Aotea Station Main Works

Air Quality Delivery Work Plan

CRL-AOT-RME-LKA-PLN-800030

Revision: 001

Date: 8 May 2020

CRL-AOT-RME-LKA-PLN-800030

Revision: 001

Date: 8 May 2020

This document is uncontrolled when printed. This document should be printed in colour

Status

Approval Status

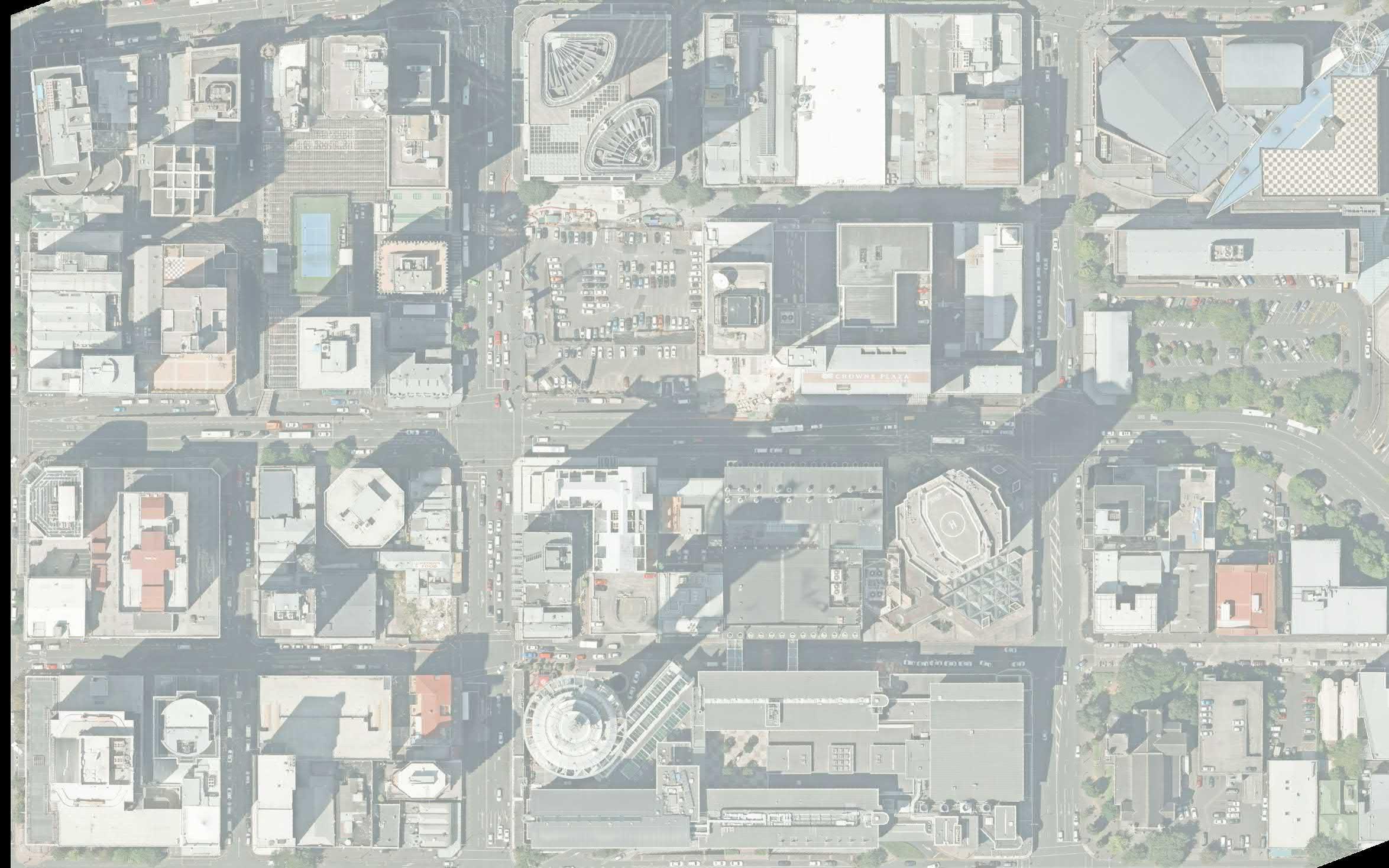

The City Rail Link (CRL) project comprises the construction, operation and maintenance of a 3.4 km underground passenger railway, running between Britomart Station and the North Auckland Rail Line in the vicinity of Mt Eden Station. The CRL also involves the construction of two new underground stations at Aotea and Karangahape and the redevelopment of the station at Mt Eden (refer to Figure 1-1). The design and construction of the CRL infrastructure between the Aotea and Mt Eden Stations is being delivered by the Link Alliance.

This Air Quality Delivery Work Plan (AQ DWP) has been prepared in relation to the Aotea Station main construction works

Once completed, the Aotea Station will include platforms, lifts, escalators, rooms for housing stations and tunnel services equipment, an entrance building at Wellesley Street, two additional entrance buildings at Victoria Street, a Plenum at Kingston Street, services, internal and architectural finishings, structural fittings, utilities services diversions and connections.

The location of the Aotea Station is primarily beneath Albert Street, connecting the Contract 2 (C2) cut and cover tunnels to the north and the tunnel-boring-machine (TBM) tunnels to the south. The works are approximately 380m long by 18m wide and will be excavated around 18-20m below ground level. Additional boxes branch off from the tunnel alignment at Kingston Street (to form the Plenum), Victoria Street (for two entrance buildings to the Aotea Station) and Wellesley Street (to form the main entrance building to the Aotea Station) (refer to Figure 1-2 below)1

1 Auckland Transport (AT) has obtained a resource consent for an Over Station Development (OSD) on the Bledisloe Car Park site (Council Reference R/LUC/2016/2647). The proposal involves the construction of a 24-level building comprising offices, retail and food and beverage tenancies, and public features including a plaza and a through site link. The proposed OSD is not part of the Link Alliance contract and will be progressed separately by Auckland Council / Panuku.

5 | Aotea Station Main Works

Given the nature and scale of the Aotea Station construction, works will be undertaken in a staged manner, involving:

• Five stages of early works (canopy removal, network utility relocation and site establishment work), being undertaken from October 2019 to March 2020 (Stages 1 to 3) and December 2019 through to August 2020 (Stages 4 and 5); these works have been authorised by separate Outline Plans (Council ref. OPW60345651 and OPW60348747);

• Main construction works (the ‘Aotea Station main works’) involving construction of the station box, associated above ground structures, mined tunnels for the rail tracks, internal finishings, structural fitout, all Mechanical, Electrical, Fire and Hydraulic (MEFH) installation, and architectural finishings2. The Aotea Station main works will be undertaken from early2020 through to late-2023; and

• Ground reinstatements (from late-2022) and urban realm improvements. These works will be described in a future Outline Plan2 .

This AQDWP relates to the main construction activities for Aotea Station, which include pilling, dwalling and excavation. All of these activities can have air quality effects and are considered by this management plan.

Refer to Section 2 of the Construction Environmental Management Plan (CEMP) for a detailed description of the Aotea Station main works.

To reflect the staged construction approach for Aotea Station, DWPs will be developed in stages.

This AQ DWP addresses the Aotea Station main works, which are detailed in the CEMP an overview is provided in Section 2 of this DWP.

This AQ DWP has been prepared to identify measures that will be implemented to mitigate and manage the potential adverse effects on air quality in the surrounding area during the Aotea Station main works

The objective of the AQ DWP is to:

• Address requirements detailed in the CRL designation and air discharge permit (Aotea to North Auckland Line (A2N) regional resource consents) conditions, which provide for the ongoing operation, use and maintenance of the CRL;

• Detail various sources of dust, odour and combustion air pollutants that may be created during the main works;

• Highlight specific sensitive locations;

• Describe methods to manage dust and odour emissions and mitigate their impact on local air quality;

• Describe methods to minimise the discharge of combustion emissions from vehicles;

2 It is noted the architectural finishing component of works (the exterior look and feel of the Aotea Station) will occur during Phase 5 of the Aotea Station main works (approx. 2022 – December 2023). These finishings are still being designed and determined. Once designs are completed a separate Outline Plan and suite of DWP’s will be prepared, describing the finishings and other urban realm reinstatements, including ground reinstatement That Outline Plan package will address the relevant Urban Design related Designation conditions (Condition 47 – 54, including landscaping (condition 55.3(c)))).

• Describe monitoring methods; and

• Specify procedures for responding to complaints regarding discharges into air and keeping compliance records.

This AQ DWP addresses the requirements of CRL designation condition 59 and the A2N consent conditions 217 to 228 and will be implemented throughout the construction period.

The CRL designation (condition 59) requires the preparation of a DWP, while conditions 217 to 228 of the discharge permit (R/REG/2016/1899) require an Air Quality Management Plan. These two separate document requirements have been combined and are addressed in this single AQ DWP.

This AQ DWP has been prepared in consultation with the Aotea Community and Business Liaison Group (CLG) and has been reviewed by an Independent Peer Reviewer (IPR) prior to submission to Auckland Council (as per designation conditions 7 and 11, and resource consent condition 19). A record of consultation outcomes and IPR review comments is included in Appendix G.

This AQ DWP has been prepared by Link Alliance and forms part of the CEMP for the Aotea Station main works.

Table 1-1 identifies the designation and resource consent conditions relevant to this DWP and where they are addressed in the document.

Table 1-1: Relevant conditions and location in Plan

59.1 An Air Quality DWP shall be prepared to avoid, remedy or mitigate the adverse effects on air quality during the construction of the City Rail Link or any part of it.

59.2 The objective of the Air Quality DWP is to detail the best practicable option to avoid dust and odour nuisance being caused by construction works and to remedy any such effects should they occur. This document

59.3 To achieve the above objective the following shall be included in the Air Quality DWP and implemented as required:

(a) The procedures to be implemented for the continuous monitoring of Total Suspended Particulate (TSP) concentrations and meteorology including, but not limited to, the establishment of two monitoring sites (to the north and south of the site);

(b) Identification of the sensitive locations, and the specific methods for monitoring, including trigger limits to determine whether further action (such as implementation of the mitigation measures discussed below or other mitigation measures) is required;

(c) Procedures for responding to malfunctions with construction machinery or works causing accidental dust discharges including, but not limited to, the requirement to remedy any malfunction within 24 hours;

(d) Procedures for monitoring weather conditions and the requirement that water spray is used on soil stockpiles, any non-paved construction

Section 6.3

Section 3.3

Section 6.5

Sections 6.3.3, 5.2

areas, and the wheels of trucks where dust may disperse beyond the site;

(e) Procedures for establishing when the covering of trucks will be required;

(f) Procedures for determining when hard surfaced areas in construction yards and active construction areas should be cleaned including, but not limited to, the requirement that such areas be cleaned whenever dust generation occurs due to traffic on these surfaces;

(g) Procedures for responding to discharges of odour (including in the event of excavation of contaminated sites) including, but not limited to, the requirement to address discharge of objectionable odour by immediately ceasing the activity causing the discharge;

(h) Procedures for equipment inspection (including timeframes for regular inspections), maintenance, monitoring and recording, including baghouses, pressure relief valves and high level alarms to mitigate dust emissions;

(i) Procedures for, where practicable, limiting dust and odour nuisance and the methods for monitoring these procedures including Identification of contingency measures to address identified and verified adverse effects on sensitive receptors. Contingency measures may include options such as:

i. Cleaning of air filtration intakes; or

ii. Cleaning of other buildings and infrastructure; and

(j) Procedures for responding to any complaints received and the timeframes for response to complaints and reporting;

(k) Cross references to the specific sections in the Communication and Consultation Plan, which detail how the communities in the vicinity of construction works are to be communicated with on the management of the adverse effects relating to air quality.

Discharge permit (air – construction) R/REG/2016/1899

217 This resource consent shall expire 15 years after the consent commences unless it has been surrendered or been cancelled at an earlier date pursuant to the RMA.

218 The Consent Holder shall ensure that all processes on the Project work site shall be implemented, operated, maintained, supervised, monitored and controlled so that any emissions authorised by this consent are maintained at the minimum practicable level.

219 Unless provided for by Condition 220, there shall be no dust or odour beyond the boundary of the Project work site caused as a result of on-site processes which, in the opinion of Council, is noxious, offensive or objectionable.

220 Any noxious, offensive or objectionable dust or odour beyond the boundary of the Project work site caused as a result of construction and earthworks activities associated with the Project shall be mitigated as soon as practicable in accordance with the requirements of the certified Air Quality Management Plan as required by Condition 222.

Section 6.6

Sections 5.2 and 6.2

Sections 6.6 and 5.4

Sections 5.2.1, 5.2.2, and 6.5

Sections 5 and 6

Section 7.2

Section 7.1

This document

This document

This document

This document

221 The Consent Holder shall ensure that beyond the boundary of the Project worksite, there shall be no hazardous air pollutant caused as a result of construction and earthworks activities associated with the Project that causes, or is likely to cause, adverse effects on human health, environment or property.

222 The Consent Holder shall review the draft Air Quality Management Plan –Aotea Station to North Auckland Line dated May 2016, and submit to Council (Team Leader Central Monitoring) a final AQMP/s which is generally consistent with the draft AQMP provided in support of the application.

223 The final AQMP/s shall be prepared by a Senior Qualified Person, provided to the Council (Team Leader Central Monitoring) for certification at least 20 working days prior to the commencement of construction and shall include:

a. a clear identification of the type and location of the controls proposed;

b. a detailed framework for the management, mitigation and monitoring of construction and earthworks activities associated with the Project;

c. a focus principally on the sources of dust discharges, and

d. an assessment of the risk of discharges from each ACZ and the associated CSA.

224 The final AQMP/s shall also provide detailed methods including, but not limited to, the following matters:

a. methods to ensure exposed surfaces remain dampened to minimise dust emissions (possible examples include a water spray system or other suitable system, water carts and other suppression methods);

This document

This document

Section 5

Section 5

Section 2.3 and Table 5-1

Section 5.1 and Appendix C

Sections 5.2 and 6.2

b. ensuring a 20 km/hr vehicle speed limit within the ACZs and CSAs; Section 5.2

c. operation of wheel washes;

d. regular sweeping of public roads around the exit points of ACZs and CSAs and sealed vehicle accessways within these areas;

e. measures for supressing dust from any temporary stock piles (demonstrating how they are to be limited to no more than 24 m³ of uncovered spoil at any one time in each ACZ);

f. measures for the handling of cement associated with the forming of cement stabilised columns, including filter systems and high level alarms where a silo is used;

Sections 5.2 and 6.2

Section 6.2

Section 5.2

Section 5.2

g. covering of loads of material being delivered and removed from the site; Section 5.2

h. instrument monitoring of dust concentrations (including identification of a monitoring methodology, monitoring network and appropriate alert thresholds) to ensure that any significant dust effects arising from the ACZs or CSAs are identified and remedied as soon as practicable throughout the Project;

Section 6.3

i. the locations of instrument dust monitoring sites, including at least three re-locatable and/or fixed monitors to be associated with each of ACZs A, K and M, and the duration of this monitoring; Section 6.3

j. measures for responding to continuous instrument dust monitoring trigger alarms, including contingency measures to reduce measured concentrations below the trigger thresholds and provisions for responding after standard operating hours; Section 6.3

k. measures for undertaking meteorological observations and visual inspections of dust or other air discharges from the Project, to be completed at least on a daily basis, with all relevant information logged; and

l. information regarding complaint logging, investigation and response procedures, training and roles and responsibilities.

The Team Leader Central Monitoring shall be requested to respond to the AQMP/s with any suggested changes within 10 working days from receipt of the AQMP; otherwise the AQMP may be considered by the Consent Holder to be certified by the Council. Section 7.2

225 Any change to the AQMP/ shall be submitted to the Council (Team Leader Central Monitoring) for certification. No activity reliant upon a change to the AQMP can be undertaken until the change has been certified.

The Team Leader Central Monitoring shall be requested to respond to the proposed change within 10 working days from receipt of the change; otherwise the AQMP may be considered by the Consent Holder to be certified by the Council.

N/A

226 All works shall be undertaken in accordance with the certified AQMP/s. N/A

227 Prior to the commencement of construction, and for the duration of excavation and construction associated with the Project which have the potential for significant dust emissions, the Consent Holder shall install, operate and maintain continuous dust monitoring undertaken using mobile instruments for the purposes of monitoring Total Suspended Particulates (TSP).

The locations, durations and methods of TSP monitoring at each of ACZs A, K and M shall be in accordance with the details in the certified AQMP(s) required by Condition 222.

228 The dust monitoring instruments shall be fitted with an alarm system that sends a warning to the responsible person identified by the AQMP/s when dust concentrations exceed alert levels specified by the certified AQMP/s.

The Consent Holder shall ensure that the responsible person, or other nominated person, is available at all times to take immediate action to reduce dust emissions from the site.

Section 6.3

Section 6.3

The Link Alliance is seeking an Infrastructure Sustainability Council of Australia (ISCA) Infrastructure Sustainability (IS) Rating. Further details can be found in the Aotea Station main works CEMP and Sustainability Rating Management Plan. Project sustainability requirements that relate directly to

this AQ DWP are included in Appendix A. These requirements are imbedded within the AQ DWP to ensure that sustainability is a key focus and ‘the way we do things’.

In some cases the IS requirements and sustainability goals enhance the designation and consent requirements.

This AQ DWP is a live document that will be reviewed at least annually, or as a result of a material change to the project, or to address unforeseen adverse air quality effects arising from construction, or unresolved complaints. Any material changes to this AQ DWP must be approved by Auckland Council prior to any on-site activity reliant upon the change commencing. Refer to Section 6 of the CEMP for further detail on the review and updating process.

This AQ DWP has been prepared by a team of air quality specialists including:

• The DWP has been authored by Jason Pene, a Senior Environmental Engineer and Principal of Tonkin & Taylor Ltd (T+T), with support from other T+T air quality specialists. Jason has over 18 years of experience in the assessment and management of air quality impacts, including management and monitoring of dust associated with linear infrastructure construction projects.

• The DWP has been reviewed by Richard Chilton, a Senior Air Quality Specialist of T+T. Richard has 20 years of experience assessing and managing air quality impacts, and was the technical lead for the assessment of air discharges associated with the regional consenting process for the CRL project.

The Aotea Station main works will involve three main phases of work. Each phase of work involves multiple construction activities which will be undertaken throughout the Aotea project site. The phases associated with the Aotea Station main works involve:

• Foundation works to form the perimeter walls of the station box and underground running tunnels. This involves diaphragm wall construction, roof construction, piling and jet grouting;

• Construction of the Aotea Station platforms, main station structure, concourse, entrance structures and Plenum, and;

• Structural fitout of the Aotea Station including MEFH installation, and internal and architectural finishings.

The works require the operation of a Construction Support Area (CSA) within the Bledisloe House car park site and a portion of Mayoral Drive. Equipment used to undertake these works will be predominantly situated in the CSA. Upon completion of the Aotea Station main works, the area will be repurposed in preparation for public realm reinstatement works2

The methodology for the construction of the Aotea Station is predominantly based on a ‘top down’ and ‘bottom up’ approach. The ‘top down’ approach relates to the southern end of Albert Street (south of Durham Street) and involves the installation of the ‘roof structure’ early on, which enables a limited number of traffic lanes to operate concurrently with the construction of the station, which occurs beneath. This approach reduces the construction effects on traffic flow within the city centre. The tunnel alignment on the northern end of Albert Street (north of Durham Street) will be constructed using a ‘bottom up’ methodology.

A detailed description of the Aotea Station main works is included in the CEMP and includes:

• an overview of the works including indicative timeframes in Table 2-1.

• the construction sequencing including equipment and earthworks volumes for the works in Table 2-2.

• further detail of the CSA in Section 2.6.2 of the CEMP. Drawings indicating the staging of the construction activities and proposed layout of the CSA are provided as Appendix B.

It is noted that public realm reinstatement works and details of architectural finishings for the Aotea Station (Condition 47 – 54 of Designation 2500-1), will form part of separate Outline Plan packages to be prepared in the future prior to the commencement of the respective works.

The Aotea Station main works are anticipated to take approximately 45 months to complete, occurring from April 2020 to December 2023 (approximately) as detailed in Table 2-1 in Section 2.2 of the CEMP. Some construction activities outlined in each phase of the main works will occur in parallel.

The main discharge to air from the construction activities during the Aotea Station main works will be particulate matter (dust). Dust has the potential to cause nuisance or soiling of property if

deposited in sufficient quantities in the environment. Fine dust particles present in dust have the potential to affect respiratory heath while suspended in air. Bentonite powder used in the construction of diaphragm walls and concrete removed from excavation areas may contain respirable crystalline silica (RCS), which can also have respiratory health effects. Waitakere Group rocks containing erionite, may be encountered during excavations. Erionite can also have respiratory health effects if inhaled in suspended dust.

Aotea Station main works construction activities include dust generating activities occurring at or near ground level or within open trenches. Dust from these activities may be discharged diffusively from works activities direct to atmosphere.

Following construction of the initial underground floor level of the station and overlying ground level roof slab, dust generating activities will occur underground enclosed by overlying roof slabs. Dust generated from these activities is likely to be relatively well contained and discharged via active ventilation exhaust vents or passively through perforations in the ground level floor slab.

The following proposed activities have the potential to result in discharges of dust/particulate matter to air:

• Removal of hardstand, foundations and retaining walls;

• Excavation and drilling;

• Outdoor spoil handling/removal (including during the de-sanding operation);

• Wind erosion of spoil and other stockpiled material;

• Mixing of bentonite powder (stored in bags) to form bentonite slurry;

• Conveyance of cement powder to silos and mixing to form cement grout;

• Piling;

• Backfilling of excavation; and

• Movement of vehicles over unsealed surfaces (this includes trucks, loaders and excavators required for the tunnel excavation and spoil removal, and the delivery of construction materials such as concrete and steel).

Other minor discharges to air could include:

• Combustion emissions from vehicles and machinery on site, which can affect respiratory health in the environment with sufficient exposure; and

• Odour from excavation or disturbance of contaminated soil (if encountered), which has the potential to cause nuisance.

This section of the AQ DWP describes the environment surrounding the Aotea main works site in terms of meteorological influences on the transport of air contaminants and sensitivity of adjacent activities to those discharges.

The Aotea Station main works are to be undertaken along and beneath Albert Street with station entrances at Victoria Street and Wellesley Street West. The construction support area (CSA) for the works is to be located at the former Auckland Council Bledisloe Carpark on Mayoral Drive The Site is located in an urban environment adjacent to dense urban development comprising a range of commercial, residential and recreational activities. Due to the density of development and human occupation in surrounding areas, the receiving environment in general is of a high sensitivity to air pollution.

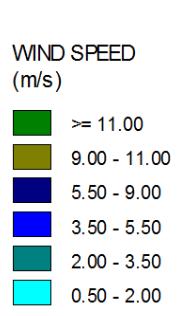

Figure 3-1 shows wind roses of wind speeds and directions measured at the NIWA weather station at the Auckland Museum of Transport and Technology (MOTAT), Western Springs over year round, summer (December to February) and winter (June to August) periods.

The weather station is located approximately 3 km south west of works area. Wind measurements at this station are likely to be generally representative of overlying wind conditions in central Auckland as it is relatively free from nearby obstructions or eddies created by adjacent buildings.

Although tall buildings and topographical features in the area will alter localised wind conditions, the wind direction frequency trends illustrated below are likely to be broadly similar to those experienced at the site.

Based on the wind roses in Figure 3-1, winds are predominantly from the southwest and northeast, and therefore sensitive locations to the northeast and southwest of the site, respectively, are likely to be most frequently exposed to any off-site dust emissions from site activities. The amount of dust generated also largely depends on whether conditions are dry, and the wind speeds, with faster wind speeds increasing effect of wind erosion and the distance that the dust travels.

All months, 2016-2019, Calms = 5.52%

Winter months, 2016-2019, Calms = 6.28%

Summer months, 2016-2019, Calms = 2.25%

Figure 3-1: Wind rose frequency analyses of wind speeds and directions at the Auckland MOTAT weather station for August 2016 to August 2019, year round, winter and summer months. Source: NIWA Cliflo database.

Figure 3-2 shows that the expected drier months are during summer, when wind speeds also tend to be higher. Over the year winds from the southwest, which will transport any emitted dust towards sensitive receptors to the northeast of works activities, are relatively frequent over the Auckland Isthmus Northeast winds become more frequent over summer months.

Figure 3-2: Percentage of wet days (rain exceeding 1 mm) over each month of the year at MOTAT. Source: NIWA Cliflo database.

The Site is located in a mixed use (City Centre) zone, in Auckland City Centre, so features a range of adjacent activities.

Nearby activities that may be sensitive to dust nuisance include:

• Residential apartments on Albert Street, Elliot Street, Federal Street, Victoria St West, and Wellesley St West.

• Hotel and Hostel accommodation on Albert Street and Federal Street.

• Bars and restaurants, particularly where premises include outdoor dining or entertainment areas.

• Education facilities: Media Design School and Royal Business College, on Albert St and Federal Street, respectively and the Childcare facility on Durham Street.

• Pedestrian access and parked vehicles along neighbouring roads.

• Cathedral of St Patrick & St Joseph, Wyndham Street

• Retail, office and commercial premises, including the Auckland Council.

As required by the CRL designation and A2N discharge permit conditions, the purpose of this DWP is to ensure that construction air quality effects are kept to a practical minimum, recognising the sensitivity of the environment within which the works are being undertaken.

The key air quality compliance requirement for construction activities is that dust and other air discharges from the activities do not result in offensive or objectionable levels of dust or other contaminants beyond the site boundary.

A range of air quality management and monitoring measures are specified in sections 5 and 6 of this AQ DWP to minimise the potential for adverse air quality effects and avoid the occurrence of offensive or objectionable dust or contaminants in the surrounding environment.

These measures include monitoring trigger levels and response actions, which are intended to provide operational feedback to improve air quality management. The monitoring trigger levels are not intended as environmental performance standards in and of themselves.

A range of routine measures will be used to manage and mitigate the effects of discharges of dust, odour or construction vehicle exhaust emissions during the Aotea Station main works. Additional mitigation may also be required in the event that:

• Monitoring indicates that abnormal discharges of dust are occurring;

• Weather conditions are changing such that dust or odour discharges are more likely as determined using the Dust Risk Assessment; and / or

• Complaints are received regarding discharges of dust, odour or construction vehicle exhaust emissions.

If the available mitigation methods are unsuccessful in controlling discharges (i.e. dust or odour) that cause significant adverse effects on receptors beyond the main works boundary, the activities causing the discharge shall be suspended until adequate mitigation can be put in place.

To provide guidance to the Environmental and Sustainability Manager, and area supervisors on implementing dust mitigation, the main works will use a Dust Risk Assessment (DRA) approach.

The DRA is described in Appendix C and assigns a risk classification to each proposed activity with the potential to generate dust based on the scale of potential dust emissions and local environmental conditions (including sensitivity of adjacent activities and weather conditions).

As the dust risk is dependent on local environmental conditions, the dust risk associated with activities should be re-calculated as conditions change.

A “traffic light” indication of dust risk will be posted in each work area so that Project staff are aware of the dusk risk. The dust risk will be indicated as:

• Low risk (green).

• Moderate risk (orange).

• High or extreme risk (red).

Dust management measures are specified for proposed ground level works activities in Table 5-1 and below ground activities in Table 5-2 Dust management measures may differ based on the dust risk of the activity calculated in accordance with Appendix C

The control measures specified for the calculated dust risk level should be employed in addition to the measures for all preceding levels– e.g. a medium risk activity requires application of measures applicable to the corresponding low risk activity as well as measures specified for medium risk.

Alternate methods may be employed after the effectiveness of those methods is demonstrated and this AQ DWP updated accordingly. The list of control methods is not exhaustive and additional methods may be found to be effective.

Enclosed stockpiles (or located at base of trench) Low

Outdoor stockpiles Medium

3 Dust risk

• Minimise handling of stockpiled material and drop heights to stockpiles during unloading to decrease potential for dust generation.

• Minimise vehicle entry and exit to/from the enclosure to maintain containment of dust.

• Store stockpiled material containing a high content of fine material indoors or undercover where practicable.

• Outdoor stockpiles of spoil are to be maintained in damp condition with regular application of water (such as via water sprays).

• Limit the height of any outdoor stockpiles to reduce wind entrainment (generally no greater than 3 m).

• Orientate outdoor stockpiles to maximise wind sheltering as much as practicable.

• Dampen, cover or stabilise inactive stockpiles if they are producing visible dust emissions.

• Stabilise stockpiles using various means depending on the length of inactivity (e.g. soil binders if inactive for 28 days).

• Minimise handling of dry stockpiled material and drop heights to stockpiles during unloading to decrease potential for dust generation.

• Bunker or cover stockpiles of fine, dry materials if stockpile is existing for prolonged periods (greater than 1 month).

Environmental Sustainability Manager or delegated person

Environmental Sustainability Manager or delegated person

Surface vehicle movements (over sealed and unsealed surfaces)

Low and medium

Excavation and removal of hard stand or structures

High

Medium and High

• Limit vehicle speeds to 20 km/h (or less) within the Site.

• Limit load sizes to avoid spillages.

• Cover loads of fine materials leaving or entering the Site in dry, windy conditions

• Minimise on-site travel distances through appropriate site layout and design.

• Minimise mud and dust track out from unsealed areas to sealed areas by using wheel cleaning facilities at site exits to sealed roads.

• Sealed access routes are to be inspected on a daily basis (at a minimum) and deposited material is to be cleaned with a vacuum sweeper truck as required.

• Any material identified to be tracked onto public roadways during regular inspections (or via notification from the public) is to be cleaned with a vacuum sweeper truck.

• Wheels of all trucks exiting the Site to public roads are to be inspected and washed as required to prevent tracking of material off-site.

• In dry conditions (e.g. less than 1 mm of rain in the preceding 48 hours), maintain unsealed surfaces in regular use in damp condition through surface watering (e.g. with water carts or fixed irrigation).

• If water suppression is ineffective, synthetic dust suppressants may be used as an alternative. The use of recycled oil-based suppressants is expressly prohibited.

• Maintain regularly used unsealed road surfaces in damp condition through surface watering in all conditions.

• Limit the extent of excavation, mining and material handling activities in exposed areas carried out during dry and/or windy conditions as far as practicable.

• Limit drop heights of material during handling, including from any conveyor transfer points.

• Stabilise exposed areas not required for construction, access or parking, along with completed fill and spoil areas as soon as practicable.

• Remove excavated spoil from site on a regular basis.

• Maintain surfaces of active earthworks areas in damp condition during excavations in dry weather. This should include pre-watering of dry soil surfaces, prior to excavation allowing enough time for moisture to penetrate the soil.

Environmental Sustainability Manager or delegated person

Environmental Sustainability Manager or delegated person

Loading and unloading of dry material

Unpaved surfaces (including roads and yard areas)

Medium and High

• Only wet cutting of concrete should be undertaken.

• Any breaking of concrete should be done under controlled conditions (e.g. using water sprays or fog cannons directed at where the breaking is occurring).

• Limit loading or unloading during windy conditions that cause dust to be emitted beyond the site boundary.

• Cover loads of fine, dry materials.

• Minimise drop heights when loading and unloading dry material.

Low

• Limit the amount of unpaved surfaces as much as possible.

• Use water sprays or watering trucks to dampen dry unpaved surfaces.

• Stabilise cleared areas not required for construction, access or for parking if liable to cause excessive dust during windy conditions. Methods may include placing metal or other coarse material on surfaces.

Environmental Sustainability Manager or delegated person

Environmental Sustainability Manager or delegated person

Piling

Medium

Use and handling of bentonite powder

Cement silos

All dust risk levels

• All spoil to be placed in a pre-identified stockpile location and removed from site as soon as possible.

• Any spilled material to be cleaned up immediately.

• Emptying of bentonite powder bags and mixing of bentonite shall occur within an enclosure.

All dust risk levels

• Cement silos are to have either an automated remote filling system or be fitted with a high level alarm that has both an audible and visual indicator and when the alarm is triggered it will stop the filling of the silo

• Each cement silos is to be fitted and operated with a filtration system with a filter surface area of at least 24 m2 .

Environmental Sustainability Manager or delegated person

Environmental Sustainability Manager or delegated person

Environmental Sustainability Manager or delegated person

Rock drilling in exposed areas

Medium and High

• Drills used on rock or concrete in exposed areas should be operated with dust suppression mechanisms where practicable.

Environmental Sustainability Manager or delegated person

Miscellaneous All dust risk levels

• Ensure sufficient water is available for dust sprays on-site.

• Taking account of daily of weather forecast wind speed and wind direction, and the condition of any excavated spoil (such as its dampness) before commencing an operation that has a high wind potential.

• Maintenance of surface moisture content: Watering or wet suppression is used to dampen dry or dusty exposed areas.

Environmental Sustainability Manager or delegated person

Surface vehicle movements (over unsealed surfaces)

Low

Medium

Excavation and mining Low and medium

• Limit vehicle speeds to 20 km/h (or less).

• Limit load sizes to avoid spillages.

• Maintain dry surfaces of active earthworks and mining areas in damp condition.

• Stabilise exposed areas not required for construction, along with completed fill and spoil areas as soon as practicable.

• Only wet cutting of concrete should be undertaken.

• Any breaking of concrete should be done under controlled conditions (e.g. using water sprays or fog cannons directed at where the breaking is occurring).

Environmental Sustainability Manager or delegated person

Environmental Sustainability Manager or delegated person

Rock drilling Low

Medium

Ventilation Low

Medium

• Drills used on rock or concrete should be operated with dust suppression mechanisms where practicable.

• Pre-dampen all rock or concrete pre-drilling.

• Maximise distance between exhaust vents and off-site activities as far as practicable.

• Apply additional management systems (such as scrubbing or misting sprays) are installed on the output of the ventilation system

4 Dust risk levels for each underground activity are to be calculated in accordance with the procedure described in Appendix C.

Environmental Sustainability Manager or delegated person

Environmental Sustainability Manager or delegated person

The supplier of any dust control equipment is to provide information on the following:

• Procedures for equipment inspection (including timeframes for regular inspections), maintenance, monitoring and recording, including baghouses, pressure relief valves, high level alarms and dust suppression mechanisms such as fog canons or sprays.

If construction equipment fails and causes accidental dust discharges, it will be shut down immediately, and the fault repaired and tested prior to being allowed to continue operation.

If equipment associated with dust control fails (such as a baghouse) the activities reliant on the equipment will be suspended until the fault can be repaired.

The location, duration and time of any dust discharge caused by equipment failure will be recorded in the Air Quality Log (described in Section 9.1 and example log sheet provided in Appendix E).

When site operators are alerted to a potential off-site dust nuisance through any of the monitoring techniques described in Section 6 of this AQ DWP, or as a result of a complaint from a third party, the Site Supervisor will immediately undertake a review of site activities to determine the source of the dust and implement further mitigation measures as required in order to reduce the dust generation to acceptable levels. As appropriate the Site Supervisor will notify the Environmental and Sustainability Manager.

In general, the additional mitigation will be those measures set out in Table 5-1.

Once the additional mitigation has been implemented the Site Supervisor will review the monitoring data to ensure that it has been effective.

5.3.1.

The following are locations where information necessary for determining the DRA and general dust control can be obtained:

• Site Specific monitoring web site where TSP and meteorological data can be accessed (to be established); and

• Met Service: http://www.metservice.com/towns-cities/auckland/auckland-central

• MetVUW North Island forecast charts: http://metvuw.co.nz/forecast/

Odour may be emitted if contaminated soil is encountered during the excavation works, depending on the nature of the contamination. This section of the AQ DWP sets out the mitigation required by CRL designation Condition 59.3(g) for minimising any potential for odour if contaminated material is encountered.

Odour emissions will be monitored in accordance with Section 6.6 of this AQ DWP during the excavation of contaminated material and the following techniques considered if necessary:

• Limiting the time that the odorous material in the excavation is exposed;

• Removing excavated odorous material from site as quickly as possible in covered trucks; and

• The use of odour masking agents, chemical counteractants or digestive deodorant sprays.

If significant odour is detected and the odorous material cannot be removed quickly and odour masking agents, chemical counteractants or digestive deodorant sprays are not immediately available, the odorous material shall be covered with uncontaminated soil or other suitable material to suppress odour emissions, and work in that area suspended until suitable mitigation measures can be put in place.

The following key actions shall be carried out to minimise emissions from vehicle exhausts:

• All construction machinery used on the site will be maintained at least in accordance with manufacturers’ requirements;

• Where excessive exhaust smoke is identified from any construction vehicle that vehicle will be serviced as soon as is practicable and taken out of use until such maintenance has been completed; and

• Unless warm-up or turbo maintenance procedures require it, construction vehicles will not be left idling while parked or unattended.

In the event of significant long-term, unavoidable dust emissions, that results in verified complaints of dust inside buildings, the contractor will implement the following contingency measures, dependent on the nature of the complaint:

• Link Alliance will arrange for routine commercial cleaning of properties that are affected by adverse effects of dust.

In the event that instrumental monitoring, dust observations or investigation of complaints indicates that further control of dust from outdoor stockpiling is required, the following measures shall be implemented:

• Windbreak fencing or other wind reduction structures of no less than 3 m in height shall be installed along the periphery of outdoor spoil storage areas (except at vehicle entrances). Porosity of fencing material should be in the order of 50%.

• If outdoor stockpiling activities result in visible dust emissions beyond the site boundary outside of operating hours, automation of water sprays to maintain surface material in dry windy conditions may be required.

The overall approach to dust control for the works is based on visual monitoring combined with targeted ambient instrumental dust monitoring; good management of the construction areas; and a rapid response to any of the triggers outlined in Sections 6.3.2 and 6.3.4 or complaints received. Good practice focusing on proactive measures will aid in avoiding significant dust emissions, however if dust emissions do occur, the monitoring will help to identify such occurrences and enable a prompt response.

Visual monitoring of all construction areas will be undertaken on a daily basis, or more frequently if conditions change. This type of monitoring relates to the control measures described in Section 5 of this AQ DWP and will include proactive measures to avoid dust emissions.

Table 6-1 below describes the visual dust monitoring activities to be undertaken during construction. Outcomes of visual inspections are to be recorded in the Air Quality Log (log sheet template provided in Appendix E).

Table 6-1: Visual dust monitoring programme

Check weather forecasts for strong winds and absence of rainfall to plan appropriate work schedule and dust management response.

Inspect land adjacent to the site, construction exits and adjoining roads for the presence of dust deposition and/or accumulation of dust material

Observe weather conditions including wind and rain via observations and data outputs from weather stations.

Inspect all exposed un-stabilised surfaces for dampness and that the extent of those areas is being minimised

Inspect stockpiles for dampness and height of no more than 3 m (or enclosure, covering or stabilisation where required)

Inspect dust generating activities for effectiveness of dust management measures and avoidance of visible dust emissions beyond the boundary of the Site

Inspect watering systems (sprays and water carts) to ensure equipment is maintained and functioning to effectively dampen exposed areas.

Monitor dust generating activities and water application rate.

Inspect wheels of all trucks exiting the site to public roads for evidence of tracked material (to be washed and removed as required)

Check for dust on local roads being used to access the site.

Inspect vehicle exits to ensure that wheel inspection and washing is effective and dust or sediment laden water is not being tracked off site by vehicles.

Daily

Twice daily

Daily and as conditions change

Daily and as conditions change

Daily and as conditions change

Daily and as new activities are commenced

Weekly

Daily in dry conditions and as wind conditions change

All truck departures

Daily

Daily during removal, weekly at other times

Inspect sealed vehicle access routes within the site for deposition of material (to be removed via vacuum sweeper truck)

6.3.1.

Continuous instrumental dust monitoring will be carried out at representative locations adjacent to sensitive areas when in the vicinity of dust generating activities. It is expected that at least two dust monitors are to be used to monitor dust from the site.

Condition 224 (i) of discharge permit R/REG/2015/1899 infers that three dust monitors are to be associated with the Aotea Active Construction Zone. However, installation of a total of two monitors located downwind of outdoor storage and construction activities, coupled with regular visual dust inspections in accordance with section 6.2, should provide an appropriate level of feedback information for the management of dust during the works

The location of the monitors will be re-evaluated by the Environmental and Sustainability Manager (or delegated person), and potentially moved, as the construction stages progress and the location of dust generating activities shifts. Where practicable (subject to physical, electrical and security constraints) the monitors are to be located downwind of dust generating activities in prevailing wind conditions (generally to the northwest or west) at locations representative of off-site exposure of property or people.

If dust monitoring results indicate that on-going or long-term monitoring is required at a fixed location (e.g. in proximity to an on-going dust source of particular concern), an additional dust monitor may be required. This would allow two moveable monitors to continue to monitor dust levels in proximity to other dust sources as the works progress.

Indicative monitoring locations as the Aotea Station main works progresses (and dust sources move or change) are described in Appendix F.

As required by Condition 227 of discharge permit R/REG/2015/1899, ambient dust monitoring will commence prior to activities that have the potential for significant dust emissions. Dust monitoring will be installed on-site prior to the commencement of construction works to enable background dust levels to be established. This pre-construction monitoring will enable revision of trigger levels if they are too high (not reflective of dust impacts), or too low (they are being frequently exceeded due to off-site dust emission sources).

Particulate instrumental monitoring for the works will include:

• Continuous instrumental monitoring of dust concentrations at the locations downwind of works locations;

• Calculation of 1-hour average concentrations from real-time monitoring data;

• Remote display of real-time particulate data (e.g. via the internet);

• Provision for alarms on 1-hour average concentrations measured above dust trigger levels (visual and/or via internet, email and mobile phone);

• Recording/logging of monitoring data; and

• Where practicable the monitors shall be located in accordance with AS/NZ 3580.1.1:2016 Method for Sampling and Analysis of Ambient Air – Guide to Siting Air Monitoring Equipment.

Dust Sentry nephelometers manufactured by Aeroqual are to be installed to monitor dust. These monitors are to be fitted with a particle size selective head to measure PM10 concentrations.

Other monitor options that meet the requirements of the CRL designation and resource consent conditions include:

• Particle counters; and

• Beta attenuation monitors.

Dust monitoring results are to be compared with trigger levels to indicate where dust levels may have the potential to cause adverse air quality effects and where modification to dust management measures may be required to avoid this outcome.

In the first instance, trigger levels published by the Ministry for the Environment (MfE)5 are adopted as operational dust trigger levels. In the event of monitoring results exceeding the trigger level, response actions are to be taken as outlined below. The trigger level values are described in Table 6-2

Table 6-2: Dust trigger levels

Dust monitoring*

Dust deposition

• MfE recommended trigger values for TSP concentrations: 200 µg/m3 (rolling 1-hour average)** OR

• MfE recommended trigger values for PM10 concentrations: 150 µg/m3 (rolling 1-hour average)**

• Evidence of dust on windows (a finger run down the glass leaves a clear line)

• Dirt on clean washing

*The dust monitoring trigger levels should be updated to reflect the method of monitoring employed, if required (refer below).

** The MfE recommended trigger values do not relate specifically to rolling averages, which are specified in this case to provide instantaneous feedback on dust levels.

The dust monitoring trigger levels should be reviewed once the monitoring method is confirmed and through regular (at least monthly) review of monitoring results. The regular review should include comparison with:

• The trigger alerts specified in Table 6-2;

• A review criterion for 24-hour average particulate concentrations of 60 µg/m3 for TSP or of 50 µg/m3 for PM10 (if TSP is not measured)6;

• Visual monitoring records;

5 Ministry for the Environment. 2016. Good Practice Guide for Assessing and Managing Dust: Ministry for the Environment.

6 The MfE Good Practice Guide (2016) does not recommend a 24-hour average trigger for PM10 and the threshold concentration for 24-hour average PM10 concentrations specified in the National Environmental Standards for Air Quality has been specified as the PM10 review criterion (where TSP concentrations are not measured).

• Dust complaints.

If review of monitoring results indicates the triggers specified in Table 6-2 have not provided suitable advance indication of potential adverse air quality effects, the triggers may require modification. The monitoring equipment will be set up with text alerts to key personnel in the relevant work zone, when dust concentrations exceed the trigger values set out in Table 6-2. At a minimum this will include:

• The Project Manager;

• The Environmental and Sustainability Manager;

• The Construction Manager; and

• Site Manager.

If Project personnel change, the Instrument Technician will be contacted to update the alerts.

If a dust trigger alert is sent, one of the above staff members will immediately (within 30 minutes) respond and investigate the cause of the alert. This investigation will:

• Determine if the alert is real and not caused by equipment malfunction; and

• Identify the source of dust and check to see that all of the required mitigation measures are being implemented.

If it is determined that construction activities are the cause of dust, and that mitigation measures outlined in Section 5 of this AQ DWP are not effective for controlling dust, the Link Alliance will implement the dust contingency procedures outlined in Section 5.6 of this AQ DWP. If these measures fail to effectively manage dust to acceptable levels, works shall be halted until it can be determined why dust emissions are occurring and what additional mitigation measures are required to control ambient dust to acceptable levels.

The findings of the investigation will be recorded in the Air Quality Log (refer to Section 9.1 of this AQ DWP).

Continuous instrumental monitoring of weather conditions at the Site can provide useful information for dust management. A meteorological station that can continuously measure the following parameters is to be installed as part of the Aotea Station main works:

• Continuous instrumental monitoring of wind speed and direction;

• Calculation of 1-hourly averaged data;

• Provision for alarms on 1-hour average wind speed data measured above wind speed trigger levels (visual and/or via internet, email and mobile phone);

• Remote display of real-time meteorological data (e.g. via the internet); and

• Recording/logging of monitoring data.

Additionally, at least one meteorological station that can continuously measure rainfall, relative humidity and temperature is to be installed as part of the CRL Aotea to Mt Eden construction works.

Where practicable weather instruments shall be located in general accordance with AS/NZS 3580.14:2014 - Methods for sampling and analysis of ambient air – Meteorological monitoring for ambient air quality monitoring applications. It will preferably be located to avoid adjacent buildings and other obstructions, where possible.

In the absence of on-site weather monitoring data, information of current and preceding wind conditions may be obtained from:

• Weather observations from other CRL works areas (if available);

• Weather observations from other weather stations in Central Auckland (if available);

• Current wind observations are displayed by the Met Service at www.metservice.com.

The Trigger Levels proposed for wind speed measurements (if wind monitoring is employed at the Site) are detailed in Table 6-3.

Table 6-3: Wind speed trigger levels

Wind speed

• Wind warning level:

5 m/s (1-hour average)

10 m/s (1-minute average occurring twice in 20 minute period)

In the event that wind speeds exceed the trigger values set out in Table 6-3 of this AQ DWP, text alerts will be sent to nominated Project personnel in the relevant work zone. As a minimum, the nominated personnel will include:

• The Project Manager;

• The Environmental and Sustainability Manager;

• The Construction Manager; and

• The Site Manager.

If 1-hour average wind speeds exceed 5 m/s then the visual monitoring of the work area will be undertaken to ensure that all appropriate mitigation outlined in this AQ DWP is being implemented and are effective.

There is the potential that continuous instrumental measurement of particulate concentrations may be influenced by either background particulate emission sources (not associated with the Aotea Station main works, such as other construction activities, domestic home heating or motor vehicle emissions) or rainfall/high humidity conditions that can affect dust monitoring instruments.

Previous experience at other CRL construction sites has shown that comparison of continuously measured ambient particulate concentrations with defined trigger levels may not always be indicative of adverse dust effects or a potential for dust nuisance experienced beyond the Site boundary.

If investigations of exceedance trigger levels establish that trigger events are not associated with onsite dust generation, an alternative dust risk assessment approach can be implemented. In that instance and if identified to be required by the Environmental and Sustainability Manager in consultation with the Auckland Council Monitoring and Compliance team, the following alternative approach will be taken:

• A response to individual dust trigger alerts in accordance with section 6.3.2 will not be mandatory and instrumental dust monitoring results will instead be reviewed against the trigger levels specified in by the Environmental and Sustainability Manager (or delegated person) on a daily basis.

• Visual dust inspections are to continue in accordance with section 6.2. If identified by the Environmental and Sustainability Manager as a result of a review of instrumental dust monitoring results, visual inspections may be required at an increased frequency.

• Dust risk is calculated each morning by site engineers in accordance with Section 5.1 and Appendix C and used to inform appropriate management procedures.

All monitoring data from the dust monitors and the on-site meteorological station will be available to Project staff on-line, and electronically recorded for future reference.

The dust monitoring equipment and meteorological equipment will require periodic maintenance and calibration checks. These will be done at a frequency and as per manufacture specifications by either site personnel, who have received appropriate training, or an Instrument Technician.

Unless the instrument recommends a higher frequency, at least quarterly maintenance and calibration will be carried out by a qualified Instrument Technician familiar with the equipment installed.

In the event that there is an equipment malfunction, or the equipment needs to be relocated for some reason, then the Instrument Technician will attend to this.

Odour monitoring (observations) will be undertaken when it is considered likely that odorous material may be encountered (such as contaminated soil materials) during excavations. The decision to undertake monitoring by a suitable experienced odour observer will be made by the Environmental and Sustainability Manager.

The frequency of odour monitoring will be dependent on the nature/scale of the source, location in relation to sensitive receptors, and meteorological conditions during exposure. Odour observations will occur:

• When potentially contaminated material is excavated and loaded onto trucks; and

• When odour complaints have been received.

The Environmental and Sustainability Manager will ensure that a trained odour scout is available to undertake odour observations as required.

Monitoring will involve the odour observer being positioned downwind of the works and assessing odours on the intensity scale set out in Table 6-4. Where odours are identified as being “Distinct” and above, and the odour characteristic unpleasant, mitigation measures will be implemented. All observations will be recorded in the Air Quality Log (refer Section 9.1 of this AQ DWP).

The odour observer will reassess the level of odour once the mitigation measures have been implemented. If the odours are still ‘Distinct’, further mitigation will be implemented, and / or the works halted until more conducive meteorological conditions are present, i.e. not blowing towards the sensitive receptor.

If it is suspected that sources upwind of the works are responsible for any odour, the odour observer shall make appropriate observations and document these also.

As exposed odorants may potentially also present health risks, the procedures outlined in the Contamination DWP for unexpected discovery of contamination should also be followed.

Sections 11 of the Aotea Station main works Communication and Consultation Plan (CCP) details how communities in the vicinity of the construction works will be communicated with in relation to the management of adverse effects relating to air quality. Communications will focus around informing communities of dust management and monitoring measures to be implemented during the works and providing updates on these aspects as appropriate during the construction works.

Although the mitigation measures described in this AQ DWP are aimed at avoiding discharges to air, complaints may be received by members of the public. It is important to ensure that any complaints are recorded and promptly investigated to identify and resolve the cause of the complaint. The requirements and procedures relating to complaints are detailed below.

A complaint may be received from a member of the public via the following:

• Direct call to the CRL Hotline (0800 CRL TALK)

• Complaint received by Auckland Council which notifies CRLL/Link Alliance of the complaint.

• Written or email correspondence (aotea@linkalliance.co.nz).

In all circumstances, correct and accurate information needs to be recorded by the person receiving the complaint in order to help investigate the cause of the complaint, and ensure appropriate mitigation has or will be undertaken.

Any complaints received should be recorded in a complaints file, and an investigation undertaken as outlined in the CEMP and Aotea Station main works CCP. The following guide should be followed when a complaint is received:

• Record the details provided about the incident by the complainant.

• The name and contact details of the person(s) who raised the complaint (unless they elect not to provide this).

• Acknowledge receipt of the concern or complaint and assure that an initial response shall be undertaken within 24 hours of receiving a complaint and resolved as soon practicable.

• Known construction activities at the time and in the vicinity of the complainant during the concern or complaint period.

• Remedial actions undertaken (if any) and the outcome of these, including monitoring of the activity.

• Weather conditions at the time of the concern or complaint, including wind direction.

• Reporting of the investigation in the complaints file.

The investigation of all complaints relating to air discharges will involve the following:

• Information about the incident as described by the complainant.

• Weather conditions at the time of the complaint, including wind direction and speed, and rainfall (if any)

• Reporting the findings and recommendations.

• Actions and time taken to close-out complaint.

• Communication with the complainant.

• Ensure reporting of the investigation is recorded in the complaints file.

An investigation of the complaint will require the Site Supervisor or delegated staff member to go around the whole site and make visual observations about activities occurring on site. This may also include going to the location where the complainant observed the impact.

At all times during the complaint’s investigation, appropriate health and safety procedures must be followed

All Project staff (contractors and subcontractors) will undergo general environmental awareness training and training about their responsibilities relating to this AQ DWP. Training requirements are described in full detail within the CEMP. Specific training requirements relating to this AQ DWP are outlined in Table 8-1

Table 8-1: Air Quality DWP specific training requirements

Training requirements

Introduction to the on-site monitoring equipment

Responding to continuous dust monitoring trigger alarm alerts

Responding to complaints regarding dust and air quality concerns

Frequency

As required and during new staff induction

As required and during new staff induction

As required and during new staff induction

Attendance

Site Manager, Environmental and Sustainability Manager, delegated staff member and duty managers

Site Manager, Environmental and Sustainability Manager, delegated staff member and duty managers

Site Manager, Environmental and Sustainability Manager, delegated staff member and duty managers

Construction activities can be affected by a number of different external and internal factors, such as weather conditions or equipment malfunction, which can contribute to an increase in dust emissions. Various control and mitigation measures will be carried out on-site to prevent such effects and monitoring and inspection procedures will be used to assess the level of dust emissions both on the Site and beyond its boundary. Recording relevant monitoring and inspection results, as well as the conditions of external and internal factors, can help assess if control measures are being effective, and to define appropriate corrective or preventive actions in case any undesirable effects are detected.

The procedures for recording daily air quality inspections are detailed below:

• The Construction Manager (or delegated person) will fill out an Air Quality Daily Log (refer to Appendix E) form each day and maintain the record on site.

• The following information will be recorded:

• Records of dust monitoring trigger events specified by this AQ DWP, including identification of the monitor ID which registered the trigger event, the time and the averaging period of the TSP trigger event;

• Any dust control equipment malfunctions and any remedial action(s) taken;

• Results of the Visual Inspections of dust emissions;

• General weather conditions during the day (i.e. windy, calm, warm, rain, etc.);

• The frequency of watercart and/or water sprinkling system use; and

• The date and signature of the person entering the information.

The key management roles in relation to environmental management during construction are outlined in Section 4.1 of the Aotea Station main works CEMP. Specific roles relating to this AQ DWP are detailed in Table 10-1.

Table 10-1: Air Quality DWP specific training requirements

Organisation Role

Link Alliance Project Manager

Environmental and Sustainability Manager

Responsibilities

Overall responsibility for site environmental management. Reviewing CEMP and sub-plans, including the AQ DWP.

Reporting on environmental performance.

Inspection of works to assess compliance with the AQ DWP and sub-plans.

Prepare, review and update CEMP, including the AQ DWP and other sub-plans.

Assess requirement for alternative dust management approach. Assess the requirement for odour monitoring.

Construction Manager

Auckland Council Monitoring and Compliance Team

Report to AT any changes to construction techniques or natural environmental changes which require alterations to existing consents or new resource consents.

Update and maintain the environmental portion of the Project Risk Register.

Maintain Daily Logs and Complaint Records.

Training of all staff including subcontractors.

Approve the CEMP, including the AQ DWP and other sub-plans. Auditing to assess that compliance with the AQ DWP.

This AQ DWP is a live document that will be reviewed at least annually, or as a result of a material change to the project, or to address unforeseen adverse air quality effects arising from construction, or unresolved complaints. Any material changes to this AQ DWP must be approved by Auckland Council prior to any on-site activity reliant upon the change commencing.

A review of the AQ DWP will be undertaken at least annually and will take into consideration:

• Compliance with the designation or consent conditions, the CEMP, DWPs and MPs (including site specific plans) and material changes to these plans

• Any significant changes to construction activities or methods

• Key changes to roles and responsibilities within the Project team

• Changes in industry best practice standards

• Changes in legal or other requirements (social and environmental legal requirements, consent conditions, relevant policies, plans, standards, specifications and guidelines)

• Results of inspections, monitoring and reporting procedures associated with the management of adverse effects during construction

• Comments or recommendations from Auckland Council regarding the CEMP, DWPs and MPs

• Unresolved complaints and any response to complaints and remedial action taken to address the complaint

• Any further information obtained in relation to the presence of hazardous material in dust emissions from construction activities at the Site including composition levels of silica, asbestos, erionite or other hazardous material7

Reasons for making changes to the AQ DWP will be documented. A copy of the original AQ DWP document and subsequent versions will be kept for the Project records and marked as obsolete. Each new / updated version of the AQ DWP documentation will be issued with a version number and date to eliminate obsolete AQ DWP documentation being used.

A summary of the review process will be provided annually to Auckland Council and made available to Council on request.

7 Receipt of further information relating to increased levels of hazardous material in dust emissions from the Site may initiate a review of this DWP.

Table A-1 identifies the ISCA Credit Requirements relevant to this AQ DWP and where they are addressed in the document.

Table A-1: ISCA requirements

Credit Requirement

DIS-4

Level 1

DIS-4

Level 1

DIS-4

Level 1

DIS-4

Level 3

Measures to minimise adverse impacts to local air quality identified and implemented

Monitoring of air emission and/or quality is undertaken at appropriate intervals

Monitoring of air emission and/or quality is undertaken in response to complaints

Monitoring and Modelling demonstrates no exceedances of air emission or air quality goals

Table 5-1

Section 6

Section 7.2

Section 6

Also refer to Erosion and Sediment Control Plan for the works

Note dust trigger levels specified in section 6.3.2 are not intended as air quality goals.

Also refer to Monitoring Results and Reports.

SHOULDBESTABILISEDINACCORDANCEWITHTHE EROSIONANDSEDIMENTCONTROLPLAN.

LinkAlliancehaspreparedthisdocumentforthesoleuseoftheclientandforaspecific purpose,eachasexpresslystatedinthedocument.Nootherthirdpartyshouldrelyonthis documentwithoutthewrittenconsentofLinkAlliance.LinkAllianceundertakesnoduty,nor acceptsanyresponsibility,toanythirdpartywhomayrelyuponorusethisdocument.

Thisdrawingisconfidentialandshallonlybeusedforthepurposeofthisproject.Thesigningofthistitleblockconfirmsthedesignanddraftingofthisprojecthavebeen preparedandcheckedinaccordancewiththeLinkAlliancequalityassurancesystemtoISO9001-2000.

(NOTPARTOFAOTEA STATIONMAINWORKSCEMP)

STREETPLENUM

BLUESTONEWALL (NOTPARTOFAOTEA STATIONMAINWORKSCEMP)

FUTUREKINGSTON STREETPLENUM

PHASE3PHASE4/PHASE5 CONSTRUCTIONNORTHERNSECTION

FUTUREVICTORIASTREET WESTEASTERNENTRANCE

FUTUREWELLESLEY STREETWESTENTRANCE

PHASE4/PHASE5 CONSTRUCTION

PHASE4PHASE5CONSTRUCTION -SOUTHERNSECTION

FUTUREVICTORIASTREET WESTWESTERNENTRANCE

(NOTPARTOFAOTEA STATIONMAINWORKSCEMP)

STREETPLENUM

PHASE4PHASE5

The risk of adverse off-site dust impacts and the level of dust mitigation and management processes required to minimise will vary depending on various factors including:

• Proximity of activity to sensitive locations in the surrounding environment;

• Weather conditions such as wind speed and whether the ground is dry; and

• The dust emission potential associated with the type of activity being undertaken.

The objective of this dust risk assessment (DRA) procedure is to provide guidance to the Environmental and Sustainability Manager, and site supervisors of the level of dust management procedures that should be implemented depending on what activity is being undertaken on site. The DRA procedure is based on those implemented by London Council and is outlined in Figure C-1 below8,9

Calculate environmental dust senstiivity from local weather conditions and proximity of sensitive receptors (Table C-1).

Calculate dust risk for each activity to be undertaken (Table C-2).

Ensure the appropriate level of dust management processes are implemented (Section 5.2), and that the dust risk is displayed on-site.

Dust generating activities in the Main Works phase will occur both at (or near) ground level underground (underneath previously constructed floor slabs). Dust from underground activities will be contained and will not be influenced by external weather conditions. Any residual dust in air ventilated from underground works areas will be discharged via fixed vent locations.

Conversely, dust from most above ground activities associated with the works will not be physically contained and will be discharged diffusely, potentially from a wide variety of locations. Above ground activities will also be subject to ambient weather conditions.

The environmental influences on the potential for above and below ground activities to cause dust nuisance therefore differ and environmental dust potential of above and below ground activities is therefore calculated via separate activities below.

As the sensitivity of the local environment surrounding the Aotea Station main works area is generally high (due to the density and nature of adjacent city centre activities), calculation of the environmental dust potential is based solely on weather conditions:

8 The Control of dust and Emissions during Construction and Demolition. Greater London Authority, July 2014.

9 Guidance on the assessment of dust from demolition and construction, Version 1.1, Institute of Air Quality Management (UK), February 2014.

1. Review local weather forecast over works period for wind speeds (e.g. via https://www.metservice.com/towns-cities/auckland/auckland-central) and on-site meteorological data for rainfall in preceding 48 hours.

With this information the environmental dust sensitivity rating can be calculated from Table C-1 below.

Table C-1 Environmental dust potential calculation

Meteorological conditions

Predicted 1-hourly average wind speeds

>5 m/s AND <1 mm of rain in the preceding 48 hours

Predicted 1-hourly average wind speeds >5 m/s OR <1 mm of rain in the preceding 48 hours

Calculating environmental dust potential for below ground activities

Predicted 1-hourly average wind speeds <5 m/s AND >1 mm of rain in the preceding 48 hours

Environmental dust sensitivity and potential fort dust transport associated with below ground works is considered differently as dust generation from these activities will not be influenced by ambient weather conditions and dust will only be emitted from fixed discharge points in the ventilation system.

The environmental dust potential for underground dust generating activities is therefore calculated based on the state of discharge from ventilation exhaust points as follows:

• LOW – Exhaust free of visible dust emissions; and

• MEDIUM – Visible dust emissions are observed from external exhaust vents.

Dust risk calculation

The dust risk for each prescribed activity associated with the works is subsequently derived from the dust emission potential and the calculated environmental dust potential as outlined in Table C-2 for above ground activities and Table C-3 for below ground activities.

C-2 Dust risk calculation for above ground activities Overall dust risk of activity

Rock drilling in exposed areas

Earthworks in exposed areas (including excavation and handling of spoil)

Vehicle movements over unpaved surfaces

Demolition/removal of hardstand and structures

Handling of cement (or other bulk solid/powder materials including pneumatic conveyance)

Handling of bentonite powder (or other bulk solid/powder materials without pneumatic conveyance)

Piling

Outdoor/uncovered stockpiling

Vehicle movements over paved surfaces

Ground

Indoor/enclosed stockpiling

* Each activity has a different dust emission potential

Table C-3 Dust risk calculation for below ground activities (enclosed by floor slab)

Overall dust risk of activity

Vehicle movements over unpaved surfaces

Excavation, mining and construction

The calculated dust risk should be displayed on-site to ensure site staff implement the appropriate level of dust management procedures as specified in Section 5.2. The dust management procedures for each activities’ risk level is described in Appendix D.

To be completed by the construction manager or others involved in the implementation of controls based on the requirements of section 5.2.

Source

*Levels (extent) of visible dust emissions:

(1) Minor visible emissions (<5m from source);

(2) Moderate visible emissions (<30m from source);

(3) Major visible emissions (>30m from source).

Date event was investigated:___/___/_____ Person responsible for investigation and response:________________________________

Possible cause(s):

Dust from wind erosion of exposed ground

Watercart not used properly

Exceedance of speed limit in unpaved surface

Materials not handled or stored properly

Loading/Unloading not carried out properly

Other_________________________________________

Corrective actions: Date: ___/___/_____

Description:

Preventive actions: Date:

Description:

Equipment identification Excessive or prolonged visible emissions observed?