Bridging the Talent Gap in a Tech-Powered Logistics Sector

CONNECTING TRADE PROFESSIONALS WITH INDUSTRY INTELLIGENCE

Bridging the Talent Gap in a Tech-Powered Logistics Sector

CONNECTING TRADE PROFESSIONALS WITH INDUSTRY INTELLIGENCE

Ghassan Aboud Holding and OK Mobility are setting a new rhythm for mobility, where logistics and innovation move in perfect harmony

Aramex Taps Logistics Powerhouse

Amadou Diallo as Its New CEO

New IVECO S-Way: high technology and efficiency on all missions

A wide choice of Euro III / V diesel engines, delivering class-leading power from 360 hp to 560 hp Euro III / 570 hp Euro V and superior fuel economy. 12-speed HI-TRONIX automated transmission with the most advanced technology in its category, electronic clutch and best-in-class torque-to-weight ratio. Full range of fuel-saving devices, such as anti-idling feature, EcoSwitch, Ecoroll and Smart Alternator. Top levels of comfort and safety, with a completely redesigned and reinforced cab, featuring enhanced direct visibility and enlarged cab livability.

GHASSAN ABOUD HOLDING AND OK MOBILITY ARE SETTING A NEW RHYTHM FOR MOBILITY, WHERE LOGISTICS AND INNOVATION MOVE IN PERFECT HARMONY

46 MARITIME WAVES WITHOUT HANDS 48 ANALYSIS

INVISIBLE THREAT IN GLOBAL TRADE

ESG REPORTING IS REWIRING THE GULF’S TRADE INFRASTRUCTURE 16 EXPERT INSIGHT BRIDGING THE TALENT GAP IN A TECH-POWERED LOGISTICS SECTOR

GLOBAL SUPPLY CHAIN ANXIETY SUBSIDES, YET RISKS PERSIST

SUSTAINABILITY

Nestled by the coast of Lusail sits the splendor of Raf es and Fairmont Doha, where luxury is rooted in even the smallest details. Open the doors to mesmerizing hospitality and make memories in a world of sophistication.

CONNECTING TRADE PROFESSIONALS WITH INDUSTRY INTELLIGENCE

CEO

Wissam Younane wissam@bncpublishing.net

Managing Director

CEO

Rabih Najm rabih@bncpublishing.net

Wissam Younane wissam@bncpublishing.net

Group Publishing Director

Joaquim D’Costa jo@bncpublishing.net

Director Rabih Najm rabih@bncpublishing.net

Commercial Director

Group Publishing Director

Andrea Mocay andrea@bncpublishing.net

Joaquim D'Costa jo@bncpublishing.net

Editor-in-Chief

Editor Aya Zhang aya@bncpublishing.net

Vibha Mehta vibha@bncpublishing.net

Digital Reporter

Managing Editor

Reeba Asghar reeba@bncpublishing.net

Kasun Illankoon kasun@bncpublishing.net

Creative Lead

Christian Harb chriss@bncpublishing.net

Design Christian Harb

Editorial Design

Marketing Executive

Rizaldi Febrian

Aaron Joshua Sinanbam aj@bncpublishing.net

Marketing Executive

Digital Media Producer

Aaron Joshua Sinanbam aj@bncpublishing.net

Alexander Bungas

Videographer

Eduardo Buenagua

Joel Amparo CONNECTING TRADE PROFESSIONALS WITH

SUBSCRIBE

subscriptions@bncpublishing.net

subscriptions@bncpublishing.net

PO Box 502511 Dubai, United Arab Emirates P +971 4 4200 506 | F +971 4 4200 196

For all commercial enquiries, contact jo@bncpublishing.net T +971 50 440 2706

PO Box 502511 Dubai, United Arab Emirates P +971 4 4200 506 | F +971 4 4200 196

For all commercial enquiries, contact jo@bncpublishing.net T +971 50 440 2706

All rights reserved © 2025. Opinions expressed are solely those of the contributors. Logistics News ME and all subsidiary publications in the MENA region are officially licensed exclusively to BNC Publishing in the MENA region by Logistics News ME.

No part of this magazine may be reproduced or transmitted in any form or by any means without written permission of the publisher.

Printed by United Printing and Publishing | upp.ae

All rights reserved © 2023. Opinions expressed are solely those of the contributors. Logistics News ME and all subsidiary publications in the MENA region are o cially licensed exclusively to BNC Publishing in the MENA region by Logistics News ME. No part of this magazine may be reproduced or transmitted in any form or by any means without written permission of the publisher.

Printed by United Printing and Publishing | upp.ae

Images used in Logistics News ME are credited when necessary. Attributed use of copyrighted images with permission. All images not credited courtesy Shutterstock.

In addition to our print edition, we’re bringing you all sorts of industry news on our web mediums. We’re looking forward to interacting with our readers on all of our social media and web platforms. See you on the web!

addition to our we’re bringing you all sorts of industry news on our web mediums. We’re looking forward to interacting with our readers on all of our social media and web platforms. See you on the web!

Every month, the logistics world reminds us that it never sits still. But as we put together this issue, it became clear that something bigger is taking shape. This month feels like the moment when the future stops knocking and simply walks right in, fully formed and unapologetically ambitious.

Across the region, we are witnessing breakthroughs that were once ideas on drawing boards. Offshore vessels are now navigating without crews on board. Supply chains are being redesigned around intelligence rather than instinct. New logistics powerhouses are entering the market with

confidence. And leadership transitions at major companies signal that the next chapter of growth will be defined by vision, strategy, and bold execution.

While reviewing this month’s stories, a single theme kept echoing through every interview, announcement, and insight. Reinvention. Not the loud kind that comes with dramatic headlines, but the quieter, determined reinvention that begins inside control rooms, engineering labs, and boardrooms where teams are quietly rewriting the future of the industry. This is the type of transformation that starts small and then suddenly becomes the new normal.

In this issue, you will find a region that is not waiting for change. This edition is both a snapshot and a signal. A snapshot of where we are today, and a signal of how fast we are moving toward a smarter, cleaner, more resilient logistics ecosystem. I hope you enjoy exploring these stories as much as we enjoyed bringing them together.

Aya Zhang Editor aya@bncpublishing.net

Xiaoyue (Aya) Zhang xiaoyuezhangg

From cold chain storage to last-mile delivery, AKI Logistics is Al Khayyat Investments’ latest venture to streamline and modernise logistics across the UAE.

Al Khayyat Investments (AKI) has launched a new business unit offering third-party logistics (3PL) services to business customers across the UAE. Operating from multiple locations, AKI Logistics is anchored by its central hubs in Dubai Industrial City and Dubai Investment Park.

The end-to-end 3PL services will cater to UAE businesses in the retail, healthcare, and FMCG sectors, among others. AKI Logistics customers will benefit from AKI’s industry-leading solutions, facilitating product customs clearance, product track-and-trace, co-packing and relabelling, specialised product handling such as cold chain storage, and last-mile delivery.

AKI has already been awarded a large Dubai government contract for its 3PL services in the UAE. Following its initial rollout in the UAE, AKI plans to expand its services across the wider region, leveraging its existing footprint across nine markets in the MENA region.

Zaid S. Al Khayyat, Managing Director of AKI, said: “For decades, we have been a growth partner to some of the biggest global brands to reach a varied portfolio of channels, from healthcare providers to large and small retailers, to hotels, airlines, as well as direct to consumers. The launch of AKI Logistics is part of our continued efforts to power businesses, communities, and people’s well-being whilst setting new benchmarks in speed, agility, and sustainability across the region.”

Samer Sabri, Chief Supply Chain Officer of AKI, added: “Our logistics operations are designed to give our customers an edge, whether that’s faster delivery, reliable cold chain solutions, or the ability to scale seamlessly. With our Fulfilment and Innovation Centre as the backbone, AKI Logistics is setting the standard for efficiency and innovation in the UAE and beyond.”

The launch of AKI’s 3PL services follows the opening of its next-generation Fulfilment and Innovation Centre in Dubai Industrial City this April. Serving as the hub of AKI’s supply chain, the one-millionsquare-foot facility has quadrupled the company’s fulfilment capacity in the UAE to over 1.5 million units per day, and includes provisions for an additional 200,000 square feet of future expansion. The facility already serves more than 30,000 business customers. In total, AKI now operates a combined warehouse footprint of 2.4 million square feet just in the UAE alone.

AKI’s influence in the UAE logistics market goes back over four decades since its founding in 1982. The family-owned conglomerate was an early investor in facilities in Dubai Investments Park (DIP), and today operates across multiple sectors spanning pharmaceuticals, medical equipment, retail, food and non-food consumer goods, fitness, automotive, environmental services, manufacturing, contracting, and now, logistics.

Etihad Cargo, the cargo and logistics arm of Etihad Airways, is continuously redefining traditional air freight while supporting the airline’s overall business growth ambitions. The carrier has recently signed an agreement with LODD Autonomous, a leader in advanced air mobility and autonomous logistics, to explore the integration of nextgeneration ‘Hili’ hybrid VTOL aircraft into UAE operations. This collaboration will complement conventional fleets with agile, short-range capacity that enhances operational resilience and service speed while ensuring lower emissions and more sustainable logistics.

With a payload capacity of 250 kilograms and a range of more than 700 kilometres, the ‘Hili’ aircraft offers the ideal balance between capacity and agility, being capable of transporting high-value shipments across a wide range of terrains and conditions.

The new partnership will centre on experimental operations to test the efficiency, safety, and ground logistics compatibility of LODD Autonomous’ flagship drone for point-to-point UAE-wide transfers. The impact on logistics could be significant, as ‘Hili’ removes the need for runways

and traditional airport infrastructure, cutting delivery times by hours or even days.

As part of the trial, Etihad Cargo will also explore the operational and commercial potential of integrating ‘Hili’ aircraft into its future fleet.

Stanislas Brun, Chief Cargo Officer of Etihad Airways, said, ‘As a fellow Abu Dhabi-based company, LODD Services shares Etihad Cargo’s ambition to transform the future of air mobility. We’re continuously looking for new ways to enhance connectivity within the UAE, empowering both the people and businesses behind every shipment. Together with LODD Autonomous, we hope to open up new possibilities for air cargo, creating smarter, faster, and more sustainable ways to move goods across the country.’

Based in Abu Dhabi, LODD Autonomous is transforming civilian logistics through automation, autonomous vehicles, and AIdriven software. Simplifying operations, reducing costs, and minimising emissions, its automated solutions serve industries spanning e-commerce, freight forwarding, healthcare, and beyond. LODD Autonomous’ focus on reliable, efficient transport seamlessly aligns with Etihad Cargo’s role as a local connector, ensuring every shipment is handled with purpose and precision.

‘We designed the ‘Hili’ Hybrid VTOL UAV to address the gaps in traditional logistics, particularly in the middle-mile sector,’ added Rashid Al Manai, Chief Executive Officer of LODD Autonomous. ‘By creating direct air corridors between logistic hubs and warehouses, it enables seamless and rapid transfers. This is especially important for high-value, timesensitive shipments such as pharmaceuticals and industrial components, where even minor delays can disrupt operations and lead to substantial financial losses.’

This partnership marks an exciting new chapter for Etihad Cargo and the middle-mile logistics sector, unlocking new efficiencies that could transform how goods are transported across the UAE. Through collaborations with the likes of LODD Autonomous, Etihad Cargo remains focused on empowering partners with faster and more reliable means of moving cargo.

The construction is set to begin in October 2026, with completion targeted for August 2028.

DHL Express, the world’s leading express and logistics provider, has announced plans to construct a world-class aircraft maintenance hangar at Bahrain International Airport. With a total investment of $85.1 million, the project marks one of DHL’s largest aviation infrastructure investments in the Middle East and North Africa.

The new facility will be the first DHL maintenance hangar in the region, designed to support the company’s growing fleet and expand its line maintenance capabilities. Covering a total built-up area of 33,850 square metres, the development will include a 9,800-square-metre hangar and 21,515 square metres of land, equipped to handle a range of line maintenance tasks for DHL’s global fleet of Boeing 777 and 767 aircraft.

Construction is expected to commence in October 2026, with the facility scheduled to go live by August 2028. Once operational, the hangar will consolidate DHL’s MENA Aviation (AVI) team, which encompasses management, maintenance, operations, and administrative support, into one unified location.

The project also reflects DHL’s commitment to environmental sustainability and operational efficiency. The hangar will feature solar panels capable of generating up to 40% of its power consumption, along with advanced data network provisions to support streamlined operations. Compliant with international aviation authority standards, the facility will ensure a fit-for-purpose maintenance environment for the maintenance of DHL’s expanding fleet.

Chief Executive Officer of DHL

On the occasion, Abdulaziz Busbate, Chief Executive Officer of DHL Express MENA, commented, “This investment will significantly strengthen our ability to manage the growing scale and complexity of DHL’s expanding air operations across MENA. By centralising maintenance, logistics, and technical functions within a single advanced facility, we will achieve new operational synergies while reducing maintenance-related emissions in line with our sustainability goals. This development also underscores DHL’s confidence in the region’s continued economic growth and its strategic role as a hub for the future of global trade.”

Richard Gale, Vice President of Aviation at DHL Express MENA, added, “Beyond operational advantages, the new hangar will help rationalise DHL’s global maintenance network by offering additional capacity for its international fleet and other DHL airlines. It will enable us to better manage spare parts and optimise inventory planning, while reducing turnaround times and enhancing the reliability of our international fleet.”

Once complete, the modern facility will contribute to DHL’s global strategy of decentralising maintenance operations across key hubs worldwide, ensuring greater efficiency and sustainability across its network. It further underscores Bahrain’s importance as a key gateway equipped with world-class infrastructure and regulatory readiness for aviation and logistics development.

Turkish Airlines is accelerating its fleet and infrastructure upgrades as it charts its path toward a bold new decade of growth.

Turkish Airlines, the airline flying to more countries than any other, has successfully completed a landmark financing transaction with Bank of China, arranged by Bank of China Türkiye A.Ş. The five-year facility, amounting to 2.9 billion Chinese Yuan (equivalent to USD 412 million), will support Airline’s core development initiatives, including fleet expansion, business growth, the construction of new facilities and infrastructure projects at Istanbul Airport.

The transaction marks a new milestone in Turkish Airlines’ ongoing efforts to diversify its funding sources while reinforcing its commitment to sustainable and globally inclusive growth. Coordinated by Bank of China Türkiye and BOC Macau branch as the lender of the facility, the financing also represents a strengthening of financial cooperation between Türkiye and China, further aligning with both countries’ long-term strategic initiatives.

Commenting on the successful transaction, Turkish Airlines

Chief Financial Officer and Member of the Board of Directors and the Executive Committee, Assoc. Prof. Murat Şeker stated: “We are pleased to deepen our collaboration with Bank of China through this important financing transaction. As Turkish Airlines continues to pursue sustainable growth and global expansion, we highly value the trust and partnership established with leading international institutions such as the Bank of China. This cooperation not only strengthens our flag carrier’s financial position but also contributes to the broader economic and cultural ties between Türkiye and China.

This transaction highlights Turkish Airlines’ strategic vision of embracing innovative and diversified financing solutions that support its long-term sustainability goals. The airline remains committed to advancing its financial strategy through partnerships with globally respected institutions, reinforcing its leadership in the global aviation industry as it continues to expand its fleet and network toward its 2033 centennial targets.

Murat Şeker, Chief Financial Officer and Member of the Board of Directors and the Executive Committee, Turkish Airlines

Dr. Shereen Nassar, Global Director of Logistics Studies and Director of MSc Logistics and Supply Chain Management Suite at Heriot-Watt University Dubai

The logistics sector in the Middle East has been a leading driver of economic growth for decades. According to a report by IMARC, the market size was USD 250 billion in 2024 and is expected to reach USD 407 billion by 2033, showing a strong CAGR of 5.57 per cent over the period. The region’s strategic geographic location, combined with the government’s focus on developing a robust logistics sector as part of broader economic diversification efforts, has further propelled the market. For instance, the National Industrial Development and Logistics Program was introduced in 2019 as part of the Saudi Vision 2030 program to position Saudi Arabia as a leading industrial power and a global logistics hub through the development of ports, simplification of customs processes, and enhancement of transportation infrastructure. The UAE has also set ambitious goals to empower its logistics sector under the aegis of We the UAE 2031. Under this vision, the government aims to position the UAE among the top three globally in the Logistics Performance Index and increase the logistics sector’s economic contribution from approximately AED136.7 billion (USD 37.2 billion) in 2024 to over AED200 billion (USD 54.4 billion) within the next seven years.

The logistics sector is undergoing profound change driven by technological advancements, changing customer behaviours, and sustainability needs. As the industry adopts digital platforms, it faces a significant shortage of talent that can hinder its progress. Bridging the gap requires an employee cohort that continually upskills and adapts to emerging technological advancements in every element of logistics, including transportation, warehouse operations, and last-mile delivery. As warehouses become automated, fleets become electric, and data informs decisions, logistics professionals must acquire new skills to prepare for the future, which are:

Digital Competency

Manual processes and disintegrated systems have characterised the logistics sector. As digital technologies such as the Internet of Things (IoT), artificial intelligence (AI), big data analytics, and blockchain emerge, logistics processes are being revolutionised

at a core level. These technologies enable real-time tracking of shipments, predictive analytics to anticipate demand, and enhanced visibility across the supply chain.

The logistics industry of tomorrow relies on tech-enabled logistics professionals who can readily embrace Transport Management Systems (TMS), Warehouse Management Systems (WMS), Enterprise Resource Planning (ERP) systems and IoT and AI-based visibility solutions. They need to learn to excel at intricate dashboard reading, real-time analysis, predictive modelling, and the use of automated warehousing systems and robotics. This will enable them to deliver actionable and data-driven insights to enterprises, resulting in enhanced accuracy and efficiency.

Because logistics activities often cross cultures and borders, practitioners must possess excellent knowledge of international trade regulations. This helps them understand the complexities of cross-border transactions and comply with various legal requirements. These include export control compliance, trade agreements, and customs regulations. This makes understanding compliance and international

trade regulations crucial in today’s globalised economy. Developments in tariffs and duties, import and export documentation, and Free Trade Agreements can have a significant impact on an organisation’s viability, making personnel with the proper knowledge a highly valuable asset. Artificial intelligence and digital technologies continue to transform international trade and logistics, as the rapid rate of change in AI challenges the role of AI in international trade regulation (WTO Report, September 2025).

Furthermore, professionals should possess cultural awareness and sensitivity. This includes understanding different business practices, communication styles, and regulatory environments.

A significant portion of a company’s carbon footprint often results from outdated supply chain processes, making sustainable logistics a key priority. Freight and warehousing logistics emissions alone account for a minimum of 7 per cent of worldwide greenhouse gas emissions, which is why there is a growing demand for green logistics that is expected to amount to some USD 350 billion by 2030. In such a context, experts with formal education and skills in implementing sustainable systems will be in high demand with corporations. This includes data on freight transport emissions, environmentally friendly packaging materials, carbon offsetting actions, alternative fuels, and the circular economy.

Additionally, International trade environmental regulations are increasingly important to be aware of, particularly as most organisations emphasise sustainability. Professionals should be aware of how regulations impact logistics operations, including packaging, waste disposal, and emissions controls.

The operations of warehouses and distribution centres are being reshaped by automation and robotics. Autonomous mobile robots (AMRs), automated storage and retrieval systems (AS/RS), drones for inventory management, and AI-based picking systems are now widely implemented, clearing the path for individuals capable of working these technologies with precision and dexterity.

The logistics sector is no longer driven by firefighting but by decision-making. Statisticians with analysis and forecasting skills, pattern recognition, and scenario modelling will allow organisations to unlock data intelligence and succeed in a global, competitive world.

Communications & problem-solving

Supply chains today are fast-paced, cross-border, and cross-functional. Current employees must be capable of communicating with all stakeholders, whether internal sales and finance teams or external customs agents and vendors. Negotiating contracts, conflict resolution, managing a virtual team, and delivering client presentations are some of the key skills required for leaders in the logistics sector of the future.

All these abilities are in high demand from employers today, who are looking to hire individuals who are flexible and dedicated towards continuous learning. A skills gap in a technology-based logistics company can only be

bridged through collaboration among organisations, training institutions, and prospective employees.

Organisations are required to ensure that they have robust upskilling and onboarding programs in place for their staff members, offering them a well-defined process through which to achieve the desired technical proficiency. Training institutes can also play a crucial role in shaping the upcoming workforce by providing relevant learning and courses that cater to the evolving needs of the logistics sector. Lastly, students and prospective employees can stand out by being current with the latest industry trends, attending industry conventions, and obtaining internationally accepted certificates and degrees.

BEGA pole-top luminaires with BugSaver® technology protect nocturnal fauna by reducing the color temperature from 3000 Kelvin to an amber color around 1800 Kelvin, which reduces the light attractive effect. The color temperature and output can be controlled dynamically. bega.com/bugsaver

A recent report shows 54% of large organisations see supply chain vulnerabilities as the biggest threat to cyber resilience. From ransomware on logistics firms to software breaches disrupting ports, these risks are already reshaping global trade.

By Richard Staynings

Richard Staynings is a globally renowned cybersecurity thought leader. He serves as Chief Security Strategists for Cylera, and as Professor of Healthcare Cybersecurity at the University of Denver. A 25-year veteran of cybersecurity leadership, Richard has served as a subject matter expert on government Committees of Inquiry into some of the highest profile cyber-attacks and data breaches.

The rapid expansion of globalised manufacturing in the 1990s has led to the formation of lengthy complex supply lines that now circumnavigate the planet. Securing this supply chain is perhaps one of the greatest of all cybersecurity challenges given its complexity. Obscured by lengthy supply chains of fourth, fifth- and sixth-party suppliers, risk is often impossible to quantify or qualify and a changing mix of supplier vendors and partners makes this a moving target, as parties shop around for the best quality, availability, and price.

But it’s not just manufactured goods that are the concern, cybersecurity risks are growing in the digital and software supply chains that feed government, education, and other critical infrastructure industries like healthcare, where risks are measured in patient lives rather than simple downtime or delays.

Nearly every industry sector today has a high and growing dependence upon technology and the interconnected systems, IoT devices, and cloud-based platforms that power them. An expanding cyber-attack surface formed by misconfigured software, API vulnerabilities, and poorly designed

OT and IoT connected devices, all lead to inevitable breaches.

According to Security Magazine, 91% of organisations have suffered a software supply chain attack in the past year. In fact, a recent study found that, since 2017, supply chain cyber-attacks have increased by 2,227% in the US alone, and ultimately, software supply chain attacks will cost the world $60 billion in 2025, and $138 billion by 2031.

Systems and software vulnerabilities ultimately lead to exploitation by criminals and pariah states. One is intent on monetising its access through theft, extortion, and terrorism, while the other is intent on espionage or causing disruption to its enemies. While both ultimately lead to operational disruption, cyber-attacks usually also lead to productivity delays, financial loss, regulatory and reputational damage.

Perhaps the biggest software supply chain attack is that of the SolarWinds Orion hack in 2020, which injected an espionage backdoor into network monitoring software that was delivered to more than 30,000 companies and government agencies.

In addition, the most devastating software supply chain attack is that of NotPetya, malicious code that wiped the hard drives of thousands of computers when companies installed an update to the Ukrainian M.E.Doc tax accounting software in 2017. The attack impacted computer systems worldwide and caused an estimated $12 billion in damages.

While container ships, ports and rail systems are increasingly reliant upon operational software to load and balance freight, and schedule ‘just-in-time’ delivery of supplies, these too are subject to supply chain risks.

As recently as last week, an IT outage caused a systemwide ground-stop on all Alaska Airlines flights - its second this year. An August 2025 ground-stop for United Airlines was caused by a technology issue in its weight and balance computer system. Other airlines have suffered complete technology meltdowns when crew scheduling software failed stranding flight crews, or when a software glitch in a CrowdStrike update blanked thousands of

airline computer systems worldwide. These logistics stoppages were all the result of vulnerabilities and failures in third party software.

Maritime ports, responsible for 80% of global trade and serving as critical NATO logistics hubs, are facing a surge in cyberattacks from state-linked actors, according to a new policy brief from the NATO Cooperative Cyber Defence Centre of Excellence (CCDCOE). The report detailed how surveyed countries have experienced cyber-attacks within the past five years against access control systems and vessel traffic management systems in particular.

The transportation of goods is also subject to natural disasters like typhoons and hurricanes, geopolitical tensions and trade wars, and armed conflict that close transportation routes such as the Red Sea, Suez Canal, or flights over Russia. Port congestion, and operational errors that wedge container ships in narrow waterways can cost millions in delayed or diverted traffic. While the distribution of software is subject to supply chain attacks and the poisoning of AI systems through adversarial machine learning

and fake training data. Indeed, a growing ocean of disinformation is impacting more than just supply logistics but messing with demand itself.

The greatest risk to security and resiliency is lack of visibility into lengthy opaque supply chains where nefarious parties may have coded in backdoors for observation, foothold, and delayed cyber-attack. Insider threats should also be evaluated with rising use of pariah state agents to plant software backdoors in critical components, or with countries subject to international sanctions covertly inserting untrustworthy developers into global software engineering organisations.

Thorough and deep risk assessments are now necessary to identify vulnerabilities throughout the entire supply chain before any level of operational resiliency can be achieved. Diversification of suppliers to hedge against failures or geopolitical tensions is now a necessity. The February 2024 ransom attack against Change Healthcare, part of United Health Group (UHG), which impacted a third of all US healthcare providers, is an example of what happens where a single point of failure is allowed to develop. So too was South London’s dependence upon a single pathology provider, when in June 2024 Synnovis was attacked by ransomware, resulting in the death of one patient and injury to 14 others. Geographical diversification is also necessary to avoid environmental difficulties, national lockdowns, trade spats and geopolitical tensions.

Perhaps of all the conceivable risks to supply chains, technology is now the single greatest potential point of failure. Our slow ability to secure application code and its underlying infrastructure, combined with an insatiable appetite for greater automation of systems and processes using further technology, sets us on a high-risk path. Investment in cybersecurity and resiliency has now become critical to ensure continued availability of goods and services.

THOROUGH AND DEEP RISK ASSESSMENTS ARE NOW NECESSARY TO IDENTIFY VULNERABILITIES THROUGHOUT THE ENTIRE SUPPLY CHAIN BEFORE ANY LEVEL OF OPERATIONAL RESILIENCY CAN BE ACHIEVED.

Ghassan Aboud Holding and OK Mobility are setting a new rhythm for mobility, where logistics and innovation move in perfect harmony.

In the rapidly evolving world of mobility, few partnerships promise to redefine the way people and goods move across a region. Ghassan Aboud Holding and OK Mobility are joining forces in the UAE, blending decades of local expertise with global innovation to create a seamless, forward-looking mobility ecosystem.

For Maher Aboud, Group CEO of Ghassan Aboud Holding, and Othman Ktiri, Founder and Executive Chairman of OK Mobility, this is more than a business alignment, it’s a shared vision for how logistics, technology, and customer experience converge to shape the future of movement.

In the pages that follow, they reflect on the challenges, opportunities, and ambitions driving this collaboration, revealing how two distinct approaches can merge to create a new benchmark for mobility in the region.

Your two companies have recently aligned through OK Mobility’s entry into the UAE market, supported by Ghassan Aboud Holding. What strategic goals are you both pursuing through this collaboration, and how does logistics enable that vision?

Othman: Our collaboration with Ghassan Aboud Holding marks a pivotal step in OK Mobility’s global expansion. The UAE represents a dynamic and strategic market where innovation and customer experience define success.

By partnering with a trusted group that shares our forwardlooking mindset, we are combining operational excellence with cutting-edge global mobility solutions to offer a seamless and flexible experience for customers across the country.

Maher: This partnership perfectly reflects Ghassan Aboud Holding’s mission of “Building a better future, together.” Through Transit Auto Rental, our automotive mobility arm, and with over three decades of experience across automotive, logistics, and retail sectors, we provide the local expertise, infrastructure, and agility needed to enable OK Mobility’s successful entry into the UAE market. Together, we’re setting a new benchmark for smart and sustainable mobility solutions in the region.

Othman — OK Mobility is expanding from Europe into the Gulf. What were the main logistical and operational challenges of entering the UAE market?

Expanding from Europe into the Gulf presented new logistical and operational challenges, from navigating regulatory frameworks to adapting to the UAE’s climate and diverse customer base.

We focused on localising our services to meet these expectations, offering convenient retail locations in highdemand areas and personalised Meet & Greet services at key airports, all while maintaining the high-quality standards that define OK Mobility across Europe.

Maher — From your side, what capabilities or infrastructure did Ghassan Aboud Holding provide to support OK Mobility’s entry into the region?

Ghassan Aboud Holding, through its established automotive and logistics capabilities, provided OK Mobility with a strong operational foundation. With our long-standing presence in the UAE and diversified expertise, this partnership demonstrates how our integrated ecosystem helps international partners scale effectively and sustainably in this market.

With Ghassan Aboud Holding’s logistics infrastructure, including the Global Auto Hub and Gallega Logistics, and OK Mobility’s technology-driven operations, how do your strengths come together to create a seamless mobility ecosystem in the UAE?

Maher: Our Group’s assets, including the Global Auto Hub and Gallega Logistics, play a vital role in enabling efficient vehicle movement, servicing, and regional distribution. These capabilities form a solid backbone for OK Mobility’s operations in the UAE, ensuring reliability and speed across the value chain. It’s a prime example of how our logistics and automotive infrastructure empower partners to achieve operational excellence.

Othman Ktiri, Founder and Executive Chairman of OK Mobility

“TOGETHER, WE’RE SETTING A NEW BENCHMARK FOR SMART AND SUSTAINABLE MOBILITY SOLUTIONS IN THE REGION.”

Maher Aboud

Othman: OK Mobility brings complementary expertise in fleet management and digital-first operations. By integrating our technology-driven approach with Ghassan Aboud Holding’s logistics and infrastructure, we’re building a seamless end-to-end mobility ecosystem. This synergy allows us to deliver a superior customer experience, combining innovation, efficiency, and convenience in a fast-evolving market like the UAE.

The boundaries between mobility and logistics are becoming increasingly blurred, from fleet leasing and EV logistics to last-mile enablement. How do you both see this convergence shaping your businesses, and what new models are you planning to pursue in the next 2–5 years?

Othman: The line between logistics and mobility continues to blur, creating new opportunities for collaboration. We see strong potential in areas like

fleet leasing, EV logistics, and lastmile enablement. Over the next few years, we aim to expand these models through smart technologies and datadriven solutions that enhance efficiency and user experience.

Maher: Ghassan Aboud Holding is deeply invested in shaping the future of logistics and mobility across the region. We believe the convergence of these sectors will drive innovation and efficiency, from supporting electric vehicle adoption to enabling smarter, greener supply chains. Working alongside OK Mobility, we’re building the infrastructure and partnerships that will define the next generation of mobility solutions.

From predictive fleet management to end-to-end supply chain visibility, what technologies are you prioritising to optimise operations, enhance efficiency, and prepare for future growth?

Othman: Technology sits at the core of OK Mobility’s operations. From predictive fleet management to AIdriven demand forecasting, our goal is to optimise every aspect of the customer journey. This allows us to provide real-time mobility solutions while improving efficiency and reducing environmental impact.

Maher: Digitalisation is a cornerstone of Ghassan Aboud Holding’s growth strategy. Across our automotive and logistics verticals, we are investing in platforms that enhance supply chain transparency, automation, and customer connectivity.

By aligning our digital capabilities with OK Mobility’s advanced fleet technology, we’re building a fully integrated, data-driven ecosystem that supports future growth.

You both operate across Europe, the Middle East, and Africa — each with

“BY PARTNERING WITH A TRUSTED GROUP THAT SHARES OUR FORWARDLOOKING MINDSET, WE ARE COMBINING OPERATIONAL EXCELLENCE WITH CUTTING-EDGE GLOBAL MOBILITY SOLUTIONS.”

Othman Ktiri

distinct regulatory, infrastructural, and customer dynamics. What’s your shared vision for the logistics and mobility ecosystem across these regions over the next 5–10 years?

Maher: With a presence across the world, Ghassan Aboud Holding’s vision is to create interconnected ecosystems that drive trade, innovation, and sustainable growth. Our diversified portfolio and international footprint position us to support the next wave of mobility and logistics evolution across these regions, with the UAE as a hub for innovation and connectivity.

Othman: Our shared goal is to make mobility more global, sustainable, and accessible. Together with Ghassan Aboud Holding, we are committed to expanding responsibly across key regional markets, leveraging our combined expertise to deliver valuedriven, customer-focused solutions that align with the UAE’s leadership in innovation and smart mobility.

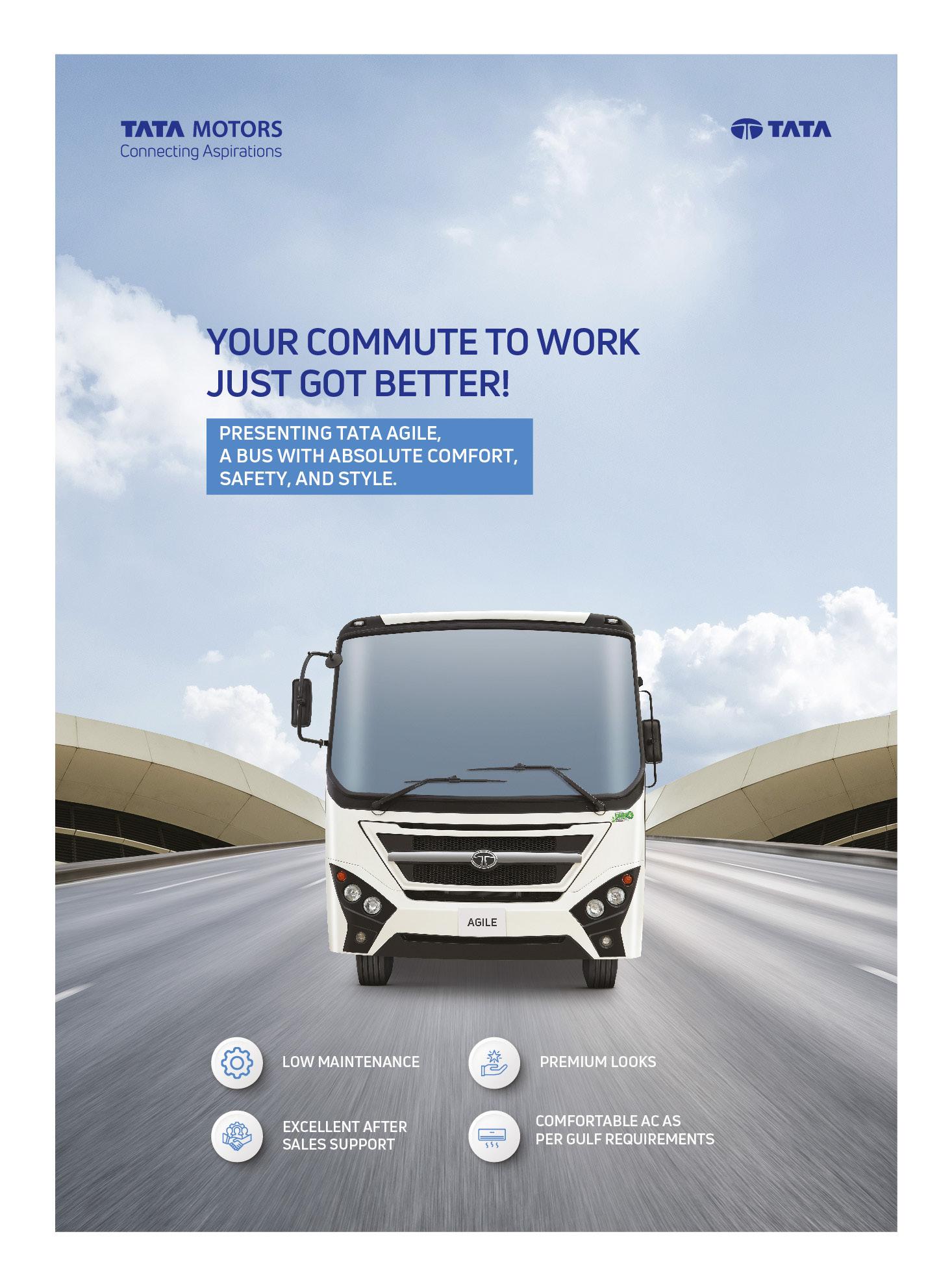

Tata Motors is shifting gears in the Middle East where innovation, sustainability, and smart engineering meet the road, with insights from Mr. Asif Shamim and Mr. Anirudhha Kulkarni.

In the bustling streets and industrial hubs of the Middle East, commercial vehicles are more than just machines, they are the lifeblood of commerce, construction, and connectivity. Amidst this dynamic landscape, Tata Motors, India’s automotive giant, is redefining what it means to lead in the commercial vehicle sector, blending cutting-edge technology, sustainability, and customer-centric innovation.

With over six decades of presence in the region, Tata Motors has become a household name for reliability and performance. “Our legacy in the Middle East is built on understanding our customers and providing value consistently,” said Mr. Asif Shamim, Head, International

Business, Tata Motors Commercial Vehicles, during a recent showcase in the UAE, one of the largest commercial vehicle markets in the region. “We have survived and thrived because we know the segments we operate in and continuously adapt to meet evolving demands.”

Customer-Centric Approach

Tata Motors’ success in the Middle East stems from a deep understanding of its customer base. Unlike many global brands that adopt a one-size-fits-all strategy, Tata Motors tailors its offerings to meet the specific operational and environmental conditions of the region. From the extreme heat of the Gulf deserts to the

demanding logistics requirements of construction and retail supply chains, the company designs vehicles that are robust, reliable, and efficient.

“Our philosophy is simple,” Mr. Shamim continued. “We don’t wait for the future— we make it happen. That’s why we are proactive in offering solutions before the market demands them. Safety, reliability, and cost-efficiency are not optional—they are mandatory.”

Innovation lies at the heart of Tata Motors’ strategy. The company emphasises three key pillars: world-class products tailored for local conditions, a strong distribution and service network, and customer-focused financing solutions. Each pillar reinforces the other, ensuring that customers not only acquire highquality vehicles but also benefit from support systems that maximise uptime and efficiency.

Tata Motors’ commitment to innovation extends to safety, comfort, and total cost of ownership (TCO). Its commercial vehicles, including the Tata Prima and Alta ranges, feature cabins compliant with stringent European safety standards—an attribute rarely matched in the region. Advanced features such as electronic stability control, anti-lock braking systems, and ergonomic design ensure driver safety and comfort, while smart engineering reduces operational costs, fuel consumption, and maintenance frequency.

Moreover, Tata Motors leverages artificial intelligence and digital validation in its vehicle development process. “Every component—from engine calibration to suspension systems—is simulated and tested digitally, allowing us to predict performance under extreme conditions,” explained Mr. Anirudhha Kulkarni, Head Engineering, Tata Motors Commercial Vehicles. “This not only enhances reliability but also accelerates innovation cycles, ensuring that we remain ahead of competitors in delivering superior products.”

Asif Shamim, Head, International Business, Tata Motors Commercial Vehicles

“OUR LEGACY IN THE MIDDLE EAST IS BUILT ON UNDERSTANDING OUR CUSTOMERS AND PROVIDING VALUE CONSISTENTLY. WE HAVE SURVIVED AND THRIVED BECAUSE WE KNOW THE SEGMENTS WE OPERATE IN AND CONTINUOUSLY ADAPT TO MEET EVOLVING DEMANDS.” - Asif Shamim

In an era of environmental consciousness, Tata Motors is pushing the envelope with its commitment to sustainability. The company is actively exploring alternative fuels—from compressed natural gas (CNG) and liquefied natural gas (LNG) to hydrogen and battery-electric solutions. These initiatives are part of Tata Motors’ ambitious net-zero target by 2045, which encompasses circularity in product life cycles, energy-efficient production, and broader biodiversity considerations.

“Our goal is not only to meet regulatory standards but to exceed them,” Mr. Shamim said. “We are committed to creating vehicles that are not just functional, but responsible, contributing to a cleaner, safer, and more sustainable world.”

“EVERY COMPONENT, FROM ENGINE CALIBRATION TO SUSPENSION SYSTEMS, IS SIMULATED AND TESTED DIGITALLY, ALLOWING US TO PREDICT PERFORMANCE UNDER EXTREME CONDITIONS.” -

Anirudhha Kulkarni

This commitment resonates with a growing demand in the Middle East for vehicles that align with national sustainability agendas, particularly in the UAE and Saudi Arabia, where governments are incentivising clean energy adoption and emissions reduction in the transport sector. Tata Motors’ focus on alternative-fuel technologies positions the company as a frontrunner in the transition toward greener commercial mobility.

The UAE, as the largest commercial vehicle market in the Middle East, serves as a strategic hub for Tata Motors. However, the company’s vision extends far beyond a single market. With a strong presence in Saudi Arabia and other GCC countries, Tata Motors aims to expand its product portfolio, strengthen after-sales services, and develop strategic partnerships. One notable collaboration is with Mohamed Yousuf Naghi Motors Co. in Saudi Arabia, which enhances distribution capabilities and customer support.

“Our growth strategy is region-specific but globally informed,” Mr. Shamim said. “We leverage insights from our operations in India and other international markets to introduce products and services that are relevant for our Middle Eastern customers.”

The “Next is Now” Philosophy

Tata Motors embodies a forward-thinking philosophy captured by the tagline “Next is Now.” Rather than reacting to market trends, the company anticipates them, ensuring that customers experience innovation, safety, and efficiency before they become industry standards. Whether

it’s adopting Euro 6 emissions compliance ahead of local regulations or integrating AI-driven diagnostics in vehicle fleets, Tata Motors consistently stays one step ahead.

The company’s connected vehicle platform, the largest in India for commercial vehicles, is gradually being adapted for the Middle East. This system allows real-time monitoring of vehicle health, predictive maintenance, and fleet optimisation, offering tangible cost savings and operational benefits for businesses.

Behind every Tata vehicle is a network of skilled engineers, technicians, and regional partners who embody the company’s customer-first philosophy. Training programs, local workshops, and continuous engagement with fleet operators ensure that the company’s commitment to quality extends beyond the factory floor.

“Our partnerships are more than business arrangements,”

Mr. Shamim emphasised.

“They are collaborations built on trust, performance, and shared values. Together, we deliver vehicles that meet the exacting standards of our customers while driving industry evolution in the region.”

As the Middle East continues its rapid development in logistics, construction, and urban infrastructure, the demand for safe, reliable, and environmentally responsible commercial vehicles is expected to grow. Tata Motors is uniquely positioned to meet this demand with its combination of legacy, innovation, and vision.

By integrating AI-driven engineering, sustainability initiatives, and customercentric strategies, Tata

Motors is not just participating in the region’s growth, it is shaping the very future of commercial mobility. The company’s journey reflects a rare blend of pragmatism and ambition, rooted in decades of experience but propelled by a clear vision for tomorrow.

As Mr. Shamim summed up: “We are not waiting for the next revolution in mobility. We are creating it. In every market, in every vehicle, and in every

partnership, Tata Motors is leading the charge toward a safer, greener, and smarter future.”

In the fast-moving world of commercial transport, where uptime, efficiency, and safety are paramount, Tata Motors’ story is a testament to foresight, innovation, and unwavering commitment to customers—a story that is only just beginning in the Middle East.

Anirudhha Kulkarni, Head Engineering, Tata Motors Commercial Vehicles

TAPS LOGISTICS POWERHOUSE AMADOU DIALLO AS ITS NEW CEO

With a proven global track record and a passion for innovation, Aramex is charting a bold new course under the leadership of Amadou Diallo.

Dubai-based logistics leader Aramex has announced the appointment of Amadou Diallo as its new Group Chief Executive Officer (CEO), effective 1 May 2026.

Amadou Diallo brings over 30 years of experience in the logistics sector to the role. He most recently served as CEO for the Middle East & Africa at DHL Global Forwarding, where he led the company’s regional operations.

Over the course of his distinguished career, he has held a range of senior leadership positions, including CEO, CFO, and COO roles, across major business units spanning Europe, Asia Pacific, the Middle East, and Africa. His extensive operational expertise, global perspective, and strategic acumen are complemented by a leadership style grounded in collaboration, performance, and innovation.

Until Amadou formally assumes his new position, Nicolas Sibuet will continue to serve as Acting Group CEO, guiding the company through the close of the 2025 financial year and into 2026. Nicolas has demonstrated strong, steady leadership throughout a period of significant transformation, ensuring consistency, focus, and delivery across all areas of the business.

Aramex remains fully committed to ensuring a seamless leadership transition and enters this next chapter with confidence. Under Amadou’s stewardship, the company

will continue to advance its Accelerate28 strategy and transformation programme, driving sustainable growth, operational excellence, and long-term value creation.

Founded in 1982, Aramex has grown into a global leader in logistics and transportation, renowned for its innovative services tailored to both businesses and consumers.

Headquartered in the United Arab Emirates and listed on the Dubai Financial Market since 2005, the company leverages its strategic location to provide seamless connectivity, effectively bridging the gap between East and West.

“WE ARE DELIGHTED TO WELCOME AMADOU DIALLO AS THE NEW CHIEF EXECUTIVE OFFICER OF ARAMEX. WITH HIS EXTENSIVE GLOBAL EXPERIENCE, STRONG OPERATIONAL EXPERTISE, AND PEOPLE-CENTRED LEADERSHIP APPROACH, AMADOU IS EXCEPTIONALLY WELL PLACED TO GUIDE THE COMPANY INTO ITS NEXT PHASE OF GROWTH. HIS APPOINTMENT REFLECTS OUR FULL CONFIDENCE IN HIS ABILITY TO SUSTAIN OUR MOMENTUM AND DELIVER LONG-TERM VALUE FOR ALL STAKEHOLDERS. WE WOULD ALSO LIKE TO EXPRESS OUR SINCERE GRATITUDE TO NICOLAS SIBUET FOR HIS STEADFAST LEADERSHIP AND DEDICATION THROUGHOUT THIS IMPORTANT PERIOD OF TRANSITION.”

In this interview with Aya Zhang, Mr. Mansoor Al Malik, Executive Director for policies and legislation Division, reveals how Dubai Customs’ Project Zero gives counterfeit goods a second life, turning seized items into sustainable solutions that benefit both the community and the environment.

What is “Project Zero”, launched by Dubai Customs, and what is its main goal?

“Project Zero” is a pioneering initiative launched by Dubai Customs in collaboration with the DP World Foundation and Landmark Group — the first of its kind in the region. The project aims to combat the illicit trade in counterfeit goods not only by seizing them but by repurposing them sustainably within a circular economy model.

Its core objective is to transform confiscated counterfeit goods into useful, usable products instead of destroying them, thereby achieving the principle of “zero waste”, protecting the environment, and promoting social responsibility.

How does “Project Zero” support circular economy and sustainability concepts?

“Project Zero” contributes to the circular economy by recycling counterfeit goods in a way that prevents them from ending up in landfills or causing environmental pollution.

It represents a paradigm shift in how customs authorities handle counterfeit items — focusing on waste reduction, resource efficiency, and cutting carbon emissions from destruction processes. Additionally, the recycled products are redirected to communities in need, adding a social and humanitarian dimension to the initiative.

What role does Landmark Group play in the implementation of the project?

Landmark Group has been tasked with handling around 500,000 counterfeit items through a sustainable recycling system designed to achieve zero waste.

Mansoor Al Malik, Executive Director for policies and legislation Division, Dubai Customs

The group’s role includes refurbishing and rehabilitating these goods to make them suitable for use once again — reducing the environmental footprint of seized products and increasing their community value.

What are the social and economic dimensions of the initiative?

Socially, the initiative provides usable products to underprivileged and affected families across various countries through our strategic partner, the DP World Foundation. This helps meet essential needs and reinforces the values of community solidarity and social responsibility.

Economically, the project reduces waste disposal costs and maximizes the use of existing resources instead of discarding them. It also strengthens Dubai’s position as a global hub that balances economic oversight with environmental and social

sustainability — attracting investments and partnerships that prioritize environmental responsibility.

How does the initiative reflect Dubai Customs’ future direction in customs work?

The initiative reflects Dubai Customs’ forward-thinking approach — evolving from a purely regulatory and enforcement body into an active partner in sustainability and innovation strategies.

It underscores the idea that modern customs work must adapt to environmental and social challenges, helping build a resilient and sustainable economy. This vision reinforces Dubai’s global leadership in adopting smart, green solutions and places Dubai Customs at the forefront of entities driving comprehensive and sustainable development.

Landmark Group is rewriting the rules of retail logistics in the Middle East. Mr. Ashish Sood, Chief Supply Chain Officer, shares how Logistiq is turning automation, AI, and cross-border reach into a seamless, next-generation fulfilment network.

Tell us more about Logistiq.

We are a Landmark Group company, with 50+ years of supply chain expertise in the Middle East, offering express lastmile delivery across GCC and X-border shipping from China & India, with integrated fulfilment solutions and contract logistics.

Our in-house delivery network, with its own hubs and vehicles, ensures complete operational control & reliability. We provide timely COD remittances, doorstep-returns & realtime visibility, all powered by our AI-driven tech platform - delivering a faster, smarter, and fully connected last-mile experience.

What specific gap or challenge within Landmark Group’s supply chain led to the creation of Logistiq, and how has that founding vision evolved?

The Landmark Group has made significant investments in its supply chain, infrastructure, technology, fleet, and network. Logistiq was created to leverage this deep supply chain expertise and build a new business vertical serving external customers.

With online retail surging, Logistiq has evolved its infrastructure to deliver faster, more flexible, and reliable fulfilment across its three core service lines—Last Mile, E-commerce Fulfilment, and Cross-Border Freight.

Ashish Sood, Chief Supply Chain Officer, Landmark Group

THE LANDMARK GROUP HAS MADE SIGNIFICANT INVESTMENTS IN ITS SUPPLY CHAIN, INFRASTRUCTURE, TECHNOLOGY, FLEET, AND NETWORK. LOGISTIQ WAS CREATED TO LEVERAGE THIS DEEP SUPPLY CHAIN EXPERTISE AND BUILD A NEW BUSINESS VERTICAL SERVING EXTERNAL CUSTOMERS.

In Last Mile, we power e-commerce through seamless deliveries ensuring every shipment reaches its destination with speed, precision, and quality. We offer express, same-day, and next-day solutions supported by automated COD and returns management and 24x7 customer service. Our in-house delivery network— covering 100% in UAE and 90% in KSA—ensures full operational control. With direct hub-to-hub connections and first-mile pickups across all major cities, we meet every customer promise: same-day/ next-day in Tier 1, and within 48–72 hours for Tier 2/3 cities.

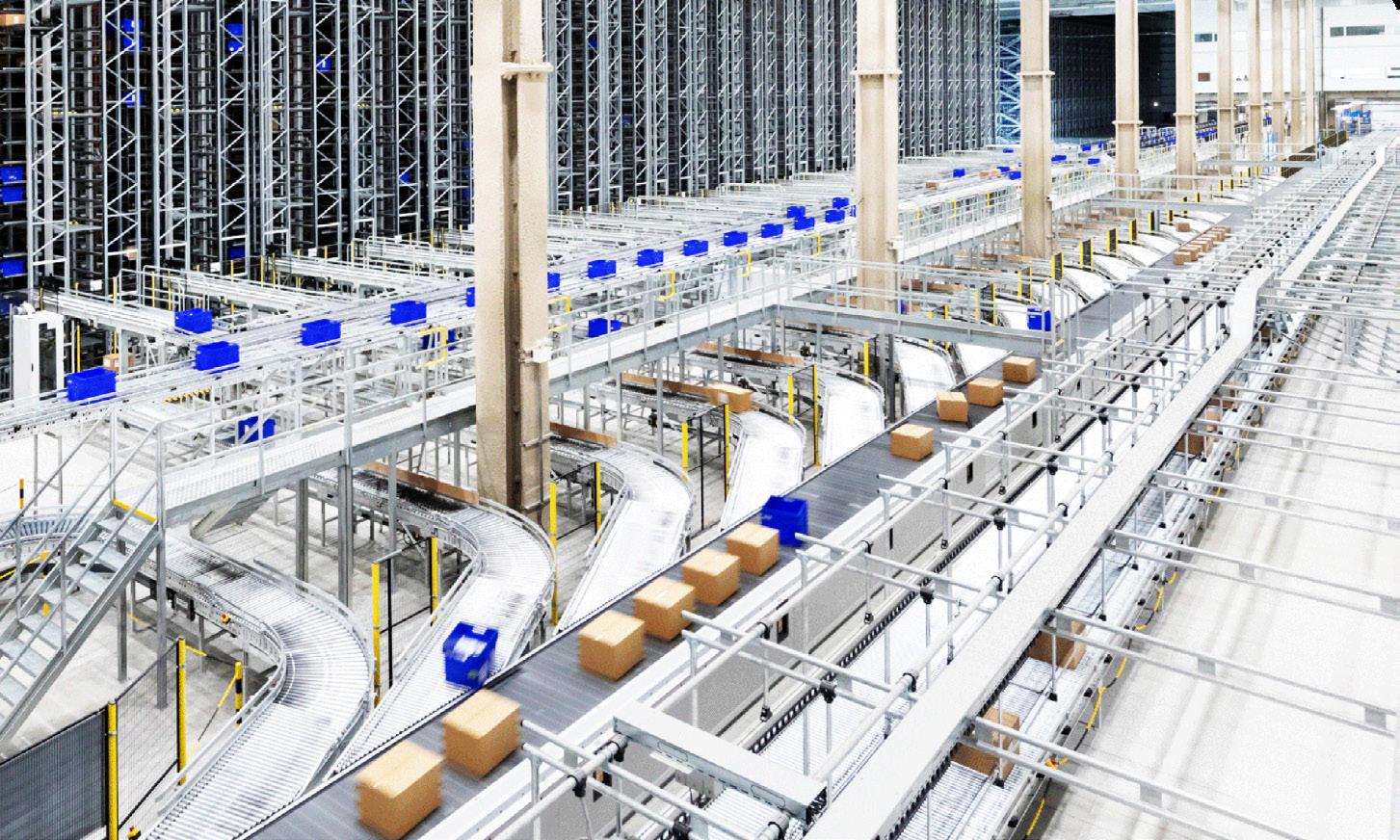

In Fulfilment, our smart storage and fulfilment network streamlines every stage—from inbound receipt to dispatch. Strategically located GCC-wide hubs combine automation, multi-format racking, temperature control, and real-time visibility for efficient warehousing. Our bonded and non-bonded facilities handle storage, order processing, and regional distribution, powered by an advanced WMS for speed and accuracy. At the core stands the Logistiq Mega Distribution Center—the region’s most advanced facility—featuring ASRS, GTP systems, automated GOH, matrix sorters, and 1,300 robotic multi-shuttles, the largest such installation globally. It sets new benchmarks in automation, scalability, and efficiency, positioning Logistiq as a trusted partner for technology-driven warehousing.

In Cross-Border Freight, we simplify complex regional logistics through integrated road, air, and sea freight solutions. With a 1,000+ truck fleet, we provide reliable door-to-door delivery across the GCC, supported by FTL/LTL flexibility and real-time tracking. Our air and sea forwarding network connects key trade lanes from China and India, while our customs clearance teams ensure compliant, end-to-end movement across all major UAE and KSA ports.

We also offer specialised large-format delivery services tailored for furniture and homeware brands, covering delivery, assembly, and returns via trained crews. With 500+ dedicated vehicles, optimised routing, and 93% FTIF performance, Logistiq ensures exceptional and reliable customer experience across the GCC.

How are data analytics and AI shaping the way Logistiq plans routes, manages inventory, and forecasts demand across different retail brands? Logistiq has implemented several AI/ML-driven initiatives to enhance delivery efficiency and accuracy. The Customer Address Book identifies repeat customers for optimised routing. Fake Attempt Validation uses GPS tracking and AI (ChatGPT) to verify genuine delivery attempts.

The Order Success Prediction Engine assigns success scores to orders based on factors like location and customer behavior, guiding dispatch planning. The Customer Address Completeness Score evaluates address quality to improve delivery accuracy.

Future initiatives focus on capacity optimisation—predicting hub workload dynamically—and network optimisation through ML-generated heatmaps to identify high-demand areas for new feeder hubs.

Data Analytics plays a key role in transforming fulfilment and last-mile operations at Logistiq. Data Analytics supported by AI/ML/IOT models drive NDR and fraud prediction, route and workforce optimisation, and customer profiling to improve delivery accuracy and efficiency.

Advanced analytics support damage reduction through AI-driven root cause analysis and bin space and inventory optimisation for better warehouse utilisation, real time operational intelligence dashboard for decision making on volume/revenue variances. IoT solutions enable realtime vehicle and route tracking, efficient last-mile delivery, capacity utilisation, ensuring operational visibility and datadriven decision-making across the logistics network.

As Landmark expands across the GCC and beyond, how is Logistiq balancing regional standardisation with the need for local adaptability?

Logistiq is well positioned to build a pan-GCC and crossborder network, creating a key differentiator in the region. We have already established China, India, Turkey, UK sales partnerships, use freight forwarders and partners for customs, and are in the process of building a pan-GCC own last-mile network (Rest of GCC - Oman, Bahrain, Kuwait, Qatar) to achieve 100% GCC coverage.

As our customers expand across the GCC and beyond, Logistiq is focused on creating the right balance between regional standardisation and local adaptability across our service lines — last mile, e-commerce fulfilment, and cross-border freight.

We’re building region-wide operating standards for processes, technology platforms, and performance metrics - ensuring consistency, reliability, and scalability. At the same time, we embed local intelligence into our operations — tailoring

delivery models, partner networks, and regulatory compliance to each market’s unique infrastructure, customer expectations, and cultural nuances.

Looking ahead, what trends do you believe will redefine retail logistics in the Middle East and how is Logistiq positioning itself to lead that change?

The Middle East retail logistics landscape is driven by multiple emerging trends:

Omnichannel Fulfilment – Rapid digital adoption is blurring lines between online and offline retail. Retailers expect real-time visibility and same/next-day fulfilment as the norm. Logistiq invests in AI-driven multiple interchangeable fulfilment models, automated hubs, and integrated tech platforms to power seamless omnichannel operations.

Advanced Automation & Robotics – Mega distribution centers are shifting toward high-density, automated operations. Our Mega Distribution Center—featuring ASRS, GTP, robotic shuttles, and smart sortation—is setting new efficiency benchmarks. Our network of last mile hubs across other GCC countries are equipped with the latest technology, applications and infrastructure.

Cross-border & regional network consolidation – GCC retail is becoming borderless, requiring unified logistics networks. Logistiq is developing a pan-GCC and cross-

border network to enable fast, compliant, door-to-door movement across markets.

Sustainability & Green Logistics – Customers and regulators are demanding eco-efficient operations. Logistiq is investing in electric fleets, optimising processes to eliminate waste, converting fleets into using biofuels, and paperless operations to cut emissions and waste.

AI/ML/Data Analytics -led decisioning, Cloud Technologies & Predictive Operations – AI/ML and other supporting technologies will drive routing, demand forecasting, and customer personalisation. The Logistiq Data Labs team is embedding analytics and AI across last mile, fulfilment, and freight to enable predictive, agile logistics.

Social Commerce & Influencer-driven Retail – Social media is becoming a powerful retail channel, driving small-batch, high-frequency delivery needs. Logistiq is adapting its fulfilment and last-mile models to support influencer stores, live selling, and dark stores for agile response.

In essence, Logistiq is positioning itself as the region’s technology-led logistics partner, combining automation, data intelligence, and regional reach to deliver faster, greener, and smarter retail supply chains.

The UAE’s offshore waters are getting a high-tech upgrade as ADNOC L&S launches its first remotely controlled landing craft vessels.

At the inaugural Abu Dhabi Autonomous Week 2025, ADNOC Logistics & Services Plc (ADNOC L&S) made waves in the maritime world by unveiling the UAE’s first Remotely Operated Landing Craft Vessels, a bold step that signals the future of offshore logistics. These 60-metre vessels, developed in partnership with SeaOwl, marry cutting-edge AI with satellite-linked control systems, allowing operations to be fully managed from ADNOC L&S’s Remote-Control Center in Mussafah. The result is a game-changing blend of safety, efficiency, and sustainability that sets a new benchmark for the global maritime industry.

At the inaugural Abu Dhabi Autonomous Week 2025, ADNOC Logistics & Services Plc (ADNOC L&S) made waves in the maritime world by unveiling the UAE’s first Remotely Operated Landing Craft Vessels—a bold step that signals the future of offshore logistics. These 60-metre vessels, developed in partnership with SeaOwl, marry cutting-edge AI with satellite-linked control

systems, allowing operations to be fully managed from ADNOC L&S’s Remote-Control Center in Mussafah. The result is a game-changing blend of safety, efficiency, and sustainability that sets a new benchmark for the global maritime industry.

“This milestone showcases ADNOC L&S’s leadership in redefining the future of maritime logistics and represents a major leap in our digital transformation journey,” says Captain Abdulkareem Al Masabi, CEO of ADNOC L&S.

“By advancing AI-powered remote vessel technology, we are enhancing safety, cutting emissions, and improving operational efficiency—supporting both ADNOC’s and the UAE’s Net Zero ambitions.”

The vessels’ innovative design eliminates the need for onboard crew accommodation, reducing weight, improving fuel efficiency, and enabling 24/7 operations.

AI-enabled route optimisation is expected to cut CO2 emissions by up to 30% compared with traditional vessels, a tangible step toward greener maritime

operations. Construction of two prototype vessels will begin by the end of 2025, with delivery slated for Q4 2026, followed by rigorous sea trials and safety validations in UAE waters.

“This collaboration with ADNOC L&S and the UAE maritime authorities sets a new global benchmark for autonomous vehicle operations,” said Xavier Genin, CEO of SeaOwl. “It brings together advanced teleoperation and AI capabilities to reshape the future of offshore logistics.”

With this initiative, ADNOC L&S is doing more than launching vessels—it is redefining what is possible in offshore operations. By combining digital mastery, AI innovation, and a strong commitment to sustainability, the company is charting a course for a safer, smarter, and greener maritime future.

The vessels’ innovative design eliminates the need for onboard crew accommodation, reducing weight, improving fuel efficiency, and enabling 24/7 operations.

AI-enabled route optimisation is expected to cut CO2 emissions by up to 30% compared with traditional vessels, a tangible step toward greener maritime operations. Construction of two prototype vessels will begin by the end of 2025, with delivery slated for Q4 2026, followed by rigorous sea trials and safety validations in UAE waters.

“This collaboration with ADNOC L&S and the UAE maritime authorities sets a new global standard for autonomous vessel operations,” adds Xavier Genin, CEO of SeaOwl. “By merging advanced teleoperation with AI capabilities, we are reshaping the future of offshore logistics on a truly international scale.”

With this initiative, ADNOC L&S is doing more than launching vessels—it is redefining what is possible in offshore operations. By combining digital mastery, AI innovation, and a strong commitment to sustainability, the company is charting a course for a safer, smarter, and greener maritime future.

The latest CIPS Pulse Survey (Q3 2025) indicates a slight easing in global supply chain anxiety following record highs earlier in the year.

The latest CIPS Pulse Survey (Q3 2025) reveals that while global supply chain anxiety has eased slightly from record highs earlier this year, procurement leaders remain alert to mounting risks, including tariffs, geopolitical instability, and a sharp rise in cybersecurity threats.

The quarterly survey, conducted by the Chartered Institute of Procurement and Supply (CIPS), found both short-term and 12-month concern levels have moderated since Q2, but remain above 2024 averages. The findings highlight that despite temporary relief, global supply chains are still operating under significant pressure.

Across the Middle East, procurement and supply professionals report similar trends: a cautious improvement in sentiment but heightened vigilance over digital vulnerabilities and tariff exposure.

Ben Farrell MBE, Chief Executive Officer of CIPS, said: “Procurement and supply chain professionals report that the panic spikes of earlier this year have eased, but the fundamentals - tariffs, geopolitics, and global

volatility - haven’t gone away. Leaders are now prioritising long-term resilience, with cyber threats emerging as a risk equal to physical supply shocks. Recent high-profile breaches underscore the need for organisations to embed cybersecurity at the heart of supply chain strategy or risk severe operational and reputational consequences.”

Cybersecurity Emerges as the New Frontline For the first time, the CIPS Pulse Survey asked respondents about cybersecurity. Nearly one in three organisations (29%) reported an increase in cyberattacks on their supply chains over the past six months, a clear sign that digital risk has become a core boardroom issue.

Sam Achampong, Regional Director of CIPS MENA, commented: “Cyber resilience is now a fundamental part of procurement leadership. In the Middle East, where digital transformation is accelerating across industries, supply chains are becoming increasingly data-driven and interconnected. This brings enormous opportunity but also heightened exposure. Procurement professionals must now act as the first line of defence, ensuring suppliers, partners and systems are secured from end to end.”

Achampong added that the survey’s findings mirror discussions at recent regional CIPS events, where leaders emphasised the strategic shift toward local manufacturing and technology-driven transparency.

“Nearshoring and local content development are becoming real priorities for MENA economies. These strategies not only mitigate tariff and logistics risks but also create stronger, more self-reliant supply ecosystems that are critical for longterm economic sustainability,” he added.

The Q3 survey data highlights several emerging trends shaping procurement strategies worldwide:

> Technology supply risk is on the rise, with 19% of respondents citing significant price increases in computers and high-tech equipment.

> Petroleum and transport equipment also remain elevated at 16%.

> 59% of procurement teams are now exploring local manufacturing or nearshoring to reduce tariff exposure.

> 54% are renegotiating supplier contracts, and 41% are consolidating spend for volume leverage.

Dr John Glen, CIPS Economist, noted: “We are seeing a structural pivot in supply chains. Tariffs are no longer a theoretical risk - they’re reshaping where and how businesses source. The fact that nearshoring and contract renegotiation are leading strategies shows how procurement is moving from firefighting to long-term redesign.”

While the global data indicates a measured improvement in sentiment, CIPS highlights that procurement teams in

every region, including MENA, must continue to strengthen their resilience against emerging digital, geopolitical and environmental risks.

Ben Farrell concluded: “The data tells us procurement is adapting fast. Nearshoring, contract renegotiation, and cyber defence are now everyday boardroom topics. The pressure may have eased slightly this quarter, but global supply chains remain fragile, and procurement leaders are still sounding the alarm.”

The CIPS Pulse Survey is a quarterly global study of procurement and supply professionals, forming part of the wider Global State of Procurement & Supply programme supported by GEP. Q3 2025 results were collected in September from hundreds of senior procurement leaders worldwide across industries including manufacturing, energy, healthcare, construction, government, and technology.

As governments roll out national visions for decarbonisation and diversification, logistics companies are discovering that robust ESG disclosure is the passport to international credibility, investment, and future growth.

In recent years the realm of logistics, often regarded purely as a mechanistic backbone of global trade, has increasingly come under the spotlight for its environmental, social and governance (ESG) credentials. Nowhere is this more evident than in the Gulf Cooperation Council (GCC) region, where the convergence of ambitious national visions, transportintensive economies and mounting investor pressure has brought ESG reporting in logistics from the margins into the mainstream.

Yet the journey is far from complete. In the fallout of this shift, the question stands: can ESG reporting in the logistics and supply-chain sector truly become a value-creating engine for trade-driven economies of the GCC, or will it remain an aspirational “tick-box” exercise?

To begin with, the logic for applying ESG frameworks to logistics is compelling. The sector sits at an intersection of carbon‐intensive transport flows, major warehousing footprints, complex labour‐and-supplier relationships, and a high degree of regulatory intensity. As one recent study puts it: “the logistics industry, as a key link connecting production and consumption, is facing many challenges, and ESG scores are gradually becoming a key indicator of the ability to measure the sustainable development of enterprises”.

In the GCC, where ports, freight corridors and multi-modal infrastructure form part of national strategic platforms (for example, as enablers of trade diversification under national visions in Saudi Arabia and the UAE), the need to align logistics operations with ESG principles is particularly acute.

But turning the logic into reality demands more than ambition. One peer-reviewed study of 117 companies across the UAE, Saudi Arabia and Qatar between 2021-22 found that while ESG performance overall has advanced, the pace and depth vary considerably, with the UAE leading, Saudi Arabia progressing moderately, and Qatar lagging behind, particularly on governance and social pillars. This unevenness matters, because strong ESG reporting depends not only on environmental disclosure but on governance rigour and social ballast, dimensions that logistics firms in the region must contend with, often under challenging structural constraints.

Consider the logistics player Gulf Warehousing Company (GWC) of Qatar, which in its 2024 ESG report explicitly sets out “sustainable logistics” as one of its key pillars. That is indicative of a broader shift: logistics firms in the GCC are increasingly placing ESG not as an add-on but as core to their operational and strategic identity. Equally telling, consultancy reporting on the sector notes that in the GCC: “The ESG imperative in GCC logistics and transportation” is becoming

a major talking point, with firms recognising that tomorrow’s “licence to operate” will depend on credible sustainability disclosures and green-logistics practices.

Why all the urgency? The trade-logistics eco-system in the Gulf is exposed to multiple pressures. First, climate-policy alignment: ports and freight corridors must increasingly account for emissions, fuel-intensity and energy use, especially given the region’s commitments under net-zero and decarbonisation frameworks.

Second, investor and stakeholder scrutiny: while GCC listed firms have generally fewer mandatory ESG disclosure requirements compared with mature markets, there is growing evidence of “high-performers on ESG” emerging in sectors including logistics.

Third, trade competitiveness: as global supply chains evolve, buyers are seeking increased transparency, carbon-footprint data and traceability, meaning logistics links that cannot credibly report ESG risk being bypassed.

Given the stakes, the “how” of ESG reporting in logistics deserves scrutiny. Effective reporting should move beyond mere metrics to narrative, context, and forward-looking commitments.

Logistics operators ought to align with recognised frameworks (for example, the Global Reporting Initiative (GRI), Sustainability Accounting Standards Board (SASB), or Task Force on Climate-related Financial Disclosures (TCFD), yet adapt them to the idiosyncrasies of freight, warehousing and multi-modal networks.

They must measure not only Scope 1 and 2 emissions (direct and energy use) but increasingly Scope 3 (supplier-chain emissions) and social-governance factors such as labour standards in logistics networks, diversity of workforce, and board oversight of sustainability strategies. They must invest in data-collection, verification and supplier engagement, especially in a region where standardisation of ESG measurement remains nascent. Critically, reporting must be coupled with targets and progress-against-targets (not simply rear-view disclosure) if it is to build credibility and stakeholder trust.

In the GCC logistics sector the time is ripe for a pivot from aspiration to action. Logistics companies that treat ESG reporting as mere compliance risk will fall behind those that seize it as an enabler of operational superiority, trade-route competitiveness and future readiness.

Policymakers, too, have a role: harmonising ESG disclosure requirements, enabling green-finance instruments for logistics players, incentivising green corridors and lowemission freight hubs will accelerate the transition. The potential is clear: logistics in the Gulf can become not just the physical arteries of trade but the sustainable veins that power it into the future.

“THE LOGISTICS INDUSTRY, AS A KEY LINK CONNECTING PRODUCTION AND CONSUMPTION, IS FACING MANY CHALLENGES, AND ESG SCORES ARE GRADUALLY BECOMING A KEY INDICATOR OF THE ABILITY TO MEASURE THE SUSTAINABLE DEVELOPMENT OF ENTERPRISES”.