WATER TREATMENT PLANT WATER FACILITIES MASTER PLAN

For the City of Tyler

Prepared by: Halff Associates, Inc.

Firm Registration No. 312

halff.com

For the City of Tyler

Prepared by: Halff Associates, Inc.

Firm Registration No. 312

halff.com

The City had previously contracted Halff Associates, Inc. (Halff) to build the water system inventory in GIS and provide an up-to-date set of tools to manage the current system more effectively and plan for the future. The scope of services for the Water Master Plan builds upon that previous study and includes the following:

• Water Distribution System Master Plan (separate report)

• Water Distribution System Asset Management Plan (AMP) (separate report)

• Water Treatment Plants Facility Plan, including Raw Water Supply Transmission Facilities

This report focuses on the City’s water treatment plants and associated raw water supply systems and provides a 25-year Capital Improvement Plan (CIP) for those facilities. For a WTP that has been in operation for many years, it is essential to consider rehabilitation and replacement of critical older equipment in the master planning process while also planning for future growth. Halff developed a list of the significant aboveground plant assets and below-ground piping and identified those areas/equipment needing immediate improvement or replacement. The asset inventory tables and maps are provided in Appendix A and aim to identify the major equipment and piping that may lead to a significant disruption in plant operation upon failure.

This report also reviews regulatory requirements for drinking water quality before evaluating the City’s Water Treatment Plants. TCEQ compliance is explained in addition to industry standards, which include taste and odor treatment. Geosmin is the primary culprit for taste and odor issues in the City, particularly water originating from Lake Palestine and processing through the Lake Palestine WTP. The report evaluates different geosmin treatment options and breaks down the costs associated with pursuing dual ozone-hydrogen peroxide setup that can remediate taste and odor issues during high geosmin periods.

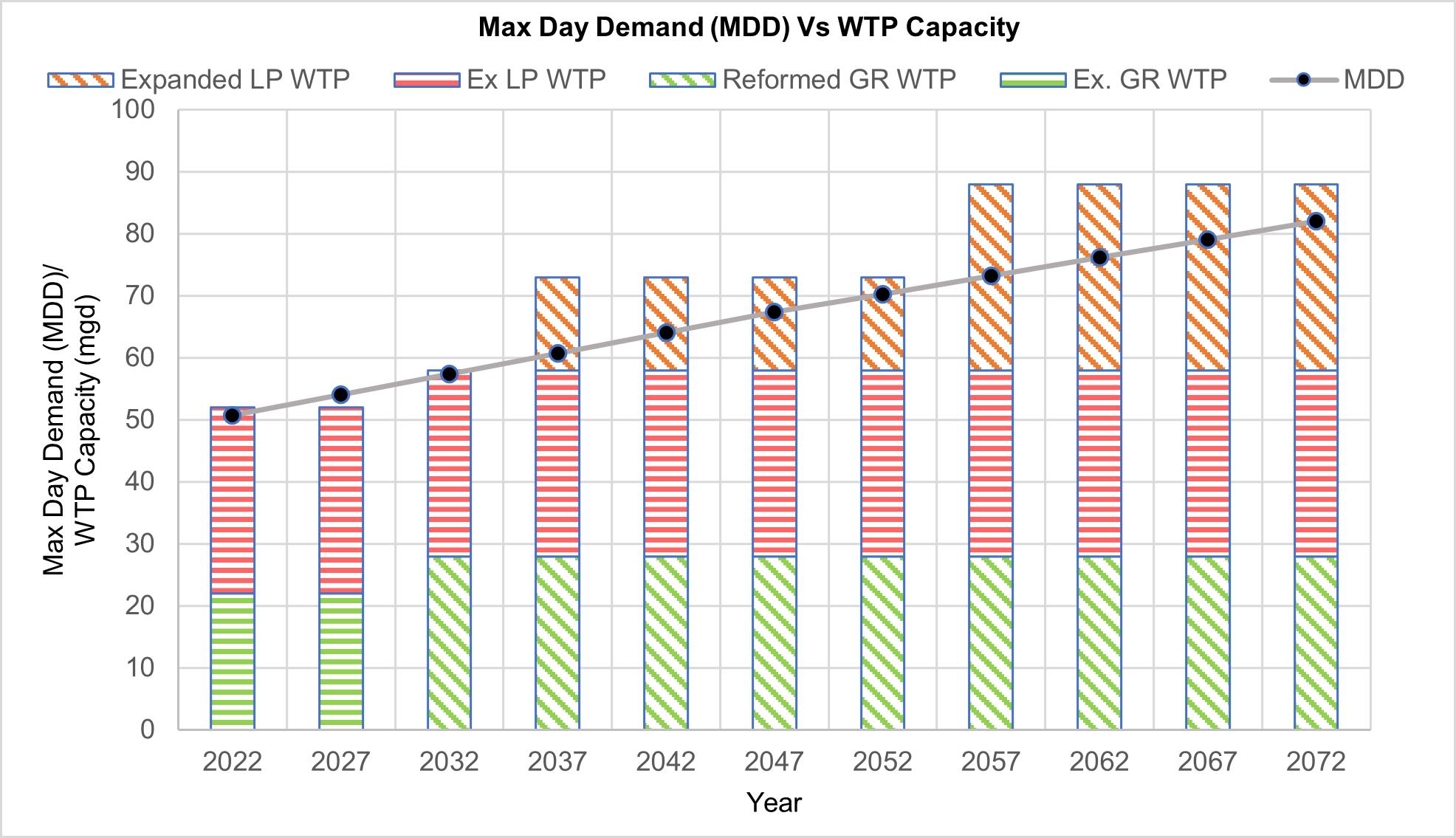

Phasing expansion of water treatment facilities to accommodate future growth within the City is a subject of this report in addition to the Water Distribution System Asset Management Plan. This section of the report details how demand will be split between

the two WTPs over time, utilizing future expansion of the Lake Palestine WTP and a reformed version of the current Golden Road WTP. The option of an entirely new Southeast WTP is evaluated in this report as well, understanding that the merits of large capital investment in preferred infrastructure must be weighed against political and financial realities. This report adopts the financial constraints the City has expressed, prioritizing an option that keeps Golden Road in service. Each WTP is reviewed from its respective raw water intakes to the high-service pumps that direct the water to the distribution system, and elements of the production are identified for upgrades where necessary. This includes improvements such as enhanced geosmin treatment and replacing equipment that has reached its anticipated end of service life.

Ultimately this report produces a series of recommendations and an accompanying capital improvement program (CIP) based on estimates from real projects and non-binding quotes provided by manufacturers. The purpose of the CIP, found in Appendix I, is to enable the City to begin financially planning for these improvements and understanding which elements of the water system’s maintenance represent the greatest capital investment. A summary of the CIP projects is shown in Table ES.1 below. Elements included in the five-year improvement plan include the following:

• Lake Palestine geosmin treatment system– ozone generators, ambient monitors, and hydrogen peroxide dosing system. The existing contact diffuser expires in 2032 and will be replaced with a new side-stream model; the City may choose to make this upgrade early, alongside the five-year improvements listed here.

• Thorough evaluation of Golden Road that identifies all necessary upgrades to bring regular production at the plant up to its 28 MGD-rated maximum output. During its rehabilitation, electrical and mechanical upgrades shall be meticulously planned to minimize the operational impact on Golden Road.

Note: The City has expressed intent to rehabilitate Golden Road Clariflocculators 3 and 4 by 2025. Their omission from this table is based on this understanding. All costs represent the present value.

1 The need, cost, and schedule of these projects are subject to change based upon the results of the Plant-Wide Assessment. The CIP should be updated once the assessment is complete and the results analyzed.

2 Timing of new High Service Pump Station is triggered by the City’s decision to start up the proposed Lower Pressure Plane

10 Figure 2.1 Ozone Contact Basin at Lake Palestine WTP

11 Figure 2.2 Rapid Mixers at Lake Palestine WTP

15 Figure 2.8 Filtration basins at Golden Road WTP

15 Figure 2.9 Ammonia containers at Golden Road WTP

16 Figure 2.10 Clearwells at Golden Road WTP

18 Figure 3.1 Raw Water Pumps at Lake Palestine Intake (left) and Lake Tyler Intake (right)

18 Figure 3.2. Ozone Generator (left) and Rapid Mix Unit (right) in Lake Palestine WTP

Appendix A: WTP Asset Inventories

Appendix B: Facility Location Map and Process Flow Diagrams

Appendix C: SDWA Process Flow Diagram, Drinking Water Regulations, Drinking Water Quality Report

Appendix D: TCEQ Compliance at GR WTP and LP WTP

Appendix E: Additional Information about Geosmin and its Treatment

Appendix F: Geosmin Treatment Information and Costs

Appendix G: WTP Service Areas

Appendix H: Proposed WTP PFDs and Site Layouts

Appendix I: CIP Costs and Assumptions

Appendix J: Drone Survey

Appendix K: Documents Received From the City of Tyler

• Ac [Acre]

• Action Level [AL]

• ASU [Arizona State University]

• Avg [Average]

• AMP [Asset Management Plan]

• AOP [Advanced Oxidation Process]

• ARJWS [Anderson Regional Joint Water System]

• BTEX [Benzene, Toluene, Ethylbenzene, and Xylene]

• BOM [Biodegradable organic Matter]

• CCI [Comprehensive Compliance Investigation]

• CEC [Contaminants of Emerging Concern]

• CIP [Capital Improvement Plan]

• CT [Concentration-Time]

• CWS [Community Water System]Serves 25 year-round residents or has 15 year-round service connections

• DO3 [Dissolved Ozone]

• DOC [Dissolved Organic Carbon]

• DBP [Disinfectant Byproduct Plan]

• DBPR [Disinfectant Byproduct Product Rule]

• DIP [Ductile Iron Pipe]

• EBMUD [East Bay Municipal Utility District]

• EPA [Environmental Protection Agency] - Federal agency responsible for the creation of water quality rules

• EPDM [ethylene-propylene-diene rubbers]

• EST [Elevated Storage Tank]

• ft [Feet]

• fps [feet per second]

• GIS [geographic information system]

• GAC [Granular Activated Carbon]

• gph [Gallons per hour of flow]

• gpm [Gallons per minute of flow]

• GR [Golden Road]

• HA [Health Advisory]- provide technical guidance on health effects, analytical methodologies, and treatment technologies associated with contaminants. HAs are not legally enforceable under SDWA but serve as technical guidance to PWS.

• HAA [Haloacetic]

• HAL [Health Advisory Level]

• HDPE [High-Density Polyethylene]

• HP [Horsepower]

• In [inch]

• LCR [Lead and Copper Rule]

• LCRR [Lead and Copper Rule Revisions]

• LCRI [Lead and Copper Rule Improvements]

• LP [Lake Palestine]

• LPUV [Low-pressure ultraviolet]

• LRAA [Locational running annual averages]

• LOX [Liquid Oxygen]

• MCL [Maximum Contaminant Level]

• MCGL [Maximum Contaminant Goal Level]

• MDBP [Microbial and Disinfection Byproducts]

• MTBE [methyl tertiary butyl ether]

• MIB [2-methylisoborneol]

• Min [Minimum]

• MG [Million Gallons]

• MGD [Million Gallons per Day]

• MCC [Motor Control Centers]

• NDMA [N-Nitroso-dimethylamine]

• NOM [Natural Organic Matter]

• NPDWR [National Primary Drinking Water Regulations]

• NTU [Nephelometric Turbidity Unit]

• O&M [Operation and Maintenance]

• OPCC [Opinion of Probable Construction Cost]

• PAC [Powdered Activated

Carbon]

• PFAS [Per- and Poly-Fluoroalkyl Substances]

• PFOA [Perfluorooctanoic Acid]

• PFOS [Perfluorooctane Sulfonic Acid]

• PPB [Parts Per Billion]

• PPD [Pounds Per Day]

• PPM [Parts Per Million]

• PS [Pump Station]

• PVC [Polyvinyl Chloride]

• PWS [Public Water Systems]

• RCP [Reinforced Concrete Pipe]

• RTCR [Revised Total Coliform Rule]

• RWPS [Raw Water Pump Station]

• Std [Standard]

• SDWA [Safe Drinking Water Act]

• su [Standard Units]

• SWMOR [Surface Water Monthly Operating Reports]

• SWTR [Surface Water Treatment Rule]

• TAC [Texas Administrative Code]

• TC [Total Coliform]

• TCEQ [Texas Commission on Environmental Quality]

• TCR [Total Coliform Rule]

• TPUC [Texas Public Utility Commission]

• TTHM [total trihalomethanes]

• TWDB [Texas Water Development Board]

• T&O [Taste and Odor]

• UCM [Uniform Costing Model]

• UCMR [Unregulated Contaminant Monitoring Rule]

• UV [Ultraviolet]

• USEPA [United States Environmental Protection Agency]

• USGS [United States Geological Survey]

• VOC [Volutile Organic Carbon]

• WEF [Water Environment Federation]

• WTP [Water Treatment Plant]

The City of Tyler (City) owns and operates two water treatment plants (WTPs). The Golden Road WTP has a design treatment capacity of about 28 million gallons per day (MGD) and was constructed in 1951. This plant accepts raw water from Lake Tyler and Lake Tyler East via a raw water intake structure and pump station located at Lake Tyler. It is a rapid sand filter facility that uses sedimentation, flocculation, filtration, and disinfection. The Lake Palestine WTP has a current treatment capacity of about 30 MGD and was constructed in 2003. This plant accepts raw water from an intake structure and pumping station located on Lake Palestine. It is also a rapid sand filter facility that uses sedimentation, flocculation, filtration, and disinfection.

This report begins with a detailed background of both WTPs. It reviews how they integrate into the larger regional water supply as well as the technical ins and outs of their operation. It describes individual components and notes any relevant rehabilitation or upgrades the City has done. Following this background is an inventory of these components that assesses their condition and criticality to prioritize future improvements. It identifies piping and equipment that should be replaced immediately versus those that have not yet reached their end of service life.

The following two chapters review various regulatory requirements affecting the City’s water quality and how the City performs in comparison. This includes evaluating the Water Treatment Plants for overall compliance with TCEQ and industry standards.

This report then discusses geosmin, a chemical that causes taste and odor issues for the water supplied from Lake Palestine. This section details different treatment options, describes case studies of successful treatment, compares them to the existing treatment at Lake Palestine WTP, and ultimately recommends improving the current system.

The following chapter overviews how the City can expand its water treatment facilities to accommodate expected population growth. It identifies key capital improvements critical for growth and explores a schedule on which to undertake them. The final section of this report compiles the recommendations from previous chapters, clarifying which are proposed Capital Improvement Plan (CIP) projects and which focus on optimizing day-to-day operation and maintenance.

A series of appendices supplement this report. Digital deliverables provided to the City will include the asset inventory produced for this report and drone footage of each Water Treatment Plant.

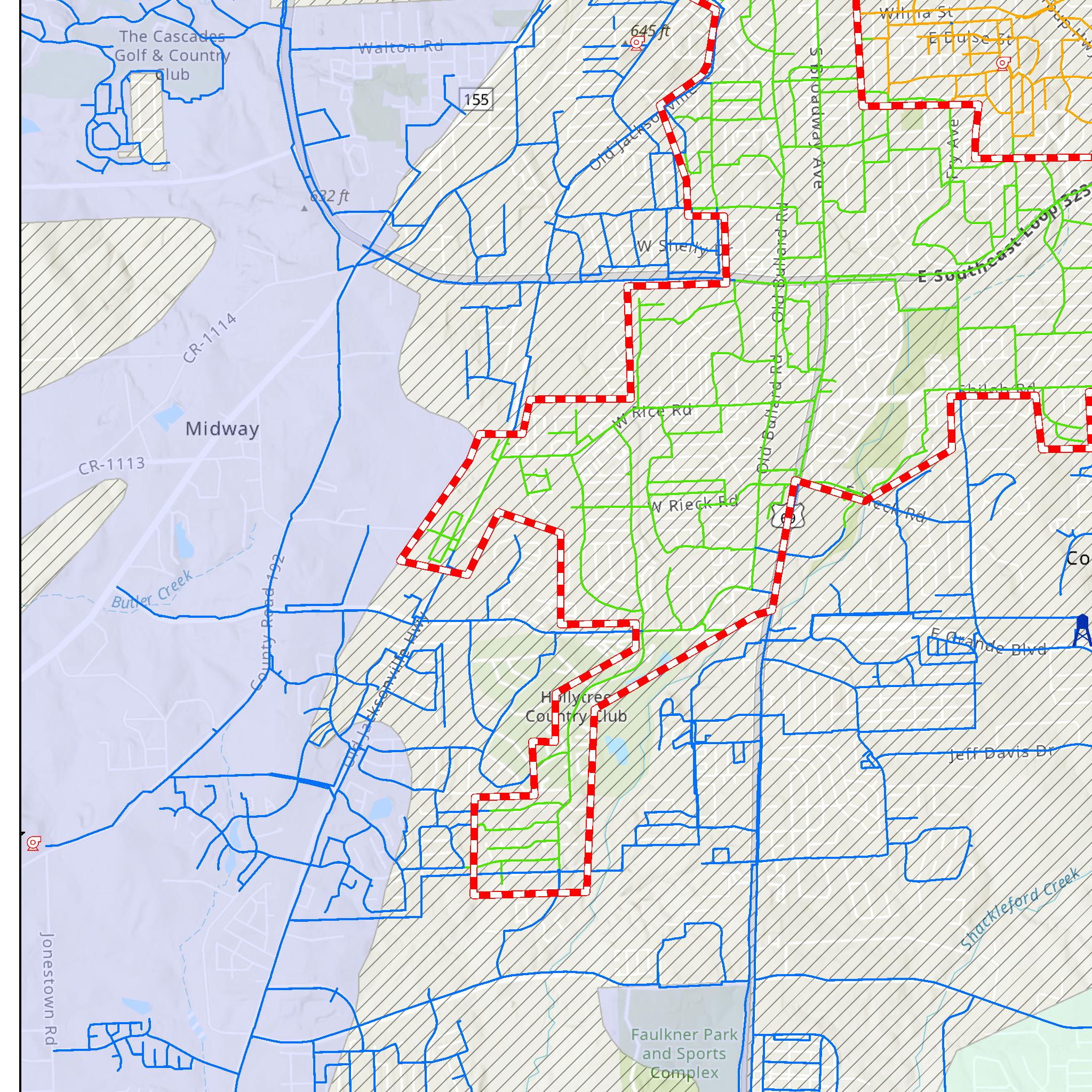

The City of Tyler Water Utilities Department (TWU) is the primary finished water supplier for the City of Tyler (City) residents and commercial properties. TWU is also the wholesale provider for Whitehouse, Walnut Grove WSC, and Community Water Company. TWU also serves some Southern Utility customers. The City’s water utility service area, defined by the water Certificate of Convenience and Necessity (CCN) boundary, covers approximately 228 square miles, including 126 square miles of overlapping area with other water utility companies. The service area covered exclusively by the City is approximately 102 square miles.

The City has a population of approximately 106,000 people, according to the United States 2020 Census estimates. The majority of the City’s finished water distribution system is located within the city limits and is divided into seven pressure planes. This distribution system includes two water treatment plants (WTP), five elevated storage tanks (EST), one standpipe (SP), four booster pump stations (BS), and 708 miles of water mains. The EST, BS, and water mains are considered in the Water Distribution System Asset Management Plan.

TWU operates two WTP’s that provide the entire drinking water supply to all City customers. The Lake Palestine and Golden Road WTP operate under the Public Water Systems (PWS) ID No. 2120004. The location of the WTP, raw water lines, and intake structures are shown in Exhibit 2.1. Golden Road WTP is located in the central-east region of the distribution system, and treats surface water from Lake Tyler and Lake Tyler East. Lake Palestine WTP is located in the southwest region of the distribution system, and treats surface water from Lake Palestine. Upper Neches River Municipal Water Authority has water rights for Lake Palestine. The cities of Palestine, Tyler, and Dallas have contracts for supplies from Lake Palestine. The firm yield and water rights from these sources are shown in Table 2.1

1 Report on Water Supply, Population, and Water Use in Relation to Lake Tyler Water Rights Adjudication (1983)

2. Permit No 1843 TCEQ

3. City of Palestine, City of Tyler, and City of Dallas have contracts for supplies from Lake Palestine

4. Hydrology Report on Lake Palestine and Neches River Channel Dam and Reservoir (1984),

5. Available supply decreases to 189010 ac ft/year (168 MGD) by 2070

The following section briefly describes both plants’ existing WTP background, treatment units, and processes. Appendix B includes location maps and process flow diagrams of Lake Palestine and Golden Road WTP, respectively.

Halff conducted an initial site visit to Tyler WTPs on October 27th, 2020. The Golden Road and Lake Tyler intakes were visited on January 26th, 2021. Golden Road WTP was revisited on December 14th, 2021. While on the site visit, Halff communicated with the plant operators and inspected the treatment units and equipment. The information in the following section is based on the site visits, recent studies conducted in the WTP documents, and plans provided by the City on both WTP’s. Appendix K contains an inventory of the information received from the City to aid this study. Halff will deliver scanned images of this inventory as one of the project’s electronic deliverables.

The Lake Palestine WTP, rated for a treatment capacity of 30 MGD, was built in 2003. The 20-year-old surface WTP treats source water from Lake Palestine using raw water ozonation, coagulation, flocculation, sedimentation, and gravity filtration. The Lake Palestine WTP was intended to take more load from Golden Road WTP, and the City owns adequate property at this plant to accommodate a second 30 MGD treatment train. The presence and treatment of geosmin is a significant challenge at Lake Palestine WTP.

The raw water at Lake Palestine is pumped to the treatment plant through approximately 9 miles of 54-inch ductile iron (DI) pipeline. The intake structure consists of a concrete platform that supports 3-1000 HP vertical turbine pumps (1 standby pump) with a capacity of 10,500 gpm each. The pumped water travels down the concrete bridge via a 48-inch DI pipe, which ties into a 54-inch underground discharge line initially constructed in 2003. Raw water in Lake Palestine can be withdrawn from a specific level associated with each pump based on information from record drawings:

◦ Pump 1: 323.5±0.5

◦ Pump 2: 328.5±0.5,

◦ Pump 3: 333.5±0.5

The raw water turbidity from Lake Palestine is typically less than 5 NTU. The lake has geosmin issues, in which levels climb from December to March. No chlorine or other disinfectant is added at the raw water source location.

The 54-inch raw water line reduces to a 48-inch DI line 400 feet from the WTP. The raw water enters the WTP through a 48-inch diameter pipeline. The 12-inch recycle line joints the influent raw water line before reaching the ozone contact basins. Each ozone contactor is rated for 15 MGD. The basin has two parallel compartments, and ozone gas is applied to the raw water as it flows through the contact basin.

Ozone: Ozone acts as a disinfectant and oxidizing agent to reduce taste and odor issues. There is no set dosage that ozone is fed. It can range from 1.6 mg/l to a max of 6.0 mg/L. A typical range is 2.0 -3.5 mg/L, depending on the time of year and raw geosmin levels. Ozone dosage is increased during winter. The ozone generation building has two generators, and ozone is generated on-site from liquid oxygen stored in two 11,000-gallon tanks.

The raw water flows from the ozone contact basin into a common open channel where powdered activated carbon is dosed. The raw water flows from here into the rapid mix basin with three parallel channels where alum and lime are dosed. Two mechanical mixers are within each compartment downstream and upstream equipped with variable frequency drives. Copper sulfate is seasonally dosed upstream of the common open channel.

Alum: Aluminum sulfate is used as a primary coagulant in Lake Palestine WTP. Alum dosage changes based on water quality conditions and jar test results. A typical range over the past few years is 48 to 56 mg/l. Alum is stored in liquid form as aluminum sulfate and fed through metering pumps.

Powdered Activated Carbon (PAC): Typically, PAC is dosed to control MIB and Geosmin-related taste and odor (T&O) events. Geosmin is present year-round from Lake Palestine; therefore, carbon and ozone are fed year-round. There is no set carbon dosage as the demand changes throughout the year. The dosage range is 5mg/l -42mg/l. PAC is fed at a lower dose during the off-season (April to November). Refer to Section 6.4 for additional information on the PAC unit.

Based on the site visit, it was understood that feeding the carbon system involves a lot of manual work. The remaining PAC in the super bag has to be continuously monitored. The PAC feed rate is adjusted weekly or more frequently during peak geosmin season based on the calculation tied to geosmin sampling of raw water feed. This sampling is conducted bi-weekly during non-peak geosmin seasons, and it takes $2,400 to test each sample. Currently, there is high operational and maintenance (O&M) cost associated with PAC.

Lime: Bulk pulverized lime is batched and mixed in a lime handling facility. Milk of lime solution is fed through metering pumps. Per a previous study, lime was dosed at 0.9mg/L. Lime is used to increase raw water alkalinity.

Flow passes from rapid mix basin water to the sixflocculation basin. Each flocculation basin has three compartments with tapered mixing decreasing upstream to downstream. The gravity flocculation

basins provide sufficient mixing. However, the underground electrical conduits caused issues due to high humidity. Currently, aerial tray wires are being added to resolve this issue.

From the flocculation chamber, water flows to the threerectangular sedimentation basin. Each sedimentation basin has three compartments with mechanical sludge scraping mechanisms and separate sludge blowdown boxes which run automatically. The sediment basins are taken out of service once a year. Cleaning is labor intensive and a considerable challenge due to the drain line outlet being seven feet off the floor. From the site visit, it was noticed that sedimentation basins have concrete cracks and leaks. However, according to discussions with staff, this does not cause significant operational problems. They described the leaking as “dripping at most” and blowdowns every three to four hours as sufficient to deal with drainage concerns. The settled water is dosed with free chlorine and filter aid polymer.

Chlorine: Chlorine is fed from six one-ton cylinders as a gas and mixed with water for disinfection. There are six one-ton standby cylinders. Per a previous study, the flow through WTP was 16 MGD, and chlorine was fed at a rate of 840 pounds per day. The free chlorine dosage of settled water ranges from 5mg/l -18mg/l. The plant is equipped with four chlorine injection locations.

◦ Upstream of ozone contactor – Currently, not active

◦ Filters influent trough – Primary application point

◦ Downstream of filtration basins – Recent addition

◦ Finished water before clear wells – Currently, not active

Polymer: Filter aid polymer, aqualum, is added to the settled water trough. The filter aid was dosed at 0.8 mg/L.

operators on all filter control valves. The backwash system operates satisfactorily. Air scour system uses two blowers. During the site visit, air scour was an issue due to a suspected electrical issue or an issue with the PLC. Hence filter washing was done manually. The settled water from filters is dosed with ammonia. The backwash water from the filters flows to the twobackwash clarifiers. The liquid decant is recycled to the head of the plant before ozone contactors.

Ammonia: Ammonia is stored in a two-bulk pressure tank as liquid anhydrous ammonia. Two ammoniators (one duty, one standby) serve to meter ammonia. Ammonia is fed as a gas to the treated water downstream of the filters to form chloramine. The ammonia injection point in the plant was relocated based on a recommendation from a previous study to control total trihalomethane (TTHM). The chlorine-toammonia ratio was 3:1.

Sodium Hydroxide: The plant was initially designed to control pH using lime. Currently, lime is added only for alkalinity, and sodium hydroxide is used to control the finished water pH. The addition of sodium hydroxide reduces lead and copper concentration and helps produce finished water with the desired pH and alkalinity levels. Optimal pH of 8.8 to 9.2 is to be maintained in drinking water to maintain a strong monochloramine residual. The plant uses both 50% and 25% caustic dilution, dependent upon ambient temperatures throughout the year.

Lake Palestine WTP has two 2-MG clear well tanks to store finished water. The clear wells are covered to protect the sanitary conditions needed for potable water.

The clarified water flows through parallel pipes to eight-rapid sand filters. The heaviest filter loading is on the upper four filters (5-8) due to how the settled water channel feeds filters. The filter media consists of 12-inch sand and 24-inch anthracite. Filter media is 17 years old (beyond the recommended service life of 7 years) and is not currently a critical issue. However, the City has allocated funds to replace the filter media in 2024. Filter valves utilize pneumatic

There are four vertical turbine high service pumps equipped with variable frequency drive (VFD) in Lake Palestine WTP. The pump capacities are rated as 8680 gpm.

The raw water pump station generator is fully manual and supplies power to the raw water pumps. Lake Palestine WTP plant generator (2000 KW) is fully manual and supplies power to the plant, excluding the high-service pumps (HSPs). The high-service pump

generator (2000 KW) is fully manual and supplies power to all the HSPs. The generator (510 KW) at the administration building is automatic and supplies power to the building operations and administration.

The Golden Road WTP was built in 1951 and upgraded in 1965 and 1980. A new caustic chemical feed building was added recently, and there is a current project to refurbish existing filters. The plant was initially rated for a capacity of 32 MGD. The plant is currently rated at 28 MGD, and the typical production rate is 22 MGD. The 70-year-old conventional surface WTP treats source water from Lake Tyler using coagulation, flocculation, sedimentation, and gravity filtration. The Golden Road WTP was working during the winter storms in 2021.

The raw water intake at Lake Tyler was built in conjunction with the WTP in 1951 and was further upgraded in 1978. This facility was replaced in March 1999 with a new intake and pumps equipped with VFD. The intake structure consists of a concrete platform that supports three 1250 HP vertical turbine pumps (one standby pump) with a capacity of 12,500 gpm each. The pumped water travels down the concrete bridge via a 42-inch ductile iron pipe. This line ties into 27-inch and 36-inch underground discharge lines. The 27-inch was constructed around the 1950s, and the 36-inch in 1964. The water from Lake Tyler is generally clean and free of geosmin. No chlorine or other disinfectant was added at the raw water source location.

The surface water enters the plant through parallel raw water pipelines. Each raw water line discharges into an open channel at the head of WTP, into which fluoride, alum, and lime are being dosed. From the open channel, the raw water flows into the first-stage rapid mixer equipped with two electric mixers. From there, a short underground pipe conveys the flows into a second mixing basin where the lime slurry is dosed to boost the pH above 7 to 7.2 standard units (SU). The motorized mixer in the second mixing basin is operational only under certain circumstances.

Alum: Alum is purchased and stored as aluminum sulfate. Per a previous study, alum was dosed at 55 mg/L. Jar tests are conducted weekly to determine the optimum alum dose based on water quality.

Fluoride: Fluoride is added as hydrofluosilicic+acid, stored in bulk containers, and fed from a day tank using metering pumps. The natural fluoride in Lake Tyler (approximately 0.2-0.3mg/L) is supplemented by fluoride at the open channel in WTP to maintain a target concentration of approximately 0.7mg/L based industry accepted standards.

Lime: Bulk pulverized lime is stored in dry form and is batch mixed in the lime handling facility. The milk of lime solution is fed through metering pumps in the second stage rapid mixer to boost the pH above 7 to 7.2 SU. Per a previous study, lime was fed at the rate of 10mg/L. Optimal pH of 8.8 to 9.2 SU was required to maintain a good monochloramine residual in the distribution system. This led to the decision to add sodium hydroxide to address the issue.

Water from the rapid mix basin flows into four 110-foot diameter clari-flocculators with an inner compartment (flocculation well) and outer compartment (clarification zone). Clarifier #1, #2, and #4 flocculators have mixing-style flocculation devices, and the sludge rack is at the bottom of the tank. Clarifier #3 has large flocculation arms attached at the top of the mechanism and protrudes downward about 8 feet. The sludge rack also has arms that point upwards and mesh with the flocculator arms. The flocculators and sludge rack move in different directions and assist in forming floc. The clari-flocculator motors are not currently working. Free chlorine and polymer are added to the settled water flow junction box.

Polymer: Filter aid polymer, aqualum is added to the settled water flow junction box. The filter aid was dosed at 0.35 mg/L.

Chlorine: Chlorine is fed from six two-ton cylinders as a gas and mixed with water for disinfection. There are six two-ton standby cylinders. Per a previous study, the flow through WTP was 8 MGD, and chlorine was fed at a rate of 475 pounds per day. The free chlorine dose of settled water was 7.1 mg/L, with a measured free chlorine residual of 3.8 mg/L. The plant is equipped with four chlorine injection locations:

◦ open channel where fluoride and alum are dosed –currently not active

◦ clarifier influent flow splitter box – only active seasonally to remove algae from weirs of the clariflocculator weirs

◦ filters influent junction box – primary application point

◦ finished water leaving clear wells – typically used in the event of a power outage

The Golden Road Plant has 16 rapid sand filters, and the current capacity of each filter is 1.5 MGD. The first four filters were constructed in the 1950s, and filter units were upgraded in future in 1978, 1993, and 2019.

point is located at the combined filter effluent piping. The backwash water from the filters flows to the backwash clarifier. The decanted water from the filter is transferred to City’s wastewater treatment plant and sludge to the sludge thickener unit.

Ammonia: Ammonia is stored in a two-bulk pressure tank as liquid anhydrous ammonia. Two ammoniators (one duty, one standby) serve to meter ammonia. Ammonia is fed as a gas to the treated water after chlorination to form chloramines. This compound will serve as a residual disinfectant for the clear well and the distribution system. Per a previous study, the free chlorine residual in settled water was 3.8 mg/L, and the free ammonia residual was less than 0.1 mg/L. The ammoniator dose was 1 mg/L. The chlorine-toammonia ratio of 3.8:1 is slightly lower than the optimal chloramination process. To reduce the formation of disinfectant byproduct (DBP), the ammonia injection point was relocated to combined filter effluent piping.

Filters four and five were rehabilitated recently, six and seven are currently rehabilitated, and eight will be rehabilitated in the future. Filters one, two, and three have also been rehabilitated. The 2009 Tyler Water System Master Plan states that the hydraulic capability of the filter piping system limits filter capacity. At a minimum, the filter+ media is to be replaced every ten years. However, the replacement schedule would only cycle through all 16 filters once every 40 years. An underdrain supports filter media. A new filter backwash system was installed in 2016 with two backwash pumps at 11,500 gpm each. The combined filter effluent flows to the clear well/high-service pump suction junction box. The ammonia and sodium hydroxide injection

Sodium Hydroxide: A caustic injector is installed on filters one through eight effluent lines in the existing manhole. A new caustic bulk storage and containment structure is built at the WTP.

Water from filters flows through a junction box where pH is monitored. From there, it flows into clear well for temporary storage, pumped directly by the high-service pumps to the distribution system.

pH Sensor: pH sensor is installed in the clear well/ high service pump suction junction box

Golden Road WTP has two 2 MG clearwell tanks for finished water storage. The clear wells are covered to protect the sanitary conditions needed for potable water. Clear wells have new baffles, and a gentle swirl of flow within the tank helps with chemical mixing. Total chlorine is measured at clear wells.

There are six horizontal split-case high-service pumps in Golden Road WTP. The pumps have been rehabbed and repaired to different stages throughout the years. The pump capacities are as follows,

◦ Pump #1 – 4 MGD

◦ Pump #2, #3, and #4 – 8 MGD

◦ Pump #5 and #6 – 18 MGD

Based on the operation manual, pumps are used in different combinations to meet the demands.

Pumps #3 and #4 are not used simultaneously since the discharge line has a history of flow separation. Similarly, Pumps #5 and #6 are not used together. The pumps do not run if the clear well water elevation drops below ten feet. Thus, the pumps use only the top five feet of clearwell volume. Due to the high service pump station’s risk of flooding, flood-prone doors were installed recently.

Golden Road WTP and Lake Tyler intake do not have generators, and there is no emergency power backup for the intake and Golden Road WTP. A recent study at Golden Road WTP estimated a cost of $8 million to install generators and replace VFD.

Tyler WTP assets were listed based on site visit notes, input from City personnel, photographs, record drawings, historical aerial imagery, and drone survey. This inventory list was used to document the ages, current conditions, and previous repairs and maintenance to identify areas and equipment needing immediate improvement or replacement. Exhibit 3.1 and 3.2 illustrates the assets considered for this study.

Asset condition was determined based on plant staff input, field observation, and equipment installation dates. A summary of this information and the reason for rating has been incorporated into the asset tables in Appendix A. Possible conditions were new, good, fair, and poor.

In the absence of input from staff or field observation, condition rating was based on criteria listed in Table 3.1. It should be noted that some of the installation years were assumed in the absence of data, as detailed in Appendix A. The staff can conduct more condition assessment work and revise this analysis if required. For all items, but particularly for the assets for which the installation year is assumed, it is recommended that the City performs a condition assessment to more accurately determine the condition of the pieces of equipment. Items were labeled “Poor” strictly based on the input from staff or field observation or if the asset exceeded its anticipated life. Refer to section 3.4 for more information on service life. The process of condition assessment is ongoing and should be performed on a routine basis.

Anticipated Life) *100

Poor a) Based on the input from staff or field observation

b) Exceeding anticipated life

The criticality of each significant piece of equipment and each major pipe was also evaluated. The criticality scale and the condition of each piece of equipment should be used to determine the replacement priority for each item. If no major process units are shut down due to a pipe or piece of equipment failure, the plant can wait until it fails before replacing it without a significant interruption in operation.

An example of a noncritical failure would be if one of the pumps in the raw water pump station in Lake Palestine WTP were to fail. Since the pump station has redundancy, the plant can continue to operate without one of the pumps. However, more critical pieces of equipment and pipes will cause the entire plant to shut down upon failure. For instance, the 54-inch raw water line coming into Lake Palestine WTP is critical to the operation of the plant and should be replaced or rehabilitated before it fails. As failures of critical pipes or other critical pieces of equipment cannot be predicted, the plant staff should monitor the system closely for potential pipe or equipment failures as the end of their anticipated life approaches. Nondestructive testing may be performed on these critical items as they approach the end of their anticipated life to determine the estimated replacement timeline.

Close monitoring of these critical items will allow the plant staff to replace them before failure and avoid significant disruption in plant operation. Assets running parallel, such as pumps, were classified under ‘Shuts down no major process unit’ due to redundancy in equipment. However, a few of these units have been noted as out of service during the field visit, such as rapid mix unit 1 in Lake Palestine WTP. Thus, the plant staff should confirm the present condition of these assets and re-categorize the criticality if required.

Once the plant staff knows the criticality and condition of their major assets, they can monitor the high-risk items more closely than others and better prioritize replacement and rehabilitation projects. Figure 3.3 is a graphical comparison of asset condition to its risk. As illustrated in the figure, the resulting score based upon the simple multiplication of the condition rating times the criticality rating indicates the magnitude of replacement or rehabilitation urgency. In other words, the numbers in figure 3.3 represent an asset’s “risk points” if it falls in that square. Items in red need to be monitored the closest, followed by items in yellow. The plant should consider replacing or rehabilitating the items falling into the red category based upon a follow-on condition assessment, as appropriate. The items in red, yellow, and green categories are assigned risk ranks of 1 (high risk), 2 (moderate risk), and 3 (low risk), respectively, in Appendix A. The risk assessment of the sub-equipment items within the main asset could not be judged due to a lack of data. For example, since the condition and criticality of equipment in the electrical building were unknown, these were not included in this study. The plant staff can add any further information on these sub-units to the asset list. The categorization of risk scores and delineation of the color schemes are based on the engineer’s experience.

To estimate remaining service life, the current age of the major asset was determined either from design or record plans or from the previous replacement date as provided by plant staff. The plant staff reviewed the draft chapter and verified the installation dates. However, any discrepancy in the age or date of the installation based on the knowledge of equipment replacement should be updated.

Table 3.2 and 3.3 lists the construction and maintenance dates of the WTPs. These dates are based on the design or record drawings, and the actual construction/installation dates could be marginally different from what is specified in the plans.

Average service life was determined for specific asset types from various industry sources. The remaining service life would be the current age subtracted from the average service life. Each evaluated equipment was placed into a category with a corresponding anticipated life. See Appendix A to see how each piece of equipment was categorized. Table 3.4 shows the assumptions used for the life of materials and equipment.

1 Water Environment Federation (WEF), Collection Systems 2010, p. 299

2 United States Environmental Protection Agency ( USEPA) Asset Management Training Workshop PowerPoint, Slide 119

3 The remaining are based on Engineer’s experience

The plant should take this information and build upon it by tracking its assets from this time forth. Whenever the plant purchases additional assets, the replacement cost and anticipated life of that asset should be documented in the GIS asset database. This documentation will assist the plant in planning for future replacements of assets. The plant staff should also include other items not included in Appendix A.

The plant should maintain and replace its equipment as it ages to keep the plant operating efficiently and within regulatory/permit limits. Figure 3.6 and 3.7 shows the number of major equipment items in each category in Lake Palestine and Golden Road WTP, respectively.

Per the figures, 21% of the documented assets in Lake Palestine WTP are in the high and moderate risk category (i.e., risk rank of 1 and 2). Whereas 54% of the documented assets in Golden Road WTP are in the high and moderate risk category. The relatively higher number of assets in the high and moderate risk categories in Golden Road WTP is due to the overall age of the plant.

The assets within each criticality rating are illustrated in Appendix A, Exhibits 3.3 and 3.4. The table presented in these exhibits lists the assets in the high and moderate risk categories and should be taken as a general idea of the future maintenance needs of the plant. The assumptions in Appendix A should be verified before the plant staff considers taking the next step of condition assessment and possibly replacing any equipment based on the categories. The items in the Table 3.5 appear to be the high-risk items for the plants and intakes. Exhibits 3.5 and 3.6 in Appendix A show the full raw water pipeline routes.

27-30” RC Raw Water Line

36-42” RC Raw Water Line

72’’ RC Standpipe 1

72” RC Standpipe 2

42” DI Raw Water Line (near intake)

48” DI Raw Water Line (near intake)

54’’ DI Raw Water Line

48’’ DI Raw Water Line (near WTP)

Figures 3.8 and 3.9 show the anticipated dates of equipment replacements in Lake Palestine and Golden Road WTP, respectively. It is a graphical representation of the number of equipment types anticipated to be replaced yearly. For example, from Figure 3.8, it can be inferred that in 2053, 14 process pipes, five civil units, and 27 miscellaneous mechanical equipment needs replacement in Lake Palestine WTP. In the same year, five civil units in Golden Road WTP need replacements, per Figure 3.9. The equipment replacement start date of 2021 in Figure 3.9 indicates

that six pipes and four mechanical equipment have run into or exceeded their anticipated equipment life. Specific categories were combined, for example, scrapper, generator, and flocculator were combined into the miscellaneous mechanical category.

Figure 3.10 and 3.11 shows the anticipated dates for replacing lower-risk equipment (i.e., risk rank of three) ten years after the end of their anticipated life and high-risk items (i.e., risk rank of one and two) at the end of their anticipated life. Figure 3.8 illustrates

eight valves and two civil assets at Lake Palestine WTP to be replaced in 2033. However, since these assets were under the mild risk category, the replacement of these units could be delayed to 2043 (10 years post actual date of replacement), as shown in Figure 3.10. However, replacing the two valves in Lake Palestine WTP in 2033 is important since these assets are under the high to moderate-risk category. Similar inferences can be drawn for Golden Road WTP from Figure 3.11.

These figures, along with Exhibits 3.3 and 3.4, can be used by the City to help gauge the funding levels needed to perform necessary replacement/rehabilitation projects. Thus if there is a shortage of funds to replace all the assets in Figures 3.8 and 3.9 for a particular year, it could prioritize the replacement/rehabilitation work for the high and moderate-risk assets and rehabilitate the non-critical items ten years after the post-actual date of replacement as shown in Figure 3.10 and 3.11. This information should be beneficial for facility sustainability by making repairs proactively.

Appendix A prioritizes equipment replacement at both treatment plants based on the equipment age vs. the equipment’s anticipated life expectancy and criticality. The results identified several pieces of equipment nearing or past the end of their anticipated life expectancy. The equipment items anticipated to require replacement are listed in Tables 3.6, 3.7, and 3.8. This table shows equipment/units anticipated to need replacement in one year, five years, and ten years at Lake Palestine and Golden Road WTP. The equipment/units highlighted in red, blue, and green belong to high, moderate, and low risk, respectively.

*30-inch and 36-inch High-Pressure Lines reached their end-of-service life in 2021. This replacement project, however, is triggered by the City’s pursuit of a lower-pressure plane in the distribution system.

The following recommendations are made regarding this initial Asset Inventory for the Lake Palestine WTP & Golden Road WTP. The City should:

◦ Verify the actual age, criticality, and condition of assets, starting with those with the highest ranking in Appendix A. Any changes in condition from what was determined in this effort should be updated in the analysis. Condition assessment should be considered an ongoing effort since the condition does change over time.

◦ Monitor closely the performance and condition of assets ranked high in risk and are approaching the end of their useful life, particularly those in the red categories. Although the action may not be immediately necessary regarding these items, the plant, and future consultants can keep in mind the apparent weak points in the system. The goal would be to allow the replacement and/or rehabilitation of these assets quickly before their failure, which might lead to operational disruptions.

◦ Inspect the following raw water feed lines to determine the current condition. Based upon the condition assessment results, evaluate the need for pipeline rehabilitation or replacement, or update the remaining service life.

◦ 48-inch DI raw water discharge line from Lake Palestine pumps to upstream of the water meter. A major part of this pipeline is above ground.

◦ 54-inch DI raw water line upstream of the water meter to 54x48-in Tee Joint, 430 feet upstream of Lake Palestine WTP

◦ 48-inch DI raw water line from 54x48-in Tee Joint to Lake Palestine WTP

◦ 42-inch DI raw water discharge line from Lake Tyler pumps to the 27-inch to 36-inch tie-in location. A major part of this pipeline is above ground

◦ 36-42-inch RC raw water line to Golden Road WTP

◦ 27-30-inch RC raw water line to Golden Road WTP

◦ Inspect the following process lines to determine the current condition. The inspection could be prioritized based on the replacement year. Based upon the equipment replacement schedule results, evaluate the need for pipeline rehabilitation or replacement, or update the remaining service life.

◦ 24-inch DI Coagulated water in Golden Road WTP (Replacement Year: 2022)

◦ 33-inch RC Drain Pipe in Golden Road WTP (Replacement Year: 2022)

◦ 48-inch RC Clarified Water in Golden Road WTP (Replacement Year: 2024)

◦ 36-inch RC Coagulated Water in Golden Road WTP (Replacement Year: 2028)

◦ 30-inch and 36-inch High-Pressure Water Lines in Golden Road WTP (Replacement Year: 2021)

◦ Inspect the following equipment/units to determine the current condition. The inspection could be prioritized based on the replacement year. Based upon the equipment replacement schedule results, evaluate the need for equipment rehabilitation or replacement, or update the remaining service life.

◦ Ozone Generators 1 and 2 in Lake Palestine WTP (Replacement Year: 2023)

◦ Clariflocculator Basin 2 in Golden Road WTP (Replacement Year: 2025)

◦ Clear Well 1 in Golden Road WTP (Replacement Year: 2025)

◦ Raw Water Meter in Lake Palestine WTP (Replacement Year: 2031)

◦ 16-inch Surge Anticipator Valve in Lake Palestine WTP (Replacement Year: 2031)

◦ 16-inch Surge Relief Valve in Lake Palestine WTP (Replacement Year: 2031)

◦ 12-inch Surge Anticipator Valve in Golden Road WTP (Replacement Year: 2029)

◦ 12-inch Surge Protector Valve in Golden Road WTP (Replacement Year: 2029)

◦ Raw Water Meter in Golden Road WTP (Replacement Year: 2029)

◦ 1st and 2nd Stage Mixers in Golden Road WTP (Replacement Year: 2021)

◦ High Service Pumps in Golden Road WTP (Replacement Year: 2022)

◦ 72-inch Standpipes supporting Golden Road WTP (Replacement Year: 2022)

◦ Update the listing in Appendix A, Asset Inventory, into GIS as new equipment is installed or rehabilitation or replacement is conducted on existing assets. Also, include existing assets that are not in Appendix A.

◦ Special consideration should be given to rehabilitation/replacement recommendations for the Golden Road WTP. Subsequent sections of this report recommend eventually abandoning the existing plant and replacing it with a new one at a different location. So before proceeding with renewal projects at Golden Road, consideration

should be given as to the necessity of those projects given the likely short remaining life of the existing plant.

◦ After executing its planned filter media replacement at Lake Palestine in 2024, the City should evaluate any performance differences in the next five years. The basins currently use their original filter media, which has served over twice its target life cycle. The City should establish a regular schedule on which to replace the filter media based on the manufacturer’s recommendations.

◦ According to staff, the sedimentation basins at Lake Palestine WTP do not have significant operational problems due to its cracks and leaks. While periodic blowdowns are currently sufficient for the plant’s needs, the City should consider having an engineer evaluate the structure’s integrity and determine an appropriate time to pursue its repair or replacement.

Drinking water quality standards ensure that water collected, treated, and distributed by a public water system (PWS) is safe to consume. Environmental Protection Agency (EPA) is an agency of the United States federal government tasked to set and enforce a minimum national drinking water standard. EPA authorizes Texas Commission on Environmental Quality (TCEQ) to implement the safe drinking water act in Texas. It is responsible for ensuring the compliance of a system with TCEQ rules, conducting required monitoring, and providing public notifications. TCEQ has published the drinking water standards governing drinking water quality in Chapter 30, Texas Administrative Code (TAC) Chapter 290, Subchapter F. The City is authorized to treat raw water from Lake Palestine WTP and Golden Road WTP following the current regulatory requirements. The section below describes the drinking water regulations recently updated and/or anticipated for revision in the future with respect to drinking water quality aspects.

SDWA was formulated in 1974 to protect public health by regulating the public drinking water supply. It was amended in 1986 and 1996. The 1996 amendments greatly enhanced the existing law by recognizing the importance of protecting water from the source to the tap. Source water protection, operator training, funding for water system improvements, and public information were added as components of SWDA. The general flow of the SDWA regulatory process is outlined in Appendix C, as is a summary of the regulations described below.

Exposure to lead and copper may cause adverse health effects such as stomach distress to brain damage. The recommended exposure level of lead is zero for children. Lead typically enters drinking water when lead and copper plumbing materials, commonly used before 1986, begin to corrode. Lead

is subject to a treatment technology standard rather than a maximum contaminant level (MCL). The LCR was published in 1991 by the EPA to control lead and copper in drinking water.

The treatment technique for the rule necessitates systems to monitor drinking water at customer taps. If 10% of the samples exceed the action level (AL) of 15 parts per billion (ppb) and 1.3 parts per million (ppm) of lead and copper, respectively, additional actions such as corrosion control treatment, source water monitoring and treatment, lead service line replacement, and public notification must be undertaken. Additionally, the samples should be monitored every six months after the corrosion control techniques have been initiated or optimized. However, the frequency of monitoring can be reduced if systems continuously meet AL.

According to the City of Tyler 2020 Drinking Water Quality Report, the water system is below the action limit for lead and copper. Before 2012, the lead and copper samples were collected triennially. For failing to take lead and copper tests in 2014, the City of Tyler received a “Notice of Violation” in 2014 and was required to submit a “Public Notice” in January 2015. Tyler water system was below the action limit for lead and one-tenth over the action limit for copper, according to the 2015 lead and copper sampling suite results. Old households in the City have lead fittings. The City’s Water System has complied with the lead and copper rule since 2016. Refer to Appendix C for the detailed report. The City conducted a water system corrosion control study on September 2020 in response to the letter from TCEQ. Tyler currently utilizes pH treatment in the form of sodium hydroxide (caustic) to control corrosion within the City’s water system.

The lead and copper rule revisions (LCRR) took effect on December 16th, 2021. The four major improvements in the rule are provided below.

The rule maintains a 15 ppb action level but establishes a new threshold of 10 ppb, which, when exceeded, requires rapid corrosion control treatment to reduce lead in drinking water. The systems that currently treat for corrosion would be required to re-optimize their existing treatment at this trigger level. Alternatively, systems that do not treat for corrosion will conduct a corrosion control study, which aids the system in responding quickly when necessary.

The current rule emphasizes corrosion control to protect against lead and prepares systems for soluble and particulate lead. Improved corrosion control will improve protection against soluble lead, whereas service line replacement will reduce particulate lead.

Under the current revision, the EPA proposes improving sample collection procedures, sample site location, monitoring frequency, and public notification. If a sample collected is above AL, water systems should notify the homeowners within 24 hours. Additionally, the EPA requires community water systems to test for lead in drinking water in elementary schools and childcare facilities. The tap sampling plan must be complete by October 16th, 2024.

The rule requires local governments and water systems to create a public inventory of lead service lines. This helps to determine areas likely to have lead-contaminated drinking water needing remediation. A find-and-fix assessment is initiated if LCR compliance sampling at an individual home produces a result of 15 parts per billion (ppb). The lead service inventory must be submitted by October 16th, 2024.

As per the current EPA proposal, if a customer replaces the customer-owned portion of the line, the water system owner will have to replace the

system-owned portion of the lead service line. The proposal requires systems to replace a minimum of 3% of lead lines annually if the action level is exceeded. Systems above 10 ppb but below 15 ppb must work with the state to set an annual goal for lead line replacement.

The full compliance date for LCRR is proposed as October 16th, 2024. The two actions water systems must complete by the compliance date are the lead service line replacement and tap sampling plans. Additionally, EPA proposed to develop a new rule, the Lead and Copper Rule Improvements (LCRI), to reinforce the regulatory framework. The final action date for LCRI is scheduled before October 16th, 2024.

EPA started rule-making to establish perchlorate regulation in 2008. In 2009, the EPA published an interim health advisory of 15 µg/L for perchlorate and, in 2011, decided to regulate perchlorate in drinking water. Since 2011, EPA has found that perchlorate levels in drinking water supplies have declined due to actions taken by the EPA, states, and local communities, including reducing sources of perchlorate contamination and improving water system operations. The EPA published a notice of proposed rule-making for perchlorate in drinking water in the Federal Register in June 2019. The EPA proposed setting the MCL and Maximum Contaminant Goal Level (MCGL) at 0.056 mg/L (56 µg/L). The treatment technologies demonstrated to be effective in reducing levels of perchlorate are anion exchange, biological treatment, reverse osmosis, point of use, and point of entry reverse osmosis.

On July 21st, 2020, the EPA made a final action regarding the regulation of perchlorate under the SDWA. The EPA determined that perchlorate does not meet the criteria for regulation under the SDWA considering the available science and positive steps that EPA, states, and public water systems have taken to reduce perchlorate levels. Therefore, the agency is withdrawing the 2011 regulatory determination. The EPA is making a final determination not to issue a national regulation for perchlorate.

In October 2014, the EPA preliminarily determined to regulate strontium in drinking water. Strontium can impact bone strength in people who do not consume enough calcium.

EPA set non-regulatory health advisory levels for strontium for one-day, ten-day, and lifetime duration. The health advisory threshold for the one-day and ten-day duration is 25,000 µg/L. The health advisory threshold for lifetime exposure is 4000 µg/L per the EPA 2018 Edition of Drinking Water Standards and Health Advisories Tables.

On January 4th, 2016, the EPA delayed the final regulatory determination on strontium to further review data and determine if there is a meaningful opportunity to reduce health risks by regulating strontium in drinking water.

Coliform is bacteria found naturally in the environment and utilized as a marker for the presence of other potentially hazardous bacteria or a potential channel for contamination to infiltrate the drinking water distribution system. The presence of E. coli could indicate contamination, resulting in diarrhea, cramps, nausea, headaches, or other symptoms.

The Total Coliform Rule (TCR) formulated in 1989 set both an MCGL and MCL for the presence of total coliforms in drinking water. MCGL level is at zero, and MCL levels are based on the positive sample tests for total coliforms (monthly MCL) or total coliforms and Escherichia coli (E. coli) or fecal coliforms (acute MCL). The purpose of the 1989 TCR was to monitor microbial contamination, such as total coliforms, in the drinking water system and protect public health by ensuring the integrity of the drinking water distribution system.

Refer to Appendix C for the City of Tyler Drinking

Water Quality Report from 2013 to 2020. Although two samples collected in 2020 tested positive for E. coli., the resamples tested negative. The MCL for Total Coliform Bacteria was exceeded in October 2020, and the repeated test results were negative. Level 1 assessment was executed by the City, and TCEQ accepted the City’s Assessment identifying no sanitary defects in the City of Tyler’s Public Water System. Additionally, the City conducted a level 1 assessment and adopted the corrective action in 2017 due to the presence of coliforms.

On February 13th, 2013, EPA published the Revised Total Coliform Rule (RTCR) in the Federal Register (78 FR 10269). The rule took effect on April 1st, 2016. This revision focuses on a preventative approach (“Find and Fix) rather than a response based.

RTCR specified the frequency and timing of microbial testing based on the system-specific sampling plan for total coliforms and the population served. Systems must assess Level 1 or 2 based on the triggers of the treatment technique.

Level 1 Trigger:

◦ If testing 40 or more samples per month, the system exceeds 5% total coliform-positive sample

◦ If testing fewer than 40 samples per month, the system has two or more total coliform positive sample

◦ Fails to monitor with all repeats after a Total Coliforms (TC)+

Level 1 Assessment:

The basic examination of the water system to try to identify the cause of TC+ samples such as examination of source, treatment system, distribution system, operational practice, sampling location, and procedure

Level 2 Assessment Trigger:

◦ E.coli MCL violation

◦ Second Level 1 trigger in 12 months

◦ Level 1 trigger in 2 consecutive years

In-depth examination of water system source, treatment system, distribution system, operational practice, sampling location, and procedure

Treatment technique violations occur when an assessment is triggered and fails to timely complete the assessment or corrective action. Severe violations are based on a positive E.coli when a repeat sample is E.coli following a Total Coliform positive routine sample or a system fails to test for E.coli when any repeat sample is TC+. Systems must measure disinfectant residual at least at the exact location and time as total coliform samples are sampled.

Cyanobacteria found naturally in surface waters can produce cyanotoxins under certain conditions that pose health risks to humans, such as musty taste and smell, gastroenteritis, liver damage, and kidney damage. Conventional water treatment (coagulation, sedimentation, filtration, and chlorination) can remove intact cyanobacterial cells. However, this can pose challenges to the water treatment system during a severe bloom event. The selection of effective treatment procedures depends on the growth patterns and species of cyanobacteria.

In 2015 EPA released an algal toxins health advisory for cyanotoxins, cylindrospermopsin, and microcystins, as shown in Table 4.1. Health Advisory describes concentrations of drinking water contaminants at which adverse health effects are not anticipated to occur over specific exposure durations (e.g., one day, ten days, several years, and a lifetime).

EPA did not propose any regulatory determination regarding cyanobacteria or cyanotoxins. The unregulated Contaminant Monitoring Rule (UCMR 4) includes an assessment of nine cyanotoxins and one cyanotoxin group, such as microcystin, nodularin, anatoxin-a, and cylindrospermopsin. Based on this assessment, the limited occurrence of cyanobacteria did not justify the need for national regulation.

The City detected the unregulated contaminant Anatoxin-a in the year 2018 and 2019. Refer to Appendix C for the City of Tyler Drinking Water Quality Report from 2013 to 2020.

The SWTR protects the PWS from pathogens, such as Giardia lamblia, Legionella, and Cryptosporidium, and contaminants that can arise during drinking water treatment. These microorganisms can induce gastrointestinal disease if consumed. The SWTR emphasize treatment techniques instead of MCLs for microorganism.

This SWTR is a combination of rules designed to protect from microbial pathogens and applies to all PWS using surface water. A minimum of three and four log removal of Giardia and Virus are required per this rule. The disinfectant contact time requirements are shown in Table 4.2.

This rule applies to all systems using conventional or direct filtration treatment that recycle spent filter backwash water, thickener supernatant, or liquids from the dewatering process.

Treatment technique requirement: All recycle flows must be returned at the head of the plant so that complete treatment of recycle stream is provided.

Long Term 1 Enhanced Surface Water Treatment Rule (LT1ESWTR)

This rule applies to all PWS using surface water. Treatment efficacy is demonstrated by combined effluent turbidity ≤ 0.3 Nephelometric Turbidity Unit (NTU) measured at conventional and direct filtration units in 95% of monthly measurements. The maximum turbidity limit is 1NTU. If the PWS meets filtered water turbidity criteria, it is assumed to achieve the required 2-log Cryptosporidium removal.

Long Term 2 Enhanced Surface Water Treatment Rule (LT2ESWTR)

This rule applies to all PWS using surface water. Monthly monitoring of Cryptosporidium for two years is required to characterize the source water. Calculated Cryptosporidium concentration defines the required level of additional treatment.

The City has met all turbidity requirements since 2013. Refer to Appendix C for the turbidity results from the City of Tyler Drinking Water Quality Report from 2013 to 2020. Additionally, Halff analyzed the surface water monthly operating report for both WTPs from June 2021 to November 2021. The treatment plant’s performance on turbidity, disinfectant residual, pH, and TOC removal requirements was within acceptable standards. Cryptosporidium is found only in the City’s untreated water as the treatment process removes cryptosporidium.

EPA identified 8 National Primary Drinking Water Regulations as candidates for revision at the 3rd 6-year review in January 2017. A few of the eight candidates are Cryptosporidium, heterotrophic bacteria, Giardia lamblia, Legionella, and viruses.

The EPA determined that new information on health effects, treatment technologies, etc. requires a detailed analysis of the SWTR and its components. The EPA is currently seeking public comments. No regulatory decision has been made regarding these contaminants. The schedule for the draft and final rules are proposed to be out by July 2024 and September 2027, respectively.

Disinfection of potable water is critical to protect the public from disease-causing microorganisms. The reaction between naturally occurring materials found in untreated drinking water and disinfectants such as chlorine and ozone produces disinfection byproducts. Some of these cause short and long-term health effects. Out of the hundreds of disinfectant byproducts formed in drinking water, total trihalomethanes (TTHM), five haloacetic acids (HAA5), bromate, and chlorite are regulated by the EPA.

The EPA has developed DBPR to protect public health by limiting exposure to disinfectant byproducts. The DBPR is part of the Microbial and Disinfection Byproducts Rules (MDBPs). The stage 1 disinfectant byproduct rule, formulated in 1998, applies to all Community Water Systems (CWS) and reduces drinking water exposure to disinfection byproducts. The compliance is based on the annual arithmetic average of monthly averages. The stage 2 DBPR formulated in 2005 applies to CWS that adds a primary residual disinfectant other than UV or delivers water that has been disinfected. The DBP-2 rule requires systems to conduct an initial distribution system evaluation to determine the highest-risk sample sites for DBPs in the distribution system. Based on this rule, compliance has to be calculated at each sample site individually using locational running annual averages (LRAA) contrary to a system-wide average. PWS are more likely to experience water compliance issues under DBP-2 compared to DBP-1 since distribution issues such as water age can increase locational THMs and / or HAA5s.

The SDWA sets Maximum Residual Disinfectant Levels for chlorine (4 mg/L), chloramines (4 mg/L), and chlorine dioxide (0.8 mg/L) and set MCLs for four disinfection byproducts: (1) TTHMs (0.08 mg/L), (2) HAA5 (0.06 mg/L), (3) bromate (0.01 mg/L), and (4) chlorite (1.0 mg/L).

Compliance is evaluated quarterly, based on locating running annual averages from the City’s eight current compliance monitoring sites. The City has recently experienced intermittent periods of noncompliance with DBPR. Appendix C shows the City has received Notices of Violation for exceeding the maximum contaminant level for THM in the 1st quarter and HAA5 in the 1st and 2nd quarters of 2016 and 3rd and 4th quarters of 2015. The City’s Water System has complied with the DBPR rules since 2017 (Refer to Appendix C for the detailed report). The City detected the unregulated contaminants N-Nitrosodiethylamine, Bromodichloromethane, Bromoform, Chloroform, and Dibromochloromethane in 2017 and 2016 per the drinking water quality report. Also, HAA5, HAA6Br, HAA6, and Manganese were detected from 2018-2020.

In 2015, eHT completed an operational evaluation of the WTPs and identified potential improvements for continued compliance to DBPR. Table 4.3 summarizes the WTP’s initial and potential compliance strategies and status. Refer to Initial Operational Evaluation Report (eHT, 2015) for detailed recommendations.

EPA identified eight National Primary Drinking Water Regulations as candidates for revision at the 3rd 6-year review in January 2017. A few of the eight candidates are Chlorite, haloacetic acids (HAA), and Total Trihalomethanes (TTHMs). Potential revisions focus on improving and expanding DBP protection, such as revising MCL for HAA5, expanding focus to brominated HAAs through HAA6Br or HAA9, and revising precursor removal requirements. Additionally, EPA is also assessing information on unregulated DBPs, including chlorate and nitrosamines.

EPA determined that new information on health effects, treatment technologies, etc. require detailed analysis in the DBPR. Thus, the EPA is currently seeking public comments. No regulatory decision has been made regarding these contaminants. The schedule for the

draft and final rules are proposed to be out by July 2024 and September 30th, 2027, respectively.

Table 4.3: Initial Operational Evaluation Report Recommendation (eHT, 2015)

WTP Recommendations Implementation Status from City Initial Compliance Strategies

Both Utilization of sodium hydroxide to optimize pH Implemented

Both Addition of multiple ammonia application points Not Implemented

GR Relocation of ammonia application point Implemented

LP

Both

Developing disinfection credit for ozone, specifically at the end of disinfection zones D3 or D5 Implemented

Potential Compliance Strategies

Utilize enhanced coagulation for TOC Reduction

a) Reduce lime application OR

b) Use advanced coagulant

Implemented. Optimized coagulant dose and lowered lime dose

Both Evaluation of free chlorine contact zones Not Implemented

Both Post -Clearwell chloramine boost Not Implemented

GR Modification of clearwell piping Implemented

GR Addition of raw water oxidation capability Not Implemented

PFAS are a group of synthetic chemicals utilized in various industries and consumer products since the 1940s. According to current scientific evidence, excessive amounts of some PFAS may cause adverse effects such as cardiovascular health issues. It endures in the environment and can bioaccumulate, or buildup, in the bodies of animals. However, studies are still being conducted to identify how varying levels of PFAS exposure can result in a range of health impacts. PFAS were included in UCMR 3. The most frequently detected PFAS were Perfluorooctane Sulfonic Acid (PFOS) and Perfluorooctanoic Acid (PFOA). In 2016, EPA established a formal Health Advisory Level (HAL) for these two compounds. Additionally, EPA developed a PFAS Action Plan in February 2019, which included specific goals related to additional research to regulate the contaminant.

Certain technologies have been discovered to remove PFAS from drinking water, particularly PFOA and PFOS, such as activated carbon adsorption, ion exchange resins, and high-pressure membranes.

The EPA declared that it is proposing to regulate PFOS and PFOA In February 2020 under the SDWA. The EPA has developed and provided four new draft documents to the Science Advisory Board (SAB) PFAS Review Panel for scientific review of these documents. The information from these documents would aid in updating the health advisory on PFOA and PFAS as well as setting the proposed PFAS National Primary Drinking Water Regulation for publication in Fall 2022. PFOA is a carcinogen; typically, MCLGs for carcinogens are set to “0”. Based on the revised approach for assessing the toxicity of PFOA and PFAS, lower toxicity values are proposed by EPA, as shown in Table 4.4.

While PFOA and PFOS are the most widely used and studied chemicals in the category, the EPA is seeking public input on draft toxicity assessments for GenX chemicals and perfluorobutane sulfonic acid (PFBS) to expand the public’s knowledge of other PFAS.

EPA will establish a National Primary Drinking Water Regulation for PFOS and PFOA if a positive regulatory determination is finalized. Refer to Appendix C for the strategic timelines for PFAS Roadmap. Additionally, 29 PFAS are included in UCMR 5 to analyze the occurrence and frequency of the contaminant in the nation’s drinking water system. Based on the draft UCMR, water systems will be asked to look for different sources of PFAS within their watershed in addition to monitoring.

The disinfection process in a WTP is evaluated in a CT study. The concentration (C) of a disinfectant and the theoretical contact time (T) of a disinfectant in each stage of treatment are the factors used to compute CT. Surface water monthly operating reports (SWMORs) for surface water systems are completed using the data obtained from the CT study. CT study helps to determine an effective contact time, number of disinfection zones required and verify the WTP’s compliance with disinfection requirements. CT studies are required for approval of a new WTP, WTP renovation, or to grant an exception request.

A disinfection zone is the section of the plant beginning at a disinfectant injection or monitoring point and finishing at the subsequent disinfectant injection or monitoring point. Golden Road WTP has three disinfection zones, D1, D2, D3A, and D3B. Disinfection is obtained through free chlorine in zone 1 and chloramines in the remaining zones. Golden Road WTP received an exception to the 0.5 NTU effluent turbidity rule in June 1993. Based on the submitted tracer study, the plant provided 16 minutes of T10 contact time in filters at the maximum rated capacity of 32 MGD.

PFOS 20 ng/kg-day 0.0079 ng/kg-day

Lake Palestine has eight disinfection zones, D1A, D1B, D2A, D2B, D3, D4, D5, D6, D7, D8. Disinfection is obtained through ozone in D1A to D5, free chlorine in zones D6, D7, and chloramines in D8. Based on the CT study conducted on April 24. 2012 for Lake Palestine,

the primary disinfectant and CT credit is based on measured ozone residual within the ozone contactors, followed by free chlorine and/or chloramine use in later stages. However, based on the current site conditions, ozone cannot obtain disinfection with any regularity. The only way to consistently use ozone for disinfection credit is to perform a major upgrade to the system. Disinfection zone D6 includes rapid mix, flocculation, and sedimentation basin. Disinfection zone D7 encompasses filters and disinfection zone D8 includes clearwell inlet boxes, clear wells, and high-service pump station wet wells. Halff analyzed the surface water monthly operating report for Golden Road and Lake Palestine WTP from June 2021 to November 2021. The treatment plant’s performance on giardia

and virus inactivation was within the performance standards established by the CT study.

The City is authorized to treat raw water from Lake Palestine WTP and Golden Road WTP following the current regulatory requirements from EPA and TCEQ. WTP expansion and upgradation works must stay abreast of the new development in drinking water regulations because they will undoubtedly have a significant impact on the choice of design of other treatment processes. The following table summarizes the City’s compliance with the current regulation and potential regulations to be on City’s radar.

City of Tyler compliance with the regulation Potential regulations/revisions to be on City’s radar

◦ Compliant based on the 2020 DWR

◦ LCRR compliance date: October 16th, 2024

◦ Trigger Level (10ppb)

◦ Monitoring, testing procedure, location, and frequency of regulatory updates

◦ Lead service line public inventory development and replacement plan

◦ New regulation: Lead and Copper Rule Improvements (LCRI). The final action date before October 16th, 2024

◦ Compliant based on 2020 DWR and repeated sampling results. TCEQ accepted the level 1 assessment conducted by City

◦ Compliant based on the 2020 DWR

◦ Draft and final revised rules to be released in July 2024 & September 2027

◦ The City has experienced intermittent periods of noncompliance with DBP regulations. Currently compliant with the DBPR rule since 2017

◦ Not yet regulated, so there is no compliance status to speak of yet.

◦ Potential revision to MCL for HAA5

◦ Focus on brominated HAAs and revised precursor removal requirements

◦ Draft and final revised rules to be released in July 2024 & September 2027

◦ Proposed PFAS DWR for publication in Fall 2022

◦ Monitor 29 PFAS in UCMR 5

◦ Water systems to look for different sources of PFAS within their watershed

Environmental legislation and regulation requirements are a significant consideration in selecting technology and designing the treatment process. The TCEQ has regulations on WTP design, operation, and maintenance requirements for PWS. To communicate these requirements, the TCEQ has published a set of rules and requirements compiled in 30 TAC, Chapter 290 Subchapter D. This chapter lists the minimum standards a public drinking water system must meet to comply with these rules. TCEQ conducts a comprehensive compliance investigation (CCI) of each community’s PWS every three years. The City is authorized to operate and maintain Lake Palestine WTP and Golden Road WTP following the TCEQ regulatory requirements. The capacities and characteristics of the treatment units were compared against the requirements established in the TCEQ. See Appendix D for a detailed evaluation.

Capacity: Any surface water treatment plant that provides or is being designed to provide

1. 7.5 MGD or more must be able to meet either the maximum daily demand or

2. the minimum required 0.6 gpm per connection, whichever is larger, with the largest filter offline.

Lake Palestine and Golden Road WTP design treatment capacity are 30 MGD and 28 MGD, respectively. The actual capacity at Golden Road WTP is 28 MGD, and the typical production rate is 22 MGD. With the largest filter offline, the WTP capacity exceeds the maximum daily demand.

Capacity: Surface water supplies must meet the following requirements:

1. a raw water pump capacity of 0.6 gpm per connection with the largest pump out of service

2. a treatment plant capacity of 0.6 gpm per connection under normal rated design flow

3. a covered clear well storage capacity at the treatment plant of 50 gallons per connection or, for

systems serving more than 250 connections, 5.0% of daily plant capacity

The total number of connections in the study area is 34,040. For an assumed peaking factor of 2.5 and 60/40 split between Lake Palestine and Golden Road WTP.

Lake Palestine WTP:

1. Required RW pump capacity: 12254.4 gpm, RWPS (1 stand-by) = 20833.2 gpm

2. Required treatment plant capacity = 17.6 MGD, Rated treatment plant capacity = 30 MGD

3. Required clear well storage capacity = 1.5 mg. Actual storage capacity of 1 tank = 1.99 mg (total two tanks)