PO Box 333 Roberts, Idaho 83444

Telephone: (208) 520-6461

Circulation: (503) 724-3581

OnionWorld.net

OniOn WOrld COntaCts

Editor Denise Keller editor@ColumbiaMediaGroup.com

Publisher / advertising Manager

Dave Alexander dave@ColumbiaMediaGroup.com

director of Operations

Brian Feist brian@ColumbiaMediaGroup.com

EditOrial inFOrMatiOn

Onion World is interested in newsworthy material related to onion production and marketing. Contributions from all segments of the industry are welcome. Submit news releases, new product submissions, stories and photos via email to: editor@ColumbiaMediaGroup.com.

adVErtisinG salEs

For information on rates, mechanics, deadlines, list rental, direct mail, inserts or other information, call (208) 520-6461 or email: dave@onionworld.net

sUBsCriPtiOns

U.S. $24 per year

Canada $40 per year

Foreign $80 per year

subscribe online at: www.OnionWorld.net/subscribe or call (503) 724-3581.

Email address changes/corrections to brian@ColumbiaMediaGroup.com or mail to:

Onion World PO Box 333 Roberts, ID 83444

Onion World magazine (ISSN 0892-578X), is published eight times a year and mailed under a standard rate mailing permit at Idaho Falls, Idaho and at additional mailing offices. Produced by Columbia Media Group PO Box 333, roberts, id, 83444. Copyright 2025. all rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose without the express written permission of Columbia Media Group. For information on reprints call (208) 520-6461.

Case studies and data collection were conducted in partnership with the University of Georgia Extension, Oregon State University, and Ag Metrics Group.

1

2

16% MORE SINGLE CENTERS

Laserweeding increased premium grade, single-center onions by 16% compared to herbicide treated onions. Location: ID/OR

36% FIRMER ONIONS

Laserweeded onions were 36% firmer than those treated with pre- and postemergent herbicides. Location: CA

3

4

45% COLOSSAL & 40% JUMBO

Laserweeding produced 53.66 tons per acre, with 45% colossal and 40% jumbo grade processing onions. Location: CA

SEEDED ONIONS IN VIDALIA

Laserweeding enabled direct seeded onions, boosting bulb diameter and weight by 200% compared to herbicide alone. Location: GA

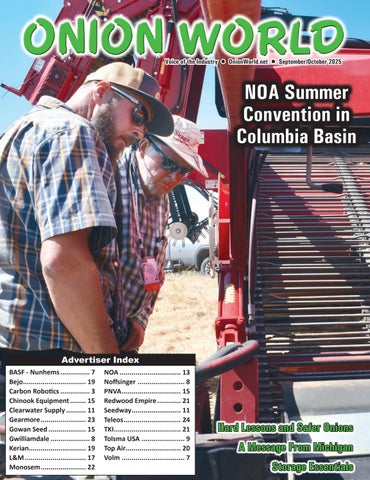

Story and photos by Dave Alexander, Publisher

Let’s face it – running a business and making decisions are tough these days. High interest rates, tariff uncertainty, inflation and low consumer confidence are all adding to trouble and indecision. But for farmers, perhaps labor problems trump everything.

At the National Onion Association (NOA) summer convention, held July 9-12 in Richland, Washington, Barry Vculek with Four Star Ag talked about his own labor issues. During the Legislative Committee meeting, Vculek, NOA first vice president, said that while the H-2A labor program for foreign workers has been a godsend for his farm, the program needs changes.

“It (H-2A) is becoming heavily favored to the employee versus the employer. We just got an email this morning that our Adverse Effect Wage Rate will be reported to us again tomorrow and it

goes into effect immediately. I'm sure it’s going to be up again. We’re paying guys that we have to train how to stack 50-pound bags and paying them 20 bucks an hour,” he said.

The Adverse Effect Wage Rate (AEWR) is the minimum wage that growers must pay H-2A temporary foreign workers. For Vculek, $20 per hour has made it harder than ever to make a profit. Hiring locals in oil-rich North Dakota has been impossible, as energy wages are even higher than that.

Stabilizing H-2A wages is just one facet of the Farm Workforce Modernization Act of 2025 (FWMA), currently in U.S. House committees. Previous iterations of this bill failed to clear the Senate despite passage in the House. If passed, the bill would overhaul the H-2A temporary worker program and make it possible for foreign farmworkers to get legal status. The aim is to create a more stable and efficient workforce and reduce farm labor shortages. Though no bill checks every box for every person, FWMA easily cleared the House on two different occasions, only to get stalled in the Senate.

Sen. Mike Crapo (R-Idaho) originally lauded the FWMA, saying on his website, “We applaud our colleagues in the U.S. House of Representatives – on both sides of the aisle – for their work on this crucial legislation to make much-needed reforms to our immigration system for our producers and farmworkers.”

He later flipped his stance, writing that the bill did not offer a sufficient number of year-round visas and disagreeing with a clause that would have allowed H-2A workers the right to sue over workplace violations.

While the bipartisan-friendly 2025 bill will likely clear the House without difficulty later this year or in 2026 as it did in 2019 and 2021, lobbying efforts may be needed to get senators like Crapo on board.

This is where the NOA’s annual lobbying trip to Washington D.C. can help. Previous trips have been successful in getting positive changes made, and the NOA encourages all interested members to sign up for the upcoming February

From size, shape, color, disease resistance and more, we sweat all the details so you don’t have to.

Visit nunhems.com for more information.

2026 trip. Other issues likely to be discussed with lawmakers will be pushing for greater enforcement of the 1944 U.S.-Mexico Water Treaty and a flat-rate duty on imported Mexican onions instead of a tariff. If you’re not an NOA member, this is a good time to join and make your voice heard because the larger the group that travels to D.C., the more impact it will have.

Not everyone has the time or resources to go to Washington D.C. with the group, but you can still make a difference.

The special guest at the Legislative meeting was Rachel McClure, a staff member from the office of Rep. Dan Newhouse (R-Washington), sent to discuss the FWMA. She recommended inviting members of Congress to local meetings or proposing a meeting when a congressperson or senator is going to be in your area.

“Follow that up with an email. Say ‘thank you for meeting, here’s our points from the meeting.’ You get that message across multiple times,” she said.

Obviously, you don’t need to be an NOA member to rattle your Senator, but membership has more benefits than just the organization’s lobbying efforts. Chief among these are the conventions themselves, which have the best networking opportunities you’ll find in the industry.

And if D.C. in the late winter is not your cup of tea, Hawaii in the late fall could be your favorite drink. The NOA annual convention is Nov. 30 - Dec. 5, 2025, in Kaua’i, Hawaii. It is a combined conference with the National Allium Research Conference, expanding networking opportunities even more.

Optimal air circulation

Humidity control that works

Energy efficient

Plug and play

Why settle for traditional methods when you can store smarter?

DRIVING EFFICIENCY, ENSURING QUALITY

BASF’s vegetable seeds business, operating in the market under the Nunhems brand, has expanded its seed portfolio with the addition of three new short-day onion varieties: Adhora, Rosefire and Isidea. This rollout comes after more than a decade of research and development.

“Our strategic planning and excellent breeding program has enabled us to deliver onion varieties that provide consistent quality and meet growers’ market needs effectively,” said Kaitlyn O’Neal, regional crop lead for BASFNunhems. “Adhora, Rosefire and Isidea are bred to enhance market potential through robust quality and uniformity.”

Adhora is a yellow onion designed for Vidalia, Georgia, and Texas. It’s said to be characterized by its early maturity, excellent yield potential and distinctive sweet flavor, as well as its reliable Granex shape and market quality.

Rosefire is a short-day red onion developed for growers in California and Texas. It boasts improved bolting tolerance and superior leaf health, maintaining high uniformity and enhancing market appeal with its consistent performance.

Isidea is a short-day white onion with early maturity and robust disease resistance in Texas and Mexico. It is marketed as offering consistent bulb size, superior color, reduced variability and high yield potential.

The uniformity of each of these varieties means growers may experience less waste, according to the company. Specifically, Adhora is proven to reduce waste to 1-2% versus the industry average of 8-10%.

BioSafe Systems has expanded its product portfolio with the addition of BioPhyter, a biostimulant. BioPhyter utilizes a plant-derived strain of the fungus Beauveria bassiana to colonize the plant systemically, from root to leaf, improving key physiological functions within the plant. This systemic activity can strengthen the vascular system, maximizing nutrient distribution, photosynthesis and structural integrity. As a result, plants are better equipped to withstand both abiotic and biotic stressors, promoting healthier, more resilient growth, according to BioSafe.

Visit www.biosafesystems.com.

Vive Crop Protection has hired Bryce Eger as executive advisor, Canada commercial development. Eger brings more than 30 years of experience in agriculture, with a career at companies including Cargill, Pioneer Hi-Bred International, Corteva Agriscience and Crop Life Canada.

Vive credits Eger with having an ability to drive innovative growth, foster transparency and cultivate talent within expanding teams. In his new role with Vive, Eger will support the company’s continued expansion in the Canadian ag market.

UNITED STATES

UNITED STATES

MEXICO

MEXICO

California (661) 699-0055

Lancaster & San Joaquin Valley (661) 978-5342

Irapuato

+52 (462) 220-0453

Torreón, Coahuila (461) 117-3878

Desert Southwest (928) 446-7737

California, New Mexico (661) 300-9109

Torreon

+52 (461) 117-3878

Colima, Col. (461) 104-0134

Colorado & New Mexico (970) 396-9728

Southern California, Arizona (760) 791-0325

Chihuahua

+52 (648) 109-1597

San Luis Potosi (461) 140-9452

Colorado (208) 550-7733

Idaho, East Oregon, Utah & Nevada (208) 941-1421

San Luis Potosi

Chihuahua (461) 171-9401

+52 (449) 196-1848

Idaho, Eastern Oregon, Utah, Nevada, North Dakota (208) 941-1421 (208) 550-7733

Skagit Valley, Washington (360) 941-7503

Rio Grande Valley & West Texas (956) 618-5574

Washington, Western Oregon (509) 820-9887

Texas (956) 618-5574

Tamaulipas

Tamaulipas (461) 134-2421

+52 (461) 346-1531

Irapuato, Gto. (461) 546-5792

Colima

+52 (461) 104-0134

For 65 years, Agri-Stor Companies has innovated post-harvest storage solutions. The Agri-Star Control Panel can provide onion storages with climate control for temperature, airflow and carbon dioxide levels. It can be customized to suit storages in any climate, including handling curing mode and burners. The intuitive app will save time and provide peace of mind for post-harvest storing challenges.

Agri-Stor’s quality crop protection options, including a line of organic products, can help shield onions in storage from bacteria and fungi. Agri-Stor’s team of technicians utilizes years of experience in providing quality applications that will produce great results in holding quality.

For over 50 years, Industrial Ventilation Inc. (IVI) has put the needs of growers at the forefront of its products and services. IVI pioneered the storage control panel, and IVI’s Imperium panel provides reliable control within 0.01 degree Fahrenheit of the target set point. Made in the U.S., the Imperium offers 12 or more sensors. Growers can easily and precisely manage storage climates by controlling fans, VFDs, evaporative coolers, humidification, heaters, refrigeration equipment and Thermadoors. Users can operate on-site with touchscreen, or remotely with an app or internet.

IVI also offers an extensive line of treatments to protect, aid curing and address the threat of disease. Service is backed by the experience and expertise to best address the optimal outcome of stored onions.

Suberizer offers turnkey storage systems that are engineered for maximum efficiency. As a proven industry leader in raw product storage, Suberizer’s commitment to innovation has impacted the way raw products are stored. Suberizer Curve and Envelope storage systems use AirEverywhere floors that ensure optimum airflow through the pile. This system minimizes loss, maintains quality and maximizes return.

Symach has a long history of palletizing onions and innovating to provide customized modular designs guaranteeing a high stacking rate with maximum flexibility. From 50-pound bulk and baled bags to complex Octabins, Symach has solutions to handle all customers’ palletizing needs.

Symach also offers options to stabilize the pallet at the end of the line, including wrapping and double stacking, palletizing within the margins of the pallet to ensure ease of loading during the shipping process.

Titan Steel's buildings are designed to provide maximum efficiency and convenience for produce preservation. Engineered with the latest industry standard technology, the company offers a perfect solution for producers. With third-party climate controlled systems, paired with ventilated floors or pipe, Titan Steel buildings ensure that onions stay fresh and in optimal condition prior to reaching consumers.

This material is provided courtesy of Claudia Nischwitz, Associate Professor and Plant Pathology Specialist, Utah State University.

Several years ago in the spring, unusual symptoms developed in some onion fields. Affected onions were scattered across a field. Samples of symptomatic and non-symptomatic leaves were collected. Until the leaves were processed the next day, they were placed in a fridge. Interestingly, the symptomatic leaves were frozen the next morning while the healthy leaves were not, providing the first clue to a potential culprit.

answers on page 22

By Stuart Reitz and Joy Waite-Cusic, Oregon State University

Dry bulb onions were traditionally considered a lowrisk produce item for human foodborne diseases, but three recent outbreaks that have been linked to onions have challenged that view. In 2020 and 2021, two large outbreaks (> 1,000 cases per outbreak) of Salmonella were tied to red onions, and in 2024, an outbreak of E. coli O157:H7 was linked to slivered yellow onions served on hamburgers at multiple locations of an international fast food chain.

Investigations to identify sources and causes of foodborne disease outbreaks are challenging and often fail to definitively identify the particular product that was the source of an outbreak, let alone the specific cause of how that product became contaminated (for example, the use of contaminated irrigation water). There is an inherent lag between when people become ill, when an outbreak is declared, when potential food sources are identified, and when corrective actions, such as recalls, can be implemented. Because of this inherent lag time, recalls are often implemented after much of the implicated product has passed through the chains of commerce.

Part of the belief that onions were “low risk” for foodborne diseases stems from characteristics of the crop, such as their papery wrapper scales and antimicrobial compounds produced in the bulbs. The wrapper scales of the bulbs are relatively impervious to water and protect the edible portion of bulbs from contamination; however, not all bulbs have intact wrappers, and they are not always completely removed during post-harvest handling. Onions do produce compounds (e.g., allicin and quercetin) that have antimicrobial activity when they are concentrated and purified; however, these defensive flavonoids are not active against Gram-negative bacteria, like E. coli and Salmonella, at the natural concentrations found in onions.

The onion industry has recognized the importance of proactively minimizing food safety risks. It has been a leader in produce safety efforts since the original draft Food Safety Modernization Act (FSMA) rules were issued over a decade ago. Even before the introduction of the FSMA rules, the National Onion Association (NOA) developed a best practices guide. In 2022, this guide was updated with the assistance of the International Fresh Produce Association (IFPA) and is available to NOA members online at onions-usa.org (Fig. 1).

No definitive cause of either the 2020 and 2021 outbreaks was identified, but contaminated agricultural water was cited as a potential cause, and growers should be aware of the microbial quality of water they use for irrigation, pesticide applications and other pre-harvest operations.

Our research has shown that drip and furrow irrigation pose little risk for contamination as soil naturally filters out much of the bacteria from the water as it moves from the drip tape or furrow to the onion bulbs (Fig. 2a, b). Overhead water applications (e.g., sprinklers, pesticide applications) pose higher risks for contamination because water is directly applied to the plant, contaminating the surface of the onion and can also move down the leaves through the neck into the interior of the bulb (Fig. 3). Bacteria on the outer leaves of the onion die off during the curing process; however, bacteria in the neck or interior of the bulb will be unaffected by curing and may grow during curing or post-harvest storage.

Regulatory investigations also identified cross-contamination in packing operations as a contributing factor in the outbreaks (Fig. 4). Over the last two years, we have been quantifying the risks for cross contamination between onions and food contact

surfaces during packing operations. Onion packing requires a dry environment, and water is generally excluded from the packing facility to prevent microbial growth. While this is a good overall strategy, the lack of regular wet cleaning and sanitation prevents establishment of a “clean break” to prevent cross-contamination between production lots. The lack of clean breaks consequently promotes largescale recalls.

To help mitigate cross-contamination risks, we have been testing the effectiveness of “dry” alcohol-based sanitizers on surfaces commonly used in packinghouses. We have demonstrated that sanitizers with an alcohol content of ~60% or more reduce bacterial loads on conveyor belts and plastic surfaces but are only minimally effective on wood. Lower alcohol products (10-30% alcohol) should be avoided because

they are ineffective and spread the bacteria, creating a larger surface area that is contaminated.

Upcoming research efforts will focus on using our research findings to model cross-contamination risks at commercial scale to quantify the potential benefit of using these sanitizers (Fig. 5). These models will be used to develop a web-based application so that industry members can explore and quantify the impact of implementing dry sanitation practices to support decision-making. Initial models will be shared at the joint National Onion Association and National Allium Research Conference in Hawaii in December 2025. We hope that these and other research findings will be incorporated into food safety plans for growers and shippers. Please reach out if we can be of assistance with your food safety plan.

There is more to learn about food safety practices in onion production, packing and fresh cut operations. In the meantime, we encourage growers to follow good agricultural practices to keep their crop as healthy and vigorous as possible. Minimizing pest and disease problems and other stresses are likely to reduce the risks of human pathogens contaminating onion bulbs. We encourage growers and packers to embrace produce safety as an integral component of their business because without this foundation, there could be no business to manage.

Jumbo yellow onion with excellent skin retention. Small neck, upringht, healthy tops. Capable for very long-term storage!

� HR: Pt

Fast – Up to 150,000 lb/hour

Gentle – Proven for Tomatoes, Peaches, & Other Delicate Products

Accurate –

YAKAMA F1 (EXP 363)

Mid-season Spanish onion! Mid-term storage, vigorous medium green Spanish tops and high single centers.

� HR: Pt, Foc

EAGLE F1 (EXP 386) Dark red, jumbo, that’s highyielding, and a vigorous variety. Excellent long-term storage potential!

� HR: Pt, Foc

By Greg Bird, Executive Director, Michigan Onion Committee and Michigan Vegetable Council

Asyou read this article, at least you will know it’s not AI generated, but more from the pen of someone who writes at the 10th grade level. This is from someone who took too many math classes in college and has typed too many brief emails since. So now, without further ado, here’s a look at what’s happening in Michigan.

There will be fewer onion acres in Michigan in 2025 as a large grower who farmed on sandy\mineral soil reached an opportune time to retire. Those acres did not go back to onions. I know some of those acres went to potatoes, but I wish

LIFTERS / DIGGERS

EFFICIENT UNDERCUTTING AND WINDROWING

• RIGID FRAME + FOLDING MODELS IN A WIDE RANGE OF CONFIGURATIONS

they had all stayed in specialty crops. I do not think any of those acres were developed into solar farms, but I know some other land did make that transition to solar this year. I hate to see the best ground leaving the vegetable industry. The volume of the 2025 crop seems good, so hopefully this makes up for those lost acres. Some onion growers are dry, but are still doing fine, while others are wet, but not too wet.

With the help of Dr. Daniel Brainard of Michigan State University (MSU) and Vriesland Growers Cooperative of Hudsonville, Michigan, the state’s onion growers have been continuing to fight off the white campion weed. Some fields are fine, but once it moves in, it is very

TOP AND CURE ONIONS IN WINDROWS

• HIGH CAPACITY

• GENTLE HANDLING

• STANDARD + XL MODELS

evasive. More field research is in place for 2025. White campion, beware: Dr. Joshua Miranda is the soon-to-start new weed scientist at MSU, and onion growers will support his efforts to get rid of white campion.

The National Onion Association (NOA) does more work for onion growers than the Michigan Onion Committee can manage. Industry information from the NOA is vital to Michigan growers. For this reason, the Michigan Onion Committee has purchased NOA memberships for each of the past three years for all Michigan growers who make their onion assessment payments.

Michigan State Senator Sam Singh sponsored a bill that changed the

INDUSTRY LEADING TOPPING AND CAPACITY FOR OPERATIONS OF ALL SIZES

• SUPERIOR DIRT & DEBRIS ELIMINATION

• BEST IN CLASS RELIABILITY

• MODELS FOR ALL GROWING CONDITIONS

Michigan 232 checkoff stature. The Michigan Onion Committee and the Michigan Carrot Commission are small enough that a yearly audit costs a significant chunk of the yearly budget. These organizations only have a handful of transactions a year. The bill that was passed allows 232 checkoff programs of the size of onion and carrot to only have a required audit once every five years. For continued transparency, the state agriculture department will help provide informal financial reviews as needed.

Well, I would give this article a B+ and that means I should get to borrow the family station wagon to go to the game this Friday night.

Nov. 19-20

Pacific northwest Vegetable association Conference and trade show

Three Rivers Convention Center Kennewick, Wash.

Sheri Nolan, (509) 585-5460 or www.pnva.org

Nov. 30 - Dec. 5

nOa annual Convention Royal Sonesta Hotel Kaua'i, Hawaii www.onions-usa.org

Dec. 9-11

Great lakes Fruit, Vegetable and Farm Market Expo

DeVos Place Conference Center Grand Rapids, Mich. www.glexpo.com

Sectagon for nutsedge suppression

Sectagon for sodium-sensitive crops

Sectagon for germinating weed seeds

Sectagon for soil preparation

Sectagon for metam potassium

Sectagon for metam sodium

Sectagon for Verticillium suppression

Sectagon for Phytophthora suppression

Sectagon for root-knot nematode suppression

Sectagon for high pH soils

Sectagon for calcium carbonate soils

Sectagon for nematode suppression

Sectagon for weeds

Sectagon for onions

Sectagon for carrots

Sectagon for potatoes

Sectagon for tomatoes

Sectagon for strawberries

For proven protection from the start, ask for Sectagon.

The symptoms seen in the photos are caused by a strain of the bacterium Pseudomonas coronafaciens.

The bright yellow of the leaves gives the disease its name “yellowbud.” It occurs sporadically, especially during cool temperatures. It is unknown which environmental conditions influence disease development and how they play a role. The bacteria are ice nucleating, which means they can act as a nucleus for water molecules to arrange themselves to form ice crystals at temperatures just above freezing. Under the right conditions, this can lead to frost damage of plant tissue that is colonized with the bacteria, while leaf tissue without the bacteria is unaffected.

There are two phases to the disease. In the first phase, the bacteria colonize the leaf surface. They produce a toxin called coronatine that affects chloroplasts and leads to the yellowing of the leaves. Toxin production is affected by temperature. The higher the temperature, the less toxin is produced. The toxin also opens stomates, which become entranceways for bacteria to get inside the leaves. The second phase, which does not always occur, results in leaf blight and plant death. It takes place if the plants are exposed to the toxin for a long time. If temperatures warm up quickly after initial infection, the second phase may not develop and plants recover.

For diagnosis, the bacteria can be cultured from infected leaves. Compared to other bacteria, these bacteria are very slow growing. Current management recommendations include controlling weeds which can harbor the bacteria, avoiding entering fields when leaves are wet, and applying fixed copper products tank mixed with EBDC fungicides.

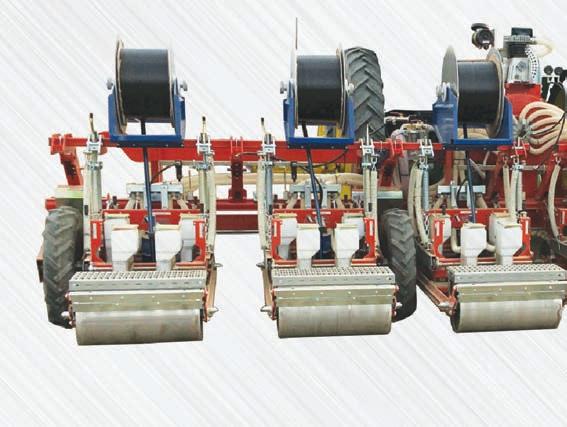

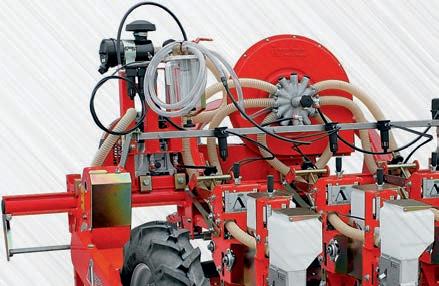

The Gearmore Precision Vacuum Planters are designed for extremely accurate seed placement. We custom build planting systems to growers individuals requirements.

The AI-640-SNT-2-27 Modular Frame Planter has been the go-to choice for successful onion farmers in the Western United States and Canada for more than 35 years, featuring frames that range from 25” to 65” in width.

The SNT-2-110 Planter is designed for double line sowing and features two seeding units for each planter frame. This unit can be equipped with as many planter frames as needed.

TELONE™ II by Teleos soil fumigant is the world's best defense against destructive plant parasitic nematodes, including stubby-root, root-knot, lesion, stem & bulb, as well as pesky wire worms. Applying TELONE™ before planting leads to healthier plants, higher yields, and improved quality. A custom blend of TELONE™ (to combat nematodes) and chloropicrin (to target soil borne diseases such as pink root) is an effective one-two punch for your onion needs.

REMEMBER, THERE'S NO COMING BACK FROM A POOR START!

Contact your Teleos Ag Solutions TELONE™ Specialist for more information. www.TeleosAg.com