Show Draws Nearly 140,000 Visitors

Massive crowds were on hand to see the latest in equipment, technology and applications at ConExpoCon/AGG 2023 in Las Vegas. see page 22 for story.

Massive crowds were on hand to see the latest in equipment, technology and applications at ConExpoCon/AGG 2023 in Las Vegas. see page 22 for story.

By Lucy Perry CEG CORRESPONDENT

By Lucy Perry CEG CORRESPONDENT

Net-zero engine emissions is a construction industry goal, and everyone’s got ideas on how to get there. Sectors of the industry are taking respective stands on federal emissions rulemaking. They are pushing for more of a voice in the rulemaking process while driving the fed to work harder at setting policy that both makes sense and benefits the environment.

The Association of Equipment Manufacturers (AEM) and its members “have aggressive goals to Equipment manufacturers have made several recommendations to government policymakers regarding future emissions regulations, including to consider practicality versus investment. see EMISSIONS page 72

T 972 2017 CAAT lf A03042. 9,376 total frame 4,259 Actual work Documented history, , Lo

y clean machine i d spade nose ar $438,000 Y , dd 0 Ya d p hi hi , history s nce new. , 6.25 y y urs

ard GP bucket, w utilization machine ew y (2)2018 CA ) h5000 ( L AT T 74 Less than 5,000 hour pair available. N 8 warranty, , Michelin 8

A

$

Yaard scr r, , ery id inspected. 1 owner wellmaintained

More than 5,500 machine operators worldwide have been competing in the Caterpillar Global Operator Challenge since the spring of 2022, and now one of them has emerged as the “World Champion.”

An exciting rebranding of a familiar and reliable line of construction equipment officially kicked off in mid-January, but the products themselves were formally introduced to the public at the ConExpo-Con/AGG 2023 show in Las Vegas.

The Reunion Resort in Kissimmee, Fla., served as backdrop once again for the mid-February gathering of IEDA dealer members along with dozens of product and service suppliers/exhibitors.

The past year marked the completion of the third full year of Gov. Pritzker’s Rebuild Illinois, the capital program that is investing $44.8 billion into the state’s aging infrastructure over six years, with $33.2 billion identified for transportation.

The American Rental Association (ARA) indicates that United States equipment rental revenue surpassed its pre-pandemic highs in 2022, ending the year as a $56.1 billion industry.

In the 76 years that Madison Tree has operated, tree care has evolved; so has the equipment. While this makes the work significantly easier to accomplish, it also means businesses have to invest in the right equipment.

After receiving hundreds of applications earlier this year, Carhartt awarded its Spring 2023 round of grants totaling $225,000 to seven U.S. nonprofit organizations that support women in the trades.

Founder Emeritus (1930-2021) Edwin M. McKeon Sr.

Midwest Publisher Joseph S. McKeon

Executive Publisher Teddy McKeon

Editor In Chief Craig Mongeau

Senior Editor Robby Chakler

Editorial Assistant Katherine Petrik

Production Mgr. John Pinkerton

Controller Judith Nixon

Circulation Mgr. Cathy Printz

Main office 470 Maryland Drive Fort Washington, PA 19034 215/885-2900

Toll Free 800/523-2200

Fax 215/885-2910

Web site www.constructionequipmentguide.com

Advertising e-mail production@cegltd.com

Case Construction Equipment is teaming up with nonprofit Crew Collaborative to sponsor and help build from the ground-up an-all new career counseling and mentoring program for high school students.

The Indiana Department of Transportation announced that $127.6 million in federal transportation funding is being awarded to 38 cities, towns and counties across rural Indiana to invest in local road and bridge improvements.

Three members of Yanmar America’s customer service team have been awarded for their outstanding results at the Yanmar Global Customer Service Awards at the Portopia Hotel in Kobe, Japan on March 10.

73 A CENTURY OF INNOVATION: KENWORTH TURNS 100 IN 2023

The history of Kenworth began in 1923 when Harry W. Kent and Edgar K. Worthington incorporated the Gersix Motor Company as Kenworth. The name was formed from a combination of letters from the founders’ last names.

76 WORK TRUCK WEEK 2023 ROARS BACK WITH BIG SHOW, ATTENDANCE

Work Truck Week 2023 was back to full strength as a verified 14,885 industry professionals gathered at Indiana Convention Center in Indianapolis March 7 to 10 for North America’s largest work truck event.

83 COMMUNITY REVITALIZATION GRANT PROGRAM NOW OPEN

Kubota Tractor Corporation announced its continued commitment to its dealers, customers and local communities with the launch of its third annual Kubota Hometown Proud grant program.

For advertising rates Contact

Joseph S. McKeon

• Illinois • Wisconsin • Northwest Indiana • Missouri • Kansas

773/769-4090

Cell 312/953-0375

e-mail jmckeon@cegltd.com

51 G&G UTILIZES HIGH REACH EXCAVATOR FOR COMPLEX DEMO

52 SHEARCORE, EXODUS MAKE PERSONNEL ANNOUNCEMENTS

54 TOMRA HOSTS EVENT TO CELEBRATE EXTENSION OF TEST FACILITIES

56 FECON ANNOUNCES TAYLOR AS ITS NEW BULL HOG DEALER

56 SCREEN MACHINE NAMES TAYLOR AS NEW DEALER

60 EXODUS GLOBAL ANNOUNCES ROCKWHEEL AMERICAS PURCHASE

Kent Hogeboom

•

Construction Equipment Guide Midwest Edition (ISSN 1081-7034) is published bi-weekly by Construction Equipment Guide Ltd. Advertising and Editorial Offices are located at 470 Maryland Dr., Ft. Washington, PA 19034. Toll Free 800/523-2200 or Fax 215/885-2910. Annual Subscription Rate $65.00. Call for Canadian and foreign rates.

Periodicals postage paid at Ft. Washington, PA and at additional mailing offices. POSTMASTER: Send address changes to Construction Equipment Guide Midwest Edition, 470 Maryland Dr, Ft. Washington, PA 19034.

Contents Copyrighted ©2023, by Construction Equipment Guide, which is a Registered Trademark, registered in the U.S. Patent Office. Registration number 0957323. All rights reserved, nothing may be reprinted or reproduced (including framing) in whole or part without written permission from

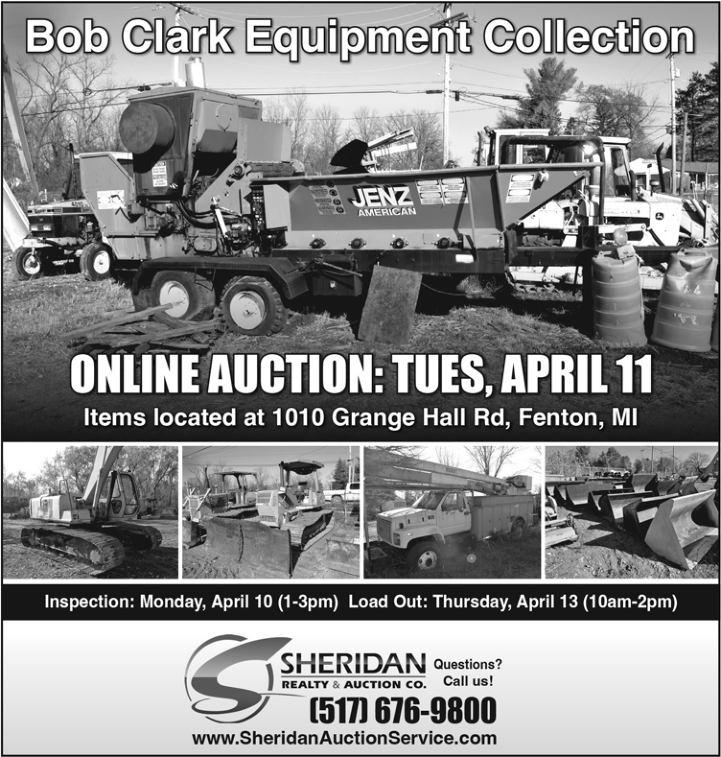

85 COMING AUCTIONS

86 BUSINESS CALENDAR

36 ESCO PosiGrab II Hydraulic Coupler

78 STELLAR TMAX 1-13 Aluminum Mechanic Truck

the publisher. All editorial material, photographs, drawings, letters, and other material will be treated as unconditionally assigned for publication and copyright purposes and are subject to Construction Equipment Guide's unrestricted right to edit and comment editorially. Contributor articles do not necessarily reflect the policy or opinions of this publication.

Call or write for advertising rates, publication schedule and media kit. The Construction Equipment Guide is not responsible for clerical or printer's errors, every care is taken to avoid mistakes. Photographs of equipment used in advertisements are not necessarily actual photographs of the specific machine. Similar photographs are used occasionally and every effort is taken to depict the actual equipment advertised. The right is reserved to reject any advertising.

WE ARE

SAKAI SV544T - ’18, approx. 350 hrs, 83” padfoot drum w/smooth drum kit, #C001431 $P.O.R.

ROADTEC RP190 - ‘13, approx.. 6200 hrs. EZIV Carlson screed, Moba grade & slope controls......................................................$58,900

SAKAI SW770HF - ‘17 w/approx. 1550 hours, 67” drum, tier III Isuzu engine, fleet machine ..........................................................$69,450

ROADTEC RP195 PAVER - ’08, approx. 8890 hrs. Carlson EZIV 10 screed, Moba grade & slope controls $37,500

WACKER RD12 - approx. 280 hrs, 36” drum, Honda engine, ROPS, #C002618 $10,500 SAKAI SW300 - approx. 450 hrs, 39” drum, #C000211............................................$26,850

*Comes with any remaining standard and 3 year extended power train warranty.

Liebherr A904C Wheeled Excavator - ‘16, approx 550 Hrs, 2-piece boom, pin grabber coupler, aux hyd ..................................$P.O.R.

Liebherr R946 - ‘14, approx.. 800 Hrs, 12’6” stick, QC66 coupler, aux. hyd ..............$P.O.R.

LIEBHERR HS855HD LITRONIC – (’08), 7616 hrs, #15499…$756,000

MANITOWOC 10000A-1 – (’19), USED, 793 hrs, C003846...$CALL

AGGREGATE EQUIPMENT

JCI K400, (’06), Portable Cone Crusher, 400 HP Elec, 42”x30” Feed Conveyor, #40236 $295,000 CRANES

GROVE RT650E, (’14) 50-Ton, Tier 4, 105’ Boom, 51’ Jib, #C001600 $319,000 GROVE RT765E-2, (’14), 65-Ton, 110’ Boom, 56’ Jib, 2831 Hrs, #C001601 $CALL GROVE RT880E, (’14), 80-Ton, Cummins QSB6.7L (Tier 4) turbo-charged six cylinder diesel, 41’ to 128’ 4 section full-power synchronized Megaform boom, #C001236

$374,000

Superior DT74J - ’20, approx.. 850 hrs. AC, side shift, #C002327 $63,700

ASTEC GT104 - ‘17, 325 Hrs, 5.25cyd Hopper, 4’x9’ Top & Bottom Screens, #C001154............ ..........................................................$161,700

ASTEC GT205MF – ’17, approx. 1800 hrs, 5x20 top deck w/high frequency bottom deck, #C001180..........................................$275,000

BOMAG BM600 - ‘16, 565 Hrs, 24” Drum, Load Out Conveyor $174,000

BOMAG BM1200/35 - ‘15, 1150 Hrs, 4’ Drum, 3’ Also Available, Front Conveyor, #C000846 $298,000 Roadtec RX-100 - ‘18 w/475 Hrs, 20” drum, #C001554..........................................$185,900

PAVERS / ROAD WIDENERS

Roadtec RP190 – ’13, 5860 hrs, Carlson EZIV 10-19’ screed w/12” ext, #C001909 $48,000 P.O.R. items may be on rent causing pricing and hours to vary.

LIEBHERR L550, (‘14), Liebherr diesel, stepless hydrostatic travel drive , traction & ride control systems,, Michelin XHA 23.5R25EM (L3) radial tires, enclosed ROPS cab with a/c 3.92 yard gen purpose bucket. Quick coupler, #C001328

$174,118

LIEBHERR L550 XPOWER, (‘18), an innovative machine concept which combines performance, fuel efficiency, robustness and comfort. With their power split driveline, XPower wheel loaders work with the greatest level of efficiency in all applications, #C003574

$208,947

LIEBHERR L550 XPOWER, (’17), an innovative machine concept which combines performance, fuel efficiency, robustness and comfort. With their power split driveline, XPower wheel loaders work with the greatest level of efficiency in all applications, #C003118

LIEBHERR L550, (‘11), 6732 Hours, #C005016

$169,900

$80,126

LIEBHERR LR636, (‘18) 3.25cyd bucket w/teeth & segments. Front and rear aux. hydraulics for 4 in 1 bucket, winch or ripper. 3 year/6000 hour full machine warranty, #C001745

$249,700

LIEBHERR PR736 LGP, (‘15), 204 HP, 32” Pads, 6-Way Blade, EROPS, #C001941 $CALL

LIEBHERR R936 LC, (’19), EROPS w/ AC & Heat, auto lube, rear camera, 54” bucket, #C004148 $CALL SAKAI SW354, (’18), #C003395 $CALL

Milwaukee, WI

1-800-236-6900

Fax 414-541-1892

Wausau, WI

1-800-242-7113

Fax 715-675-9748

Crushing & Screening Div. Little Chute, WI

1-800-236-8318

Fax 920-788-6753

For information on our in-stock equipment, contact Matthew Pehler at:

More than 5,500 machine operators worldwide have been competing in the Caterpillar Global Operator Challenge since the spring of 2022, and now one of them has emerged as the “World Champion” — the best Cat construction machine operator on the planet.

On March 14, Patrick Doheny of Australia took the crown out of nine finalists from around the world who competed in the final round of the Global Operator Challenge in the Cat Operator Stadium in Las Vegas.

Caterpillar’s year-long Global Operator Challenge is one of the largest construction industry events, with operators from nearly threedozencountriesparticipating. The Challenge highlights the amazing ways construction machine operators masterfully guideCatmachinesandusethelatest technologies to get the job done.

“Caterpillar created this competition to celebrate machine operators who build our world, advocate anddriveawarenessfortheirtrade, andhighlightsolutionsthataddress jobsite challenges,” said Jason Hurdis, Caterpillar Global Operator Challenge Execution Lead and Global Market Professional. “All of the competitors — and especially our nine finalists — showed tremendous skillsandabilitiesoperatingthelatest Cat construction machines and technologies, maneuvering through some difficult challenges and showing the world the invaluable role they play in infrastructure creation.”

The Challenge kicked off in the spring of 2022 with more than 10,000 operators worldwide signing up to compete. After a pre-qualification phase,thefirstroundfeatured 5,500 contestants competing in local events organized by 77 Cat dealers in 32 countries.

The second round in the fall of 2022 consisted of four regional events held in the United States, Brazil, Spain and Japan. These competitions included digging a trench, loading a precise amount of dirt and hauling or maneuvering the machines through obstacles.

The third and final round this week in Las Vegas was the ultimate test of precision. Grouped into teams of three — Team Americas, Team Europe and TeamAsia — the nine finalistscompetedindividuallyand as teams, as they faced three challenges in a specially constructed stadium featuring stands, fans, bigscreen TVs and play-by-play announcers.

The finals kicked off with the “Fork ‘n Loader” challenge, where each operator used the Cat 950 wheel loader with Payload technology to load and move material through specified locations on the course.

The “Backhoe Services” challenge had operators using both

ends of the Cat 420 XE backhoe to open a small box and precisely place small objects inside. This challenge was designed by Jaus Neigum, the 2020 Caterpillar Global Operator Challenge World Champion, and highlighted Caterpillar’s Customer Value Agreementsandservicesofferings.

During the final “Trench Run” challenge, operators showed off their trenching skills using a Cat 315 excavator equipped with Grade technology.

Final scores were based on the operator’s skills, efficiency and competence in executing a variety

of tasks, with penalties imposed for errors. Awardsweregiventothe overall event champion, the individual with the lowest time in each skills challenge, and the team with the lowest combined score. The operators completed the challenges using Cat construction machines integrated with the latest machine-control and payload technologies, including Cat Payload, Grade and Command, Cat Grade Assist, rearview cameras, return to dig and return to carry.

Patrick Doheny from Australia was crowned the champion. Caterpillar awarded him with a trip for two to a location where Caterpillar has one of its worldwide production facilities.

“I am beyond thrilled to have earned the title of the best Caterpillar machine operator on the planet,” Doheny said. “Kudos to Caterpillar for hosting such an incredible event to highlight the importance of our profession. It is trulyadreamcometruetoseeyour life’s passion be rewarded in such an amazing way.”

In second place was Matt Ferris from the United States, and third place was awarded to Łukasz Mokrzyński from Poland.

Other awards presented were:

ï “Fork ‘n Loader” challenge

winner — Patrick Doheny from Australia

ï “Backhoe Services” challenge winner — John Schiedeck from the United States

ï “Trench Run” challenge winner — Łukasz Mokrzyński from Poland

ï Team champion Team Americas (Fernando Do Nascimento from Brazil and Matt Ferris and John Schiedeck, both from the United States)

Representing Europe, Africa andtheMiddleEast:

ï Sebastian Behr — Germany (placed third in the 2019/2020 Caterpillar Global Operator Challenge) with 35 years as an operator

ï Pontus Ericksson — Sweden with 11 years as an operator

ï Łukasz Mokrzyński — Poland with 15 years as an operator

Representing the Americas were:

ï Fernando Do Nascimento — Brazil with 28 years as an operator

ï Matt Ferris — United States (Arizona)with20yearsasanoperator

ï John Schiedeck — United States (Texas) with 16 years as an operator

Representing Asia-Pacific were:

ï Patrick Doheny — Australia with 25 years as an operator

ï Masato Imai — Japan with 20 years as an operator

ï Nick Thompson — Australia with 15 years as an operator

For more information, visit www.cat.com/operatorchallenge.

CALL INDUSTRIAL SALES 866-372-7368

RUN WITH THE BEST IN USED EQUIPMENT: QUALITY, EXPERIENCE & SUPPORT

An exciting rebranding of a familiar and reliable line of construction equipment officially kicked off in mid-January, but the products themselves were formally introduced to the public at the ConExpoCon/AGG2023tradeshowinLasVegasthe week of March 14-18.

DEVELON is the new name for South Korean-based Doosan’s popular and diverse line of construction equipment. During the five-day trade show, Todd Roecker, vice president of growth initiatives for DEVELON NorthAmerica, was joined by DEVELON Senior Marketing Manager Alice Banach and many others to highlight the newly branded company and its equipment.

Banach said that the new name evolved by combining the words “develop” and “onwards,” which encompasses DEVELON’s willingness to move onwards to the future through innovation and to relentlessly change the world with top-level products and solutions.

“We are excited about it because it is something that we can own and claim rather than being part of another company,” she said.

To help build DEVELON’s product awareness, Roecker noted that his company brought more than 15 machines bearing the newnametotheannualtradeshow,attended by hundreds of dealers and contractors from around the world.

“There are several DEVELON machines in one booth, and then we have two at some partner booths,” he said during the event. “Bypartners,Imeanattachmentmakersthat wanted to showcase their products on our machines. Additionally, we have our DX65W-7miniwheeled-excavator,anewproduct in North America, at a static display by the ConExpo entrance.”

ConExpo presented DEVELON with a terrificopportunitytoshowoffitsnewminiexcavator line, which many customers may not have seen before in the marketplace, according to Roecker.

Five models of DEVELON mini-excavators were on display at ConExpo, including a prototype of the all-electric DX-20ZE-7, a two-ton piece of equipment that is likely to beonthemarketnextyear.Inaddition,dealers and contractors could inspect the DX35Z-7, the DX-50Z-7, the previously mentioned DX-65W, and the DX89R-7, a new model for 2023.

But the new mini-excavator line was just one of many new DEVELON construction equipment that the manufacturer was enthu-

siastic about unveiling at the show. The othersincludednewcrawlerexcavators,dozers, an articulated dump truck, a wheel loader and a log loader.

The company also took the wraps off a prototype of its innovative new DTL35 compact track loader that is slated to be available early in 2024.

“What is neat is we get to leverage this major event to launch our brand on a global stage, but we also get to showcase how we are developing our new products,” added Roecker. “For example, we have the new DD100 dozer on display here, and the DD130,whichwillbeavailabletothepublic in the fourth quarter of this year.”

He explained that the difference between the yet-to-be-released DEVELON DD130 dozer and the DD100 model are the sizes of the two.

“Larger sizes seem to take up a bigger share of the market,” Roecker said, “and the DD130 has a bigger engine, more horsepower, more weights, and more pushing power. It also has a larger blade, which attracts a bigger customer base.”

In 2019, Doosan introduced Concept-X, a comprehensive control solution for the construction site of the future. This forwardthinking initiative is now being utilized by DEVELON and will soon be commercialized, such as on the upcoming DD-130 dozer. In the meantime, the second generation of the manufacturer’s innovative technology was highlighted in the DEVELON

booths at ConExpo, Roecker said.

According to a description on the DEVELON website, Concept-X technology “can be used to survey worksite topography via 3D drone scanning, establish operational plans based on the topographical data, and operate construction equipment such as excavators, wheel loaders, and articulated dump trucks without humans at the controls.”

Thegoalistocreateaworksitewheredifficult and arduous construction work can be performed autonomously, thus leaving peoplefreetoconcentrateonmoresophisticated analysis and management tasks.

“We get asked a lot of questions about Concept-X,” Roecker said. “Our customers understandtheconceptofautonomousoperation, but questions such as, ‘What are the brains behind it, how does it work, and how do you re-create the jobsite to become autonomous?’ are often asked. So, we are highlighting our XiteCloud technology, which explains how that all comes together with3Dmappingoftheconstructionsiteand the taking of soil samples, and the technology behind dividing that jobsite into work groups and work zones so we can accurately measure the performance taking place.”

Another ingenious bit of high-tech can be found on the latest DEVELON wheel loaders to improve visibility and productivity for their operators.

The equipment maker’s exclusive Transparent Bucket option offers a supplemental view from a monitor inside the cab.

With an unobstructed view in front of the solid-iron wheel loader bucket, operators can see objects or challenging terrain to do their work safely and more quickly. The innovative system works by using two cameras — one mounted high and one mounted low — on the front of the machine.The system’s processor automatically adjusts the camerainputsintoasingleimagethatmakes the bucket appear transparent on an in-cab monitor — almost like X-ray vision.

The imaginative feature was demonstrated live at ConExpo on the DEVELON DL320-7 wheel loader, Roecker said, along with “our all around View Monitoring System’s object detection, so if there is an object or a person that is approaching that machine, it will highlight them as a danger sotheoperatorknowsthatheorsheneedsto shut down the machine or stop running it for optical safety.”

Not surprisingly, DEVELON’s autonomousequipmentworksduetoalotof programming taking place before their use, but as operators increasingly become more productive,theycanlearntorunitabitmore manually.

“We spent a lot of time programming the work zones, programming the limits that they want as operators, such as the amount of material, and the height or depth that needs to be dug to move material,” Roecker added.“Andthen,thesystemdoesitthrough DEVELON’s proprietary global satellite software.”

Complex-X does not employ artificial intelligence (AI) when it comes to autonomous operations, he said, but it does help measure a machine’s identified failure points.

“We can set limits on the failure points, meaning that if you want to get to a 70 percent, 80 percent, or 90 percent failure point, AI can trigger an alarm that a technician is needed or that a part needs to be ordered and dispatched to the job site to fix that machine before it is critical and shut down,” according to Roecker.

After Conexpo attendees inspected all the inventive hardware and clever features found on DEVELON’s new and upcoming construction equipment, Banach and Roecker heard an overwhelming number of positive comments about the manufacturer’s re-branding and the machines from construction professionals, said Banach.

“The dealers are giving great feedback about us being our own brand, which is really what DEVELON is all about, along with producing innovative products,” she explained.“Iamgladthedealersareexcited, and I think our customers, as 2023 progressesinto2024,aregoingtobethrilledaboutall the new models and what we have to offer.”

If Oscars were handed out for events that produce the best networking and business learning experience, the Independent Equipment Dealers Association’s 2023 Annual Meeting would walk away with the show — including categories of best directed, best scenery,bestattendedandbestcast.

The Reunion Resort in Kissimmee, Fla., served as backdrop once again for the midFebruarygatheringofIEDAdealer members along with dozens of product and service suppliers/exhibitors, as well as the association’s supportive sponsoraffiliates, which includes several OEM-authorized dealers. IEDA is distinguished as the independent dealer organization whose membersareindividuallyvettedforethical business practices by a board of their peers.

Many dealers and suppliers supported the event with generous sponsorships.

Titanium-level, $5,000-sponsors of the 2023 Annual Meeting were: Advantage Construction Equipment & Parts Inc.; Alliance Funding Group; Easton Sales and Rentals; JT Bates Group; Machinery Trader; Newman Tractor; Streamline Financial; Stretch Transports; CIT; Ritchie Bros.; ConTrac Equipment Ltd.; Components Only; and Earthmoving Supplies.

Gold-level, $3,500-sponsors were Niece Equipment; simex Baumaschinenhandel GmbH; Bryan Auction Co.; FR8Star; United States of Freight, Trophy Tractor, UNI International, CJ Equipment Inc.; RDO Equipment Co.; and 2-C Equipment LLC.

All these sponsors made the annual meeting a top-tier, extravagant weekend that was also affordable for all members.

Leadingofftheweekend,afirstever IEDA members auction was sponsored by Bryan Auction Feb 17. A complementary catered lunch plus cash bar were provided to all, and a huge assortment of vehicles and equipment were sold throughout the day. A variety of fun consumer items were also auctioned, and all the proceeds were

donated to the IEDA.Agrand total of $10,000 was raised for the 501(c)(3) organization.

With a record-breaking total attendanceofmorethan200industry professionals, IEDA’s meeting officiallykickedoffFeb.17,witha welcome party brought attendees together in the Reunion lobby and patio. Live music — sponsored by Hall Equipment — provided a fun backdrop for lively conversations among dealers, suppliers and vendors, staff and speakers.

A hot breakfast buffet was provided Feb. 18 by sponsors Granite Mountain Machinery and RAW Machinery. Then, from economic outlook and contractor data to a federal policy discussion, compelling Right to Repair panel and sales-focused keynote, the meet-

ing’s business program addressed some of the most relevant, poignant issues in the independent dealer’s daily life today.

“This was the best event I’ve personally taken part in by a long shot,” said Steve Udelson, IEDA 2023 president, co-owner of Easton Sales and Rentals.

“Executive Director Dave Gordon and his team give 110 percent and it shows in everything they do for the IEDA. I had so many people come and tell me how glad they were they came. And that’s what it’s all about — giving our members a great event and great tools they can go home with. They’re the real rock stars, and we are excited to keep growing and building this organization to make them more successful.”

During the business program, members enjoyed a hearty lunch buffet, sponsored by RJB Hydraulic Hammers and Machinery Trader. Gordon opened the lunch program with a focus on the association’s new IEDA Foundation that awards $5,000 scholarships to students enrolled in heavy diesel technician programs at post-secondary institutions.

After the four 2022 winners were announced, a dynamic video introduced those students and gave aclose-upabouttheirlivesandstories. Another video showed local television news coverage about the scholarships, students and the school.

The IEDA scholarship program was launched in the fall of 2021 when IEDA gave three $5,000 scholarships to students atWestern Technical College in Lacrosse, Wis.At the annual meeting, IEDA introduced one of the inaugural scholarship recipients, 33-year-old U.S. Army veteran Natasha Norman.

Following her six-year service to her country, including one tour of duty to Iraq, Norman struggled withPTSDandaddiction.Shealso is a single mom to four-year-old daughter, Aurora, and, she said, to a black lab service dog named Diesel.

She set her mind on pursuing

COMPACTORS CRANES

Hamm 3412P, 2012, 84” vibratory padfoot compactor, EROPS w/ heat & A/C, 1,200HMR . . . . . . . . . .$82,500

Cat 815F, 2006, EROPS cab, 12’4” S-Blade w/ tilt, new paint job, very good condition, 9,400 HMR $195,000

Hamm GRW-5 Pneumatic Roller, 1994, Deutz Diesel, ROPS Canopy, (9) Ea. 7.50-15C1 Tires $15,500

Volvo A40, 1998, 40 tons, 10991 hrs, 395 hp, 8WD, 29.5R25, A/C, 29 cy cap. sideboards, tailgate (currently off work), work ready

Volvo A40, 1996, 40 tons, 395 hp, 6WD, A/C, 29.5R25, working everyday

Broderson IC80-2E, 1997, 8.5 ton, 24’ boom, dual fuel, 10.00R15 tires, 3,400 hrs $21,500 Grove RT58C, 1981, down cab, 18 ton r.t., 70' boom anti-two block, GM dsl, clean . . . . . . . . . . . . . .$49,500

AIR COMPRESSORS

(4) Cat 825C’s, 1981-1990, EROPS, S-blade w/tilt, all work ready .

Volvo A40, 1996, 40 tons, 11,000 hrs, 6WD, 20.5R25, A/C, P/S trans, 29 cy cap., 6/06 hitch rebuilt .$115,000

IR 185’s, JD diesels

From $79,500

Rammax Walk Behind Rollers, over 25 in stock, lever & remote . .

Volvo A40, 1995, 40 tons, 395 hp, 8WD, 29.5R25, A/C, P/S trans, tailgate, work ready $115,000

$4,000 to $10,000

(8) Sheepsfoot, 48" and 60", double drum & single drum, tow type .

HYDRAULIC

Cat 336EL, 2012, 33.5” TBG pads, Q/C, aux hyd, 6,700 HMR, work ready .

Cat 336FL, 2015, 33.5” TBG Pads, Q/C, aux hyd, 4,300 HMR, work ready $224,500

Komatsu PC220LC-8 Longreach, 2011, Young Boom/Stick 60’ reach, 3,500 HMR

Kobelco SK210LC, 2007, Q/C, aux hyd, 31.5” TBG Pads, 3,900 HMR

Volvo A35C, 1998, 35 tons, 6WD, 26.5R25 tires, approx 7,000 hrs, good condition

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5x25, A/C, P/S trans, working everyday on jobsites . . . . .

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5R25, A/C, P/S trans, 26 cy, working everyday on jobsites . . . . . .

Volvo A30C, 1996, 30 tons, 11,000 hrs, 296 hp, 6WD, 23.5R25, 21 cy cap, A/C, P/S trans, works everyday . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DOZERS

Cat D5NXL, 2006, 10’ PAT Blade, Paccar PA55 winch, 22” Pads, 4,100 HMR $82,000

Cat 613C Water Wagon, 1994, 5000 gal drop tank, ROPS, spray heads . .

Cat 621F, 1996, Scraper, OROPS, 33.25x2, very good condition

Cat 621E, 1989, Scraper, OROPS, 33.25x29, very nice

Cat D6NLGP, 2008, VPAT Blade, Drawbar, 33” Pads, 9,900 HMR

Cat D6NLGP, 2014, Foldable VPAT Blade, Paccar PA55 winch, 7,200 HMR . . . . . . . . . . . . . . . . . . . . .

Komatsu D155AX-6, 2007, Sigma S-U Blade, 4-bbl Single Shank Ripper, 8,400 HMR $229,500

Cat D6TXW, 2013, 13’6” VPAT Blade, Carco 70APS winch, 28” pads, 7,300 HMR $152,500

(12) Allmand Light Plants, 2008-2010, diesel, s/a towtype, (4) MH lights, excellent From $5,200

SPECIALS BACKHOES

Case 580L Rubber Tire Loader Backhoe, 1997, OROPS, std stick, 24" bkt . . . . . . . . . . . . . . . . . . . . . . .$24,500

MISCELLANEOUS

(2) Balderson Broom Attachment for Cat IT Machines, 8' wide, good condition $4,000 Ea.

NUMEROUS Rivinius R600’s, 10’ Wide, Mount on Dozer Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .$25,500

BUCKETS

Over 100 Excavator, Loader, Specialized & Grapple Buckets in Stock -Call ForYour Needs

FORKS

(8) IT28F/G Forks, Balderson qc, 48"-60" pallet style, excellent . . . . . . . . . . . . .

Others Available Call

$4,000

Prices Are Negotiable - At Your Inspection

All Equipment is Owned & Operated By ALEX

5,808 hrs.

“One of the largest sources of used Komatsu equipment in North America”

The past year marked the completionofthethirdfullyearofGov. Pritzker’s Rebuild Illinois, the historic, bipartisan capital program that is investing $44.8 billion into the state’s aging infrastructure over six years, with $33.2 billion identified for transportation. Rebuild Illinois is not only the largest capital program in state history but the first that touches all modes of Illinois transportation: roads and bridges, transit, waterways, freight and passenger rail, aviation, and bicycle and pedestrian accommodations.

As of Sept. 30, Rebuild Illinois has made $9.6 billion in improvements statewide on 4,546 mi. of highway, 422 bridges and 645 additional safety improvements, ranging from routine maintenance projects to extensive interstate and bridge reconstructions.

One of the biggest, most complex projects in state history was declared substantially complete when all lanes and ramps on the new, improved Jane Byrne Interchangeopened.The$806million project revamped the junction of Interstate 90/94, Interstate 290 and Ida B. Wells Drive in Chicago with several capacity and safety improvements, as well as enhanced access to bike, pedestrian and transit options.

A new Interstate 57/74 interchange is taking shape in Champaign-Urbana as the $216.8

million Rebuild Illinois cornerstone focuses on building two flyover bridges central to the project. With anticipated completion in 2025, the updates will modernize anoutdatedcloverleafinterchange, while improving safety and mobility at a major freight juncture.

Work is moving forward on the $167 million eastbound McClugage Bridge replacement in Peoria, highlighted by a 650-ft.long, 130-ft.-tall arch that will be moved by crane into its final position next summer. This bridge is anticipated to open in early 2024.

Federal approval was received in 2022 on another major piece of Rebuild Illinois: the $1.2 billion reconstruction of 16 mi. of Interstate 80 inWill County.While the replacement of bridges east of the Des Plaines River continues, the section from Ridge Road to the DuPage River will be under construction in 2023.

Also in Will County, the state’s fourth diverging-diamond interchange opened at Weber Road and Interstate 55 in November. By routing vehicles to the opposite side of Weber Road and eliminating left turns across traffic, the design helps decrease crashes and improve pedestrian and bicycle access across I-55.

A major investment in I-57 unfolded this construction season, as 38 mi. of roads and bridges in Cook, Will, Kankakee, Iroquois and Ford counties were improved. In southern Illinois, work included

replacing bridges in Jefferson County and adding lanes in Franklin County. The total combined cost is $477.2 million, with the ongoing effort to make I-57 six lanes from I-24 south of Marion to Mt. Vernon a focal point.

The resurfacing of the entire length of I-24 in Illinois passed a milestone with the completion of a $28 million pavement patching, resurfacing and bridge repair on the two miles approaching the Ohio River this fall.

In October, Pritzker broke ground on the Forest Hill Flyover and 71st Street grade separation,

part of the 75th Street Corridor Improvement Project to help eliminate the most congested rail bottleneck in the Chicago area — the largest piece of the Chicago Region Environmental and TransportationEfficiencyProgram.

Another CREATE project advanced in 2022 with IDOT receiving a $70 million federal grant for the Ogden Junction. The project will rehabilitate, replace, remove and upgrade nearly 2 mi. of track, signaling and viaduct structures, as well as build 10,000 ft. of new track.

In the Metro East, a $10.1 million project to modernize rail operations,improvesafetyandenhance

the mobility of goods, people and services was declared finished in October with the replacement of the Lenox Tower. The project, a joint federal and state effort with several railroads, reconfigured an outdatednetworkoftracksandsignalswhilemodernizingoperations.

The past year saw a new schedule implemented for Amtrak Lincoln Service trains, reflecting 90 mph speeds as a result of improvements made along the Chicago-St. Louis corridor. Work continues toward the ultimate goal of increasing speeds to 110 mph in 2023. New Siemens Venture passenger rail cars entered service in early 2022 in Illinois and other Midwest states, with continued delivery and rollout of more Venture cars to follow in 2023.

Downstate transit providers were awarded nearly $111 million through a competitive application processviaRebuildIllinoistobuild bus shelters, stations and maintenance facilities that will expand and improve service, provide more transportation options in communities and enhance quality of life.

All told, Rebuild Illinois provides $4.5 billion to improve transit service throughout Illinois, the most spent on transit in any state capital program since 1968.

Plans to establish a new inland port in Cairo were furthered with the release of $3.4 million through

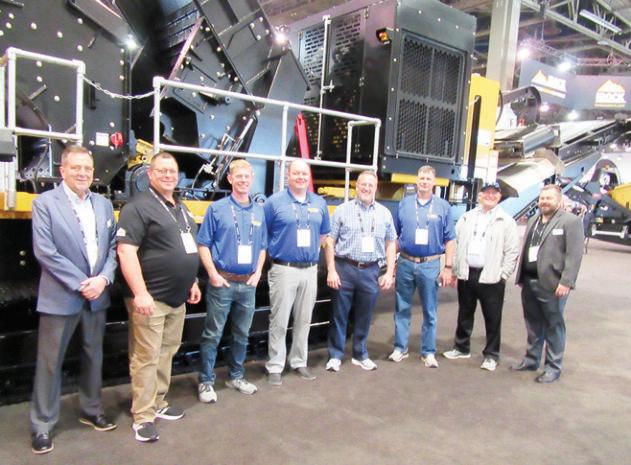

After five days of a plethora of innovative product launches and major company announcements, enlightening education sessions and seemingly infinite networking opportunities, ConExpo-Con/AGG & IFPE 2023 came to a close Friday, March 18, 2023, but not before taking the construction industry to the next level.

AccordingtoAEM,theshowcrushedexpectedattendance numbers, drawing more than 139,000 construction and fluid power professionals from 133 countries to Las Vegas from March14-18,2023,makingitthelargesttradeshowinNorth America with more than 2,400 exhibitors from 36 countries spread out over 3 million sq. ft. of exhibit space.

“Theinnovationsintheconstructionindustryunveiledthis week will play a role in helping construction professionals drive meaningful and sustainable economic growth,” said Phil Kelliher, Caterpillar senior vice president and ConExpoCon/AGG show chair. “Live events in the construction industry are very important, because you can see, touch and experience the products. That value was reaffirmed this past week across the show floor.”

This year’s show emphasized how the construction industryisevolvinginmanywaystoadapttosustainabletechnologies, products and practices. Show attendees were treated to sustainabilityinaction,fromelectric-andhydrogen-powered construction equipment, to more recyclable materials and waste reduction opportunities.

One of the biggest sustainability efforts on the part of ConExpo-Con/AGG directly is a partnership between the showandtheArborDayFoundation.ConExpoandtheArbor Day Foundation will be planting more than 139,000 trees, one for every show registrant in a forest of greatest need.

Additionally, ConExpo exhibitors, attendees and fans of theshowcancontributetotheArborDayFoundation’sfunds, allowing it to further its goal of involving itself in its mission of planting, nurturing and celebrating trees around the globe.

Theshowalsofeaturedawiderangeofeducationalopportunities, including 190 expert-led sessions on topics such as construction safety, equipment technology and sustainable building practices.

“The success of ConExpo-Con/AGG & IFPE 2023 is a testament to the resilience and strength of the construction and fluid power industries,whichhascontinuedtoadaptandinnovatedespitethechallengesofthepastthreeyears,”saidMarciaKlein,treasurerofCasappa Corp., and show chair of IFPE. “We’re proud to have provided a platform for industry professionals from around the world to connect, learn, and discover new solutions for improving their businesses and the world we build.”

Afterthedifficultiesfacedsincetheprevioustimetheindustrygathered for the show in 2020, attendees and exhibitors expressed excitementtoseethereturntonormalcy.Oneofthoseindividualsis89-yearold Leonard McCurley. McCurley has attended the show for the past six decades and is a true ConExpo veteran.

Raised on a farm in Michigan and working in construction his whole life, McCurley has found the show to be a home away from home throughout his adult life. He attended his first show in 1963 and has made it back to each and every one in the 60 years that have followed.

“There are so many interesting people I’ve talked to; it’s an educationjusttotalktoallofthem,”saidMcCurley.“Ithinkeverybodythat is around heavy equipment should go to that show.”

ConExpo is a family reunion of sorts for McCurley. Several of the companies he has worked for in the past have booths at the show, and helookedforwardtoreconnectingwiththeirrepresentativeswhenever and wherever he possibly could during the week.

In addition, his own children and grandchildren were in Las Vegas attending the show. However, McCurley recalled his fondest memories of attending ConExpo were with his wife in years past.

“Shewenttoeveryshowwithmewhenshewasalive,andshereally enjoyed them, too,” he said.

Now that he has made it to this year’s ConExpo, McCurley said he has nothing but love for North America’s largest construction trade show and would like to attend the show moving forward for as long as it makes sense for him to do so.

1981 Dresser TD7E 65 HP, International D239. Solid running machine. $12,000

TheAmerican RentalAssociation (ARA) indicates that United States equipment rental revenue surpassed its pre-pandemic highs in 2022, ending the year as a $56.1 billion industry. The ARA released the updated first quarter forecast at The ARA Show 2023 in Orlando.

In 2023, the United States equipment rental industry’s growth will soften, but still grow. Year-over-year, growth in 2022 was around 13.5 percent and year-over-year growth is expected to be around 5.3 percent in 2023 and 1.9 percent in 2024. Despite a slowdown, positivity is evident among ARA members with large and small operations.

Tom Doyle, ARA vice president of program development, said, “In speaking with rental companies across the United States and Canada, despite some unprecedented headwinds, their businesses are strong. It’s generally a great time to be in rental.”

ARA’s third annual construction equipment survey, released in January, showed fleet growth in all 30 product groups. Rental

companies in NorthAmerica that responded are estimating a 58 percent increase in new equipment purchases. Of those respondents, 79 percent said their orders included mobile elevating work platforms (MEWPs) and 59 percent said their orders included earthmoving equipment.

Federal policy and investments will continue to affect the rental industry, from the Infrastructure Investment and Jobs Acts to the tax policy of the Tax Cuts and Jobs Act to $185 billion available for new projects.

“The outlook for equipment rental continues to be positive. With significant funding for infrastructure coming in 2023, the demand for equipment will continue to grow,” said John McClelland, ARA vice president for government affairs and chief economist.

“In addition, more funding is coming from the Inflation Reduction Act as we begin to build out the electricity infrastructure for both vehicles and equipment.” For

capacit m/

McCurley said it’s impossible to attend six decades worth of ConExpos without at least having some advice to share with newcomers.

“You’ve got to have a good pair of shoes and make sure you go to see the whole thing, because if you don’t, you’re missing a lot,” he said.

ï More than 3 million net sq. ft. of exhibits (10.5 percent larger than 2020).

ï More than 139,000 registered attendees (6 percent increase over 2020).

ïMorethan2,400exhibitors,from36countries,including 603 new-to-the-show exhibitors.

ï More than 24,000 international registered attendees from 133 countries.

ïMorethan91,000scansofbadgestoaccessthe190education sessions.

ï More than 600 global media from 33 countries. ThenextConExpo-Con/AGG&IFPEwillbeheldMarch 3-7,2026,attheLasVegasConventionCenterinLasVegas.

CEG

Look for continuing ConExpo-Con/AGG 2023 coverage in the next edition of Construction Equipment Guide.

(All photographs in this article are Copyright 2023 Construction Equipment Guide. All Rights Reserved.

see CONEXPO page 32

see CONEXPO page 42

Taking in the sights at ConExpo in Las Vegas (L-R) are Chad Ketelsen. president of U.S. operations, Alex Lyon & Son; Jack Lyon, president, CEO of Alex Lyon &

(L-R) are Jonathan Schneider, Schmillen Construction Inc., Marcus, Iowa; Scott Lovell, president and CEO of Smithco Trailers, LeMars, Iowa; Steve Schmillen and Brent Fassler, both of Schmillen Construction Inc. Marcus, Iowa, with the Smithco 7 axle dump trailer.

Pages 35-41

If a tree falls in a forest, it may or may not make a sound. But if a tree fell in southwest Ohio any time after 1946, there’s a chance that Madison Tree and Landscape has been there to help clean up the mess.This family-owned business hasbeenastapleinthegreaterCincinnatiareaprovidingtree careandlandscapingservices.Asthebusinessentersitsthird generation, it’s clear to CEO Jon Butcher that it is possible to teach an old dog new tricks.

In the 76 years that Madison Treehasoperated,treecarehas evolved; so has the equipment. Whilethismakestheworksignificantly easier to accomplish, it also means businesses have to invest in the right equipment to handle whatever a job requires. That’s why the Butcher family has chippers, cranes, backyard lifts, bucket trucks, gravel trucks, mini-skid loaders, skid steers and stump grinders at the ready.

But as time went on, the leadership team noticed something missing from the business’s tool belt.

“We were doing some jobs where we could have saved some time if we had used a mulcher instead of cutting with chainsaws and pulling out debris with mini-loaders,” Butcher said.

So, he added a 125VRT Fecon mulching tractor compact track loader (CTL) to his arsenal and saw not only time savings, but more business opportunities as well.

In multiple instances, Butcher wouldn’t have committed to a job without his new mulching tractor to ensure he could get the job done. Not just because they didn’t own a piece of equipment, but also because of the hurdles of the rental market.

“Rental costs are in excess of $1,000 a day but the real issue is that rentals have been unavailable when ground conditions are suitable,” Butcher said.

Plus, rentals come with their own baggage and can be more prone to break down during the job. Eventually Madison Tree decided that it was done playing the rental roulette.

Madison Tree recently worked on an 8-acre land clearing

project in Indian Hill, Ohio, a neighborhood in Cincinnati. The project involved removing invasive species, including honeysuckle and pear trees, along with the brush and understory. Doing so transformed densely covered woods into a park-like setting and preserved the remaining trees in the process. The tricky part, however, was that the land included a creek with a two-to-one slope on both sides. Butcher’s team also had to deal with a pile of logs that were droppedontheslopesfromapreviouslandscapingjobyears before.

Tostart,theMadisonTreeteamusedamulchingtractorto shred the invasive species that ranged from 4 to 12-in. Vegetation of that size can be a tall order but the variable speed motor on Butcher’s mulcher automatically adjusts to maximizerotor-speedandtorquetochangingmaterialloads. This means that for heavier material, the mulching attachment delivers more rotor torque keeping the rotor turning when other mulching heads may stall.

Then, after tackling the vegetation on level ground, the team turned their sights on the creek.

“We had unpassable valleys where we had to pull out a bunch of undergrowth by hand,” Butcher said.

The team had to get even more creative when it came to the old logs that were left behind.

“We had to use a second skid steer to pull logs out of the creek slope before mulching them.”

The entire project lasted about a week with the mulching portion lasting two to three days. Without the new mulcher, Butcherknowsthejobwouldhavebeenmuchmorecomplicated to the point of Madison Tree being unable to take on the task.

“I probably wouldn’t have taken the job on if we didn’t have the 125VRT. Beforehand, on similar jobs we had guys with chainsaws and mini-loaders cutting stuff down and hauling it out. Then we’d still have the stumps to grind. The 125VRT did the work five guys could do in a day doing the same thing.”

The125’sabilitytoeffectivelymulchstartsandstopswith the teeth doing the heavy lifting. In this case Butcher’s CTL utilizes Fecon’s Bull Hog VM6020 mulching attachment with a depth control rotor that creates consistent chip sizing andlesshorsepowerdrawfromitscarrier.Thismakesitideal for dealing with stringy or fibrous material or whenever a finer finished product is required. The attachment also utilizes Viking Axe teeth which are double sided and can be easilyflippedforabrand-newcuttingedgeandtoeffectively double the life of the teeth. The mulching attachment offers a 61-in. working width and 76-in. overall width and requires 30 to 50 gpm, 6,000 psi and 132 max hp from the carrier.

While the mulching capability of 125VRT is unquestionabletoButcher,thebiggerbenefitoftheCTLisitsversatility.“We use it for hauling logs, landscaping grading tasks, snow removal…It’s a Swiss army knife,” Butcher said of the tasks he can do with his mulching tractor.

The additional capabilities even further helped to justify Madison Tree’s purchase.

Madison Tree purchased its CTL from Vermeer Heartland, an authorized supplier of Vermeer equipment, covering Kentucky, West Virginia, eastern Tennessee and southern Ohio.

Fecon’s 125VRT mulching tractor is a powerful and nimble CTL. The vehicle’s suspended track drive provides swift and durable system for work in demanding terrain, and its 125 hp 3.4L Cummins Tier IV Final engine delivers plenty of power. The CTL 50 gpm auxiliary attachment flowprovides119hptotheBullHog mulcher or other attachments which can be easily swapped with the hydraulic quick attach system.

Afull forestry spec cab features a ¾-in. polycarbonate front door, and ½-in. poly side windows for safety. An 8-in. color display offers users enhanced visibility in the spacious and comfortable operator station. The improved loader arm with no cross bars allows operators even more visibility to their attachment.

Hinged belly pans and tilting cooler and condenser guards allow for easy cleaning of the CTL while sealed fuse panels and improved wiring routing provide better durability and serviceability for the unit. A52-gal. fuel tank allows for nearly double the run time between fill-ups while the steel hood ensures greater in-woods durability during operation.

In Butcher’s opinion, Madison Tree is arguably the most reputable tree and landscaping company in Cincinnati. While his opinion might bealittlebiased,it’shardforanyone to argue with more than 75 years of results.Thetoolsarecertainlydifferent than when Butcher’s grandfather started Madison Tree, but the happy customers remain a constant.

Developed for ease-of-use and operator safety, ESCO’s latestinnovation—theESCOPosiGrabIIhydrauliccoupler — has undergone extensive testing and benchmarking against similar products.

A key feature is independently secured front and rear locks that provide redundant retention security. The natural position of the coupler is locked and only opens when hydraulic pressure is applied. Specifically, the coupler will remain lockedintheeventofhydraulic system failure or a sev ered hydraulic hose, according to the manufacturer.

The new design includes a weight reduc tion averaging 12 percent over previous ESCO mod els.

The PosiGrab II coupler is a multi-pindesignthatenablesengagement withtherangeofbucketsandattachmentswithin a given tonnage class and can be fully operated, includ ing locked confirmation, from the comfort and safety of the machine operator’s cab.

The PosiGrab II coupler, when properly matched with

OEM (Original Equipment Manufacturer) excavator buckets and attachments, will provide a safer and more reliable attachment engagement and change-over of various implements for maximum machine productivity and versatility, according to the manufacturer.

For more information, visit

The PosiGrab II coupler is a multi-pin design that enables engagement with the range of buckets and attachments within a given tonnage class and can be fully operated, including locked confirmation, from the comfort and safety of the machine operator’s cab.

CONEXPO from page 33

Luke

gives the crowd the specifics of the company’s DT12 tracked dumper, which fea-

a three-cylinder turbo diesel engine, is hydraulically activated and is good for a variety of job site applications.

Your work involves more than moving material. You need to stay on top of jobsite productivity.

Our new 450 P-Tier, 550 P-Tier, and 650 P-Tier Dozers can put you in charge of the challenges. Precise hydraulics, nimble machine stability, a comfortable cab with advanced displays and expansive jobsite visibility, simplified service, and flexible grade-control solutions including fully integrated SmartGrade™ help you keep things running smoothly and on schedule.

mccoycf.com

Ashland, WI 715/682-5522

Chippewa Falls, WI 715/834-2924

Merrill, WI

715/536-0633

Duluth, MN

218/722-7456

Bemidji, MN 218/759-1996

Grand Rapids, MN 218/326-9427

Escanaba, MI 906/789-9054

Fenton, MO

636/349-0200

Foristell, MO

636/463-2500

Cape Girardeau, MO 573/334-0563

Cuba, MO 573/885-0500

Owensboro, KY 270/684-2339

Paducah, KY 270/554-1131

Mount Vernon, IL

618/244-6800

Evansville, IN 812/473-0484

www.aisequip.com

Bridgeport, MI 989/777-0090

Grand Rapids, MI 616/538-2400

Lenox, MI 586/727-7502

New Hudson, MI 248/437-8121

Williamsburg, MI 231/267-5060

www.brookstractor.com

Madison (Sun Prairie), WI 608/837-5141 Milwaukee, WI 414/462-9790

Green Bay (De Pere), WI 920/336-5711

La Crosse (West Salem), WI 608/786-2644

Stevens Point (Plover), WI 715/254-2777

Racine (Mt. Pleasant), WI 262/898-6700 Sparta,WI 608/351-2101

JohnDeere.com/Dozers

www.westsidetractorsales.com

Lisle, IL 630/355-7150

Rockdale, IL 815/730-9011

Rockford, IL 815/961-3160

South Holland, IL 708/331-6362

Wauconda, IL 847/526-7700

Bloomington, IN 812/333-9677

Fort Wayne, IN 260/482-8576

Indianapolis, IN 317/544-3411

Lafayette, IN 765/447-6933

South Bend, IN 574/232-1461

Terre Haute, IN 812/645-7160

Blackhawk Equip

*Compact Excavators Only blackhawkequip.com

Lake Crystal, MN 507-375-5544

Buck & Knobby Equip Co. buckandknobby.com

Ottawa Lake, MI 734-856-2811

CSTK cstkequipment.com

Kansas City, KS 888-566-5743

Diamond Equip diamondequipment.com

Mt. Vernon, IL 618-242-2273

Evansville, IN 812-425-4428

Terre Haute, IN 812-299-4747

Bowling Green, KY 270-781-1061

First Choice Farm and Lawn firstchoicekubota.com

Mayfield, KY 270-856-4355

G. W. Van Keppel

vankeppel.com

St. Louis, MO 314-872-8440

Hardings Heavy Equip hardingsinc.com

Lowell, IN 219.696.8911

Hayden Machinery LLC haydenmachineryllc.com

Springfield, MO 417-855-7057

Holbrook Equip

holbrookequipment.com

North, Campton, KY 606-668-7261

Holland Equip Services

hesequipment.com

Holland, MI 616-396-5535

J Gross Equip Inc. jgeinc.com

Aberdeen, SD 605-229-4037

Midland Engine midlandengine.com

Midland, MI 989-631-4608

Reco Equip, Inc. recoequip.com

Belmont (Mt Pleasant), OH 724-696-4555

Columbus, OH 614-276-0001

Ft. Wayne, IN 260-255-3115

Monroe (Dayton Area), OH 513-539-5255

Toledo, OH 419-874-6001

Richfield, OH 330-659-0800

Florence, KY 859-727-7970

Indianapolis, IN 317-781-8100

Rueter’s rueterco.com

Council Bluffs, IA 712-366-5221

Grand Junction, IA 515-738-2571

Carroll, IA 712-792-9294

Elkhart, IA 515-367-3054

Osceola, IA 641-223-8171

Sioux City, IA 712-266-3832

Neligh, NE 402-917-5604

St. Joseph Equip, Inc. stjosephequipment.com

La Crosse, WI 608-788-1775

Eyota, MN 507-545-2000

Team Boone teamboone.net

Bardstown, KY 502-369-2475

United Truck Sales utsmi.com

Clinton Township, MI 586-630-0355

Universal Truck Sales utssales.com

Roseville, MN 651-639-0017

West River Equip westriverequipment.com

Mandan, ND 701-751-0995

Yes Equip & Services yesequipment.com

Milwaukee, WI 414-263-9001

Madison, WI 608-243-9253

Hyundai articulated dump trucks have the power and performance — not to mention top-notch interiors, clear sight lines and handy tech — that make life on the jobsite easier. So you can do more without longtime fans.

See the Hyundai difference yourself at your local dealer or hceamericas.com.

Carhartt’s bi-annual “For the Love of Labor” grant program awarded funds to seven U.S. nonprofits cultivating skilled trade opportunities for women in celebration of International Women’s Day 2023.

Mid Country Machinery

3478 5th Ave S Fort Dodge, IA 50501 800-206-5936

4734 Sergeant Road Waterloo, IA 50701 319-234-8710

106 8th Stree Sergeant Bluff, IA 51054 866-539-8106

www.midcountrymachinery.com

Miller-Bradford & Risberg, Inc.

TextIn celebration of International Women’s Day, familyowned premium workwear brand Carhartt announced the Spring 2023 recipients of its bi-annual “For the Love of Labor” grant program that dedicated this latest round of grants to award critical funding to organizations that work toward placing women in skilled positions.

After receiving hundreds of applications earlier this year, Carhartt awarded its Spring 2023 round of grants totaling $225,000 to seven U.S. nonprofit organizations that support women in the trades: ANEW, Building Pathways, Chicago Women in Trades, Nontraditional Employment for Women, Oregon Tradeswomen, Tradeswomen Inc., and Vermont Works for Women. This year’s Spring 2023 grants are part of the brand’s ongoing commitment to empowering the next generation of America’s diverse workforce.

“Women are an important part of Carhartt’s history — and our future,” said Linda Hubbard, president and COO at Carhartt. “This round of grants means so much more to us than just funding.Advancing women and other diverse audiences is a fundamental part of our goal to create a more inclusive, equitable workforce and this grant program is just one way Carhartt is evolving to support the next generation of workers. By backing these like-minded organizations, we’re providing fulfilling job opportunities and helping pave the way for women who want to work with their hands.”

First introduced in August 2022, Carhartt’s For the Love of Labor grant program was founded to support communitybased nonprofit organizations that educate, train and place workers into meaningful skilled trade jobs that are critically needed across the country. With this round of grants focusing on supporting organizations that train women, following is overview of the organizations awarded grants for Spring 2023:

• ANEW (Tukwila, Wash.) — The oldest, continuously running pre-apprenticeship program in the nation, ANEW is committed to improving the access and advancement of women in non-traditional career pathways such as construction and manufacturing.

• Building Pathways (Boston, Mass.) — Founded by the Greater Boston Building Trades Unions, Building Pathways is dedicated to the recruitment, retention and advancement of

under-represented groups in the union building trades, including women, people of color and other under-served communities.

• Chicago Women in Trades (Chicago, Ill.) — Ensuring all women who want to work with their hands and earn a good living have equal access to information, training, and employment opportunities in the industry, Chicago Women in Trades has been supporting, advocating, and training women in the Chicagoland area for the past 40 years.

• Nontraditional Employment for Women (New York, N.Y.) — Through innovative training programs, Nontraditional Employment for Women prepares women for nontraditional careers that provide structured career pathways to the middle class and economic independence, ultimately enabling women to achieve economic self-sufficiency.

• Oregon Tradeswomen (Portland, Ore.) — Helping transform women’s lives by building community and putting women on a path to economic independence, Oregon Tradeswomen offers empowerment, training, career education, advocacy and leadership development in the skilled trades.

• Tradeswomen Inc. (Oakland, Calif.) — Founded in 1979, Tradeswomen Inc. was one of California’s first organizations for women in the trades, and continues to be one of the most active and effective organizations in the nation focused exclusively on the needs of women in the skilled trades.

• Vermont Works for Women (Winooski, Vt.) — Working to promote economic justice, Vermont Works for Women is a statewide nonprofit that has been advancing gender equity and supporting women and youth at every stage of their career journeys since 1987.

While applications are accepted year-round, the next formal call for submissions will be announced later this summer, with grants being awarded in celebration of Labor Day 2023. Eligible organizations must be a U.S.-based 501©3 designated organization in recognized apprenticeship industry1 that has established programs serving at least 100 individuals annually.

For more information, visit www.carhartt.com.

W250 N6851 Hwy 164 Sussex, WI 53087

262-246-5700

Fax: 262-246-5719

DeForest, WI 608-222-9191

Eau Claire, WI 715-832-3443

De Pere, WI 920-338-5800

Marathon, WI 715-443-6000

Negaunee, MI 906-475-4181

www.miller-bradford.com

Southeastern Equipment Co., Inc. Corporate Office 10874

REP Rents 429 Haven Hill Road Shelbyville, KY 40065 502-633-9928

www.reprents.com

Case Construction Equipment is teaming up with nonprofit Crew Collaborative to sponsor and help build from the ground-up an-all new career counseling and mentoring program for high school students interested in the construction industry trades: FrameWork.

“At Case, we are customer-led in all we do,” said Terry Dolan, vice president, Case Construction Equipment, NorthAmerica. “It’s no secret that our industry has faced labor shortage issues over the past several years, and

we can’t think of a better way to supportourcustomersthantohelpidentify enthusiastic students who will make incredible contributions to the construction industry.”

Crew Collaborative joined Case in its ConExpo-Con/AGG booth to solicitstoriesofhowmentorshavechanged the lives of those in the construction industryandwhatpathsindustryveterans would recommend to best begin a career in the trades. It also gathered namesofthoseinterestedinpotentially serving as mentors to interested high

school students.

“A couple of months ago, FrameWork was merely an idea on a sheet of paper,” said Kristina McMillan, Crew Collaborative founderandboardmember.“Whenwe brought the initial concept to Case leadershipandaskedabouttheirpotential partnership on it, they replied ‘We’re all in.’”

Post ConExpo-Con/AGG, Crew Collaborative will host an in-person retreat with Case employees and other industry insiders to build out the program and begin beta testing. A full FrameWork program launch is slated for first quarter of 2024.

“Although Case has 180 years of experience in the earthmoving business, we are making moves with the speed and agility of a startup,” said Dolan. “Partnering with Crew Collaborative to bring the cutting-edge conceptofFrameWorktolifewillhave a true impact on the construction industry here in North America and beyond for years to come.”

Formoreinformation,visitcrewcollab.org/framework/.

The Indiana Department of Transportation (INDOT) announced that $127.6 million in federal transportation funding is being awarded to 38 cities, towns and counties across rural Indiana to invest in local road and bridge improvements, as well as sidewalk and trail projects. Combinedwithlocalfunds,approximately$156.9millionis being invested to improve transportation infrastructure in communities receiving funds.

“Improving local infrastructure is essential to the constant growth of communities across Indiana,” said Gov. Eric J. Holcomb. “Enhancing our state’s transportation network allowsforcontinuedeconomicsuccesstofollowandabetter quality of life for Hoosiers.”

Types of projects receiving funds include 26 bridge rehabilitation/replacement projects; 11 resurfacing/reconstruction projects; three Transportation Alternative Program (TAP) projects that involve sidewalks, ADA ramps and trails; and seven traffic safety projects.

For this latest round of funding, local communities will design,developandpurchaselandforprojectsthatwouldbe bid during the fiscal year beginning July 2027. While the

To streamline and simplify HDD guidance for operators completing shallow bore projects, Subsite introduced The Marksman.

The Marksman is the second product introduced in the Marksman series of HDD guidance systems, following the release of the Marksman+ in 2021.

The Marksman features single-button calibration, minimizing the risk of human error and speeding up the preparation process. Six frequency options and simplified features make the Marksman ideal for completing shallow bores for service installation, enabling operators to quickly move from one job site to the next.

The Marksman is an economical option for contractors who want to stay efficient and increase drilling uptime, according to the manufacturer.

funds awarded now are dedicated to construction, INDOT will financially participate in design, engineering and rightof-way acquisition components for some projects.

“Modernized infrastructure strengthens communities,” said INDOT Commissioner Mike Smith. “INDOT's commitment to improve local roads and bridges, as well as expand sidewalks and trails illustrates the partnerships in place that are making Hoosier cities, towns and counties great places to live, work and play.”

INDOT dedicates approximately 25 percent of its federal highway funds to supporting local projects each year. Metropolitan Planning Organizations (MPOs) distribute those funds to cities, towns and counties within the state’s larger urbanized areas while INDOT distributes funds outside MPO areas. Communities must contribute at least 20 percent in local matching funds and meet other federal requirements to receive federal funding.

Rural communities were invited to submit project applications to INDOT for potential funding during a call for projects announced last fall.

For more information visit in.gov/indot.

“Efficiency is a top priority for our customers. That’s why we developed this simplified HDD guidance system to help operators get in and out quickly,” said Braxton Smith, HDD guidanceproductmanageratSubsite.“Theintuitiveinterface oftheMarksmangivesoperatorstheconfidencetheyneedto successfully prepare for any shallow bore directional drilling projects.”

The Marksman is compatible with Subsite’s TD Recon and Commander 7, as well as the Subsite Field Scout. The Marksman is operated with a single joystick control, with no extra buttons or triggers — for a more intuitive operator experience.

The system also gives operators their choice of the user interface.Thecommonalityofuserinterfaceoptionsprovides operators with a simplified transition between products, savingtimeonthejobsiteforcrewstolearnanewinterface.The compatibility and streamlined controls work together to help operators be more productive from day one.

“The ROI and simplicity of the Marksman for contractors doing routine bores make it an obvious choice in HDD guidancesystems,”saidSmith.“Thefamiliarityandintuitivefeatures of the Marksman make it easy for operators to improve efficiency as they prepare to drill.”

For more information, visit www.subsite.com.

Tom Groninger started G&G Hauling and Excavating in his family home in 1966 nearWarsaw, Ind. He instilled hard work, integrity and a commitment to quality from day one, which created many loyal customers over the decades. Now under the control of Tom’s sons, Cary and Rich, G&G has more than 50 employees and serves multiple industries, including excavation, hauling, aggregate production and demolition.

G&G recently started its first demolition project that required a high reach excavator for Culver Academy, a privateboardingschoolinCulver,Ind.Theschoolprovidescollege preparation courses and experiences to nearly 800 students on its 1,800-acre campus. The job involves demolishing the Main, North and East barracks, which have housed students for nearly 100 years. Funds from a recent $65 milliondonationwillgotowardthedemolitionandconstruction of the new barracks.

The new barracks will include modern updates while maintaining the previous buildings’Collegiate Gothic architecture.According to the school, each barrack is expected to housebetween80and175students.Thebarracksareexpected to be move-in ready within the next three to five years.

The first step of the project was identifying the location of severalutilitysystems,includinglivesteamandpowerlines.

Some of these utilities ran into the basement of the Main Barrack,sobracingwasinstalledtohelpavoiddamagetothe area during the demolition process. G&G also meticulously disposed of the nonrecylable materials inside the building to make the post-demolition cleanup and crushing and screening process easier.

After completing the preparation, G&G evaluated its machine options. Randy Shilling, G&G’s maintenance and aggregate manager, determined a high reach excavator was the best choice for a precise, productive teardown of the four-story, 48-ft. tall Main Barrack. He contacted Company Wrench, who has more than 20 years of experience renting, selling and servicing demolition equipment across the country.

Doyle Burgess, Company Wrench’s sales territory manager, recommended a Kobelco SK350 with a 60-ft. Kocurek highreacharmandaLaBountyMDP20.Thisrentalpackage was ideal for G&G’s job because it provided a small footprint,thenecessaryworkingrangesandtheabilitytoprecisely cut material from the building.

Once the machine was delivered, Burgess gave Shilling detailed instructions on proper operation techniques and working ranges. Shilling was impressed with the high reach excavator’s ease of use, stability and attachment weight capacity.

G&G Hauling and Excavating photo G&G recently started its first demolition project that required a high reach excavator for Culver Academy, a private boarding school in Culver, Ind.

Exodus Global announced that both Vaughn Ali and Betsy McDevitt have expanded their regional business manager roles to include responsibility for ShearCore.

Aliwillberesponsible for sales for both the ShearCore and Connect Work Tools product lines for the Southeastern states. He has been a part of the Connect Work Tools team, since 2021 serving as the regional business manager, and has two decades of experience serving the scrap and demolition industries.

ExodusGlobalannouncedthatBobbyOldhamhasjoined the team as a field service technician and will provide serviceandtrainingforalltheExoduscompanies—BladeCore, Connect Work Tools, OilQuickAmericas and ShearCore.

Oldhambringsmorethan25yearsofdiverseandprogressive experience in mechanical, fabrication, management, and business planning from small to large scale companies.

“It’s a great pleasure to have Bobby Oldham join our Exodus team”, said Brian Hawn, vice president of service. “I’ve personally had the honor to work with Bobby in the past and know firsthand he will be a great addition to our growing service team. His knowledge in the industry, as well as his passion for customers, make him a great fit for Exodus.

“Bobby is located in the south-east region, which means we will provide more proficient support to our customer base while giving a piece of mind we have someone close by when needed.”

Most recently, Oldham

worked at LaBounty as a training specialist and InSite Administrator where he provided technical support and trainingforLaBountyproductscoveringNorthAmerica.He also updated and expanded their training materials and programming for new and existing dealers.

“I have always been a service and support guy,” said Oldham. “Great customer support goes a long way. Service without knowledgeable support can set up technicians and dealers up for failure.

“Exodus Global and companies share the same value of providing the best support and training to maximize the equipment. I look forward to working with all the Exodus Global companies and expanding our service training.”

Exodus Global and its companies manufacturer and distribute products under four divisions for both the domestic and international scrap recycling, demolition and construction markets. For more information, visit Exodusglobal.com.

“I am very excited to add the Fortress shears and crackers to my product portfolio. Being able to solve customers’needsinan industry I love is what I am all about. This opportunityallowsme to provide a more comprehensive solution of industry leading products to our customers and dealer partners in the Southeast,”Ali said.

McDevitt will maintain her role with BladeCore across the Midwest, and add responsibility for ShearCore sales in Oklahoma, Arkansas and Tennessee. She has been a part of the BladeCore team since 2017 and has made an incredible impact, developing countless customer relationships with her knowledge and outstanding customer service, the company said.

“In addition to providing my customers with personalized customer service and top-quality replacement parts for their shears,InowhavethehonorofsellingourFortressshearline and I look forward to being even more of a resource for the men and women I serve in this amazing industry,” said McDevitt.

For more information, visit ShearCore.com.

ShearCore, an Exodus Global company, announced that Tim Jacobson has joined the team as the service manager. Jacobson will be the primary liaison between the customer, field service, inside sales, outside sales, engineering and operations.

Jacobson brings with him a wealthofknowledgewithmorethan 20 years’ experience in mechanical repair. Most recently, he was employed as the mobile equipment shop planner at US Steel-Minntac, where he supported the equipment department through strategic workflow management, including sublet coordination, repair dispatch, appointment scheduling, warranty and claims pricing, and authorization clearances.

He also was responsible for developing maintenance schedules, 5S projects and hazard elimination projects that ensured jobsite safety for standard operating procedures.

“I am absolutely thrilled, and

honored, to be a part of a company withsuchastrongteamatmosphere, and the desire to make the working experience not only productive, but, also, fun,” said Jacobson. “Thank you, again, for the opportunity and I cannot wait to become an integrated member of this team.”

Brian Hawn, vice president of service, said, “I can’t be more excited to have Tim join our ShearCore Team. He brings a wealth of experience to not only help service our customers/dealers and ultimately reduce overall downtime but will also be a direct liaison for customer feedback and provide data to our engineering/manufacturing team in order to continue to build the best product for customer’s needs.”

ShearCore, a division of Exodus Global, offers a full product line for the recycling and demolition industries that includes the Fortress Mobile Shears and Concrete Processors, manufactured in Superior, Wis.

TOMRA Recycling Sorting opened a second test facility at its headquarters in Germany to meet growing demand for material trials. The company now operates one test center each for waste and metal sorting applications at the same location.

From Feb. 28 to March 2, TOMRA welcomed industry partners, customers and media representatives to celebrate the opening of a second test center at its headquarters in Mülheim-Kärlich,Germany.Theeventtookplacewithinthe framework of the company’s Integrator’s Conference. More than 200 participants from 26 countries joined the two-day event and enjoyed a diverse conference and event program.

Onthefirstconferenceday,participantslistenedtonumerouspresentationsdetailingthecompany’sstrategicdirection, including one held by TOMRA CEO Tove Andersen. The second day focused on the extension of the test facilities that marked another milestone in TOMRA Recycling Sorting’s long-term goals.

“With more stringent legislation and higher recycling targets, the demand to recover recyclables from waste is at a record high and so is the demand for our sorting solutions andmaterialtests.We’veobservedthissituationoverthelast few years and came close to our test capacity limits in Germany. We had to act to ensure the best service for customers and partners,” said Fabrizio Radice, VP and head of global sales and marketing at TOMRARecycling Sorting.

Previously, TOMRA’s test center incorporated both its wasteandmetalsortingsolutionsandisoneofeightfacilities operated at seven locations worldwide. They give recyclers and plant operators the unique opportunity to test their materials on TOMRA’s advanced sorting machines before making an investment.

“Apart from the increasing demand for tests, we are continuously developing new sorting systems that are all installed in our test center. In the last few years, we have introduced multiple new products into the market and will rolloutmoreinthefuture.Thus,weneededtomakesurethat wehavesufficientspaceforourgrowingportfolioanddecided to invest in an additional building,” added Radice.

TOMRA itself will use the extra space for the development of innovations that can be extensively tested and optimized by specialized teams on-site. The company conducts approximately650customerandinternaltrialseachyearand anticipates the demand to grow in the future.