52 singlefamily lots ranging in size from 0.63 acres to 5.55 acres, four condominium buildings of 22 to 28 units each, and 36 duplex townhome buildings, for a total of 72 units.

Sugarloaf Mountain Corp. also proposes building a 2,400-sq.-ft. skier services structure to house a restaurant, lodge and office as part of the 565-acre expansion. A network of hiking and biking trails would wind throughout the new expansion.

The site plan was prepared in 2021 by VHB Inc., a consultant headquartered in Watertown, Mass., with offices in Maine. The project would involve about 290 acres of land with 51 acres of developed area on managed forest located south of Maine’s Route 27, and east of the existing West Mountain Quad ski lift.

The resort is about a 45-mi. drive northwest of Skowhegan, Maine.

The West Mountain project is considered one of the most transformative enhancements in the resort’s 70 years and

is a key part of the 10-year “Sugarloaf 2030 Road Map,” published in 2020 by Boyne USA.

Three-Phased Expansion

The first phase of the Sugarloaf West Mountain expansion includes most of the ski trails, the ski lift, many of the new roads, the skier services building, two of the parking lots, a number of new house lots and buildings off West Mountain Road, and associated stormwater management structures and utility lines, Mainebiz noted.

Following that construction, Phase II will consist of seven new townhomes off Bucksaw Drive, and one of the condominium buildings.

Finally, the third phase will include the building of the remaining ski trails, the drop-off parking lot, and the remaining roads and housing. To accommodate future growth, added parking and lift access are planned at West Mountain.

At times, the popularity of the resort in recent years has caused 250 or more cars to be parked on the main access road, leading to traffic congestion.

With more onsite residential units, Sugarloaf officials hope to increase skier visits and mitigate a shortage of housing

units available at the mountain, according to Mainebiz. The ski lift plans to provide access from the base of the trail system to an area already occupied by the upper terminal of the West Mountain Quad ski lift. The addition of the lift also is seen as an opportunity to better utilize facilities for summer events, such as weddings, concerts and food beverage services at the midmountain Bullwinkle’s Restaurant.

According to the Lewiston Sun Journal, Sugarloaf’s other stated goals for the expansion include improving the ski resort’s mix of trails to provide more intermediate and beginner terrain, and enhancing its protection against high winds that require partial shutdowns of lifts.

The Sun Journal reported the total estimated cost of Sugarloaf’s West Mountain expansion project is to be funded with a combination of corporate revenue and financing through the ski resort’s parent company, Boyne Resorts, as well as through the sale of the proposed singlefamily house lots on the mountain.

Sugarloaf, at 4,237 ft., is the secondhighest peak in Maine after Katahdin. With a 2,320-ft. vertical drop, 1,240 skiable acres and 162 trails and glades, the ski resort is one of the largest in the Northeast.

Funding to Help Upgrade Small Towns Like Greenville

The omnibus funding package recently passed by Congress includes more than $308 million for nearly 200 projects across Maine, including a few in the town of Greenville in the state’s Highlands Region.

Under federal appropriations bills, the Maine Department of Transportation (MaineDOT) will receive $16 million to rehabilitate Maine Route 15 from Abbot to Greenville, while more than $1.5 million will go to the Moosehead Caring for Kids Foundation to help the Greenville Little School House Childcare, Pre-K and Community Center, and another $902,000 will boost the Greenville Public Safety Building project.

“So good stuff for Greenville, excellent stuff,” Town Manager Mike Roy said during a Select Board meeting on Jan. 4, according to the Piscataquis Observer.

Road, School Improvements Needed

Currently, the road conditions on Maine’s Route 15 are rated poor to very poor by MaineDOT and Federal Highway Administration (FHWA) metrics. The rehabilitation project will restore the 20-plus miles of road from Abbot to Greenville to a state of good repair, the news source noted.

The Moosehead Caring for Kids

Foundation will receive $1,561,000 for its projects. The foundation is partnering with the town and Greenville Consolidated School to build a facility to house a childcare center, pre-K classrooms, and a community recreation center.

Roy said he would be meeting with Greenville School Superintendent Kelly MacFadyen and Moosehead Caring for Kids Foundation representatives to discuss the project, which will have its own committee.

Building to Combine Fire, Police Departments

If all goes to plan, construction on the new Greenville Public Safety Building will begin in March, Fire Chief Sawyer Murray told WABI-TV in Bangor.

It will house the fire and police departments together to help with current outdated spaces and building code violations. The project’s building site is on Minden Street, across from the town office, and will include a community room for public use.

“We’re hoping to build a building to have it set up for the future, and that’s what we’re going into it thinking,” Murray added.

More than 20 firefighters make up the fire department. They are dedicated to serving not just the town of Greenville, but all surrounding communities as part of a Mutual Aid

Agreement. It is customary for them to travel more than an hour to answer a call, according to Murray.

“We really only go about 15 minutes south to Monson, but when we go north, we go up to the Golden Road, and even north of [there to handle] log truck and snowmobile accidents,” he said.

The department just wrapped up its busiest year on record — tripling its calls from 2017.

Over the past three years, the department has been developing plans for a new public safety building to replace the firefighters’ outdated space, which has several issues, including no hot water, showers, and only one restroom. In addition, there is little lighting, and firefighting gear is often left exposed to diesel exhaust.

“Right now, our gear is behind two trucks, so if we start the trucks, the gear is soaking up all the exhaust,” Murray explained to the Bangor news station. “That’s going to be a huge thing to have an exhaust system [to] vent that out.”

Police Now Squeezed Into Tight Space

Currently located across the street in the Greenville Town Office, the police department will be joining the firefighters in the new building.

Murray noted that the police will have the use of three indoor vehicle bays for the first time in the new facility.

“They park their vehicles outside, so they are always running them in the winter to keep them brushed off and such,” he said.

Like the Greenville fire squad, the police department has received an uptick in calls in recent years, and Murray, a member of the police reserve, said the new public safety building’s larger space should help its officers better conduct their work.

To illustrate the problem of having too little space, he told WABI-TV that one day last fall, the police arrested three people and brought them into the town office meeting hall to do interviews, but a Greenville Select Board meeting also was going on at the time. The officers tried to use the same room as the meeting before realizing their mistake.

“They gave us some funny looks and said we [could not] use that room,” he said with a chuckle, adding that the suspects ended up being interviewed in different offices.

“It is going to be huge for Greenville to have a larger space,” Murray noted. “This is one step in the right direction for emergency services that are getting busier, and, hopefully, we’re going to be set up for the future when we have to answer more calls more frequently.”

Page 16 • January 18, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

• www.constructionequipmentguide.com • January 18, 2023 • Page 17 THE DOER’S DREAM See the Hyundai difference yourself at your local dealer or hceamericas.com Loved for the features. Trusted for the performance. Hyundai articulated dump trucks have the power and performance — not to mention top-notch interiors, clear sight lines and handy tech — that make life on the jobsite easier. So you can do more without longtime fans. Chappell Tractor www.chappelltractor.com 251 NH-125 Brentwood, NH 03833 603/642-5666 454 RTE 13 Milford, NH 03055 603/673-2640 391 Loudon Rd. Concord, NH 03301 603/225-3361 Butler Equipment www.butlerequip.com 631 New Park Ave West Hartford, CT 06110 860-233-5439 Kahn Tractor & Equipment, Inc. www.kahntractor.com 520 Pond Road North Franklin, CT 06254 860/642-7596 Lorusso Heavy Equipment, LLC www.lhequip.com 160 Elm Street Walpole, MA 02801 508/660-7600 Quality Fleet Service, Inc. www.qualityfleetservice.com 548 New Ludlow Road South Hadley, MA 01075 413/213-0632 Whited Equipment Co. www.whitedhyundai.com 2160 Hotel Road Auburn, ME 04210 207/346-0279 17 Houlton Road Presque Isle, ME 04769 207/346-0279 837 Portland Road Saco, ME 04072 844/430-6810

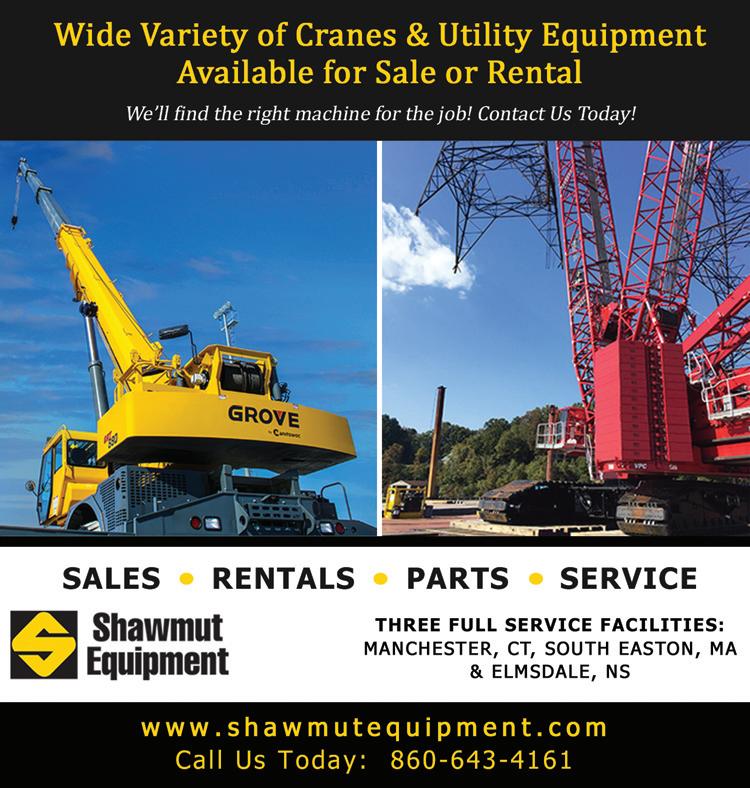

Page 18 • January 18, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide NEW ENGLAND SUPPLEMENT ADVERTISER INDEX The Advertisers Index is printed as a free editorial service to our advertisers and readership. Construction Equipment Guide is not responsible for errors or omissions. ABLE TOOL & EQUIPMENT..........................................12 ALTA EQUIPMENT COMPANY/NITCO LLC..................11 BARRY EQUIPMENT CO. INC.......................................20 BOSTON FREIGHTLINER/NEW ENGLAND..................13 CHAPPELL TRACTOR....................................................9 EQUIPMENT EAST........................................................1,5 FOLEY INC - WORCESTER............................................1 GORILLA HAMMERS........................................................1 HYUNDAI CONSTRUCTION EQUIPMENT....................17 J R VINAGRO CORPORATION........................................1 M G EQUIPMENT............................................................1 MILTON CAT..................................................................18 POWERSCREEN NEW ENGLAND................................15 ROGERS BROTHERS CORPORATION........................19 SHAWMUT EQUIPMENT CO INC....................................6 T-QUIP SALES & RENTAL INC........................................6 THE N.I.C.E. COMPANY................................................10 THE W. I. CLARK COMPANY..........................................2 TIBBITS EQUIPMENT SERVICES INC............................1 TYLER EQUIPMENT CORPORATION............................3 WOODS CRW CORP........................................................7

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • January 18, 2023 • Page 19 The Ultimate in Trailers® ROGERS BROTHERS CORPORATION ALBION, PA Over a CENTURY of building the very best heavy-duty trailers for your hauling needs! Contact your local dealer for a quote today. TRAILERS TO MEET EVERY HAULING CHALLENGE! Committed to building superior quality, reliability and durability into every trailer. Tyler Equipment www.cn-wood.com 200 Merrimac St. Woburn, MA 01801 (781) 935-1919 140 Wales Ave. Avon, MA 02322 (508) 584-8484 3 Rocky Hill Road Smithfield, RI 02917 (401) 942-9191 C.N. Wood Co., Inc. www.tylerequipment.com 251 Shaker Road East Longmeadow, MA 01028 (413) 525-6351 • (800) 292-6351 Parts: (877) 255-6351 1980 Berlin Turnpike Berlin, CT 06037 (860) 356-0840 • (800) 352-4473 Parts: (860) 356-0848

barryequipment.com

WEBSTER 508-949-0005 7 Harry’s Way Webster, MA TheDoosant yundai Doo H yund 2021 H ©

SOUTH WINDSOR 860-288-4600 1608 John Fitch Blvd. South Windsor, CT Schedu ation. om Doosan Corpor , is used under license fr trademark, oup yundai Heavy Industries Gr acoreisanaffiliateofH san Infr ved eser ll rights r e. A acor ai Doosan Infr

. y. ule a demo today

Page 20 • January 18, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide AUTHORIZED DOOSAN DEALER

WEBSTER 508-949-0005 30 Birch Island Road Webster, MA