WATER DISTRIBUTION SYSTEM MASTER PLAN

For the City of Tyler

Prepared by:

Halff Associates, Inc.

Firm Registration No. 312

halff.com

For the City of Tyler

Prepared by:

Halff Associates, Inc.

Firm Registration No. 312

halff.com

The Water Distribution System (WDS) Master Plan for the City of Tyler (City) documents an overview of the existing WDS, development of the Tyler WDS hydraulic model, and provides an inventory of and basis for the 25-year WDS Capital Improvement Plan (CIP). A hydraulic model of the existing Tyler WDS was created and calibrated, then used to develop the 2047 Tyler WDS hydraulic model based on planning assumptions established in this report. The existing and 2047 systems were evaluated against hydraulic performance standards, regulatory capacity requirements, and needed infrastructure within the 25year effective planning window. The Water Master Plan and CIP are tools to provide the City with the ability to effectively manage the current system and plan for the future of their water system.

The Water Master Plan and CIP provide TWU with a system-wide perspective on infrastructure needs. The primary goals of the Master Plan and CIP are to:

◦ Identify existing hydraulic performance or operational issues and establish recommendations to address deficiencies,

◦ Identify infrastructure needs to attain and maintain regulatory compliance and meet projected water demands through 2047,

◦ Increase operational efficiency and resiliency of the Tyler WDS, and

◦ Evaluate alternatives for infrastructure improvements to reduce costs.

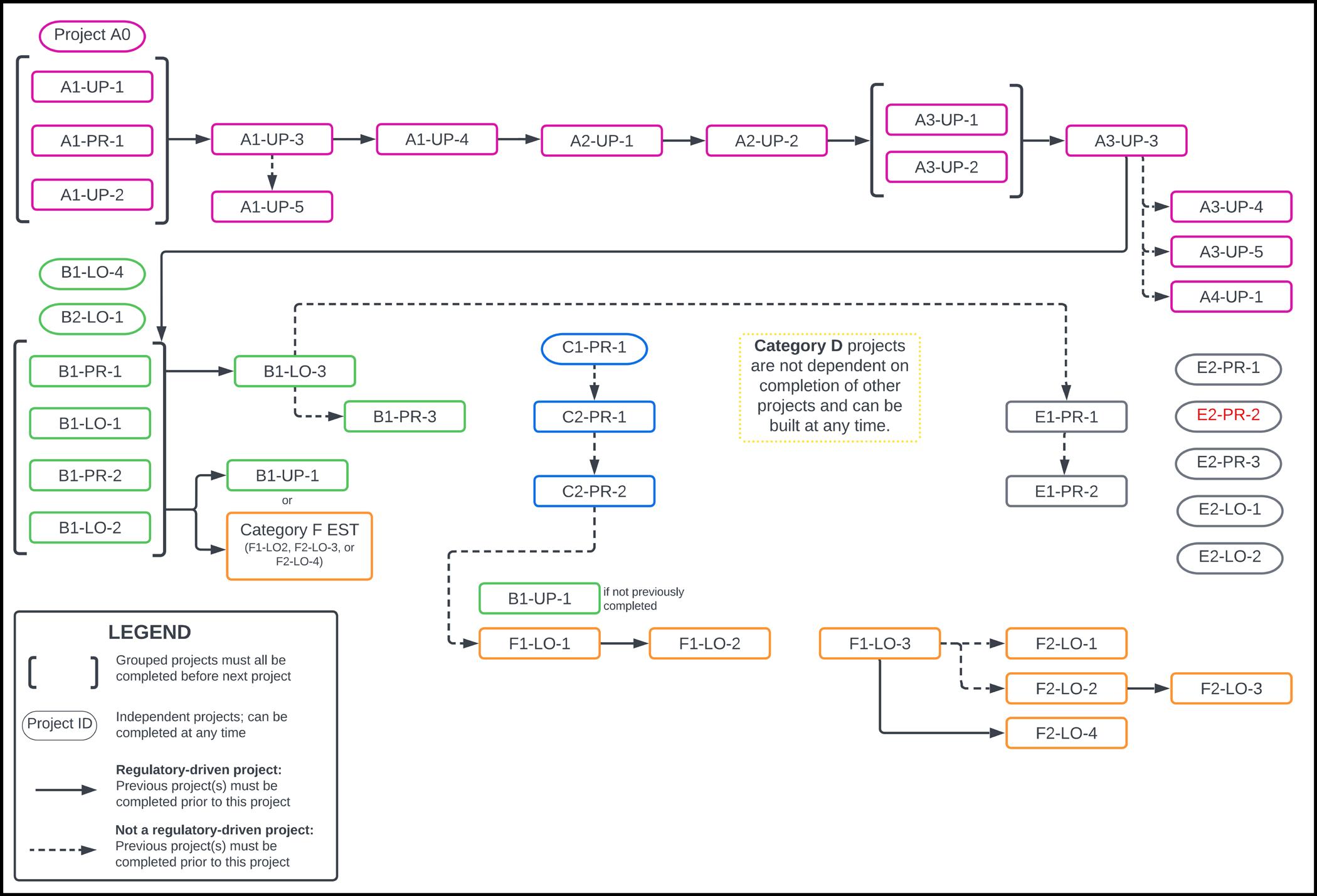

The most prominent challenges facing Tyler’s existing WDS include high service pressure variability throughout the system, regulatory elevated storage and pumping capacity deficiencies, and inadequate system monitoring and control capabilities. The 25year WDS CIP (Section 6.3 and Appendix D) was developed to resolve existing system issues and to

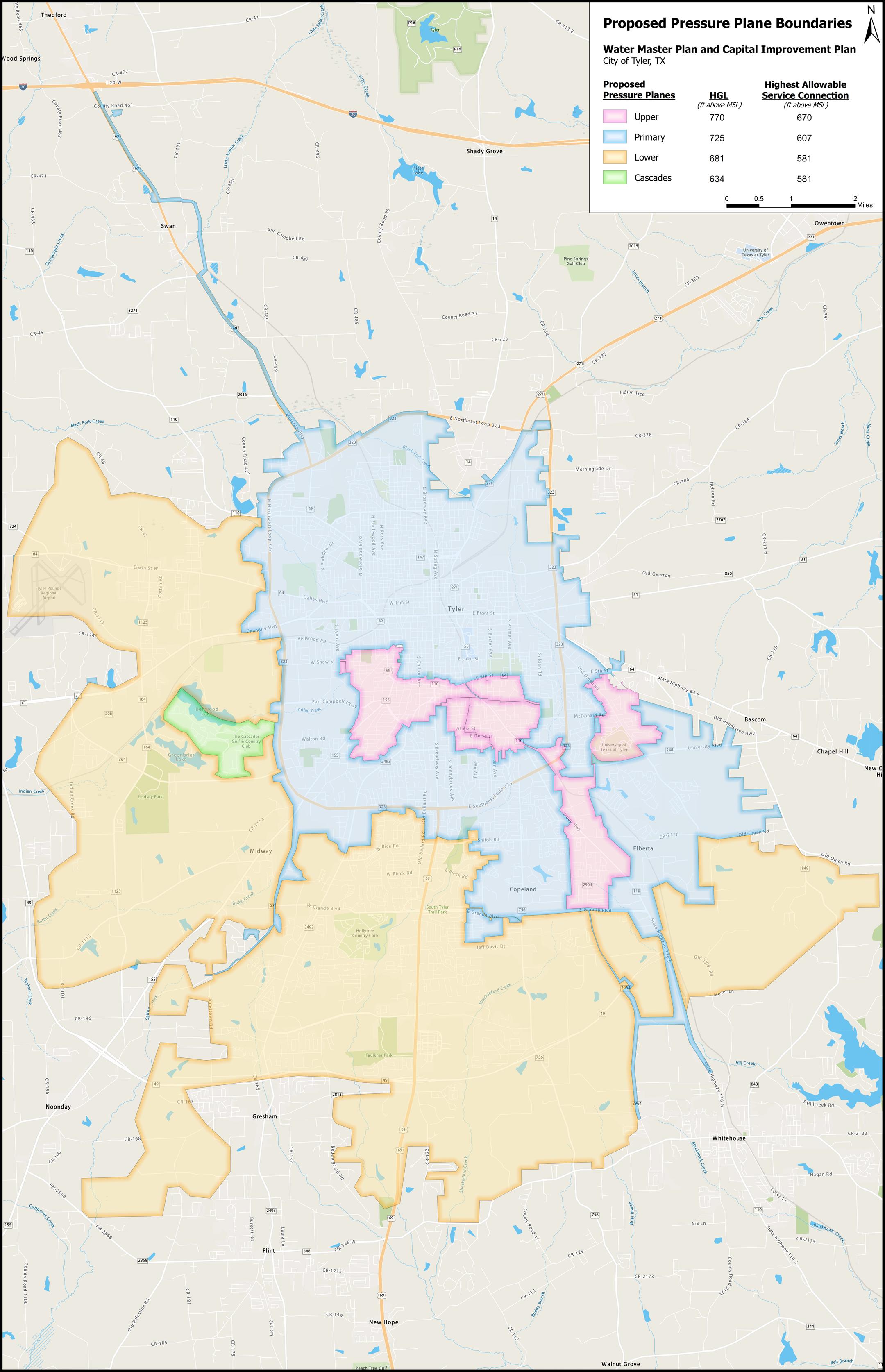

ensure regulatory compliance and reliable system performance as the system expands within the 25year planning window. Various combinations of system improvements were evaluated to determine the most beneficial solutions to meet the system’s needs. Overall, the 25-year WDS CIP includes retrofitting the existing system to re-delineate pressure plane boundaries, establishing sufficient capacity within each proposed pressure plane, and adding facilities when needed to accommodate growth. Total project costs were estimated for each recommended project based on actual construction costs for similar projects in North Texas and included contingencies and estimated engineering and survey fees. The total cost of the CIP is approximately $157.6 million in 2022 dollars. The CIP is shown in Table ES.1.

In addition to the CIP, recommendations for immediate or continued application to address some existing issues that can be resolved with minor improvements or modifications to operations (See Section 5 for discussion) include the following:

◦ Install pressure-sustaining valves on the Jan BPS and Terre Haute BPS inlet lines,

◦ Throttle the Charleston Park GST inlet valve,

◦ Modify the Hollytree PP and Thigpen PP pressure regulating stations settings, and

◦ Create the Cascades PP

General recommendations applicable to the entire distribution system (See Section 6.6 for discussion), not included as CIP projects, including the following:

◦ Install remote pressure monitors throughout the system,

◦ Update the Tyler WDS hydraulic model to include all system pipes, and

◦ Apply and utilize the City’s Asset Management Plan

Connect the Jan Street PP to the Upper PP

Initial Creation of the Lower PP

= 770 ft above MSL)

Expand the Upper PP boundary

Terre Haute BPS and connect the Terre Haute PP to the Upper PP

Jan BPS and connect the Jan Street PP to the Upper PP

PP 8-inch water main

PP 8-inch water mains

to Broadway 30-inch transmission main

Construct 2.0 MG “Cumberland Rd” EST in the Lower PP (Overflow = 681 ft above MSL) and 24-inch transmission mains

the new Lower PP

water main to address high velocities

F1: Lower PP Supply

Mackey Road and Highway 49 - 18- to 30-inch transmission mai

F1-LO-2 Construct 1.75 MG “Oscar Burkett Road” EST in the Lower PP (Overflow = 681 ft above MSL)

Lower PP HSPS at Lake Palestine WTP and 36inch transmission main to Three Lakes Parkway

F2: Growth-Driven Capacity Additions

Construct 0.5 MG “Dixie Drive” EST in the Lower PP (Overflow = 681 ft above MSL)

Construct 1.75 MG “Grande Blvd” EST in the Lower PP (Overflow = 681 ft above MSL)

BPS booster pump station

million gallons per day (unit of flow)

CCN Certificate of Convenience and Necessity mi miles

CIP Capital Improvement Plan

City City of Tyler

DFS Data Flow Systems

EPA Environmental Protection Agency

EPP Emergency Preparedness Plan

EPS extended-period simulations

EST elevated storage tank

ETJ extraterritorial jurisdiction

ft above MSL feet above mean sea level (unit of head)

ft/k-ft feet per 1,000 ft (unit of head loss) TAC

fps feet per second (unit of velocity)

gpcd gallons per capita per day

gpm gallons per minute (unit of flow)

GST ground storage tank

HGL hydraulic grade line

HSPS high service pump station

LF linear feet (in Appendix D)

LS lump sum (in Appendix D)

opinions of probable construction cost

Pressure Plane (used for pressure plane names only)

pressure-reducing valve

pounds per square inch (unit of pressure)

pressure sustaining valve

Right of Way

supervisory control and data acquisition

standpipe

Texas Administrative Code

Texas Commission on Environmental Quality

Tyler Water Utilities Department

Texas Water Development Board

variable frequency (speed) drive

water distribution system

Water Supply Corporation

Water Treatment Plant

The City of Tyler (City) retained Halff to create a dynamic, updateable City-wide water distribution system (WDS) model and to prepare an accompanying Water Master Plan and Capital Improvement Plan (CIP). This study aims to determine improvements for the water distribution system to address existing performance issues and accommodate projected future growth. This report documents the existing WDS, hydraulic model development, and assumptions. It provides an inventory and basis for improvements, including operations and maintenance recommendations and a CIP. The model, master plan, and CIP are focused on the WDS, starting at the water treatment plant’s clearwells and terminating at the wholesale and retail water meters.

The scope of services for the Tyler City-wide water system model, master plan, and capital improvement plan (Task 1) include the following summarized tasks:

◦ Build a calibrated water distribution system hydraulic model: Halff developed an existing conditions hydraulic water model from revised GIS system data, consisting of 8-inch diameter pipes and larger, to analyze the current system (2022) performance (6-inch diameter pipes included on an as-needed basis). This model was calibrated hydraulically with hydrant flow tests, hydrant pressure monitoring data, and, to a lesser extent, hourly operator logs.

◦ Establish Land Use Assumptions: Halff projected water demands for the 25-year planning window using future land use assumptions. A 25Year (2047) conditions hydraulic model was built by applying projected 2047 water demands to the calibrated existing system model.

◦ Develop a Water Master Plan: Halff evaluated the WDS to identify deficiencies based on regulatory requirements, hydraulic performance, and needed infrastructure within the 25-year effective planning window. The existing and 2047 distribution system models were analyzed under maximum day demand (MDD) conditions

to identify issues related to standard hydraulic performance criteria and system operations.

◦ Develop a Capital Improvement Plan: The needs identified by the existing system hydraulic model were used to determine appropriate capital improvements to address current deficiencies. Deficiencies identified by the 25-year system analysis were used to determine additional capital improvements to accommodate future growth and improve the future water system.

◦ Develop Opinions of Probable Construction Cost (OPCC): Halff developed an OPCC for the water CIP.

Additionally, the Scope of Services includes the development of a Water Treatment Plants Facility Plan (Task 2) and a WDS Asset Management Plan (Task 3). These components are covered in the separate Water Facilities Master Plan Report and the Water Distribution System Asset Management Plan Report, respectively.

The CIP consists of projects identified to address issues of non-compliance with regulatory requirements and inadequate hydraulic performance, in addition to projects required to accommodate future growth. The regulatory and hydraulic performance criteria are documented in this section.

The Texas Commission on Environmental Quality (TCEQ) is responsible for ensuring the Environmental Protection Agency (EPA) water quality rules are enforced. To communicate these requirements, the TCEQ has published a set of rules and requirements compiled in Chapter 30 of the Texas Administrative Code (TAC)(30 TAC). Chapter 290 Subchapter D within 30 TAC lists the minimum requirements a Public Drinking Water System must meet to remain in compliance. The regulatory capacity and minimum pressure requirements applicable to the Tyler water distribution system are shown in Table 1.1.

§290.38 Storage (Elevated)

To be considered ‘elevated storage’, storage must be at least 80 feet above the highest service connection.

Minimum total storage capacity of 200 gallons per connection (Excludes pressure tank capacity).

Storage

Elevated storage capacity of 100 gallons per connection (required for systems with over 2,500 connections) or a pressure tank capacity of 20 gallons per connection, up to 30,000 gallons for up to 2,500 connections. Note: to qualify for lower pumping capacity requirements, 200 gallons per connection of elevated storage must be supplied.

§290.45

Pumps

§290.44 & §290.46 Pressure

Each pump station or pressure plane must have a service pump capacity of two or more pumps that have a total capacity of 2.0 gpm per connection or have a total capacity of at least 1,000 gpm and the ability to meet peak hourly demands with the largest pump out of service, whichever is less. For systems with an elevated storage capacity of 200 gallons per connection, 2 service pumps with a minimum combined capacity of 0.6 gpm per connection are required at each pump station or pressure plane.

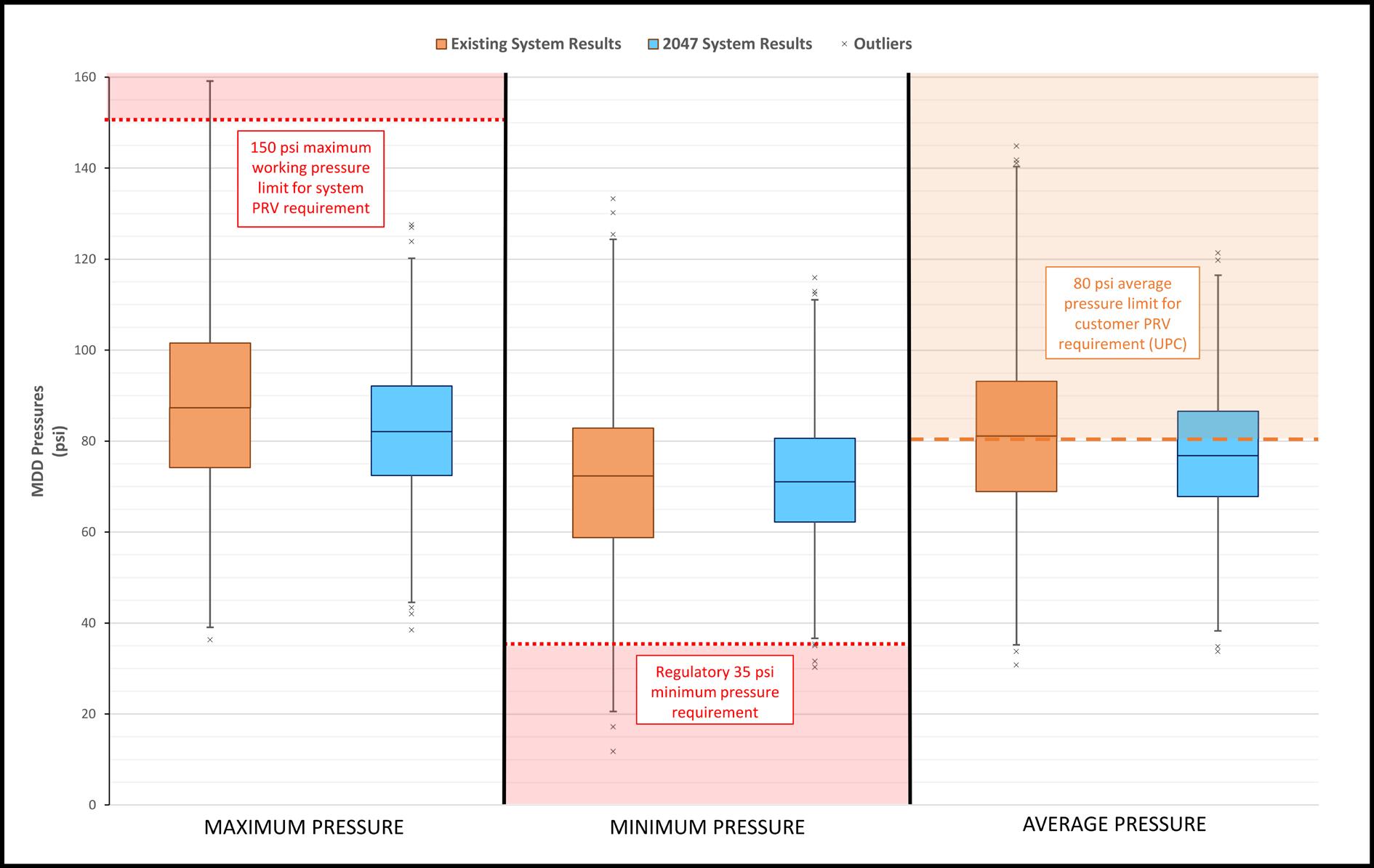

The system must be designed to maintain a minimum pressure of 35 pounds per square inch (psi) at all points within the distribution network at flow rates of at least 1.5 gpm per connection.

If the system is intended to provide firefighting capability, it must also be designed to maintain a minimum pressure of 20 psi under combined fire and drinking water flow.

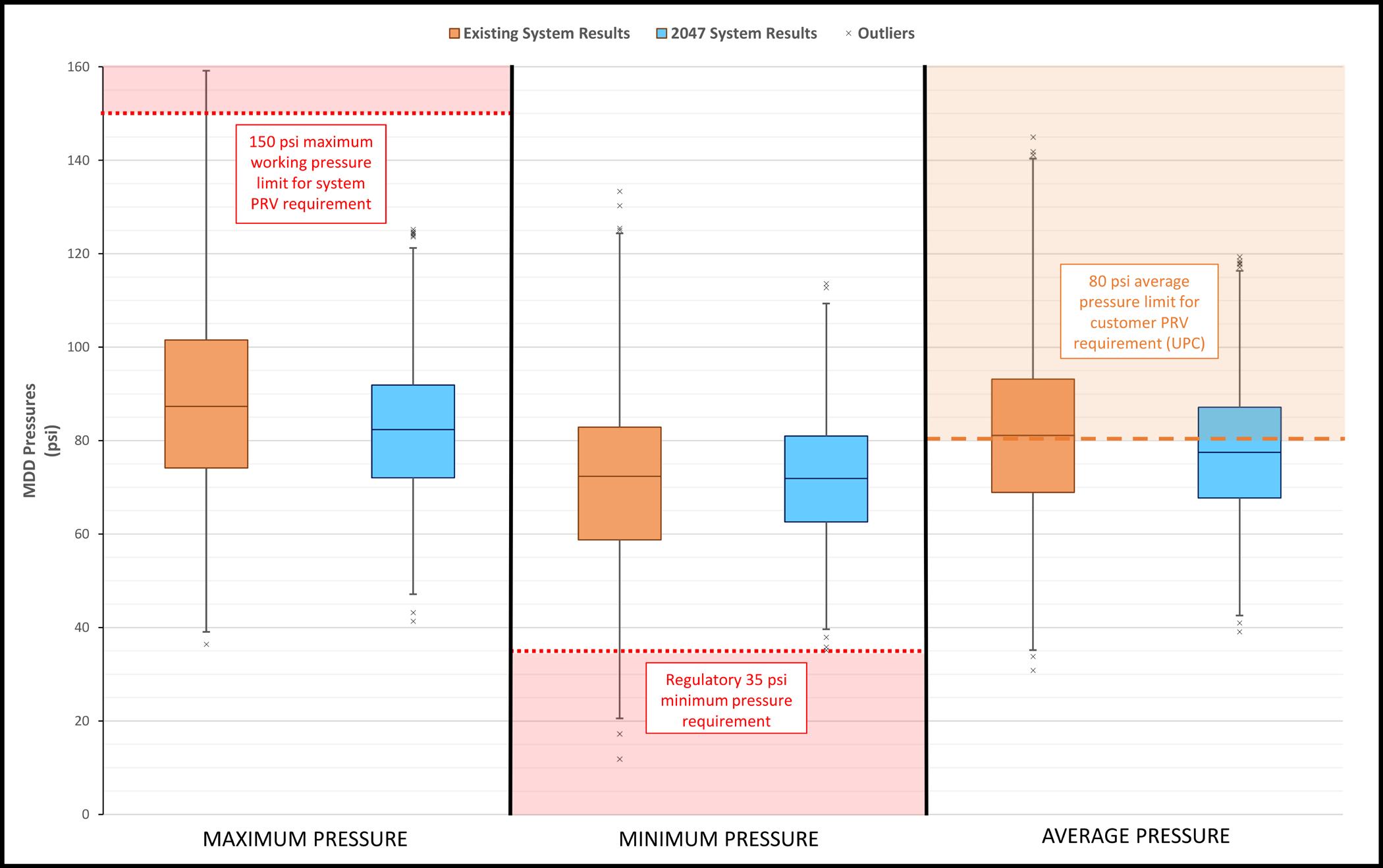

In addition to the regulatory requirements of the TCEQ, there are industry-accepted standards for water distribution system performance, shown in Table 1.2. Table 1.2. Industry Standards

Pumps

Piping

Capacity

Minimum high service pumping capacity of 150% of the Maximum Day demand. Emergency Scenarios

Maximum Velocity

Minimum Velocity

Maximum Head Loss

Pressure

All pump stations should be equipped with permanently installed automatic starting generators.

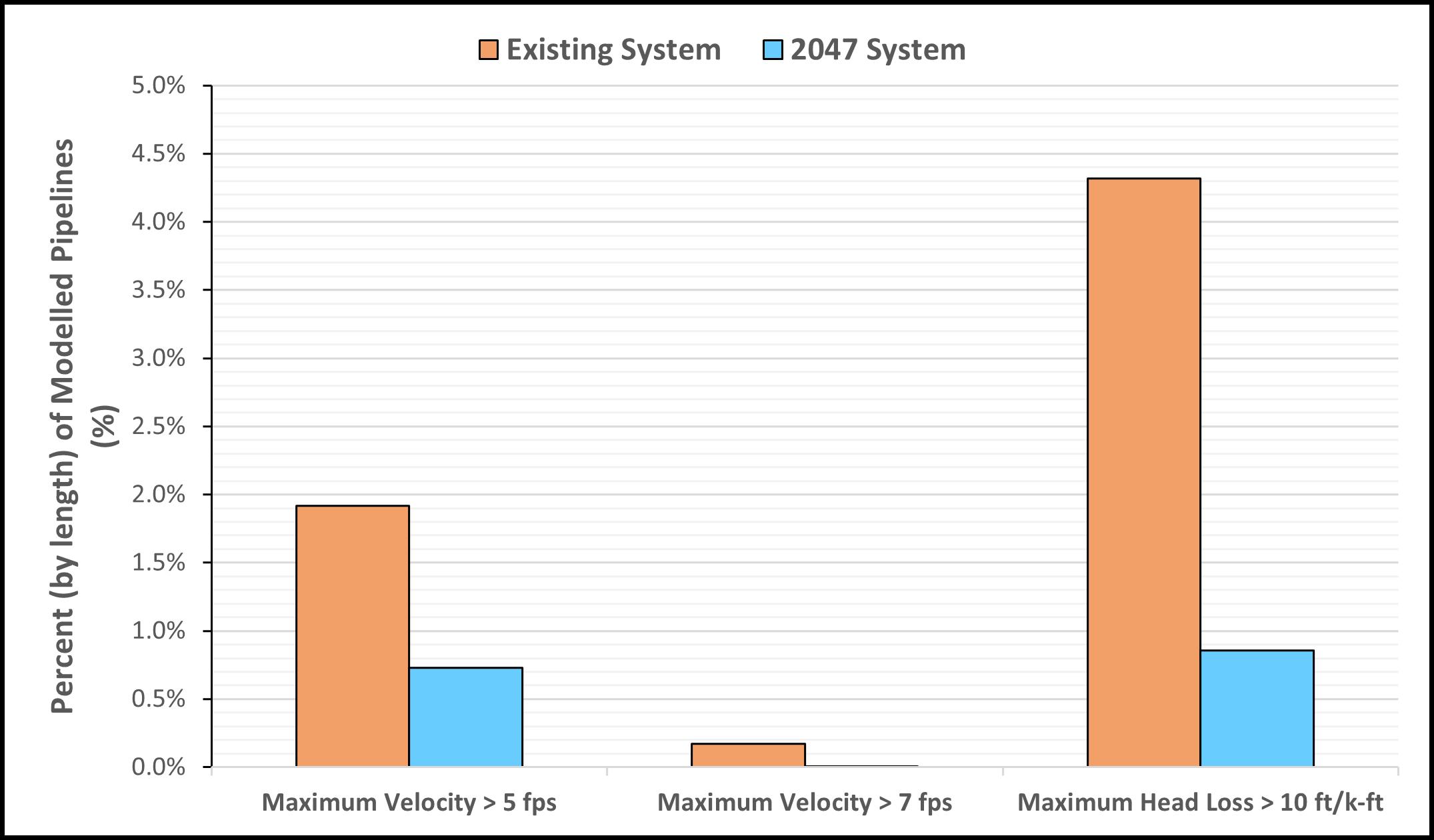

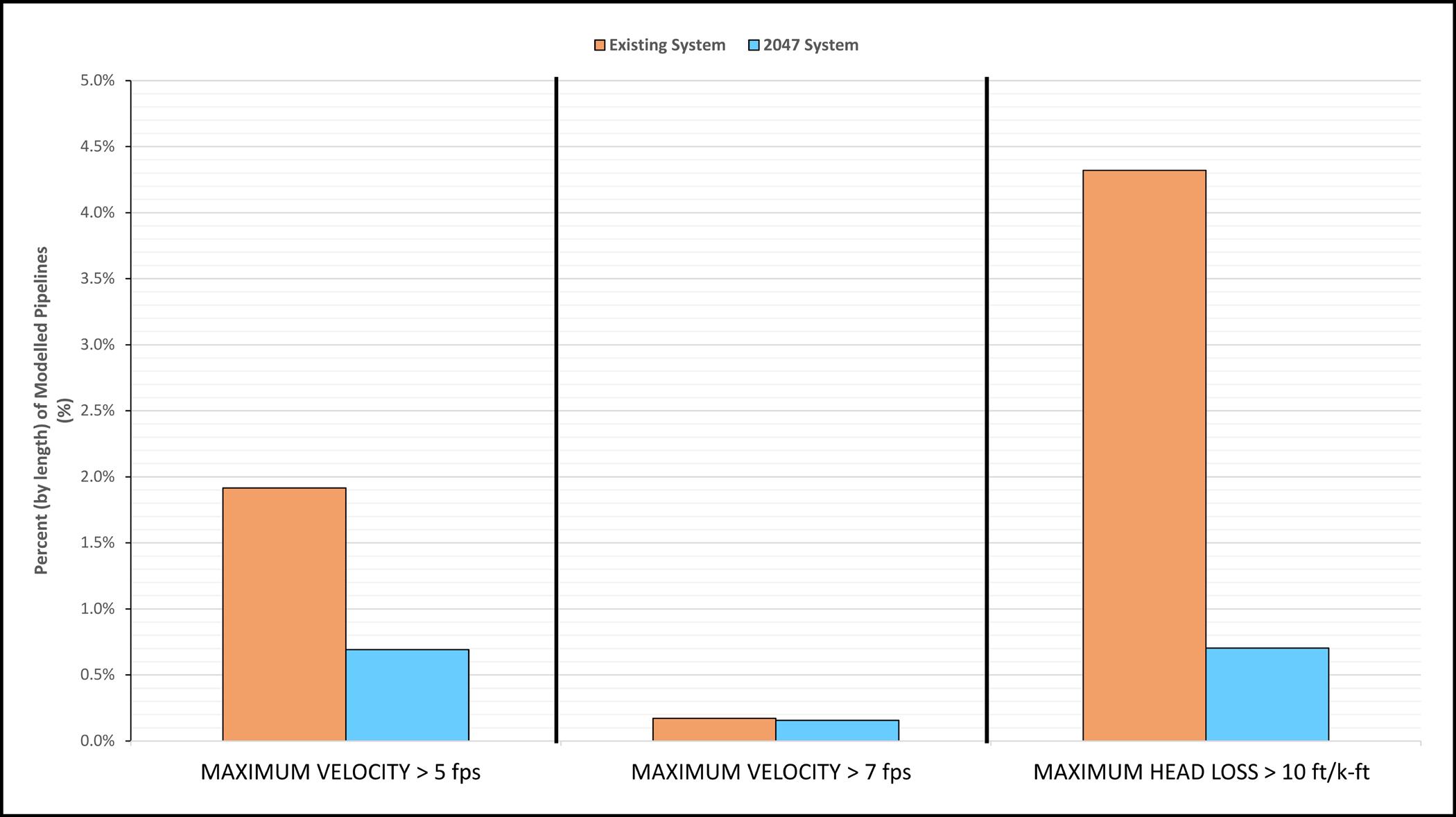

[Domestic demands]: Maximum of 7.0 feet per second (fps) but preferably less than 5.0 fps.

[Fireflow demands]: Maximum of 10.0 fps.

Maximum velocities should reach a minimum of 2.0 fps.

The City of Tyler Design Guidelines for Subdivision Improvements1 identifies a maximum allowable head loss of 10 feet per 1,000 feet (ft/k-ft) of pipe.

Since a typical service meter is designed for a working pressure of 150 psi, it is recommended to install a pressure-reducing valve on the upstream side of the meter when pressures exceed 150 psi. (Uniform Plumbing Code requires pressure regulators on service lines when static pressure in water supply piping exceeds 80 psi. This is a requirement on the customer side of the meter.)

1 City of Tyler Design Guidelines for Subdivision Improvements (Revision Date: May 14, 2021)

The criteria identified in this section will be used to evaluate the hydraulic performance and operational capacity of the existing distribution system in Section 5 and the 25-year distribution system in Section 6.

The Tyler Water Utilities Department (TWU) is the primary finished water supplier for the City of Tyler residents and commercial properties and also provides finished water to three wholesale customer water suppliers: the City of Whitehouse, Walnut Grove Water Supply Corporation, and Community Water Company. The City’s water utility service area, as defined by the water Certificate of Convenience and Necessity (CCN) boundary, covers approximately 228 square miles, including 126 square miles of overlapping area with other water utility companies, as shown in Exhibit 2.1. The service area covered exclusively by the City covers approximately 102 square miles. The City service area overlaps with the following cities and water utility companies:

◦ City of Lindale

◦ Community Water Company

◦ Lindale Rural Water Supply

◦ Southern Utilities Company

◦ Lindale Rural Water Supply

◦ Walnut Grove Water Supply Corporation

The City of Tyler has a population of approximately 106,000 people, according to the United States 2020 Census estimates. The majority of the utility’s finished water distribution system is located within the City limits and is divided into seven pressure planes. This distribution system includes two water treatment plants (WTPs), four elevated storage tanks (ESTs), one standpipe (SP), four booster pump stations (BPSs), and 707 miles of water mains. Note the Shiloh Road EST and BPS have been offline for several years

and are not included in the capacity compliance assessment (per 30 TAC §290.45(a)(5)) or modeling analyses. Exhibit 2.2 shows the existing Tyler system with facility locations and pressure plane boundaries.

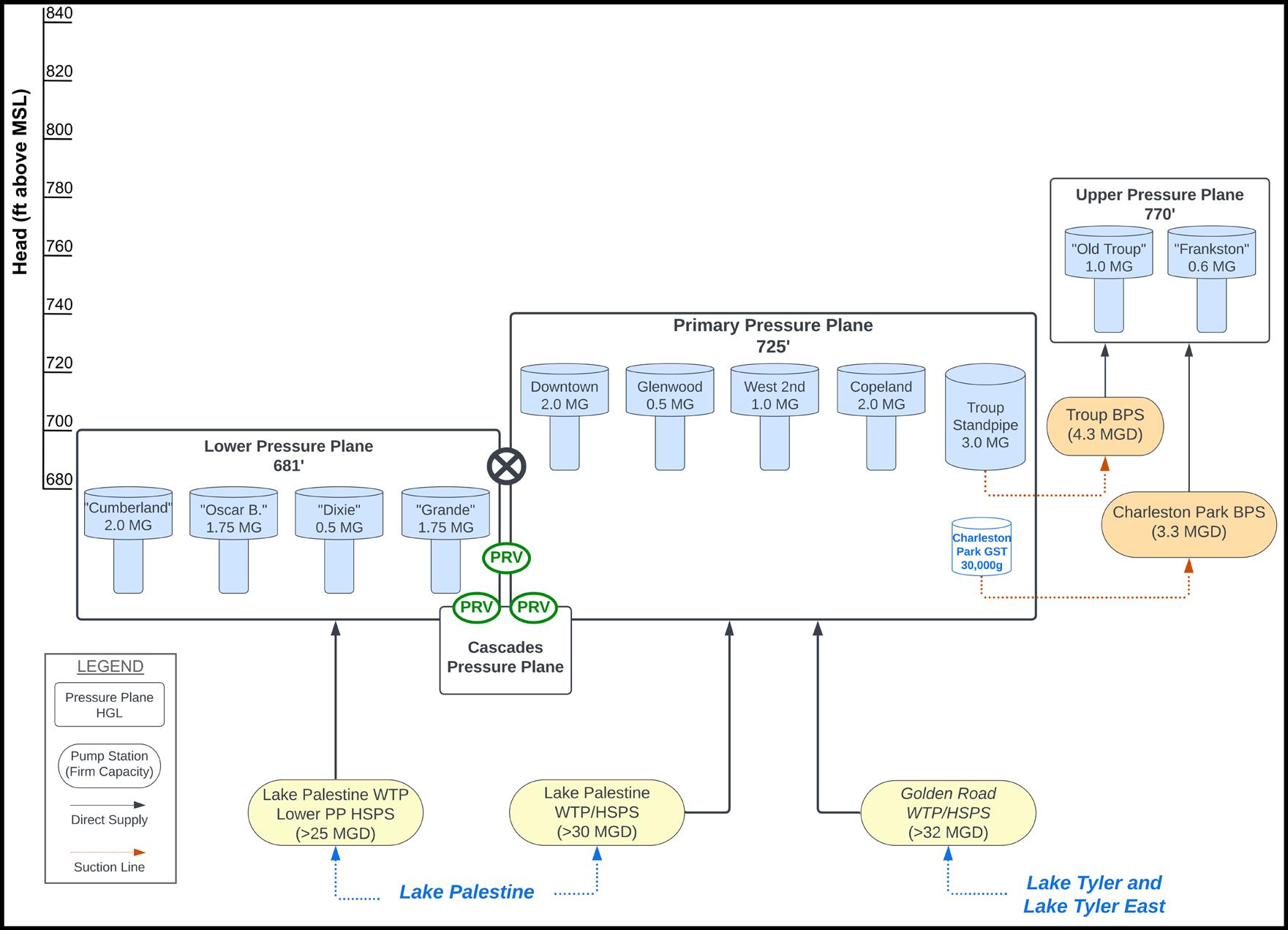

TWU operates two WTPs that provide the entire drinking water supply to all City customers. Golden Road WTP is located in the central-east region of the distribution system, and treats surface water from Lake Tyler and Lake Tyler East. Lake Palestine WTP is located in the southwest region of the distribution system, and treats surface water from Lake Palestine. The two WTPs have a rated total high service pumping capacity of 88.0 million gallons per day (MGD), with 38.0 MGD from Golden Road WTP and 50.0 MGD from Lake Palestine WTP. The raw water system is not included in this model and report per the Project Scope. The raw water and WTP facilities are considered in the Water Facilities Master Plan Report.

The distribution system includes 15 inactive, plugged, or abandoned groundwater wells. Historically, these wells supplemented the finished water supply but are currently considered inactive by TCEQ and for emergency use only. These groundwater wells are not included in the model and are not considered further in this report.

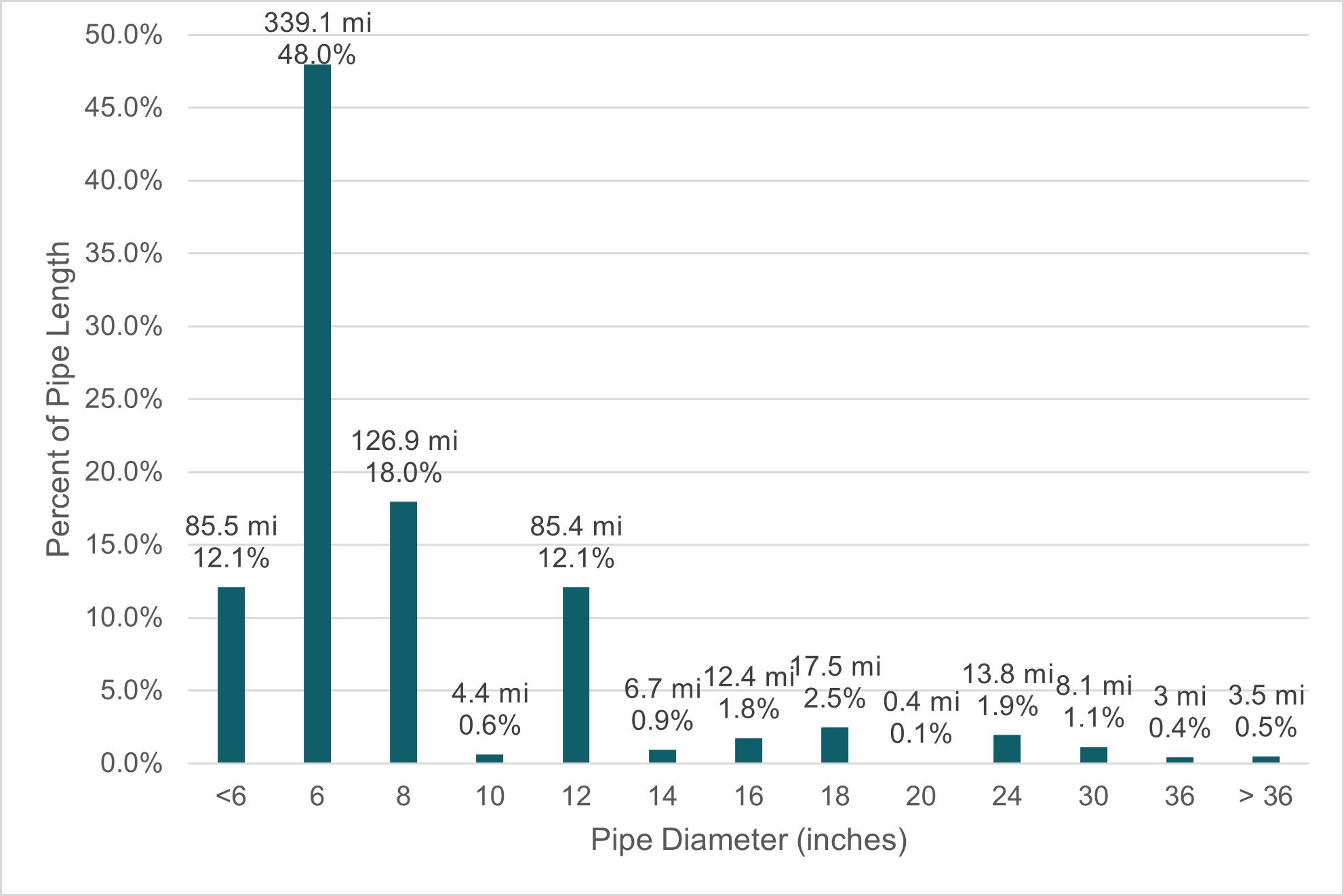

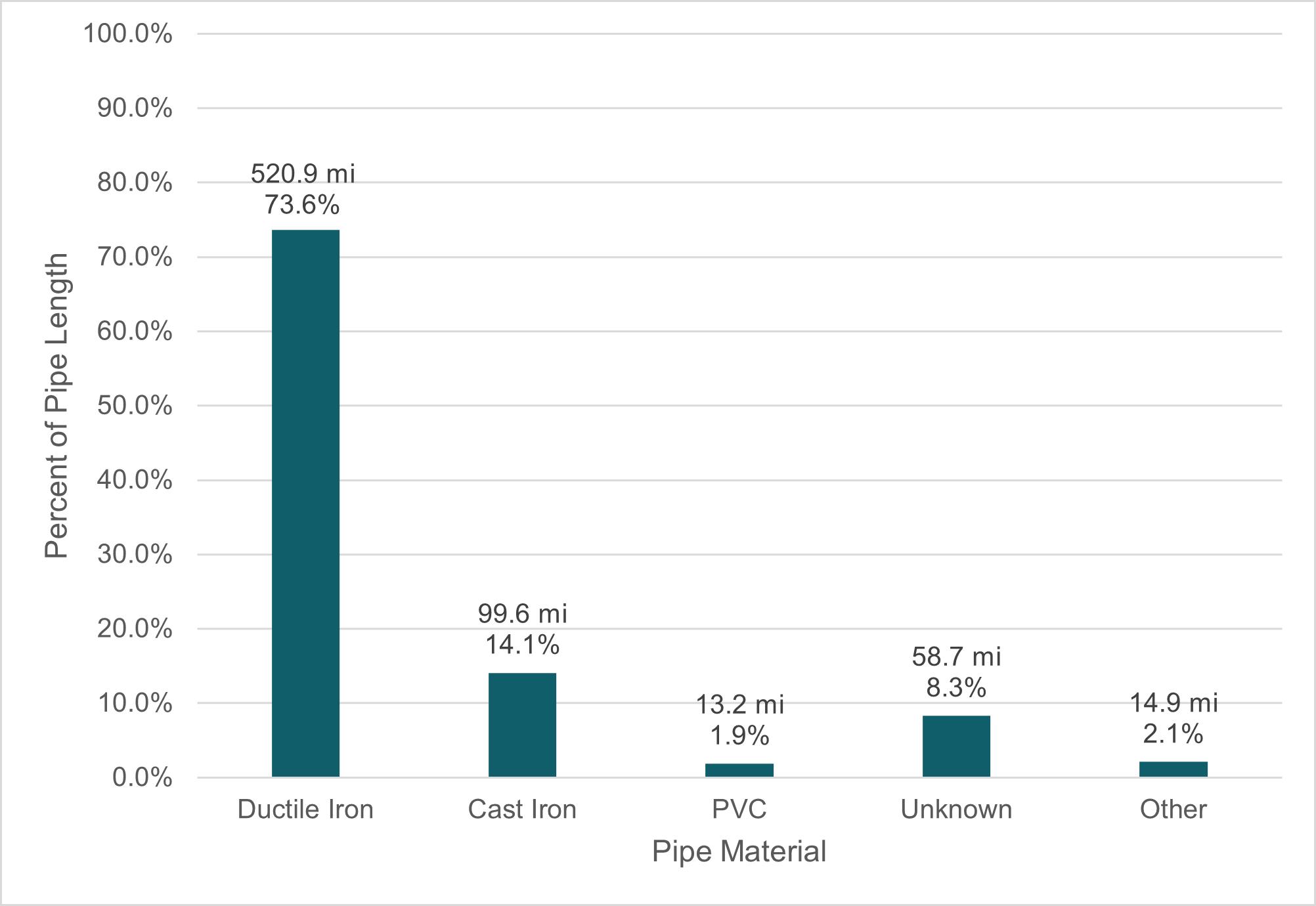

A private water utility first developed the City WDS, Tyler Water Co., in the late 1800s and served by groundwater until 1951, when the Golden Road WTP was built. Piping from the distribution system purchased from Tyler Water Co. by the City in 1916 is still in service today. The existing system consists of almost 710 miles of water mains, serving approximately 34,040 meters. The total pipe length by diameter and material are shown in Figures 2.1 and 2.2, respectively. Data labels identify the pipe length in each category as miles (mi) and percent of total distribution system pipe length (%).

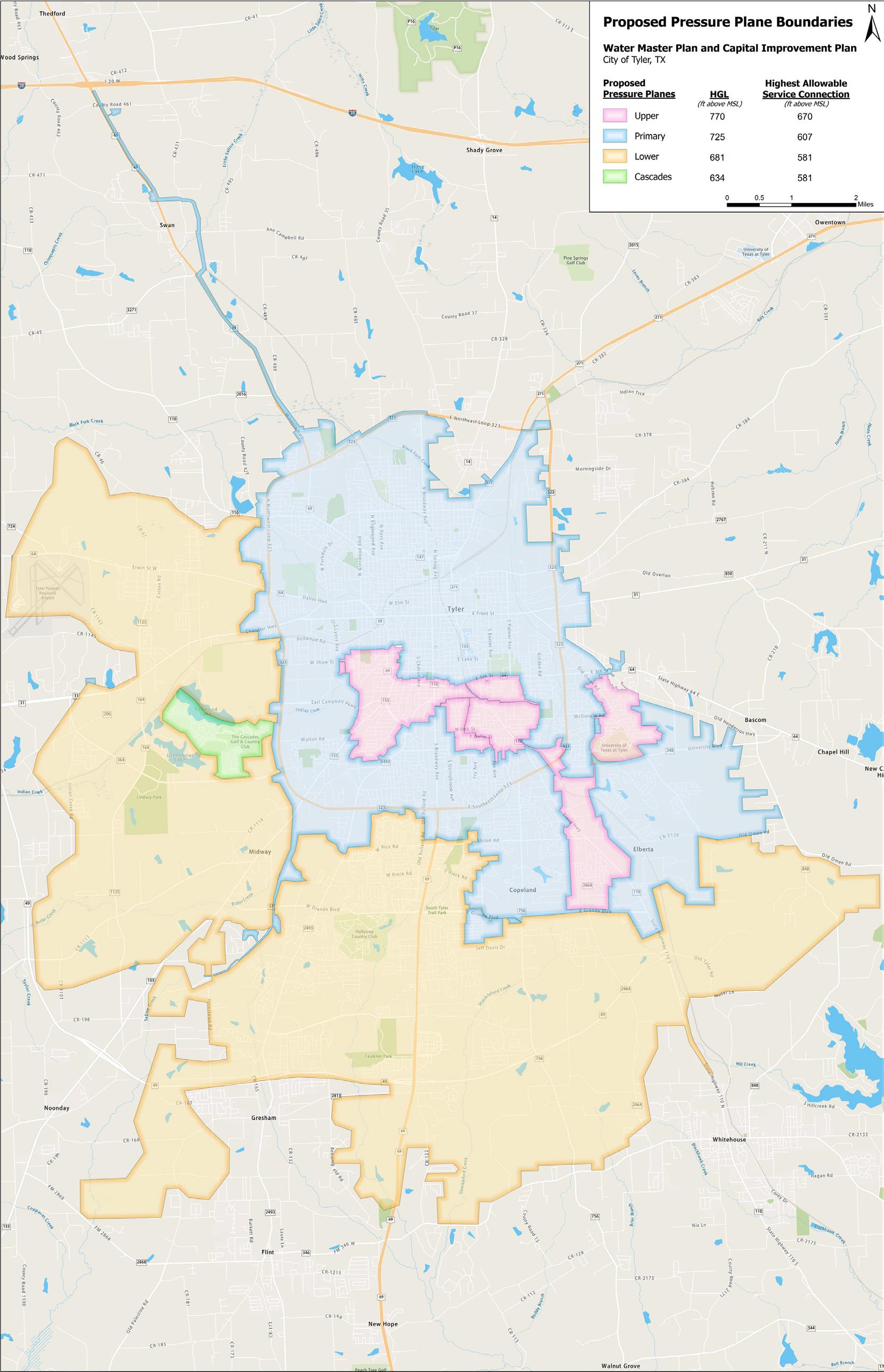

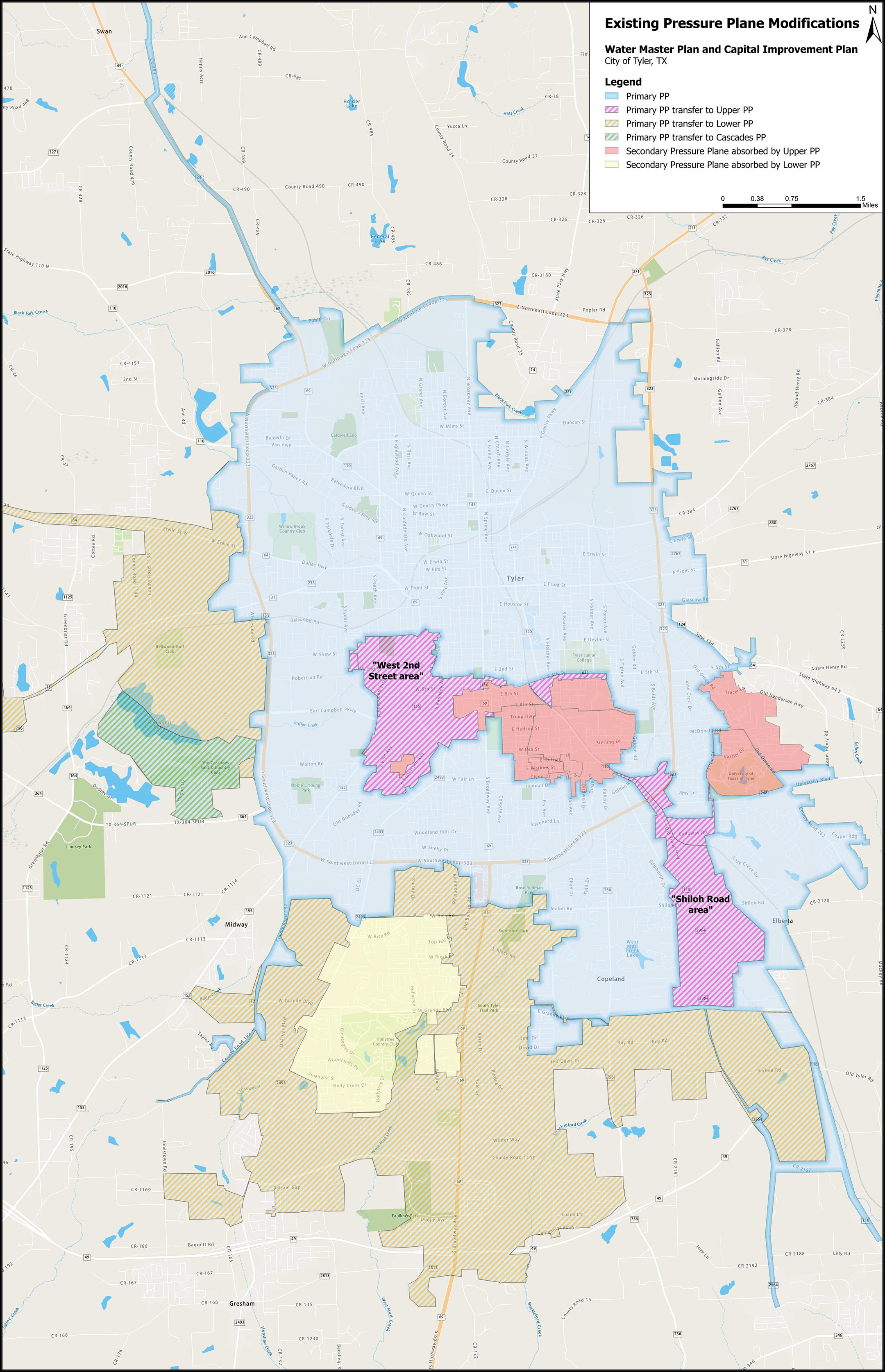

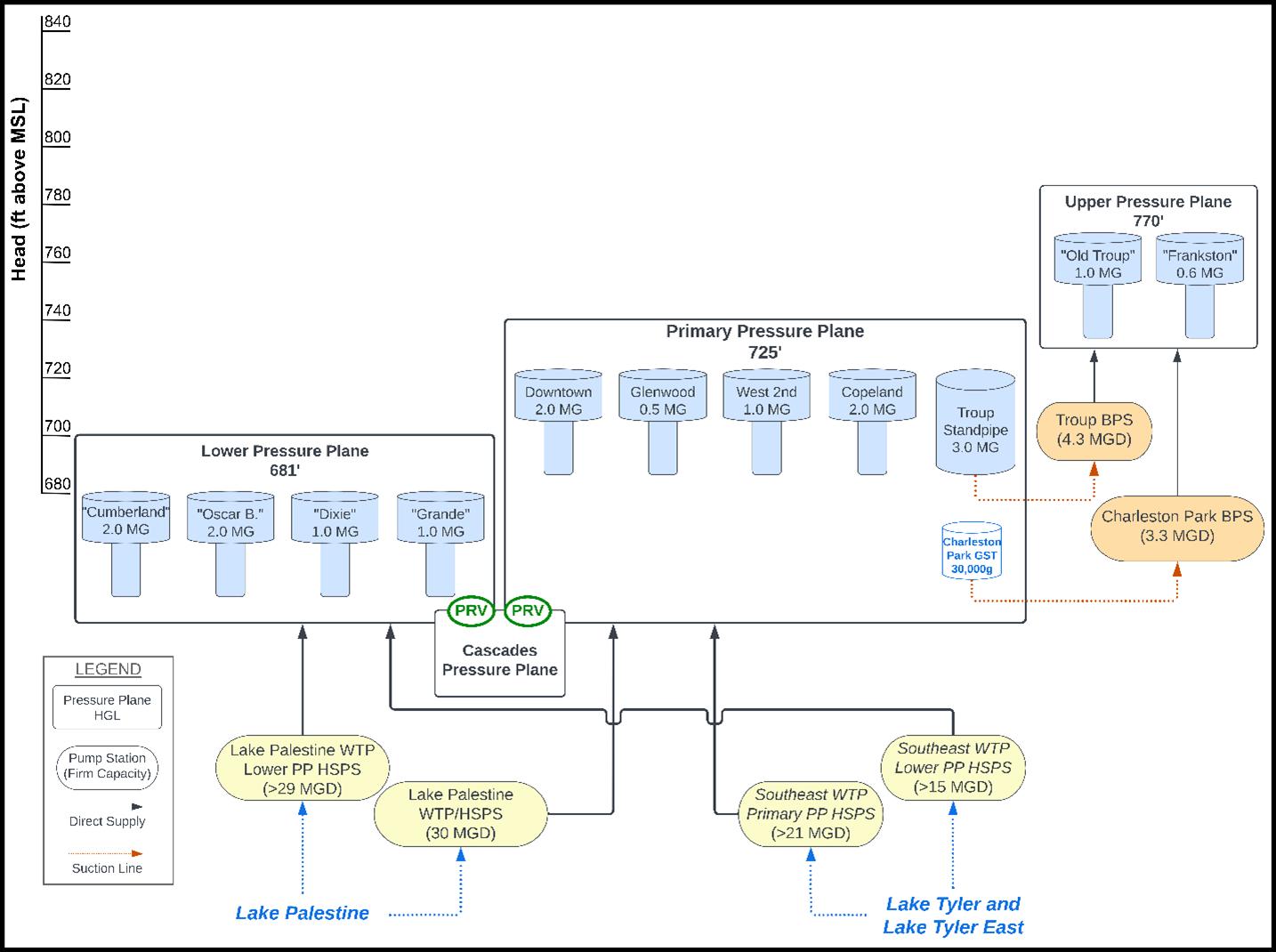

The Tyler WDS consists of seven pressure planes distributed as six secondary pressure planes within a ‘Primary’ pressure plane (PP) (This study terms this pressure plane as the ‘Primary PP’, in lieu of an existing designation). The Primary PP has a hydraulic grade line (HGL) of 725 feet above mean sea level (ft above MSL) set by the overflow level of the ESTs. The secondary pressure planes have HGLs ranging from 650 to 838 ft above MSL. The secondary pressure plane HGLs lower than the Primary PP HGL are established through pressure-reducing valves (PRVs)

that limit incoming pressure from the Primary PP. These areas have been isolated to avoid excessive pressures for service connections at relatively lower elevations in the system. The secondary pressure plane HGLs higher than the Primary PP HGL are established through BPSs that increase pressure from the Primary PP. These areas require additional pressure input to maintain adequate pressure for service connections at relatively higher elevations in the system. The seven pressure planes and defining HGLs are listed in Table 2.1. Figure 2.3 schematically shows the existing WDS and the system’s existing connectivity.

*Primary HGL is defined by the EST overflow

†Boosted secondary pressure plane HGLs defined by downstream pressure setting ‡HGL determined from PRV settings

The topography within the City service area ranges from 406 ft above MSL in the southern region of the system near Hill Creek and, separately, West Mud Creek to 672 feet above MSL within the Jan Street PP. Generally, the highest elevations are located in the central and central-southeast regions of the service area. Many higher elevation areas are isolated within the Troup, Charleston Park, Terre Haute, and Jan Street boosted secondary pressure planes. The 100year floodplain of multiple nearby waterways falls within the service area such that the topography is defined by subtle ridges and valleys. The Hollytree and Thigpen PPs constitute the only lower elevation regions within a secondary pressure plane.

The Tyler WDS has over 100 MGD of total pumping

capacity at six pump stations housing 20 pumps, including nine variable frequency drives (VFD). The two high-service pump stations (HSPSs) are located at the WTPs and are the initial pressure input to the distribution system. Four BPSs receive finished water from the Primary PP and are the pressure input to their respective secondary pressure planes. The Shiloh Road BPS is currently offline and not included in these analyses. Table 2.2 defines the attributes of all TWU pumps. Firm capacity is defined as the pump station capacity with the largest pump out of service and is used for regulatory capacity compliance evaluation. The values listed in Table 2.2 reflect the information received by the applicable pump manufacturers; modeled pump performance was modified during calibration and may not match the original design points.

*Pumping capacities consider existing physical and electrical limitations at Golden Road HSPS that inhibit the utilization of all pump combinations, as described further in this section; see Table 2.4.

The HSPS at Golden Road WTP houses six centrifugal pumps that pump finished water from the clearwells and a pump suction tank to the Primary PP. Finished water from the clearwells is delivered to a pump suction tank via a 30-inch pipe and directly to Pumps 5 and 6 via a separate 36- to 24-inch suction pipe. Pumps 1-4 receive water from the pump suction tank via two 20to 16-inch suction headers. Pumps 1-4 discharge to a 30-inch pipe that splits at Golden Road and Pumps 5 and 6 discharge to a 36-inch pipe that follows Clubview Drive once out of the WTP property. The two discharge pipes are interconnected within the WTP property by a 30-inch pipe.

The HSPS at Lake Palestine WTP houses four vertical turbine pumps that pump finished water from a pump suction tank to the Primary PP. Finished water is delivered via a 48-inch outlet pipe from each clearwell to a 54-inch pipe that fills the pump suction tank. All four pumps discharge to a 48-inch pipe that follows Old Noonday Road to connect with the finished water distribution system.

The Troup, Charleston Park, and Terre Haute BPSs are configured such that the pumps receive finished water

from an upstream storage tank that is supplied from the Primary PP and pump to their respective secondary pressure planes. The hydropneumatic tanks on the downstream side of these pumps serve to control pressures within the secondary pressure plane through pump control setpoints. The Jan Street BPS does not have any upstream storage tanks and pulls water directly from the Primary PP that is then pumped to the Jan Street PP without downstream hydropneumatic tanks. Note the Shiloh Road BPS is “offline”; the configuration and controls have not been defined and are not included in these analyses.

The HSPS at both WTPs and the Jan Street pumps are operated manually, while the Troup, Charleston Park, and Terre Haute BPS pumps are automatically controlled based on discharge pressure. Data Flow Systems (DFS) Supervisory Control and Data Acquisition (SCADA) systems control the automated BPS operations. Pump operations were determined from operator knowledge, field visits, and available pressure data, then further refined during model calibration. Pump controls for each pump station are described in Table 2.3.

The system's demands are met exclusively by production at the two WTPs. The operators aim to supply approximately 40% of daily system demands from Golden Road WTP and the remaining 60% of daily demands from Lake Palestine WTP. The manual controls at Golden Road WTP intend to discharge a certain flow while working within the limitations of the pump station deficiencies. Particular pumps on the same discharge header are not operated together due to physical and electrical limitations at the WTP. Each pump has a typical flow rate determined from historical performance, and these flows are used to determine pump combinations to achieve a desired total discharge from the HSPS. Table 2.4 summarizes the pump combinations used at Golden Road WTP to achieve the approximate total discharge flow shown in the right column.

The manual controls at Lake Palestine WTP intend to achieve a daily 5- to 10-foot drop in the Copeland EST during morning hours, then maintain a fairly constant level for the remainder of the day. Operator knowledge and seasonal demand patterns decide the number of pumps in operation and motor speeds. Generally, fewer pumps in operation and lower motor speeds are sufficient to maintain desired water levels in the winter, while more pumps and higher motor speeds are used in the summer.

TWU’s existing ground storage volume of 11.8 MG is distributed between four clear wells, two HSPS suction tanks, one SP, and two ground storage tanks (GSTs). The clearwells and HSPS suction tanks are located at the two WTPs and receive finished water from their respective WTP to be pumped to the Primary PP. The two GSTs receive finished water from the Primary PP (at a lower HGL) and provide the source water for the booster pumps at the Charleston Park BPS and Terre Haute BPS. The SP receives finished water from the Primary PP and dually provides the source water for the Troup BPS pumps and acts as elevated storage for the Primary PP. TWU’s existing elevated storage volume of 6.7 MG is distributed between four ESTs and one SP (SP elevated volume is calculated as the

volume above 686 ft above MSL, corresponding to the lowest EST low water level in the system). A portion of this volume can qualify as elevated storage capacity depending on the highest service connection elevation. All elevated storage is located within the Primary PP with an overflow elevation of 725 ft above MSL.

Additionally, five hydropneumatic tanks are distributed between three secondary pressure planes. The hydropneumatic tanks receive finished water from their respective BPSs to maintain a specific pressure within their secondary pressure plane. The five hydropneumatic tanks are not included in the total storage capacity, per state regulations.

The offline Shiloh Road EST has an estimated overflow elevation of 762 ft above MSL and is configured to receive flow from its upstream BPS. The Shiloh Road EST is not isolated within a secondary pressure plane, so filling this tank has historically been challenging, given its overflow elevation in excess of the Primary PP HGL. However, the Shiloh Road facilities are currently offline and have been out of service for several years. This EST and BPS are not considered in the existing system model.

An inventory of the water storage tanks in the Primary PP is shown in Table 2.5, and the secondary pressure planes in Table 2.6. Facility locations are shown in Exhibit 2.2.

Bold volumes indicate tanks that are within and receive water from the Primary PP

Underlined volumes indicate tanks that serve as suction storage for their respective pump station

Bold volumes indicate tanks within and receiving water from the Primary PP. Terre Haute GST is a top-fill tank and is not hydraulically connected to the Primary PP. Underlined volumes indicate tanks that serve as suction storage for their respective pump station *Troup and Charleston Park BPSs each have two-15,000-gallon hydropneumatic tanks installed in 2018 and 2013, respectively. Terre Haute BPS has one 2,000-gallon hydropneumatic tank installed in 2011. Hydropneumatic tanks do not count as storage capacity, per state regulations.

The GSTs at the Golden Road HSPS are not included in the total storage capacity since this facility is not equipped with emergency power, as indicated in the City of Tyler Emergency Preparedness Plan (EPP). Consequently, the 4.5 MG volume from the Golden Road clearwells and suction well would not be accessible to the system during an emergency. Similarly, the ground storage at Terre Haute BPS does not qualify towards the Terre Haute PP total storage capacity as this pump station is not equipped with emergency power. Instead, the Terre Haute and Jan Street PPs have redundant interconnections to the Primary PP through check valves that allow the storage requirements of these pressure planes to be met from the Primary PP storage capacity. The Troup and Charleston Park PPs also have redundant interconnections to the Primary PP through check valves. However, Tyler’s EPP2 indicates that these interconnects are not the intended source of

emergency supply to these PPs, as their respective pump stations are equipped with emergency power.

GST and elevated tank water levels are maintained within a specified range by upstream control valves. These control valves have parallel equal-diameter bypass check valves. This valve configuration allows flow into the tank through the control valve and out of the tank through the control valve and check valve. The control valve will close when the water level reaches a tank-specific high setpoint, and flow will exit the tank through the check valve once system pressures allow. The control valve will reopen at the tank-specific low setpoint to refill the tank. The control valve setpoints and associated head ranges at each elevated tank are shown in Table 2.7, and the controls assumed for modeling purposes at each GST are shown in Table 2.8.

All elevated tank overflow levels are 725 ft above MSL

The EST and SP setpoints vary between 706 to 724.4 feet above MSL (with the system HGL being defined as 725 ft above MSL) attributed to the Troup SP and West 2nd EST, respectively. The percent of bowl height utilized by each head range varies between 5.2% and 23.7%, also attributed to the Troup SP and West 2nd EST, respectively. The two GSTs maintain a significantly lower head range and are not intended to maintain pressure in their respective secondary pressure planes but to provide a supply for the booster pumps.

Currently, no system tanks are equipped with tank mixers. However, the Glenwood EST will be equipped with a submersible mixer per the Glenwood Elevated Storage Tank Rehabilitation plan set (2021).

Discussions with Operators revealed the following existing WDS operational issues:

◦ The operational capacity of Lake Palestine HSPS is limited by high pressures in the south and west sections of the system, such that full utilization of

the HSPS would result in excessive pressures for a significant portion of the system. The current workaround is to utilize fewer pumps and lower VFD speeds.

◦ Operators suspect a short circuit between the Troup PP and Primary PP but have not been able to successfully locate the open point of connection.

◦ The Jan Street BPS is set to have one pump continually running, as previous attempts to allow the pump to rest have resulted in significant drops in pressure for the Jan Street PP.

◦ Low-pressure fluctuations are frequently reported in the UT Tyler area of the Primary PP.

◦ High pressures are frequently reported in the Hollytree development area.

◦ Existing 2-inch diameter water mains require a significant degree of flushing, resulting in localized low-pressure issues (the Azalea District has a high concentration of 2-inch diameter mains).

◦ Water age is a concern for the Primary PP ESTs.

Existing issues identified by the hydraulic model analyses are identified and discussed in Section 5.

The existing population and future service connections within the City WDS service area are defined to identify the required system capacities to meet future demands. Current population and system demands are evaluated to identify water usage trends and to estimate future system demands in relation to the projected population. The calculations in this section provide the basis for increased demand allocation in the 25-year horizon for the Tyler WDS and for identifying capital improvement needs.

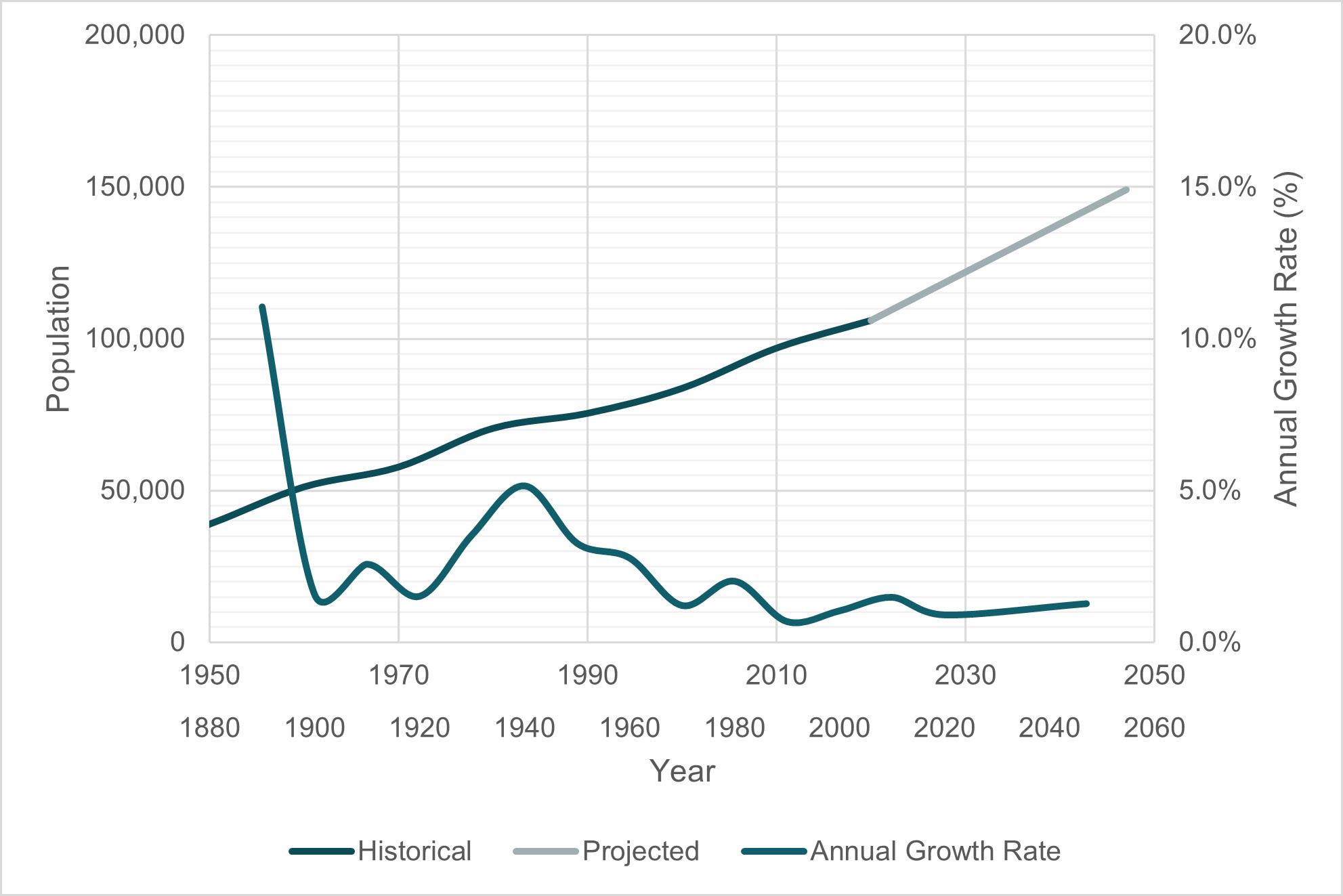

According to the U.S. 2020 Census estimate, the City of Tyler’s population was recorded as 105,995. Dating back to 1880, the City of Tyler has grown at an average rate of 2.8% per year, or approximately 35.8% per decade. The average household in Tyler has 2.72 people per dwelling, according to the US Census 2020 estimates. The historical population and corresponding growth rates are shown in Table 3.1. The decennial populations are sourced from the US Census Bureau.

Population growth is expected within existing City limits in the city center and through infill development, but the majority of future growth is anticipated in the surrounding Extraterritorial Jurisdiction (ETJ), which is primarily rural currently and can accommodate significant growth. Significant growth is expected in the ETJ, generally to the south and west of existing city limits. Twenty-two (22) growth areas were identified to account for population growth within city limits and areas in the ETJ that could be incorporated into the city through annexation or be serviced by TWU via a current or new wholesale customer entity. The growth areas were determined by examining land available and/or suitable for development and/or redevelopment based on 2021 GIS parcel maps from the Smith County Appraisal District. The land area in major floodplains was not identified for future development and was excluded from the calculations. Exhibit 3.1 shows the location of each growth area.

The number of additional service connections in the growth areas at buildout was determined by identifying a units per acre factor specific to each growth area based on the availability of sanitary sewer service

and anticipated development trends. This factor was applied to the growth area acreage and scaled by 75% to account for undevelopable land, including the right of way (ROW), steep slopes, easements, and minor floodplains to obtain the total number of buildout units in each growth area.

The service connection estimates in 2047 are needed to estimate demands through the 25-year planning period identified for the Water Master Plan and CIP. To obtain 25-year service connection estimates, the buildout service connection estimates were scaled by a factor representing the percentage of a total ultimate buildout expected after 25 years. The percent buildout factor was determined for each growth area based on existing and anticipated development trends, which reflect more accelerated development in the south and central growth areas that are either closer to central Tyler or adjacent to current growth areas where it is anticipated growth will happen the quickest. An additional 15,090 service connections are projected as potential customers of the water distribution system by 2047. Table 3.2 summarizes the service connection projections for each growth area.

*The documented buildout values for the identified growth areas represent a likely 75-80 year period.

**Growth Area 24 accounts for service to be provided to the John Soules Foods, Inc. property. No residential population is included in this growth area.

To facilitate demand projection, the total number of service connections for each growth area was converted to a population estimate by applying a persons per unit factor of 3.0, except in areas of anticipated multi-family land use where a factor of

1.5 is more appropriate. An additional population of 43,064 is projected in the identified growth areas by 2047. Table 3.3 summarizes the population projection calculations in each growth area, correlating with map units in Exhibit 3.1.

Historical and projected population estimates are shown in Figure 3.1.

The projected population in Figure 3.1 assumes that all growth areas are incorporated into the City through annexation or will still exert demand on the Tyler system via a current or future wholesale customer. This should be considered a maximum estimate considering the extensive CCN overlap with Southern Utilities and Walnut Grove Water Supply Corporation (WSC). In areas of CCN overlap, future customers may choose which utility to request service from, and therefore, a smaller population than projected may become direct customers of the Tyler WDS, dependent on existing infrastructure at the time of development. However, the demands from the population that will become Southern Utilities and Walnut Grove WSC customers are accounted for through increased wholesale demands and demands at existing Southern Utilities master meters in the 25-year system model, as described in Section 3.4.

Regulatory capacity requirements depend on customer connection count rather than the population served.

The connection count must include the individual living units associated with residential complexes (i.e., apartments, condos, assisted living). The existing meter count (34,040) does not account for individual living units, as these properties typically have a single meter serving the entire property. Halff accounted for these additional connections by estimating ‘equivalent units’ for residential meters. To estimate residential connections, the average demand associated with residential use was divided by an equivalent unit of 0.2 gpm per meter (representing typical single-family residential use). This method resulted in a connection count estimate of 50,537 for the existing Tyler WDS. The 2047 system connection count estimate is 65,627, which accounts for the additional 15,090 service units projected for the system by 2047 (Table 3.3).

The connection count estimate of 50,537 is used in Section 5.0 to evaluate existing regulatory capacity requirements. The connection count estimate of 65,627 is used in Section 6.0 to evaluate 25-year regulatory capacity requirements. These estimates do not impact the existing and projected water demands discussed below.

According to provided data, the existing Tyler WDS serves approximately 34,040 water billing accounts. TWU maintains a record of monthly water consumption data for each meter in the system, and this recorded data was provided from October 2019 to September 2020. The monthly water consumption data was used to develop average monthly demands for each meter and, consequently, the overall system. The system ADD is 20.3 MGD based on the provided consumption data from October 2019 to September 2020. Table 3.4 displays the monthly average demands based on this metered water consumption data.

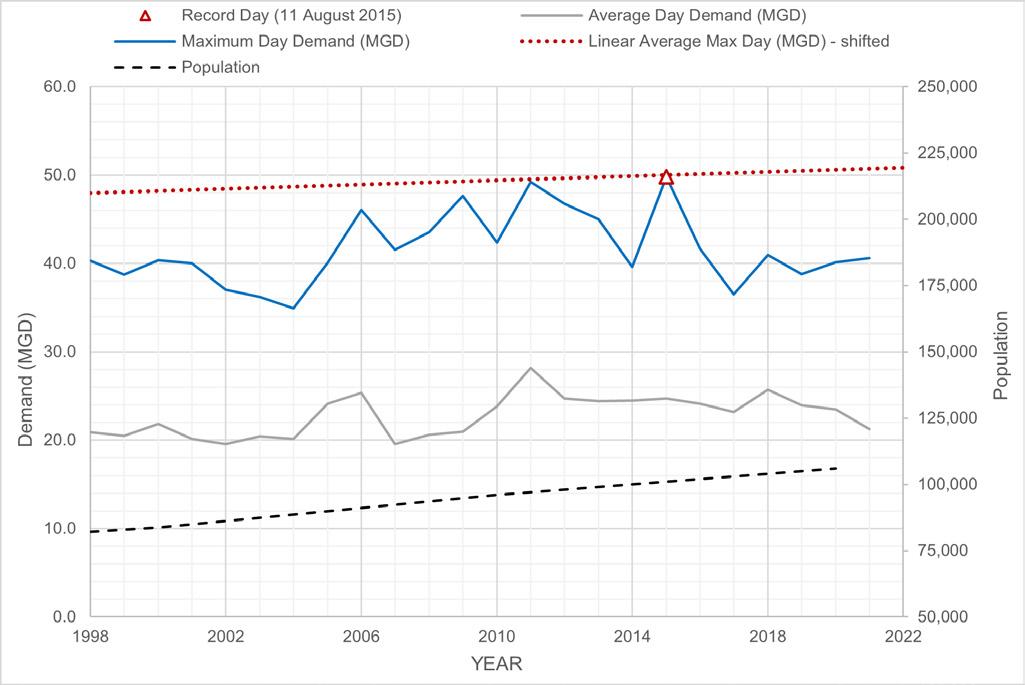

generally increases by 12% annually. To account for possible drought conditions and the higher associated demands with the current population, the 12% yearly increase in MDD was projected from the record day demand in 2015. This results in an existing MDD estimate of 50.7 MGD. A graphical representation of the MDD estimate is shown in Figure 3.2.

TWU also maintains historical daily pumping reports that record pumping contributions from the HSPS and the groundwater wells; the groundwater wells were taken out of service in May 2018. The pumping reports from 1998 to 2021 were used to estimate a current MDD based on historical trends and the system record day. This estimate assumes that daily flow into the system is a sufficient estimate for customer demands as deviations resulting from net system storage are relatively minor. The historical records indicate a maximum total pumping output record of 49.79 MGD that occurred on 11 August 2015. Golden Road HSPS discharged 21.34 MG, and Lake Palestine HSPS discharged 27.28 MG for a total HSPS output of 48.62 MGD and a total groundwater discharge of 1.172 MGD on this day. The pumping reports show that the MDD

TWU also maintains historical daily pumping reports that record pumping contributions from the HSPS and the groundwater wells; the groundwater wells were taken out of service in May 2018. The pumping reports from 1998 to 2021 were used to estimate a current MDD based on historical trends and the system record day. This estimate assumes that daily flow into the system is a sufficient estimate for customer demands as deviations resulting from net system storage are relatively minor. The historical records indicate a maximum total pumping output record of 49.79 MGD that occurred on 11 August 2015. Golden Road HSPS discharged 21.34 MG, and Lake Palestine HSPS discharged 27.28 MG for a total HSPS output of 48.62 MGD and a total groundwater discharge of 1.172 MGD on this day. The pumping reports show that the MDD generally increases by 12% annually. To account for possible drought conditions and the higher associated demands with the current population, the 12% yearly increase in MDD was projected from the record day demand in 2015. This results in an existing MDD estimate of 50.7 MGD. A graphical representation of the MDD estimate is shown in Figure 3.2.

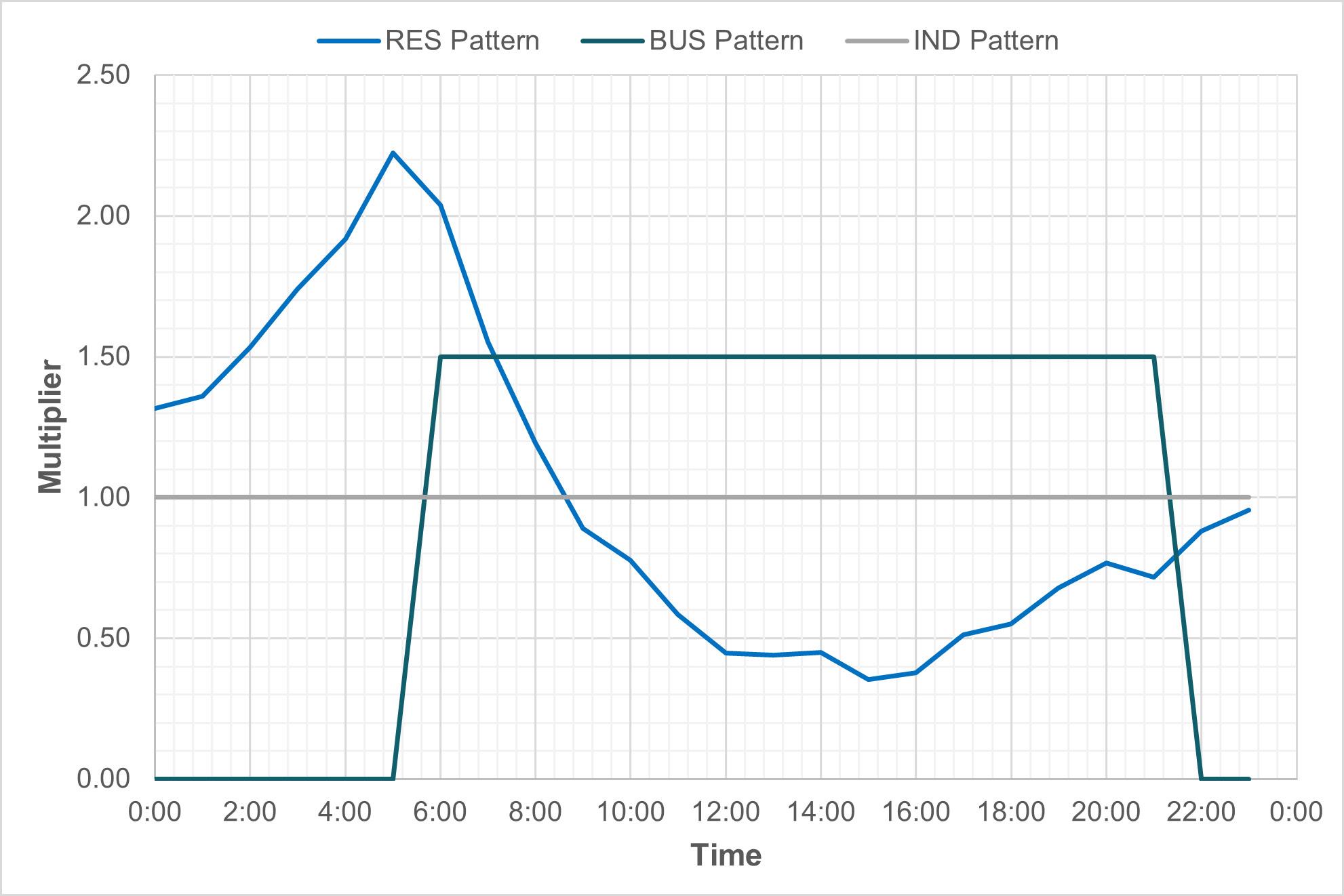

The highest water users in the system are industrial facilities, wholesale water customers, and commercial properties, including a zoo, hospital, and university. The majority of these categories of use are limited to certain hours for consumption related to their set hours of operation. Additionally, many of these categories are not subject to wide variations in hourly use. The overall diurnal pattern was separated into residential (RES), commercial (BUS), and industrial (IND) use to account for these categories of use with different hourly demand habits. Each meter was assigned one of these three diurnal patterns based on the meter account owner. The three diurnal patterns applied in the model are shown in Figure 3.4.

The system demands and conversion factors described in this section are summarized in Table 3.5.

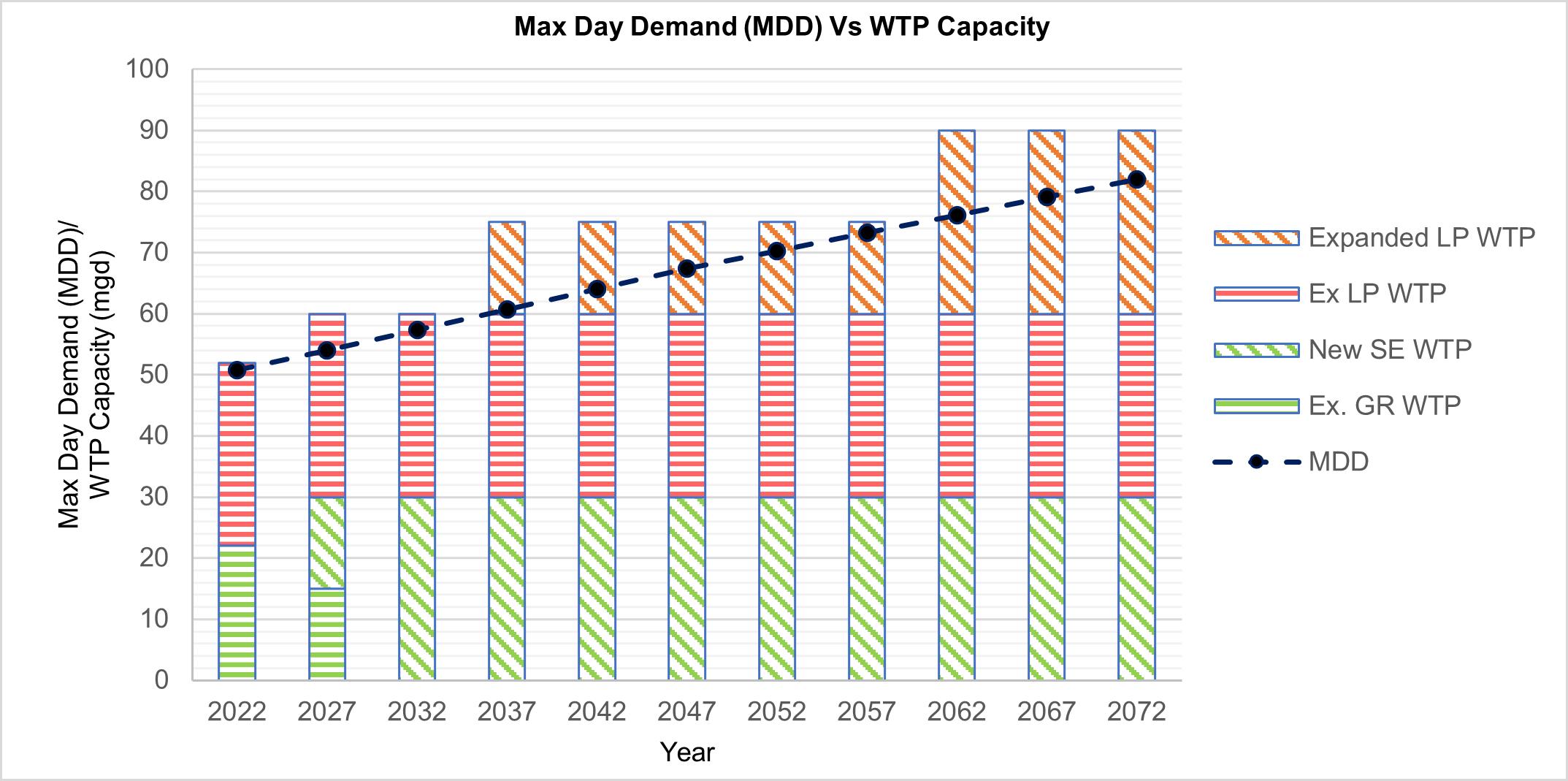

Water demands are expected to increase each year in correlation with additional service connections; service connection projections are defined in Section 3.1. Record day intensity is also expected to increase due to the increased frequency of extreme weather conditions. Anticipated water management strategies and efforts to reduce per capita water usage include city-wide conservation efforts, reduced water loss from the proactive inception of the City’s Asset Management Plan, and installation of low flow fixtures in future developments and retrofitting in existing homes. To represent the changes in water use trends and the projected accelerated increase in new customers, the historical MDD trend is not used to project the 25-year MDD. Trends in per capita water use and ADD to MDD factors with estimated wholesale obligation increases are used to project the 25-year MDD.

The average day per capita water use (in gallons per capita per day (gpcd)) has been decreasing for the City of Tyler over the last few decades, from a maximum of 280 gpcd to a minimum of 184 gpcd. An average day per capita water use of 200 gpcd has been selected for the demand projection calculations to reflect water use trends and anticipated water management strategies. Average day gpcd values were adjusted to account for the City of Tyler retail customers only for the 25-year MDD calculations.

The ADD to MDD factor was determined from the linear average trendline projected to the Record Day, as described in Section 3.3 and shown in Figure 3.2. This method accounts for potential drought conditions and results in a conservative MDD estimate. An ADD to MDD factor of 2.1 has been selected for the demand projection calculations as a conservative estimate that considers inherent assumptions while also reflecting anticipated increases in record day intensity. Increases in wholesale contractual obligations were estimated

by applying gpcd estimates from current wholesale customer populations to 2047 population estimates, where information was available, or using demand projections from the 2021 Region I Water Plan approved by the Texas Water Development Board (TWDB). The Town of Bullard is the only new potential wholesale customer identified by the Region I Water Plan to require service from the Tyler WDS by 2047. Projected wholesale customer obligations for the 25year system analysis are presented in Table 3.6.

25-year water demands were calculated by applying the 200 gpcd estimates to existing and projected populations and increasing demands to wholesale customer meters, as estimated in Table 3.6. The 2.1 ADD to MDD factor was applied to retail customer demands for MDD system evaluation. Growth Area 24, the John Soules Foods property, is anticipated to have an MDD of 1.25 MGD from provided historical water use estimates. In areas of CCN overlap with Southern Utilities, a small percentage of projected service connections, determined from Region I Water Plan demand projections, were assumed to be served from the Southern Utilities distribution system, and the associated demands were applied at the existing Southern Utilities master meters in the Tyler WDS. Table 3.7 summarizes the increases in demand from the existing system to the 25-year system. As actual

development occurs over the next 25 years, the demand split between Wholesale Customers and Growth Areas with Tyler may deviate from the assumptions in Table 3.7. Subsequent updates of this master plan should evaluate the most recent population and growth trends and revise these estimates accordingly

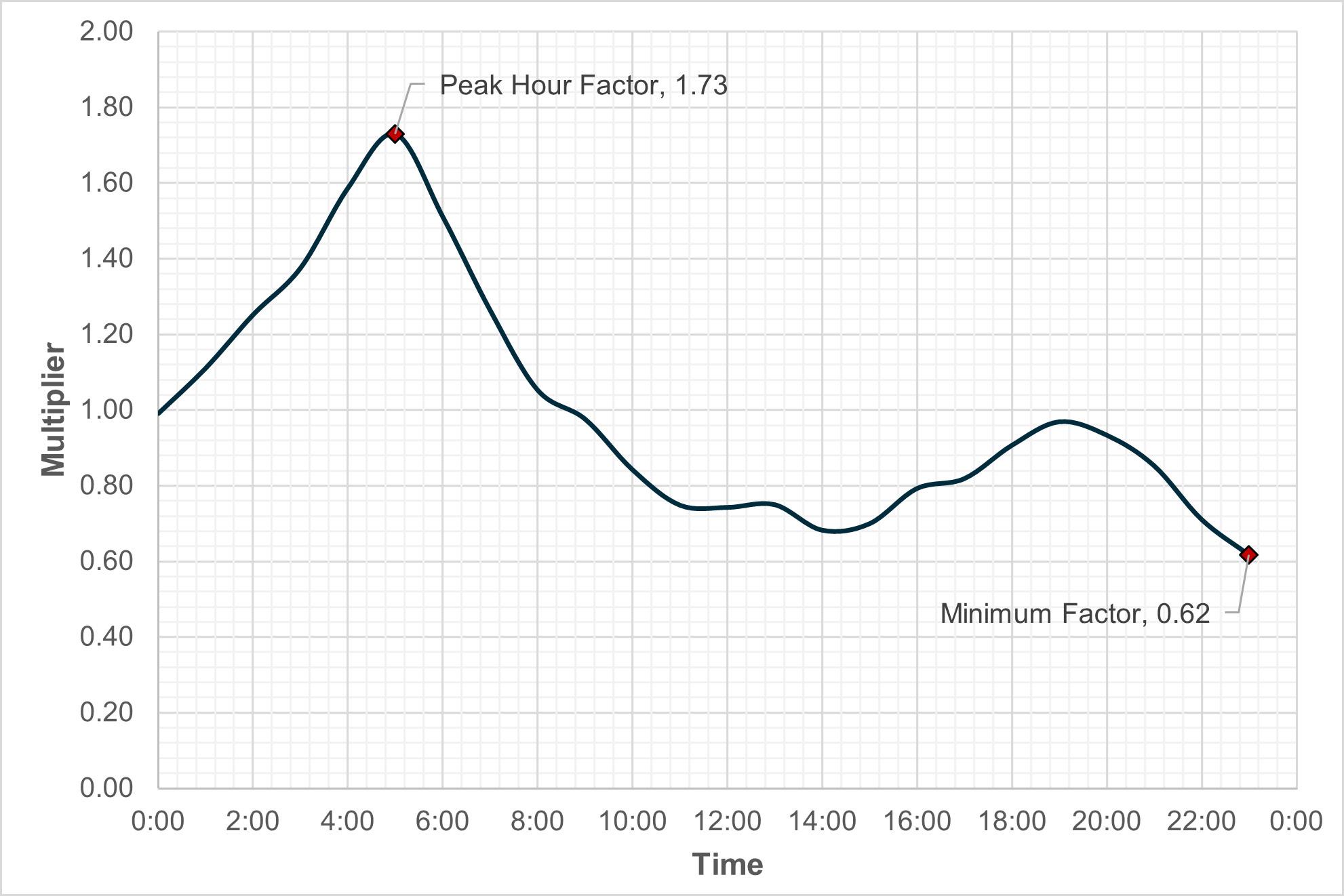

All additional demands from the identified growth areas are assigned the overall system diurnal pattern, shown in Figure 3.3. The usage classes can be refined in future model updates to more accurately reflect the proper zoning as the zoning is created. The 2047 system demands and conversion factors described in this section are summarized in Table 3.8.

A hydraulic model of the Tyler WDS was developed to provide a basis for this Water Master Plan and additionally to deliver a tool that TWU can utilize for system planning and operational evaluation. The hydraulic model was developed using Innovyze’s water distribution modeling software, InfoWater Pro Version 3.5 Update #3, but can be exported to EPANET-compatible files. The overall objective for the WDS model is to produce a computerized hydraulic model of the existing system, including each pressure plane, that accurately reflects the existing hydraulic conditions and to provide a tool to predict future system conditions for planning purposes. The model will help guide revisions to system operating procedures and identify locations in need of capital improvements to reduce the occurrence of existing and future hydraulic and operational issues. This section describes the development of the model and the calibration process.

TWU provided a significant amount of information to Halff, covering the physical attributes of the system and its facilities, customer consumption data, and operations information. The following data was provided for the model-building and calibration process:

◦ Operator Logs from both WTPs were provided for the historical maximum day with groundwater wells in service (August 11, 2015), the historical maximum day without groundwater wells in service (August 12, 2016), and various dates in 2019 and 2021 corresponding with fire hydrant flow and pressure test dates, respectively. The daily Operator Logs included the following data:

◦ Pump Status for all high-service pumps (ON/ OFF)

◦ Clearwell levels at both WTPs (feet, to the nearest tenth)

◦ Effluent flow from both WTPs (MGD to the nearest integer)

◦ Discharge pressure at both WTPs (psi to the nearest integer)

◦ EST water levels (feet above tank floor to the nearest tenth) for Copeland EST, West 2nd EST, Downtown EST, Glenwood EST, Troup SP, and Shiloh Road EST

◦ Monthly consumption data, including:

◦ Total monthly demand at each meter from October 2019 to September 2020.

◦ Operator discussions and site visits, including:

◦ Typical VFD speeds for Lake Palestine HSPs

◦ Operating pressure ranges for BPSs

◦ Normal tank levels for pump controls

◦ Miscellaneous data received from TWU:

◦ Open and close setpoints for control valves at ESTs (open and close setpoints for control valves at BPS GSTs are assumed)

◦ PRV settings at the Hollytree and Thigpen PP’s pressure regulating stations from the December 2019 Pressure Regulating Station Assessments completed by Brannon Corporation.

◦ Pressure plane boundaries and associated isolation and check valve locations from system maps, engineering plan sets, and City GIS data.

◦ Daily pump flow data for Golden Road and Lake Palestine HSPSs for the dates corresponding to provided Operator Logs.

There is a considerable lack of detail associated with using the Operator Logs for comparison to model results during calibration. The HSPS flow rate and discharge pressure are recorded to the nearest integer, with recordings taken at one-hour intervals. One-hour intervals are adequate for regulatory reporting but do not capture enough detail to accurately calibrate a hydraulic model of this system’s magnitude. Also, Operator Log records occasionally show HSP status adjustments without corresponding changes in effluent flow and discharge pressure. Additionally, the motor speeds of LP HSP VFDs are not recorded. The EST levels are recorded to the nearest tenth of a foot, with recordings taken at onehour intervals in both WTP Operator Logs. These water level recordings can vary by at least two feet between the two WTP Operator Logs. The accuracy of the Operator Log recordings is subject to user inconsistencies and various degrees of calibration accuracies of the recording and telemetry equipment used at the two plants. Improved equipment accuracy and finer data recording intervals will allow higher calibration levels to be attained. The Operator logs were used to set up calibration event simulations and for comparison of model results in the calibration step described in Section 4.3. However, it is recommended

that a secondary calibration effort is completed once an acceptable SCADA system is in place to increase the accuracy and reliability of model results.

Halff built a new hydraulic model for the 8-inch and above system, with smaller diameter pipes included as needed to maintain relevant system looping. The hydraulic model is defined by the physical attributes of pipes and facilities, water consumption magnitude and patterns, and operational data. Geometric and other physical attributes for the elements were supplied by the revised GIS system data and engineering plan sets provided to Halff as part of the Water System Inventory GIS project completed by Halff on behalf of the City. To construct the hydraulic model, the following physical attributes were required at each identified element:

◦ Supply: supply was modeled as constant-head reservoirs based on clearwell-level data

◦ Storage tanks: bottom of tank elevation, diameter, minimum and maximum level

◦ Pipe: start/end elevation, diameter, length, roughness

◦ Elevation data outside of facilities such as pump stations and water storage tanks were estimated from 2017 Lidar data using the ground elevation as a conservative estimate of pipe depth.

◦ Friction losses were estimated with a HazenWilliams coefficient (C) estimated from the pipe material and age; roughness coefficients were further adjusted during calibration.

◦ Pumps: elevation, diameter, pump flow/head performance curves

◦ Pump performance data was provided by the applicable manufacturers and used as pump curve starting points; pump curves were adjusted during calibration to more closely match reported values. Pump curve adjustment is admissible to account for reduced output relative to manufacturer data caused by apparent wear on the impellers over time.

◦ Junction: demand and diurnal pattern

◦ Historical monthly TWU billing account information was used to calculate existing demands.

◦ Each meter was geocoded using the billing address, and the associated ADD values were distributed to model junctions using the Demand

Allocation Manager within InfoWater Pro. Demands were applied such that the demand from each meter was distributed between the two model junctions connected to the closest pipe to that meter.

◦ Valves: type, elevation, diameter

Extended duration modeling requires operational logic to control automated and manual system operations, including water level control valve setpoints and pump operations. The water level control valves are set to open and close based on setpoints provided by TWU at the ESTs, and assumed levels are used at the BPS GSTs. The HSPs are operated following the operation goals described in Section 2.5. The remote BPS pump operation setpoints are based on information gathered during field visits and operator discussions. Unvarying system conditions, including the settings and status of pressure valves, isolation, and check valves enclosing pressure plane boundaries, were initially set based on data provided by the City and modified in calibration when deemed necessary.

The limits of the modeled system are the WTP clearwells or pump suction tanks, where applicable, to the end-user junctions. The scope of work for this effort is limited to the distribution system itself; it is assumed that sufficient water supply is transmitted to the clearwells, which are modeled as constant-head reservoirs.

The Tyler WDS hydraulic model is a mathematical representation of the water distribution system that predicts actual water system performance. Calibration is necessary to verify that model predictions closely match actual system performance so that decisions made from model results are accurate. Calibration is the iterative process of comparing model results to actual field data under identical system conditions and adjusting appropriate system parameters to better match field data. This step serves to identify whether the physical, consumption, and operational parameters described in this section are correct and guides any modifications made to these attributes. The Tyler WDS hydraulic model was calibrated under steadystate (SS) and 24-hour extended-period simulations (EPS) with fire hydrant flow tests and pressure logger hydrant tests. The fire hydrant flow tests were

conducted in 2019 for multiple hydrants throughout the entire distribution system. The flow tests provide static pressure at the tested hydrants and associated residual pressure when a high flow is induced from a nearby open hydrant. The pressure logger hydrant tests were conducted in 2021 for several hydrants located in specific areas selected by the modeling team to capture boundary conditions, including near pump stations, elevated storage tanks, pressure plane boundaries, and remote areas of the system. The hydrant pressure tests provide pressure readings at the selected hydrants over several days to capture the HGL fluctuations in that area over time.

A detailed summary of the steady-state and extended-period calibration can be found in Appendix A (Calibration Technical Memo). The goal of the calibration was to achieve modeled results within 10% of measured values for at least 90 percent of the collected data. Higher calibration levels should be pursued once the appropriate SCADA system upgrades are completed. The SS calibration results indicate that the static head and head losses are accurately simulated by the model within this established criteria. The EPS calibration results indicate that existing variable hydraulic conditions are accurately simulated by the model within the established criteria.

The following efforts are recommended to improve the quality of data to be used for future model calibration updates and to improve the accuracy of model predictions:

◦ Install a SCADA system as recommended in Section 5.3 to provide more reliable data for model calibration and diurnal pattern development.

◦ Recalibrate all flow meters, pressure recorders, and water level indicators systemwide.

◦ Survey all ESTs to confirm the physical attributes of the bowls. Current estimates are typically based on plan sets not confirmed as record drawings.

◦ Update model junction elevations once new Lidar data is available for the Tyler area to account for developments and associated earthworks since 2017.

◦ Flow test major transmission pipes to verify roughness factors.

◦ Conduct a water audit based on TWDB guidelines to identify system leaks or other non-revenue water.

The model could not be calibrated within the defined criteria in two distinct areas, the Troup PP boundary west of South Broadway Avenue and the Southeast quadrant of the distribution system where a high number of water mains previously owned by the water utility company, Southern Utilities, are assumed to have been tied-in to the Tyler WDS. Appendix B (Tyler Water Distribution System Mapbook) documents the assumed tie-in configuration of water mains purchased from Southern Utilities instead of actual records. The following additional efforts are recommended to improve model accuracy in these areas:

◦ Investigate potential open/closed valves for the Troup PP boundary to confirm the delineation of this high-pressure zone (this recommendation is included with Project A1-UP-3 of the CIP).

◦ Investigate how water mains previously owned by Southern Utilities were tied into the existing system or replaced to serve the purchased water meters.

The purpose of the model is to identify basic infrastructure needs so that TWU can plan and budget for the construction of the projects. The alignments and sizes presented in the model are based on the assumptions established as part of this report. The information generated from the model runs does not preclude TWU or a developer from utilizing proper engineering practices and design before constructing any capital projects or development plans. Care should be taken when using specific data from model results, such as pressures at junctions or velocities in pipes. These are estimated values subject to the inherent inaccuracies of the various assumptions necessary to build the model.

A finished water distribution system should be able to meet customer demands while maintaining adequate pressures and without operating in such a way as to degrade system facilities beyond normal wear and tear. This section evaluates the Tyler WDS against regulatory requirements and industry standards intended to ensure acceptable hydraulic performance. The evaluation criteria are defined in Section 1.2 and are used to identify deficiencies in the Tyler WDS throughout this section. The junctions and pipes under evaluation do not include pump stations and other facilities in the distribution system designed to withstand velocities and pressures outside the ranges considered acceptable for the distribution system.

The minimum water system capacity requirements are based on the number of retail customers and the total amount of water contractually obligated to wholesale customers, per TAC §290.45(e)(1). The capacities associated with the Shiloh Road EST and BPS are excluded from the regulatory capacity analysis per TAC §290.45(a)(5) as the facilities have not been operating for several years.

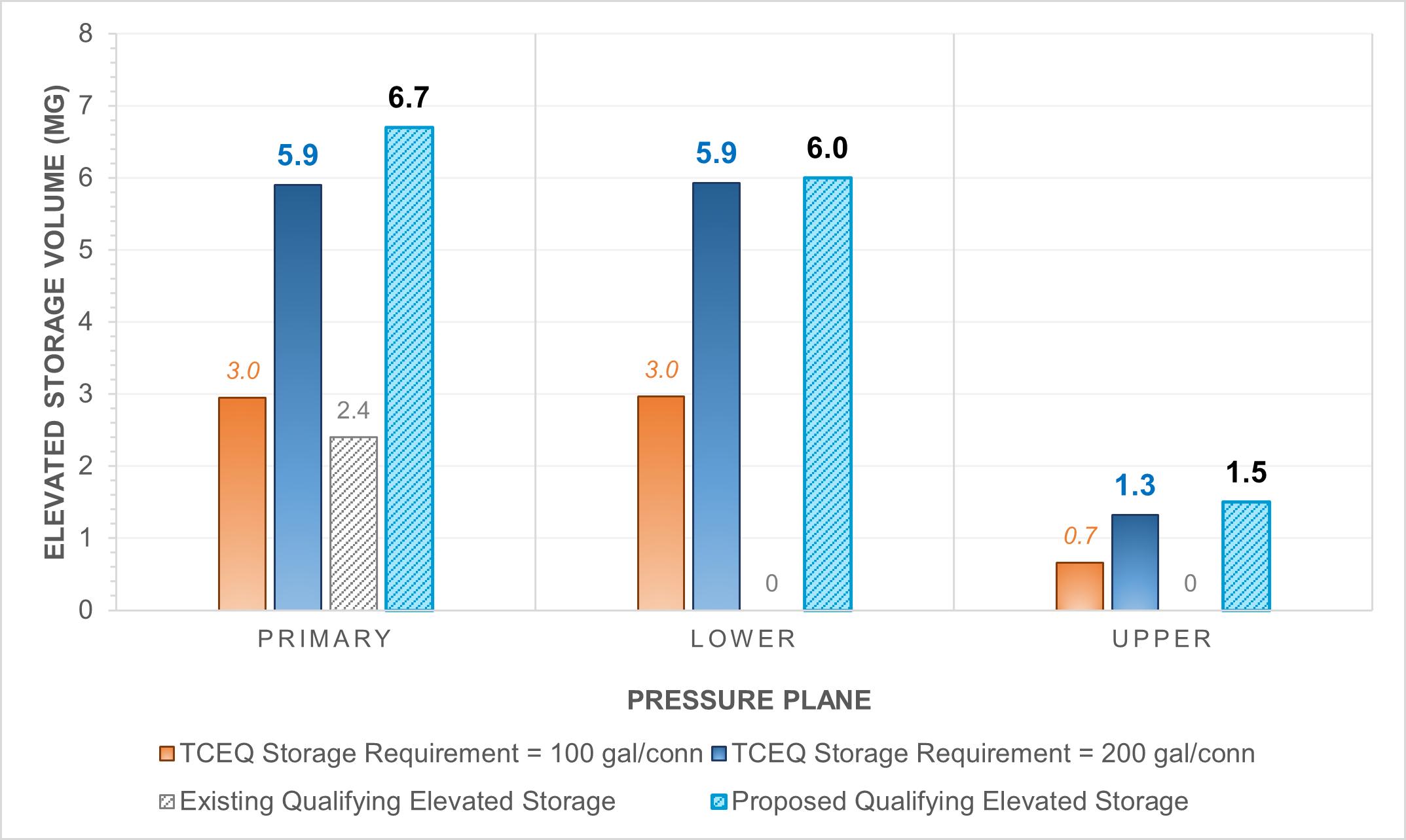

The Tyler WDS must provide a minimum total storage capacity of 200 gallons per connection, which equates to 10.1 MG. The existing system has a total applicable storage capacity of 15.8 MG; an inventory of system storage can be found in Section 2.6. The existing system has a surplus of 5.7 MG total storage and meets the total storage capacity requirement. Table 5.1 summarizes the existing system’s total storage capacity evaluation for each pressure plane.

Notes:

1 The total storage requirement for connections within Hollytree, Thigpen, Terre Haute, and Jan Street PPs is accounted for in the Primary PP capacity given their hydraulic connectivity to the Primary PP through PRVs or check valves and the lack of emergency power at the Jan Street and Terre Haute BPS’s.

2 Existing system storage is cataloged in Tables 2.5 and 2.6.

3 The total qualifying storage in the Primary PP is limited by the lack of emergency power at the Golden Road WTP and HSPS. Consequently, the 4.5 MG volume from the Golden Road clearwells and suction well would not be accessible to the system during an emergency, per Tyler’s EPP2

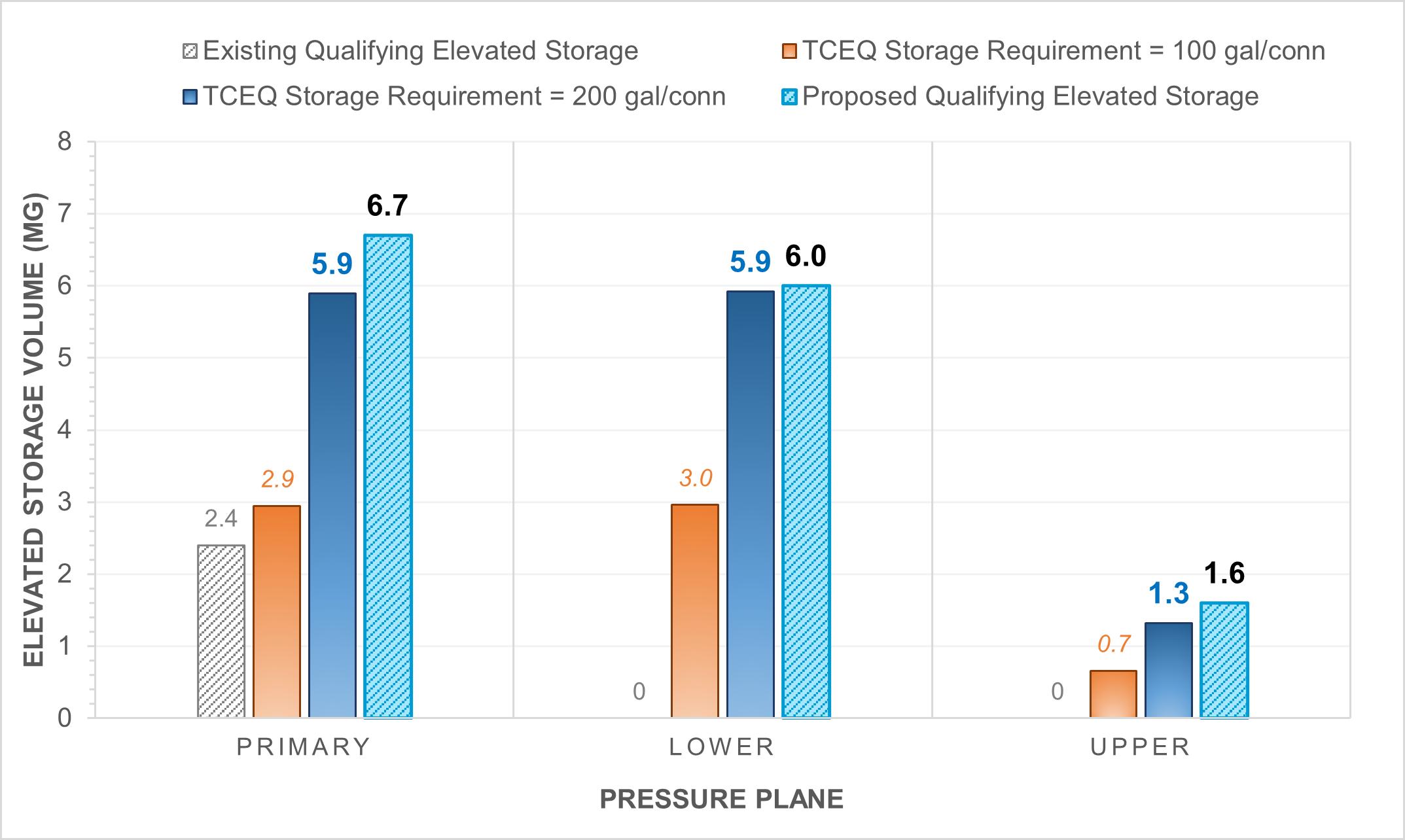

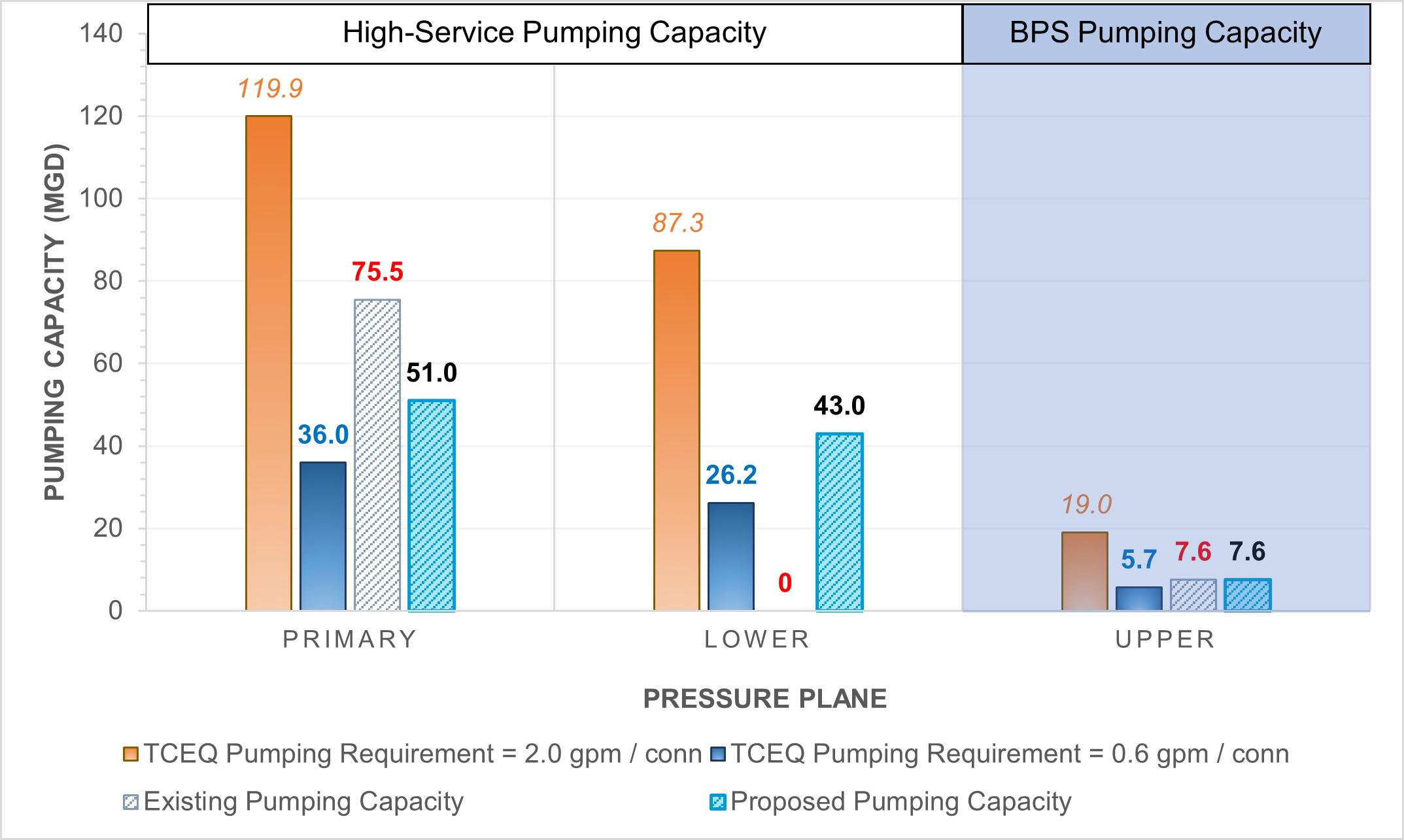

The Tyler WDS pressure planes must meet elevated or pressure tank minimum capacities based on the connection count within each pressure plane. Pressure planes with less than 2,500 connections must provide 20 gallons per connection of pressure tank capacity, up to 30,000 gallons. Pressure planes with more than 2,500 connections must provide at least 100 gallons per connection of elevated storage. This elevated storage requirement is paired with a higher pumping capacity requirement. The lower pumping capacity requirement is paired with an elevated storage requirement of 200 gallons per connection. This existing system capacity analysis uses the higher pumping capacity option associated with the lower elevated storage requirement, as the existing system does not provide 200 gallons of elevated storage. The pumping capacity requirements are covered in the pumping capacity analysis later in this section.

The Primary PP HGL typically influences the HGLs of the Hollytree and Thigpen PPs through the PRVs that supply these secondary pressure planes from the Primary PP. Given this hydraulic connectivity, the elevated storage requirement of the Primary PP includes all connections in the Hollytree and Thigpen PPs. Connections within the boosted secondary pressure planes are not included, as their HGLs are not typically dependent on the Primary PP. Therefore, all boosted secondary pressure planes are subject to elevated or pressure tank capacity requirements. The regulatory definition of elevated storage limits the qualifying elevated storage in the Primary PP as the volume above 712 ft above MSL. The Primary PP has a 2.3 MG elevated storage deficit and currently does not meet this regulatory requirement. The Troup, Charleston Park, and Terre Haute PPs meet their pressure tank capacity requirements. The Jan Street PP has a pressure tank capacity deficit of 1,960 gallons and currently does not meet this regulatory requirement. Table 5.2 summarizes each pressure plane’s existing system elevated and pressure tank storage capacity evaluation.

Notes:

1 The Hollytree and Thigpen PPs do not require pressure tank capacity, given their hydraulic connectivity to the Primary PP through PRVs.

2 Existing system storage is cataloged in Tables 2.5 and 2.6.

3 The qualifying elevated storage in the Primary PP is limited by the highest service connection in the Primary PP on Rhones Quarter Road with an elevation of ~632 ft above MSL. Only storage 80 feet above this meter can qualify towards the elevated storage requirement, per TAC §290.38(25).

Each pressure plane or pump station must meet a minimum pumping capacity requirement based on the connection count and/or the elevated storage capacity of that pressure plane. Generally, the pumping

capacity requirement is higher when less elevated storage has been provided and lower when more elevated storage has been provided. A decision tree to identify the applicable pumping capacity requirement for a pump station or pressure plane is provided in Table 5.3.

PROVIDED BY THE SYSTEM:

1. 100 gallons per connection

(a) <1,000 gpm

(i) Two or more pumps with a total pumping capacity of 2.0 gpm per connection

The lesser of (i) or (ii):

A. >2,500 connections

B. <2,500 connections

(b) >1,000 gpm

2. 200 gallons per connection -

The system must provide 20 gallons per connection of pressure tank capacity, up to 30,000 gallons

(a) <1,000 gpm

(ii) The ability to meet peak hourly demands with firm capacity.

Two service pumps with a minimum combined capacity of 0.6 gpm per connection

(i) Two or more pumps with a total pumping capacity of 2.0 gpm per connection

The lesser of (i) or (ii):

(b) >1,000 gpm

(ii) The ability to meet peak hourly demands with firm capacity.

Each pressure plane or pump station must meet a minimum pumping capacity requirement based on the connection count and/or the elevated storage capacity of that pressure plane. Generally, the pumping

capacity requirement is higher when less elevated storage has been provided and lower when more elevated storage has been provided. A decision tree to identify the applicable pumping capacity requirement for a pump station or pressure plane is provided in Table 5.3.

Notes:

1 The pump capacity requirement for the Primary PP accounts for all TWU customers since all secondary pressure planes receive water from the Primary PP.

2 Existing system pump capacities are cataloged in Table 2.2.

3 For TCEQ rules ending in (i), the listed required pumping capacity is 2.0 gpm per connection; for TCEQ rules ending in (ii), the listed required pumping capacity is peak hour demand. Contractual wholesale obligations are added to the Primary PP required capacity.

4 The Primary PP pump capacity is the total firm capacity from the Lake Palestine HSPS and the Golden Road HSPS. The qualifying pump capacities in the Primary PP are limited by the physical and electrical limitations at the Golden Road HSPS, as described in Section 2.5.

5 There are no additional pumping requirements for the Hollytree and Thigpen PPs since they are connected to the Primary PP through PRVs and, consequently, do not require supplemental pressure input.

The Tyler WDS model was evaluated under maximum day and fireflow demand scenarios in extended periods and steady-state simulations. Demand development for the existing system is described in Section 3. The time-variable inputs required for the EPS model runs are listed below and defined by the following parameters:

◦ Flow into the system: HSPS operations replicate the goals of manual pump operation as described in Section 2.5. BPS operations are as defined in Table 2.3.

◦ System HGL: Open and close setpoints for EST and GST water level control valves are defined in Table 2.7 and 2.8, respectively.

◦ Flow out of the system: Diurnal usage patterns are defined in Section 3.3 and Figure 3.4.

Model results and analysis of system performance are summarized in this section with associated exhibits in Appendix C (Model Results Exhibits).

The range of pressures experienced in the distribution system was reviewed for an MDD 24-hour simulation. High-demand periods typically result in low system pressure related to dropping EST water levels and high velocities, and head loss through system pipes. The minimum pressures experienced at each junction during the 24-hour simulation were documented to help identify areas prone to insufficient pressures during low-pressure system conditions.

Model results indicate five distinct areas prone to insufficient pressures, shown in Exhibit C.1. These areas are located within the Primary PP. Approximately 3.4% of modeled distribution system junctions experienced pressures below the regulatory requirement of 35 psi in a maximum-day demand scenario. Therefore, the minimum pressure regulatory requirement is not currently satisfied.

Low-Pressure Areas 1 and 2:

Low-Pressure Areas 1 and 2 are located near Charleston Park BPS and Terre Haute BPS, respectively. Both BPSs have a GST that receives water from the Primary PP to provide source water for the BPS pumps. These are the only GSTs in the Primary PP and have overflow levels at least 100 feet below the pressure plane HGL of 725 ft above MSL. Refilling the BPS GSTs causes non-compliant low pressures in the nearby distribution pipes by introducing a boundary condition that is substantially lower than the HGL of the Primary PP. The new boundary condition, dictated by the fill line for each GST, causes a steep slope in the HGL with the lowest point at the GSTs. This translates to low pressures for the distribution pipes in the vicinity of the two BPSs when the GSTs are filling. The following nearterm recommendations are proposed to reduce the occurrence of low pressures in Low-Pressure Areas 1 and 2:

◦ Low-Pressure Area 1 - The flow rate into the Charleston Park GST should be reduced by throttling the existing valve on the GST inlet. Utilizing a partially opened valve downstream of the existing backpressure sustaining valve (PSV) results in sufficient upstream pressure to allow the filling of the Charleston Park GST while

protecting the WDS from a significant reduction in boundary conditions dictating the Primary PP HGL in this area. The operation status of this control valve should be communicated into the SCADA system to ensure staff can control and monitor its status. Project C1-PR-1 of the CIP (Section 6.3) includes long-term recommendations to increase capacity to the Charleston Park GST and address associated low pressure issues.

◦ Low-Pressure Area 2 - Install a temporary PSV on the Terre Haute GST inlet to maintain at least 35 psi upstream in the Primary PP during GST refill periods. This PSV will be retired once the Terre Haute BPS is retired, as detailed in the CIP (Appendix D). The operation status of this PSV should be communicated into the SCADA system to ensure staff can control and monitor its status.

Low-Pressure Areas 3, 4, and 5:

Low-Pressure Areas 3 and 4 encompass a significant area in the southeast quadrant of the distribution system, near the Shiloh Road and Copeland ESTs, respectively. Low-Pressure Area 5 includes a small area in the central section of the distribution system near West 2nd Street. Areas 3, 4, and 5 include the highest elevated areas in the Primary PP and experience the lowest pressures of this pressure plane during peak hour demands. During peak hours, flow demanded from the system exceeds flow into the system resulting in a minimum system HGL. Still, average pressures in these areas for MDD conditions are less than 35 psi.

Given the high elevation range served by the Primary PP, areas of typical-high and typical-low pressure are expected. As more connections are added to the Primary PP, minimum pressure regulatory violation frequency will increase. The CIP (Section 6.3) includes the creation of an ‘Upper Pressure Plane’, which would encompass Low-Pressure Areas 3, 4, and 5 to maintain a higher HGL for these high-elevation areas. This recommendation eliminates existing low-pressure issues. Remote pressure monitors should be installed at high and low elevations in each pressure plane and communicated into the SCADA system to allow sufficient monitoring of system conditions.

There are no regulations imposing maximum allowable pressures in a finished water distribution system at the time of this report. However, plumbing codes may require PRVs for meters that experience static pressures above 80 psi. This is a requirement on the customer side of the meter, not an obligation of the water service provider. The 80 psi static pressure limit is in reference to year-round static pressures, but as a reference point, the MDD 24-hour simulation identified that 53% of modeled distribution system junctions had average pressures above 80 psi. High pressures are generally experienced in the southwest and northwest sections of the system, as shown in Exhibit C.2.

Given the wide elevation range served by the Primary PP, areas of typical-high and typical-low pressure are expected. The CIP (Section 6.3) includes the creation of a ‘Lower Pressure Plane’, which would encompass much of the western and southwestern high-pressure areas to maintain a lower HGL for these lower elevation areas. This recommendation significantly improves existing high-pressure issues. Remote pressure monitors should be installed at high and low elevations in each pressure plane and communicated into the SCADA system to allow sufficient monitoring of system conditions.

High pressures can also occur from automated or unmonitored BPS operations. There is currently not a centralized SCADA system in place to allow monitoring or control of operations at remote facilities. Data recording and remote control capabilities for all remote facilities (including BPSs, ESTs, pressure plane boundary facilities, etc.) are needed so that operators are equipped with the tools required to sufficiently monitor and operate the water distribution system.

Some high pressures can be alleviated in the near term by changing the Hollytree PP PRV settings. It is recommended that the Hollytree PRVs be modified to maintain an HGL of 625 ft above MSL, which results in a pressure range of 45-80 psi. However, according to the data collected in the December 2019 Pressure Regulating Station Assessments3 completed by The Brannon Corporation, it is likely that many of these PRVs are not operating as intended. It is recommended that the number of pressure regulating stations required

to enclose this pressure plane be limited to three PRVs. By limiting the number of PRVs in operation, this pressure plane will require less maintenance to maintain and have a lower risk associated with PRV failures. The setting of these PRVs and upstream/ downstream pressures should be communicated into the SCADA system to ensure staff can monitor and control system conditions.

Additionally, a blowoff valve is recommended in the Hollytree PP at a setting 12 feet higher than the recommended HGL to protect the pressure plane in the event of PRV failure. The blowoff valve should be located so that the water spray generated by the valve activation is visible and will discharge to a nearby creek or storm drain. The operation status of this blowoff valve should be communicated into the SCADA system to ensure staff is notified if this valve is releasing water from the system. The configuration in Exhibit C.3 shows the recommended modifications to enclose the Hollytree PP until the interim Lower PP is established.

It is also recommended that the Thigpen HGL is reduced to 635 ft above MSL, which results in a pressure range of 65-80 psi, to account for moderately high pressures in this pressure plane. The setting of these PRVs and upstream/downstream pressures should be communicated into the SCADA system to ensure staff can monitor and control system conditions. Additionally, a blowoff valve is recommended in the Thigpen PP at a setting 12 feet higher than the recommended HGL to protect the pressure plane in the event of PRV failure. The blowoff valve should be located so that the water spray generated by the valve activation is visible and will discharge to a nearby creek or storm drain. The operation status of this blowoff valve should be communicated into the SCADA system to ensure staff is notified if this valve is releasing water from the system. The configuration in Exhibit C.3 shows the recommended modifications to enclose the Thigpen PP until the interim Lower PP is established.

Lastly, it is recommended that a new secondary pressure plane is created to enclose the Cascades development within its own lower-head pressure plane. The connections in the Cascades development can experience pressures in excess of 110 psi. It

is recommended that a PRV be installed on the water main in Briarwood Road, near Loop 323, to establish an HGL of 634 ft above MSL, which results in a pressure range of 40-85 psi. The setting of this PRV and upstream/downstream pressures should be communicated into the SCADA system to ensure staff can monitor and control system conditions. The parallel 6-inch water main in Briarwood Road should be tied in downstream of the PRV and closed at its connection to Loop 323 to complete the pressure plane boundary.

Additionally, a blowoff valve is recommended in the Cascades PP at a setting 12 feet higher than the recommended HGL to protect the pressure plane in the event of PRV failure. The blowoff valve should be located so that the water spray generated by the valve activation is visible and will discharge to a nearby creek or storm drain. The operation status of this blowoff valve should be communicated into the SCADA system to ensure staff is notified if this valve is releasing water from the system. The configuration in Exhibit C.4 shows the recommended modifications to create the Cascades PP. This recommendation is included with Group B2 of the CIP (Project B2-LO-1; Appendix D).

At the time of this report, there are no regulations imposing maximum velocities for distribution system piping. However, the industry-accepted standard is to maintain velocities below 7.0 fps during typical customer demands, preferably below 5.0 fps, to reduce the likelihood of facility degradation.

High velocities are indicated near some pump stations and pressure plane boundaries. The percentage, by length, of distribution system pipes with maximum velocities above 5 and 7 fps is approximately 1.9% and 0.2%, respectively. Most high velocities occur in the Primary PP, with minor occurrences in the Troup PP. Distribution system piping with high velocities is shown in Exhibit C.5. The categories of high velocities in the system with recommended improvements are listed below:

a. Troup BPS discharge pipes

i. High velocities will be addressed with the creation of the Upper PP, detailed in the CIP (Appendix D).

b. Terre Haute GST fill line along Terre Haute Drive

i. The PSV recommendation to address LowPressure Area 2 (recommendation above) will also reduce velocities during GST fill periods.

c. Hollytree PP west boundary PRV [TYL183]

i. The Hollytree PP boundary recommendations (Exhibit C.3) include the retirement of the pressure regulating station on the west boundary of the Hollytree PP, which will address the high velocities in this area.

d. Interconnects between large-diameter transmission pipes to smaller-diameter distribution pipes

i. Interconnects should be upsized to at least one nominal diameter greater than the connecting distribution piping. This can be completed during any repair/rehabilitation work as determined by the City’s Asset Management Plan or any upsizing projects as determined by the CIP (Appendix D).

Capital improvements are not recommended to reduce velocities in pipes with reported values between 5 and 7 fps. These velocities are within the industry standard and, in reality, are likely attenuated by the smalldiameter pipes not included in the model.

There are no regulations imposing maximum head loss for distribution system piping at the time of this report. However, the City of Tyler Design Guidelines for Subdivision Improvements1 identifies a maximum allowable head loss of 10 ft/k-ft of pipe. Pipes with a maximum head loss greater than 10 ft/k-ft are identified in Exhibit C.6. High head loss indicates pipes in need of upsizing due to diameter bottlenecks and undersized pipes along the main system flow paths or pipes in need of renewal or rehabilitation due to high friction factors. However, the CIP (Section 6.3) involves significant changes to the main flow paths in the system to accommodate the creation of new pressure planes. The 25-year system, as outlined in the CIP, alleviates a significant portion of the system’s high head loss. Therefore, no near-term improvements are recommended to alleviate high head loss.

Per regulatory requirements, the distribution system must maintain a minimum pressure of 20 psi under combined fire and finished water flow. The City of Tyler Design Guidelines for Subdivision Improvements1 identifies minimum fireflows defined for multiple property types. Fireflow duration is assumed to be three hours for this analysis. The minimum fireflows for different zoning categories used for this analysis are defined in Table 5.5.

suction directly from the public water system to be equipped with PSVs that maintain upstream pressure above 35 psi.

◦ On the Terre Haute GST fill line, at a setting of at least 35 psi.

◦ Throttle the Charleston Park GST inlet valve setting to protect the upstream distribution pipes from low pressures.

◦ Hollytree PP reconfiguration includes the retirement and closure of four existing pressure regulating stations and setting modifications to three existing pressure regulating stations (to remain in service until Category B capital improvements are complete).

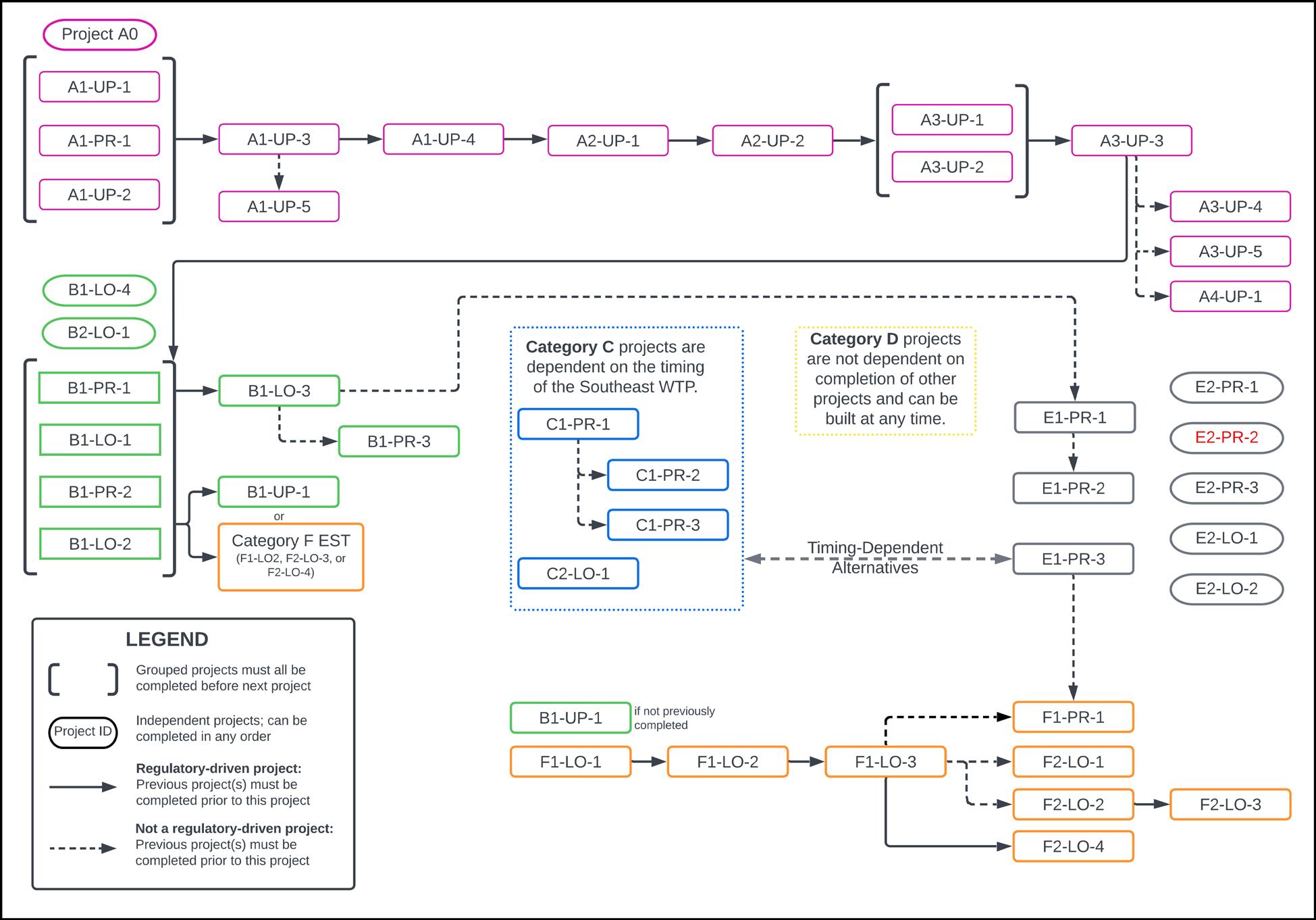

◦ Thigpen PP PRV setting changes at the two existing pressure regulating stations (to remain in service until Category B capital improvements are complete).