This Issue

(Volume 4 / Issue 1)

• CIM MER Society Member’s Corner p. 2 - Historical Background

• Calendar of CIM MER Events p. 3

• Stories of Interest to MER Society Members p. 4–9 - “The pursuit of autonomous mining” - “Loading up on improvements”

• CIM MER Society AWARDS p. 10

• CIM MER Society SCHOLARSHIPS p. 11–14

- Introductory remarks by Dean Millar - CIM MER 2022 Scholarship Winners

• CIM Journal & Paper Submissions p. 15

• MER Abstracts from Latest Articles p. 16-20

- Special Issue – Innovations in Underground Ventilation

• MTL 23 Technical Program p. 21

• Hoist & Haul 2023 Technical Program p. 22

• CIM MEMO 2023 Conference Topics p. 23

• CIM MER Executive & Newsletter Committees p. 24

• Some CIM MER Society Supporters & Patrons p. 24

MER Today

MER Today is our digital publication covering CIM MER Society news and improvements in Maintenance, Engineering and Reliability in mining.

CIM/ICM StrategicPlan 2021–2023

Quotes:

Vision - Advancing minerals industry knowledge

Purpose - Collaborating towards a sustainable future

1 | MER Today– Spring 2023 MERToday–Spring2023

CIM MER Historical Background

In 1961, the CIM Council approved formation of the “Mechanical-Electrical Division ” In 1984, the name was changed to the “Maintenance and Engineer Division ” During the March 2013 CIM Council meeting, the name was again updated to the “Maintenance, Engineering and Reliability Society (MER).” During the past 50 years of existence, the Society name has been updated to reflect a growing mandate due to the increasing technology, innovation, research, and complexity in all aspects of mining, milling, smelting, and refining processes.

In 1898, the organization now known as the Canadian Institute of Mining, Metallurgy and Petroleum (CIM) was incorporated through an act of the Parliament of Canada. Since its inception 125 years ago, the CIM continues to grow while sustaining its vision of being the leading and preferred technical society providing “World class professional development, networking and knowledge sharing” for everyone from students to all professionals working in the minerals, metals, materials, and energy industries. The CIM now boasts close to 15,000 members, of which more than 1,600 are international members in 30 Branches and 10 Societies (Professional Groups or Divisions) covering all of Canada and expanding globally.

2 | MER Today– Spring 2023

Calendarof CIM MER Events

CIM Convention & Expo

Apr 30 – May 3, 2023, Montreal, QC

“Building Trust to DECARBONIZE the World”

International Conference on Hoisting and Haulage

August 13 – 16, 2023, Montreal, QC

CIM MEMO 2023

Sep 17 – 20, 2023, Saskatoon, SK

3 | MER Today– Spring 2023

Stories from CIM Magazine of interest to MER Society members

The pursuit of autonomous mining

Ryan Bergen, Editor-in-Chief, CIM Magazine

Using short-term underground mine scheduling for autonomous fleets can bring efficiency benefits

By Angelica Zagorski

By Angelica Zagorski

Using constraint programming can lead to higher efficiencies in scheduling autonomous vehicle fleets at mine sites Autonomous mining is trending across the industry, but there are still obstacles to its implementation. Among these roadblocks are mine scheduling processes, which put simply, tell mining vehicles where to go and when. Scheduling is still mostly done manually, but with the possibility of automating scheduling, workers could be moved above ground from dangerous underground environments.

In a new study titled, “Short-term Underground Mine Scheduling: An Industrial Application of Constraint Programming,” Max Astrand, R&D lead engineer at the Switzerland-based technology corporation, ABB, explained how automating the short-term mine scheduling process can increase efficiency in a vital part of the underground mine planning chain.

Short-term scheduling plans are the basis for operational mine production and operation schedules. They make long-term mine plans more feasible and also ensure a steady flow of products, allowing companies to meet production targets.

At the same time, however, they are also becoming a bottleneck in the planning chain. Modern mines are moving to automated equipment and semiautonomous machines, and scheduling what a machine does, when it does it, and where it does it, is still done by humans. As a human activity, scheduling is prone to human errors, not to mention its timeconsuming nature. Astrand’s research moves towards fully automating the scheduling process to a solution with minimal risk or error.

“By automating this, you can react faster to process disturbances like task delays and machine breakdowns,” says Astrand

Astrand’s research presents a mine scheduling algorithm that draws inspiration from artificial intelligence, operations research, and computer science to develop a method called “constraint programming.” This method is not new to industrial processes; it is frequently used in other industries.

4 | MER Today– Spring 2023

In simple terms, constraint programming is when you specify a problem through the constraints it needs to satisfy. An algorithm using constraint programming will use these constraints to reduce the possible values of the decision it needs to make, reducing the number of actions it can take. The deductions made from the first decision then propagate to further decision variables until a solution is found that satisfies all constraints.

Constraint programming has become an important technology for solving hard combinatorial problems in a diverse range of application domains. Astrand gave the example of using constraint programming to automate the gate allocation at the Hong Kong airport. This type of programming is also used to create plans for one of the world’s largest container shipment hubs in Singapore and creates the daily timetable for the public railway system in the Netherlands. Needless to say, the method is not new and is thoroughly tested and used in everyday life.

“With these methods, you can not only construct schedules fast, but you can make better schedules by making good use of the available resources,” says Astrand.

By using constraint programming, a company can automate the schedule construction, answering the when, what, and where of hundreds of activities in a couple of seconds, without introducing resource conflicts. This kind of task would normally takehours if done manually. According to Astrand, this

programming can improve mine productivity by up to 12% while ensuring safe operations: “In an industry where throughput is everything, and every percentage counts, this presents a major opportunity to sustain mine operations as costs increase.”

“Using an autonomous short-term scheduler has its benefits and saves a company time and money,” says Astrand. “You can make the scheduler emphasize higher-level decision making, adjust to monthly plan compliance and these kinds of things, rather than spending the entire day putting out fires.”

Things often go wrong in mining, and manual scheduling simply leaves room for more error with conservative schedules. “To avoid ending up in situations where you need to reschedule, you introducethis kind ofartificial bufferin your schedule. And these buffers, when they are not exploited, are like missed opportunities for production,” Astrand says.

Through using well-functioning scheduling algorithms, miners are getting closer and closer to operating fully automated mines. Dangerous underground environments could be a notion of the past if the pursuit of the autonomous mine continues.

“The actual short-term scheduling problem becomes more complex as you go deeper and it makes it harder for manual schedulers, that currently are on the edge of what they can handle, to cope going into the future,” Astrand says. “I foresee that this becomes increasingly important as mines go deeper.”

5 | MER Today– Spring 2023

Stories from CIM Magazine of interest to MER Society members

Loading up on improvements

Combining electrification and automation can lead to operating efficiencies

By Robert Hiltz

Direct drives on electric loaders, like this Sandvik LH518B, give operators precise control of their vehicles. Courtesy of Sandvik

More than just environmental efficiency, electrification brings precision to mining operations far and above what is possible with diesel equipment.

This means that when electrifying parts of a mining fleet, you can create all sorts of benefits for your operation down the line. The advantages become particularly evident once loading and drilling activities are automated.

David Hallett, Vice-President of Automation at Sandvik, explains that the precision advantage of electric equipment will help his company solve some difficult automation problems.

“Loading, in particular, autonomously has been a tough nut to crack over the years. We are able to engage the loader in a much more effective way utilizing electric drives, rather than traditional mechanical drives, so our fill factor is realized. And

Ryan Bergen, Editor-in-Chief CIM Magazine

we’re also able to control the wheel spin in a much more efficient way.”

Unlike their internal combustion engine (ICE) counterparts, electric vehicles typically use directdrive technology. This means that rather than connecting the motor to the moving parts of the vehicle through a transmission (with its assortment of gears and clutches), the motor is essentially connected directly to the wheels. This results in less loss of power from the motor to the wheels than experienced by ICE equipment, and at the same time, provides more precise control over the vehicle.

Typically, when loading from a muck pile whether there is a driver in the cab, an operator running the loader remotely, or an autonomous system in command driving a diesel loader into the pile requires a certain amount of finesse and judgement to accurately place the bucket into the rock and fill it to capacity. Diesel-driven equipment has a lag time from when the throttle is applied to when the power makes its way to the wheels, and this can result in too much or too little power being used at the exact moment it is needed. Too much power and the wheels spin, causing damage to their rubber; too little power and the loader needs to take a second run into the pile to come away full.

6 | MER Today– Spring 2023

Electric drives solve this by reducing the lag time and delivering more precise control of how quickly the vehicle encounters the pile and where exactly the loader meets the rock. Brian Huff, Vice-President of Technology for battery and hybrid electric vehicles at Sandvik, says the control comes from the accuracy and speed of data that is available from an electric pieceof equipment. “Because we have very direct and accurate feedback on motor torque, we can translate that directly to tractive effort.” Tractive effort is the force exerted by powered equipment and is measured at the rim of the driving wheels.

“We know exactly how hard we’re pushing into the muck pile. That feedback variable was really difficult to obtain with a torque converter on a diesel engine,” says Huff. “You don’t know how much of that power is actually getting to the wheels.”

According to Huff, the telematics data generated by a BEV is one of the enabling factors to more precisely control and automate the handling of a vehicle.

“Where you had less feedback before [from ICE vehicles], now you’ve got so much information that it’s accelerating the improvements in the loading cycle,” he says. “We can vary torque about 5,000 times per second, so we have really, really tight control over power and speed. It’s not just the speed feedback, we know the position of the rotor at every instant. It’s that refined, and it’s inherent in the driveline technology that we’re implementing. That translates to controllability.”

Drilling is another function where an electric drive’s controllability makes a compelling case for its use, according to Johannes Välivaara, Sandvik’s global product line manager for mining and tunnelling.

“The customer would first drill a full fan and then move the unit two or three metres backwards, continuing to drill the next [fan],” Välivaara says. “Electrification, by its nature, provides much better precision on how you actually position the unit, because now we have a direct mechanical connection from the electric motor to the drive line versus a conventional solution, where you might have a diesel engine, the torque converter and the gearbox.

“That electrified solution brings much better accuracy in drilling, particularly when you are looking to position your equipment at the right location from where the drilling would continue,” he says.

A battery-powered drill also offers a side benefit, in that the onboard battery can make up for drops in power availability to the mine’s infrastructure during high-load times or when faced with other limitations.

“We can draw the reserve power from the batteries to balance the drilling itself. Being able to adapt in conditions where there are limitations – for example, how much power you can pull through the electrical infrastructure – actually represents a possibility to boost your drilling productivity,” Välivaara says.

7 | MER Today– Spring 2023

Of course, automation is still possible with diesel equipment. But getting close to the same levels of precision that are achievable with electric vehicles requires adding sensors to ICE equipment, often on the outside of the parts in question, putting them in vulnerable areas.

“Those are often add-ons that are external sensors outside of the gearbox, or the axle, which are susceptible to wear and tear and damage in mining environments,” Hallett says

For companies building new mines, considering both electrification and automation means that the new facilities can be designed with productivity maximization in mind and with a lower price tag.

“Using battery electric vehicles, together with automated systems, [mean] you can also then reduce the development of the [mine footprint] size required for your equipment, which would then reduce the overall total investment that would need to be done for an extraction level,” Hallett says He explains that mine drifts could be much smaller andcheapertooperate without the need to make room for people to walk or ride in a machine, provide sufficient ventilation so that large numbers of people can breathe underground, eliminate diesel engine exhaust, or provide air for internal combustion engines.

Whether they are building new mines or retrofitting existing ones. Sandvik's customers are thinking about automation and electrification at the same time.

“I can see, almost invariably, every customer for battery equipment wants to know if it’s automated,” Huff says “If they’re at that level where they’re looking at technology advancements and they’re looking for optimizing their operation, they’re looking for both. It definitely is not an either or, it is always both.”

That, however, is not the case for every original equipment manufacturer. Patrick Marshall, VicePresident of Product Management at MacLean Engineering, says that, while many of his customers are looking for automation or electric vehicles, these efforts can be siloed within the mining companies.

“Often, the team evaluating electric vehicles for the mine site is different from the team trying to get automation into the mine site,” says Marshall. “This can result in overlooking the combined benefits.”

He can, however, see the day when the two converge. “They’re closing the gap for sure where people will talk about how the two work together much more frequently ”

8 | MER Today– Spring 2023

As to why some customers are currently looking to do both at once, a large part of the explanation may be generational. Joshua Marshall (unrelated to Patrick Marshall), an engineering professor in the Mining Department at Queen’s University, focuses on automation. He says that some of the reason for these mines picking both comes down to demographics.

“The people who are becoming the managers at mines are now the people who grew up with video games and the Internet and have that kind of technology mindset,” he says. “They’re asking, ‘Why are we not doing this with robots, and why are things not electric?’”

Those questions are even being asked about the tasks that were previously considered impossible to automate, such as changing the bits on a drill, plugging in a machine, or filling a fuel tank. And mining equipment companies are trying to answer them. Sandvik, for example, has created an

AutoSwap system that allows for quick battery changes without the operator leaving the cab. The whole process, from powering up a secondary battery source (so the machine can perform the battery swap without its existing battery), to disconnecting the current battery’s high- and low-voltage connections, to dropping off and picking up a new battery, is automated at the push of a button. All the operator needs to do is position the equipment next to the fresh battery after the used one is dropped to the ground.

“You could deliver a battery to the machine if you wanted to. You don’t have to have a [maintenance] location to take it to,” Huff says “There’s lots and lots of flexibility inherent to the design, it doesn’t need to be flat ground, it doesn’t need to be a prepared surface really in any way. You can swap anywhere.”

“That’s going to directly lead to automating the swapping practice going forward,” Huff says

Down the road, the only underground human intervention to the process might be simply to plug in the dropped-off used batteries into the charging units and return to the surface.

“Somebody just has to come in, unplug one battery, plug in the other battery and then leave. It’s not a continuous labour need, it’s about every four to five hours,” says Huff And it will be just one further step on the road to fully automated mines, or at least as fully automated as possible.

9 | MER Today– Spring 2023

If needed, electric drills like this Sandvik DD422iE, can divert power from their onboard batteries to balance drilling demands. Courtesy of Sandvik

CIM MER Society AWARDS

McParland Memorial Award

For Excellence in Maintenance, Engineering and Reliability

CIM Distinguished Service Medal

For meritorious service to the Institute or the minerals industry

CIM Distinguished Lecturers

For accomplishments in scientific, technical, management, or educational activities related to the minerals industry

CIM Fellowship

For outstanding continuous contributions to CIM and/ or the mining, metallurgical and petroleum industries

The CIM MER Graduate Student Research Excellence Award

The aim of the award is to provide a platform for the dissemination of innovative thinking of benefit to the mining industry from the Society’s brightest new minds, and to provide a means to allow such contributions to be recognized

The CIM MER Graduate Student Research Excellence Award

The aim of the award is to provide a platform for the dissemination of innovative thinking of benefit to the mining industry from the Society’s brightest new minds, and to provide a means to allow such contributions to be recognized.

The award will permit a current or recent graduate student to attend the MER Society’s MeMO conference to present their findings. The winner of the award will be recognized through the peer review process of the CIM Journal. The award is expected to be made annually. It is open to graduate students currently enrolled at a University, or those who have obtained their postgraduate qualification no more than six months prior to submission.

Click HERE for more details.

10 | MER Today– Spring 2023

CIM MER Society SCHOLARSHIPS

1. CENTENNIAL SCHOLARSHIP

2. KEN HILDEBRANT MEMORIAL SCHOLARSHIP

3. EDWARD MELVILLE (Ed) PATTON MEMORIAL SCHOLARSHIP

4. J.D. "PAT" PATTERSON MEMORIAL SCHOLARSHIP

5. MER MEMORIAL SCHOLARSHIP

MER Scholarship Assessors:

Dean Millar, Dick McIvor

For descriptions of all the CIM MER Scholarships, click HERE to access CIM MER website.

Michelle Levesque, Dominique Privé

MustafaKumral,AgusSasmito

MER MEMORIAL SCHOLARSHIP

The CIM MER Memorial Scholarship was created in 2017 and is awarded each year in remembrance of one or more of the Society’s individuals who have attracted prominence and recognition for contributions and service to the activities of the Society.

In 2016 the CIM Diversity and Inclusion best practice guidelines articulated the goal that Diversity become an ingrained, systemic value of the CIM and the mining industry as a whole. Consequently, in 2017 the MER Society decided that MER Memorial scholarship should be used to strengthen the opportunities for access and inclusion to the industry via a post-secondary education pathway for awardees, so that diversity within the Canadian mining industry and associated industries is improved.

Type of Scholarship: Access and/or maintenance scholarship for academically excellent post-secondary students, non-renewable.

Value of Scholarship: $2,500 payable in two equal portions in December and the following February of the academic year for which the award is made. In order to receive the second installment, the recipient must provide an official communication from their institution confirming successful completion of the fall semester.

Eligibility: This scholarship is open to any CIM National member (including student members), or the child or spouse of a CIM National member, enrolled full time at any Canadian post-secondary institution and following a program of relevance to the Canadian mining industry.

Application form

11 | MER Today– Spring 2023

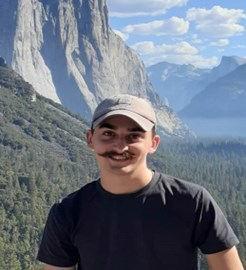

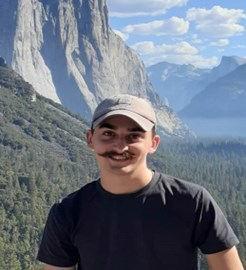

CIM MER 2022 SCHOLARSHIP WINNERS

Introductory Remarks by Dean Millar, PhD, PEng, DIC, FIMMM, CEM, CIM MER Director of Education, Laurentian University

Remarks

Our society wants to encourage brilliant young individuals to join the mining industry to help secure its future. Each year, the Society makes scholarship awards to students studying at post-secondary institutions in Canada in subjects that are relevant to the Society’s mission. The scholarships are open to any CIM National member (including students) or the child or spouse of such a member.

There are currently five named scholarships. For some of them, we are fairly broad minded about relevance of the subject. However, for a couple of them, we are quite strict about the subjects: we confine these to mechanical, civil, electrical, instrumentation, chemical, and manufacturing engineering, together with materials and computer sciences. Check out the details on the MER Society website: https://societies.cim.org/mers/en/awards-and-scholarships/scholarships/

It is never too early or too late to make an application. All applications received by October 31 each year are considered by our Society’s scholarships committee, with awards being made early the following year.

Over the last 10 years, the number of named scholarship programs has grown and on occasion, we have made more than one award under one scholarship heading. The last ‘new’ named scholarship program was the MER Memorial Scholarship, created in 2017. It specifically aims to recognize individuals who have something to contribute to the industry in the areas of inclusion and diversity. We did this because we wish to do whatever we can to ensure that diversity and inclusion become ingrained systemic values of our Society. Our scholarships are not just for university students; those studying at college are eligible too. In future, we will be promoting the availability of these scholarships to the colleges more visibly.

The MER Society’s Graduate Student Research Excellence Award recognizes outstanding articles published in the CIM Journal where the lead author is a graduate student. The winners receive travel and subsistence support from the Society to attend and present their work at the Society’s MEMO conference or the CIM Annual Convention

Finally, we are planning to introduce more named scholarships in future. While the existing named scholarships have academic excellence as a principal criterion, we recognize that traits of excellence aren’t only manifested academically. We are responding with proposals for an award for individuals who have expressed their excellence in non-academic ways.

12 | MER Today– Spring 2023

CIMMER2022SCHOLARSHIPWINNERS CONGRATULATIONS!

Ken Hildebrant Memorial Scholarship

Shubham Arora

Shubham is a 4th year Chemical Engineering Student at Laurentian University. Previously, he completed an advanced diploma in Chemical Engineering from Sheridan College. He also recently completed an internship with a mining company, where he worked in process control and optimization. He also has experience working as a research student, lab analyst, and tutor. He has achieved many accomplishments in his academic career, including the CanadianMineral IndustryEducation Foundation (CMIEF) scholarship, certification of excellence in academics, and an award for outstanding achievement in academics and community involvement. He considers himself to be an engineering student with a strong work ethic, integrity, and leadership skills. He is looking forward to completing his undergraduate degree next year and moving forward in his career.

Centennial Scholarship

François-Xavier Bonin

François-Xavier is a current graduating geology student at McGill University. At 21 years old, he has already won several distinctions, which highlight his academic and leadership skills: NSERC research award, Osisko Scholarship, John Steers Scholarship, and many more. He has been and is still currently working with Prof.

Dean Millar, PhD, PEng, DIC, FIMMM, CEM, Laurentian University

Baker on meimechitic melts. He will pursue a Master’s degree at Laval University next year, working on the Bellefond corridor of the Val-d’Or orogenic gold district with Prof. LaFlamme. A s trong believer in community involvement and giving back, he always hopes to have a positive impact on his environment wherever he goes.

Ken Hildebrant Memorial Scholarship

Knut Lokken

Knut is in his final year of study, pursuing a Bachelor of Science in Engineering and majoring in Geological Engineering from the University of New Brunswick. He previously completed a Bachelor of Science, majoring in Geoscience from Vancouver Island University. He has worked in the mining industry for multiple consulting firms in exploration geophysics and mining hydrogeology. He is interested in continuing to grow a career in the mining industry following graduation. He hopes to gain work experience in dam construction or arelatedfield.The mining industry interests him as it is a dynamic and changing work environment, providing interesting challenges to overcome.

13 | MER Today– Spring 2023

CIM MER Director Education

Ed Patton Memorial Scholarship Jovana Plavšić

Jovana is a PhD student at UBC, where she conducts research on virtual reality-enabled digital twins for remote monitoring and maintenance in the mining industry. Her areas of expertise aredigitaltechnologies andvirtual reality visualization. She has completed several international virtual reality-based projects in the fields of architecture, urban and spatial planning, historical documentary film making, business, higher education, and hydrology. Prior to joining UBC, she worked as a teaching assistant at the Faculty of Digital Production at Educons University.

Ken Hildebrant Memorial Scholarship Lauryne Robertson

In her previous life, Lauryne was a French country girl, an equestrian, and a bakery and pastry chef. She became interested and enthusiastic about mining when she met her husband a Canadian mining engineer in Mongolia. Today, she is an Albertan cowgirl (in her heart at least, even if she doesn’t have a horse anymore), who spends her time between mining technology classes and chasing adventures and wildlife observation in the beautiful Rocky Mountains. Five years ago, she was barely able to speak English and she couldn’t have imagined that she would be on the verge of a career in mining in Canada. She doesn’t know where this path will lead but is proud of who she became and where she is today. She is looking forward to starting her new work life.

MER Memorial Scholarship Luis Urena-Tejada

Luis is currently an 18-year-old second-year student at Laurentian University, striving to become a Mechanical/ Mechatronics Engineer. His passions are video games, cooking and sports. He is a great communicator, with the ability to utilizetechnology effectively and engage with clients and colleagues to meet goals. Additionally, he is able to make use of procedural knowledge acquired through on-the-job training and use basic information-gathering skills to solve problems and concerns in an organized manner. Furthermore, he is independent, resourceful, and able to work in a fast-paced environment with little supervision. He is also continuously motivated to learn and gain more experience through challenging positions.

14 | MER Today– Spring 2023

CIM Journal

CIM Journal is a quarterlydigital publication for peerreviewed technical papers available to all CIM National Members for free and to non-members for a fee. Papers cover all facets of the mining and minerals industry, including geology, mining, processing, metallurgy, materials, maintenance, environmental protection and reclamation, social responsibility, mineral economics, project management, health and safety, risk management, researchand development, operations, and regulatory practices and issues. (Article updated by Janice Burke)

CIM Journal also publishes periodic special-themed issues. The first issue of 2023 is a seven-paper Special Issue, Innovations in Underground Ventilation, including invited papers from the North American Mine Ventilation Symposium (Editors: A. P. Sasmito, McGill University and P. Tukkaraja, South Dakota Mines).

As of 2020, CIM Journal is published by Taylor & Francis. CIM National Members continue to have free access to the journal, but new papers are now hosted on the CIM Journal website at https://www.tandfonline.com/toc/ucim20/current. Papers published prior to 2020 can be found on the CIM Technical Paper Library or on OneMine.

Paper Submissions

CIM Journal welcomes original papers in English or French. Submissions are assigned to a CIM Technical Society for double-blind peer review. Journal authors and audience are international in scope. Topics covered in CIM Journal include geology, mining, processing, metallurgy, materials, maintenance, environmental protection and reclamation, social responsibility, mineral economics, project management, health and safety, risk management, research and development, operations, and regulatory practices and issues.

Read the instructions for authors then create an account at Taylor & Francis.

15 | MER Today– Spring 2023

Agus P. Sasmito, PhD, Peer Review Chair, MER; Editor, CIM Journal (agus.sasmito@mcgill.ca)

Janice M. Burke, MSc, Editorial Coordinator, CIM Journal

Industrial applications of digital twin technology in the mining sector:

https://doi.org/10.1080/19236026.2022.2145431

J. Plavšić and I. Mišković

The Norman B. Keevil Institute of Mining Engineering, University of British Columbia, Vancouver, Canada ABSTRACT

In recent years, digital twin (DT) technology has received much interest from the mining community. Despite the potential to revolutionize mining processes in the long-term, this technology is still nascent, and many companies are unsure how to leverage it for their industry-specific applications. For successful integration in the field and to meet user expectations, the roles, capabilities, and potential applications of this evolving technology need to be demystified. This paper provides an overview of industrial applications of DTs in the mining sector. To identify relevant industry examples, we performed a systematic search of electronic resources. Thirty-two reallife examples of early adopters in the field were analyzed based on the application purpose and classified into eight categories:

(1) collaborative decision-making;

(2) data analysis and

visualization; (3) design; (4) management and coordination; (5) monitoring and maintenance; (6) operational efficiency and production; (7) optimization of the mine value chain; and (8) safety and reliability. It was found that application categories that provided immediate and profitable benefits for companies contained the most case studies. To the best of our knowledge, this is the first attempt to showcase the opportunities that DTs hold for the mining sector. This summary of state-of-the-art industry applications is the first step to demonstrate the opportunities of DTs for mining operations and support the development of this emerging field

16 | MER Today– Spring 2023

An overview

Submit an article Abstracts from Articles peer reviewed

MER &

by

published by Taylor & Francis online

MER Society of CIM Peer-Review Team

CIM Journal Latest articles Journal Homepage

Abstracts of articles from seven-paper Special Issue, Innovations in Underground Ventilation, Issue 14(1), 2023

Including invited papers from the North American Mine Ventilation Symposium (Editors: A. P. Sasmito, McGill University and P. Tukkaraja, South Dakota Mines)

Peer reviewed by the CIM MAINTENANCE, ENGINEERING and RELIABILITY SOCIETY (MER)

Janice M. Burke, MSc, Editorial Coordinator, CIM Journal

Janice M. Burke, MSc, Editorial Coordinator, CIM Journal

Procedures for mitigating safety risks associated with post-blast re-entry times

https://doi.org/10.1080/19236026.2022.2095197

E. De Souza AirFinders Inc., Kingston, Canada

ABSTRACT

In this paper, management procedures for post-blast re-entry that offer safety, efficiency, and economic benefits to mining operations are introduced. Such management procedures include use of dedicated and inaccessible exhaust airways for directing blast toxic and explosive gases, supported by use of advanced remote atmospheric monitoring technology and automated monitoring. A decrease in post-blast re-entry time with reliable remote monitoring processes and with effective ventilation management procedures results in safer and more efficient mining process and increased production yield. The presented management programs also aid mines in keeping their re-entry practices in compliance with regulatory bodies and company policies. A practical case study demonstrates the implementation of the program in an operating hard rock mine and provides evidence of actual realized benefits.

17 | MER Today– Spring 2023

A discussion on underground mine ventilation design considerations for diesel vs. battery electric mobile equipment

https://doi.org/10.1080/19236026.2022.2096398

N. Saeidi and C. Allen Vale North Atlantic Operations, Sudbury, Canada

ABSTRACT

The total air volume requirements of underground mining operations are determined based on several factors, including mining method, ambient air temperature, rock type, and mobile equipment emissions. With the introduction of larger battery-electric mobile fleets (i.e., large trucks and scoops) to replace existing diesel fleets in underground hard-rock operations, mobile equipment emissions become mostly limited to the heat generated. Battery-electric mobile equipment has the potential to reduce the air volume needed to ventilate an underground mine. However, air velocity is an important factor to ensure that the air reaches the working areas of the mine economically while minimizing entrainment of large contaminant particles, maximizing dilution of fine particles, and maintaining a safe air velocity for human occupancy. This paper reviews key parameters to support air volume determination and, using an example, discusses the influence of battery-electric vehicles on determining the total air volume.

Estimating the effect of blast and ventilation parameters on blast fume dilution time in underground development blasting using computational fluid dynamics

https://doi.org/10.1080/19236026.2022.2158642

A. Adhikari, P. Tukkaraja, and S. Jayaraman Sridharan South

Dakota Mines, Rapid City, USA

ABSTRACT

In underground mining, blasting-induced pollutants are diluted and exhausted out of the working area using the auxiliary ventilation system, which can account for up to 50% of the total mine ventilation electricity consumption. Few detailed studies have been published on the mechanisms and the dilution efficiency of forcing, exhaust, and overlap ventilation systems. To date, no systematic investigation has considered the effect of important factors, such as porosity, muckpile profile, type of explosives, and humidity on the post-blast dilution time. This research seeks to address these issues and make post-blast dilution time estimation more accurate and realistic. Numerical models were developed using computational fluid dynamics software to simulate blast fume dispersion and clearance in an underground development heading. Phase 1 study results show that on average, the time to reach the permissible exposure limit is approximately five-fold faster for the forcing system than the exhaust system and slightly more efficient than the overlap system. Phase 2 study results show that the porosity of the muckpile and explosive type have a significant impact, the muckpile profiles have an inverse effect, and the relative humidity has little to no impact on dilution time at lower temperatures (~0–30°C).

18 | MER Today– Spring 2023

Machine learning model for predicting blast fume dilution time in underground working areas

https://doi.org/10.1080/19236026.2022.2142432

A. Adhikari, P. Tukkaraja, S. J. Sridharan, and A. Verburg South Dakota Mines, Rapid City, USA

ABSTRACT

In underground mines, accurate prediction of dilution time is crucial to protect miners from toxic fumes as well as minimize production delays and ventilation costs. Previous researchers have used empirical equations, mine ventilation software, and computational fluid dynamics to calculate dilution time. These traditional methods have high computational cost and design limitations. In this research, machine learning (ML) techniques and data analytics were used to: (i) develop a ML model to predict dilution time based on five on-site blasting and auxiliary ventilation parameters and (ii) determine the order of importance of these parameters. The advantages of using the ML model over the traditional methods are its ability to consider a large number of factors, detect complex nonlinear relationships, and predict the dilution time near-instantaneously. Results show that the normalized artificial neural network has the best prediction capability with an R2 of 0.987. Among the blasting and ventilation parameters measured, air volumetric flow rate significantly affected the dilution time, followed by duct distance from face and the amount of explosive.

Investigation of airflow through porous zones: Integrating computational fluid dynamics modeling into mine ventilation network simulation

https://doi.org/10.1080/19236026.2022.2161120

P. H. Agson-Gania, L. Amirib, S. Poncetb, F. P. Hassania, and A. P. Sasmitoa aMcGill University, Montreal, Canada; bUniversité de Sherbrooke, Sherbrooke, Canada

ABSTRACT

Using mine ventilation network (MVN) software to model airflow through porous zones in underground mining operations is arduous due to its complex and dynamic nature. However, accurately measuring airflow is essential to control underground mine air quantity and quality. This study integrated the computationally expensive conjugate porous media model into versatile MVN software to efficiently analyze airflow through the porous zone. In MVN software, a novel friction factor coefficient was compiled into the broken rock-filled drawpoint model, which was later verified against the three-dimensional (3D) computational fluid dynamics model. Several simulations were conducted to ensure model reliability by varying the porosity and broken rock diameter of the porous zone. Results demonstrate that the novel friction factor coefficient can accurately predict airflow through porous media using MVN software and reduce computation time by > 99% compared to the 3D solver. In addition, sensitivity analyses were conducted to assess the effects of various factors on the system. This method enables mine ventilation engineers to effectively plan the rapidly changing underground MVN.

19 | MER Today– Spring 2023

Design of different shapes of drill shroud to reduce dust deposit using computational fluid dynamics method

https://doi.org/10.1080/19236026.2022.2124496

Y. Zheng, W. R. Reed, and J. D. Potts National Institute for Occupational Safety and Health, Pittsburgh, USA

ABSTRACT

Effective dust control using drill shroud air-blocking shelves was confirmed previously through laboratory tests, field studies, and computational fluid dynamics (CFD) simulations. However, when the drilling machine moves to different locations, deposits on these shelves can produce a large dust cloud. To minimize the dust exposure hazard, this study modified the drill shroud air-blocking shelves by using the concept of angle of repose to eliminate the deposits while at the same time, confining the dust inside the drill shroud. Two types of drill shroud inner shapes were evaluated using CFD models: U-shaped and V-shaped. In addition, a drill shroud with 45° blocking shelves was built to examine its dust control capacity. The angle of repose used to minimize dust problems during mast lowering was shown to be effective in reducing the dust problems during drilling. However, care must be taken to use a properly designed shroud because the V-shaped drill shroud can potentially exacerbate dust leakage.

Determination of underground hazard location using machine learning techniques

https://doi.org/10.1080/19236026.2022.2164133

D. Bahrami, L. Zhou, Y. Xue, and L. Yuan Pittsburgh Mining Research Division, National Institute for Occupational Safety and Health, Pittsburgh, USA

ABSTRACT

Underground mine accidents, such as mine fires, remain a concern for mine operators, posing a health and safety risk to mine workers. Dealing with an unknown location of an accident underground can be a challenging task, creating hazardous conditions for miners during an evacuation and rescue operation. Timely determination of an underground fire event location and size is of great importance in reducing the risk of injuries. Machine learning (ML) has made its way into mining, enabling the development of data-driven predictive models that can be applied to miner health and safety problems. A new methodology has been developed using the application of an ML technique to characterize underground accidents such as the size and location of an underground mine fire using the post-fire airflow data. This paper describes the methodology and its verification through examples. The National Institute for Occupational Safety and Health (NIOSH) is endeavoring to develop workplace solutions to improve the detection of and reduce the risk of hazardous conditions. The results demonstrate a promising application of ML-based models and provide a useful tool for solving the problem of unknown fire locations and reducing the risk of hazardous conditions.

20 | MER Today– Spring 2023

TECHNICALPROGRAM

Topic and Subtopics primarily of interest to CIM MER Society Members:

Topic: Mining in the 21st Century

Agus Sasmito, MER Technical Chair

• Digital applications in mining

data collection and processing

Mining communication

Remote-controlled operations

Autonomous trucks, excavators, drills, and other equipment

– Using artificial intelligence (AI) algorithms to improve mine planning

• Asset management

Remote sites

• Equipment maintenance and reliability

Maintenance planning

– Inventory management

– Minimizing risk and capital inefficiency

Use of the software and AI to predict equipment failures

– Best industry practices

21 | MER Today– Spring 2023

–

–

–

–

–

–

–

Register

International Conference on Hoisting and Haulage

August 13 – 16, 2023, Montreal, QC

CONFERENCE CHAIRPERSONS

Dick McIvor, Conference Chair

Jean Vavrek, Sponsorship Chair

CIM Contact

Chantal Murphy, Convention Planner

TECHNICALPROGRAM

Hoist and Haul is the latest in a series of International Conferences on Mine Hoisting and is held every five years. Hoist and Haul is a peer-reviewed conference and will cover systems or technology associated with the transportation of personnel, material, and minerals in and out of an underground mine.

The technical program committee is in the process of reviewing the submissions. The following topics will be covered by the technical papers.

• Mine hoist plant selection

• Hoisting and shaft ropes

• Hoist rope attachments

• Shaft conveyances

• Mine hoist electrical - motors and drives

• Head sheaves

• Mine hoist braking systems

• Loading pockets and dumping systems

• Mine shaft conveyance guiding

• Mine hoist mechanical – gears, auxiliary drives, couplings, foundations

• Hoist plant maintenance and inspections, NDE

• Wear materials for shaft conveyances and loading pockets

• Innovative mine hoist plant design

The complete technical program with presentations will be available later in 2023.

22 | MER Today– Spring 2023

CIM MEMO 2023

Sep 17 – 20, 2023, Saskatoon,

CONFERENCE TOPICS

• Mining

• Maintenance & Reliability

• Environment

• Processing

• Rock Mechanics

• Innovation

SUBMIT ABSTRACT

Deadlineforabstractsubmissions

April28,2023

Conference Co-Chairs:

Paul Labbé & Brian Fagan

• Human Resources

• Ventilation

• Health & Safety

• Communities

• Indigenous engagement

• Geoscience

CIM Contacts:

Marie Tota, Conference Planner

Nadia Bakka, Sales Manager, Exhibition & Sponsorship

23 | MER Today– Spring 2023

CIM MER Executive Committee 2022 – 2023

Chair, Dominique Privé

Immediate Past Chair, Jean Vavrek

1st Vice Chair / Chair Elect, Martin Provencher

2nd Vice Chair, Lee Weitzel Treasurer, DickMcIvor

Directors:

NewsletterCommitteeMembers

Editor-in-Chief: MarcelDjivre mailto:mdjivre@gmail.com

Copy Editor: Janice M. Burke, MSc mailto:jburke@cim.org

Contributors:DeanMillar,Martin Provencher, BrandonNikolaisen

SOME CIM MER SOCIETY SUPPORTERS & PATRONS

Page 24

20 | MER Today– Spring 2023

By Angelica Zagorski

By Angelica Zagorski