Thank you for picking up issue #22. You may be reading this online, which early birds will always be able to do. You may be reading this via a shared post on a LinkedIn feed. With the numbers our new TikTok channel (@diggerslive) is garnering, it is also possible you are on there. However you are digesting our content, my team and I thank you.

We were invited to JCB’s World Headquarters last month, where our Editor, Toby was given an impressive showcase of the launch of both the 3TE electric mini dumper as well as the 25Z-1 (zero tailswing) and 26C-1 (conventional counterweight) mini excavators. You can read about our JCB adventure from page 16.

This coincided with another invitation, this time from Hyundai Construction Equipment to see the launch of eight mini excavators. Eleventh-hour logistics stopped my trip to join them in Belgium, but our esteemed friends at Hyundai have subsequently been in touch and we have the whole launch event covered from page 48.

I did however manage to make the Midlands for the 17th staging of the Executive Hire Show last month and we have a comprehensive review from page 30.

Without leaving my office I was able to arrange a Zoom and join Keith Miller, Chairman of Miller Groundbreaking as the subject of our BUSINESS INSIDER interview, on page 26. Keith and I spoke about a variety of things, from the beginnings of Miller in 1978, to travel, food and bucket lists. I haven’t yet seen the final edit, but whatever remains will be a cracker – a fascinating man and I feel we have just touched on his success story.

We have also used Keith as a guinea pig to restart our YouTube interviews (@diggerslivetv). If you would like to be considered as a subject of one of these, then please do send me an email: ben@globalnews.media.

The other regular interview, the EQUIPMENT ENGAGEMENT, was also a Zoom job this month, where Toby interviewed Leigh Harris, Business Development Director at SANY, continuing our close working relationship with the highend equipment manufacturer. See page 10.

Also in this issue, we have a technology feature as well as the ever-popular yearly excavator feature for you to get a grasp of what innovation and engineering is available right now.

To all our readers, contributors and advertisers, thank you for making us your construction equipment publication of choice.

Toby

Ben Chambers, Publisher

Government calls for evidence from plant users on future power sources

Molson granted Scottish distribution rights for XCMG

With Leigh Harris, Business Development Director of SANY

JCB delivers the goods at World HQ

• JCB 3TE adds 3-t model to electric site dumper range

• Roll on – completing the ride-on tandem roller range with CT380/430

• New generation backhoes bring greater levels of versatility

• Stage V powertrain for large platform skid steer loaders

With Keith Miller of Miller Groundbreaking

• Abas

• Altrad Belle

• Auger Torque

• Dragon Equipment

• Genesis Equipment Sales

• JCB

• Mecalac

• SANY

• Sunward Europe

• Takeuchi

Sharing ideas for a low carbon construction future

Bobcat: RogueX2 autonomous loader concept

Komatsu: Safety, electrification and connectivity

DEVELON: Maximum impact

Liebherr: Alternative drives and a wide range of digital solutions

HD Hyundai breaks new compact excavator standard

• Bobcat E10e electric mini-excavator

• CASE launches Essential 20-tonne CX210E-S –supplied by Warwick Ward

• Finning supports installation of Europe’s largest waterwheel with Caterpillar

• HD Hyundai Construction Equipment – HX-A-Series excavators

• DEVELON launches new DX17Z-7 and DX19-7 mini-excavators

• JCB mini models bring new generation benefits to 2.5-t class

• KX085-5: Kubota’s next-generation 8-t mini-excavator

• Liebherr R 956 special excavator impresses in Austria

• SENNEBOGEN ever-ready, dual power 825 Electro Battery

• SMT GB – Volvo CE EC37 and ECR40 compact excavators

• XCMG – XE155ECR

• Yanmar unveils next-generation midi-excavators: SV867 and SV100-7

70 PROFILE

TVH: your supplier of spare parts for small earthmoving equipment

• Finning UK and Ireland taking advantage of on-board tech to enhance operator skills

• Cerebrum X – Embedded vehicle data for enhanced fleet management by OEMs and TSPs

• HD Hyundai shows future of construction at CES 2024

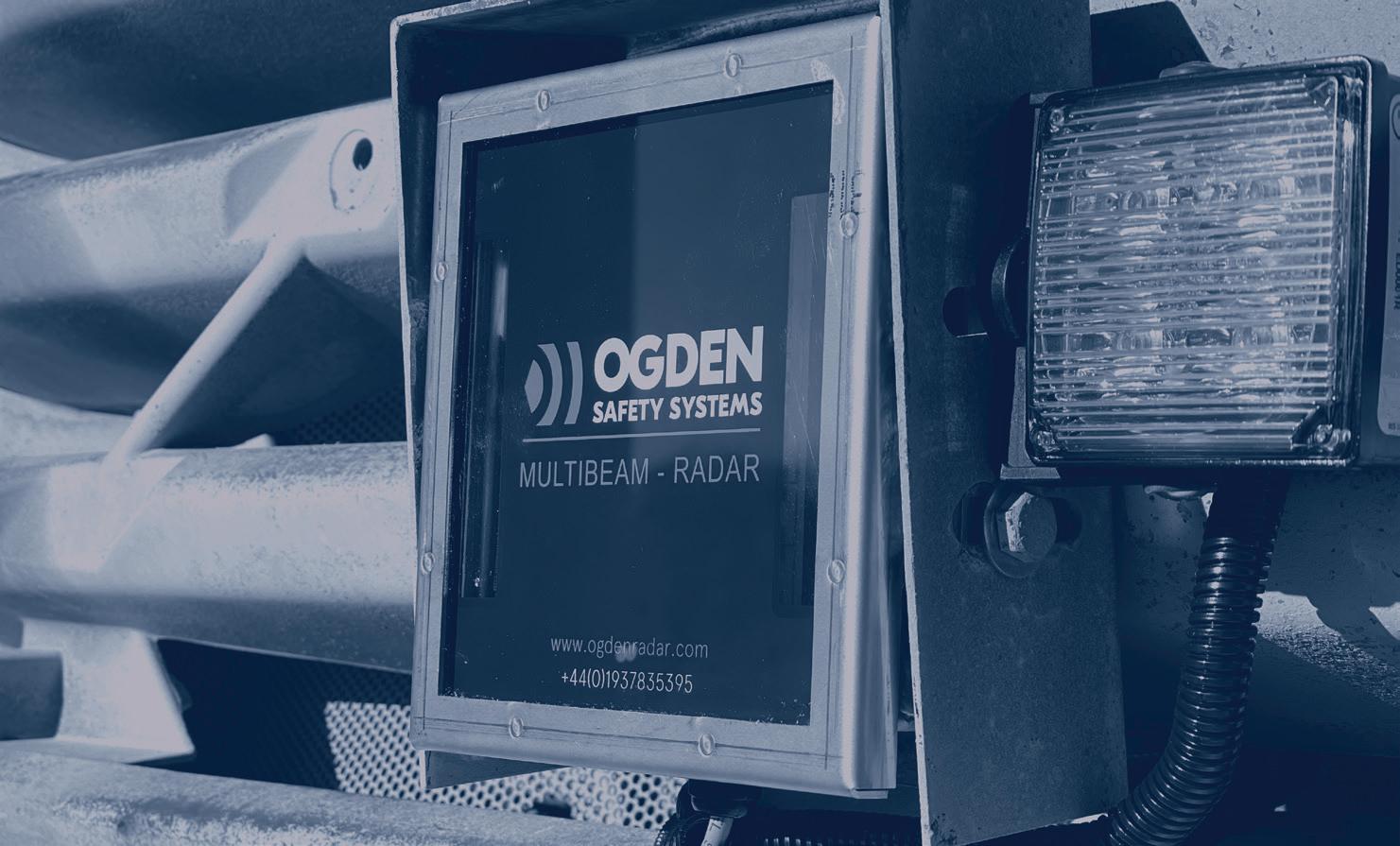

• Ogden Safety Systems – Case studies for Breedon Group & JN Bentley

• Telematics direct Rokbak customers’ efficiencies and uptime

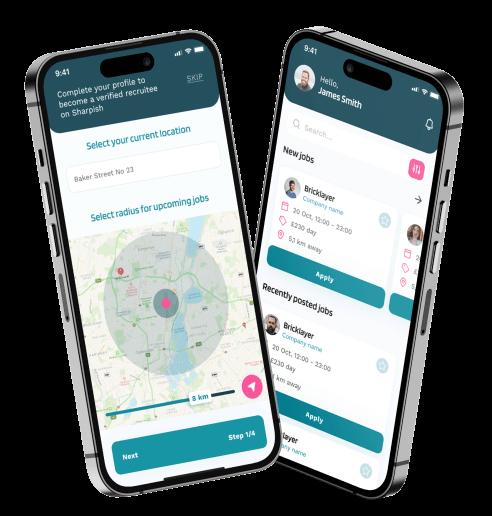

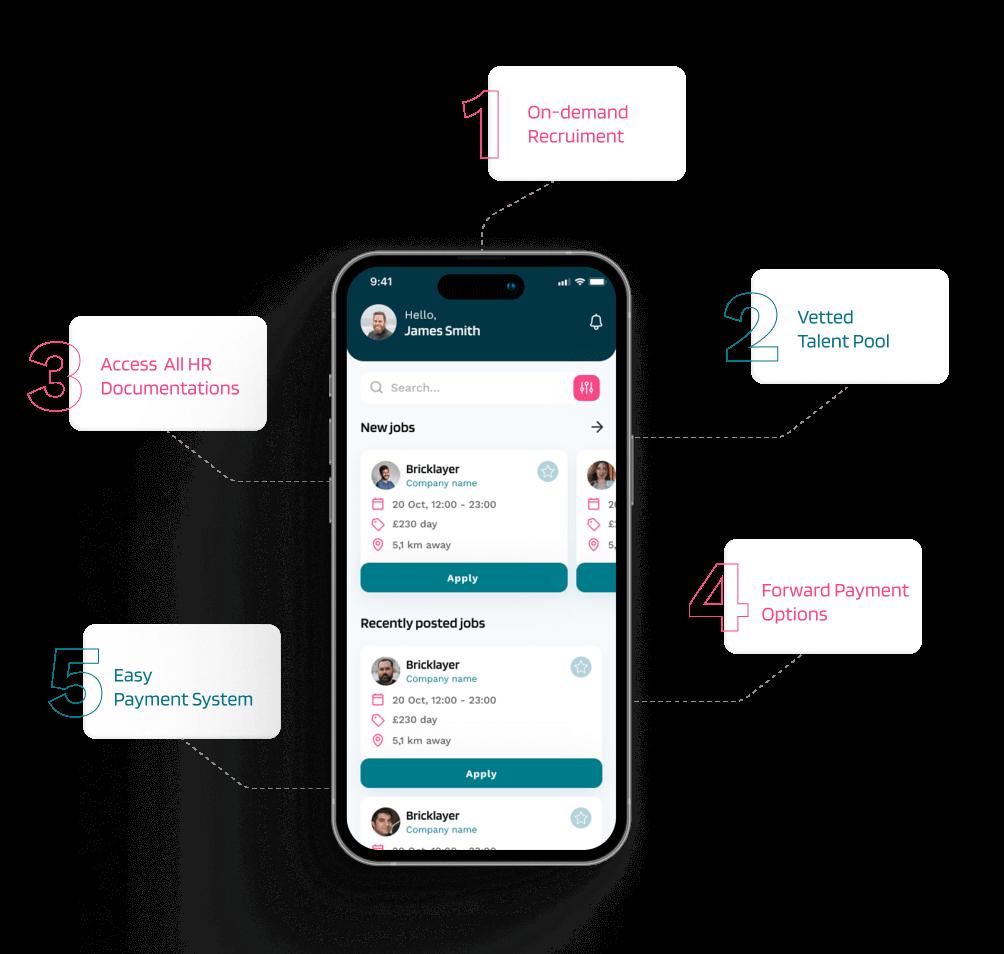

• Revolutionising plant operations: Introducing Sharpish –the ultimate recruitment solution

• SiteZone tips the scales with VEI onboard weighing

• Triton Trak revolutionising waste management

• inspHire announces integration with what3words

• ABAX UK elevates asset management with advanced tool tracking solutions

• X Watch – Tales from the underground

64

The desert becomes the new frontier in Egypt

Ritchie Bros UK gears up for 2024

Komatsu and Williams Racing reignite historic partnership

P.V. Dobson expands to cover the entire north of England

GM and Komatsu collaborate on hydrogen fuel cellpowered mining truck

Finlay welcomes Columbus Equipment as authorised distributor for Kentucky

Auger Torque opens state-of-the art manufacturing facility in China

As part of its wider net zero ambitions the government is calling on users of non-road mobile machinery (NRMM) and industry insiders such as the readers of Diggers LIVE! to share their knowledge and experience regarding how heavy plant might be powered in the future. Responses will inform the development of the government’s NRMM decarbonisation strategy.

The consultation can be found be Googling “Non-road mobile machinery: decarbonisation options” or entering the link at the end of this article.

Non-road mobile machinery broadly refers to any mobile machine, transportable equipment or vehicle that is not intended for carrying passengers or goods on the road. Examples of NRMM include excavators, forklifts, generators and other construction machinery. NRMM emitted approximately 11.4m tonnes of CO2 equivalent in 2021, equivalent to 2.7% of total UK greenhouse gas emissions.

The government is seeking evidence on areas including:

• How NRMM is currently used across the economy,

• Decarbonisation options including efficiency measures, process changes and alternative fuel sources,

• Possible opportunities and barriers to

deploying decarbonisation options,

• Whether existing policies are sufficient to decarbonise NRMM,

• Whether the Industrial Decarbonisation Strategy principles should also apply in determining the case for government intervention to support NRMM decarbonisation.

Opinion is divided on the merits of power sources such as biofuels, battery electric, hydrogen fuel cells and hydrogen internal combustion engines on differing forms of plant and the opinions of those in the industry will be valuable in developing policy.

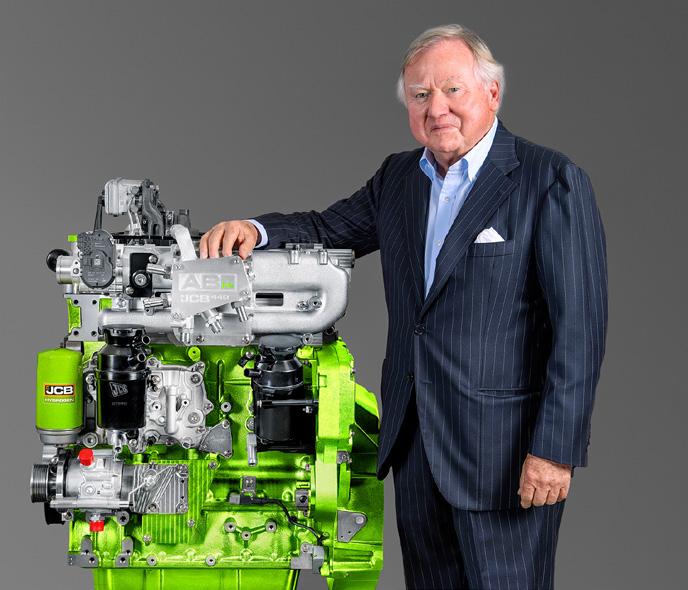

For example, JCB has developed a hydrogen internal combustion engine to power larger plant, alongside its battery electric range of smaller machines.

Chairman Anthony Bamford (right) said: “The call for evidence is a crucial milestone that should be taken very seriously by everyone who is affected, from trade associations to owners and users of non-road mobile machinery.

“It is vital everyone affected engages in this process to help determine which technologies are appropriate to achieve a net zero future. In JCB’s case, we will [be] highlighting the important role that hydrogen will play alongside electric technology for smaller products.”

Other OEMs such as Komatsu, Volvo and Caterpillar have built electric excavators in the range of 20 to 26 tonnes.

The call for evidence is being led by the Department for Energy Security and Net Zero, the Department for Environment Food and Rural Affairs and the Department for Transport. It focuses on the potential ways of decarbonising at least 58 diverse NRMM products covering construction and agricultural equipment and machinery used in warehousing, logistics, mines and quarries.

To participate in the call for evidence visit: www.gov.uk/government/calls-forevidence/non-road-mobile-machinerydecarbonisation-options. The deadline for submissions is 26 March.

Molson Group, the UK’s largest independent equipment dealer has been awarded the distribution rights for XCMG excavators and wheeled loaders in Scotland. With sales and aftercare services to be fulfilled by their specialist construction equipment division in Scotland, Molson Young Plant Sales.

The addition of the premium Chinese brand of wheeled loaders and excavators fills a gap in the Molson portfolio in Scotland. Molson Group Commercial Director, Henry Moore said: “We have been looking to introduce an alternative excavator option into the Scottish market to complement our offering. We decided that the XCMG range met our requirements for build quality and use of well-respected and well-known components, all with the reassurance of a brand with a strong global heritage.

“Adding a wheeled loader brand supports our core focus of offering a single-source supply solution to our customers. The XCMG wheeled loaders

will only cement this focus for both Molson Young Plant Sales and Molson Finlay Scotland.”

Adding the XCMG brand to the Scottish market offering will allow both Molson divisions that service the region to offer customers a comprehensive range of material handling and earthmoving solutions to suit customers in a wide range of sectors, including construction, demolition, recycling, quarrying and much more.

Whilst being a new arrival to the UK market, the XCMG products will be backed up by the national aftersales support that all Molson customers can access. With more than 95 mobile service engineers and a significant investment in XCMG spare parts already made, the Molson team will be on hand to ensure any potential issues are dealt with quickly and effectively. On top of this, the XCMG ranges will be sold with a comprehensive three-year warranty ensuring peace of mind for any purchasers.

Alan Sams, XCMG Sales Director UK and Ireland, said: “Molson have built an outstanding reputation for delivering sales based on a customer-focused approach. Thanks to their thorough and professional approach at every stage of our negotiations, I am confident they will give our customers an outstanding level of aftersales backup and help establish the XCMG brand in the UK market.

“This approach, combined with their unique use of technology following the rollout of dealerCMD across their divisions makes them a reliable and insightful partner that we are excited to work with.”

Initially, excavators from 1 to 50 tonnes and a full range of wheeled loaders will be in stock and available from February onwards, with the Molson Young Plant Sales team bringing a range of demonstration models to the market for customer evaluation. The remaining product range will quickly follow on behind.

Interviewee: Leigh Harris

Role: Business Development Director

Company: SANY

QTell us a little about SANY

The business was started as a small welding company in Changsha in China back in 1989. It grew extremely rapidly with the economic growth of China over the last 40 years and got into excavators in 2003, initially establishing itself as market leader in the far east, and then in 2021 as global market leader building over 100,000 excavators.

The business is very focused on growing overseas now. We’ve been in the UK for about eight years. But the first four years were really just trying to understand the market – we had one dealer covering the whole of the UK.

They gave us a lot of feedback on how we needed to approach the market and how we needed to improve the product

to make it suitable for western Europe and North America, which are a little bit different from the far east, the Middle East and Africa. So over the last five or six years they’ve put a real focus on improving the look of the machines and operator comfort to make them more marketable in Europe.

The word SANY means three, one (san, yi). It’s based on three founding principles: to be a first class enterprise; to foster first class talents; and to make a first class contribution to society.

The business was started on March the first (month 3, day 1) in 1989. So the first of March is san-yi day and many SANY employees get the day off in recognition.

In terms of making a first class contribution to society, there’s a huge

focus on sustainability; lots of research into electrification, decarbonisation and digitalisation of machines, whether that’s cranes, piling rigs, excavators or wheel loaders etc. There’s also a huge focus on developing our own battery technology. SANY is one of the top five wind farm producers in China and we’ve also recently invested in a capability to produce solar cells.

As I mentioned earlier, SANY has been in the UK for about eight years but we had a big push three years ago when we changed our strategy and our distribution model. That’s when I joined the business. We’ve gone from selling a handful of machines a year to now being a recognised brand in the industry. With up to 20 competitors making

excavators we’re doing similar volumes to a lot of other major manufacturers, so we feel we are making great progress in establishing ourselves as a trusted partner in the UK market.

QAnd how about the working culture as regards you and the people that you work directly with?

We’ve grown from a small team – when I started there were just eight of us and now we’ve now got around 50 people in the UK. We’ve got a fantastic team ethic, we all work very closely together and we have good communication amongst the team.

If we’re going to get established in this market, where there are many reputable and well-known brands, we need to work a little bit harder and smarter than most. Fortunately, we have managed to recruit some talented individuals from the industry, who are all very enthusiastic about growing the business too.

QYou mentioned electrification. What’s the strategy regarding smaller versus larger machines?

Our approach at the moment is electric, within the next 12 months we’ll have electric excavators all the way up to 37 tonnes. The bigger machines will have the option to be tethered. We’ve already got

a 200-tonne excavator, which can run off a tethered charge or through the diesel engines. The view from SANY is that the majority of business will be electric until we get hydrogen infrastructure readily available across the market.

SANY is also one of the largest electric truck producers in China –we’ve got a whole range of electric trucks, which gives us significant advantages when designing electric excavators. The challenge with hydrogen is mainly an economic issue. SANY has designed a hydrogen truck but it is nearly double the cost of an electric truck. As such, that is why we’re focused on electric at the moment. Our view is that hydrogen technology will be cost prohibitive for the next few years. That’s not to say we haven’t got hydrogen options as well as we have just designed the world’s largest hydrogen electrolyser.

We’ve also introduced a battery on all our machines that is cobalt free, and cobalt is probably the biggest greenhouse gas emission in the battery production process.

QDo you think ultimately hydrogen could supersede battery electric?

Personally, I’m not sure. I think it all comes down to how economically we can

produce green hydrogen, how safely we can transport it and how readily available it’s going to be. If readily available, green and cost effective then it’s probably a better solution than electric but there’s a huge amount of work involved to overcome these challenges. Hydrogen definitely has the potential to be the better solution, but there’s probably 10 years of work to do before we get there and electrification is the best solution for the meantime.

QTell us about any training schemes SANY has, bringing on board new people and developing existing employees

With all the success we have seen, we’ve had to build the company extremely quickly. We have recruited some great people from the industry who have experience of dealing with heavy machinery and want to be part of a new exciting business opportunity. We put a lot of emphasis on looking after our employees, making them feel valued and a key part of the overall business.

Internally, we’ve just recruited a trainer for our service department and a Product Manager to support our sales team. We put a lot of emphasis on training our dealers and our own staff.

And we have lots of interaction with HQ so that we understand the principles of SANY and we understand what’s going on at a global level.

Like most companies in our industry, finding engineers can be a challenge especially as we are such a rapidly growing business.

Three or four years ago I think there was a reticence for people to join a Chinese manufacturer. I think that’s gone now. People see us in the market and they see how well we’ve grown and we have a good reputation for looking after our employees so they feel excited to be part of something that’s new and on a successful upward trajectory.

QHow about other technologies, either past or future?

I think the only major technology issue I haven’t discussed is digitalisation or automation. We’re very aware of the fact that finding skilled operators is a huge issue. A lot of our competitors have invested in 3D technology and autonomous machines. We’ve got autonomous trucks that we’ve designed and we’re putting a huge amount of R&D into making excavators easier to operate with 3D systems. The easier you

make your machine to operate, the easier it is to get people into the industry and upskill people, so there’s a lot of focus on that as well.

QTell us about your product range

Our excavator range is our key product today. We’ve got a number of other products that we’re launching or are just about to launch. We’re doing a telehandler roadshow at the moment – launching two brand new telehandlers on to the market. We’re also launching cranes this year, we’ve had a new piling rig, but our core product is our excavator offering.

QSo what do SANY excavators do that other manufacturers don’t?

I guess all excavators ultimately dig a hole, which is what the customers want. SANY’s USP is value for money. It’s not that we’re necessarily cheaper than everybody else, but we do try to make sure that we give fantastic value for money and we’re pretty confident that you’ll get the best value

for money out of a SANY machine. That partly comes from the number of machines we’re building and the technology we use to build them.

If we’re building 100,000 excavators a year, you can be very efficient, which gives a good cost base. The manufacturing process is 90% robotic, which means great efficiency. High volume production also enables buying power when you’re

repeatability and reliability. What we’ve found is that when customers have invested in SANY, especially in plant hire, which is all about uptime, our customers have been absolutely delighted with the reliability and the lack of complaints from unhappy customers because their machine has broken down.

So, we have good cost base, we’ve got great reliability and we’ve got real confidence in the product – we offer a five-year, 5,000-hour warranty on every excavator we sell, which is the best in the industry.

QWhere are the European machines built?

They are built in China at the moment. We’ve also opened factories in India, the USA and Brazil. I think at some point we’ll probably have local manufacturing for Europe – there has been some research on where we should set up that manufacturing base, so that will probably happen at some point in the future. One minor challenge we have today is lead times – six weeks on the boat from China is a little longer than we’d like.

QTell us about how you came into the industry and what attracted you to it

I started out in car hire straight out of

university. After 10 years in car hire

I fancied a change and I saw a huge JCB advert in the Sunday Times job supplement for a world of opportunity in sales and marketing. I didn’t really know the first thing about a digger but it looked like a really exciting opportunity. So I joined JCB, working in a variety of roles over a 20-year period. I’ve also worked at CNH for CASE Construction during that time. And then three and a half years ago, I was approached with the opportunity at SANY to lead the UK business.

It’s a really interesting industry to be involved in, I’ve really enjoyed it. I like the people that I work with and a lot of the people within the industry, especially the customer base. There are lots of customers who started their businesses 30 or 40 years ago with one machine and they’ve now grown their businesses into multimillion-pound enterprises. So there’s lots of entrepreneurs out there and lots of great characters to be involved with.

I’ve grown from not knowing the first thing about construction machines 20 years ago, and over that time you build your knowledge and experience, learn from your mistakes, you understand the technical aspects of machines and work hard to make a positive contribution. So I’m still largely focused

on sales and marketing, but with SANY I get very involved in service parts and the technical aspects of mining the whole business as well.

QHave there been any particular projects that you’ve been involved with in your career?

When I joined CASE Construction, Kobelco had recently decided to end its relationship with New Holland and go direct to market, so I joined CASE construction as the Dealer Development Director for Europe. From having a dealer network across Europe, half of our dealerships disappeared pretty much overnight because they went with Kobelco. That was a fascinating project, setting up a new dealer network across

“We’re pretty confident that you’ll get the best value for money out of a SANY machine”

have to have the infrastructure to make sure we can provide good service and good parts backup as well. The main priority for 2024 is to make sure we’ve got a structure that can accommodate all these new products coming in so that we can give the best service support in the industry and therefore grow the business.

Who is your favourite artist?

My favourite artist is Meat Loaf. My favourite album is Bat Out of Hell

What is your desert island (exile) luxury?

That would probably be my running shoes and my running watch. [we’ll throw in a solar charger – Diggers LIVE!]

What’s your favourite cuisine?

I think working for SANY, I’d have to say it’s authentic Chinese food. Some of the food I’ve had in China has been absolutely incredible, especially from the Changsha region, which is quite spicy.

What is the most expensive nonessential you’ve ever bought?

Either my golf clubs or my running watch. If I’m not spending time with my family, then you’ll find me running up a mountain or on the golf course.

The ultimate in operator comfort, efficiency, and high productivity.

The Kubota KX085-5 is equipped with a host of built-in operational and safety technologies as standard, including engine auto-stop, intuitive control systems, an integrated rear-view camera and much more. Add a new ultra-quiet, spacious cab, and it all adds up to our most productive 8 tonne mini excavator ever.

Talk to your Kubota dealer today to find out more.

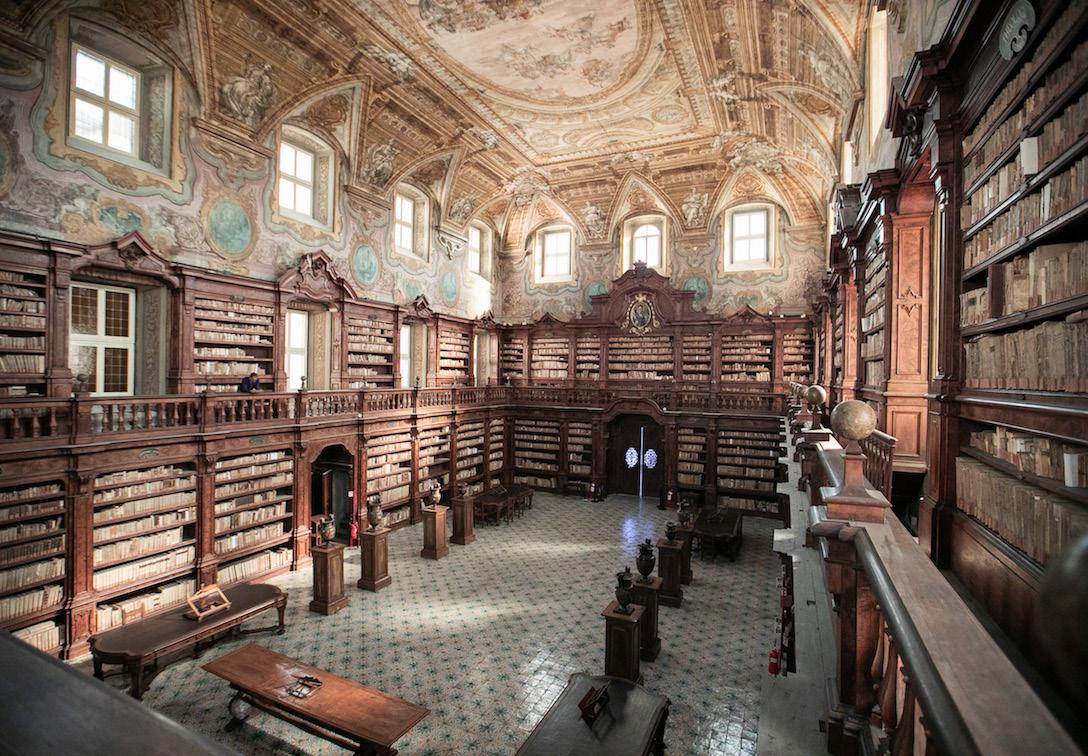

On 12 and 13 February, Diggers LIVE! was treated to a launch event and machine showcase at the JCB World Headquarters just outside Rocester, Staffordshire.

The event consisted of an on-stage product launch followed by dinner on day one, and a demonstration of a wider range of machines in JCB’s Kevin Quarry, 15 minutes’ drive away, before lunch back at HQ near Uttoxeter.

The shiny new JCB-yellow products being shown off on stage amid pyrotechnics and disco lighting on day one were the 25Z-1 zero tailswing mini-

excavator and the 3TE electric dumper. With detailed narratives of the design principles, process and end result given from the podium by executives, engineers and product specialists, followed by an opportunity to get up close and personal with the machines, it was a great opportunity to be introduced to what are bound to be highly successful additions to the JCB portfolio.

What was absolutely clear was the attention to detail and build quality of the machines, neither of will come as any surprise to followers of JCB. Full details

of the new machines can be found in this article and the excavator feature elsewhere in this issue.

On day two, after a generous breakfast the plant-hungry press crew were driven by coach to JCB’s impressive R&D and demonstration centre, built in Kevin Quarry, a couple of miles from Alton Towers – as if anyone needed a reference point for JCB. Access to the demonstration part of the facility was restricted, needless to say.

The new demonstration area, built over the last couple of years, was designed

for all weathers – which on this murky day in mid February was a good thing. We sat in the tiered seating area –shielded from the wind and rain by a high glass frontage – to hear executives, product specialists as well as those responsible for testing and promoting the machines waxing lyrical about new developments in the JCB range. Each speech was followed by an exposition

of the capabilities of the machines in the quarry outside, including JCB’s iconic dancing diggers showing off the capabilities of its re-visioned backhoe loader. Among the improvements to JCB’s signature product is the new Dual Drive feature, allowing the operator to reposition the machine while facing the excavator, without having to turn the seat to face the front.

After a comprehensive and freereining walkaround of all the machines, we were returned by coach to JCB’s World Headquarters – this time wearing plastic overshoes to protect from the mud of the quarry. Back inside, we journalists were treated to a light lunch, over which to digest what we’d seen before returning to the less brightly coloured reality of the journey home.

One of the products on stage at the launch event on that Monday night in Uttoxeter was the swivel tip JCB 3TE three-tonne electric site dumper, powered by lithium-ion battery technology. Designed to work indoors and in emissions and noise-sensitive areas, the 3TE electric dumper offers all the benefits of the one tonne 1TE with a three-times greater capacity.

Key features include:

• Zero emissions and low noise levels,

• Fast charge capability,

• Full shift operation in typical use,

• Swivel-tip skip design to enable loading and unloading in tight, confined spaces.

The 3TE site dumper is a durable, compact machine with a full steel skip and heavy-duty articulated chassis. The machine dispenses with the hydraulic pump and engine featured in the diesel powered 3T-2 model and comes with an electric motor that connects to a drop box, to provide full-time all-wheel drive. A 22.3 kW electric motor drives the drop box, while a second 16.1 kW electric motor powers the machine’s standard hydraulic circuit for steering and skip lift via a hydraulic pump.

The power is supplied by a 20 kWh lithium-ion battery pack capable of providing full shift operation in normal use. The batteries can be recharged from conventional site electrical supplies, with 110V and 230V cables available. In addition, the optional JCB Universal Charger can be used to rapid charge the batteries for extended operation.

Designed primarily for European and North American markets, the 3TE delivers zero emissions at the point of use and low noise levels, making it ideal for indoor, underground and emissionssensitive working sites.

A ROPS frame is standard, along with LED amber and green lap-belt beacons. In low light conditions, powerful LED working lights provide maximum visibility when working, and additional lighting at the operator station allows for safe dismounting. The machine offers a maximum payload of 3,000 kg and a maximum load over height of 1,566 mm.

On display at Kevin Quarry were JCB’s CT380-130 and CT430-140 tandem vibratory rollers, completing a lineup of sub five-tonne machines. Designed primarily for the rental industry, the two machines sit above the current CT16080/100 and the CT260-100/120.

With the CT380-130 weighing in at 3.8 tonnes, the first number represents the weight category of the machine, while the second denotes the drum width in cm.

Key features include:

• EU Stage V diesel engines with DOC and DPF,

• Drum offset to each side for full access to compaction site,

• Hydrostatic double drum drive delivers excellent gradeability,

• V-shape chassis ensures maximum working area visibility,

• Sliding comfort seating with safety switch and seat belt monitoring.

Both machines are powered by the latest EU Stage V JCB by Kohler diesel engine, delivering 36.5 kW. The Stage V engine features a diesel oxidation catalyst (DOC) and a diesel particulate filter (DPF). The engine can be easily accessed, with a tilt forward engine canopy providing ground level access to all fill and service points. An EPA

Tier 4 variant without DPF will also be available.

In line with the CT160 and CT260, the new models are designed for ease of use, low maintenance and to offer a simple, robust compaction solution.

The CT380-130 has an operating weight of 4.1-tonnes, generating an operating linear load of 15.8 kg/cm. With a centrifugal force of 41-59 kN, the machine has a vibrating frequency of 50-60 Hz and an amplitude of 0.50 mm. The drums can be offset to either side by up to 80 mm and the roller is capable of 30% gradeability with vibration operating, or 40% when not compacting.

The larger CT430-140 weighs in at 4.5-tonnes and offers a linear load of 16.4 kg/cm. With the same frequency of 50-60 Hz and a 0.50 mm amplitude, the heavier machine delivers a centrifugal force of 44-63 kN. The roller has the same drum offset capability and gradeability as its smaller stablemate. Both models have a maximum working speed of 10 km/h.

The rollers have a hydrostatic double drum drive system, along with hydrostatic drive to both drum vibration systems. The machines can be used with single (front or rear) or double drum vibration, allowing the operator to provide compaction to a range of materials and surfaces. Manual offset

of the drums ensures that kerbs and ironwork can be followed without risk of damage. An automatic vibration control (AVC) avoids over-compaction at layer ends.

There are steps to both sides of the machine, providing easy access to a sliding operator seat with arm rests, a safety switch in the seat and a seat belt monitoring system. A compact metal dashboard provides a clear view of operating data and machine health and there are working lights to the front and rear of the machine for maximum visibility in poor light conditions.

JCB’s LiveLink telematic monitoring system is standard, providing machine location and operating health information and allowing customers to effectively plan service and maintenance. Service and maintenance requirements have been kept to a minimum with a maintenance-free vibrator and articulation joint.

A PRO package is available as an option, providing spring loaded foldable drum scrapers, a double drive lever, a white noise reversing alarm, additional work lights on the ROPS frame and an asphalt temperature sensor. The machines can also be customised with the addition of left or right-hand side edge cutting devices, a road lighting kit, an immobiliser and a green beacon.

Another revelation in Kevin Quarry was a number of key improvements to JCB’s backhoe loader range, bringing new levels of productivity and efficiency to the legendary machine recognised across the world for its versatility.

The JCB backhoe loader is celebrating 70 years in production and the product continues to be one of the most popular machines in the construction industry. Bringing together the capabilities of a loading shovel, a forklift, an excavator and a tool carrier in a single versatile machine, the backhoe loader remains the ultimate master of all trades for many plant businesses.

With upgrades for 2024 across the range, operators of the 3CX, 4CX and 5CX now benefit from a host of improvements to make the operator’s life easier and more productive.

Key new developments are:

• The launch of Dual Drive allowing machine repositioning without rotating the driver’s seat,

• Single loader lever to reduce operator effort,

• Revised direction control for quicker and easier use,

• Return to grade function for improved performance,

• Laser level mount for simple 2D installation,

• Upgraded quickhitch with wider fork carriage.

Group Product and Innovation Director Richard Brooks said: “These upgrades and improvements maintain JCB’s position as the world’s leading backhoe loader manufacturer. By making life easier for the operator, with increased comfort and control, JCB has ensured that the 3CX, 4CX and 5CX remain the first choice for operators.”

JCB is taking the driving experience to a new level with the introduction of Dual Drive. Available as standard on 3CX Pro and 4CX Pro machines with servo controls, Dual Drive allows the operator to reposition the machine while facing the excavator, without having to turn the seat to the front-facing position.

This is particularly useful when ditch cleaning, grading, breaking or patch planning, as the operator can simply drive the machine along the job site while looking at the work area.

A roller switch on the left-hand servo lever controls the steering, while the right-hand lever has a forward-reverse selection switch. The two pedals in front of the operator are used to control the throttle and the brake system. A seveninch monitor, positioned at the rear of the machine next to the side console, provides

a wide-angle view to the front of the machine, while facing to the rear thanks to a bird’s eye camera positioned on top of the cab.

Richard Brooks said: “We have studied how operators work and concluded that the single ease of use and productivity improvement would be the ability to drive the machine in both directions while operating the excavator.

“This unique feature sets us further apart from the competition and reinforces our commitment to have the easiest and most comfortable backhoe to operate.”

A JCB backhoe loader can excavate up to 190-tonnes per hour, loading and excavating with Dual Drive is an absolute game changer for operator ease of use, which is why JCB has standardised this functionality on premium models.

Using experience from the wheeled loader market, JCB has also adopted a single lever 6-in-1 loader control lever as standard on all manual control machines, allowing operators to control the loader and transmission with one hand and the steering with the other, without the need to use the column shift. A proportional switch on the side of the lever operates the 6-in-1 clamshell function. With a large capacity shovel, autoshift transmission and return-to-dig function, it is possible to load a truck in as little as five minutes.

A switch is incorporated into the

loader lever for transmission directional control, in addition to the standard column shift control. As in JCB’s Loadall telescopic handlers, the column switch maintains priority over the loader lever switch.

To simplify angle setting of the 6-in-1 shovel for grading work, JCB has introduced a Return to Grade function on all servo control machines. With activation through a switch on the side console, the operator simply opens the clam shovel before moving the loader lever to the right. The system automatically stops the shovel rotation when it reaches the optimum angle for grading.

With widespread adoption of laser levelling systems across the industry, JCB has added a 2D laser receiver mount to the front loader torsion box. A mounting pole can be installed and extended to suit various types and sizes of receiver. This allows the operator to set grade depth and to grade more accurately while reducing time taken and fuel used. A 2D laser can increase grading accuracy to within 10 mm, offering the operator up to a 25% time saving over standard manual grade control. The 4CX can level and grade 50-tonnes of stone 63% faster using 73% less fuel, than a 13-tonne excavator.

JCB’s integrated quickhitch with forks, which allow the shovel to be removed for dedicated fork use with a 2,000 kg lifting capacity, has been upgraded with a 220 mm wider fork

carrier, to improve stability of wider loads. The forks now sit outside of the carrier frame, making it easier to reach the forks and to stow after use. Hydraulic couplings are also repositioned for easier access, to reduce changeover time. Rubber mounts have been introduced to reduce noise between the forks and the frame, while the wiring harness and hoses are repositioned for improved protection.

A twin camera and screen option is now offered with the integrated forks, for improved visibility when rehandling materials. An anti-misting camera has been integrated into the quickhitch frame, providing improved visibility of the forks and the load, especially at ground level. A second camera, mounted in the roof, allows the operator to see the quickhitch bar, making it easier to change attachments, while a seven-inch colour screen to the right-hand side of the front console can be switched to show the feed from either camera.

A standard six-speed Autoshift transmission is to replace all manual and Powershift transmissions on the 3CX and 4CX. Transforming roading and loading performance, TorqueLock will also become standard, reducing travel times by up to 10% and improving fuel efficiency by 25%. The backhoe loader can move materials up to 25% faster, using 50% less fuel than the combination of an 8-tonne

excavator and a site dumper.

The floor-mounted manual gear lever will be replaced by a simple column switch, with automatic gear changing through fourth, fifth and sixth gears. Loading is also made easier, with a kick down switch now mounted on the floor, which automatically drops a gear from second to first for maximum traction and shovel penetration.

All 3CX, 4CX and 5CX models now benefit from the standard fit of eight LED work lights, four to the front and four to the rear of the machine. Delivering 1,000 lumens each, these work lights improve visibility all-round the machine in poor conditions. A 10 LED higher powered work light package remains available as an option.

A seat interlock has been introduced on joystick machines, to avoid the possibility of longer joystick levers hitting the steering wheel when the operator turns the seat. The seat will now only rotate when the steering column is in the fully retracted position, while the steering column foot release remains on the floor of the cab.

JCB has included a host of smaller upgrades into the backhoe loader range, including simplified excavator quickhitch activation, the option of new 20-inch Michelin Power CL tyres on 3CX and 3CX Plus models, a new seat belt warning feature and a green beacon socket for the UK market.

JCB has launched EU Stage V compliant versions of its large platform skid steers, delivering increased performance, reduced fuel consumption, improved handling and upgraded operator comfort.

Key features include:

• JCB DieselMAX 430 engine delivering 55 kW, more torque and reduced fuel use,

• 7-inch touchscreen display for easy access to machine settings,

• Electro-hydraulic auto bucket levelling as standard on Teleskid,

• Soft-touch control buttons in vertical cab pillar position,

• Revised cab structure for improved allround visibility.

The upgrade applies to the 270 skid steer, the 270T compact tracked loader and the JCB Teleskid 3TS-8W. JCB’s 270 wheeled variant and 270T tracked loader have rated operating capacities of 1.25-tonnes, with near-identical load over heights of 2.9 m and 2.88 m respectively. The Powerboom single arm has a vertical lift path on both machines.

The Teleskid 3TS-8W has the singlearm design that is used by all JCB skid steers and compact tracked loaders, but with the additional benefit of a telescopic boom, providing additional load height and forward reach. With a maximum lift capacity of 1.45-tonnes, the machine has a maximum full height of more than 4 m with a radial or vertical lift path. JCB’s Smooth Ride System boom suspension is also standard.

Emissions compliant

The 3.0-litre JCB DieselMAX 430 engine achieves EU Stage V emissions compliance through a highly-efficient combustion chamber design, a diesel particulate filter (DPF) and cooled exhaust gas recirculation (EGR). There is no requirement for a diesel exhaust additive such as AdBlue. The engine produces the same 55kW output as its

larger 4.4-litre predecessor, despite being 24% smaller and 30% lighter. It also generates 10% more peak torque at 1,500 RPM, with increased torque throughout the rev range.

In addition, operators can ensure optimum fuel economy through the activation of the JCB Auto Stop feature that shuts down the engine if safe to do so after a pre-set idle period.

The biggest change to the side-entry cab is a vertical soft-touch button cluster on the right-hand cab pillar. This sits above an engine speed dial and the starter key and below the 7-inch touchscreen display. The radio, with Bluetooth mobile connectivity, sits to the left of the operator, alongside controls for the heating and cooling, orange beacon and hazard lights.

This redesigned interior layout increases the glazed area within the cab, improving forward visibility by repositioning buttons and instruments in mouldings to the top left and right of the cab. The B-post design has also been remodelled to improve the view to the left of the machine.

A wider roof window makes it easier to see a fully raised bucket or fork carriage,

while additional seat rail adjustment allows operators to sit closer to the front window to see the outer edges of an attachment. In addition, the Teleskid is equipped with a standard rear-view camera and bright LED work lights, both of which are optional for the fixed boom machines.

The touchscreen not only provides operators with essential machine status information, but can also be used to adjust settings that fine-tune the performance to suit different operating conditions. New MyChoice control functions include being able to set maximum forward and reverse speeds in 1kph increments, the ability to choose one of three acceleration rate settings for the hydrostatic transmission and four power management settings. Operators can also choose two settings to determine joystick sensitivity and customers can select between ISO and H-pattern control layouts, to suit individual operators.

A mechanical suspension seat with cloth and vinyl upholstery, increased travel and lumbar support, along with more comfortable arm rests is standard on the 270 and 270T. An air suspended seat is included on the Teleskid and available as an option on skid steer models.

Interviewee: Keith Miller

Role: Chairman

Company: Miller International Limited

Ben Chambers

I had a great experience up in Cramlington just outside of Newcastle a couple of months ago (Miller HQ). I found a real show of unity from every rank, every role, every person. There really seems to be a real family/unity there.

Keith Miller

That’s what we’ve tried to implement over the years. I founded this back in 1978 and it’s like my firstborn. When I’m here it’s like being at home. Treat people well, the way you like to be treated, just be nice, be kind. If you have something to say that is not pleasant, make it one to one, have a quiet word. Praise in public and feed back privately.

People talk about work life balance.

They say you have to make sure you have plenty of free time but I disagree with that. I say this to the team, if you don’t enjoy what you do at work, then you really shouldn’t be doing it. We spend about a third of our lives at work, we spend about another third of our life sleeping so you only have a third left. You must enjoy what you do in life and work is part of your life.

I did this mega trip to Asia with my wife and kids. I had meetings in India and Singapore and of course the kids loved it. They were going to places and seeing the diggers, machines and the dealers and all the stuff that we do. Then we would go to fancy places and have fancy dinners. It was interesting for them.

Then Abigail took the kids back home and I went down to Perth, Melbourne then on to Sydney and Christchurch. Then I went up to Shanghai, running around China for ten days and back. That was around five weeks.

It was a decent trip, it was interesting, necessary and overdue. I hadn’t been since COVID and normally I’d do a couple of weeks in China, come back, leave a month or two in between then go to India, stay 10 days and come back. It had been 10 years since I was in Australia so that was well overdue.

I thought I’d do the whole lot and get bang up to date with the markets and what’s happening, feel the temperature, the inventory levels at the dealers, what’s new and what’s not. It was a fascinating trip and I got to spend time with my wife and my kids, which was wonderful. I spent time with the Miller gang in Australia, spent time with the Miller team in India. I got to spend time with Darren the CEO – we met in Singapore and went off and did the rest of it together.

We met all the OEMs; we had dinner with the Chairman of LiuGong, the big boss from SANY and the big boss of XCMG and found out what the Chinese lads were up to. Is this really work?

Next week I’m off to San Antonio as part of the North American, National Demolition Association. It’s their conference, their AGM and we attend every year. The first year was in San Diego, would never have gone there, last year was in Phoenix, beautiful, and this year San Antonio.

KM

It’s interesting when you are meeting like-minded people, people who want to do stuff, people who get off their backside and make it happen.

We are fortunate that we are in positions that we enjoy, but if you don’t enjoy it and again, I say this to the staff here, if you’re not happy with what you’re doing can we move you to a different department? Do you want to be a welder? Do you want to be fitter? Do you want to be an engineer? Do you want to be on the road? Do you fancy an office job? Do you want to move around the business?

If none of that fits the bill, well honestly we’ll help you find something else because we don’t want you here if you’ve not got a smile on your face because it’s not good for you and it’s not good for the business. That negativity spreads around the camp. So it is a business decision, but I genuinely mean it in terms of what’s best for the staff as well.

BC

It was noticeable when I walked around your site. I had a few beers with a couple of the senior guys later on, Newcastle was playing in the Champions League, we had all that going on, but people seemed to bleed Miller.

Your name came up last week. I was at the Bobcat stand at the Executive Hire Show in Coventry and met Nick Healey, your former sales guy. I think he said he’d been with you five or six years, which is a decent stint, and he’d had a brilliant time. You could see the excitement in his eyes. He thought the world of you and thought the world of Miller.

KM

And that’s the way it should be, it really is. We’ve an ex-Miller club and we invite them to come up here as if they were part of the gang still. Stephen Ford the former boss of LiuGong UK is coming up on Thursday and he was here 15 years. Andy Raine of Watling JCB was with us for nine years, Phil Jones, Tim Rice. These were senior people. They were with us and they’ve moved on, but never with any animosity, always with friendship. I firmly believe that’s how it should be. It’s ironic because both Andy and more particular Stephen ended up being very good customers, we’re the main supplier for LiuGong UK.

Miller started in 1978. Give me a snapshot of you and how Miller came to fruition.

When I was a youngster, I was ambitious. I’m a dyslexic entrepreneur, I couldn’t spell entrepreneur to save my life but I was ambitious before I started any businesses. When I was 9 or 10 years old, I had paper rounds, I worked delivering milk and cleaned windows. I worked in a car showroom, I repaired cars, I did all kinds of jobs before I was even old enough to start work. I was always a get up and go

type of person. I then served my time as a welding engineer, fitter fabricator welder.

I’ve always been interested in cars and motorbikes. I’ve ridden motorbikes I’ve raced motorbikes; I’ve driven cars, I’ve raced cars all that kind of stuff so I’ve always been attracted to anything mechanical.

When I was 21, I was working at a company and I asked the boss what his thoughts were about me. He said: “You’re a second rate welder and that’s all you’ll ever be.” Quite endearing I thought. I was very disappointed with that, which probably was actually a good thing because it gave me the nudge to think

about what I was going to do with myself.

In my holidays, I went round the local quarries and coal sites in the northeast of England and said: “I’m thinking about starting my own welding business, if there’s any work could you give me a shot?” I gave them my mum and dad’s number and didn’t think much more of it. The phone rang a couple of times, I measured jobs up and started doing jobs at the weekend and night time.

I wanted to leave the job and start my own business and that’s what happened, starting Miller as a one man band. I bought an ex-police Ford Escort estate, which I could use as a car to drive around the country and visit customers. I could put the seats down and put the tools in the back and I put a towbar on it so I could tow the trailer and welding set and that was it. Keith Miller Welding Engineer 1978.

The Kielder Dam was being constructed in Northumberland, it was a huge, it was a joint venture between McAlpine and Balfour Beatty, I think. They hired a lot of machinery and of course those machines were working around the clock, muck shifting. It was huge.

Stokey Plant Hire were working on the dam, they got in touch with me and said they had heard that I provided welding services and asked if I could keep an eye on their machinery at Kielder. I agreed and reported on the condition of the machines. I then suggested the best thing would be if we spent a few hours at the weekend when they were not being used and maintain them.

When we got onto the Kielder Dam and were maintaining machines for Stokey all the other people that were on the site wanted us to maintain theirs as well. That’s when my brother Gary joined me. We would drive up early on a Saturday morning, the machines would be parked up by Saturday lunchtime and we’d get stuck in Saturday afternoon till about 10, 11, 12 at night. We’d get a few hours kip and start very early on the Sunday morning and do another seven or eight hours. The machines were all maintained and up to date and then the operators would jump back in them and away they go back to work. Then it was non-stop.

I realised I was earning more over the weekend than I did from my whole

working week. That gave me the weekdays off so that I could start developing the business. I went to the National Coal Board, I put my name on the tender list, and we started getting tenders and enquiries through for manufacturing and repairing buckets.

Miller started in 1978 repairing machinery. When you repair something, you really understand what goes wrong. We call it negative knowhow. When we’re on site we see machinery, and we see all of our competitors, we get them in and we repair them so we know what’s in the marketplace and we know what’s good, what’s not so good, what could be better. There’s a hell of a lot of experience in negative knowhow that we gather through the repair and the Special Projects Department.

BC

Yes, I was taken to the Special Projects Department

KM

It’s packed with dump truck bodies, there’s dozer blades, there’s visors off the big mining shovels, there’s all sorts in there at the moment. That’s a separate department, a separate division which is where we get a lot of our negative knowhow. It helps us as a company develop and design our products.

Our customer is the guy that digs a hole; that’s everybody’s customer, the customer of the dealer, the customer of the OEM. The lad with his dirty boots and jacket, he’s the customer around the world. We can help him work with products that are safer, more productive and versatile.

So what do we sell? We sell safety, versatility, productivity. Our mission to the OEMs and the dealers is not to sell them a product but to help them sell their products. We ask them how we can help them sell more machines; we need to understand the customer.

Everyone thinks digging the ground around the world is different, but it isn’t. There’s different terrain, there’s different ways of doing things, people have different choices. That’s fine and it’s not for me to tell them how to dig but at the end of the day they’re digging the ground and it’s very similar in most places that I’ve been so far.

What we understand is the production

engineering side of things and to really understand what the customer wants and what the customer needs you need to go to the customer, to the quarry, the job site, the construction site and understand what size the dump truck is, what size the bucket is, what’s the density of material, how many passes.

If you are looking into a production study, you could be talking about thousands and in some cases tens of thousands of pounds of difference. You can’t get that from just going in delivering a bucket. The value we add is the years of experience and the negative knowhow.

Our products are better than the competition because we understand the customer, we understand the environment, we understand the geometry, we understand the digging forces and we’re constantly evolving. We’ve got six engineers on constant R&D and we have a guy who’s digging holes with products. We’ve been building buckets for 46 years this year and are we learning? Yes. If you go to Dunlop or Pirelli, who have been making tyres for goodness knows how long, they’re doing the same thing.

As for where Miller is now, we’re headquartered in Newcastle; we acquired

a company a couple of years ago in Australia, so we have Miller in Australia, we have Miller in India, we have a factory in India that is actually bigger than the factory here. And we have a Miller joint venture in China, which we’ve had for 20 years. Those are our actual Miller locations, and I’m not boasting by the way, I’m just so proud of what the team have done to deliver.

BC

You said you can’t just deliver a bucket and you mentioned knowing the customers’ needs. Do you then modify your products according to their needs?

KM

If you think about the machinery, you’ve got mini excavators, you’ve got standard excavators, you’ve got large mining equipment and you’ve got wheel loaders, essentially earthmoving machines. Each of those products does a different job so if you go to the run-of-the-mill standard range of products you don’t need to change those because they don’t change much. It’s like you have standard tyres for your car, you don’t modify those all the time.

But if you get up into the larger excavators and into the mining equipment or in some cases some of the wheel loaders, we have a task range. On the standard machinery you have two or three buckets, ditching bucket, narrow bucket, trenching bucket, quick coupler and they are standard. But the special products is where you would have bespoke equipment.

BC

So about yourself Keith, who or what would you be in alternative life?

KM

I don’t think I would want to be anyone different because I am so interested in mechanical engineering. I love what I do because I’m interested in it.

BC

What do you do for fun?

KM

I am very privileged. I have a beautiful wife and I have a young family. I was running around the world building a business then I thought, hang on, what about me, I’d better get on with this

now. So now I have a beautiful family and spend time going on holidays. I like to stay fit and healthy. I ride a bike, I go to the gym. And I do a little property development in Spain.

BC

What’s on your bucket list?

KM

As a family, we like to go to different places, we are very privileged and the children live a privileged life. We live in a nice house, we drive nice cars and we like to try to educate the children that this is not normal and a lot of work has gone in to being in this position.

We’ve been to Vietnam, China, India, Morocco and we spend time with the working class people, stay in their houses cooking and eating meals with them. At Easter we’re going to Oman. It wouldn’t be the choice for many people.

As you get older you are supposed to get wiser, I’m not too sure I fit that bill by the way. I’m now more into the mind, body and soul, I’m not a preacher and I’m not highly religious but I’m definitely leaning towards a little bit more of understanding of the mind. We get a healthy body but it’s our mind where everything happens.

I would like to build some sort of retreat in the countryside somewhere down in Spain. I was talking to a property advisor about what’s happening in the world. They are saying that the big hotel groups are now looking at bespoke hotels in the countryside. People are wanting to get away into the countryside and live a clean life and I think that would be something really fun to do. Obviously, it would be commercial, but I wouldn’t be doing it to make money. I’m working on it, so we’ll see.

What’s the most expensive nonessential thing you’ve ever bought?

Bentley Continental GT convertible –I happened to have the first one in Newcastle. Back then there was the ego and testosterone thing. Now the ego’s gone and the testosterone’s not as good as it used to be. The Bentley Continental GT convertible was a beautiful car but not very practical.

Firmly etched in my diary after the brilliant London Build event in November, I was set to attend the New York Build event this past February.

And all things being equal that would have been the case, continuing to build this brand (and others) in North America as we have historically with events such as World of Concrete, ConExpo as well as the various National Demolition Associations’ Conventions.

Given the time to think about it, it would have been a safe bet I’d be looking forward to striding the sidewalks of New York once again… But, a monthly appraisal with Diggers LIVE! Brand Manager Charlotte Walsh quickly meant instead I was once again sent to Coventry.

With my tongue out of my cheek it wasn’t much of a hardship, Coventry doesn’t quite have the Manhattan skyline (or cocktails), plethora of pastrami, nor does Coventry Arena train station boast the distinctive architecture and interior design halls as the Grand Central Terminal… But what it did have was the UK’s finest in hire equipment, a busy, vibrant room of buyers and attendees and many friends old and new. Quite possibly it was the right destination for me to be there.

This was my fifth EHS and with last year’s event being particularly good and beneficial to us, I had all the confidence of yet more of the same, and only a mere hour’s train ride from London it’s an easy venue to get to and I have always enjoyed this event, so it was with no real hardship my destination had changed.

This year however, I had an additional purpose with Charlotte on the ball over the past few months she had arranged my time to go and speak with quite frankly brands that up until now had eluded me.

I have had a little check but the information wasn’t readily available so I have no idea if I am right or not, but my judgement says that the numbers were up, it was actually really busy on the first (and only) day I was there, a lot of brands keeping their favoured spot, such as Thwaites’ impressive centre stand, that allows a reference point when zig-zagging to each scheduled meeting.

I won’t go into business specifics, but needless to say you will be seeing more new names featured as we go forward and that is thanks to the Executive Hire Show.

Track and manage vehicles, machinery and tools within your fleet using ABAX’s suite of intelligent, easy-to-use solutions connected to one single data-driven platform. ABAX tracking solutions helps any business with mobile workforces and assets across a wide range of industries to reduce costs, optimise operations, and improve sustainability, efficiency, and safety.

Product Focus: ABAX Smart

Inventory:

ABAX Smart Inventory allows you to manage your inventory on the move, ensure your vans are fully equipped and be alerted if something is misplaced or left behind. Seamlessly manage your tools and equipment with real-time tracking through a smartphone interface, ensuring that every asset is precisely where it should be, saving you valuable time and resources. Smart Inventory allows you to assign tools to the correct vehicle, saving you time and ensuring you’re always carrying the critical tools needed to carry out jobs. With our solution, you’ll have a comprehensive overview of asset whereabouts, minimising the risk of unauthorised

Altrad Belle combines design and manufacturing expertise to present the most comprehensive range of light construction equipment. Our focus on engineering quality makes our portfolio of compacting, mixing, concreting, pumping, cutting, breaking, moving, generators, pressure washers and wheelbarrows the established brand it is today.

With over 50 years’ experience, we supply a truly global market from our headquarters in the UK. Intensive product development, including computer-aided simulation and physical life-cycle testing, provides industry leading equipment with advances in health and safety features and performance.

usage and you’ll be proactively alerted if an asset departs from a designated zone.

ABAX Smart Inventory streamlines operations, ensuring that you always have the right tools when and where you need them, optimising productivity across any industry or business that relies on critical equipment.

Product focus: Minimix 150E+ cordless battery powered cement mixer

The Minimix 150E+ is the latest and emission free incarnation version of the iconic Minimix 150 4/3 concrete mixer. This Li-ion battery powered mixer provides users with a robust and practical solution for mixing concrete and mortar indoors, outdoors and in poorly ventilated areas, like basements, tunnels etc. It can also be operated in environmentally sensitive areas such as green spaces, nature reserves, railway sidings, urban areas etc.

The cordless design of the Minimix 150E+ provides greater working flexibility on site – no trailing cables like electrically powered mixers and reduced noise, running and maintenance costs compared to petrol powered mixers, making it the ideal mixer option for use in areas with no access to an electrical power supply.

Auger Torque is a global manufacturer of hydraulic attachments that improve efficiency through operational cost savings and productivity in earthmoving, construction and agriculture. Auger Torque’s local in-house capability and committed dealer network ensures superior service, quality and reliability, with readily available product.

Product focus: Cone Crusher Bucket

This cutting-edge attachment promises to redefine efficiency and productivity in the construction industry. Designed to meet the demands of modern construction projects, the Auger Torque Cone Crusher Bucket boasts a range of features that set it apart from traditional solutions. The attachment provides a simple, efficient and cost-effective way to reprocess and/or recycle small volume construction rubble and debris into usable aggregate/hardcore. This allows operators to crush and process a variety of materials directly on-site, streamlining operations, maximising job site efficiency, and minimising downtime.

Whether it’s general clay construction brick, light concrete walling blocks,

hollow concrete breeze blocks, concrete pavers, asphalt and more, the Auger Torque Cone Crusher is highly effective at crushing to an output produced material size of around 40-70 mm. This attachment is ideal for use in applications including, foundation laying, track and yard surfacing, landscaping, roadways or using as a base layer below poured concrete or filling a disposal skip most efficiently.

Known internationally for its compact crushing machines and lifters, Dragon Equipment designs and builds powerful machines here in the UK. Dragon Equipment is an engineering company devoted to revolutionising how we recycle, move and use materials on domestic and commercial sites through innovation in designing and building products. Leading the company as Director, Jeff Haines has more than 37 years’ engineering experience working for leading firms, including 22 years at one of Europe’s leading woodchipper manufacturers.

Product focus: CR450 Crusher

Dragon Equipment is taking things to the next level with the launch of the CR450 diesel crusher. The first diesel-only crusher from the British company, the CR450 Diesel Crusher is designed and built at its head office and production facility in Suffolk.

The newest addition to the range of compact crushers is powered by the

Kubota D722 three-cylinder watercooled 19 hp diesel engine. The higher torque provided by this engine enables the CR450 Crusher to power through even the hardest of materials at a higher speed for a sustained period, dramatically increasing the output. Combine that with the large 33-litre fuel tank, and the machine can keep crushing for more than 12 hours.

Genesis Equipment Sales is a leading provider of powered access equipment to businesses across the UK. As part of the Ballyvesey Holdings Group, Genesis has access to a wealth of expertise and resources, allowing it to offer its customers high-quality equipment and exceptional service. Genesis is the sole UK distributor for XCMG Access Equipment, a leading manufacturer of scissor lifts, articulated and telescopic boom aerial work platforms as well as being an official UK dealer for JAC Forklifts. Its equipment is designed to meet the needs of a wide range of businesses, from construction companies to warehouses and factories.

Product Focus: JAC forklifts

Genesis Equipment Sales is proud to introduce JAC forklifts to the UK, from 1.5 to 8-t diesel, electric, LPG and lithium options. JAC Heavy-Duty

Construction Machine Company is a Chinese manufacturer established in 2003. It makes a wide range of forklift trucks including diesel, electric and LPG powered machines, rough terrain forklifts, electric pallet trucks, electric stackers as well as some non-standard forklift trucks. JAC’s products enjoy a strong reputation at home and abroad due to their reliability, durability and manoeuvrability, making its high quality material handing equipment the ideal choice for users all over the world.

As the world’s third largest construction equipment manufacturer and with a history stretching back over 75 years, JCB is renowned for its pioneering products, innovative thinking and pushing the boundaries of possibility. Its extensive product range includes excavators, telehandlers, site dumpers, access platforms and generators. JCB is a company with a proven track record of success within the hire industry, an unrivalled dealer support network and a name synonymous with strength, durability and reliability.

Product focus: JCB A45E

This recently launched aerial work platform brings zero emissions operation, increased efficiency, enhanced operator access and higher levels of monitoring.

The A45E is powered by eight 6V batteries, creating a 48V, 400 Ah operating system. The battery packs are located on either side of the lower chassis, maintaining a low centre of

Mecalac is a global leader in the design and manufacture of compact construction equipment. With more than 70 years’ experience in development and production, it continues to innovate, boasting a comprehensive portfolio of compact equipment specifically developed to revolutionise operations for construction professionals. Classleading Mecalac site dumpers, backhoe loaders, compaction rollers, wheel loaders and a unique portfolio of excavators mean embracing innovation, efficiency, operator wellbeing, safety and performance.

Product focus: Revotruk

A revolutionary earthmoving concept, Revotruck is a rear dump truck when carrying materials and a highly manoeuvrable site dumper – enabling the operator to face the skip – when loading and unloading. Setting the standards in site safety, Revotruck makes

gravity. The machine boasts four-wheel drive and two-wheel steering as standard and is capable of climbing up to 40% gradients. Maximum platform height is 13.84 m with a horizontal reach of up to 7.47 m and a lift capacity of 300 kg. In addition to four harness clipping positions, a secondary guarding system automatically halts boom functions when triggered.

JCB’s LiveLink telematics system provides real-time data on performance, service schedules and fault codes. Managers can remotely record engine operation, low fuel warnings, tilt sensor warnings and overload warnings. LiveLink also provides battery voltage, fuel level and platform load percentage data.

material transport smarter than ever before. Operators can receive a load facing the skip, before rotating the entire cab via a multi-directional joystick to face the direction of travel with no visual obstructions – improving productivity, minimising risk and maximising operator safety. Perfect for even the tightest sites, operators benefit from three steering modes (two-wheel, four-wheel and four-wheel crab), as well as the tightest turning radius on the market. With two load capacity options – six and nine-tonnes – Revotruck is powered by a Stage V-compliant 74 hp Perkins turbocharged engine, delivering 380 Nm torque @ 1,380 RPM.

SANY is one of the world’s largest, most dynamic and technologically advanced manufacturers of heavy machinery. Safety, comfort and ergonomics are the attributes that best describe working with a SANY machine. They are built to deliver incredible durability, reliability and dependable uptime and are backed by SANY’s industry leading five-year warranty. The comprehensive range of SANY products includes excavators from 1.8 to 75 tonnes, wheel loaders, cranes and piling rigs, all equipped with the latest technology and boasting maximum efficiency.

Product focus:

SANY showcased its smallest zero tail-swing excavator, the SY18U, displayed alongside a range of other products from the SANY excavator range. Unveiled for the first time in June 2023, the SY18U facilitates work in compact spaces thanks to its

zero tail-swing design, making it an ideal solution for urban construction

Ideally located in Belgium, Sunward Europe offers a wide range of equipment from excavators and loaders to drilling rigs, cranes and aerial working platforms. Sunward equipment is built for reliability, with premium components and provide a host of features as standard.

Product focus:

The Sunward stand featured four machines chosen from its comprehensive range of construction equipment.

SWE 25UF Mini Excavator: This 2.5-tonne zero-tailswing excavator is Sunward’s most sought-after model in the UK. It boasts a robust 14.6-kW Stage V compliant Yanmar diesel engine, is 1,500-mm wide with a maximum digging reach of 2,840 mm.

SWE 18UF Mini Excavator: A compact counterpart to the SWE 25UF, this 1,880-kg zerotailswing excavator has an adjustable undercarriage that extends from 900 mm for tight access to 1,320 mm for enhanced stability. It is powered by a 13.4-kW Stage V compliant Yanmar diesel engine.

SWL 3230 Skid Steer Loader: Weighing in at 3,500 kg, this skid steer loader is driven by a 55.4-kW Stage V compliant Kubota diesel engine. It has a rated operating capacity of 1,100 kg and a tipping load of 2,200 kg.

SWSL 0807DC Electric Scissor Lift: Designed for precision work in confined spaces, this electric scissor lift reaches 8 m and supports a load of 230 kg. At 0.76 metres wide, its slim profile makes it ideal for indoor and outdoor tasks.

After raising the global standard with the world’s first compact tracked excavator, Takeuchi continues to innovate year after year with new products designed and built for superior performance and reliability.

Product focus: Takeuchi TB20e

Takeuchi returned to the Executive Hire Show with one of the most highly anticipated electric mini excavators for the tool and plant hire industry – the TB20e. The power performance, workrate and operating hours have been key to the unique design and Takeuchi can confidently say that the TB20e matches its diesel equivalent, the TB216 in every aspect. It’s just quieter with zero emissions.

The TB20e offers 100% battery power and up to eight hours’ capacity at

65% load – a significant output that matches the typical work-rate of the TB216, which the TB20e also matches for dig depth, dump height, travel and slew speed. It features electro-hydraulic controls, 24.7 kW lithium-ion battery and three charging options: onboard, offboard and tethered and is available with a portable fast charger that rests securely on the blade when transporting.

This new electric Takeuchi is all set to become a first choice for electric excavating. Compact in size with retractable undercarriage and electrohydraulic controls, the TB20e is designed and built for excavator hire.

The next INTERMAT, the sustainable construction solutions and technology exhibition, will take place from 24 to 27 April at Paris Nord Villepinte exhibition centre.

This will be a year of renewal with the show covering four days instead of six and in view of the momentous environmental, economic and social challenges facing the construction sector, INTERMAT has decided to redefine itself as a place for the gathering and idea-sharing of an entire sector united to build a collective lowcarbon path.

INTERMAT 2024 will be focused on four pillars: Innovation, Energy, New Equations and Commitments, each of which will provide highlights and developments in line with these challenges

facing the construction industry. The exhibition itself will be arranged around five hubs of expertise:

• Earthmoving, demolition and transportation,

• Roads, materials and foundations,

• Lifting and handling,

• Building, civil engineering and concrete, including World of Concrete Europe (see below),

• New technologies and energies (new for 2024) to showcase alternative energy sources, virtual engineering, autonomous vehicles etc.

During the four days of the show, professionals will be able to take advantage of the demonstration zone, which will offer centre stage to innovative equipment operating in real-life conditions.

Another innovation for the show this year is the Industry Forum’s BFM Business TV set, featuring a series of round tables providing an opportunity to take a broad look at societal, energy and economic issues, the challenges of decarbonisation and digitalisation and raise public authority awareness of the fundamental role of our sector in achieving net zero.

A new area dedicated to employment and training will showcase the initiatives taken by the federations to promote the appeal of occupations in the building and public works sector and encourage connections between young talent and companies, through workshops, talks and job-dating sessions.

The low-carbon theme will be at the heart of the exhibition through the CSR charter (see opposite) that we have introduced to make the event more responsible and encourage exhibitors and visitors to lead the change.

INTERMAT welcomes the mobilisation of the sector’s five main trade associations, since collaboration between equipment and machinery manufacturers, energy suppliers and construction companies is essential if we are to provide the right solutions for professionals and meet their needs for innovative, sustainable solutions.

The biggest international

manufacturers have already chosen the event to showcase their innovations, which have significantly accelerated to tackle the challenges of the transition to net zero since the last show in 2018. The 2024 event will be their platform, and that of the entire construction industry, working together to share a common vision and showcase the latest breakthroughs on the market in terms of machinery, equipment, technologies, digitisation, energy storage solutions and plant hire.

Leading names exhibiting at the show include Alphi, Ausa, Bobcat, Cummins, EPIROC, Faymonville, Groupe Monnoyeur, Imer, Komatsu, Liebherr, Magni, Putzmeister, SANY, Sateco, Schwing Stetter, Sunward, Takeuchi, Topcon, Volvo and Wacker Neuson.

World of Concrete Europe 2024

World of Concrete Europe, the European gathering for the entire concrete sector mobilised to meet net zero challenges, will be held concurrently with INTERMAT, and will bring together the entire value chain of the concrete sector around an exhibition space and a congress.

The combination of an exhibition

space and an educational forum will enable visitors to discover the complete and varied proposition offered by the sector at every stage in the chain and an exhaustive overview of the latest breakthroughs in the European concrete market in terms of products, technologies, processes, applications and equipment.