By Lori Tobias CEG CORRESPONDENT

Five years after days of steady rain caused the failure of one dam and damaged three others in Gladwin and Midland counties, Michigan, a $400 million project to “repair, improve and restore” the dams are on schedule and on budget.

Crews with Spence Brothers are currently at work restoring spillways on the Edenville Dam, the largest of the four that also includes the Sanford, Secord and Smallwood Dams. Located on the Tittabawassee and Tobacco Rivers, the Edenville Dam provides water control for the Wixom Lake on which about 2,785 homeowners enjoy waterfront property.

“We had what is basically a big trencher come in,” said Jim McIntyre, Edenville project manager, Four Lakes Task Force. “In one pass as it’s pulling out the dirt, it puts bentonite

see DAM page 70

By Lucy Perry CEG CORRESPONDENT

In February, the FHWA published an updated Q&A document on the Build America, Buy America law. Clarifications on iron and steel construction products can be found in the document, along with a definition of what constitutes being “made in America.” Application dates for the rule, which eliminates the manufactured products waiver, are also included in the updates.

In the process, the agency keeps the Biden-era manufactured products rule unchanged and removes a waiver that

groups favored.

MnDOT announced it has awarded a total of $76.2 million through three competitive grant programs to more than 24 transportation projects statewide that will improve freight options, travel time reliability and economic development.

The Mount Pleasant Village board approved Microsoft’s plan to build 15 data centers in a move that FOX6 News Milwaukee reports will significantly expand an artificial intelligence project already under way in Racine County.

In keeping with its tradition of building America, John Deere announced plans to open two new U.S.-based facilities: a distribution center near Hebron, Ind., and an excavator factory in Kernersville, N.C., both set to open in the next year.

Founded in January 1926, the company began with a single product — Asphalt Expansion Joint, sold under the Sealtight name. The company evolved into a global manufacturer, offering more than 350 products.

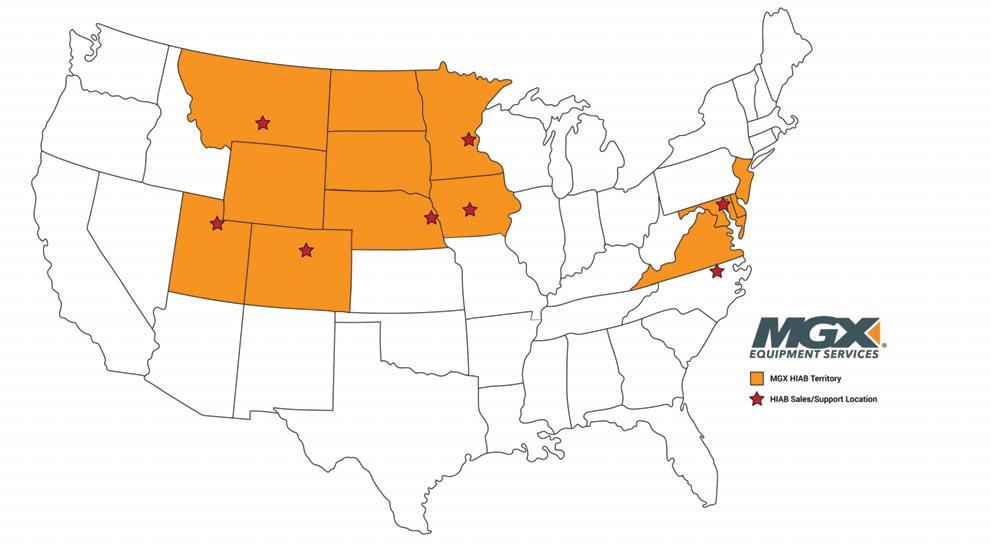

HIAB loader cranes will now be sold and serviced across the United States via the nationwide network of MGX Equipment Services. MGX now represents the HIAB brand across 13 states with sales, service and parts support.

20 RPC INC. ANNOUNCES INVESTMENT

Topcon Positioning Systems announced a strategic investment in its United States retail network — Topcon Solutions Stores (TSS) — by RPC Inc. The agreement marks a major milestone for the Topcon organization.

20

HARTZELL

Southeastern Equipment Company honored long-time sales representative Scott Hartzell for achieving an extraordinary career milestone — exceeding $100 million in lifetime sales.

Komatsu North America has entered into an agreement to acquire assets of SRC of Lexington Inc., a supplier of remanufactured components and parts for construction and mining equipment based in Lexington, Ky.

26 WEST

NOW TRIMBLE TECHNOLOGY OUTLET

West Side Tractor will now sell Trimble grade control, site positioning systems and correction services technology directly to customers using John Deere earthmoving equipment.

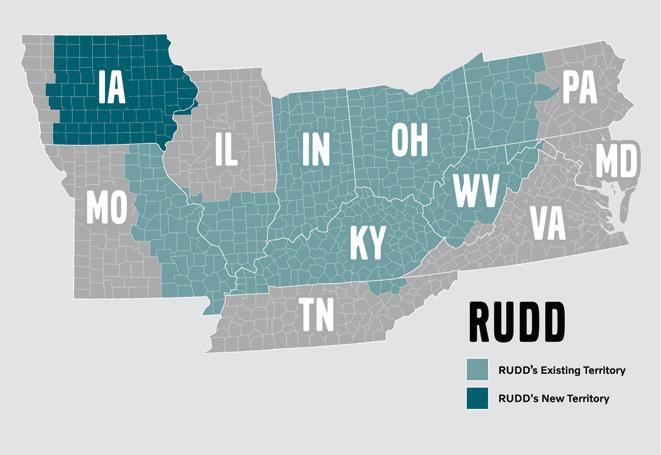

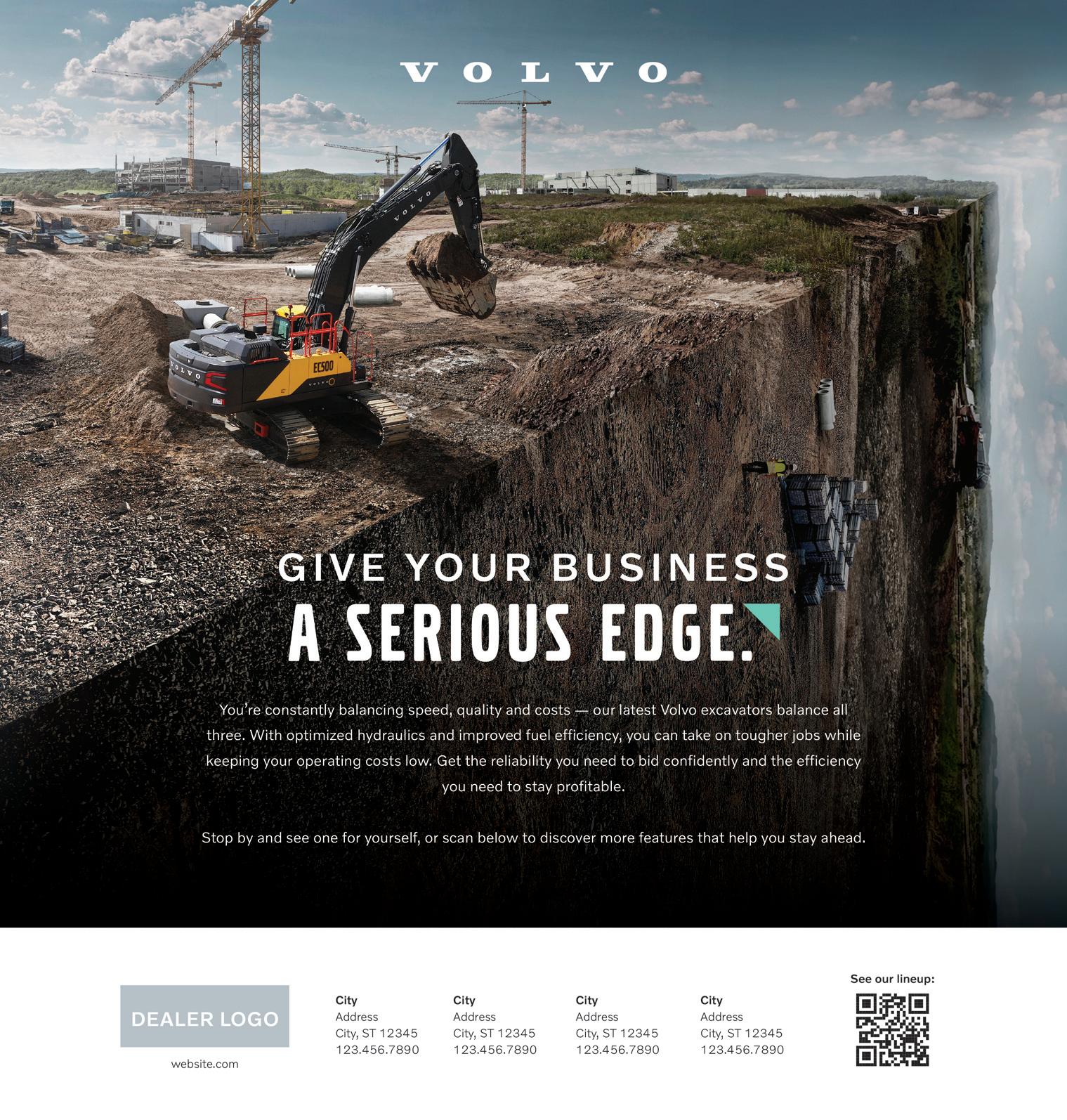

28 VOLVO CE DEALER RUDD EQUIPMENT EXPANDS ITS TERRITORY IN MIDWEST

In an asset purchase effective Jan. 30, 2026, Housby Heavy Equipment (Housby) transferred its Volvo CE inventory at three dealership locations in Iowa to Rudd Equipment Company, a subsidiary of Ferronordic.

28 MAVERICK ENVIRONMENTAL EQUIPMENT OPENS FIFTH LOCATION IN DETROIT AREA

Maverick Environmental Equipment, a provider of environmental, aggregate and recycling equipment solutions, announced the opening of its newest location in Woodhaven, Mich.

98 ALEX LYON & SON CONDUCTS 33RD ANNUAL FLORIDA AUCTION

People from all over the world flocked to Florida in search of bargains on construction equipment at Alex Lyon & Son’s 33rd annual 12-day sale in Bushnell, Fla., Jan. 29-Feb. 9, 2026.

KOMATSU’S PC365LC-11 EXCAVATOR TAKES PERFORMANCE TO HIGHER

VOLVO CE UNVEILS ITS NEW ECR355 EXCAVATOR WITH UPGRADES

LIEBHERR GEN 8 CRAWLER EXCAVATOR CHANGES INCLUDE EFFICIENCY

HYUNDAI ADDS HW100A WHEELED EXCAVATOR TO N.A. LINEUP

JOHN DEERE ENTERS NEW ERA WITH P-TIER MIDSIZE EXCAVATORS

Purple Wave Auction announced a fleet alignment auction to be held on April 21, 2026, for Standard Forwarding Freight (SFF), a less-than-truckload carrier based in East Moline, Ill.

2017 HAMM HD+110IVT $103,000 STK# HM17056, 703 HRS, Cape Girardeau, MO

2018 KOMATSU PC88MR-10 $74,500 STK# KM2023642, 3600 HRS, Marengo, IL

2022 KOMATSU WA320-8 $205,000 STK# KM2022647, 533 HRS, Springfield, IL

2008 GRADALL XL4100 II $58,000 STK# ZZ2022589 7,845 HRS, Bolingbrook, IL

2018 HAMM HD+140iVV $70,990 STK# HM18003, 1910 HRS,

2008 VALMET 840.3 $95,000 STK# VT2022063, 25,466 HRS, Escanaba, MI

2019 WIRTGEN W120CFI $435,000 STK# WG2021088, 1148 HRS, Springfield, IL

2018 KOMATSU HM400-5 $479,500 STK# KM2024111, 5506 HRS, Cape Girardeau, MO

2013 HAMM HD12VV $19,500 STK# HM2023091 3238 HRS, DePere, WI

KOMATSU PC210LC-11 $129,500 STK# KM2023069, 5422 HRS,

IL

2016 KOMATSU 931.2 $315,000 STK# VT2022024, 9946 HRS, Escanaba, MI

KOMATSU PC210LC-10 $134,500 STK# KM2023319, 3628 HRS, Eau Claire, WI

2017 KOMATSU PC88MR-10 $55,000 STK# KM2022612, 5196 HRS, Bolingbrook, IL

2020 KOMATSU WA270-8 $175,000 STK# KM2022362, 649 HRS, DeForest, WI

2014 KOMATSU D37PX-23 $99,500 STK# KM2023250 2204 HRS,

2019 KOMATSU PC170LC-11 $155,000 STK# KM2022354, 2310 HRS, Bolingbrook, IL

2018 KOMATSU PC490LC-11 $159,500 STK# KM2024254, 9121 HRS, Columbia, MO 2015 CAT 349FL $89,500 STK# CT2024019, 10,25 HRS, Escanaba,

KOMATSU 931.2 $305,000 STK#VT2023001, 10,292 HRS, Escanaba, MI

VT2023001, 10,292 HRS,

2020 KOMATSU PC210LC-11 $239,500 STK# KM2022040, 682 HRS, Bolingbrook, IL

KOMATSU PC210LC-11 $179,500 STK# KM2022040, 964 HRS, Eau Claire, WI

2015 KOMATSU PC228USLC-10 $149,500 STK# KM2021516, 4061 HRS, Escanaba, MI

2018 HAMM HD+110IVO $104,560 STK# HM18066 773 HRS, Carterville, IL

KOMATSU WA475-10 $389,500 STK# KM2023313, 1157 HRS, Columbia, MO

2020 KOMATSU PC240LC-11 $220,000 STK# KM2022017, 2323 HRS,

IL

2021 Takeuchi TL12R2, S/N 412104134 2883 Hours, CAB/AIR/HEAT, TWO SPEED, HIGH FLOW HYDRAUICS, HYDRAULIC COUPLER, 84" GP BUCKET $44,900

2022 Case SV280B, 171 Hours, S/N JAFSV280HMM403668, CAB/AIR/HEAT, HYDRAULIC COUPLER, 72" GP BUCKET, 2 SPEED, RADIO, EXCELLENT CONDITION FULL MACHINE WARRANTY UNTIL 11-22-24 $47,000

Mike Garrard • (630) 492-9115 Bolingbrook, IL Contact us at Used@McCannOnline.com

2022 Case 521G, S/N 253822, 266 Hours, CAB/AIR/HEAT, RIDE CONTROL, THIRD VALVE, LIMITED SLIP DIFF, JRB COUPLER2.5 YARD GP BUCKET, DELUXE CAB .. $129,900

2022 Case 321F, S/N NNHP04331, 241 Hours, CAB/AIR/HEAT, HIGH SPEED TRANSMISSION, SKID STEER STYLE COUPLER, 1.7 cu yd BUCKET, LIMITED SLIP DIFFERENTIAL, THIRD VALVE HYDRAULICS TIRES LIKE NEW, PREMIUM CAB

2023 Case TV370, S/N 2023 Case TR370B, 176 Hrs, CAB/AIR/HEAT, HYDRAULIC COUPLER, 84" GP BUCKET, DELUXE CAB, PREMIUM DISPLAY PANEL, GOOD TRACKS

$82,500

$72,500

2019 Case CX80C, S/N DAC080K6NKS6B2330, 1389 Hours, CAB/AIR/HEAT, COUPLER, 24" BUCKET,

$109,900

2019 Case Cx130D, S/N DAC130K7NKS7D1558, 358 Hours, CAB/AIR/HEAT, HYDRAULIC COUPLER, 18" BUCKET, AUX HYDRAULICS

2018 Case CX245DSR, S/N NJS7K1152, 1306 Hours, Cab/Air, Kent Coupler, Aux Hydraulics, No Bucket, Bucket available at additional charge, Rental Fleet Roll Out

McCann Rents a full line of heavy and light construction equipment. Call us today to supply your next rental.

Roadtec RX100e - ‘18, approx. 500 hrs. Includes grade controls $165,800 Sandvik CJ412 - ‘14, approx. 1400 hrs. Mobile jaw plant $540,800

Sakai R2H-4 - ’19, approx. 900 hrs. 83” triple drum static

$85,500

Sakai R2H-4 static roller - ‘23, approx. 120 hrs., #C002897

$108,800

Sakai SW884ND - ‘19, approx. 2900 hrs., #C002777, Double drum Oscillatory

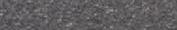

ROADTEC RP195 PAVER - ’08, approx. 8890 hrs. Carlson EZIV 10 screed, Moba grade & slope controls ....................................$35,200

Liebherr A904C Wheeled Excavator - ‘16, approx 550 Hrs, 2-piece boom, pin grabber coupler, aux hyd

$P.O.R.

Liebherr R946 - ‘14, approx.. 800 Hrs, 12’6” stick, QC66 coupler, aux. hyd

$P.O.R.

$26,850.

$148,400 Sakai SW300 - approx. 450 hrs, 39” drum, #C000211

ASTEC GT104 - ‘17, 325 Hrs, 5.25cyd Hopper, 4’x9’ Top & Bottom Screens, #C001154

$148,900

Superior DT74J - ’19, approx. 1300 hrs. AC, Side shift, gutter brush, #C001774 $35,400

BOMAG BM600 - ‘16, 565 Hrs, 24” Drum, Load Out Conveyor

$152,800

Roadtec RX-300 - ’18, approx. 600 hrs. 4’ drum

$311,400

KPI FT2650 – ’19, approx. 1800 hrs. Tracked jaw crusher

$546,950

Mauldin 1560 paver – ’22, approx. 600hrs. 8-14’, electric screed heat $99,600

P.O.R. items may be on rent causing pricing and hours to vary.

The Minnesota Department of Transportation (MnDOT) announced Jan. 6, 2026, it has awarded a total of $76.2 million through three competitive grant programs to more than 24 transportation projects statewide that will improve freight options, travel time reliability and economic development.

The funds come from the Minnesota Highway Freight Program (MHFP), the Transportation Economic Development (TED) Program and the Corridors of Commerce Readiness Advancement Program.

Collectively, these programs help fund and support important transportation projects that aim to improve freight safety, access, mobility, first and last mile connections, railroads and intermodal facilities and more to ensure the state continues to have a safe, sustainable and efficient transportation system.

“Infrastructure investments in Minnesota help people get where they need to go safely, help businesses grow and make local communities attractive to companies looking to relocate or expand,” said MnDOT Commissioner Nancy Daubenberger. “Safety is always a guiding principle of our funding decisions, and these transportation projects will help us better serve our state for decades to come.”

two roundabouts to enhance safety and traffic movement.

• Truck Parking Information Management System replacement ($1.7m MHFP) to replace truck parking information system sensors, cabinets and install new safety cameras at seven MnDOT rest areas.

Grant recipients in Greater Minnesota include:

• City of Two Harbors ($4.9m TED) for the Two Harbors Highway 61 Corridor project that will reconstruct Highway 61 from Scenic Drive (Old Hwy 61) to Park Road, add roundabouts at 7th Avenue and 11th Avenue and other intersection enhancements to extend the lifespan of the corridor.

• Meeker County ($2.7m TED) for the Highway 12 and Meeker County Road 34 Intersection Improvements project that will construct a three-legged roundabout and reconfigure access to Highway 12 from East Frontage Road.

• MnDOT District 6 ($10m MHFP) for the I-35/I-90 Interchange Freight Safety and Mobility project that will replace a bridge, construct buffer lanes, add roundabouts and extend turn lanes at the interchange north of Albert Lea to better accommodate truck movements and improve safety.

• MnDOT District 8 ($5.2m MHFP) to build a roundabout at Highway 71/19 and Redwood County Road 1 (Airport Road) near Redwood Falls.

MnDOT awarded a total of $76.2 million to more than 24 transportation projects statewide that will improve freight options, travel time reliability and economic development.

Grant recipients in the Twin Cities Metro area include:

• City of Burnsville ($10m MHFP) and city of Savage ($7.9m TED) for the Highway 13 Corridor Mobility and Safety Improvements project, which will construct new interchanges and overpasses at key intersections along Highway 13.

• City of Elko New Market ($7m MHFP) for the I35/Scott County Road 2 Interchange Reconstruction project. The project will construct a diverging diamond Interchange at that intersection and make other improvements along the corridor to improve safety and reliability of the interchange.

• Dakota County ($7m MHFP) for the I-35/Dakota County Roads 50 and 5 Interchange Reconstruction project that will add auxiliary lanes, add shared use pathways and improve signals to help increase freight mobility and safety.

• Dakota County ($3.85m TED) to expand Dakota County Road 46 (160th Street) to four-lanes from Highway 3 (Chippendale Avenue) to Highway 52 near Coates and add

Pleasant Village board on Jan. 26 approved Microsoft’s plan to build 15 additional Microsoft data centers.

• MnDOT District 4 ($2m MHFP) for snow fence improvements along I-94 to improve safety and visibility along I-94 during snow events.

• Cloquet Terminal Railroad ($1.9m MHFP) for intermodal and railroad improvements to better accommodate stacking and cargo at the Sappi Paper Cloquet Mill.

• City of Saint James ($518,000 TED) for the 12th Avenue South Highway District Expansion project that will see construction on 12th Avenue South and make turn lane improvements on Highway 4.

An additional $2.4 million from the Minnesota Highway Freight Program also will be used to update district and statewide freight plans to support statewide economic development.

The Corridors of Commerce Readiness Advancement program provides funding to help with planning, scoping, predesign and more for future projects that will improve capacity and freight movement. Grant recipients include:

City of Maple Grove ($2.5m) to help planning of future projects within the I-94 corridor at the Fish Lake Interchange (I-94/I-694/I-494) and the Maple Grove Parkway interchange.

Anoka County ($2m) to advance development of a gradeseparated interchange at the intersection of Highway 47 and Anoka County Road 132 (85th Avenue) in Blaine.

City of Elk River ($1.6m) for preliminary design and environmental analysis for Highway 10 in from Highway 169 to the eastern city limits.

Cloud Area Planning Organization ($1.5m) for planning and project development to improve Highway 15 from Highway 23 to Highway 10.

Olmsted County ($1.3m) for preliminary engineering and environmental analysis for proposed interchanges along Highway 14 at Olmsted County Roads 3 and 5.

For more information, visit mndot.gov.

The Mount Pleasant Village board on Jan. 26 approved Microsoft’s plan to build 15 additional data centers in a move that FOX6 News Milwaukee reports will significantly expand an artificial intelligence project already under way in Racine County. The new construction will join two data centers already being built on Microsoft-owned land zoned for industrial use, according to FOX6.

Village President David DeGroot told FOX6 the project positions the community at the forefront of a rapidly emerging technology sector.

“I think it is an emerging market and I think that there isn’t a better spot for us to be in,” he said.

FOX6 reports that nine of the new data centers will be constructed near Durand Avenue with work expected to begin by late summer or early fall 2026. Six more are planned off International Drive though that phase remains in preliminary planning. Village officials told FOX6 the multiyear effort will convert large areas of land into infrastructure supporting Microsoft’s AI systems.

FOX6 reported that most speakers at the meeting supported the expansion and cited opportunities for economic development and job creation.

Labor leaders also voiced support. Michael Ervin, organizing director of Operating Engineers Local 139, told FOX6 that union workers are already active on existing Microsoft sites and ready for the additional workload.

“AI is here whether you like it or not — $13 billion is a lot of work and we’re ready to do it,” he said. “We do it skillfully, we do it safely.”

DeGroot told FOX6 the scale of the project is unprecedented for the region.

“What’s being built out there is the largest supercomputer in the world by a factor of ten,” he said.

Village officials told FOX6 they expect long-term economic benefits, though they acknowledged that infrastructure demands and environmental considerations will need continued attention as the project advances.

Hamm 3412P, 2012, 84” vibratory padfoot compactor, EROPS w/ heat & A/C, 1,200HMR .

$82,500

Cat 815F, 2006, EROPS cab, 12’4” S-Blade w/ tilt, new paint job, very good condition, 9,400 HMR $195,000

Hamm GRW-5 Pneumatic Roller, 1994, Deutz Diesel, ROPS Canopy, (9) Ea. 7.50-15C1 Tires . . . . . .$15,500

(4) Cat 825C’s, 1981-1990, EROPS, S-blade w/tilt, all work ready From $79,500

Rammax Walk Behind Rollers, over 25 in stock, lever & remote $4,000 to $10,000 (8) Sheepsfoot, 48" and 60", double drum & single drum, tow type

$4,000 - $6,500

Volvo A40, 1998, 40 tons, 10991 hrs, 395 hp, 8WD, 29.5R25, A/C, 29 cy cap. sideboards, tailgate (currently off work), work ready

Broderson IC80-2E, 1997, 8.5 ton, 24’ boom, dual fuel, 10.00R15 tires, 3,400 hrs

$127,500

Volvo A40, 1996, 40 tons, 395 hp, 6WD, A/C, 29.5R25, working everyday

$21,500 Grove RT58C, 1981, down cab, 18 ton r.t., 70' boom anti-two block, GM dsl, clean

$145,000

Volvo A40, 1996, 40 tons, 11,000 hrs, 6WD, 20.5R25, A/C, P/S trans, 29 cy cap., 6/06 hitch rebuilt .$115,000

Volvo A40, 1995, 40 tons, 395 hp, 8WD, 29.5R25, A/C, P/S trans, tailgate, work ready

$115,000

Volvo A35C, 1998, 35 tons, 6WD, 26.5R25 tires, approx 7,000 hrs, good condition

$147,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5x25, A/C, P/S trans, working everyday on jobsites

$87,500

$49,500 IR 185’s, JD diesels

CALL

(12) Allmand Light Plants, 2008-2010, diesel, s/a towtype, (4) MH lights, excellent From $5,200

Cat 336EL, 2012, 33.5” TBG pads, Q/C, aux hyd, 6,700 HMR, work ready

$162,500

Cat 336FL, 2015, 33.5” TBG Pads, Q/C, aux hyd, 4,300 HMR, work ready $224,500

Komatsu PC220LC-8 Longreach, 2011, Young Boom/Stick 60’ reach, 3,500 HMR $179,000

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5R25, A/C, P/S trans, 26 cy, working everyday on jobsites

$89,000

Volvo A30C, 1996, 30 tons, 11,000 hrs, 296 hp, 6WD, 23.5R25, 21 cy cap, A/C, P/S trans, works everyday

$122,500

Case 580L Rubber Tire Loader Backhoe, 1997, OROPS, std stick, 24" bkt

$24,500 (2) Balderson Broom Attachment for Cat IT Machines, 8' wide, good condition $4,000 Ea. NUMEROUS Rivinius R600’s, 10’ Wide, Mount on Dozer Blade

$25,500

Kobelco SK210LC, 2007, Q/C, aux hyd, 31.5” TBG Pads, 3,900 HMR

$72,500

Cat D5NXL, 2006, 10’ PAT Blade, Paccar PA55 winch, 22” Pads, 4,100 HMR

$82,000

$49,500

Cat 613C Water Wagon, 1994, 5000 gal drop tank, ROPS, spray heads

Cat 621F, 1996, Scraper, OROPS, 33.25x2, very good condition CALL

Cat 621E, 1989, Scraper, OROPS, 33.25x29, very nice

CALL

Cat D6NLGP, 2008, VPAT Blade, Drawbar, 33” Pads, 9,900 HMR

$87,500

Cat D6NLGP, 2014, Foldable VPAT Blade, Paccar PA55 winch, 7,200 HMR

$142,500

Komatsu D155AX-6, 2007, Sigma S-U Blade, 4-bbl Single Shank Ripper, 8,400 HMR

Over 100 Excavator, Loader, Specialized & Grapple Buckets in Stock -Call For Your Needs FORKS (8) IT28F/G Forks, Balderson qc, 48"-60" pallet style, excellent $4,000 Others Available Call

$229,500

Cat D6TXW, 2013, 13’6” VPAT Blade, Carco 70APS winch, 28” pads, 7,300 HMR

$152,500

715-752-8112

JD 50G, A/C, Hyd Thumb, 5’7” Long Arm, Blade, Aux, #292872 ......................................$45,000

Kubota KX057-5, A/C, Hyd Thumb, Angle Blade, Aux Hyd, #296470 ........................$76,000

JD 331G, A/C, Hi Flow Aux, 2 Speed, Ride Control, #262952 .. $65,000

JD 310SL, A/C, 4X4, Ext Dipper, Ride Control, #262892 .... $99,000

JD 85G, A/C, Rubber Pads, Blade, Aux Hyd, 6’11” Arm, #291320 ........................$99,000

Komatsu PC138LC-11, A/C, Long Arm, CPLR, Rubber Pads, #298908 ......................$165,000

Bobcat T870, A/C, Joysticks, 2 Speed, Air Ride, #298789 .............. $49,000

JD 320P, A/C, 4X4, Ext Dipper, Aux, 19.5 Tires, Coupler, #302479 $119,000

JD 135G, A/C, 9’11” Arm, 24” Shoes, Reduced Tail Swing, #249203 ........................$87,000

Hyundai HX145A, A/C, Coupler, Aux Hyd, Blade, Rubber Pads, #302690 ..............$99,000

CAT D6N LGP, A/C, Winch, LGP, 34” Pads, 6 Way Blade, Trimble, #304860 $148,000

CAT 430F2, A/C, Pilots, Ext Dipper, 4X4, Aux, 19.5 Tires, #299832 $95,000

JD 210G, A/C, Hyd Thumb, Coupler, 9’7” Arm, Rev Fan, #261276 ......................$127,500

Volvo EC750EL, A/C, CWRT, 36” Pads, 9’6” Arm, 96” BKT, #305074 ......................$289,000

JD 700K, A/C, LGP, 30” Pads, 6 Way 132” Blade, Sweeps, #296466 $142,000

Deere 524K, A/C, Rev Fan, 20.5 Tires, Front Diff Lock, #300486 .. $89,000

JD 245G, A/C, Aux Hydraulics, 9’7” Arm, 32” Shoes, Air Seat, #262242 ......................$198,000

Bobcat S650, A/C, 2 Speed, Air Ride, Joysticks, #301217 ......................................$25,000

CAT D8T, A/C, 152” Semi U Blade, Ripper, Trimble Ready, #305941 $350,000

JD 844K-III, A/C, Scale, Radio, 8 YD GP Bucket, #261515 .......... $215,000

In keeping with its tradition of building America, John Deere announced plans to open two new U.S.-based facilities: a distribution center near Hebron, Ind., and an excavator factory in Kernersville, N.C., both set to open in the next year.

“Our investment in these new facilities underscores John Deere’s dedication to strengthening the backbone of American industry and supporting local economies,” said John May, chairman and CEO of John Deere. “We believe in building America, and these projects represent our intent to continue driving innovation and job creation in the United States.”

John Deere recently broke ground on a new distribution center near Hebron, Ind., located to enhance its supply chain capabilities nationwide, according to the company. This facility will be designed to streamline operations and ensure timely delivery of equipment and parts. The Indiana project is anticipated to generate employment opportunities with approximately 150 jobs, contributing to the state’s economic growth.

“This new facility is an investment in customer expectations around world class prod-

“This new facility is an investment in customer expectations around world class product support.”

uct support through parts availability for our US based ag, turf, construction, forestry, mining and turf customers,” said Denver Caldwell, vice president of aftermarket and customer support. “Indiana’s strong workforce and central location make it an ideal choice for expansion.”

John Deere will continue to maintain its primary North American parts distribution center in Milan, Ill., which has been in operation since 1973 and employs approximately 1,200 people.

The new $70 million factory in Kernersville, N.C., will bolster John Deere’s

manufacturing capabilities, leveraging new technology to produce excavators for the construction market. The North Carolina factory will assume production of future generation excavators previously produced in Japan.

This facility will employ more than 150 people and will help meet equipment demand and strengthen the company’s commitment to manufacturing within the United States.

“We are excited to bring this new facility to our Kernersville campus and to be part of the region’s thriving manufacturing community,” said Ryan Campbell, president of worldwide construction, forestry and power systems. “Our focus will be on delivering excellence, creating jobs and advancing the legacy of John Deere in American manufacturing.”

With the opening of these two facilities, John Deere will create hundreds of new jobs in the United States, further supporting local communities and advancing our mission to build a stronger America.

“These investments further demonstrate our commitment to invest $20 billion in U.S. manufacturing over the next 10 years,” May said. “It is a testament to our confidence in the future of U.S. manufacturing and our unwavering commitment to innovation, quality and economic growth.”

For more information, visit deere.com/en/.

W. R. Meadows Inc. marks its 100th anniversary on Jan. 26, 2026, celebrating a century of growth, innovation and leadership in the construction materials industry.

Founded in January 1926, the company began with a single product — Asphalt Expansion Joint, sold under the Sealtight name. The company evolved into a global manufacturer, offering more than 350 products that serve nearly every segment of the concrete construction industry through an extensive network of authorized distributors.

Over the past century, W. R. Meadows has continually expanded its product offerings to include solutions across multiple product lines, including expansion joints, construction liquids, joint sealants and complete building envelope systems, which encompass vapor barriers, belowgrade waterproofing, abovegrade air barriers and roofing materials. Its portfolio also encompasses a range of specialty

technologies designed to protect, enhance and extend the life of concrete structures.

From its Midwestern roots, W. R. Meadows has grown into an international operation with nine United States manufacturing locations, three in Canada, supported by a strong global network of distribution partners that enables the company to serve customers efficiently throughout North America and worldwide.

Growth also has come through a strong portfolio of respected brands, including, Huebert Fiberboard, Blue Ridge Fiberboard, Alcot Plastics, Gemite and Deck-O-Seal. Together, these brands bring specialized expertise that strengthens W. R. Meadows' position as a provider of comprehensive construction solutions.

A key driver of W. R. Meadows' success has been its enduring commitment to innovation and education. The company's innovation center, located at

its headquarters in Hampshire, features advanced laboratory capabilities and a dedicated training facility that supports research, product development, quality assurance and professional education for industry partners.

“As we celebrate this milestone, we honor the people, partnerships and principles that have guided us for 100 years,” said Matthew Price, president of W. R. Meadows Inc. “While we are proud of our history, we remain focused on the future — continuing to innovate, expand and deliver trusted solutions that help build stronger, longer-lasting structures worldwide.”

As a fourth-generation, familyowned company, W. R. Meadows remains committed to the core values that have defined its success — quality, service and integrity. These values are shared by the distributors and partners who help deliver its trusted solutions to builders worldwide.

For more information, visit wrmeadows.com.

ALL-NEW

Designed for construction, demolition and quarry applications, including underwater jobs, our comprehensive breaker line includes 12 models. Blue Diamond Breakers are compatible with excavators, mini-skid, skid steer and compact track loaders.

Every one of our breakers features:

• Solid mono-block design; only 2 moving parts.

• Anti-blank firing to protect internal components.

• A unique poly case shell for vibration dampening.

• Interchangeable machine mounting brackets.

THERE’S SIMPLY NOTHING LIKE IT IN THE INDUSTRY.

Choose Blue Diamond –where all we do is elevate everything you do.

BUILT STRONG. ATTACHED FOR LIFE.

Cab/AC, 3 Spool, Dual Diff Lock, Coupler, Bucket, 272 Hrs $205,000

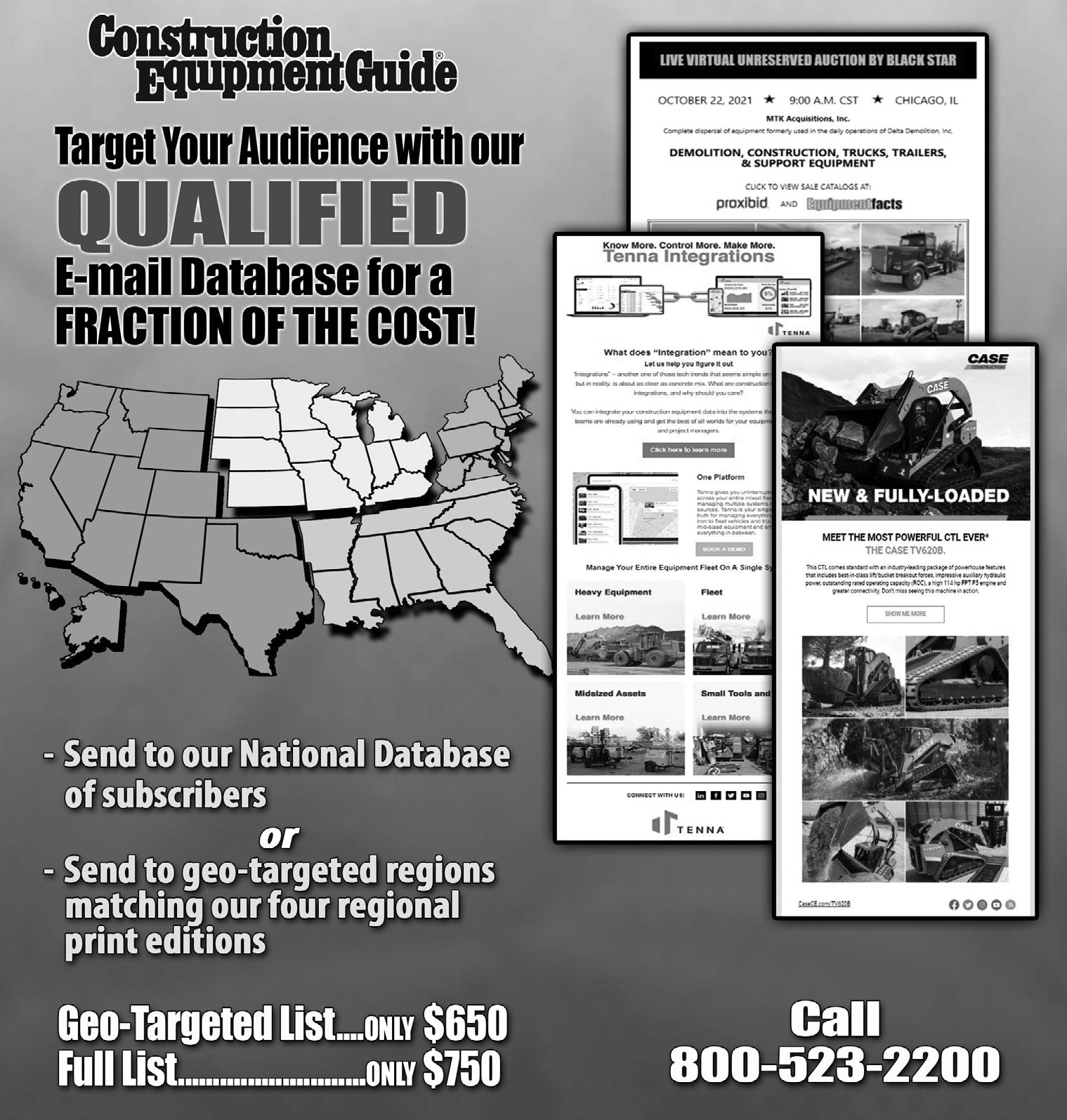

HIAB loader cranes will now be sold and serviced across the United States via the nationwide network of MGX Equipment Services. MGX now represents the HIAB brand across 13 states with sales, service and parts support.

Keith Poff, vice president and general manager of U.S. distribution of MGX Equipment Services, said the HIAB range would sit well alongside the company’s existing range of industrial products.

“We are excited to add the HIAB range of loader cranes to our offering as it represents the gold standard in loader cranes,” said Poff. “We look forward to presenting these cranes to customers and delivering value to their businesses.”

HIAB offers a broad portfolio of loader cranes, allowing customers to select the right model for their needs. These range from simple and effective manual-driven

models to advanced control units with intelligent functions. A host of efficiency-boosting technologies are available too, from remote control operation to smart features such as the load stability system (LSS) and semi-automatic folding (SAF).

MGX will carry parts for the HIAB loader crane lineup and field a team of mobile service technicians to provide full product support. The company will offer HIAB cranes sales, service and parts support in Colorado, Delaware, Iowa, Maryland, Minnesota, Montana, Nebraska, New Jersey, North Dakota, South

Dakota, Virginia, Wyoming and Utah.

“The HIAB range of cranes are perfect for a variety of applications, such as roofing, building materials handling and concrete foundation work. There are also opportunities in rail, municipal and utility work, so these really are versatile additions to just about any equipment fleet,” said Poff. For more information, visit hiab.com/en-us and mgxequipment.com.

On Jan. 12, 2026, Gov. Jim Pillen, joined by Nebraska Department of Transportation (NDOT) officials and Hastings Mayor Jay Beckby, marked a significant milestone in Nebraska’s commitment to safe and efficient transportation infrastructure with the groundbreaking of the Hastings Southeast project.

This project represents the final planned investment as part of the first 10 years of the Build Nebraska Act (BNA), which expanded 17 expressways, interstate or national high priority corridors.

The project will reconstruct approximately 2.38 mi. of U.S. Highway 6 (U.S. 6) in Adams County. It will improve safety by installing a roundabout to help with traffic flow, creating additional turn lanes and reducing congestion by using a design that will direct semi traffic out of the city center.

Gov. Pillen emphasized the project’s role in advancing Nebraska’s transportation priorities.

Construction is slated to begin as early as spring 2026, but utility work is under way in the area in preparation for construction season. The entire project is estimated to be completed in summer 2028. Werner Construction Inc., headquartered in Hastings, Neb., will serve as the contractor.

“We are standing by our commitment to modernize Nebraska’s transportation system,” he said. “The $41 million investment in U.S. 6 is not just a road project; it is a safety project. More than 10,000 vehicles are expected to use this stretch of highway daily by 2045, and this project addresses issues of freight movement and pedestrian

safety before they even arise.”

The project is a major infrastructure investment funded through state and local sources.

“This project is a long-awaited and much-needed improvement for our community,” said Beckby. “When finished, the road will safely serve the residents of Hastings and visitors to our community with an appealing entrance to southeast Hastings for many decades into the

future.”

“The Hastings Southeast project demonstrates how thoughtful design choices can maximize safety while managing costs,” said NDOT Director Vicki Kramer. “By reconstructing this corridor with modern safety features, strategic truck routing and improved pedestrian access, we are preparing U.S. 6 to safely serve growing traffic volumes while minimizing impacts.”

BNA revenue supported major improvements statewide, such as expansion of U.S. 385, known as the Heartland Expressway; U.S. 30 expansion West of Grand Island; Lincoln Bypass and Expressway expansion on U.S. 75 from Bellevue and Murray; and U.S. 30 from Columbus to Fremont.

More infrastructure projects are in development to improve safety and mobility of Nebraska’s infrastructure. NDOT is preparing projects to invest in the Omaha metro area, I-80 Interchange at Newberry in North Platte and finishing the expansion of U.S. 75 expressway between Murray and Nebraska City and the U.S. 385 Heartland Expressway.

3410 Henry St SW Bondurant, IA 50035 515-454-8626

3509 Franklin St SW Bondurant, IA 50035 515-410-9900

3478 5th Ave South Fort Dodge, IA 50501 515-574-2302

BLUFF 112 8th St Sergeant Bluff, IA 51054 712-943-4470

Brewerton Rd Brewerton, NY 13029 315-288-6473

2019 KOBELCO SK260LC-10 EXCAVATOR, 2797 HRS

KOBELCO SK260LC-11 EXCAVATOR, 145 HRS

LINKBELT 135 SPIN ACE, 5666 HRS

145X4DZ, 2044 HRS

2024 LINKBELT 145X4DZ EXCAVATOR, 91 HRS

ZX17U-5N MINI EXCAVATOR, 47 HRS

$CALL 2025 ZX17U-5N MINI EXCAVATOR, 0 HRS $CALL 2025 ZX35U-5N MINI EXCAVATOR, 90 HRS

2025 ZX35U-5N MINI EXCAVATOR, 90 HRS

2025 ZX35U-5N MINI EXCAVATOR, 56 HRS

2025 ZX35U-5N MINI EXCAVATOR, 89 HRS

2025 ZX35U-5N MINI EXCAVATOR, 73 HRS

2025 ZX35U-5N MINI EXCAVATOR, 26 HRS

2025 ZX35U-5N MINI EXCAVATOR, 5 HRS

2025 ZX35U-5N MINI EXCAVATOR, 6 HRS

2025 ZX35U-5N MINI EXCAVATOR, 49 HRS

2025 ZX50U-5N MINI EXCAVATOR, 176 HRS

2025 ZX50U-5N MINI EXCAVATOR, 113 HRS

2025 ZX50U-5N MINI EXCAVATOR, 45 HRS

2025 ZX50U-5N MINI EXCAVATOR, 4 HRS

2025 ZX50U-5N MINI EXCAVATOR, 26 HRS

2025 ZX50U-5N MINI EXCAVATOR, 10 HRS

2025 ZX60U-5N MINI EXCAVATOR, 103 HRS

2025 ZX60U-5N MINI EXCAVATOR, 49 HRS

2024 ZX85USB-7 COMPACT EXCAVATOR, 250 HRS

2024 HITACHI ZX85USB-7 EXCAVATOR, 184 HRS

2025 ZX85USB-7 COMPACT EXCAVATOR, 2 HRS

2025 HITACHI ZX85USB-7 EXCAVATOR, 3 HRS

2025 ZX85USB-7 COMPACT EXCAVATOR, 2 HRS

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

2025 LINK-BELT 145X4DZ EXCAVATOR, 10 HRS $CALL

2019 LINK-BELT 160X4EX EXCAVATOR, 621 HRS

2024 LINKBELT 220X4S EXCAVATOR, 127 HRS

2023 LINKBELT 245X4DZ EXCAVATOR, 759 HRS $CALL

2024 LINKBELT 300X4HD EXCAVATOR, 181 HRS

2024 LINKBELT 350X4 EXCAVATOR, 296 HRS

2025 LINKBELT 370X4S EXCAVATOR, 5 HRS

2025 LINKBELT 75X3 EXCAVATOR, 0 HRS

2025 LINKBELT 75X3 EXCAVATOR, 4 HRS

2020 LINKBELT 80X3 EXCAVATOR, 2205 HRS

2023 SANY SY35 MINI EXCAVATOR, 90 HRS

2025 SANY SY35 MINI EXCAVATOR, 4 HRS

2025 SANY SY35 MINI EXCAVATOR,

Southeastern Equipment Company honored long-time sales representative Scott Hartzell for achieving an extraordinary career milestone — exceeding $100 million in lifetime sales. Hartzell is the first person in Southeastern Equipment history to achieve this milestone, marking nearly 34 years of dedicated service to the company and its customers.

Hartzell exemplifies the dedication, customer service and long-term commitment that have helped shape Southeastern into the company it is today. His success stems from building lasting relationships with contractor clients who share the same values that Southeastern was founded on — dependable support, helpful solutions and honest communication.

To recognize this amazing accomplishment, Hartzell was presented with the “$100 Bill Award,” a framed $100 bill signed by Southeastern founder William L. “Bill” Baker.

But the award carries even deeper significance.

The frame’s background features a replica of the wallpaper from the Baker family home. Years ago, Baker placed a large check

photo

Southeastern Equipment Company honored long-time sales representative Scott Hartzell (C) for achieving an extraordinary career milestone — exceeding $100 million in lifetime sales. (L-R): His wife, Cindy; son, Shane; son, Spencer; and Spencer’s girlfriend, Kelly, were on hand to help celebrate.

on the family’s brand-new wallpaper (much to the chagrin of Mrs. Baker), but it symbolized Baker’s and Southeastern’s hard work and sacrifice.

As part of his recognition, Hartzell will sign and pin his own $100 bill to a replica wall in the Southeastern Equipment Museum, officially adding his name to

Southeastern history. It’s a tribute not only to his impressive sales achievement, but to the lasting mark he has made on the company and the customers he has served.

Hartzell’s achievement reflects the core values that define Southeastern:

• Passion: Hartzell’s highly engaged, solution-focused approach to every customer challenge demonstrates his passion for the industry and the people he serves.

•Hustle: For nearly 34 years, he has gone the extra mile, embraced challenges and taken ownership of outcomes for his customers.

• Customer Focused: His success is built on being deeply invested in his customers’ success and delivering tailored solutions with a personalized approach that achieves real results.

• Thoughtful: Hartzell listens with empathy, responds thoughtfully and treats others with fairness and respect, always striving for a win-win-win for customers, company and team.

“Scott’s success is the result of decades of showing up, doing the right thing for our customers and living out our values,” said Mike Mampieri, vice president of sales. “His dedication doesn’t just move machines … it moves this company forward.”

Southeastern Equipment Company congratulates Hartzell on this remarkable achievement and celebrates the legacy he continues to build within the SEC family. For more information, visit southeasternequip.com.

Topcon Positioning Systems has announced a significant strategic investment in its United States retail network — Topcon Solutions Stores (TSS) — by RPC Inc.

The agreement marks a major milestone for the Topcon organization and its impact on the construction technology market in the United States. The investment will strengthen TSS’s continued commitment to help more contractors modernize their job sites through its technology solutions, according to the company.

Long-term structural trends in the United States construction market — including housing shortages, infrastructure investment and modernization of aging assets continue to drive demand. Yet the sector has historically lagged in digital adoption, creating substantial opportunity for techenabled retailers to lead the next phase of industry transformation. RPC Inc. sees this moment as a pivotal opportunity to support Topcon Solutions Stores in their journey to drive technology adoption.

“We see tremendous opportunity in the U.S. construction sector, particularly as contractors accelerate their projects through digital transformation,” said David Alban, RPC Inc. board member and CEO and president of Ring Power Corporation. “Topcon is a global leader in positioning technology, and Topcon Solutions Stores have earned the trust of thousands of end users across the country. By investing in TSS, we are supporting a business that is positioned to modernize a massive, essential industry and deliver real value to the professionals who build America’s infrastructure.”

Ivan Di Federico, president and CEO of Topcon Positioning Systems, said, “RPC Inc.’s investment reflects

the growing recognition that positioning technology and job site automation are essential to the future of construction. Topcon Solutions Stores play a critical role in delivering that technology directly to the field, backed by training, service and trusted local support. RPC Inc.’s commitment reinforces the long-term potential of the North American market and the value of our retail network.”

“RPC Inc.’s investment is a strong endorsement of the work our TSS team does to support contractors as they adopt digital workflows, automation tools and

Lodge, executive vice president of construction of Topcon.

“The construction industry is changing rapidly, and this investment strengthens the push toward improved productivity and performance.”

“Topcon Solutions Stores currently operates in 14 retail locations and serves 22 states. We are a strong organization that will become stronger with the growth potential this investment brings,” said Mark Contino, vice president of Topcon North American retail distribution, TSS. “As a direct Topcon distributor and an Autodesk platinum partner, we

Komatsu North America has entered into an agreement to acquire assets of SRC of Lexington Inc., a supplier of remanufactured components and parts for construction and mining equipment based in Lexington, Ky. The deal is scheduled to close by the end of February 2026, subject to customary closing conditions.

The acquisition will strengthen Komatsu’s remanufacturing capabilities in North America and expand its ability to support customers as demand for reman solutions continues to grow. With this investment into a dedicated reman facility in the United States, Komatsu will further strengthen its presence in North America, one of the world’s largest construction and mining equipment markets.

Demand for remanufactured components has increased alongside the growth of the installed base of quarry and mining equipment in North America since 2010. During that period, Komatsu’s reman business has expanded significantly, with transaction volume increasing approximately fourfold from FY2010 to FY2024.

“North America is one of Komatsu’s most important markets for both construction and mining equipment,” said Danny Murtagh, vice president, parts and infrastructure, Komatsu North America. “This acquisition allows us to deepen our reman capabilities closer to customers, improve responsiveness and support dealers and end users with high-

quality, cost-effective solutions throughout the equipment lifecycle.”

“This agreement reflects a shared commitment to remanufacturing excellence, technical expertise and long-term support for customers,” said Tim Stack, president, SRC Holdings Corp. “Just as important, it reflects our responsibility to do what is right for our

people. Becoming part of Komatsu allows the Lexington team to build on over three decades of remanufacturing strength, while providing the investment, long-term support and opportunity needed to carry that legacy forward into its next chapter.”

Through its reman operations, Komatsu recovers used components from construction and mining equipment, restores them to likenew condition at dedicated facilities and returns them to the market with the same quality standards as new components. Remanufacturing can help reduce cost and lead time while supporting resource efficiency through reuse.

Komatsu established its global two-pillar reman structure with the launch of a facility in Chile in 2005 to support electric dump trucks manufactured in the United States, followed by a facility in Indonesia in 2007 serving equipment manufactured in Japan. As of 2025, Komatsu’s reman network has grown to 45 locations across 16 countries.

For more information, visit komatsu.com.

Trimble announced West Side Tractor Sales Co. as the newest Trimble Technology Outlet.

West Side Tractor will now sell Trimble grade control, site positioning systems and correction services technology directly to customers using John Deere earthmoving equipment, including dozers, excavators, motor graders, mini-excavators and compact track loaders.

Trimble Technology Outlets are an important part of Trimble’s civil construction distribution strategy. By adding authorized resellers representing a wide variety of manufacturers to the Trimble distribution channel, it becomes easier for users of various machine types to purchase, install and use Trimble technology for improved jobsite productivity and profitability.

As an authorized Trimble reseller, West Side Tractor now sells Trimble technology directly to its customers in northern Illinois, Indiana and Berrien, Cass and Joseph Counties in southwest Michigan.

“Our goal is to make it as easy as possible for civil contractors to reap the benefits of Trimble machine control, site positioning and correction services technology, regardless of machine type,” said Ron Bisio, senior vice president, field systems of Trimble. “West Side Tractor has established a reputation for going the extra mile to find solutions that help its customers advance their operations. By using proven Trimble technology on John Deere equipment, customers can improve jobsite accuracy, productivity and profitability.”

West Side Tractor customers can expect to receive the same level of support, including installation and training — for which the Trimble dealer channel is known.

“West Side Tractor is a third-generation, familyowned company fueled by hard work, passion for heavy machinery and innovation that has helped us meet our customers’ needs for more than 60 years,” said Lauren Coffaro, third generation owner and senior vice president of West Side Tractor. “We are excited to announce that we can now sell and support Trimble’s trusted technology to help our customers streamline their workflows, make better data-driven decisions and connect their operations. As a dealership built on relationships and long-term support, we take great pride in providing the right solution for every customer.”

For more information, visit westsidetractorsales.com/ and trimble.com.

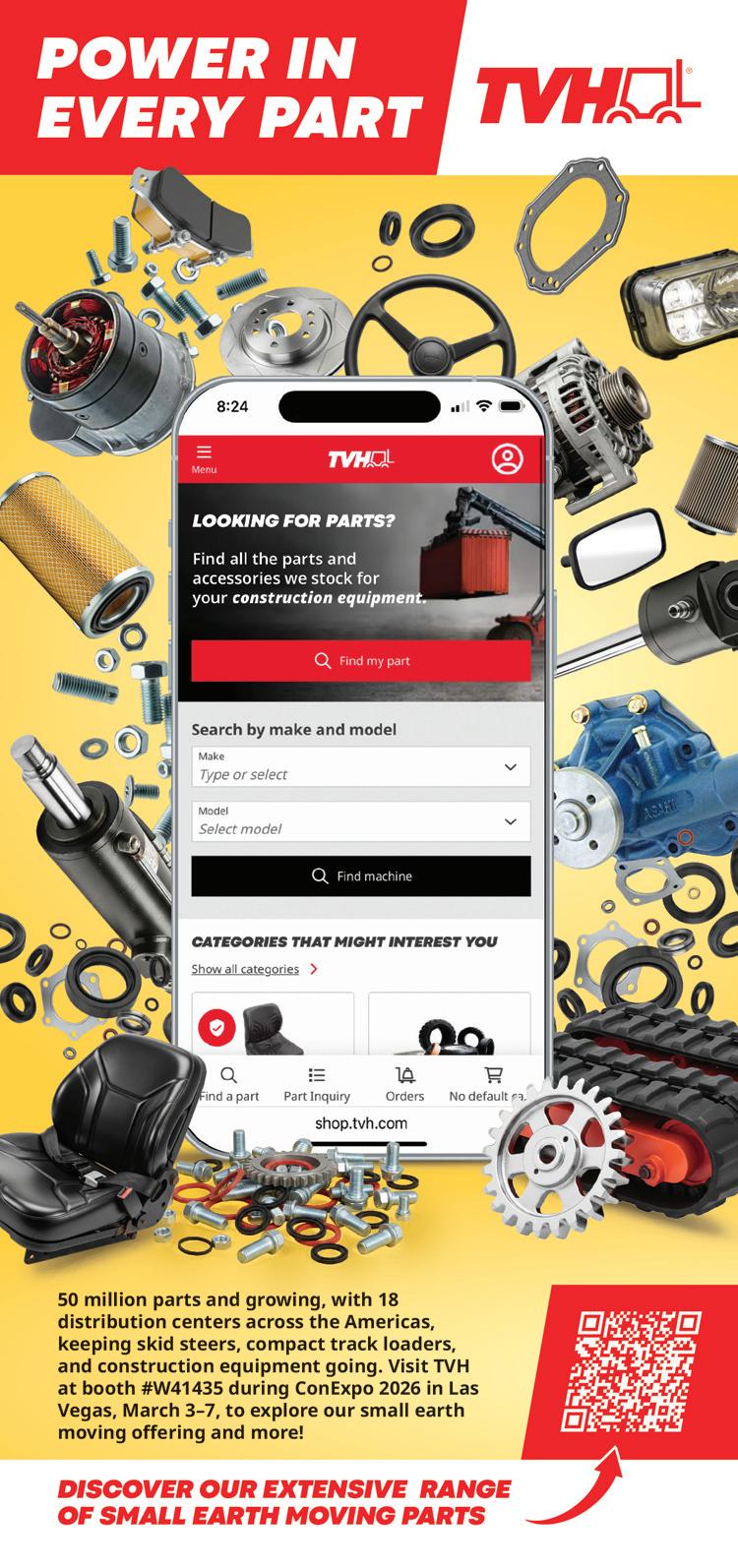

TVH is a worldwide distributor of parts and accessories for the light construction, material handling and industrial equipment markets. Since 1969, TVH has been providing replacement parts and accessories around the world.

TVH Americas is headquartered in Olathe, Kan., with 18 distribution centers throughout the Americas. The company is committed to delivering products and services that keep equipment running smoothly.

Since 1969, TVH has been providing replacement parts and accessories around the world.

TVH offers more than 50 million parts from internationally recognized manufacturers, along with a wide selection of custom-machined parts. Its inventory continues to grow through ongoing parts analysis, ensuring the right parts are in stock and ready to ship. This commitment allows 99 percent of orders to ship the same day, according to the company.

To support customers beyond replacement parts, TVH provides extensive technical knowledge through TVH University. Its training and classes are designed for employees new to the industry as well as those seeking a deeper understanding of equipment and systems. This investment helps ensure teams have the knowledge needed to work efficiently and accurately across a wide range of equipment.

TVH’s e-commerce site makes it easy to research and order parts anytime from any mobile device, according to the company. Features include browsing by category, searching by make and model and accessing catalogs and quick reference guides. TVH also offers a research request service to help verify a customer is ordering the correct part. Information spans equipment dating back 60 years and includes newer models, supporting most makes and models in the industry.

Quality is a priority at TVH. The company follows strict quality control standards, with audits performed to verify integrity, conformity and effectiveness across its systems, according to TVH.

TVH Americas will be at ConExpo-Con/AGG 2026 in Las Vegas March 3-7, 2026, at booth #W41435.

For more information, visit tvh.com.

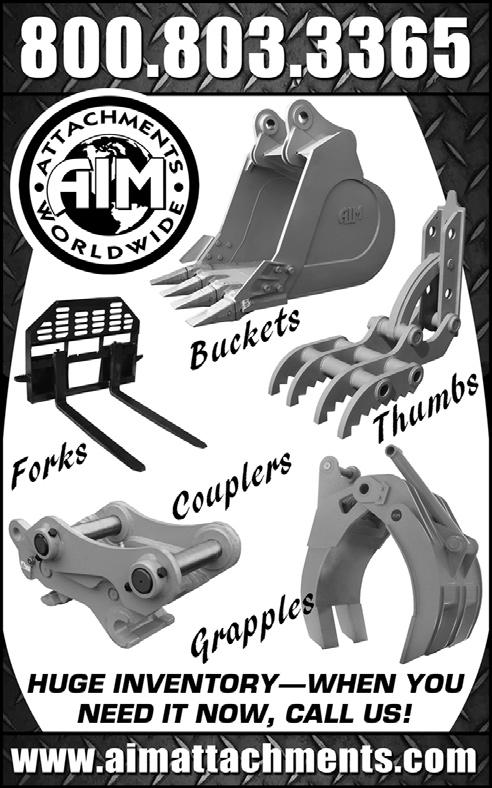

Huge attachment inventory. Over 300 attachments in stock. We Buy, Sell, and Trade. Inventory changes daily, please call to discuss your needs and how we can help.

DOZER BLADES IN STOCK

D10R/T, D9R/T, D8R/T, D7R, D7R LGP, D7E, D6R LGP, D6K, D5G, D5C.

DOZER RIPPERS IN STOCK

D10R/T SS ripper, D11R/T SS ripper, D7R MS ripper, D6N MS ripper, D5K MS ripper, D5C/D4C/D3C ripper.

EXCAVATOR ATTACHMENTS IN STOCK

Quick Couplers for Most Models from Mini - 374D/E

336 Excavator - 30”, 36”, 42”, 54”, 60” all in stock.

315 Excavator - Most Sizes from 24” - 60” ditch cleaner

312/314 Excavator - 24”, 30”, 36”, 60” ditch cleaner

320/321/312 Excavator - 24”, 30”, 42”, 54”, 80” ditch cleaner

345/349 Excavator - 36”, 48”, 54”, 60”, 72”

QUICK COUPLER FORKS IN STOCK

420 D/E/F, 950-972 Fusion, 953, 972 HPL, Cat Telehandler

WHEEL LOADER BUCKETS FROM 914-992

Many sizes and styles available. Pin-on and Quick Coupler.

M/H SERIES GRADER RIPPERS IN STOCK Also front pushblock counterweights.

RECENTLY PARTED MACHINES INCLUDE

D4c, TH83, 988F, 769C, TH460B, TH360B, 242B, 320C, 345C, 420E IT, 836G, 345CMH, M325DMH, D6T

In an asset purchase effective Jan. 30, 2026, Housby Heavy Equipment (Housby) transferred its Volvo CE inventory at three dealership locations in Iowa to Rudd Equipment Company, a subsidiary of Ferronordic. With its construction equipment headquarters based in Louisville, Ky.,

Rudd has been in business for 74 years. This acquisition brings the company to 16 total locations in eight states. The new locations cover most of Iowa and one county in Illinois, where Rudd will be an exclusive Volvo CE dealer offering Volvo CE products and services in the dealer’s new and existing territory.

“Housby has built a strong presence in their region that Rudd will undoubtedly carry forward,” said Scott Young, head of region North America, Volvo CE. “This expansion of Rudd’s territory allows Rudd to fully realize the benefits and synergies of both companies.”

“This is the first step in expanding our U.S. business,” said Henrik Carlborg, CEO of Ferronordic. “Building on the work of Kevin and Kelly Housby, we aim to continue developing a leading equipment dealership in Iowa and across the broader Midwest. We are excited to welcome the employees of Housby’s equipment dealership to Rudd and Ferronordic.”

The transaction does not affect Housby’s business for Mack Trucks or any other Housby business.

Ferronordic is a construction equipment and trucks service and sales company with branches in the United States, Germany and Kazakhstan.

For more information, visit volvoce.com.

Maverick Environmental Equipment, a provider of environmental, aggregate and recycling equipment solutions, announced the opening of its newest location in Woodhaven, Mich. This marks the company’s fifth location and represents a significant step in expanding its footprint to better serve customers throughout southern Michigan and northwestern Ohio.

The new Woodhaven facility, just south of Detroit, is strategically designed to focus on equipment service and parts sales, ensuring that customers have convenient access to expert maintenance and a comprehensive inventory of Lippmann, McCloskey, Morbark and other brands as well as aftermarket parts. By adding this location, Maverick Environmental Equipment reinforces its commitment to delivering fast, local, responsive, reliable support that keeps customer operations running at peak performance.

“Our customers depend on us for more than just equipment — they rely on us for uptime, efficiency and expert service,” said John O’Neill, CEO of Maverick Environmental Equipment. “Opening this new location in the Detroit area allows us to provide faster service and readily available parts, helping our customers minimize downtime and maximize productivity as well as reduce costs.”

The Woodhaven location will feature a well-equipped service center staffed by experienced technicians who specialize in maintaining and repairing a wide range of environ-

murphytractor.com

Park City, KS 316-942-1457

Great Bend, KS 620-792-2748

Humboldt, KS 620-473-7020

Olathe, KS 913-298-7373

Topeka, KS 785-233-0556

Ulysses, KS 620-356-1071

Dodge City, KS 620-227-3139

Gering, NE 308-436-2177

Omaha, NE 402-894-1899

Lincoln, NE 402-467-1300

Grand Island, NE 308-381-0741

North Platte, NE 308-534-7020

Kansas City, MO 816-483-5000

Springfield, MO 417-863-1000

Des Moines, IA 515-263-0055

Environmental Equipment photo

Environmental Equipment announced the opening of its newest location in Woodhaven, Mich.

mental, aggregate and recycling equipment. In addition, the facility will stock a comprehensive inventory of genuine OEM and aftermarket parts to meet the needs of customers quickly, efficiently and effectively.

This expansion reflects Maverick Environmental Equipment’s ongoing mission to support industries such as aggregate processing, organic material management, recycling and environmental services with solutions and exceptional customer care. With five locations in three states, Maverick continues to set the standard for quality, reliability and responsiveness in the material processing space.

For more information, call 734/672-6000 or visit MaverickEnvironmentalEquipment.

Fort Dodge, IA 515-576-3184

Sioux City, IA 712-252-2753 Waterloo, IA 319-235-7085

Brunswick, OH 330-220-4999

Cambridge, OH 740-439-2747 Canton, OH 330-477-9304 Cincinnati, OH 513-772-3232 Columbus, OH 614-876-1141 Jackson, OH 740-688-4100

Lima, OH 419-221-3666 Painesville, OH 440-639-0700

Poland (Youngstown), OH 330-629-6299 Rossford, OH 567-352-7001

Vandalia (Dayton), OH 937-898-4198

www.westsidetractorsales.com

Bemidji, MN 218-759-1996

Duluth, MN 218-722-7456

Grand Rapids, MN 218-326-9427

Ashland, WI 715-682-5522

Chippewa Falls, WI 715-834-2924

Merrill, WI 715-536-0633

Escanaba, MI 906-789-9054

Marquette, MI 906-789-7689

Fenton, MO

636-349-0200

Foristell, MO 636-463-2500

Mt. Vernon, IL 618-244-6800

Mitchell, IL

618-931-1034

Cape Girardeau, MO 573-334-0563

Paducah, KY 270-554-1131 Cuba, MO 573-885-0500

Owensboro, KY 270-684-2339

Evansville, IN 812-473-0484

Kingsport, TN 423-349-5001

Knoxville, TN 865-546-3207

Chattanooga, TN 423-855-0633

Nashville, TN 615-501-8600

Bowling Green, KY 270-842-3400

Louisville, KY 502-253-3721

Lexington, KY 859-788-3950

London, KY 606-862-8447

www.brookstractor.com

Madison (Sun Prairie), WI

608-837-5141

Milwaukee, WI 414-462-9790

Green Bay (De Pere), WI 920-336-5711

La Crosse (West Salem), WI

608-786-2644

Stevens Point (Plover), WI 715-254-2777

Racine (Mt. Pleasant), WI 262-898-6700

Sparta, WI 608-351-2101

www.lec1.com

Ashland, KY

606-327-1709

Pikeville, KY

606-432-0321

Marietta, OH

740-373-5255

Cowen, WV

304-226-3299

Beaver, WV

304-255-1525

Elkins, WV

304-636-6421

Cross Lane, WV

304-204-1818

www.martinequipment.com

Goodfield, IL

309-965-2502

Peru, IL 815-224-4711

Rock Island, IL 309-787-6108

Springfield, IL

217-528-4347

Tolono, IL 217-485-6755

Cedar Rapids, IA

319-365-0515

Dubuque, IA

563-588-1950

Columbia, MO

573-657-2154

Palmyra, MO

573-769-2274

3300 Ogden Ave Lisle, IL 60532 630-355-7150

South Holland, IL 708-331-6362 Rockdale, IL 815-730-9011 Wauconda, IL 847-526-7700

Realistic Scale Models

see CHART page 40

POWER SYSTEMS & SERVICES

www.cpower.com

9200 Liberty Drive

Liberty, MO 64068

816-781-8070

Wichita, KS

316-943-1231

Woodward, OK

580-256-6014

Salina, KS

785-825-8291

Colby, KS

785-462-8211

Springfield, MO

417-865-0505

Joplin, MO

417-726-5373

Riverside, MO

816-415-6787

Wichita, KS 316-789-7370

Yukon, OK 405-324-2330

St. Peters, MO

314-427-4911

Liberty, MO 816-415-6700

Tulsa, OK 918-984-6565

Komatsu introduced the new PC365LC-11 multifunction plus excavator to the North American market.

It features a refreshed exterior design, an enhanced operator cab and several new standard and optional features built and optimized for the North American construction market.

The PC365LC-11 is the only excavator in its class featuring an electric swing system with “boom-up” power assist, according to Komatsu. The dedicated electric swing motor improves swing speeds and operational efficiency, reducing cycle times in multifunction applications delivering up to a 15 percent increase in productivity compared to the PC360LC-11. The ultracapacitor stores an additional 70 electric horsepower for acceleration when the engine is in ultra-low idle for instantaneous power to the work equipment on demand.

The ultra-low idle state reduces fuel consumption by up to 20 percent, extending runtimes and lowering total cost of ownership. All electrical energy used in this system is generated during normal operation and stored in the ultracapacitor — no external charging needed. Without the need for hydraulic power for swing operations, this power is fully available for the boom, arm and bucket cylinders.

martinequipment.com

Goodfield, IL 309-965-2502

Peru, IL 815-224-4711

Rock Island, IL 309-787-6108

Springfield, IL 217-528-4347

Tolono, IL 217-485-6755

Cedar Rapids, IA 319-365-0515

Dubuque, IA 563-588-1950 Columbia, MO 573-657-2154

Palmyra, MO 573-769-2274

murphytractor.com

Park City, KS 316-942-1457

Great Bend, KS 620-792-2748

Humboldt, KS 620-473-7020 Olathe, KS 913-298-7373

Topeka, KS 785-233-0556 Ulysses, KS 620-356-1071

Dodge City, KS 620-227-3139

Fort Dodge, IA 515-576-3184

Sioux City, IA 712-252-2753 Waterloo, IA 319-235-7085

Brunswick, OH 330-220-4999

Cambridge, OH 740-439-2747

Optimizing hydraulic flow further reduces digging cycle times and reduces work equipment lag, enabling smoother operation in multifunction applications. These features also make the PC365LC11 quieter, according to Komatsu.

Compared to the previous model, this workhorse brings new features and enhancements across three key areas: operator experience, technology and attachment flexibility:

• Greater operator comfort for long shifts: A new heated air-suspension operator seat features a high leather back, improved cushioning and multiple adjustments. New proportional joysticks offer an intuitive, ergonomic feel that’s easy to use, helping reduce operator fatigue and wrist stress.

• Technology that gets the job done: The KomVision camera system comes as standard and provides a real-time bird’s-eye view of the machine and its surroundings to help improve situational awareness that drives Komatsu’s mission of zero harm. An optional Smart Construction 3D machine guidance kit can be factory-installed. This system provides operators in the field and managers in the office access to 3D design and topography data that help drive work accuracy, control load volumes and promote optimized operations.

• Efficient, fast and versatile attach-

ment operation: The tool control system is standard for machine configurations with an additional hydraulic piping line, which allows operators to configure and store flow rates/target pressures for multiple attachments. Attachment information is displayed on the in-cab monitor interface.

This system improves efficiency, precision and performance by enabling quick switching between attachments with accurate, preconfigured hydraulic settings tailored to each tool, according to Komatsu. Optional hydraulic quick coupler piping can be factory-installed for quick, easy attachment of tools, such as the Lehnhoff quick coupler system.

For added peace of mind, this machine’s electric powertrain components are covered by a 7-year/15,000hour transferable warranty.

“The PC365LC-11 was engineered for excellence in multifunction applications by leveraging its innovative electric powertrain system to boost job site productivity while reducing fuel consumption,” said Matthew Moen, product manager. “To highlight these performance enhancements, we’re emphasizing the concept of ‘multifunction plus’ as the defining feature of this machine.”

For more information, visit komatsu.com.

Gering, NE 308-436-2177 Omaha, NE 402-894-1899

Lincoln, NE 402-467-1300

Grand Island, NE 308-381-0741

North Platte, NE 308-534-7020

Kansas City, MO 816-483-5000

Springfield, MO 417-863-1000

Des Moines, IA 515-263-0055

Canton, OH 330-477-9304 Cincinnati, OH 513-772-3232 Columbus, OH 614-876-1141 Jackson, OH 740-688-4100 Lima, OH 419-221-3666 Painesville, OH 440-639-0700

Poland (Youngstown), OH 330-629-6299 Rossford, OH 567-352-7001

Vandalia (Dayton), OH 937-898-4198

www.aisequip.com

Bridgeport, MI 989-777-0090

Grand Rapids, MI 616-538-2400

Lenox, MI 586-727-7502

New Hudson, MI 248-437-8121

Williamsburg, MI 231-267-5060

www.brookstractor.com

Madison (Sun Prairie), WI 608-837-5141

Milwaukee, WI 414-462-9790

Green Bay (De Pere), WI 920-336-5711

La Crosse (West Salem), WI 608-786-2644

Stevens Point (Plover), WI 715-254-2777

Racine (Mt. Pleasant), WI 262-898-6700 Sparta,WI 608-351-2101

www.lec1.com

Beaver, WV

304-255-1525

Cowen, WV 304-226-3299

Cross Lanes, WV

304-204-1818

Pleasant Valley, WV 304-534-5454

Norton, WV

304-636-6421

Marietta, OH 740-373-5255

Ashland, KY

606-327-1709

Pikeville, KY

606-432-0321

www.westsidetractorsales.com

Lisle, IL

630-355-7150

Rockdale, IL 815-730-9011

Rockford, IL 815-961-3160

South Holland, IL 708-331-6362

Wauconda, IL 847-526-7700

Bloomington, IN 812-333-9677

Fort Wayne, IN 260-482-8576 Indianapolis, IN 317-544-3411

Lafayette, IN 765-447-6933

South Bend, IN 574-232-1461

Terre Haute, IN 812-645-7160

You know good enough isn’t good enough. Getting ahead means digging deep and delivering impressive results. John Deere P-Tier Excavators produce at high levels, day in and day out, with the optimal performance and steady dependability you’ve come to expect. Built to bring it every day — just like you.

JohnDeere.com/Excavators

mccoycf.com

Bemidji, MN 218-759-1996

Duluth, MN 218-722-7456

Grand Rapids, MN 218-326-9427

Ashland, WI 715-682-5522

Chippewa Falls, WI

715-834-2924

Merrill, WI 715-536-0633

Escanaba, MI 906-789-9054 Marquette, MI 906-789-7689

Fenton, MO 636-349-0200

Foristell, MO 636-463-2500

Mitchell, IL 618-931-1034

Mt. Vernon, IL 618-244-6800

Cape Girardeau, MO 573-334-0563

Paducah, KY 270-554-1131

Cuba, MO 573-885-0500

Owensboro, KY 270-684-2339

Evansville, IN 812-473-0484

Kingsport, TN 423-349-5001

Knoxville, TN 865-546-3207

Chattanooga, TN 423-855-0633

Nashville, TN 615-501-8600

Bowling Green, KY 270-842-3400

Louisville, KY 502-253-3721

Lexington, KY 859-788-3950

London, KY

606-862-8447

Volvo Construction Equipment is launching the latest evolution in its short swing radius excavator range.

Volvo Construction Equipment (Volvo CE) is launching the latest evolution in its short swing radius excavator range.

Addressing key productivity challenges such as tight-space operation and demanding lifting needs, the new ECR355 delivers greater fuel efficiency, increased lifting performance and enhanced operator comfort, according to Volvo. Built for the building and utilities sectors, it helps customers achieve more with less.

The ECR355 delivers up to 7 percent greater fuel efficiency than the previous generation, due to a new electrohydraulic control system and redesigned main control valve. The system uses electronic sensors and the machine’s onboard computer to optimize flow and pressure, ensuring smooth and precise control of the boom, arm and bucket movements. Electric cooling fans operate only when needed, minimizing engine load, noise and fuel consumption. Operators also benefit from a host of additional efficiency-enhancing technologies, including new engine work modes, comfort driving control (CDC), hydraulic priority setting and automatic engine shutdown, which all contribute to lower running costs and higher uptime.

Built for versatility, the ECR355 offers a 7 percent increase in lifting

capacity and 4 percent more tractive force, unlocking new possibilities for heavy lifting, grading and loading in confined environments.

Volvo’s active control system automates boom and bucket movements for up to 45 percent faster grading with less rework and fatigue. Integrated boundary limits and dig assist apps support 2D/3D machine control and in-field design, helping operators work faster, safer and more accurately. Features like boundary limits, boom/swing priority functions and a floating dozer blade ensure precision, speed and safety on every task.

Volvo excavators boast some of the longest service intervals in the industry, including 1,000-hour engine oil changes and 3,000-hour hydraulic oil changes, according to Volvo. These synchronized intervals, aligned in 1,000-hour increments, simplify servicing and help reduce costs. The ECR355 is designed to stay working longer, with service intervals and simplified maintenance access. Key components are grouped for easy reach, with ground-level refilling and quickdrain ports to minimize downtime.

Volvo smart view with people and obstacle detection uses 360 degree cameras and intelligent radar to enhance site safety. Meanwhile, CareTrack telematics and ActiveCare provide real-time machine health data and predictive maintenance alerts which keeps fleets productive and protected.

The next generation of excavators provides Volvo’s operators environment — the new short swing excavators have a full-size conventional cab, resulting in 20 percent more space compared to other short swing models.

“When designing any new product, we wanted to keep the interest of our operators at heart,” said Jaesu Kim, global product manager of Volvo CE.

“The improved productivity within the ECR355 creates an unrivalled comfortable working environment across long shifts. Operators will also find 50 percent better in-cab cooling performance, reduced noise levels due to new electric fans and a host of modern conveniences, including Bluetooth connectivity, wireless phone charging, extensive storage solutions and a two-stage filtration system for cleaner air.”

Control is smoother and more intuitive with the precision joystick system and ergonomic switch layout, allowing operators to customize settings to suit their preferences. New electric travel pedals ensure lightning-fast response, while features such as a tiltable left console and ergonomic handrails make cab entry and exit easy and safe.

As with all Volvo standard excavators, the ECR355 comes with a lifetime warranty on the frame, boom and arm. The ECR355 is now available for order in North America, Europe, Korea and Japan.

For more information, visit volvoce.com.

www.diamondequipment.com 17035 N. Illinois Hwy. 37 Mt. Vernon, IL 62864 618-242-2273

800-388-6396

1501 Lynch Road Evansville, IN 47711 812-425-4428

800-258-4428

2000 Harlan Drive Terre Haute, IN

ABC Equipment Rental & Sales www.abcequipment.com

29 Pearl Rd. Brunswick, OH 44212 888/572-3888

38525 Chester Rd. Avon, OH 44011 440/934-7368

Alta Equipment Co. www.altaequipment.com

18405 115th Avenue Orland Park, IL 60467 844/GO2-ALTA

Central Power Systems & Services www.kubotacentral.com

1285 Acraway Street Garden City, KS 67846 620/765-3118

Yes Equipment & Services www.yesequipment.com

7001 Manufactures Drive Madison, WI 53704 888/310-3902

11715 W Silver Spring Road Milwaukee, WI 53225 888/310-3902

Lano Equipment www.lanoequip.com

6140 Highway 10 NW Anoka, MN 55303 763/323-1720

23580 Highway 55 Loretto, MN 55357 763/479-8200

3021 West 133rd Street Shakopee, MN 55379 952/445-6310

McCullough Kubota www.mckubota.com

7225 Grand Ave. Gurnee, IL 60031 224/699-2200

1966 N. State Rt. 1 Watseka, IL 60970 815/432-3965

4620 W. US-6 Morris, IL 60450 815/942-6620

21730 LaGrange Rd Frankfort, IL 60423 815/658-2682

from page 32

The LOWE® trenching attachments have proven to be one of the most useful tools in the attachment market. Primarily used on skid steer loaders, trenching attachments also excel on compact track loaders and a wide range of mini-loaders. With a large selection of boom lengths and digging chains available, the LOWE® trenching attachment can make your machinery investment more useful.

The BP-Series planetary reduction auger drives bring elements of performance and dependability to the attachment marketplace.

-Features include: increased gear strength, stronger shaft support and through hardened alloy drive shaft.

Berlon’s Skeleton Rock Grapple has dual independent claws for complete clamping down on awkward loads. This bucket is ideal for rock picking, clearing fence lines, construction, scrap metal and other clean-up applications.

Berlon’s Heavy Duty Extended Lip bucket provides greater cutting edge visibility while standard heavy duty package makes it ideal for machines 75HP and greater.

Features include: ¼” body, Reinforcement tube across back of bucket for added strength, Bucket bottom includes a heavy-duty dimple plate *A Berlon Exclusive*, 3/4”x6” weld-on cutting edge w/holes.

Berlon’s Compact Articulating Loader bucket is ideal for loading feed mixers and other heavy duty material handling equipment. Features include: ¼” body, Reinforcement tube across back of bucket for added strength, Bucket bottom includes 5 wear bars for durability, 3/4”x6” weld-on cutting edge with holes.

CHART from page 41

NOTE: *No longer selling this model in the US or Canada

Liberty, MO

816-415-6700 Springfield, MO

417-865-0505

St. Louis, MO 314-427-4911

Garden City, KS

620-765-3118

Salina, KS

785-825-8291

Colby, KS 785-462-8211 Wichita, KS 316-943-1231

Oklahoma City, OK 405-324-2330 Tulsa, OK 918-984-6565

Grand Forks, ND 701-772-5006 Devils Lake, ND 701-662-5331 Williston, ND 701-572-5050

CHART from page 45 see CHART page 50

CHART from page 48 see CHART page 56

Atlas Bobcat

Elk Grove Village

847-678-3633 88-438-8014

Mokena 708-596-8050 888-438-8014

Wauconda 847-526-4255 888-438-8014

West Chicago 630-293-0606 888-438-8014

Yorkville 630-553-0150 888-438-8014 www.atlasbobcat.com

Bobcat of Champaign Champaign 217-607-1454 www.bobcatgdn.com

Bobcat of Marion Carterville 618-985-8920 www.bobcatgdn.com

Bobcat of Springfield Springfield 217-525-0349 www.bobcatgdn.com

Bobcat of St. Louis Fairview Heights 618-397-1847 www.bobcatgdn.com

Bobcat of Effingham Teutopolis 217-717-4550 www.bobcatgdn.com

Authorized Bobcat Dealers

Atlas Bobcat Merrillville 219-381-3006 www.atlasbobcat.com

Bobcat of Evansville Evansville 812-422-8200 www.bobcatgdn.com

Bobcat of Michiana Elkhart 574-584-7550 www.bobcatofmichiana.com

Bobcat of Bowling Green

Bowling Green 270-842-4253 www.bobcatgdn.com

Bobcat of Michiana Niles 269-210-2299 www.bobcatofmichiana.com

Bobcat of Columbia Columbia 573-886-9435 www.bobcatgdn.com

Bobcat of St. Louis O’Fallon 636-240-9020 Valley Park 636-225-2900 www.bobcatgdn.com

Bobcat of Bemidji Bemidji 218-751-4660 www.goironhide.com

Farm-Rite Equipment, Inc. Dassel 320-275-2737 888-679-4857

Long Prairie 866-514-0982 320-732-3715

St. Cloud 844-262-2281

Willmar 877-484-3211 www.farmriteequip.com

Lano Equipment, Inc. Anoka 763-323-1720 888-448-5266

Loretto 763-479-8200 888-479-4342

Shakopee 952-445-6310 877-753-6100 www.lanoequip.com

Lano Equipment of Norwood, Inc. Norwood Young America 952-467-2181 www.lanoequipofnorwood.com

Swanston Equipment

Bobcat of Alexandria 320-460-8773

Bobcat of Fergus Falls 218-739-4505 www.swanston.com

Tri-State Bobcat Burnsville 952-894-0894

Little Canada 651-407-3727 www.tristatebobcat.com

Bobcat of Devils Lake Devils Lake 701-662-5331 www.goironhide.com

Swanston Equipment

Bobcat of Fargo 701-293-7325

Bobcat of Minot 701-837-9901 www.swanston.com

Bobcat of Grand Forks Grand Forks 701-772-5006 www.goironhide.com

Bobcat of Williston Williston 701-572-5050 www.goironhide.com

Tri-State Bobcat Hudson 715-531-0801

2018 US Hwy 8 St. Croix Falls, WI 715-557-6010 www.tristatebobcat.com

New settings and assistance systems supplement the comprehensive range of Liebherr generation 8 crawler excavators. These developments aim to better meet the market requirements when it comes to performance, energy efficiency and ease of use, according to Liebherr.

With LPE mode (Liebherr power efficiency), Liebherr is taking an important step towards energy management for its crawler excavators. This system, now integrated as standard on R 922 to R 945 G8 models, continuously optimizes the hydraulics and the diesel engine and reduces fuel consumption by up to 10 percent — without compromising productivity, according to Liebherr.

Easy to activate and able to store the operator’s preferred settings, LPE mode also offers a temporary performance boost for key movements, ensuring fast, precise and efficient work suited to every job site.

Liebherr’s new diesel exhaust fluid filling pump enables direct filling from the ground, and eliminates any risk of overflowing, contamination and corrosion, according to Liebherr. The operator no longer has to climb onto or off the upper carriage. The procedure is designed to save time. In conjunction with the fuel filling pump, this Liebherr solution is establishing itself as a clear benefit on demanding building sites.

The Leica 2D control system is now available as standard. Fully integrated into the main display, it provides an interface with clear, color- coded visuals for leveling and earthmoving tasks. The system delivers precision within .79 in. and offers configuration to suit any project, according to Liebherr.

The 2D guidance system also is expandable, enabling “3D ready” options from Leica, including passive 3D or semi automated 3D functions for even greater accuracy on demanding jobs. The result is higher productivity, enhanced safety and ease of use through a streamlined, operator friendly interface, according to Liebherr.

With the bucket filling assistant (BFA), Liebherr is automating bucket filling in order to optimize excavation cycles. A simple joystick command is sufficient to trigger the completely automated process that allows fast, precise and consistent bucket filling, according to Liebherr.

Available as a full factory installed feature or via software update, the BFA system includes an anti stall function that prevents bucket blockage, delivering productivity, reduced operating costs and ease of use. To enable users to get to know this assistance system, Liebherr offers 500 hours complimentary BFA use.

The weighing device also is integrated directly into the main display for the generation 8 crawler excavator as standard. This system measures with a precision of approximately 2 percent in real time during the entire loading cycle. Due to automated data recording via Liebherr Connect (depending on the license), users benefit from optimum tracking and complete traceability, according to Liebherr.

This feature is available from the factory site or via a software update and guarantees optimum HGV loading, reduces the risk of overloading and avoids potential fines. To test this system, Liebherr offers the opportunity to use it for 500

Since being introduced to the marked in 2019, the generation 8 crawler excavator has proven itself around the world, according to Liebherr.

hours free of charge.

With the Skyview 360 degree assistance system, Liebherr places safety at the forefront of every job site. This system uses four heated, high resolution wide-angle cameras to deliver a complete all round view, ensuring even blind spots remain visible in cold weather, according to Liebherr.

Operators can select from six individual views or opt for a computer-generated 360 degree bird’s eye view, displayed on an adjustable additional screen. Available from the factory site or as a retrofit solution, Skyview 360 degree allows for early obstacle detection, even in tight working environment, according to Liebherr. Compatible with all Liebherr G8 excavators, the system includes cameras, a computer unit, displays and accessories — designed for straightforward installation and seamless replacement of existing systems.

The Liebherr generation 8 crawler excavators for earthmoving were introduced to the global market in 2019. They have a futuristic design and a completely redesigned architecture in order to improve convenience, safety, ergonomics and performance, according to Liebherr.

From the R 922 to the R 945, the generation 8 range combines performance with reduced fuel consumption, supported by a comfortable operator environment and simplified, safe maintenance access.

Proven in diverse applications worldwide, this generation continues to evolve, driven by Liebherr’s commitment to providing customers with performance and reliability. For more information, visit liebherr.com.

BRANDEIS MACHINERY & SUPPLY COMPANY

www.brandeismachinery.com 1801 Watterson Tr. Louisville, KY 40299 502/491-4000

Bowling Green, KY 270/780-3004

Corbin, KY 606/528-3700 Lexington, KY 859/259-3456

Stanville, KY 606/478-9201 Paducah, KY 270/444-8390

Evansville, IN 812/425-4491 Indianapolis, IN 317/872-8410 Ft.Wayne, IN 260/489-4551

ROAD BUILDERS MACHINERY & SUPPLY CO., INC. www.roadbuildersmachinery.com

1001 S. 7th St. Kansas City, KS 66105 913/371-3822 Omaha, NE 402/331-9200 Lincoln, NE 402/325-0447 Grand Island, NE 308/384-2620 Norfolk, NE 402/316-2606