the MAGIC of DRY ICE IN THE PLASTICS INDUSTRY

Increase Productivity, Improve Product Quality

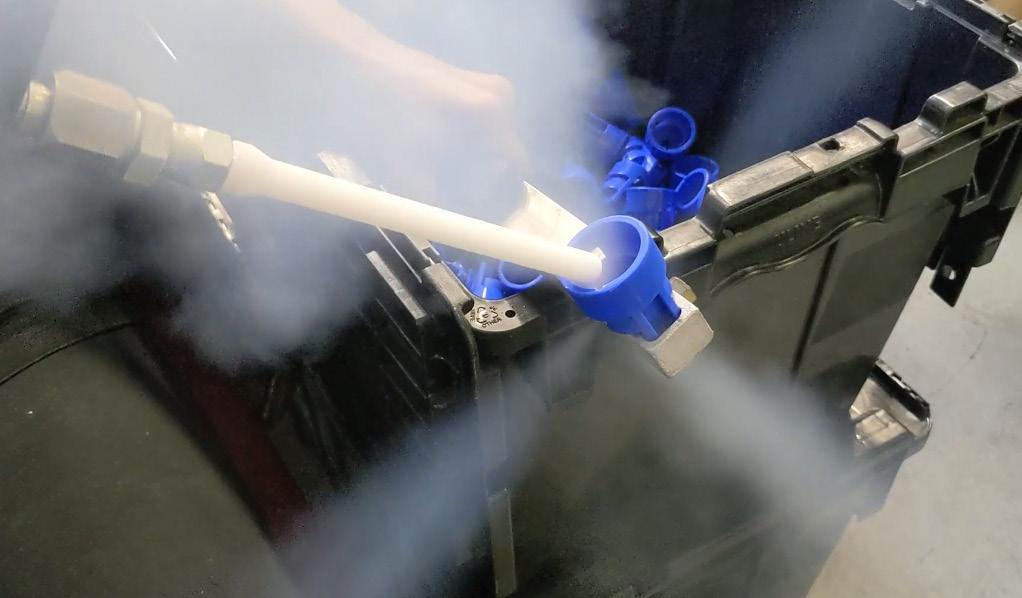

Clean mold cavities and vents are a major concern for plastic part manufactuers in maintaining today’s high quality standards. The build-up of unwanted surface residue from either the product mix itself, mold releases or the labeling process can create various problems, ranging from product release (“knock out”) to inferior product quality and possible tool damage. Flash on the product also creates challenges for manufacturers. Mold halves leave a parting line in the final product, and that parting line, or flash, must be removed for the product quality.

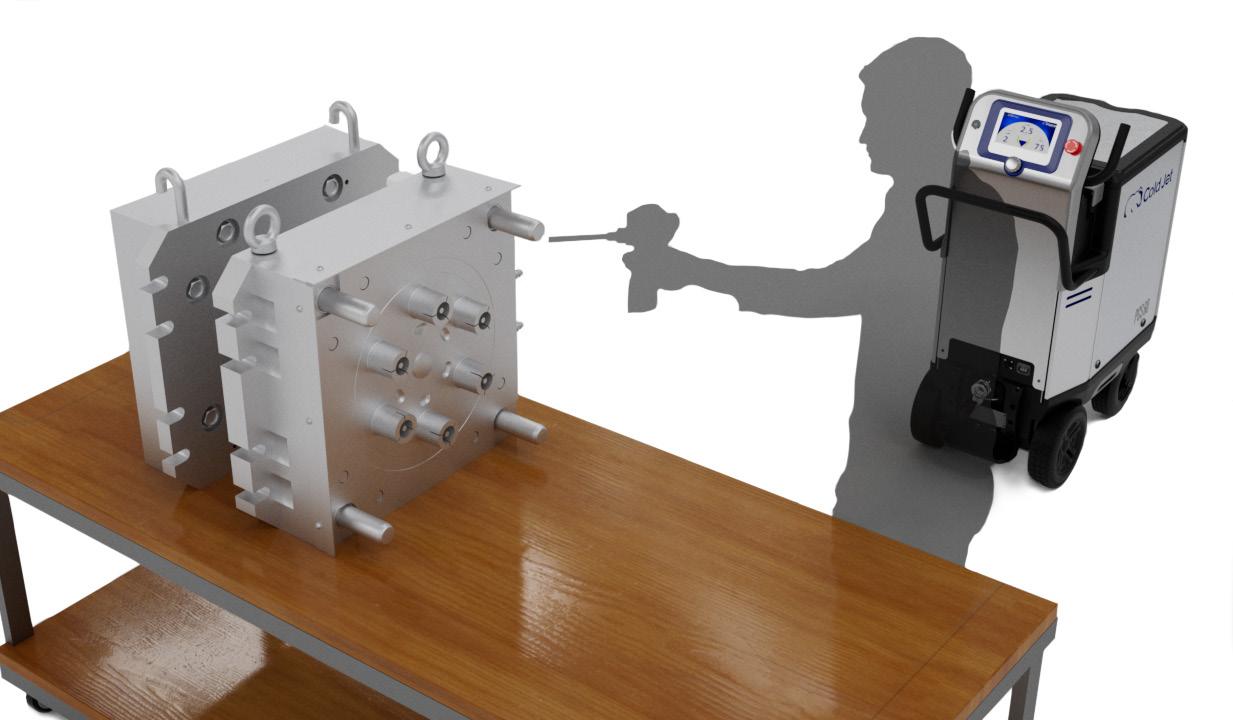

Traditional cleaning and deflashing methods involve tedious and ineffective manual processes using chemicals and hand tools. Cold Jet’s alternative cleaning provides a non-abrasive and environmentally responsible method that allows molds and products to be cleaned in a fraction of the time, allowing increased cycles between preventative maintenance. In addition, molds can be cleaned hot and in-place, without water, chemicals or creation of secondary waste.

Proven Applications

Blow Mold | Compression Mold | Extrusion Die | Injection Mold | Plastic Injection Screw | Plate-Out & Off Gassing | Thermoform Mold

Urethane Molds & Overspill. PRODUCT FINISHING: Deburring Machined Parts | Deflashing & Surface / Parting | Gloss Leveling | Line Vents

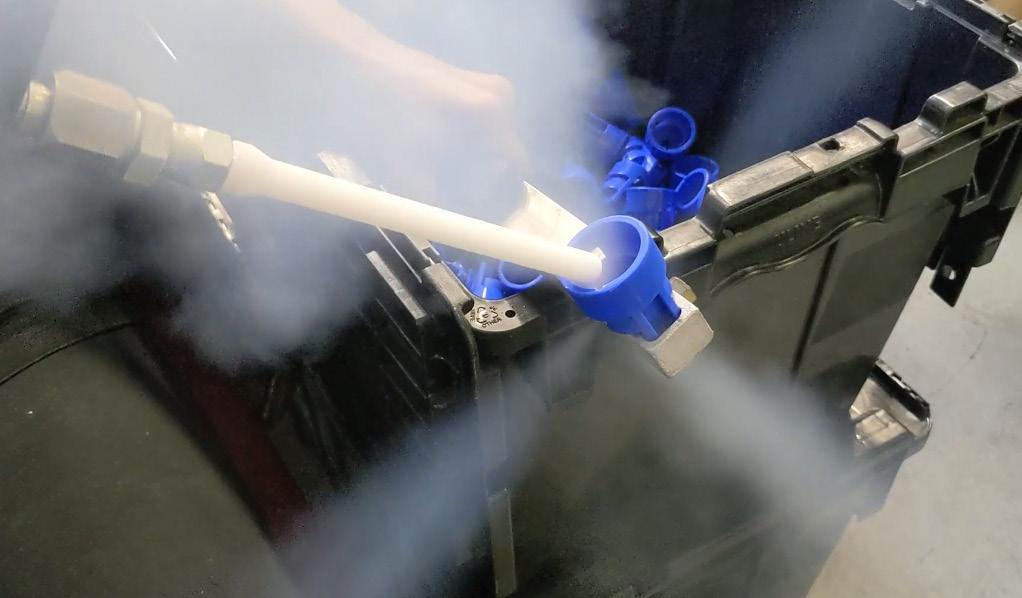

In-Machine Mold Cleaning

In-machine mold cleaning allows you to cut downtime while improving part quality.

Before After Case Study

Learn more at coldjet.com

the MAGIC of DRY ICE IN THE PLASTICS INDUSTRY

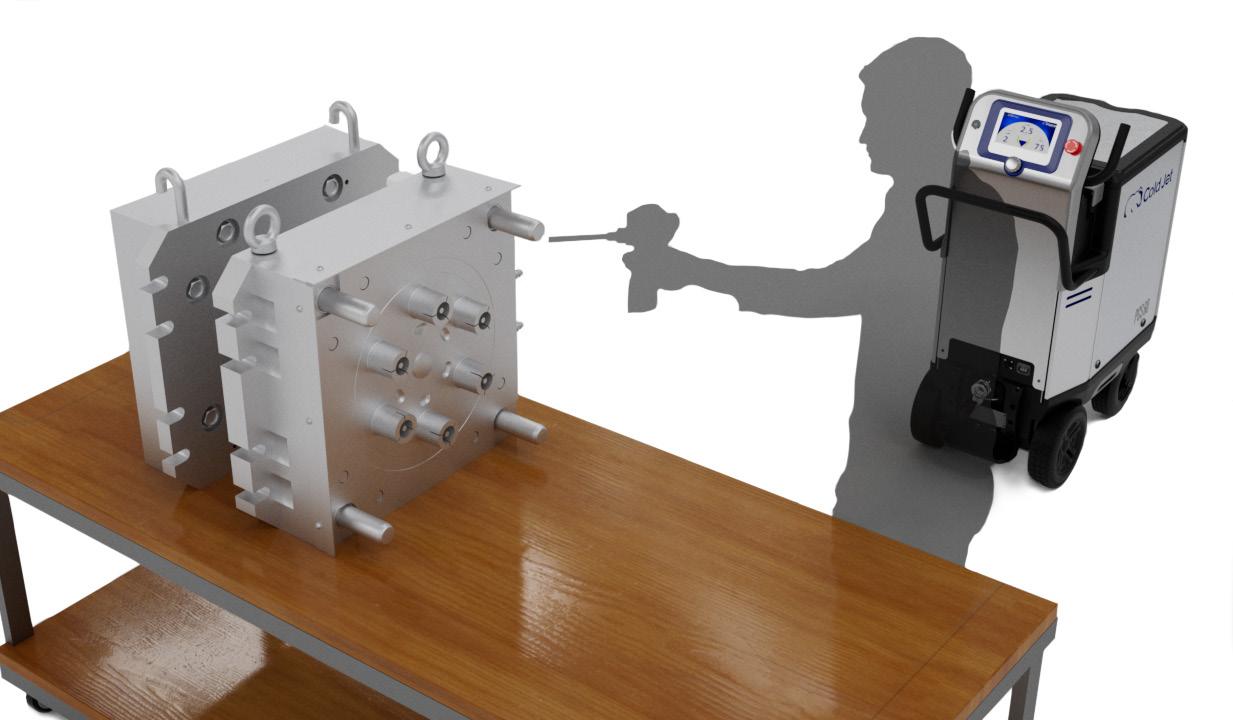

Mold Maintenance (Bench Cleaning)

Before After

Deburring/Deflashing

Before After

Case Study

Case Study

Learn more at coldjet.com

EXPENSE SAVINGS DOWNTIME SAVINGS TOTAL ANNUAL SAVINGS LABOR SAVINGS Industry Leaders Benefiting from Cold Jet Proactive Mold Maintenance Increased Productivity Increased Number of Good Items Reactive Mold Maintenance Practices Unscheduled Production Stops Contaminated Product, Scrap Availability Vs. Vs. Performance Quality Vs. Compare your current mold cleaning practices vs Cold Jet dry ice blasting by using OEE. Vs . Dry Ice Cleaning Traditional Cleaning

What is Dry Ice and Why is it Used for Cleaning?

Dry ice is non-abrasive, non-conductive and will not damage surfaces or equipment. By sublimating on impact, no secondary waste is left behind. It is also non-toxic and safer for employees than traditional cleaning methods. These attributes make dry ice cleaning an efficient, cost effective, environmentally sustainable, and occupationally safe cleaning solution.

Replicable Process PM Schedule with Replicable Method & Predictable Results Improved Asset Stewardship & Maintenance Lean Manufacturing Process Uncontrolled Cleaning Process No PM Schedule for In-Line Mold Cleaning Visual Inspection Not Possible Process Inefficiences Poka Yoke Vs Standardize Work & SOP’s 5 S Kaizen Vs. Vs Vs. Compare your current mold cleaning practices vs Cold Jet dry ice blasting by using LEAN. Compare your current mold cleaning practices vs Cold Jet dry ice blasting by using EHS. Improved Ergonomics No-Contact & Non-Abrasive No Secondary Waste, No Water Repetitive Motion, Elbow Grease & Safety Hazards Manual & Mechanical Secondary Waste & Disposal of Large Amounts of Water Vs. No Contact Cleaning Sustainability Vs. Vs. Ergonomic Improvement

Reduce Emissions Water Free Recycled Product Chemical Free Waste Free

The Most Sustainable Solution on the Market

Dry ice is based on the conversion of captured carbon dioxide (CO 2 ) into a value added, commercially useful product. It's the product of the carbon capture and utilization (CCU) process in which CO 2 is captured at industrial, biogas, or ambient air capture facilities, converted to liquid CO 2 , and transformed into dry ice - giving it a second life as a cooling and cleaning medium.

Due to the fact that dry ice is recycled CO2, it will not contribute to your greenhouse gas score. In the calculation of a carbon footprint, CO2 is accounted for at the producer level. It is not counted a second time at the point of use.

California Air Resources Board

How it Works

Dry ice cleaning is similar to sand, bead and soda blasting in that it prepares and cleans surfaces using a media accelerated in a pressurized air stream. It differs in that dry ice cleaning uses solid CO2 pellets or MicroParticles, which are blasted at supersonic speeds ans sublimates on impact, lifting dirt and contaminants off the underlying substrate.

Case Study

Case Study