Final Presentation

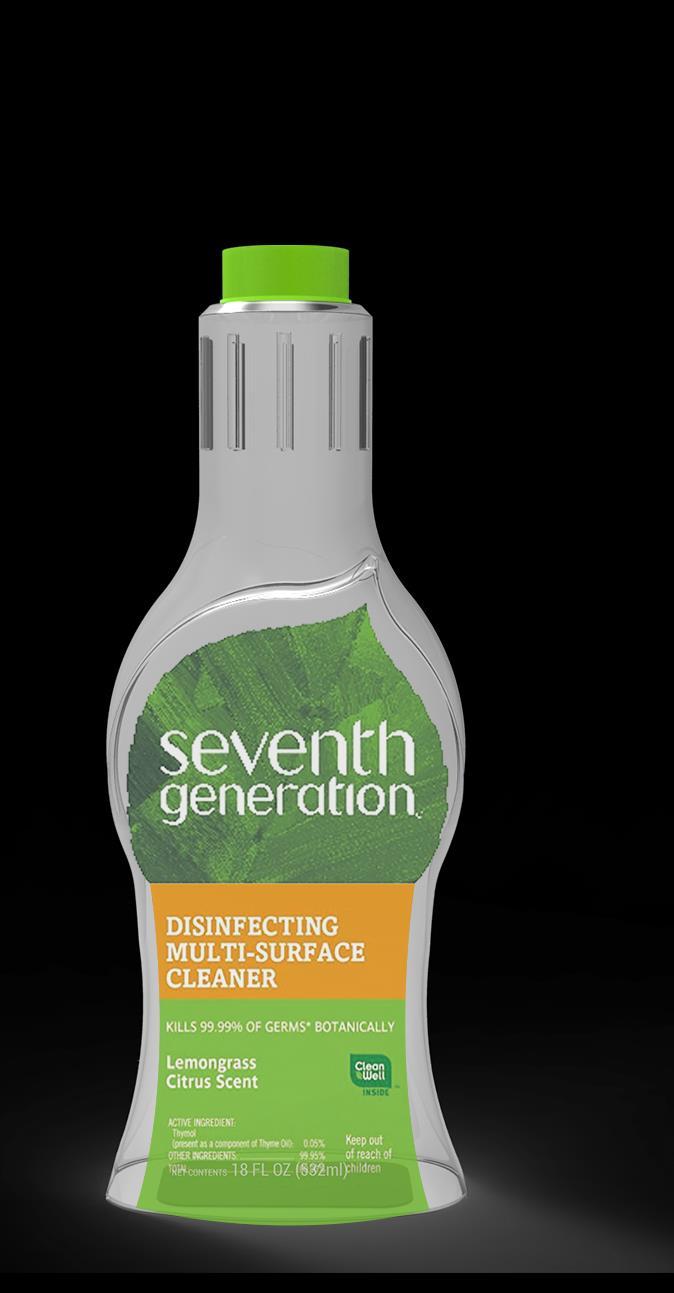

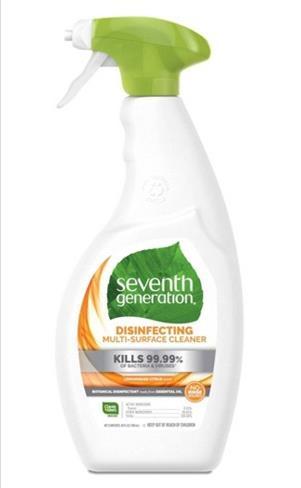

SURFACE CLEANER

Charlene, Deepak Instructor/ Karen Proctor

Agenda

• Business Case

• Market Analysis

• Design Goal

• Primary Packaging Design

• Secondary Packaging Design

• Ecoimpact Analysis

• Conclusion

2

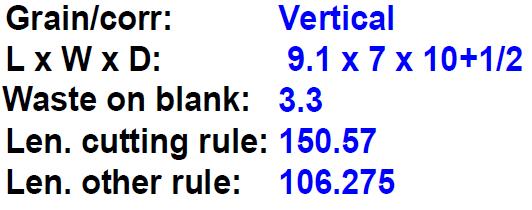

Manuf. MethExtrusion Blow Molded

Oz)26 Weight empty

MaterialHDPE

Dimensions(LxWxD)

Bottle Volume (LxWxD) (cu in)

Actual volume of the bottle to overflow (cu in)51.26 Volume Product per label(cu in)46.92 Headspace (%)8.47 Dec TypePressure Sensitive Label Label Dimension (L x H) (in)3.19x4.50 Pack/Prod Ratio (lb /fl oz))

Cube

Weight

Material

Dimensions(DxH)

Pack/Prod Ratio (lb/fl.oz)

HDPE material 0.115 lb Bottle Sprayer PP material 0.055 lb

Label

Business Case Product CMUM (Fl.

(lb)0.115

(inches)4.25 x 2.5x9.25

98.28125

0.004423077

Utilization [%]47.74054054

(lb)0.055

PP Manuf. MethInjected molded

(inches)3.25x2.5x1.25

0.002115385

Label (2 pieces) Pressure Sensitive

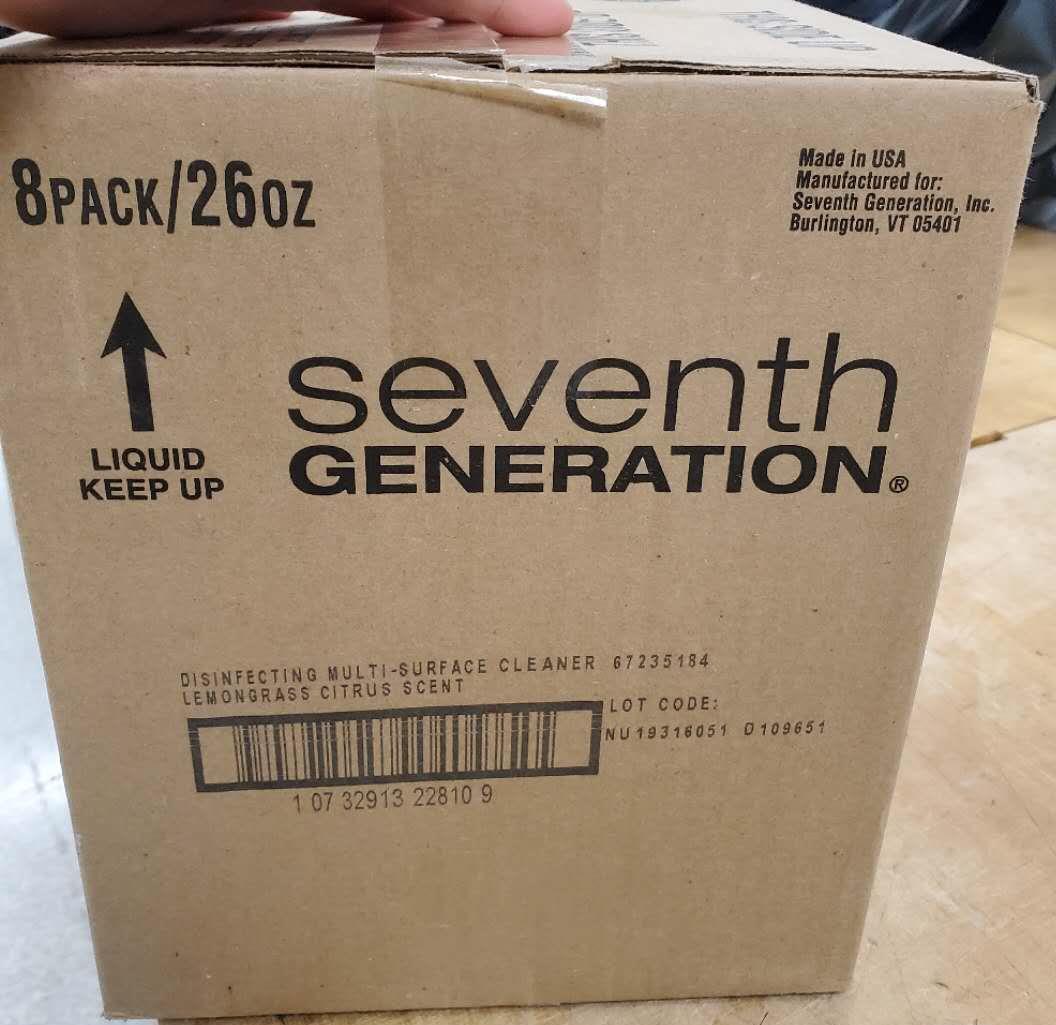

Business Case

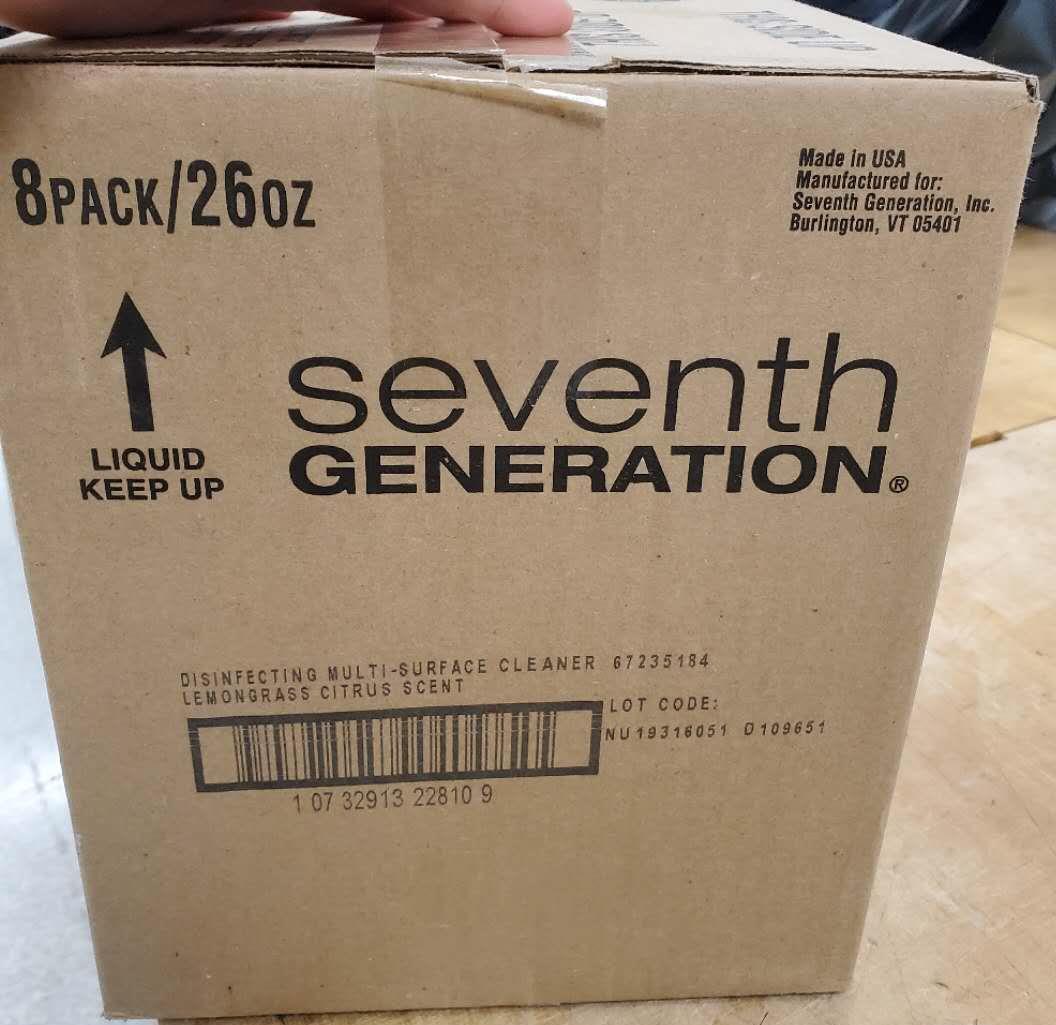

RSC box C flute 16.7802 lb

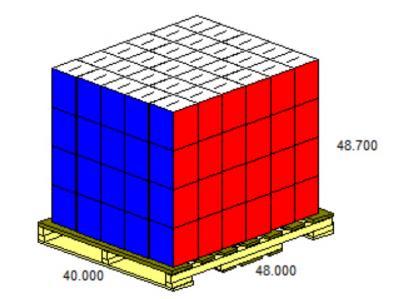

Box TypeRSC

Weight (filled) (lb)16.7802

Weight (empty) (lb)0.6

FluteC

Sq in Material (sq in)871.82

ECT (lbs/in)32

Arrangement4x2x1

Total bottles in the box8

OD (in)9x10.5x11

Dec TypeFlexo

Pack/Prod Ratio (lb/total cmums per case)0.0029086

Pack/Prod Ratio (sq in/total cmums per case)4.1914423

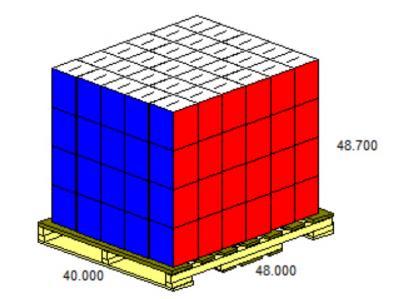

Bottles/Pallet512

Total CMUM / pallet13312

Cases/ Pallet64

Total weight of cases on pallet (lb)1073.9328

Selling Unit Volume (cu in/pallet)50320

Transport Pallet Volume

*(TPV) (cu in)99840

Cube Utilization [%]50.4

Deepak

8

Shelf Visibility

Market Analysis

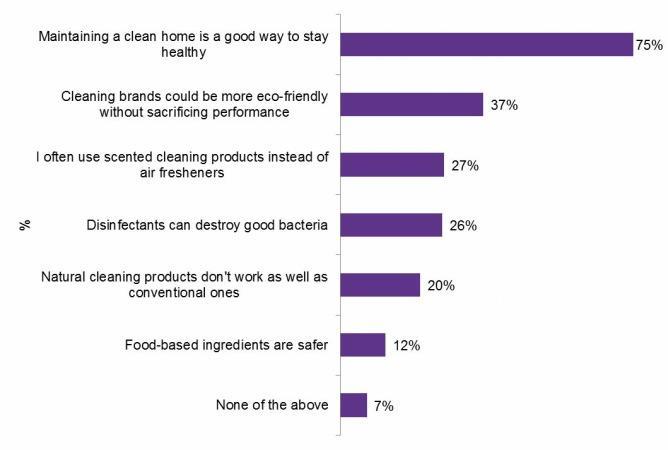

Increase the sustainability of packaging can be the crucial mission of the packaging

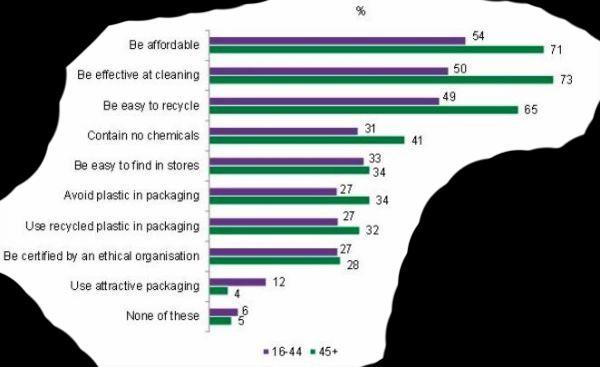

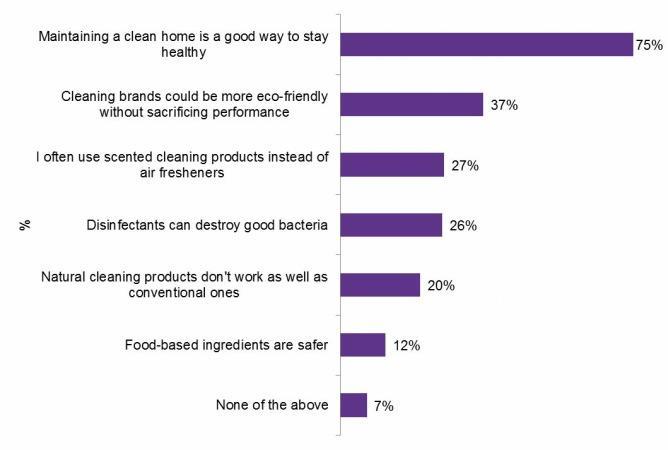

Attitudes toward surface cleaning products, July 2018

Base: 1,945 internet users aged 18+ who use surface cleaner

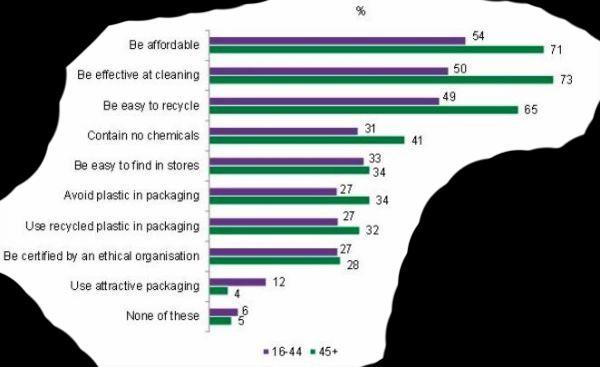

Ideal attributes of an eco-friendly product, by age, March 2019

Base: 1,939 internet users aged 16+ who have bought household care products in the last 6 months

From Mintel

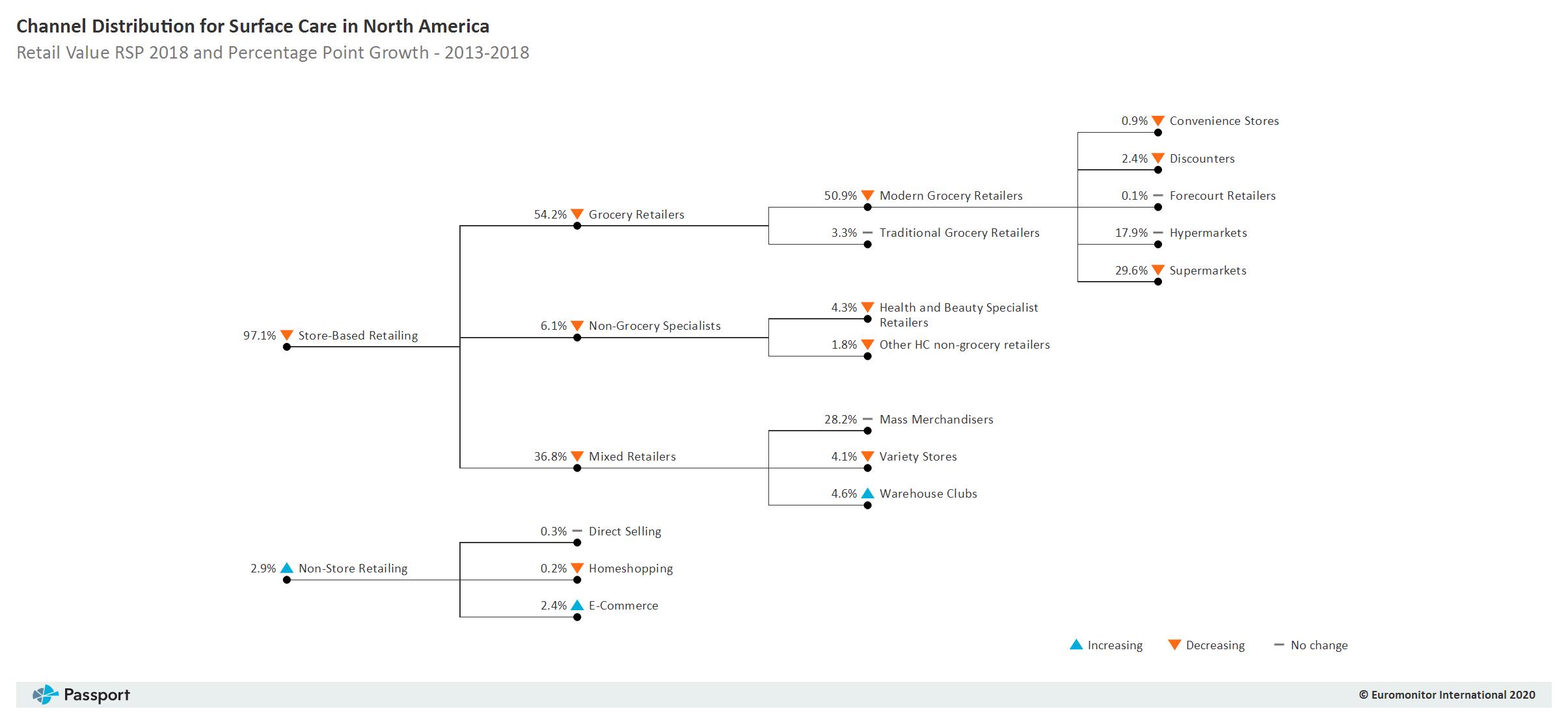

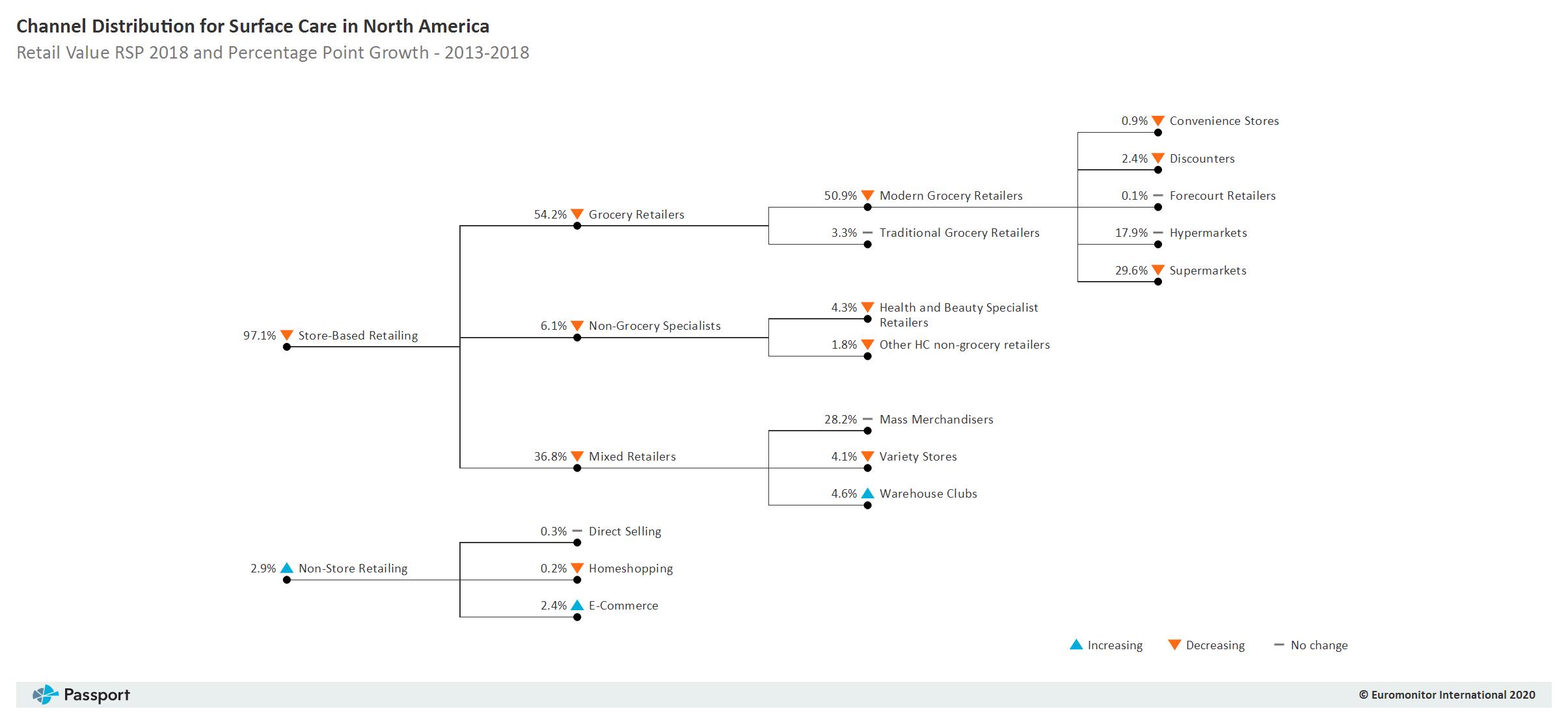

Market Analysis

The packaging design should be used for the E-commerce (Lighter weight and better cube utilization )

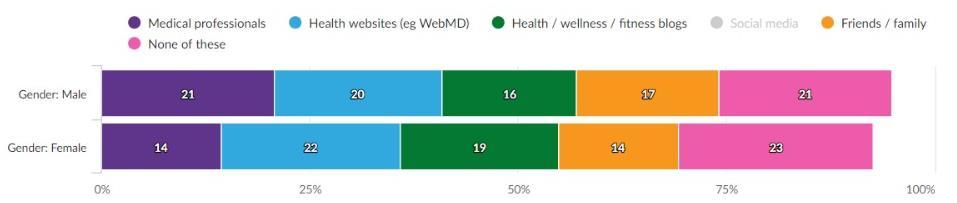

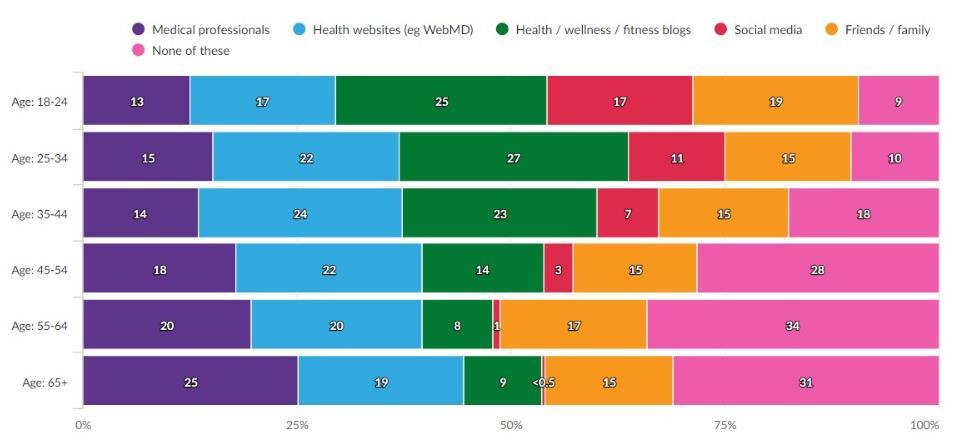

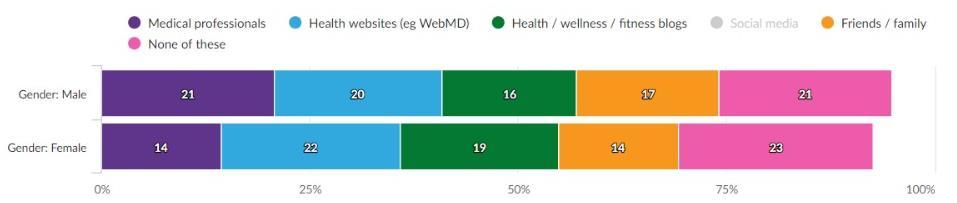

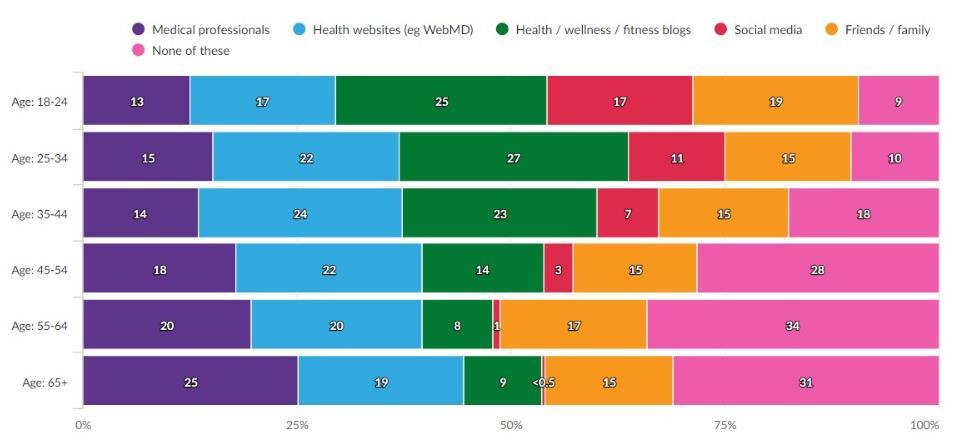

Where do you primarily obtain information about the following health/ wellness topics?

Health website + Blog

Male:36% Female:41%

18-24: 42% 25-34: 49% 35-44: 47% 45-57: 36% 55-64 :28% 65+ : 28% Health website + Blog

Mintel

From

Market Analysis

Market Analysis

Target market

1. women

2. 18-34 years old

3. Good economic condition

From Mintel

Deepak

SWOT

1. Uses 100% PCR materials in the packaging.

2. Recyclable Packaging.

3. Ingredient transparency.

4. Fragrance made from real ingredients without overpowering.

S W

1. Expensive than its competitors

2. Less visible on shelf as compared to Its competitors (Methods, Berkeley Green).

3. For Surface cleaner, doesn’t have strong brand recall

4. Less fragrance

1. Working on Improvements to make the pumps recyclable.

2. Size of eco-consumerism is increasing

1. Mrs. Meyer has ergonomic design

2. Competitors are also switching to the biobased packaging and PCR contents

O T

10

Opportunity Statement

1. The sprayer: be reusable (design refill bottle)

2. The bottle: - better ergonomic design

- more cubical

- lighter and sustainable material

- Unique shape increase shelf visibility

3. Label : - replace to shrink label

- more color

4. Product: - Reduce the volume

Project Objective

Design a more eco-friendly packaging Increase the profit Decrease the cost Increase the repurchased rate Better user experience

Consumer

Cube Utilization Increase 4% Pallet Area Usage GHG Value FFC Value Increase 7% Decrease 5% Increase 7% Cmum Shipped Per Pallet

Design Goal

Design Scope

In Scope

Primary packaging

• Material

• Structural design

• Graphic design

Secondary design

• Material • Sustainability evaluation

• Cube utilization

• Pack to product ratio

• CO2 emission

• Fossil fuel consumption

• End of life

Out of Scope

Tertiary packaging

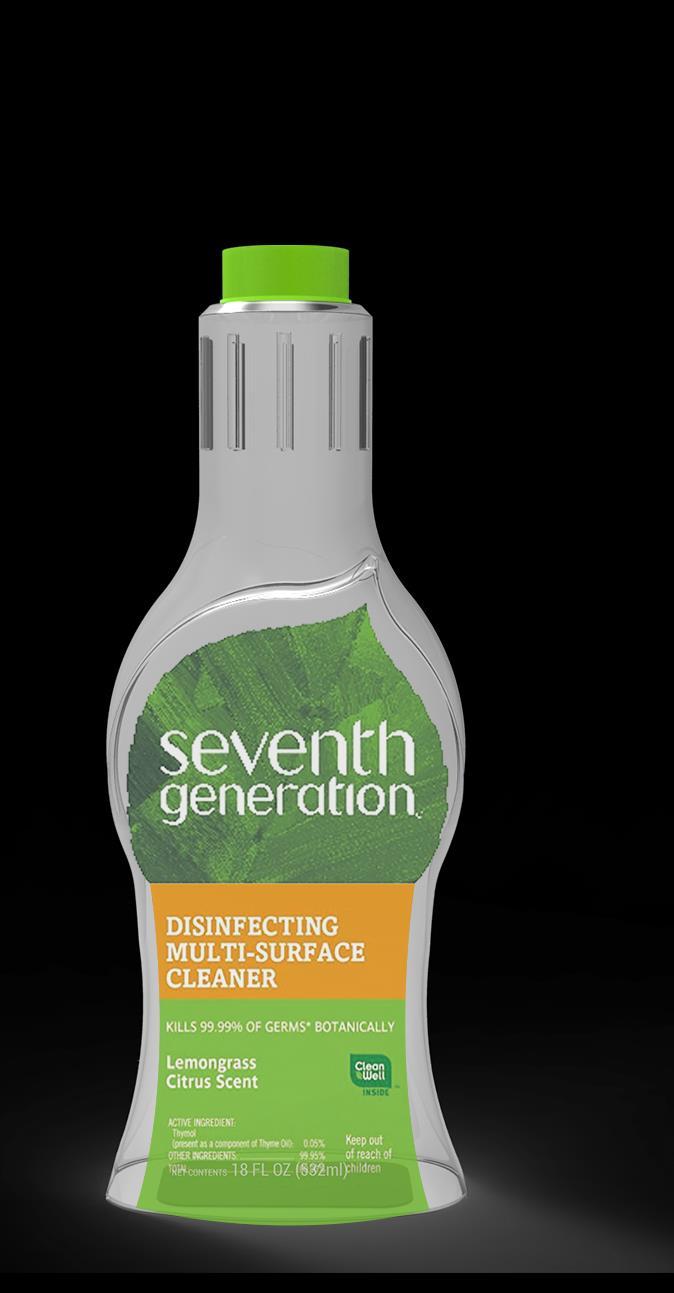

Primary Packaging Design

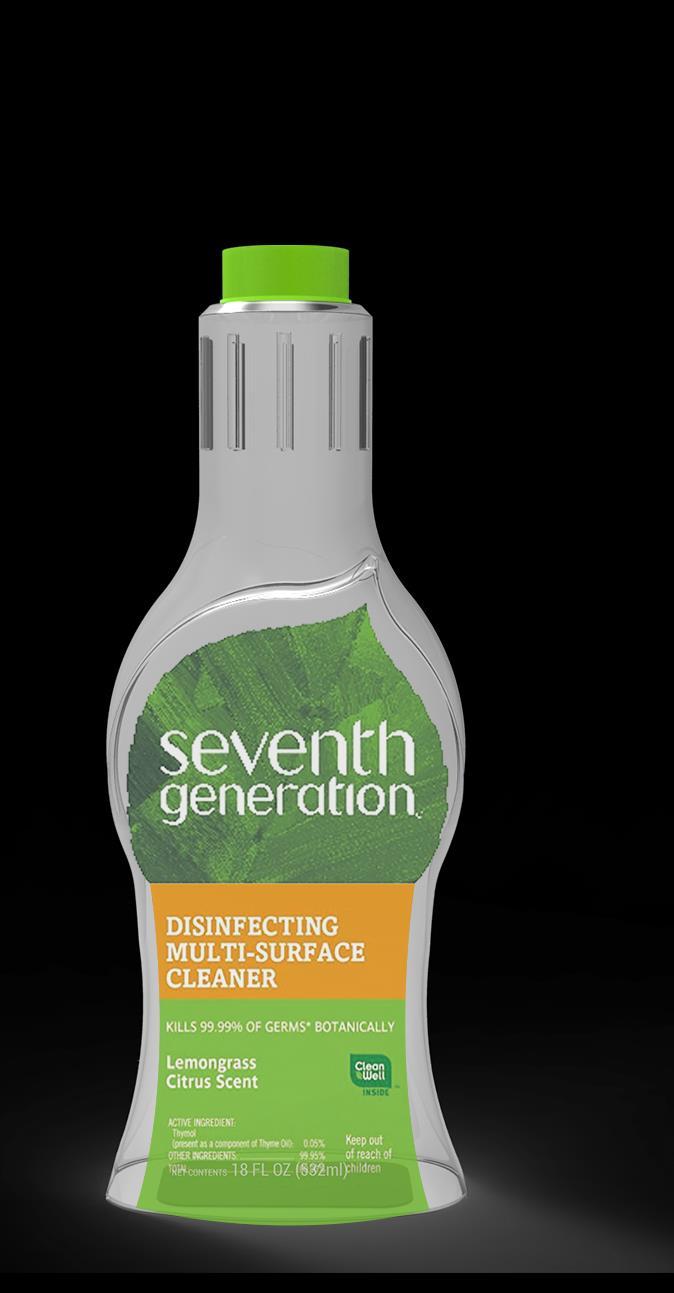

Design and Use of the packaging

Next-Gen refill bottle

Premium look

Unique shape

Engraving neck

Seven generation identity

Big label

16

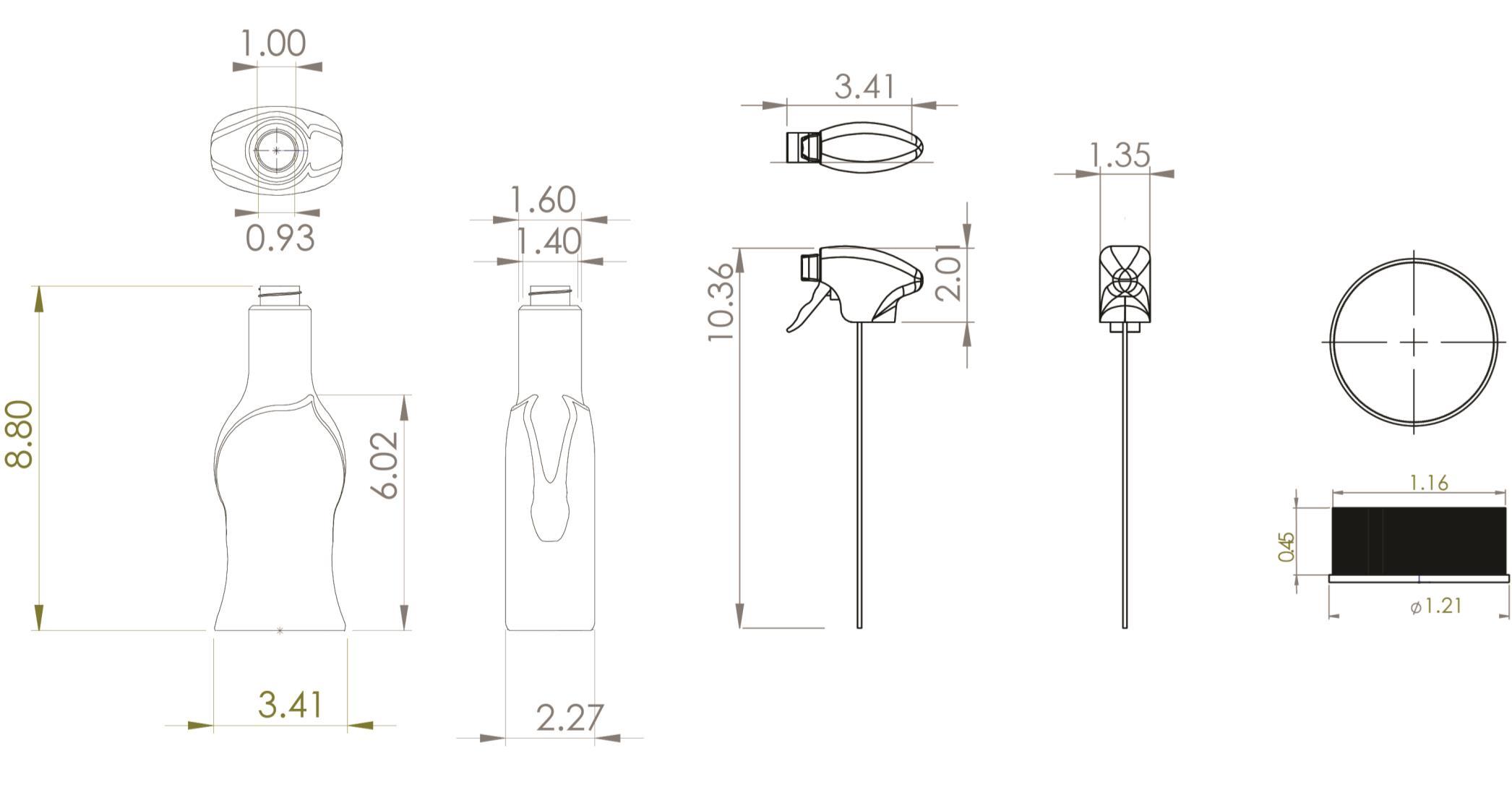

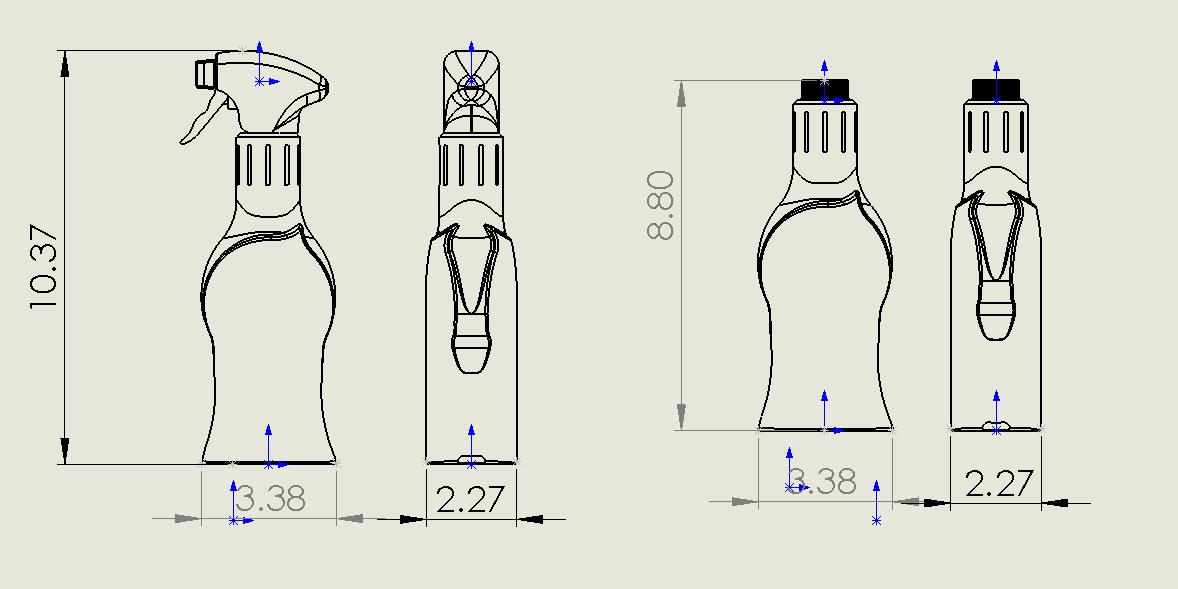

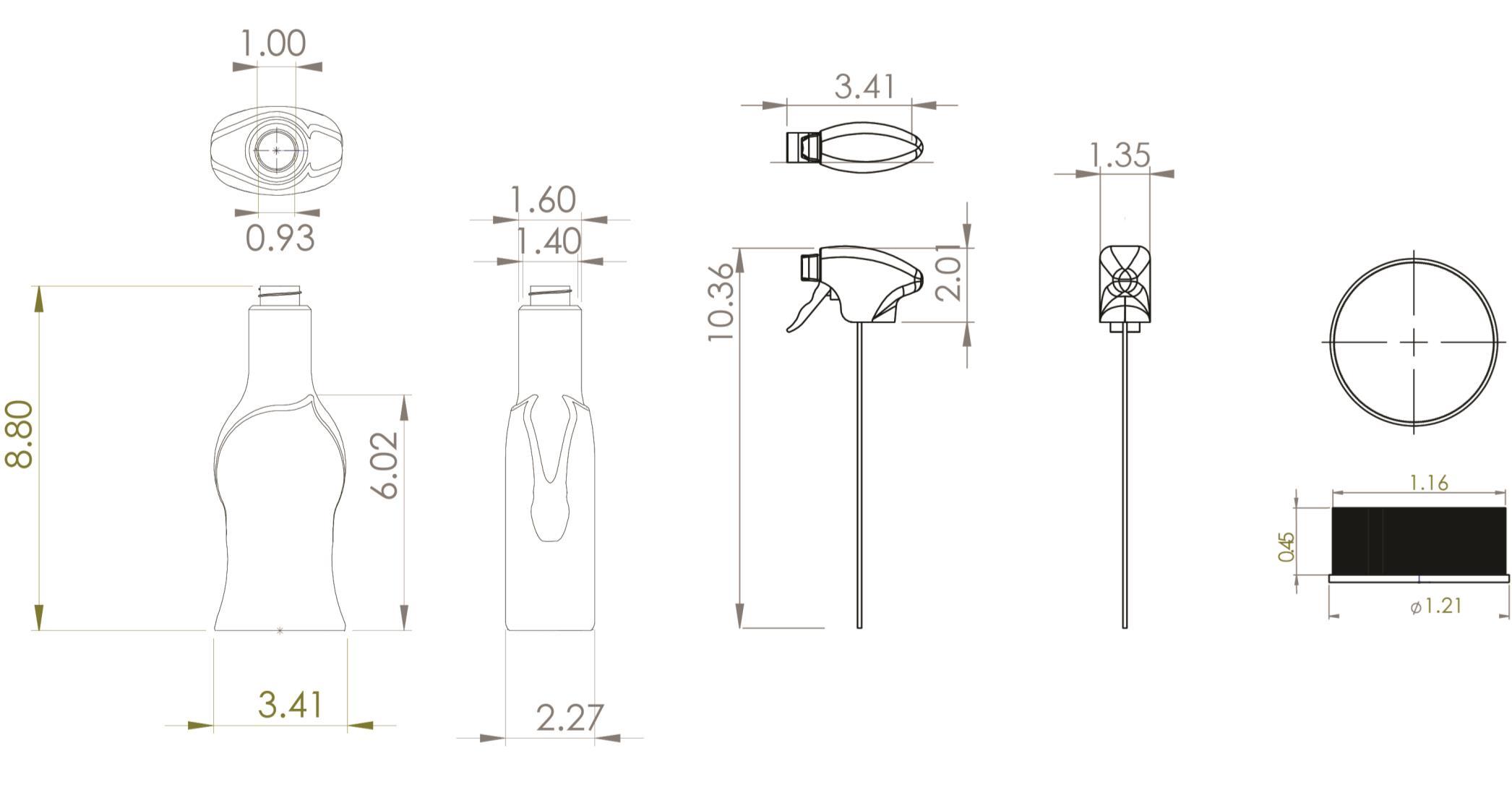

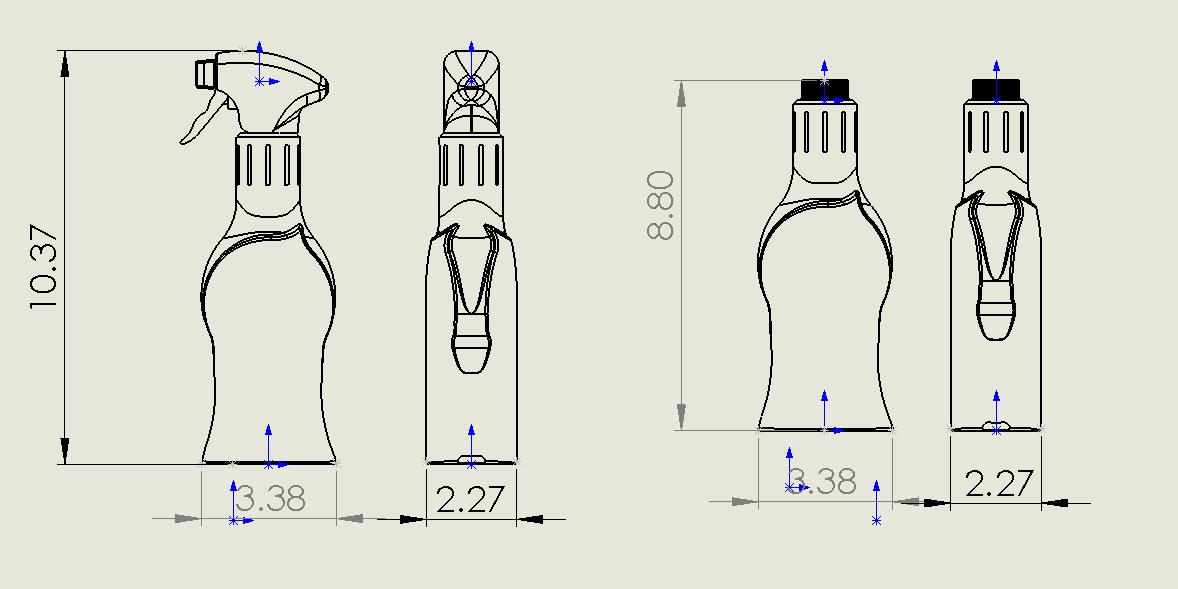

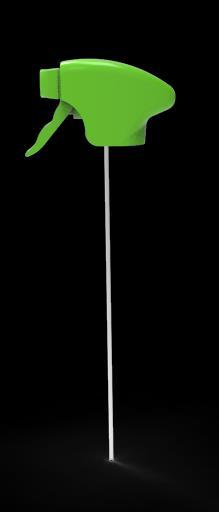

17 Bottle Trigger Cap Packaging demission- components

Unit :Inches

18

Packaging dimension- assemble

Buying DecisionBetter User Experience

Easy to hold

Lighter weight

Universal design

(Left and right hand)

Buying DecisionEasy to refill

Next-Gen refill bottle

Buying DecisionCompletive Price

Cheaper than the competitor

21

$0.17

$0.24

$0.311

18oz Approx

16oz

16oz

$0.15

18oz Approx

Buying DecisionBetter Shelf Visibility

Buying DecisionEasy to Storage

Less storage space

Next- Gen Refill bottle storage

23

Spray bottle storage

Buying DecisionEasy to Recycle (End of life)

PP (Injection Molded)

Reuse with the NEXT GEN bottle

PCR PET (Injection Blow Molded)- Recyclable

Shrink Label – Recyclable

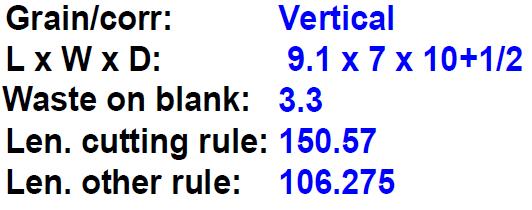

ORIGINAL BOTTLE NEW DESIGNED BOTTLE Product CMUM (Fl. Oz) 26 18 Weight empty (lb) 0.115 0.04 Material HDPE PET Manuf. Meth Extrusion Blow Molded Injection Blow Molded Dimensions(LxWxD) (inches) 4.25 x 2.5x9.25 3.41 x 2.27 x 8.8 Bottle Volume (LxWxD) (cu in) 98.28125 68.11816 Actual volume of the bottle to overflow (cu in) 51.26 33.62 Volume Product per label(cu in) 46.92 32.484 Headspace (%) 8.47 3.48 Dec Type Pressure Sensitive Label shrink label Label Dimension (L x H) (in) 3.19x4.50 3.25 x3.8 Pack/Prod Ratio (lb /fl oz)) 0.004423077 0.00222 Cube Utilization [%] 47.74054054 47.8 25

eco spreadsheet

Primary packaging

SPRAY HEAD BOTTLE CAP Weight (lb) 0.055 0.01 Material PP PP Manuf. Meth Injected molded Injected molded Dimensions(DxH) (inches) 3.25x2.5x1.25 0.45 x 1.16 Pack/Prod Ratio (lb/fl.oz) 0.002115385 0.00055 26 Primary packaging eco spreadsheet

New Design Value

Consumer

▪ Better user experience

▪ Cheap and easy use refill bottle

▪ Eye catching appearance

▪ Less storage space

Sustainability Company

▪ Sell the less products of each packaging with higher price

▪ Downsizing strategy increase the repurchase rate

▪ Long term will decrease the cost and increase profit

▪ 100%PCR

▪ Reuse the trigger

▪ Clearly recycle instruction on the label

Secondary Packaging Design

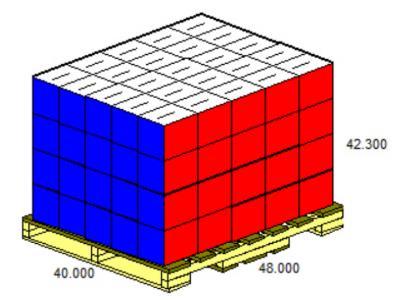

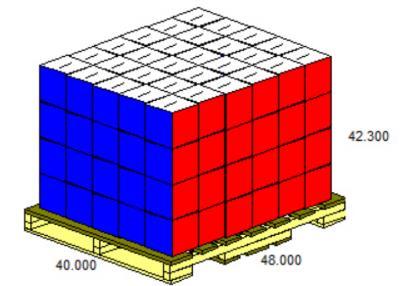

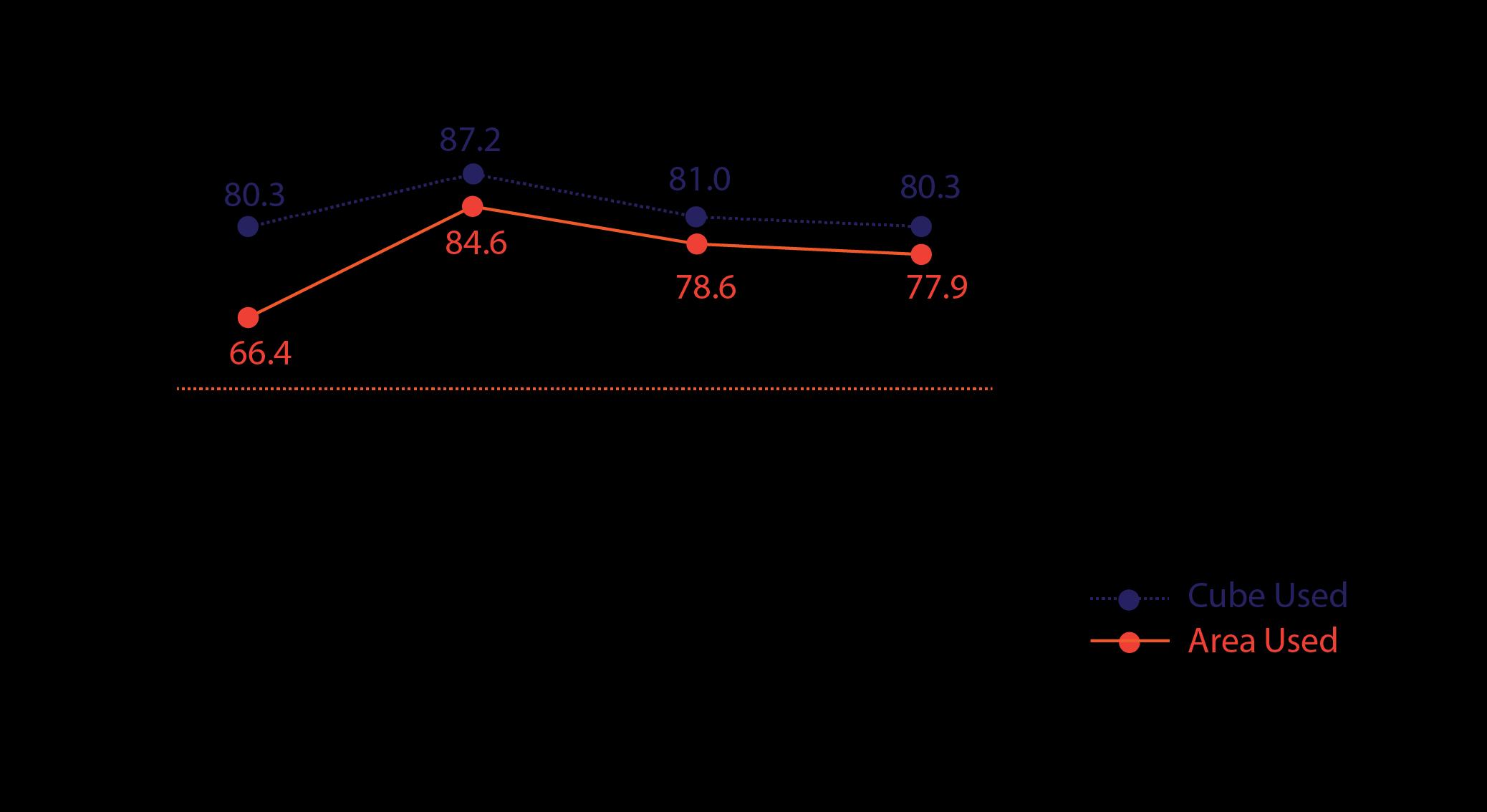

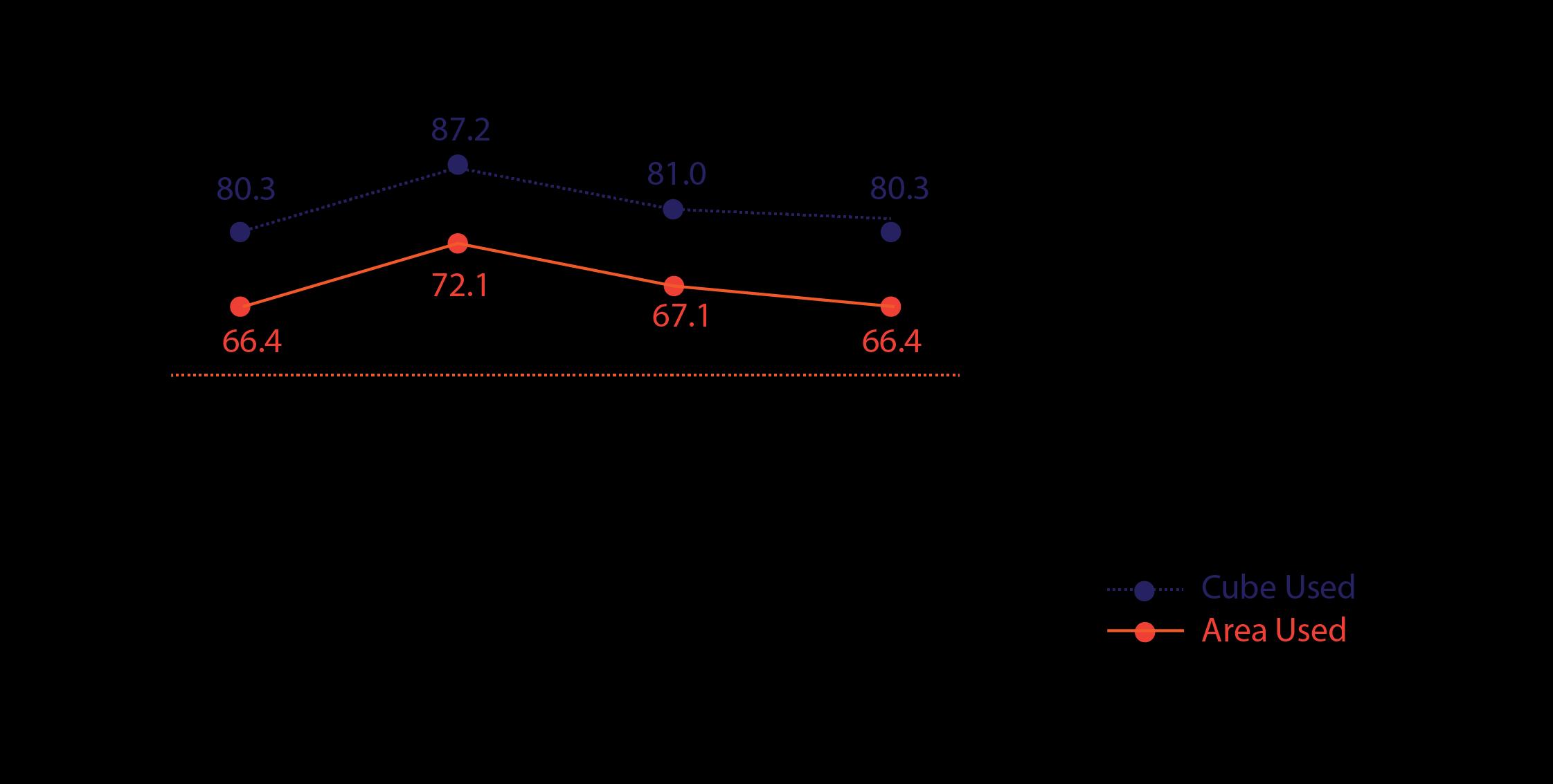

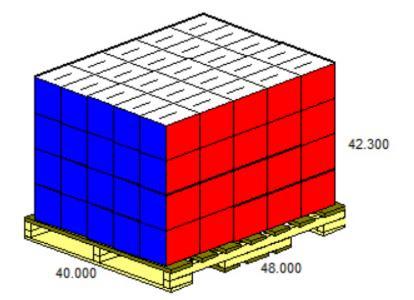

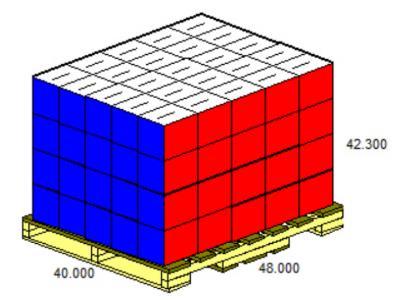

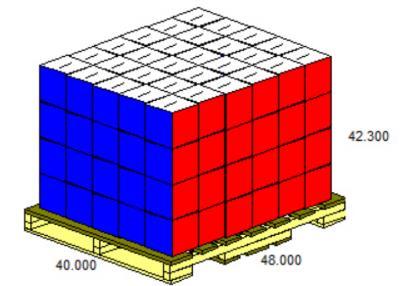

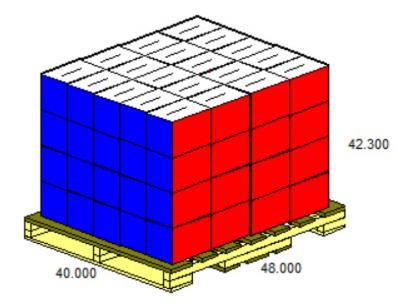

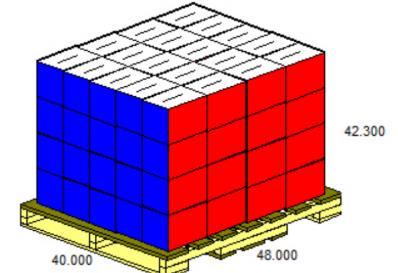

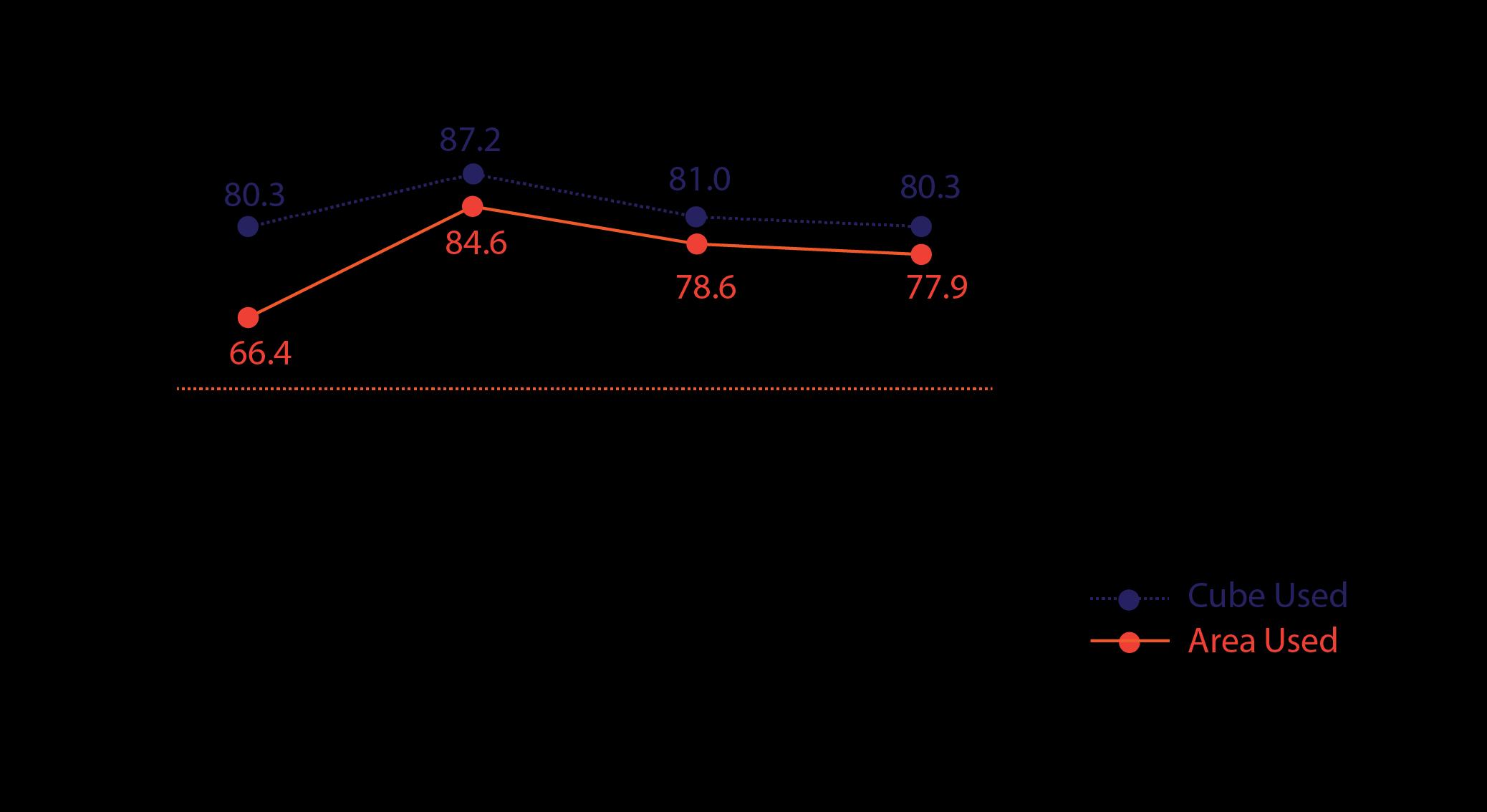

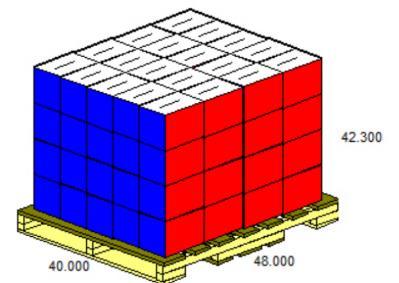

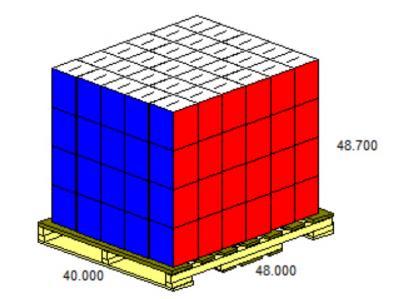

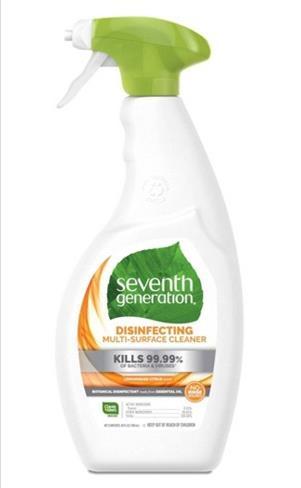

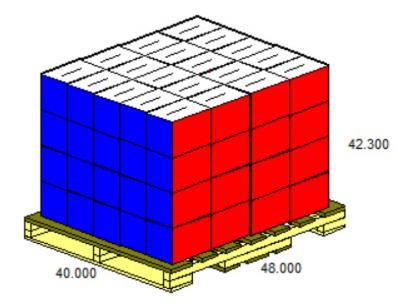

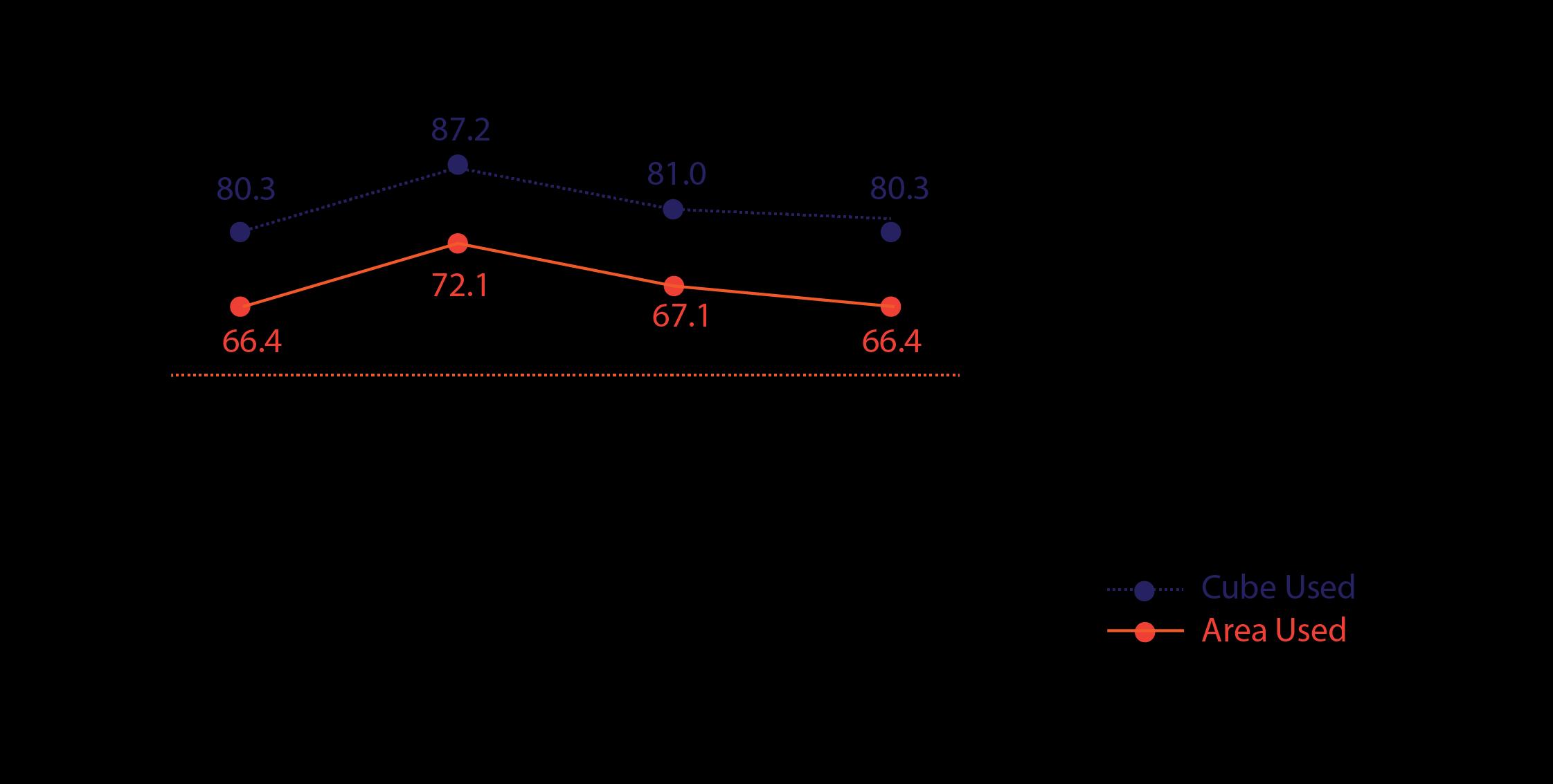

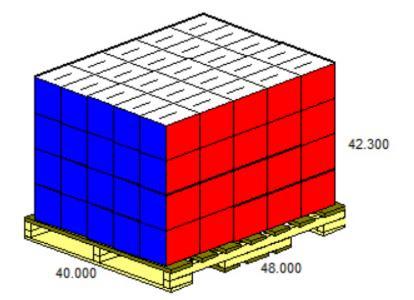

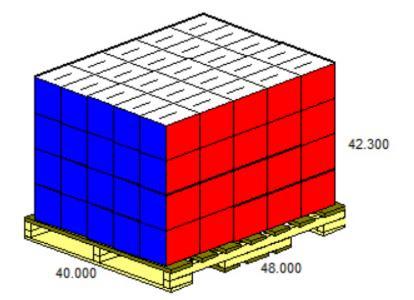

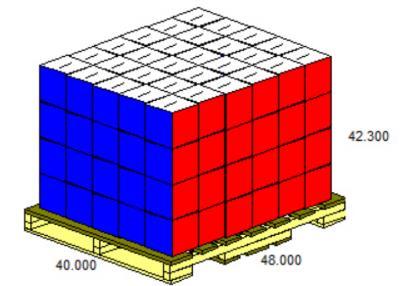

Bottle/ Case 8 8 6 9 Case/ Layer 16 25 30 20 Layer/ Load 4 4 4 4 Case/ Load 64 100 120 80 Bottle/ Load 512 800 720 720 Cube Used (%) 66.4 84.6 78.6 77.9 Area Used (%) 80.3 87.2 81.0 80.3

13

Spray Head BottleDesign and CAPE Report

8 bottles case shows it has better result of cube used and area used on load.

Spray Head Bottle- CAPE Report

30

Spray Head Bottle –Eco Spreadsheet Analysis

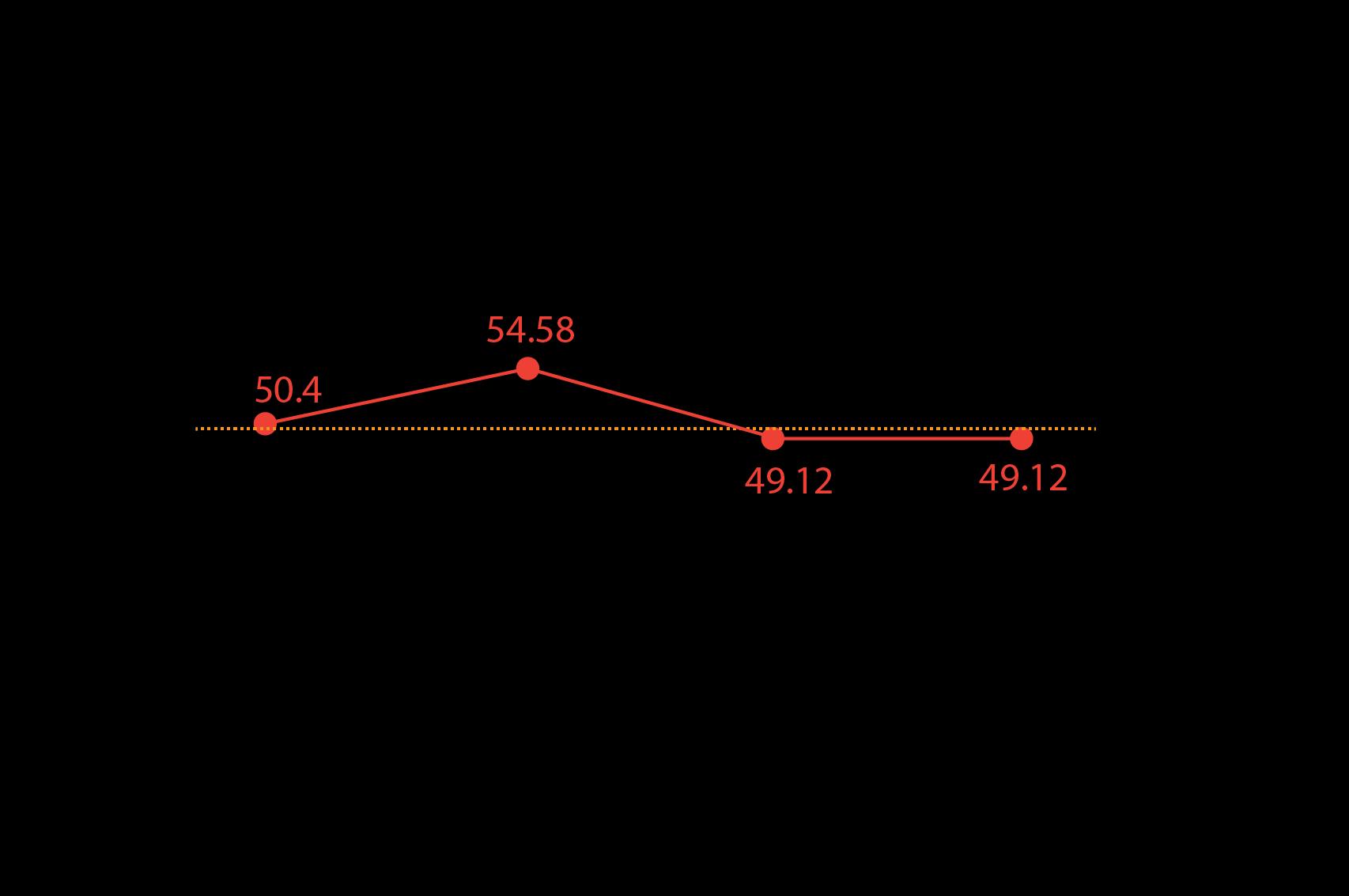

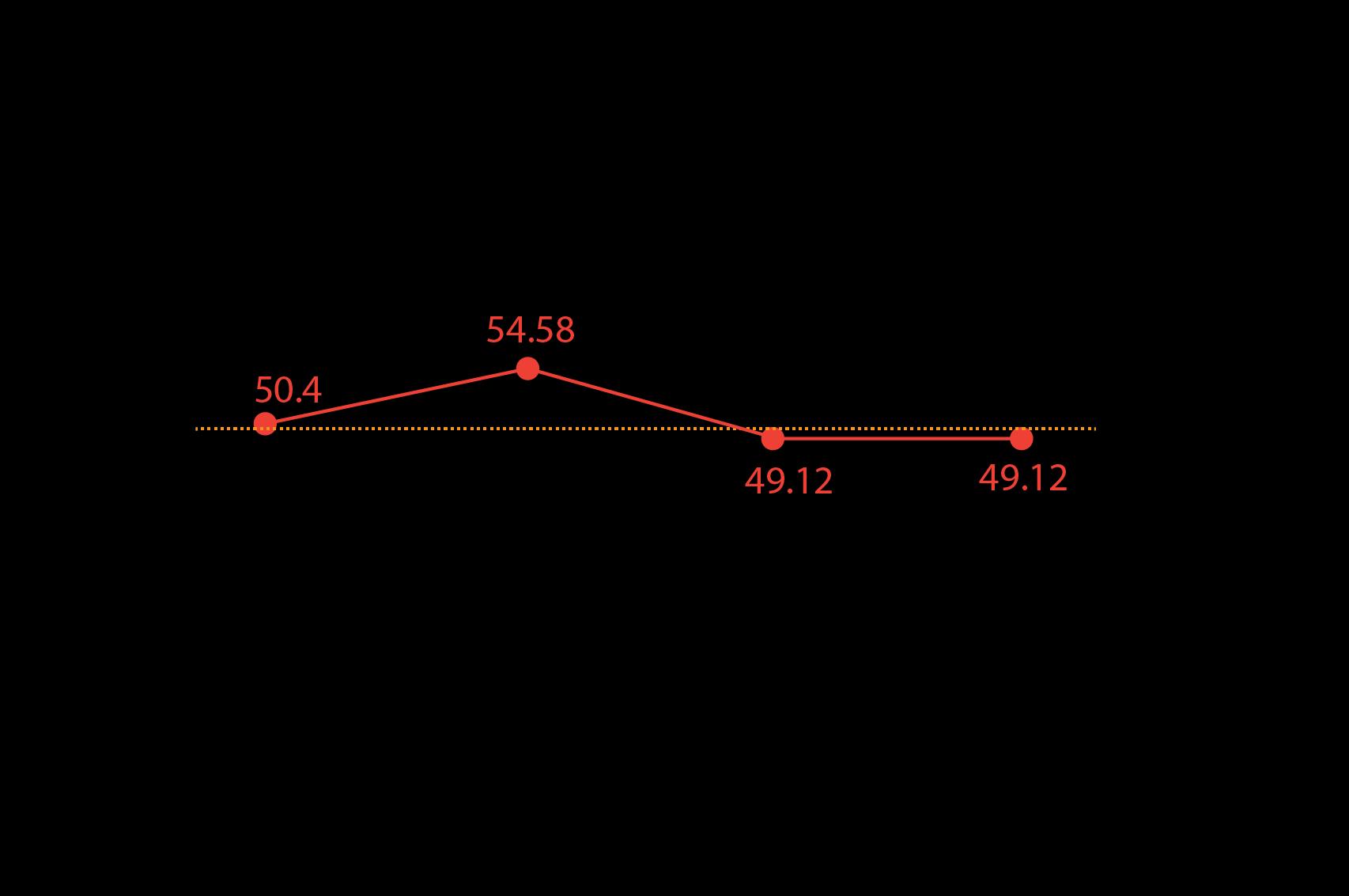

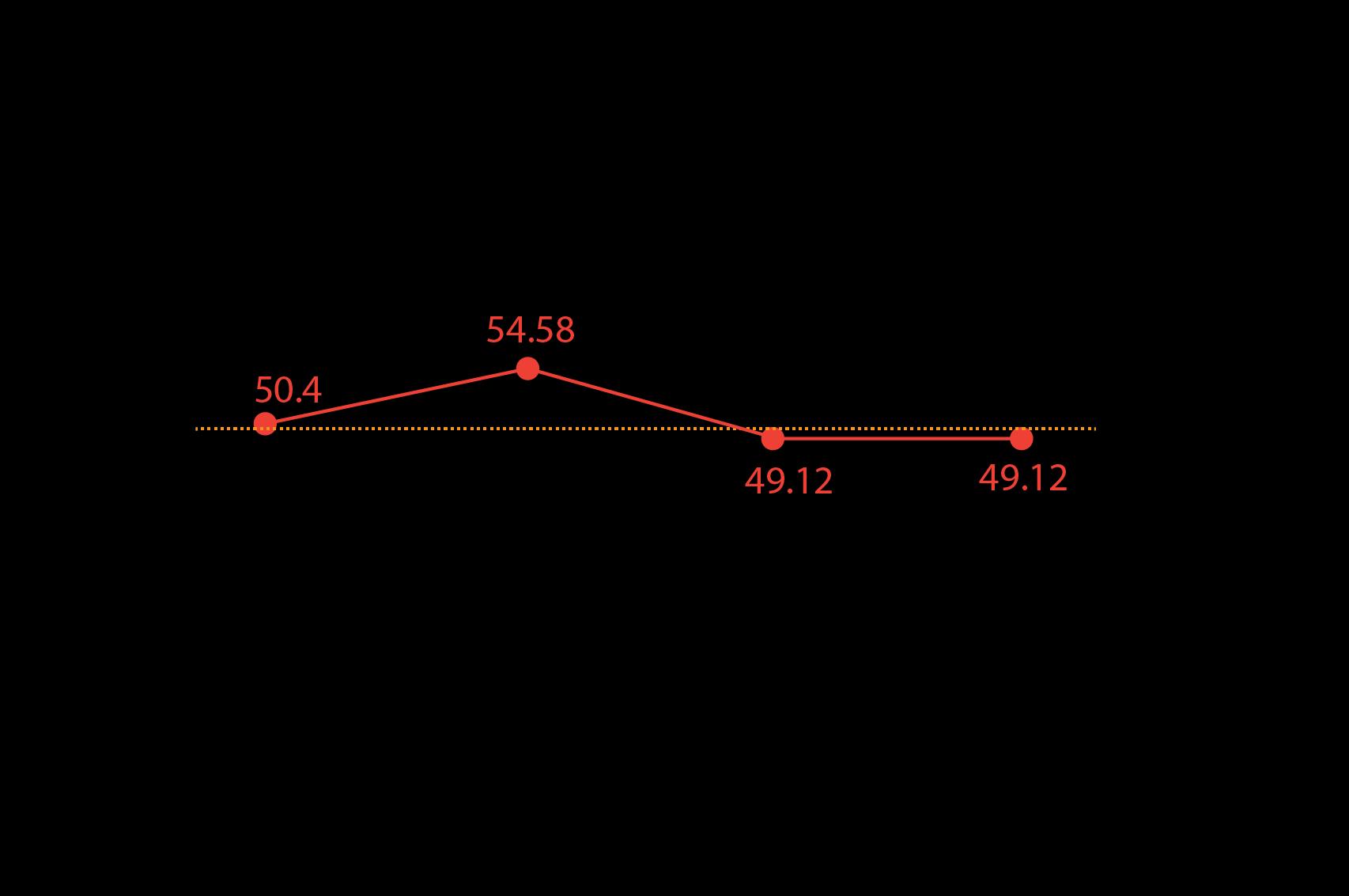

Original packaging 8 bottles 6 bottles 9 bottles Box Type RSC RSC RSC RSC Weight (filled) (lb) 16.7802 10.75 8.06 12.0963 Weight (empty) (lb) 0.6 0.54 0.53 0.56 Flute C C C C Sq in Material (sq in) 871.82 609.73 532.29 661.35 ECT (lbs/in) 32 32.00 32.00 32 Arrangment 4x2x1 4x2x1 3x2x1 3x3x1 Total bottles in the box 8 8 6 9 OD (in) 9x10.5x11 9.3x7.2x10.8 7.2x7.2x10.8 10.7x7.2x10.8 Dec Type Flexo Flexo Flexo Flexo Pack/Prod Ratio (lb/total cmums per case) 0.0029086 0.002917 0.002963 0.002963 Pack/Prod Ratio (sq in/total cmums per case) 4.1914423 4.23 4.93 4.08 Bottles/Pallet 512 800 720 720 Total CMUM / pallet 13312 14,400 12960 12,960 Cases/ Pallet 64 100 120 80 Total weight of cases on pallet (lb) 1073.9328 1,075.00 967.2 967.704 Selling Unit Volume (cu in/pallet) 50320 54,494.53 49045.07 49,045.07 Transport Pallet Volume *(TPV) (cu in) 99840 99,840.00 99840 99,840.00 Cube Utilization [%] 50.4 54.58 49.12 49.12

31 15

Spray Head Bottle- Cube Utilization Comparison 32

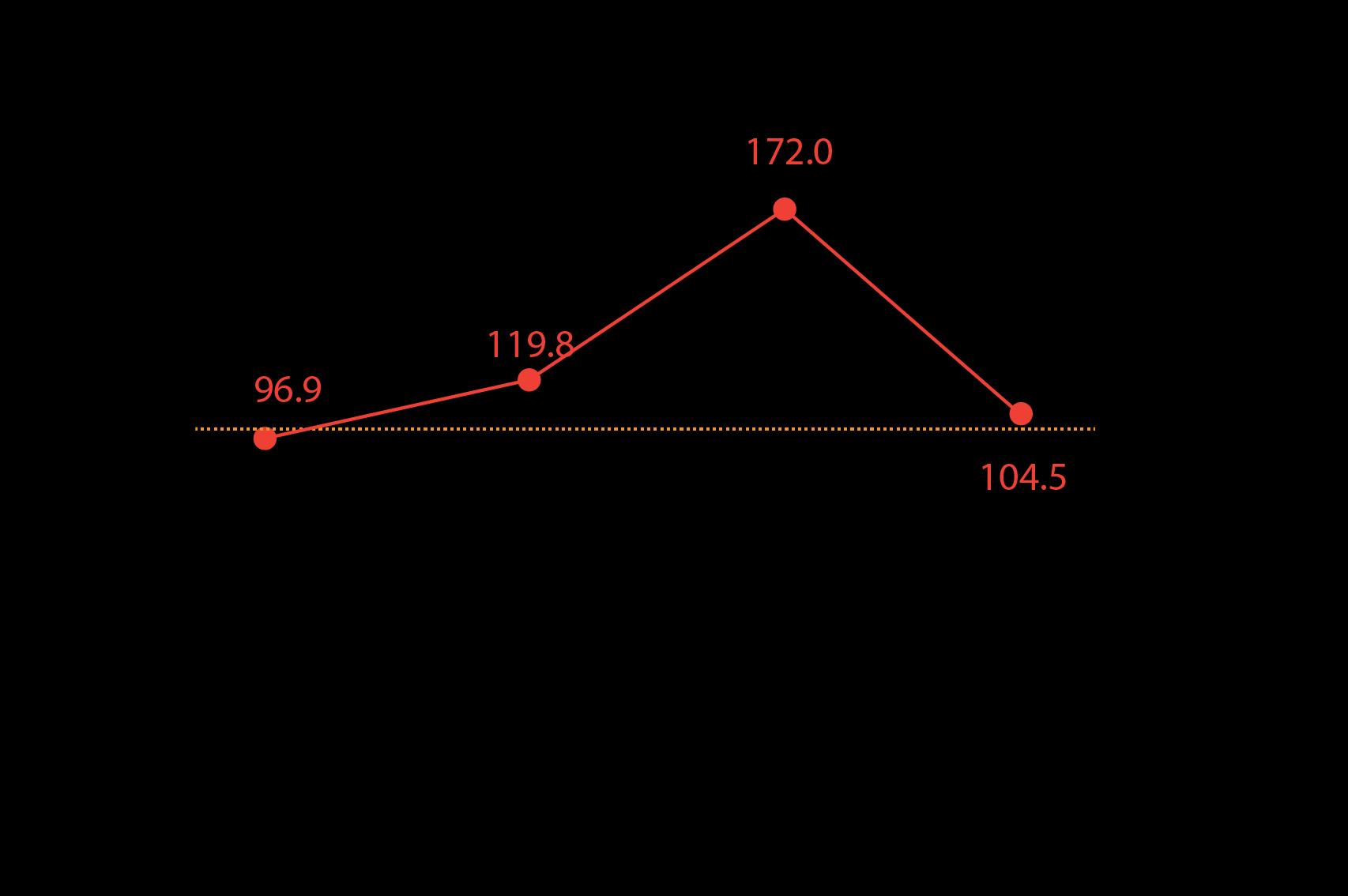

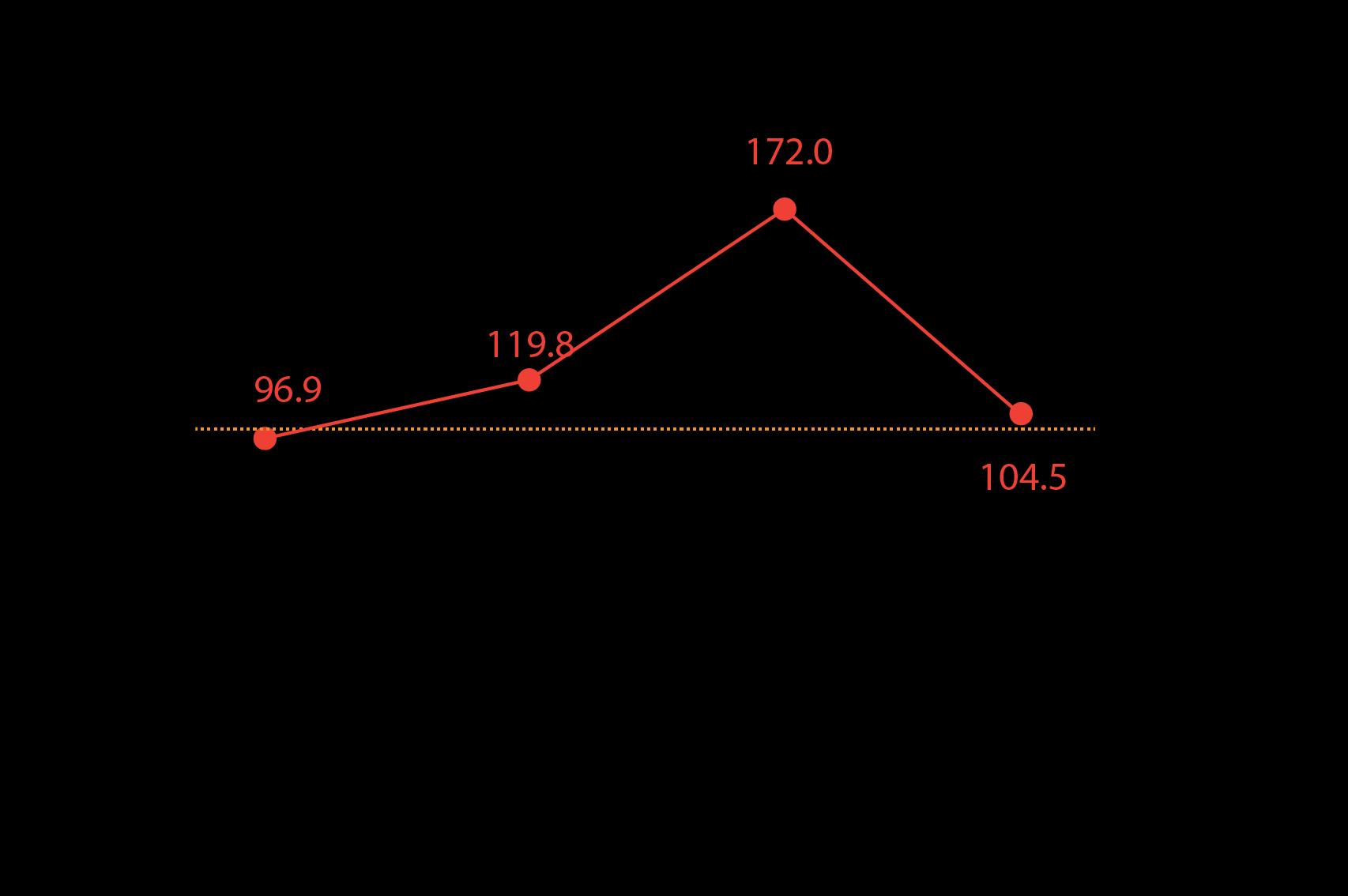

Spray head BottleCompression Strength

Humidity Level: 70%

Crossed stores for 120 Days

Internal support 10 lbs

Pallets 2 High

Partition Type 0

Flute C Flute

Ring Crush ETC 32.2

Burst Test :150

Material combination: 33-26-33

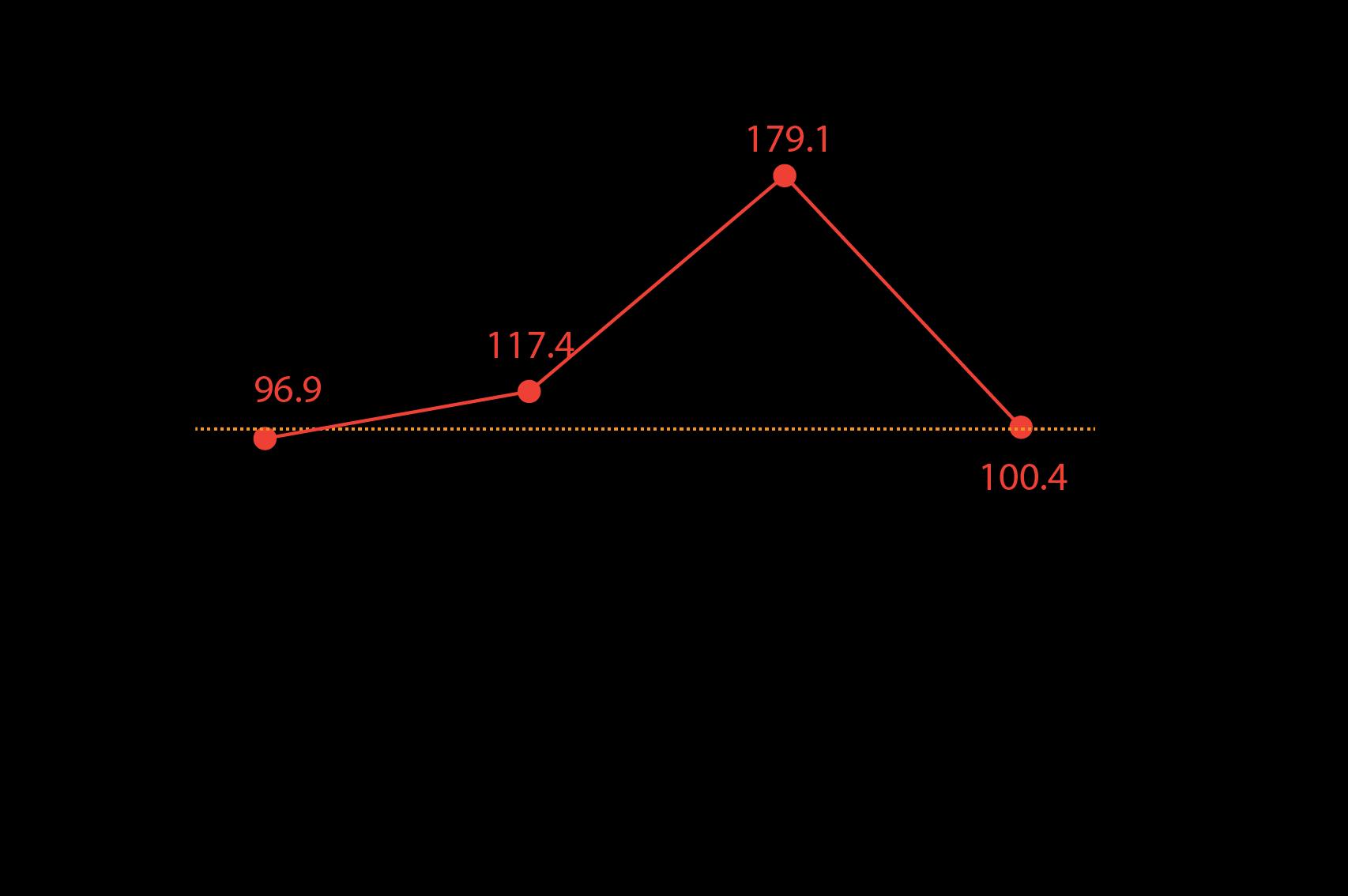

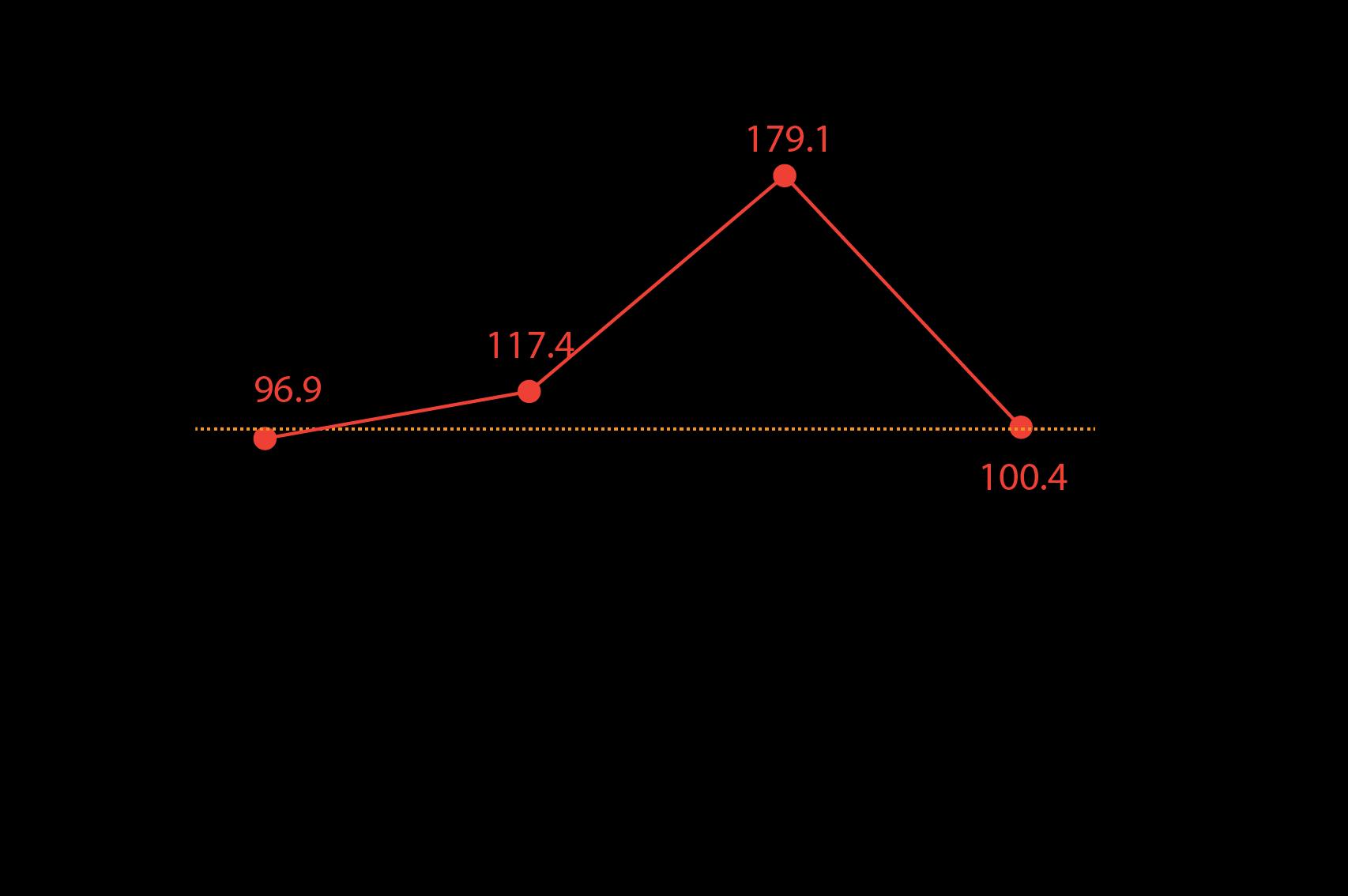

Original 8 bottles 6 bottles 9 bottles Empty Strengths 428.0 431.7 403.7 449.4 Static Strengths 428.0 431.7 403.7 449.4 Dynamic Strengths 167.5 168.9 158.6 175.4 Loads high 3.7 4.1 4.9 3.8 Safety Margin 96.9% 119.8% 172.0% 104.5%

17

All new design pass the standardization of the compression test

Spray Head Bottle- Safety Margin Comparison 34

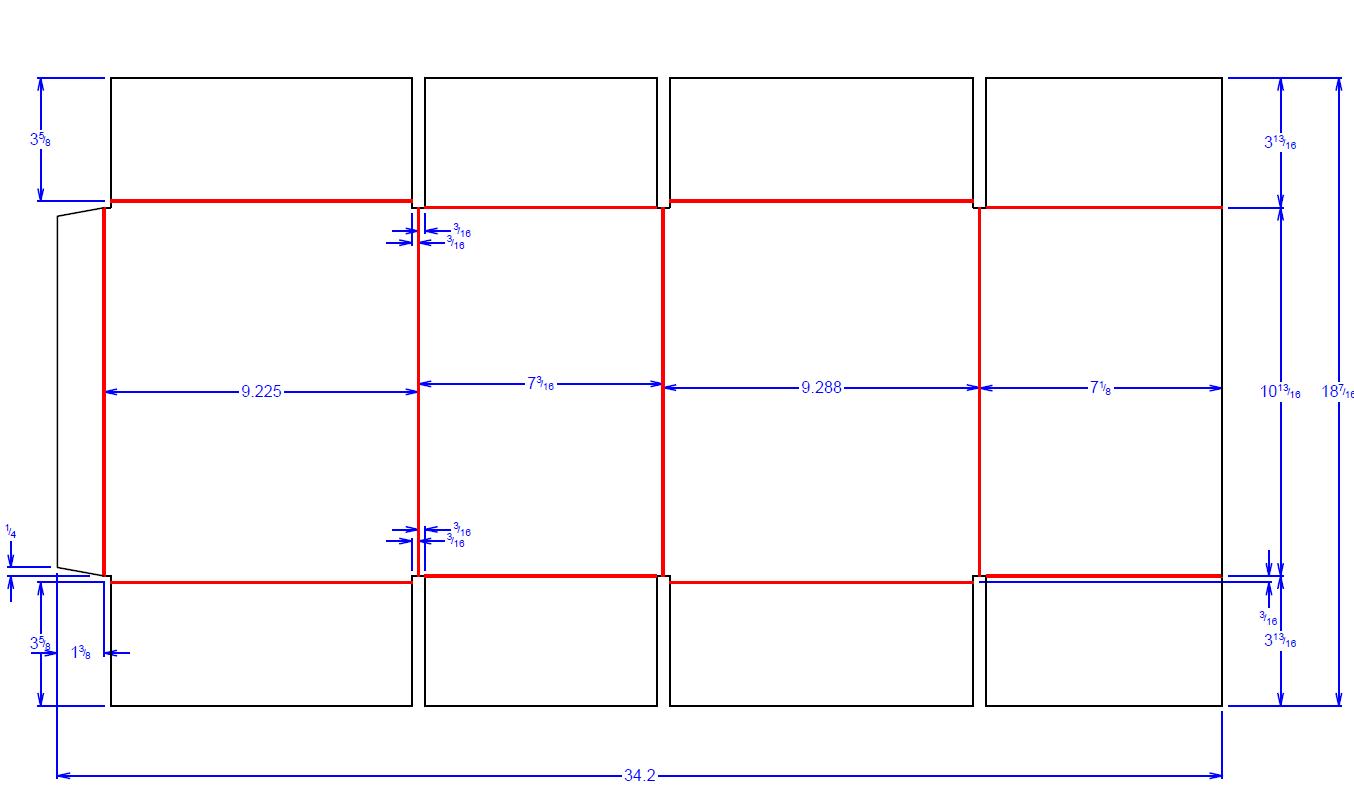

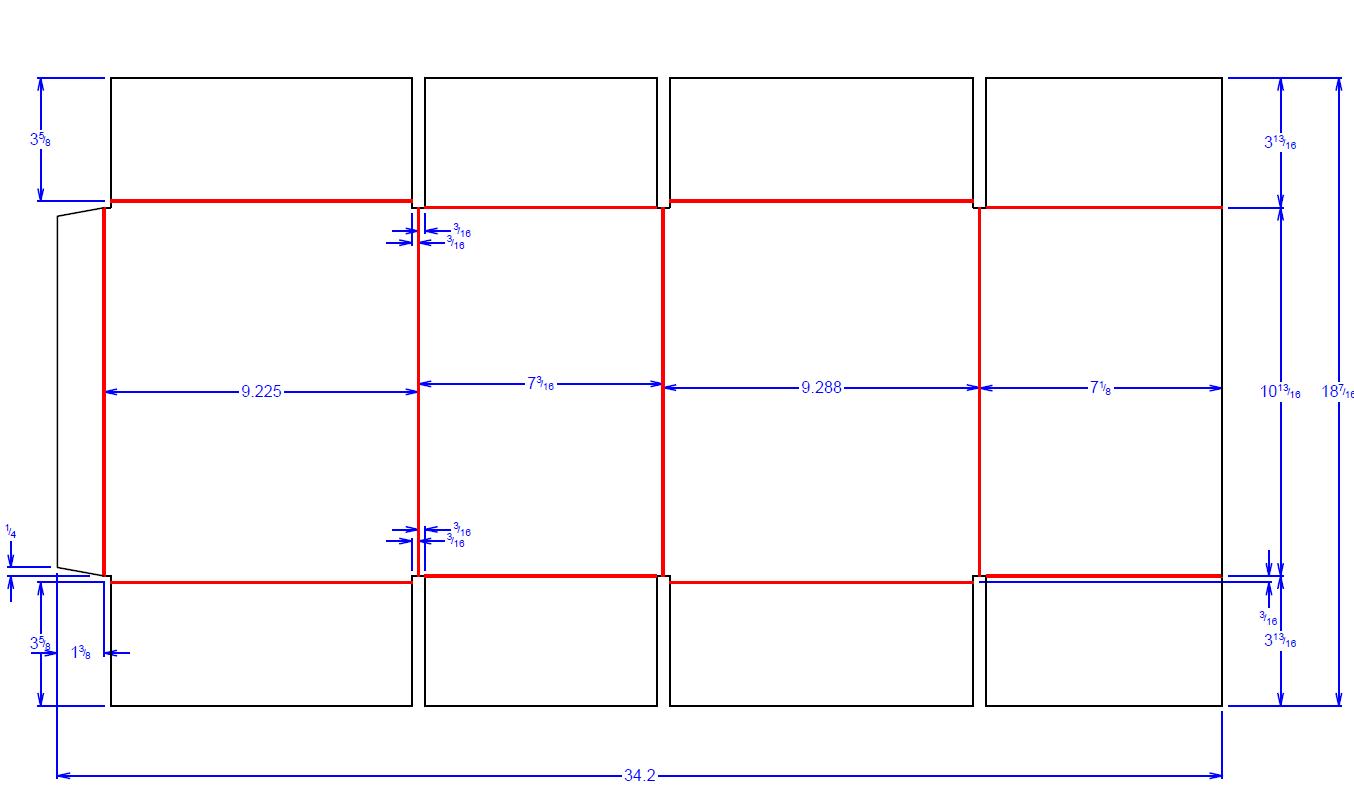

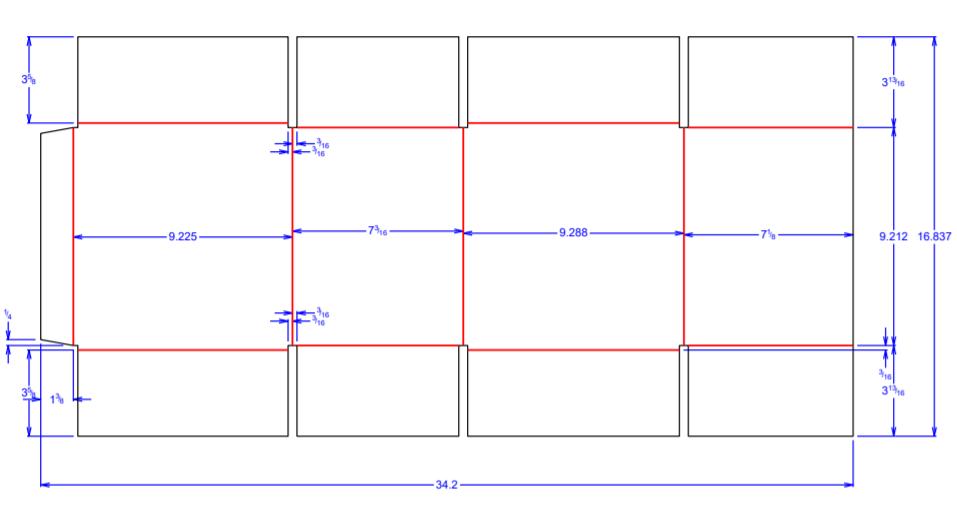

Spray Head Bottle ArtiosCAD Specification Sheet 35

Next-Gen Refill BottleDesign and CAPE Report

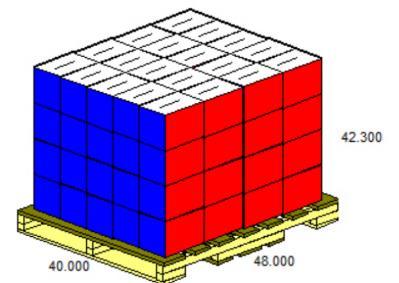

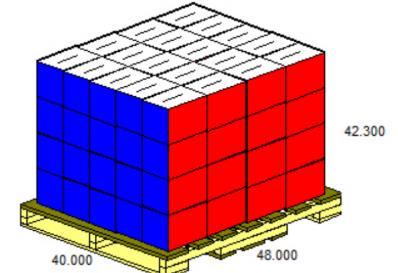

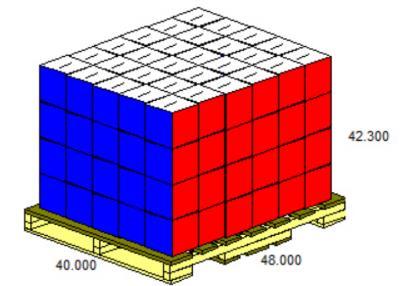

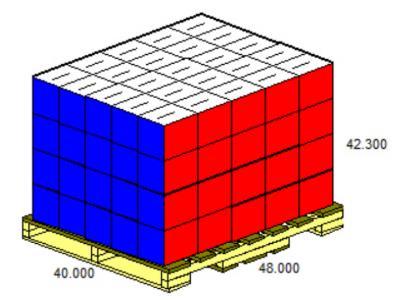

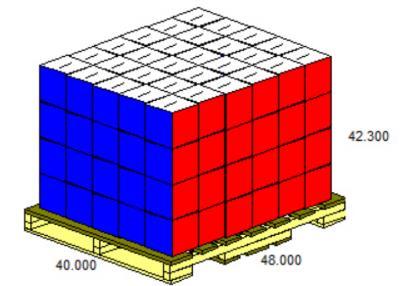

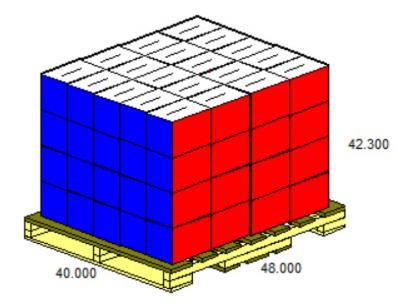

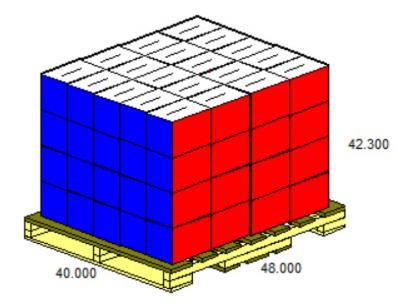

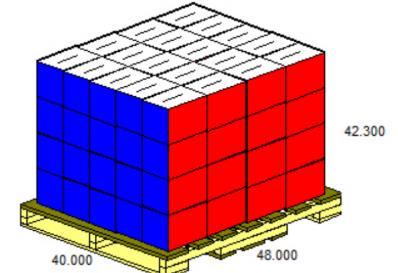

Bottle/ Case 8 8 6 9 Case/ Layer 16 25 30 20 Layer/ Load 4 4 4 4 Case/ Load 64 100 120 80 Bottle/ Load 512 800 720 720 Cube Used (%) 66.4 72.1 67.1 66.4 Area Used (%) 80.3 87.2 81.0 80.3

36

8 bottles case shows it has better result of cube used and area used on load.

Next-Gen Refill Bottle- CAPE Report

37

Next-Gen Refill BottleEco Spreadsheet Analysis

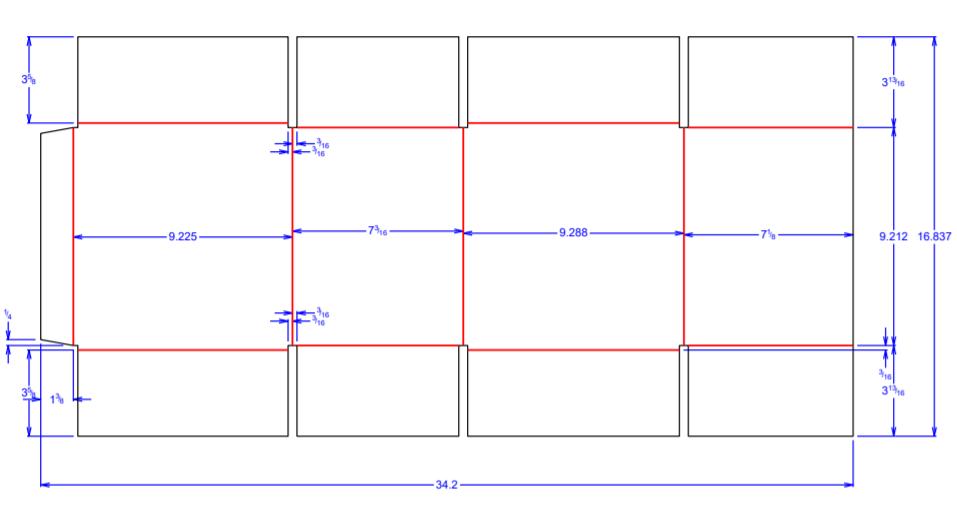

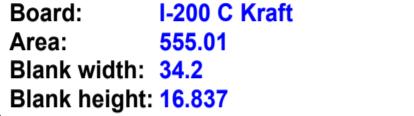

Deepak Oringinal packaging 8 bottles 6 bottles 9 bottles Box Type RSC RSC RSC RSC Weight (filled) (lb) 16.7802 9.86 7.51 11.0413 Weight (empty) (lb) 0.6 0.53 0.52 0.55 Flute C C C C Sq in Material (sq in) 871.82 555.01 484.29 602.15 ECT (lbs/in) 32 32.00 32.00 32 Arrangment 4x2x1 4x2x1 3x2x1 3x3x1 Total bottles in the box 8 8 6 9 OD (in) 9x10.5x11 9.3x7.2x9.2 7.2x7.2x9.2 10.7x7.2x9.2 Dec Type Flexo flexo flexo flexo Pack/Prod Ratio (lb/total cmums per case) 0.0029086 0.068470 0.069530 0.068156 Pack/Prod Ratio (sq in/total cmums per case) 4.1914423 3.85 4.48 3.72 Bottles/Pallet 512 800 720 720 Total CMUM / pallet 13312 14,400 12960 12,960 Cases/ Pallet 64 100 120 80 Total weight of cases on pallet (lb) 1073.9328 986.00 901.2 883.304 Selling Unit Volume (cu in/pallet) 50320 54,494.53 49045.07 49,045.07 Transport Pallet Volume *(TPV) (cu in) 99840 99,840.00 99840 99,840.00 Cube Utilization [%] 50.4 54.58 49.12 49.12 38

Next-Gen Refill Bottle- Cube Utilization Comparison 39

Next-Gen Refill BottleCompression Strength

Humidity Level: 70%

Crossed stores for 120 Days

Internal support 10 lbs

2 High

Type 0

Flute C Flute

Ring Crush ETC 32.2

Burst Test :150

Material combination: 33-26-33

Original 8 bottles 6 bottles 9 bottles Empty Strengths 428.0 411.2 403.7 428.0 Static Strengths 428.0 411.2 403.7 428.0 Dynamic Strengths 167.5 161.3 158.6 167.5 Loads high 3.7 4.0 5.1 3.7 Safety Margin 96.9% 117.4% 179.1% 100.4%

25

Pallets

Partition

All new design pass the standardization of the compression test

Next-Gen Refill Bottle- Safety Margin Comparison 41

Next-Gen Refill Bottle- ArtiosCAD Specification Sheet 42

New Design Value

Sustainability Company

Consumer ▪ Easy to recycle ▪ Lighter weight ▪ Transport efficiency ▪ Save the cost by better cube utilization ▪ Use less material ▪ Less environmental impact ▪ Less material consumption

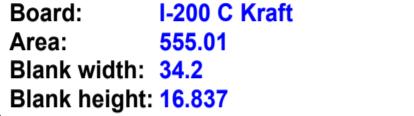

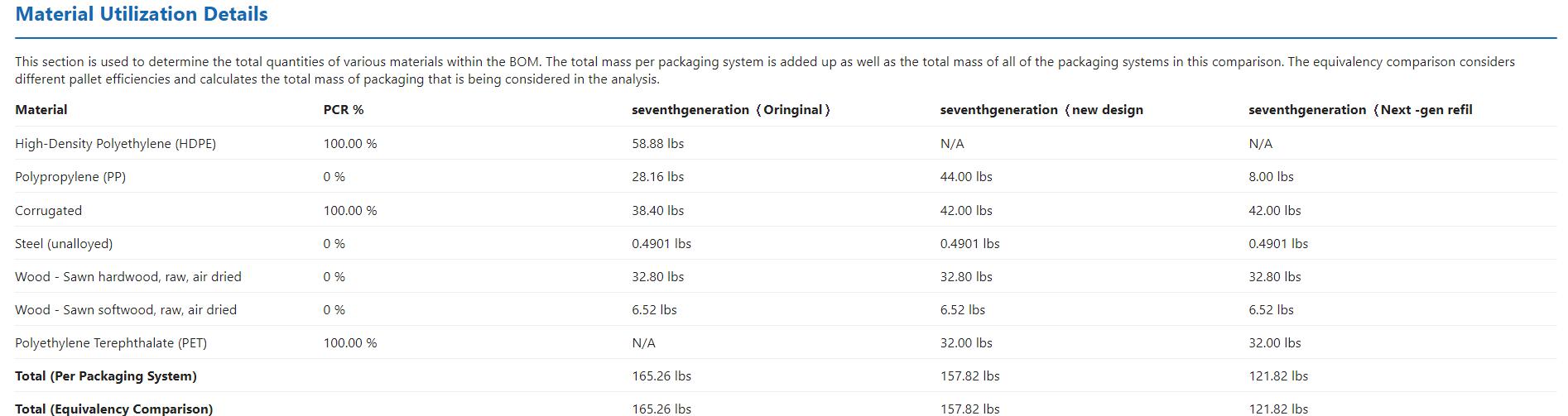

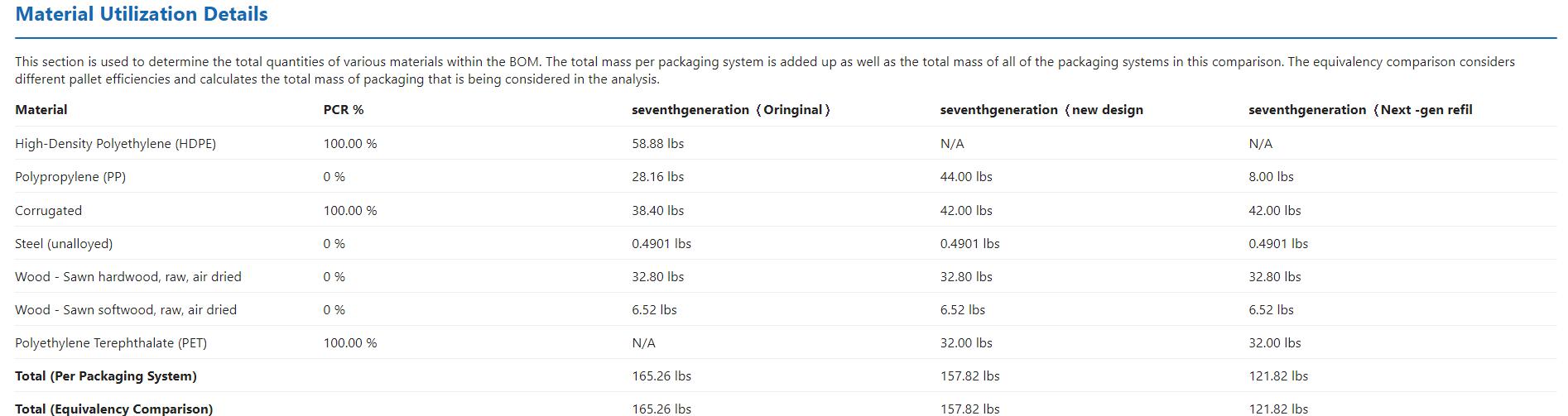

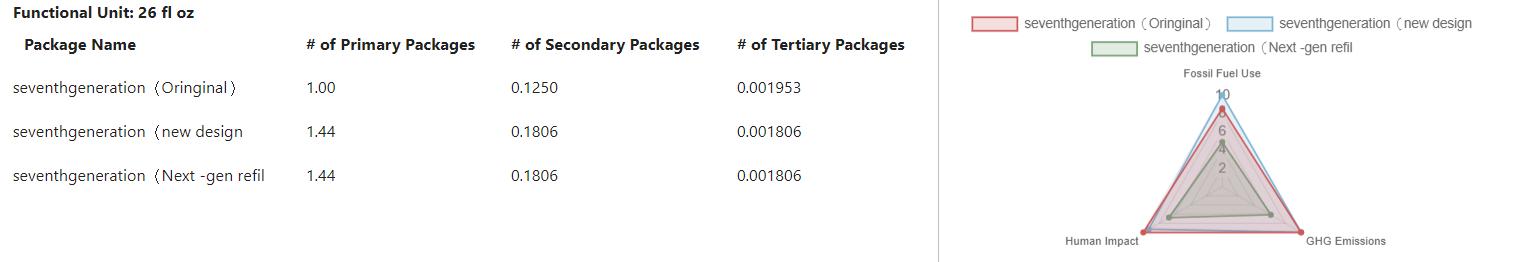

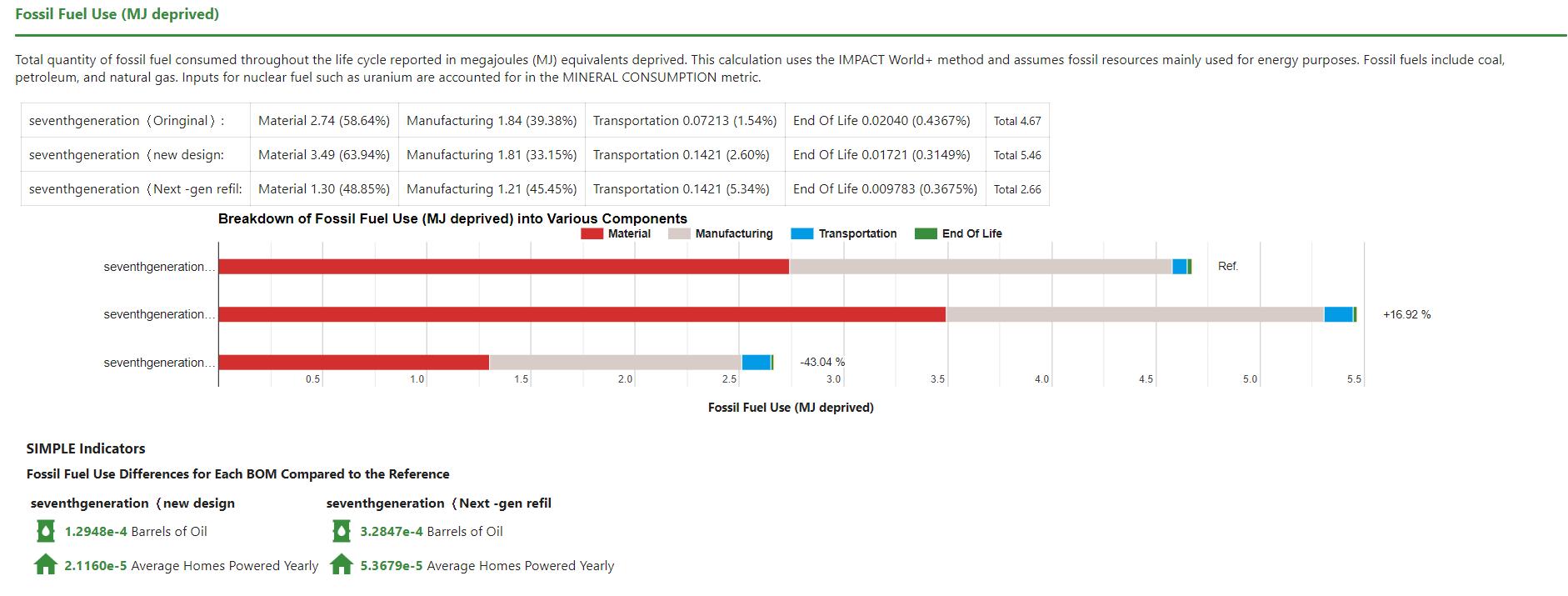

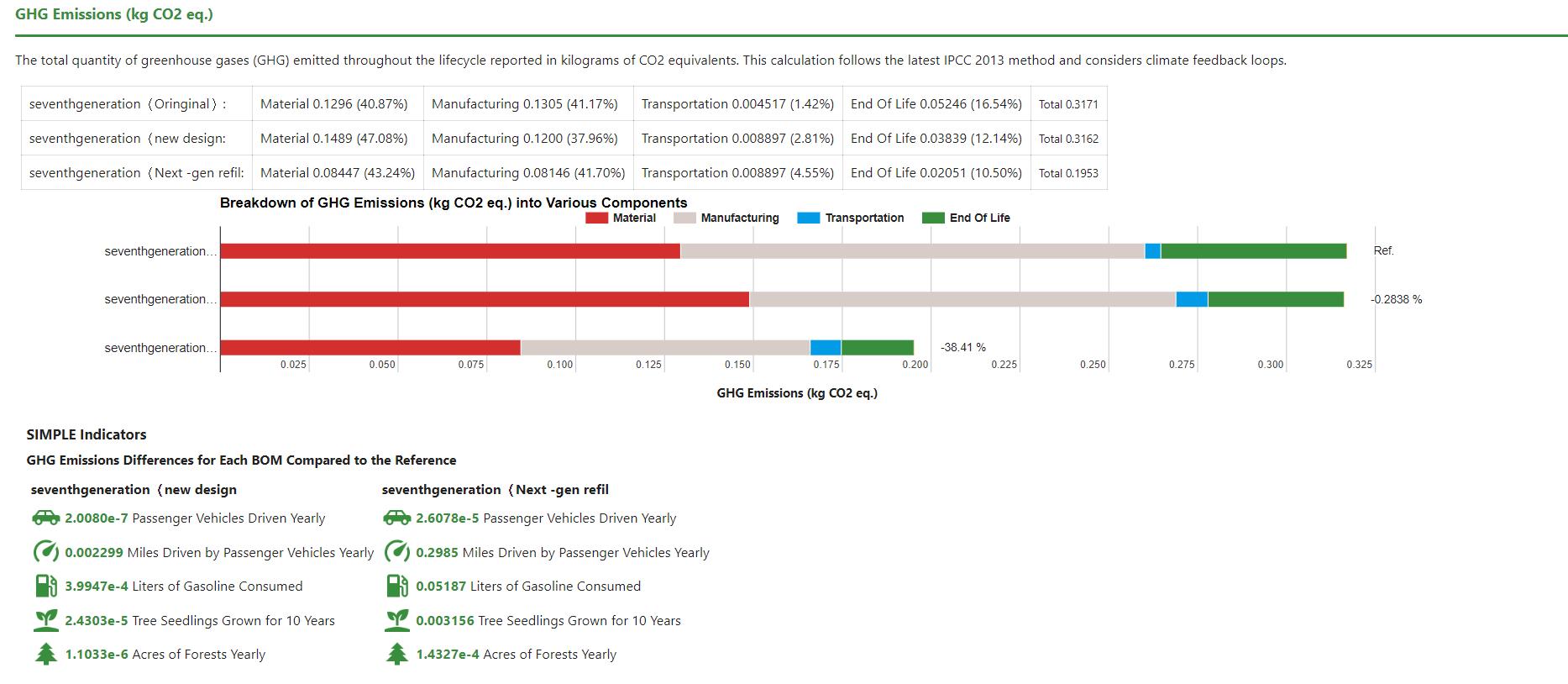

Eco-Impact Analysis

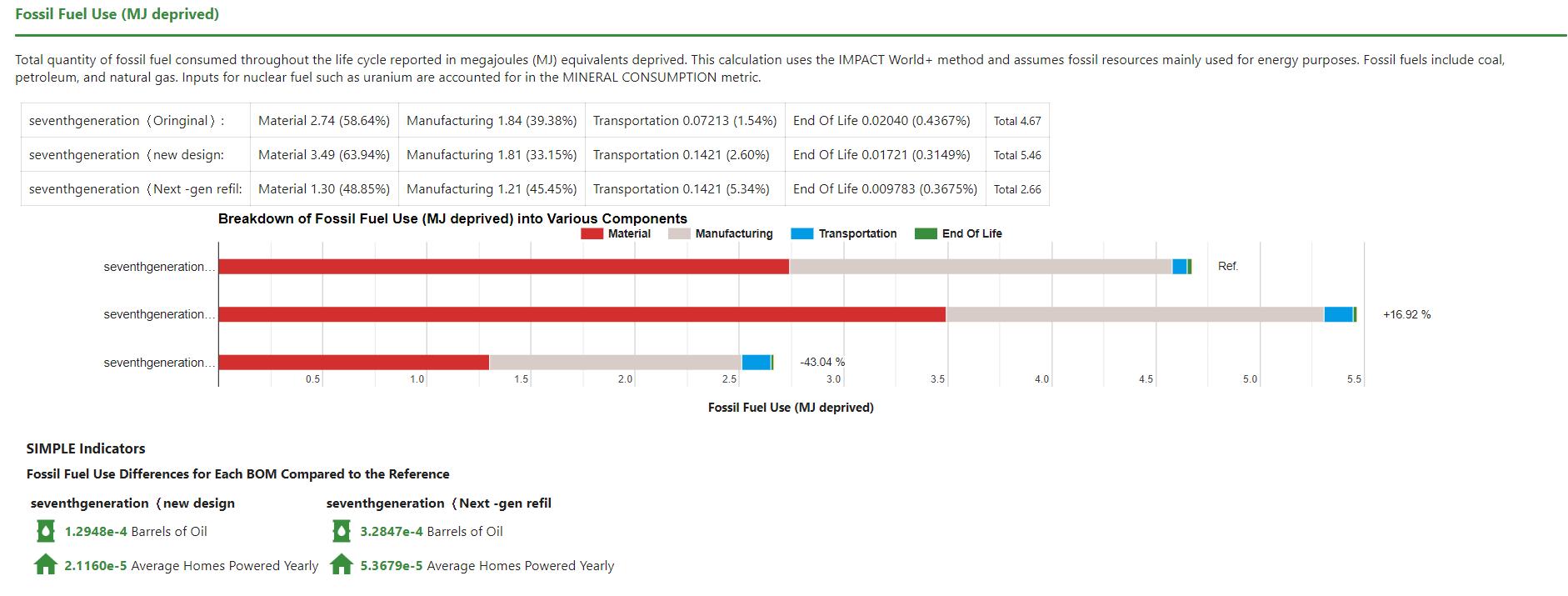

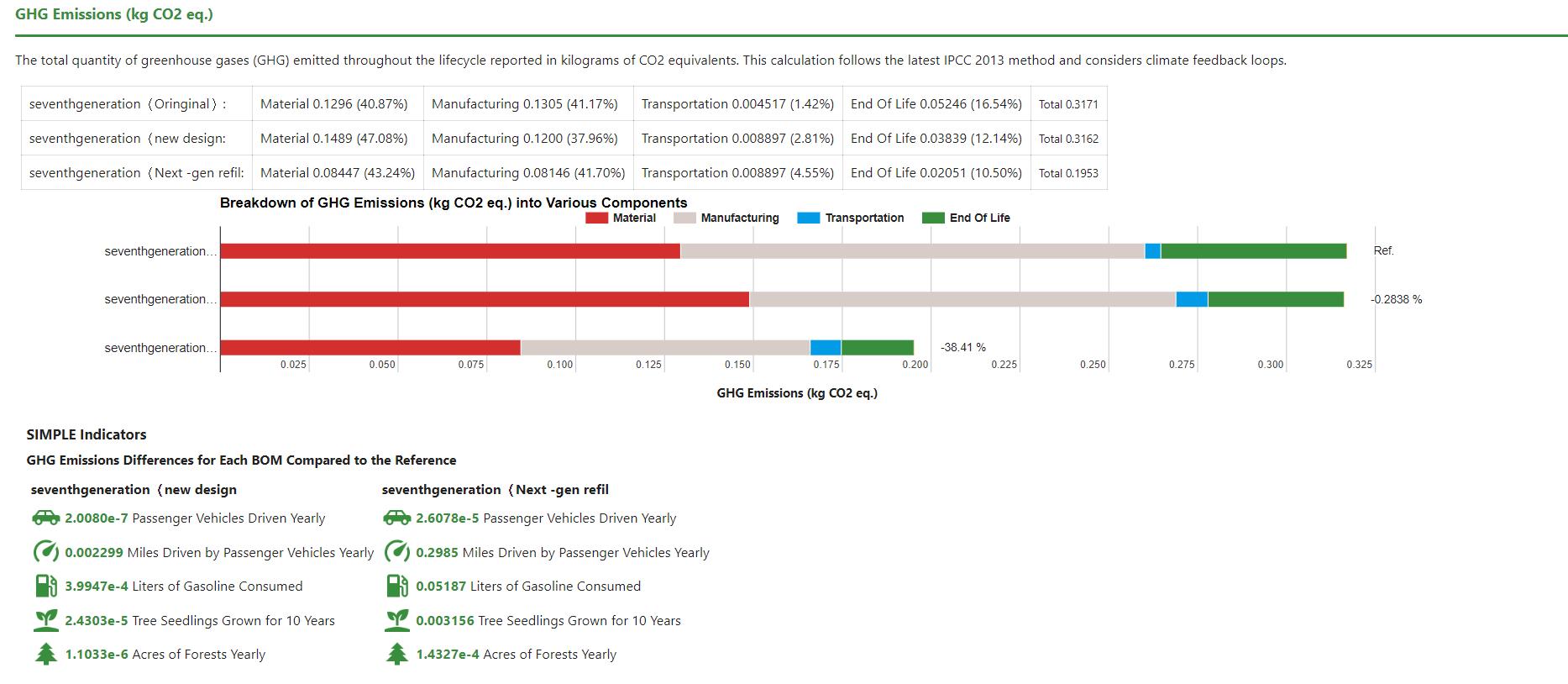

Ecoimpact Analysis

Ecoimpact Analysis

46

Ecoimpact Analysis

New Original Refill

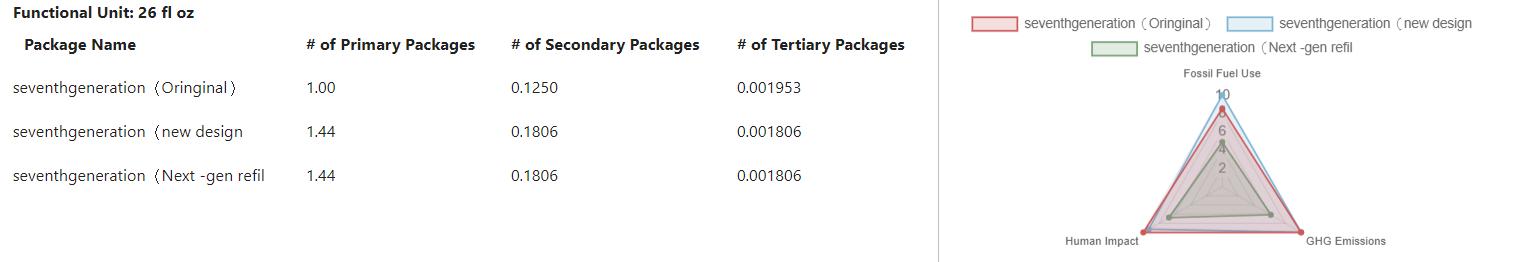

Design Goal Report

Cube Utilization Increase 4.5% Pallet Area Usage GHG Value FFC Value Increase 7.2% Decrease 38.4% Increase 7.5% Cmum Shipped Per Pallet Decrease 43.04%

What’s For Next?

WE ARE ALMOST THERE! BUT BEFORE THAT…..

• Redesigning the scorecard and Providing Practical Rankings.

• Considering Other Refill Strategies Like, Concentrates or a Pouch Refill Package.

• Running The Distribution Tests Based on ISTA 3A.

• Analyzing The Test Results, If Approved then move to next step; If not, then optimizing the structure of the package.

49