Million Semiconductor Factory Coming

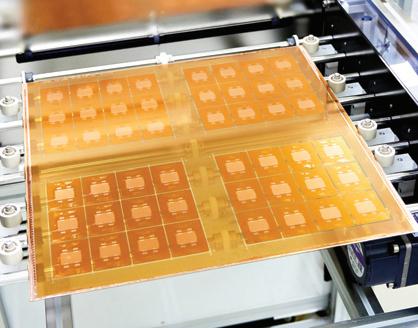

Absolics’ glass substrate nears completion in its manufacturing process. The material will reduce the space required for a multi-chip package, allowing for more chips to be packed into a single device.

A new $600 million manufacturing facility that will supply advanced materials to the U.S. semiconductor industry is set to be built in Covington, Ga., following a groundbreaking ceremony Nov. 1. Absolics Inc., a subsidiary of SKC Co. Ltd., a South Korea-based conglomerate, was formed last year. Its first factory will employ more than 400 people with high-skilled jobs in Georgia when the plant is open. The facility is being constructed to help strengthen the U.S. semiconductor supply chain by manufacturing a new material that supports next-generation computing systems.

The Georgia site will make Absolics’ inaugural product, a glass substrate, or thin layer of glass, upon which processing and memory chips can be mounted together to create the brains of a computing system. The material reduces the space needed for a multi-chip package, allowing up to four times more chips to be packed into a single device, according to a company news release.

The glass substrate is considered a technological

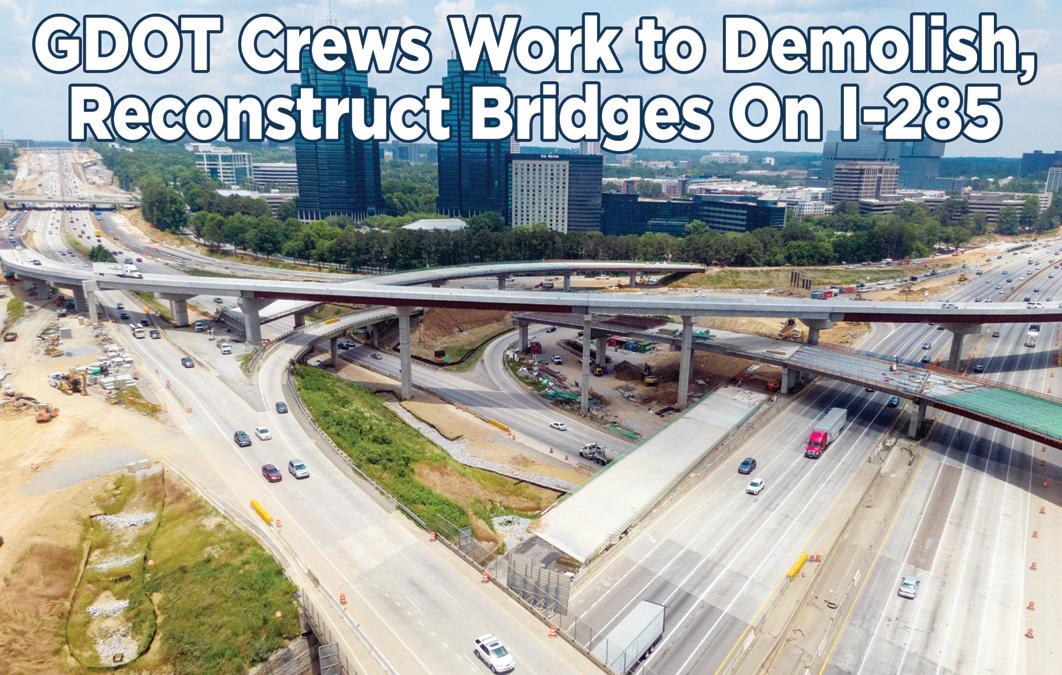

To further advance Atlanta’s Transform 285/400 interchange reconstruction project to final completion, the Georgia Department of Transportation (GDOT) closed one I-285 eastbound lane in October between Roswell Road and Ashford Dunwoody Road to allow contractors to perform bridge demolition and reconstruction at Glenridge Drive, Ga. Highway 400, and Peachtree Dunwoody Road.

The agency shut down one westbound lane of the highway on Oct. 22, 2022.

GDOT officials said the I-285 construction milestones will add more space for cars and increase new connecting lane availability outside of the existing interstate lanes, according to the Albany Herald.

The bridge replacements and associated I-285 lane closures eastbound and westbound will take at least eight months to complete, GDOT noted, and have already caused the extreme delays on I-285 that the agency predicted would occur around and approaching the work zone.

“The traveling public should expect major disruptions to their daily commutes and driving routines during this time and should be prepared for profound delays on I-285, potentially adding an hour or more to daily commutes,” GDOT Alternative Delivery Program Manager Marlo Clowers said in a news release prior to the work getting under way.

“We urge motorists to leave earlier, utilize navigation apps to select alternate routes to stay away from the construction area and consider alternative commute options. [When] traveling through the area, always pay attention and use extreme caution.”

The transportation department said lane closure schedule confirmations will come after certain I-285 construction milestones open to traffic, ensuring motorists know what to expect and when. The openings will provide added capacity for vehicles and maximize all new connecting roadway availability outside of the existing interstate lanes.

Those key milestones include:

• A new I-285 westbound connecting lane from Peachtree Dunwoody Road to past Roswell Road.

• New Ga. 400 northbound/southbound lanes and Ga. 400 southbound to I-285 eastbound connecting lane to a point past Ashford Dunwoody Road.

The lane closures will be made once these milestones are opened and updated signage is in place, GDOT noted.

The first phase of the current project has seen crews close the inside lanes on I-285 in each direction between Roswell Road to Ashford Dunwoody Road, so they can reconstruct the interior portions of the interstate’s bridges over Glenridge Drive, Ga. 400 and Peachtree Dunwoody Road. A minimum of three lanes

Crews Advance Transform 285/400 Interchange Project

from page 1

will be open in each direction. This part of the project will take approximately four months to finish.

In Phase 2, traffic will shift to the inside lanes, providing width for three travel lanes, and the existing outside lanes will close to cars and trucks so crews can demolish and reconstruct the exterior portions of the bridges. GDOT predicts this phase will likely be complete by February.

GDOT Awards, Then Defers, $93M for Two Projects Until Later

GDOT also announced in early October that it awarded seven projects valued at more than $104.7 million in August. However, the awards list that the agency provided media outlets shows that the state only distributed about $12.1 million in projects. A GDOT spokesperson said officials deferred a pair of widening and reconstruction projects worth roughly $93 million and expects to award them later.

State officials said three bridge rehabilitation contracts totaling more than $6.2 million make up 51 percent of the awarded funds. The largest allocation, approximately $4.1 million, went to Marietta’s Comanche Construction of Georgia to correct settlement issues and other work on six bridges in Carroll, Cherokee, Floyd and Whitfield counties.

The second largest contract, an approximately $2.9 million bridge construction project awarded to Williams Construction Co., in Duluth, includes 0.3 mi. of bridge construction and approaches on U.S. Highway 27 Alternate over Coleman Creek in Meriwether County. The project is 23 percent of the GDOT money awarded.

In total, construction projects account for 13.4 percent of the awarded dollars, or more than $1.6 million. Another $1 million, or 8.3 percent, of the funding was for a widening and reconstruction project, according to GDOT.

The remaining three percent went to safety projects, including signing and pavement marking upgrades at railroad crossings in Atkinson, Brooks, Cook, Lanier and Lowndes counties.

One project to receive the GDOT monies is on U.S. Highway 441/Ga. 89/Ga. 31 in Atkinson County, while the other is on Atlanta Highway in Forsyth County.

The state agency noted that so far, in fiscal 2022, which began July 1, the state has awarded $146 million.

Semiconductor Products to Be Made at New Covington Factory

from page 1

breakthrough because it can significantly increase the performance and energy efficiency of chipsets. SKC and Absolics originally developed the expertise as part of a research consortium with the Georgia Tech.

Absolics will be the first company in the world to mass produce the material.

The manufacturing facility is slated to be built in two phases, Absolics noted. The first phase, planned for completion by the end of 2023, will be a $240 million investment expected to create 140 jobs and focus on small-volume manufacturing. Mass production in this part of the factory is planned to begin in the second quarter of 2024.

The second phase of the Georgia plant is expected to be a $360 million investment that creates another 270 jobs and ramps up to high-volume manufacturing. This phase should be completed over the next three to five years.

Georgia Plant to Help Meet Product Demand

The planned investment announced at the factory’s groundbreaking, attended by officials including U.S. Sen. Jon Ossoff and state Economic Development Commissioner Pat Wilson, represents an increase from the $473 million originally

announced in October 2021. SKC and Absolics raised projections for the investment based on the need for more advanced manufacturing equipment to meet expected demand.

“Absolics will be an integral part of the semiconductor ecosystem in the U.S.,” said Woncheol Park, SKC’s president and CEO. “We are pleased to build a factory and create hundreds of jobs that will have a positive impact on the city of Covington and the state of Georgia.”

In his remarks to those in attendance at the ceremony, Ossoff said, “I am working every

day to bring jobs and business to the state of Georgia. This new plant will create Georgia jobs, support U.S. national security, and bring more advanced manufacturing to our state.”

Material Enables More Chips in Less Space

The manufacturing standard today is to place chips, like the ones Absolics plans to make, on a thin layer of silicon imposer that sits on top of a plastic substrate. The company’s new glass material replaces both layers, simplifying the manufacturing process and

reducing the thickness of the package by almost half. Certain components, such as multi-layer ceramic capacitors (MLCC), can be embedded in the glass substrate, freeing more space on the surface for chips.

Absolics noted the packaging part of the semiconductor industry is becoming more important as companies try to reach new levels of performance for their computing devices.

The energy efficiency of the glass substrate also reduces overall power consumption by up to 50 percent, driving down costs and environmental impact, especially when applied at scale in large data centers.

The company expects the first phase of the Covington factory to have an annual production capacity of roughly 14,352-sq.-yds., with the second phase ramping up to annual production capacity of 86,111-sq.-yds.

“The development of Absolics is an exciting opportunity to grow the semiconductor industry in Georgia and the entire United States — a need that is growing daily as we plan for an increasingly electrified future,” said Wilson. “Located at SKC’s existing campus in Covington, this new venture came about through research conducted at Georgia Tech, and it is the perfect example of how the state of Georgia is participating in the

of the future.”

We help build the roads that connect goods to markets, people to communities and families to one other. Astec pavers, screeds, mills, stabilizers and MTVs yield innovative and reliable Rock to Road solutions that create value and connection. We are inspired to connect with our customers through innovative design for safe and reliable roads. astecindustries.com

Birmingham, AL 205.841.6666

Montgomery, AL 334.262.6642

Mobile, AL 251.633-4020

ROCK TO ROAD®

Oxford, AL 256.832.5053 Pensacola, FL 850.479.3004 Huntsville, AL 256.536.9390

Tuscaloosa, AL 205.848.4147 Atlanta, GA 404.696.7210