FOOD & PACKAGING TECHNOLOGY

According to the latest report published by Markets&Markets agency, the overall frozen bakery products market was valued at USD 22.3 billion in 2021 to reach USD 29.5 billion by 2026, at a CAGR of 5.8%.

Frozen bakery products are increasingly becoming an integral part of the daily diet around the world, particularly in European countries. The busy lifestyle of consumers has contributed to the growth of the bread manufacturing industry to produce new products that could cater to the rise in demand from consumers. The increase in consumption of frozen bakery products in the emerging markets of Asia Pacific and Latin America has also led to a rise in the sales of frozen bakery products. The demand for frozen bakery products in developing regions is driven by the increase in disposable income.

Growing demand from restaurants and other institutional food services will drive the demand of these frozen bakery products globally. Various socio-economic factors such as busy lifestyle, high disposable income, rise in outsourcing of non-core activities by companies, and increasing trend of business travel will boost the demand of foodservice providers. Due to the increase in the number of foodservice providers, such as national and international brands, in the hotel industry, the demand for frozen bakery products is estimated to increase.

In addition to this, various technologies such as microencapsulation technology and individual quick frozen (IQF) technology will help the frozen bakery products to increase the shelf life which in turn will boost the frozen bakery products market during the forecast period.

The increase in consumer preference for convenience food products indirectly encourages the demand for frozen bakery products as they require less time and effort. The processed food market is driven by the increase in the need for convenience due to the busy customer lifestyles. This, in turn, has led to an increase in demand for frozen bakery products. In addition, the high growth of the frozen food industry due to the fast-growing urban households of developing countries is projected to drive the demand for frozen bakery products. The rise in per capita income and the increase in the trend of snacking between meals are the key factors encouraging the demand for frozen bakery products. The development of retail channels in the form of su-

permarkets, hypermarkets, convenience stores, and specialty stores has encouraged the growth of the market. Frozen bakery products do not involve scratch baking and thus require less labor. Therefore, various bakers now prefer keeping frozen baked and parbaked items in their instore bakeries.

Consumers believe that the food products processed in a year or more before it is consumed could not be nutritious. The consumer preference for freshly-baked products remains high due to the assumption that frozen food products lack nutrition. This is due to the perception that their nutritive value deteriorates during the refrigeration process, which restrains the market growth to a significant extent. The need to maintain a constant temperature for frozen bakery products sometimes becomes difficult due to the inefficient cold chains in some developing and under-developed countries. This is projected to be one of the major restraining factors for the growth of the frozen bakery products market.

individual

The high-quality frozen bakery products are mainly attributed to the development of a technology, which is known as the individual quick-frozen (IQF) method. IQF is a freezing method that does not allow large ice crystals to form in food products. With traditional freezing, large ice crystals can damage cells and crystal fibers, which makes the food products dry out. IQF foods, however, produce small ice crystals that allow the fibers of the food product to remain unscathed. Microencapsulation is a recent technology that can help manufacturers achieve the goal of increasing the shelf life and texture of their range of gluten-free frozen bakery products. This technology is used to overcome the cardboard consistency of refrigerated pizza, rising crust pizza,

and also the shelf-life extension of frozen and refrigerated dough, frozen biscuit dough, scoop and bake frozen muffins, and biscuits.

The conventional stores segment has the fastest growth

Conventional stores have the potential to be a prominent distributional channel for frozen bakery products. Niche retailers among these stores have also realized

According to the latest market analysis published by MarketsandMarkets agency, the global dietary supplements market, with a compound annual growth rate of 7.4%, is expected to grow from $167.5 billion in 2023 to $239.4 billion by the end of 2028. The factors driving the growth are the increasing elderly population, the shift from pharmaceuticals towards nutraceuticals, amino acids, and protein supplements due to the focus on preventive healthcare, and the growing personalized nutrition, which is supporting the dietary supplement industry. Consumers are shifting focus toward self-directed care driven by the growing personal health, weight management, and well-being trend. The personal care markets have changed drastically in recent years, from consumers adopting weight management and protein supplements to help manage lifestyle disorders. In most of the region, it is seen that people do not take an adequate amount of protein, and because of this, the need for amino acids and protein supplements is increasing. Additionally, due to wrong eating habits and improper lifestyles, a vast majority of consumers are opting for weight management supplements to curb obesity and overweight issues.

Shift in consumer preferences due to the increasing focus on health and prevention

According to a recent survey conducted by the Council for Responsible Nutrition (CRN), 73% of Americans will use dietary supplements in 2020. The

most important reason for the growing use of dietary supplements among consumers was their “overall health and wellbeing benefits.” The increasing health awareness has also driven consumers toward customized dietary supplements that are specific to their biological requirements. As people become more conscious the demand for products such as protein supplements, vitamins, and mineral supplements has increased significantly. Consumers are increasingly opting for herbal (botanical) supplements in their daily diet to address health-related issues and for lifestyle change.

The meat and protein processing industry is facing major challenges. Pressure on prices, a wide range of products and the ongoing shortage of skilled labour call for efficient working practices if the industry is to remain competitive globally. Increasing automation and innovative technologies such as artificial intelligence and robotics represent potential solutions: they can boost productivity and cut operating costs. Under the motto “Maximum Performance”, the world’s leading trade fair for the meat and protein processing industry, IFFA - Technology for Meat and Alternative Proteins, showed what was already possible and demonstrate the course the industry needs to take in the future.

Automation is the name of the game in many branches of industry: it not only improves the performance of machines and systems but also helps avoid production interruptions and save energy and materials. In the food industry, for example, automatic product control and traceability is virtually mandatory to ensure a consistently high level of qual-

ity and meet strict legal requirements. It is also an ideal tool for tackling challenges such as rising costs and the shortage of skilled labour.

Process automation in the meat and protein industry ranges from raw material preparation with mixing and grinding, via processing with portioning, filling and moulding, as well as thermal

tenance costs by as much as 30% and increase plant utilisation by 20%.

Machine learning lifts robotics to a new level of development

Today, industrial robots are an established feature in the food industry, especially in larg -

er companies. Operating around the clock, they can bring about considerable gains in efficiency and productivity. However, the dividing line between conventional machines and those with integrated robot technology is not clear cut. It can be said, however, that industrial robots

are mainly used to perform repetitive tasks, such as those typically found in the meat processing industry, for example cutting, portioning, packing, wrapping, sorting, picking and placing.

AI is also taking robotics to a new level of development. Generative AI can use machine learning to adapt independently to new circumstances and situations, thus enabling industrial robots to act more autonomously and agilely. A good example of this is autonomous mobile robots (AMR). Equipped with cameras and sensors, they can independently assess and analyse their surroundings. For instance, they look for new paths when obstacles block the planned route and act independently in abnormal situations. Accordingly, they are perfect helpers in unstructured production settings, as well as in warehouses or logistics centres where packaging and palletising are involved. Despite the multitude of items in such distribution centres, AI-aided industrial robots can select and retrieve the right articles, reject faulty or deformed ones and also detect packaging formats and weights. Such robots achieve pick rates of 750 to 1,400 items per hour and can, for example, pack up to 200 meat products per minute, a significant increase in productivity compared to manual processes. Robots are also superior to their human colleagues in terms of precision, e.g., they can cut meat faster and more precisely at a very specific cutting angle, as well as portion by weight and ideal shape, which not only speeds up the production rate but also minimises raw-material waste.

Multifunctional robotic work cells hold out the promise of an enormous increase in flexibility and are set to replace traditional line production in the meat industry, too. For example, using AI, the robotic work cell can independently process pork sides in a series of operations, which are carried out all at once instead of a series of small operations. Thus, different products can be processed in parallel, enabling an optimum product mix without the restrictions of line production. At the same time, the robotic work cells form autonomous networks with the AMRs, which react independently when faced with changing requirements.

AI, robotics and sensor technology boost performance and accelerate the pace of change

The meat and protein processing industry is on the cusp of radical change, driven by the use of new technologies such as AI, robotics and sensor technology. These technologies are not only an opportunity to automate processes and increase efficiency but also to enhance product quality and sustainability. Companies that integrate these technologies at an early stage are well prepared to ensure their competitiveness on the global market and meet the increasing challenges of tomorrow’s world.

IFFA - Technology for Meat and Alternative Proteins - presented the latest technological developments in Frankfurt am Main last May: www.iffa.com

In recent years, the food, pharmaceutical, and packaging industries have faced increasingly stringent hygiene and safety regulations. Today, production and packaging processes must ensure rigorous contamination control without compromising operational efficiency. It is within this demanding context that MEGALINEAR FC-S, the latest belt developed by Megadyne, is making its debut.

In sectors where the hygiene of food-contact surfaces is non-negotiable, every design detail plays a crucial role.

Engineered for environments requiring frequent washdowns and elevated hygiene standards, MEGALINEAR FC-S marks a significant advancement in the Megadyne portfolio. It joins the trusted MEGALINEAR FC, MEGAPOWER FC, and MEGAPOWER FCM product lines. Manufactured from dark blue TPU compliant with FDA and EU

standards (92 ShA), MEGALINEAR FC-S has been carefully formulated to resist hydrolysis, oils, and fats. Its compatibility with visual inspection systems further supports robust quality control processes.

Fully encapsulated steel cords and sealed edges provide excellent protection against moisture and corrosion. This robust structure prevents residue build-up and simplifies cleaning, reducing the presence of critical zones where bacteria may thrive. Adding to its hygienic design, the closed flight structure has been specifically developed to minimise bacterial growth.

Technically advanced, MEGALINEAR FC-S delivers reliable performance even under demanding conditions. The steel cords ensure exceptional rigidity, dimensional stability, and consistent pre-tensioning, essential for applications requiring synchronised

Available in a wide range of pitches and lengths - T5, T10, T20, AT5, AT10, and AT20 - the belt adapts to a broad variety of production setups. Custom machining options, including guides and cleats, are also available

to meet particular application requirements.

At a time when traceability and surface cleanliness are under close scrutiny, delivering a solution that meets both performance and safety expectations provides a clear competitive edge. With the MEGALINEAR FC-S, Megadyne has further strengthened its position as a trusted partner for industries where food safety, operational reliability, and precision help drive business performance.

The new belt is ideal for manufacturers and operators working in hygiene-critical environments subject to regular washdowns and exposure to moisture and cleaning agents, including food packaging lines, pharmaceutical production, and automated washing systems.

The new MEGALINEAR FC-S brochure, with full technical details, is now available.

Megadyne specialists are ready to support you in selecting the ideal power transmission system for your specific application needs.

(Ammega Italia - Via S. Lucia 114 - 10075 Mathi - TO - Italy - Tel. +39 011 9268052 - email: info@ megadynegroup.com - info@ ammeraalbeltech.it - www.am mega.com)

sectors such as chocolate and refrigerated foods;

• Compact systems: serpentine, recirculation, or bidirectional tanks to easily manage short stops.

A buffering system is not a mere accessory but a key component of any line. Designing it with care means reducing downtime and waste, improving continuity, and optimizing operators’ work. In other words, it is that invisible efficiency of the line we mentioned at the beginning. And when it works well, you can tell, because everything else runs smoothly.

(Material Handling - Via G. Di Vittorio, 3 - 20826 Misinto - MB - Italy - Tel: +39 0296720176e-mail: info@mhmaterialhand ling.com - www.mhmaterialhand ling.com)

An Indian study published in Journal of Food Process Engineering aimed to develop a screw press-type cocoa butter extractor optimized for small and marginal cocoa entrepreneurs and to evaluate the quality of the extracted cocoa butter.

The screw press features a tapered screw shaft with diameters of 27 mm at the inlet and 35 mm at the outlet, an expelling chamber measuring 32.7 x 294 mm, and a hopper with a pyramidal frustum-shaped design with 365 x 360 mm at the top and 82 x 34 mm at the narrow end. The heating unit consists of four 550 W coils, providing a temperature range of 50°C-200°C, along with other control mechanisms. Cocoa butter was extracted from

cocoa nibs through the combined effects of heat and pressure generated within the barrel. The extractor’s performance was assessed based on cocoa butter yield, extraction efficiency, material discharge efficiency, and extraction loss. At 120°C and a screw speed of 50 rpm, the system yielded 44% cocoa butter, with an extraction efficiency of 81.4%, material discharge efficiency of 89%, and extraction loss of 11%. The quality parameters of the extracted cocoa butter, including free fatty acid content (1.27%), iodine number (33.18), peroxide value (1.68), moisture content (0.14% w.b.), and water activity (0.428), were within acceptable limits. The machine’s rated capacity was 10

kg/h, with a power requirement of 0.9 kWh.

Overall, the developed cocoa butter extractor proved to be economically feasible for smallscale production under optimized conditions and holds commercial potential.

According to the latest report entitled Smart Food Packaging Market and published by Markets&Markets agency, the global market for smart food packaging has been estimated to be USD 26.42 billion in 2024 and is projected to grow at a rate of 6.2% between 2024 and 2029.

The smart food packaging market is revolutionizing the preservation, monitoring, and consumption of food products. In response to the increasing demand for improved food safety, extended shelf life, and sustainability, smart packaging solutions have emerged as vital innovations in the global food industry. These solutions utilize advanced technologies, such as active packaging with antimicrobial agents, gas scavengers, and humidity regulators, to actively control and enhance food quality. Intelligent packaging technologies, including indicators, sensors, RFID (Radio Frequency Identification), NFC (Near Field Communication), and blockchain-enabled traceability, facilitate real-time monitoring of food freshness and product authenticity. The integration of these technologies adds value for manufacturers, retailers, and consumers by improving food safety, reducing waste, and ensuring compliance with regulations. The market also features innovations like modified atmosphere packaging (MAP), which optimizes internal conditions within food pack-

Over 21 days of cold storage, the quality and microbial composition of beef steaks in response to different high-CO2 packaging conditions achieved by flushing gas mixtures or embedding gas emitters into the packages were studied by Australian Researchers.

The results published in Foods journal revealed that the high levels of CO2, achieved by either the gas flushing or the CO2 emitter pads, effectively controlled the number of aerobic counts. The headspace CO2 increased quickly in response to using the CO2 emitter pads, and the meat samples presented different pH levels and surface color (a* and b*) values compared to

the samples packaged with the gas flushing technique. Excessive accumulation of gas in the packages that contained CO2 emitters resulted in package swelling and higher levels of drip loss. The longest overall quality and attractive red color of the meat samples were observed when the packages were initially flushed with the headspace gas mixture containing high levels of oxygen. Overall, using CO2 emitters for meat packaging can be suggested when a topfilm with proper permeability to O2 and CO2 gases is used to regulate the internal CO2/O2 and gas/product ratios.

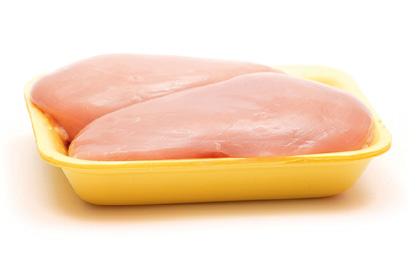

High CO2 in packages significantly extends microbiological shelf life of poultry meat. Cold plasma is an emerging antimicrobial treatment, which generates various reactive gas species and inactivates microbials effectively. The objective of an American study published in Poultry Science journal was to explore the potential effects of combining high CO2package and in-package cold plasma (IPCP) treatments on the quality and safety of raw chicken breast meat.

Noninoculated samples and samples inoculated with Campylobacter jejuni and Salmonella Typhimurium were packaged in 0, 30, 70, or 100% CO2 (with make-up gas N2) and treated with IPCP at 70 kV for 3 min. Ozone formation, microbial counts, drip loss, pH, and color were measured. There was no interaction effect between high CO2 package and IPCP on microbial counts, drip loss, and color measurements. IPCP reduced spoilage microbial growth by 0.43 log (from 7.00 log to 6.57 log, P = 0.033) and C. jejuni populations by 0.67 log (from 4.82 log to 4.15 log, P < 0.001) on meat surface but did not affect S. Typhimurium (P = 0.206). Increased CO2 in packages had more effect on spoilage microbial growth (more than 1.5 log from 8.08 log to 6.35 log, P < 0.001) and

S. Typhimurium populations (more than 0.5 log from 4.94 log to 4.39 log, P = 0.004) than IPCP but did not affect C. jejuni (P = 0.163). IPCP resulted in increases in changes in L* by 1.67 units (0.70 vs. 2.37, P = 0.016) and a* values by 0.56 units (0.73 vs. 1.29, P < 0.001) and decreases in b* values by 0.91 units (0.46 versus -0.45, P = 0.015). High CO2 levels caused increases in changes in L* values by 4.35 units (-0.82 versus 3.53, P < 0.001) with no effects on a* and b* values (P > 0.05).

Data demonstrate that there are no combined effects by high CO2 package and IPCP on meat quality and safety of raw chicken breast meat under our experimental conditions. Either high CO2package or IPCP can retain microbial quality and safety, even though they may cause changes in appearance of stored chicken breast meat.

2024 marked another record-breaking year for the Italian automatic packaging and wrapping machinery industry, with turnover reaching over €10 billion for the first time ever. Total revenues reached €10.06 billion, marking a rise of 9% against the previous year.

The data, which emerged from the 13th National Statistical Survey conducted by the Mecs Research Centre, was reported at the Ucima Annual Members’ Meeting. The research examined 619 companies in the industry, which employ 40,503 people (+6% on 2023).

We have reached a new, historic milestone” - stated Ucima chair Riccardo Cavanna - Breaking the €10 billion record provides further confirmation of the strength of our industry.

In 2024, employees in the industry reached 40,503, marking

a rise of 6% on 2023. New hires totalled 2,284.

The international markets

The propensity for export demonstrated by Italian packaging companies was further consolidated in 2024, with foreign sales reaching €8 billion, equivalent to 79.4% of the total turnover, and a double-digit growth recorded on the previous year (+10%). Export growth of over 700 million further consolidated the global standing of Italian-made products, which continued to be appreciated for reliability, flexibility, and innovation. The destination rankings remain unchanged, with the European Union confirming its role as the main market for Italian packaging technologies, registering €2.9 billion in turn -

over and a 35.8% share of total exports. Next in the tables, Asia recorded a turnover of €1.6 billion (20.2%), followed by North America with 1.3 billion (16.6%), followed by nonEU Europe (€768 million), South America (€730 million), Africa (€573 million), and Oceania (€122 million).

The domestic market is also on the rise, showing an increase of +5.2% that has brought Italian turnover to over €2 billion (against €2.07 billion in 2024). The share of domestic sales stands at 20.6% of the total. The food industry remains the lead-

ing domestic customer sector, accounting for 36.8% of the market, followed by the beverage and pharmaceutical industries.

The packaging machinery industry once again demonstrated its cross-sector relevance in 2024, with demand spread across various production chains. The majority of the turnover comes from the food and beverage industries, which together account for 56.1% of total sales, with food coming in first with €3.12 billion (31% of total turnover), followed by beverages with €2.52 billion

(25.1%). Third place is held by the industry that includes tissue paper, tobacco, and other segments, making up €1.92 billion, or 19.1% of the total. The pharmaceutical industry is also rocketing, recording a turnover of €1.74 billion (17.3%).

Primary packaging machines remain the leading source of turnover, accounting for 53% of the total. This result is driven in particular by forming-filling-closing (FFS) machines, which generated alone €2.24 billion - 22.3% of total turnover - marking a 10.3% surge. Second place is held by filling and metering machines, with a turnover of €1.90 billion (18.9%, +8.6%). Secondary packaging, which includes cartoning and case packing machines, stands at 19.9% of turnover, registering a growth of 6.6%.

Focussing on the current year, companies in the industry remain cautiously optimistic. According to the survey conducted by the Mecs - Ucima Research Centre, 37.5% of businesses forecast a growth in turnover for 2025, while 45.8% expect sales to remain stable. Factors such as international instability, changing energy costs, and industrial policies across Europe are weighing on future prospects. However, confidence in the industry’s ability to innovate and consolidate its position on global markets remains high.

In many plant-based meat and dairy alternatives, coconut oil is frequently used to replicate the textural and structural properties of animal fats due to its high saturated fat content. Concerns about the health implications of saturated fat and the sustainability of coconut oil call for an exploration into alternative fat combinations in plant-based foods.

The effects of saturated fatty acid (SFA) content on plantbased cheese physical characteristics were evaluated by Canadian

Researchers through five different ratios of coconut oil (CO) to sunflower oil (SO): 100%, 90%, 75%, 60%, 50%, 40%, 25%, 10%, and 0%. As determined through texture profile analysis, the hardness of the cheeses after setting at 5°C for 24h increased with increasing amounts of coconut oil due to the increasing solid fat content providing additional firmness. The samples with 100% coconut oil displayed satisfactory melt and stretch; however, the melt and stretch values were

matched by adding as little as 25% sunflower oil. The melt and stretch values did not continue to increase with increasing saturated fat content but instead remained constant with increasing coconut oil addition. Rheological analysis of the cheeses during a temperature ramp from 20 to 95°C was assessed where the tandelta value at 95°C was used as a measure of cheese melt, where values ≥ 1 indicated a better melt. The 0% coconut oil cheese had the lowest tandelta (G/G’) value of 0.3, whereas the addition of 25% coconut oil into the cheese resulted in the tandelta increasing to values greater than 0.5. The 25% CO cheese sample also achieved a more similar complex viscosity (eta*) to that of dairy cheese than all samples but the 75% CO cheese.

Therefore, there is an opportunity to decrease the amount of coconut oil in plant-based cheese systems while maintaining good functional properties and improving the sustainability and health benefits of the final product. These results were published in Current Research in Food Science journal.

slower in the H2 samples than in the other groups. The highest values of fat deterioration were determined for the control, while the lowest values were for the H2and BHT-incorporated samples. All biogenic amines (BAs) showed the highest values in the control, while the lowest ones were observed in the BHT samples, followed by H2 and N2. H2 incorporation into butter limited the spoilage microorganism growth,

improved the color, restricted the formation of BAs (44-61%), increased the levels of some amino acids (Met and Lys), and didn’t give an off-flavor.

The physicochemical results, published in LWT - Food Science and Technology journal, showed that H2 extended the shelf life of butter by 30 days. H2 incorporation can help the dairy industry extend shelf life and maintain the product’s quality and safety.

An Italian study published in Food Science and Technology International journal has characterized different types of commercial fibers from bamboo (BAM), cocoa (COC), psyllium (PSY), chokeberry (ARO) and citrus (CIT) for technological (oil- and water-holding capacity, solubility and bulk density) and physical (moisture, colour and particle size) features and added to a cookie recipe.

The doughs were prepared using sunflower oil and white wheat flour was substituted with 5% (w/w) of the selected fibre ingredient. The attributes of the resulting doughs (colour, pH, water activity and rheological tests) and cookies (colour, water activity, moisture content, texture analysis and spread ratio) were compared to control doughs and to cookies made with refined flour and whole flour formulation. The selected fibres consistently impacted dough rheology and, consequently on, the spread ratio

and the texture of the cookies. While the viscoelastic behaviour of the control dough made with refined flour was maintained in all sample doughs, adding fibre decreased loss factor (tan delta), except for ARO-added dough. Substitution of wheat flour with fibre decreased the spread ratio

except for the PSY addition. The lowest spread ratio values were observed for CIT-added cookie, which were similar to whole flour cookies.

The addition of phenolic-rich fibres positively affected the in vitro antioxidant activity of the final products.

The aim of a Brazilian study published in the Journal of Food Measurement and Characterization was to create a structured scale for assessing the visual quality of ice cream, develop a stabilizer-emulsifier mixture for industrial production, and evaluate the characteristics of the final product, including the visual (descriptive) index, physicochemical, rheological, sensory attributes, and associated production costs.

The development of emulsifiers and stabilizers involved a fractional factorial design 26-2, with 0 to 0.66% of mono-

glycerides of fatty acids (X1); 0 to 0.33% guar gum (X2); 0 to 0.33% carrageenan gum (X3); 0 to 0.33% carboxymethyl cellulose-CMC (X4); 0 to 0.66% tapioca fiber (X5); and 0 to 0.66% corn starch (X6), totaling 19 formulations. Parameters assessed included visual quality index (1 - “Excellent” and 5 - “Poor”), apparent density, overrun, first drop time, melt rate, and water activity. The formulation composed of monoglycerides of fatty acids (0.33%), guar gum (0.16%), carrageenan (0.16%), carboxymethyl cellulose (0.16%), tapioca fiber (0.33%), and corn starch

(0.33%) obtained an excellent visual quality index in all aspects, without significant sensory differences in relation to the control recipe. Furthermore, these formulations reduced industrial costs, allowing for the replacement of commercial stabilizers and emulsifiers.

Due to the ban of certain single-use plastics in the European Union, food contact materials (FCM) from biobased and/or biodegradable polymers are increasingly being used. Some FCM

are made from wheat or rye and therefore contain gluten, which is a food allergen and known to cause celiac disease. Legislation currently does not require allergen labelling on FCM and there is only some first information that gluten from FCM can migrate into gluten-free foods.

The aim of a German work published in European Food Research and Technology journal was to analyze the extent of gluten migration from six different FCM into a variety of liquid and solid foods to assess the risk of exposure for wheat allergy and celiac disease patients. They show that the extent of gluten migration depended on the

properties of the material, the liquid or solid food it comes into contact with and contact time. There was no clear effect of temperature or pH value. Of the six FCM studied, wheat bran-based plates had the highest potential to release gluten with concentrations of up to 203.0 mg/L of gluten in deionized water after 30 min.

To protect patients, it is important to raise awareness of the risk of gluten migration from such FCM and help patients identify and avoid gluten-containing FCM. Further, legislation needs to be adapted urgently to include mandatory labelling of allergens on these biodegradable FCM.

The fat content in cheese is important for quality characteristics, like taste, texture, melting properties, and overall appearance. Understanding the role of fat during extrusion of casein emulsion gels will support cheesemakers in developing new products with diverse textures and functionalities.

Four rennet casein emulsion gels with varying fat content (118% w/w) and a commercial rennet casein ingredient (Cagliata,

26.6% w/w fat) were extruded to investigate the role of milk fat on extrusion process and properties of the extrudate cheese. The extrusion process was assessed via specific mechanical energy (SME), and the extrudates were characterized using dynamic oscillatory rheology, texture profile analysis, confocal laser scanning microscopy (CLSM), and low-field nuclear magnetic resonance (LFNMR). Local micro-fat separation in higher fat gels (>18% w/w

fat) led to wall slip, which consequently lowered the SME from 70.3 ±4.6 to 61.4 ±2.9 kJ kg-1 Macroscopic and CLSM images revealed an anisotropic structure in higher fat gels (>18% w/w fat), with elongated fat droplets separating the casein network. LF-NMR revealed that high fat content led to a more open protein network, with higher mobility of tightly bound (T2.1) and less bound (T2.2) water, due to increased number of fat droplets and serum pockets. The strain sweep revealed an increase in storage and viscous modulus for extrudates with the highest milk fat contents and an increase in the gel-sol transition temperature from 64.0 ±0.8 to 75.5 ±0.7 degreeC. Texture profile analysis revealed lower force values with increasing fat content, indicating a softening behavior at the macroscopic level.

This Danish study, published in Food Hydrocolloids journal, provides new insights regarding the effect of fat concentration on structural and rheological properties of extruded casein gels.

US Researchers published in Journal of Food Science a study aimed at evaluating the efficacy of a blend of citric acid and hydrochloric acid (CP), peroxyacetic acid (PAA), and sulfuric acid (SA) against Salmonella and mesophilic aerobic plate counts (APC) on chicken hearts and livers. Samples were inoculated with a five-serovar cocktail of Salmonella at ca. 4.8 log CFU/g and treated by immersion with a water control (90 s), CP (5% v/v, 30 s), PAA (0.05% v/v or 500 ppm, 90 s), or SA (2% v/v, 30 s), all at 4degreeC and with mechanical agitation. Samples were vacuum packed and stored for up to 3 days at 4°C. Three independent replications were

performed for each product, treatment, and time combination. The average Salmonella reductions in chicken hearts after 3 days were 1.33 ±0.25, 1.40 ±0.04, and 1.32 ±0.12 log CFU/g for PAA, SA, and CP, respectively. For chicken livers, the values were 1.10 ±0.12, 1.09 ±0.19, and 0.96 ±0.27 for PAA, SA, and CP, respectively. All antimicrobials reduced Salmonella counts in both chicken hearts and livers by more

than one log, in contrast to the water control.

All treatments effectively minimized the growth of APC for up to 3 days of refrigerated storage, and no differences in objective color values (L, a, or b) were observed. The poultry industry may use these antimicrobials as components of a multifaceted approach to mitigate Salmonella in nonconventional chicken parts.

Elongated electrodes moderate electric field (EEMEF), an emerging milk pasteurization technology, has been proven to reduce energy consumption. A study published in Innovative Food Science and Emerging Technologies journal by Researchers from Taiwan aims to investigate EEMEF impacts on milk’s sensory and chemical parameters and shelf-life.

Independent variables, i.e., electric field intensity (EFI) of 25-35 V/cm and mass flow rate (MFR) of 0.0167-0.0333 kg/s, were imported to central composite design response surface

methodology (RSM), followed by process verification at predicted optimal conditions and a comparison with thermal pasteurization (TP). Optimal processing conditions were 30 V/cm EFI and 0.018 kg/s MFR, which reduced microbial count by 2.07 log cycles. EEMEF yielded pasteurized milk with similar peroxide value, pH, and acidity to TP but with 25% longer shelf-life and higher sensory scores. Gas ChromatographyMass Spectrometry (GC-MS) disclosed that TP altered fatty acid profile significantly while EEMEF mainly affected shorter chain fatty acids such as butyric and

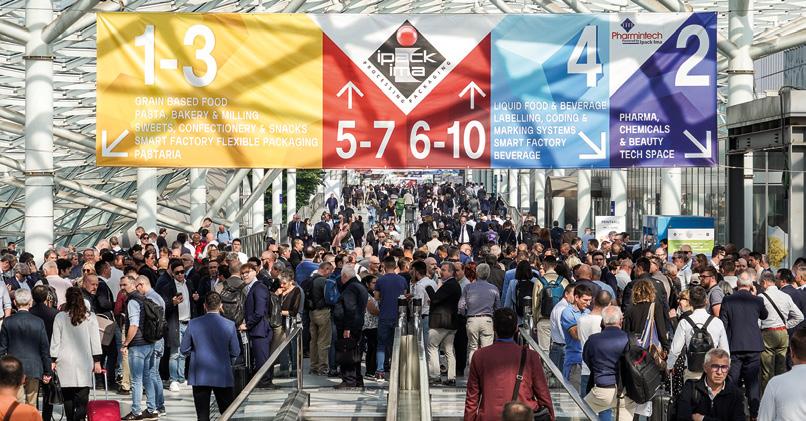

With a 2025 edition exceeding all expectations, Ipack-Ima has confirmed its position as the leading international event for process technologies, packaging solutions, and new materials across both food and non-food sectors. The exhibition, which ended on May 30 after four dynamic days of business and networking, recorded an exceptional increase in numbers: 70,560 professional visitors – with international exhibitors more than doubling (over 400 companies) and a 51% increase in foreign visitors (22,579) – reaffirming its role as a strategic hub for industrial innovation.

With high-traffic exhibition areas filled with qualified professionals, insightful content, and a vibrant, productive networking environment, Ipack-Ima and

Pharmintech 2025 marked a true turning point for the entire supply chain.

The strategic alliance between Ipack-Ima and Pharmintech has once again proven successful, enhancing an effective synergy and strengthening a collaboration capable of delivering concrete results through the integration of complementary industrial sectors.

Three complete lines – focused on flexible packaging, beverages, and coffee – showcased the most advanced technologies on the market in action. A steady stream of professionals closely followed every stage, demonstrating the demand for tangible and effective solutions. The live demos highlighted a strategic value: collaboration among competitors is not only possible but also appreciated by the market.

While packaging has traditionally been the core of the event, the 2025 edition saw significant growth in the processing sector, featuring global players from the food, non-food, and pharmaceutical industries. This synergy enriches the offering and reflects the increasing integration between processing and packaging.

“We have outperformed the 2018 numbers, our historic benchmark, but the real success of the fair is reflected by the quality of the connections created. The synergy between exhibitors and visitors and - even more significantly – among often competing companies, has generated a high-impact experience, proving that shared innovation multiplies value, effectiveness, and competitiveness.” –Simone Castelli, CEO of Ipack-Ima.

“In a rapidly changing market, Ipack-Ima has proven to be a reliable and reputable platform, capable of offering tools to understand the market, genuine business opportunities, and a vision of the future. An ecosystem that not only interprets change but also accelerates innovation and development along the entire supply chain.” –Valerio Soli, chair of Ipack-Ima.

The next Ipack-Ima will be running from 29 May to 1 June 2028 with a forward-looking approach aimed at offering an even more advanced and high-performing trade fair format.

www.ipackima.com