Graduate Defense

Constructive Paper Cushion

Presenter: Charlene Feng

Rochester Institute of Technology

Instructor: Dr. Changfeng Ge

Committee: Dr. Alexis Rich, Dr. Kyle Dunno

May 10th, 2023

01 02 03 04

Design

1

Agenda

Introduction

Testing Analysis

2

Introduction 01

Material Comparison

Plastic Cushion

- Foam Cushion

• Durability, Perfect Cushion

Properties

• Reusable

• Light weight

• Moist Resistant

• Low cost (Most common used)

• Low recyclability

Paper Cushion

- Corrugated Cushion

• Versatile (Easy to fabric/ shape)

• Limited reusability

• Not moisture-resistant

• High recyclability

• Biodegradable

3

Origami

Origami is a traditional Japanese art of paper folding. The word "origami" comes from two Japanese words, "ori" which means "folding," and "kami" which means "paper."

Benefit of Origami

Easy to produce.

Improve Paper Cushion

• Durability

• Stiffness

• Compressibility

• deployable performance

• Lightweight

4

02

Design 5

Design Method Folding method

• Stability:

• Uniform flat surface

• Strength

• Deployable

• Compactness

• Scalability

• Deployable

• Compactness

• Scalability

• Stability

6

Box Fold Accordion Fold Miura-Ori Fold

Design Method

Design Geometry

Flute height

Increase flute height to increase maximum displacement and decrease maximum stress in both static pressure and drop tests (Zhang, 2014).

Arc radius of the flute

Increase the arc radius of the flute to increase maximum displacement and decrease maximum stress in static pressure test(Zhang, 2014).

Flute angle

The optimal flute angle for maximum stress and maximum displacement is 60° for both static pressure and drop tests (Zhang, 2014).

Optimal geometry for paper cushion: The flute should have a 60° angle.

7

Design Result

8

Left to right Miura Ori-fold, Tube, Zig- zag

Design Result

Design 1- Cube Pipe

9

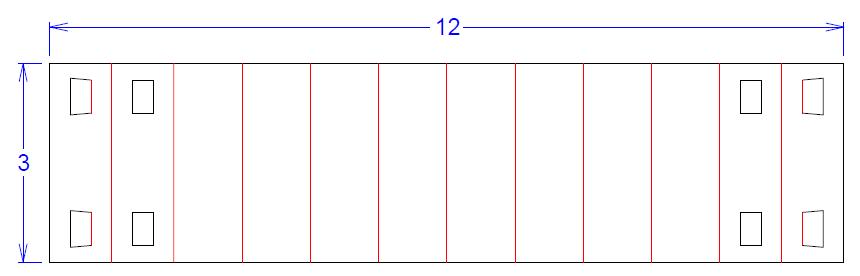

Cube Pipe Structure

Cube Pipe Die-line

Design Result Design 1- Cube Pipe

Flute arc angle: 90-degree

16 supporting point

10

Design Result

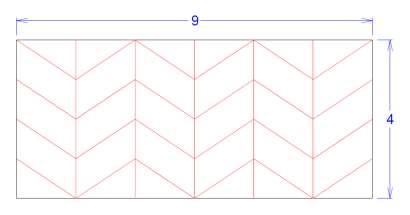

Design 2- Zig-Zag

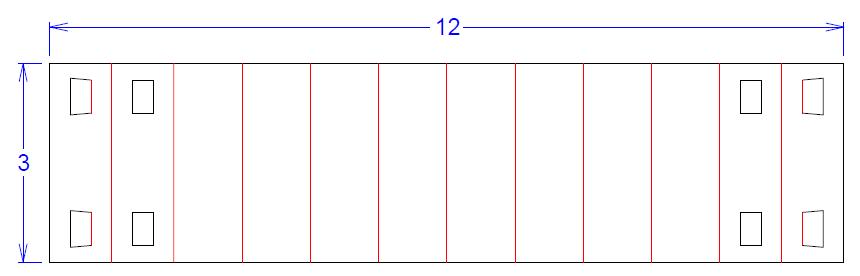

Zig-Zag Die-line

11

Zig-Zag Structure

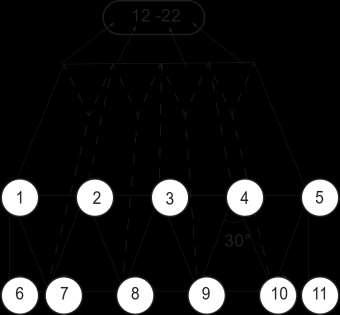

Design Result Design 2- Zig-Zag

Flute arc angle: 30-degree

22 supporting point

12

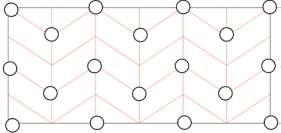

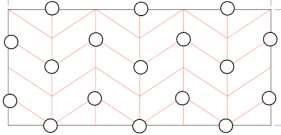

Design Result

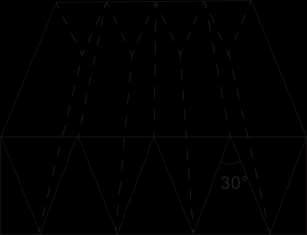

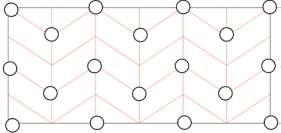

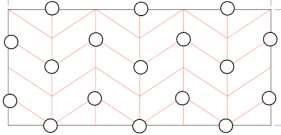

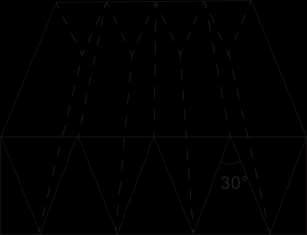

Design 3- Miura-Ori Fold

Miura-Ori Structure

Miura-Ori Die-line

13

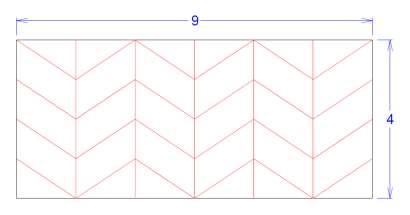

Design Result

Design 3- Miura-Ori Fold

Flute arc angle: 60-degree

34 supporting point

Mountain fold

Valley fold

14

03

Testing 15

Testing method

• ASTM D3575

• Compression Cushion Test

Testing Set Up

• Testing device : Instron 5567

• Environmental condition: Temperature: 21.5 °C/ Humidity: 30.6%

16

Hypothesis

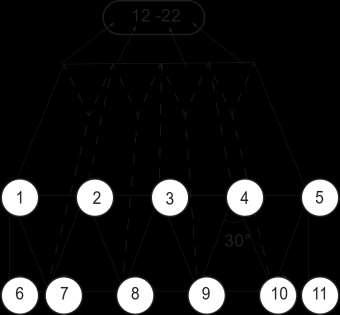

Cushion performance within three design

Miura-Ori Fold Zig-Zag Cube Pipe

17

> >

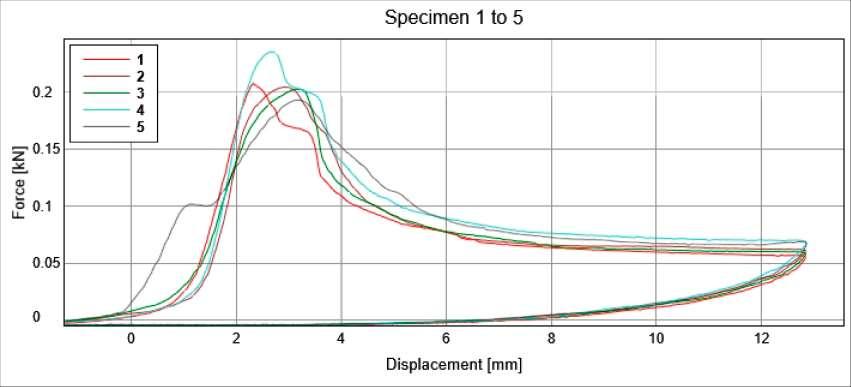

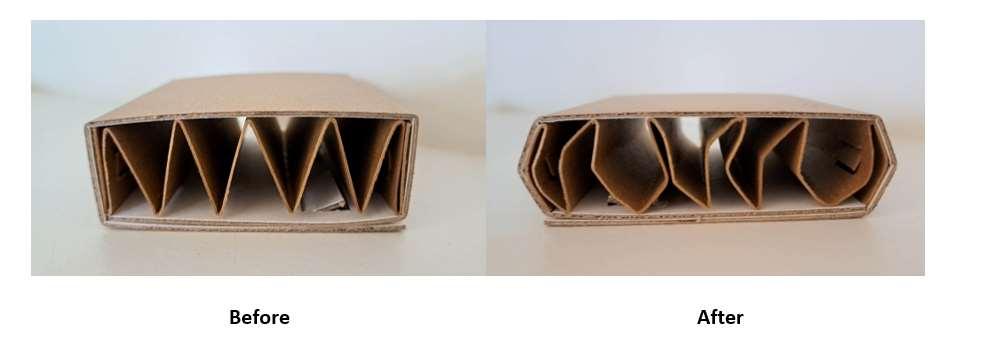

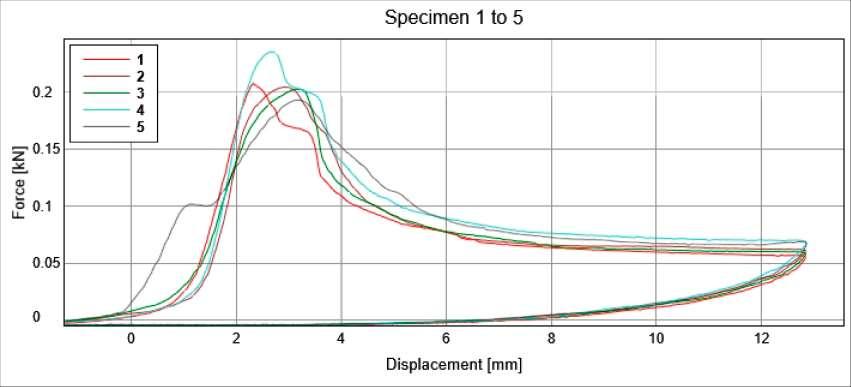

Testing Result

Specimen 1- Cube Pipe

Table 4.1

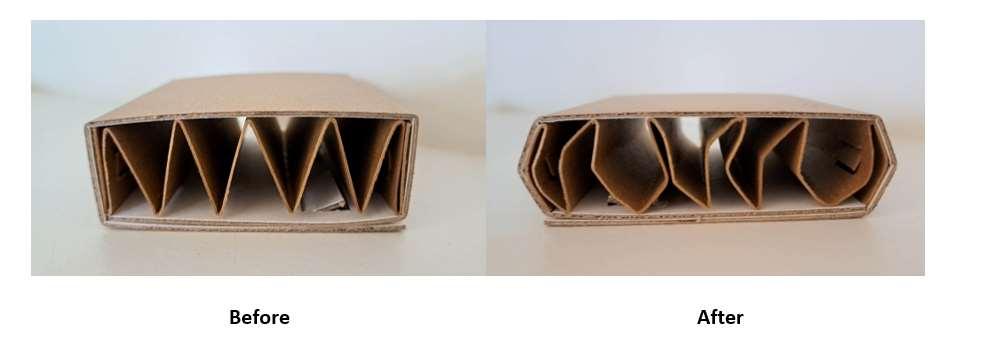

Muria-Ori Fold: Cushion Height Difference

18

Specimen 1 Specimen 2 Specimen3 Specimen4 Specimen5 Average Before 1” 1” 1” 1” 1” 1” After 0.875” 0.875” 0.85” 0.875” 0.938” 0.882”

Testing Result

Specimen 1- Cube Pipe

19

Compressive displacement at Maximum Force [mm] Compressive strain (Displacement) at Maximum Force [%] Compressive stress at Maximum Force [MPa] Maximum Force [kN] Energy at Maximum Force [J] 1 2.23 9.14 0.04 0.21 0.16 2 2.90 11.42 0.04 0.20 0.24 3 3.14 12.36 0.03 0.20 0.30 4 2.66 10.47 0.04 0.24 0.22 5 3.18 12.52 0.03 0.19 0.37 Avg 2.82 11.18 0.036 0.21 0.26

Table 4.2

Cube Pipe Compression Testing Result

Testing Result Specimen 1- Cube Pipe

20

Figure 4.2

Cube Pipe Compression Testing Result

Testing Result

Specimen 1- Cube Pipe

21

Displacement (mm) Energy Absorption (J) Specimen 1 Specimen 1 Specimen1 Specimen1 Specimen1 Average 0.500 0.000 0.003 0.003 0.001 0.013 0.004 1.000 0.009 0.009 0.014 0.006 0.050 0.017 1.500 0.035 0.025 0.039 0.023 0.100 0.044 2.000 0.098 0.074 0.091 0.078 0.162 0.100 2.500 0.189 0.160 0.173 0.178 0.241 0.188 2.820 0.290 0.259 0.270 0.295 0.331 0.289

Table 4.3

absorption during Compression testing

Cube Pipe: Energy

Testing Result

1- Cube Pipe

22

0.000 0.050 0.100 0.150 0.200 0.250 0.300 0.350 0.5 1 1.5 2 2.5 2.82 Anergy absorption (J) Dispasment (mm) Specimen 1 Specimen 2 Specimen 3 Specimen 4 Specimen 5 Average

Specimen

Figure 4.3 Cube Pipe: Energy absorption during Compression testing

Testing Result

Specimen 2- Zig-Zag

23

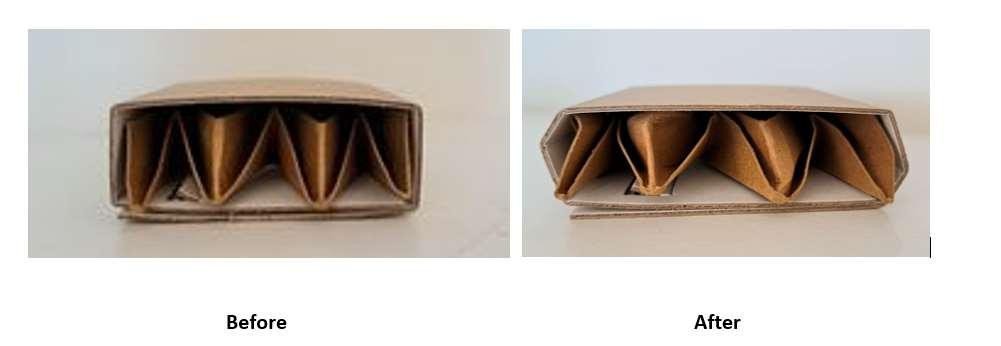

Specimen 1 Specimen 2 Specimen3 Specimen4 Specimen5 Average Before 1” 1” 1” 1” 1” 1” After 0.938” 0.938” 0.938” 0.875” 0.938” 0.925”

Table 4.4

Muria-Ori Fold: Cushion size difference

Testing Result

Specimen 2- Zig-Zag

24

Compressive displacement at Maximum Force [mm] Compressive strain (Displacement) at Maximum Force [%] Compressive stress at Maximum Force [MPa] Maximum Force [kN] Energy at Maximum Force [J] 1 3.22 12.68 0.04 0.24 0.33 2 2.84 11.18 0.04 0.24 0.25 3 3.08 12.13 0.04 0.24 0.32 4 3.36 13.23 0.04 0.22 0.30 5 3.54 13.93 0.04 0.23 0.36 Avg 3.21 12.63 0.04 0.23 0.31 Table

4.5 Zig-Zag Compression Testing Result

Testing Result Specimen 2- Zig-Zag

25

Figure 4.5

Zig-Zag Compression Testing Result

Testing Result

Specimen 2- Zig-Zag

Table 4.6

Zig-Zag: Energy absorption during Compression testing

26

Displacement (mm) Energy Absorption (J) Specimen 1 Specimen 1 Specimen1 Specimen1 Specimen1 Average 0.5 0.000 0.003 0.003 0.001 0.003 0.002 1 0.003 0.010 0.017 0.008 0.010 0.009 1.5 0.021 0.031 0.045 0.021 0.022 0.028 2 0.076 0.081 0.102 0.053 0.055 0.073 2.5 0.168 0.169 0.197 0.123 0.130 0.157 3 0.265 0.225 0.278 0.221 0.246 0.247 3.21 0.330 0.250 0.320 0.300 0.360 0.312

Testing Result Specimen 2- Zig-Zag

27

Figure 4.6

0.000 0.050 0.100 0.150 0.200 0.250 0.300 0.350 0.400 0.5 1 1.5 2 2.5 3 3.21 Anergy absorption (J) Displacement (mm) Specimen 1 Specimen 2 Specimen 3 Specimen 4 Specimen 5 Average

Zig- Zag: Energy absorption during Compression testing

Testing Result

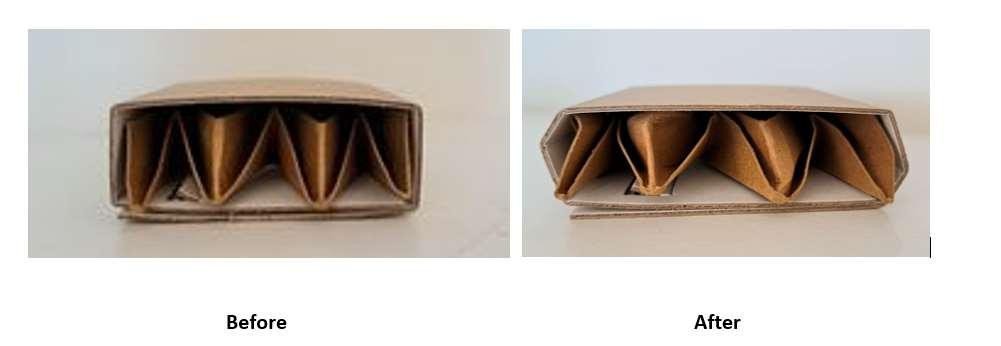

Specimen 3- Miura-Ori Fold

28

Specimen1 Specimen2 Specimen3 Specimen4 Specimen5 Average Before 1” 1” 1” 1” 1” 1” After 0.875” 0.938” 0.938” 0.875” 0.938” 0.913”

Table 4.7

Muria-Ori Fold: Cushion size difference

Testing Result

Specimen 3- Miura-Ori Fold

29

Compressive displacement at Maximum Force [mm] Compressive strain (Displacement) at Maximum Force [%] Compressive stress at Maximum Force [MPa] Maximum Force [kN] Energy at Maximum Force [J] 1 12.72 50.10 0.08 0.45 3.58 2 12.71 50.02 0.06 0.36 3.41 3 12.74 50.16 0.07 0.38 3.15 4 12.76 50.23 0.07 0.42 2.98 5 9.88 38.90 0.07 0.42 2.29 Avg 12.16 47.88 0.07 0.41 3.08 Table

4.8

Muria-Ori Compression Testing Result

Testing Result

Specimen 3- Miura-Ori Fold

30

Figure 4.8

Muria-Ori Compression Testing Result

Testing Result

Specimen 3- Miura-Ori Fold

Muria-Ori Fold: Energy absorption during Compression testing

31

Displacement (mm) Energy Absorption (J) Specimen 1 Specimen 1 Specimen1 Specimen1 Specimen1 Average 1 0.010 0.010 0.008 0.005 0.005 0.007 2 0.035 0.034 0.024 0.016 0.016 0.025 3 0.105 0.109 0.073 0.052 0.051 0.078 4 0.285 0.249 0.188 0.150 0.140 0.202 5 0.490 0.474 0.388 0.297 0.315 0.393 6 0.745 0.789 0.678 0.507 0.605 0.665 7 1.103 1.126 1.016 0.807 0.960 1.002 8 1.503 1.459 1.363 1.152 1.343 1.364 9 1.907 1.799 1.723 1.502 1.720 1.730 10 2.308 2.150 2.082 1.851 2.109 2.100 11 2.728 2.501 2.430 2.203 2.526 2.477 12.16 3.580 3.410 3.150 2.570 2.980 3.080

Table 4.9

Testing Result

Specimen 3- Miura-Ori Fold

32

Figure 4.9

0 0.5 1 1.5 2 2.5 3 3.5 4 1 2 3 4 5 6 7 8 9 10 11 12.16 Anergy absorption (J) Dispasment (mm) Specimen 1 Specimen 2 Specimen 3 Specimen 4 Specimen 5 Average

Muria-Ori Fold: Energy absorption during Compression testing

04

Analysis 33

34

Cube-Pipe Zig-Zag Muria-Ori Paper Used [sq. in.] 42 36 36 Supporting Points 16 22 34 RadiusArc [°] 90 30 60 Max. Force Displacement [mm] 2.82 3.21 12.16 Max. Force [MPa] 0.036 0.04 0.07 Max. Force [kN] 0.21 0.23 0.41 Energy at Max. Force [J] 0.36 0.31 3.08

Analysis

Table 5.1

Constructive Paper Cushion Comparison

35

Analysis

Figure 5.1

2.82 0.036 0.21 0.36 3.21 0.04 0.23 0.31 12.16 0.07 0.41 3.08 0 2 4 6 8 10 12 14 Max. Force Displacement [mm] Max. Force [MPa] Max. Force [kN] Energy at Max. Force [J] Cube-Pipe Zig-Zag

Constructive Paper Cushion Comparison

Muria-Ori

Conclusion

• The folding angle and number of supporting points are critical considerations when designing a constructive paper cushion.

• The Muria Ori fold offers superior cushioning and energy absorption, reducing product damage and returns while improving customer satisfaction. It's a sustainable and cost-effective option due to its exceptional performance with minimal material usage.

• Future research should enhance cushion curves' energy absorption and sustainability while minimizing limitations. Dynamic cushion tests and applying the cushion to real products can improve understanding of its constructive cushion property and enhance product protection and cost-effectiveness.

36

Q A &

Do you have any questions ?

37

THANK YOU

38