As I write this, we are preparing for the upcoming British Demolition Awards in London, sponsored by Luigong. In between scribing duties, I am assisting my colleagues in packing boxes of magazines, checking PowerPoints and ensuring all physical advertising is straight, stands up and we can get it back in the case again. It is all go and we look forward to celebrating British demolition with our colleagues from Demolition Hub.

Good luck to all entrants!

The busy theme continues into the rest of September as we have had a mass of interest from major OEMs and dealers.

My September calendar looks like this: Blue Group’s Open Day, off to Germany to see CASE and Wacker Neuson. If I can make it, the RWM show rolls around once more in Birmingham then it’s back to Germany to see Sennebogen before a site tour of the famous JCB compound and a meeting with MB Crusher. September will likely end with the Hitachi Open Day. My team and I are very busy and we love it and we will be bringing you all the action in the next issue (November).

In Issue #19 we have a wonderful interview with David Kocurek on a riveting history, his heroes, and the rise and rise of the excavator mod-masters Kocurek.

We have an interview with Antti Anttila, CEO Lekatech – a new name for us, expanding from its Finnish home into Europe and beyond.

Probably the most looked forward to features of the year, excavators and attachments, are in this issue also as well as all the news from the UK and global construction equipment industry.

Advertising-wise, we have a little in-house surprise in the shape of our new Brand Manager Charlotte Walsh, beginning on Monday 4 September. Charlotte, who I have worked with many times before, is a decisive and confident woman who knows the industry inside out. She is a brilliant account manager and saleswoman and will be assisting Luke in the sales department. Be ready to hear from Charlotte in the near future.

I look forward to seeing many of our readers on my continued global exploits and am always available via: ben@globalnews.media, so do get in touch.

I hope you enjoy the issue.

Ben Chambers

ben@globalnews.media

Toby Wilsdon toby@globalnews.media

DESIGNERS

Nicki Chambers nic@globalnews.media

Joe Bers joe@globalnews.media

Alex Jarrett

GENERAL ENQUIRIES info@globalnews.media

01903 952 640

SALES

Luke Chaplin luke@globalnews.media 01903 952 643

PRODUCED & PUBLISHED BY Global News Media Ltd Suite 5 & 6 Chapel House 1-6 Chapel Road, Worthing West Sussex BN11 1EX ben@globalnews.media 01903 952 640

Diggers LIVE is published six times a year by Global News Media Ltd

Articles and information contained in this publication are the copyright of Global News Media Ltd and may not be reproduced in any form without the written permission of the publishers.

The publishers cannot accept responsibility for loss of, or damage to, uncommissioned photographs or manuscripts.

16

ONS figures show construction output in Great Britain grew 1.6% in June 2023

Wacker Neuson Group remains on growth track in first half of 2023

XCMG’s export revenue in first half of 2022 marks over 157% growth

Caterpillar reports Q2 2023 results

Speakers and agenda announced for CPA Conference 2023

16

With Antti Anttila, CEO of Lekatech

20

• New 8-t E88 excavator extends Bobcat R2-Series range

• New DX140LC-7K 14-t Crawler Excavator from DEVELON

• Hyundai HX65A crawler and HW65A wheeled excavator

• JCB 245XR

• The Mecalac 15MC crawler excavator – compact, powerful, versatile

• SMT GB and Volvo excavators represent the perfect partners

• SANY SY18U

• “Solid to succeed” – for XCMG it’s all about our customers

• Wacker Neuson EW100: A new era of wheeled excavators

• Speed and stability unite: Yanmar CE’s B110W

With David Kocurek, Managing Director/co-founder of Kocurek Excavators

• Epiroc – 60 years of market leading innovation

• Approved Hydraulics

• BMC Buckets – Making the grade

• Bobcat – new Brushcat and log grapple attachments

• BPH – leading supplier of excavator attachments

• MBI enhanced MSGR grapple range, supplied by Inmalo

• Lekatech linear electric hammer technology

‘We wouldn’t use anything else’ says two-decade-long Yanmar rental customer

Collins Earthworks makes the grade with investment in Cat machines

Recycling is like magic: MB Crusher units turn waste into usable things

SMT GB announces new purchasing process for Volvo compact machinery in parts of UK

Rocket Rentals invests in 10 new SANY excavators

Interparts shows DEVELON brand for first time at MATEXPO

Vision Techniques provides latest safety equipment for Blackburn with Darwen Borough Council

Ritchie Bros. announces power-packed event with live auction, networking, industry insights and more

Collins Earthworks rewards experienced operator with customised Volvo EWR170E wheeled excavator Research reveals surprising statistics around neurodiversity in construction

Monthly construction output is estimated to have increased 1.6% in volume terms in June 2023; this came from increases in both new work (2%) and repair and maintenance (1.1%) on the month.

At the sector level, six out of the nine sectors saw a rise in June 2023, with the main contributors to the monthly increase seen in infrastructure new work and non-housing repair and maintenance, which increased 4.7% and 3.4%, respectively.

Quarterly construction output increased 0.3% in Q2 2023 compared with Q1 2023; the increase came solely from June 2023, with an increase in repair and maintenance (0.9%), while new work saw a decrease of 0.1%.

Total construction new orders decreased 7.1% (£786m) in Q2 2023 compared with Q1 2023; this quarterly fall came mainly from public other new orders and infrastructure new orders, which fell 32.9% (£576m) and 26.5% (£519m), respectively.

The annual rate of construction output price growth was 4.6% in the 12 months to June 2023; this has slowed from the record annual price growth in May 2022 (10.4%).

Construction output in June 2023

Monthly construction output increased 1.6% in June 2023. This follows three consecutive falls in monthly construction output. This is the highest level of construction output (£15,620m) since records began in January 2010 (figure 1).

Anecdotal evidence received from returns for the ONS’s Monthly Business Survey for Construction and Allied Trades suggested a positive effect of warm weather increasing output across sectors. The Met Office confirmed in its monthly climate summary that the provisional UK mean for June 2023 was the warmest since records began in 1884.

The 1.6% rise in construction output in June 2023 represents an increase of £249m in monetary terms compared with May 2023, with six out of the nine sectors seeing an increase on the month (figure 2).

Infrastructure new work and non-housing repair and maintenance were the largest positive contributors to the monthly increase in June 2023, increasing 4.7% (£116m) and 3.4% (£102m), respectively. This is the fourth consecutive monthly increase in infrastructure new work. Anecdotal evidence suggests continued strength in this sector, with warm weather allowing construction project work to progress in June 2023.

Alongside the monthly increase, construction output rose by 0.3% (£137m) in Q2 2023. This is the seventh quarter of consecutive growth in the quarterly series since Q3 2021 (1.6% fall), however, the quarterly growth has slowed in comparison with the first half of 2022.

The quarterly growth came from an increase in repair and maintenance (0.9%), as new work saw a decrease of 0.1%, and the quarterly increase was generated entirely in June 2023, as the other two months of Q2 2023 saw decreases.

Anecdotal evidence highlighted the effect of weather, with firms noting that warm weather conditions increased output (figure 3).

Of the nine sectors, five saw increases in Q2 2023, with the largest contributors being infrastructure new work, and nonhousing repair and maintenance. These sectors increased 6.1% (£433m) and 2.7% (£246m), respectively. The largest negative contributor was private new housing, which fell 3.3% (£324m) (figure 4).

Total construction new orders decreased by 7.1% (£786m) in Q2 2023 compared with Q1. This is the third consecutive fall in total construction orders, with Q2 2023 being the lowest level (£10bn) since Q4 2020 (£9.7bn).

“Six out of the nine sectors saw a rise in June 2023”

Other new work new orders (nonhousing) was the largest contributor to the decrease in Q2, as it fell by 11.3% (£903m). This mainly came from public other new work new orders, which decreased by 32.9% (£576m) and was driven by falls in health, and schools and colleges. The other largest negative contributor was infrastructure, which decreased 26.5% (£519m). Private commercial saw an increase of 14.3% (£385m), which was the largest growth out of all seven sectors.

Housing new orders saw an increase of 3.9%. This came from both private and public housing, which saw increases of 3.6% (£97m) and 5.8% (£21m), respectively.

Evidence from ONS’s data suppliers, Barbour ABI, suggests that the fall in new orders is because of the cost-of-living crisis and the related slowdown in the wider economy. This caused uncertainty in the commercially sensitive construction sectors, along with a slowdown in the award of government contracts in traditional heavy infrastructure (rail and road) (figure 5).

Prices in the construction industry, as estimated by the ONS’s Construction Output Price Index (OPI) dataset, decreased to 4.6% in the 12-month period to June 2023. The rate of annual price growth has slowed from the record increases seen in May 2022 (10.4%) (figure 6). For further information

go to www.ons.gov.uk and search “Short-term measures of output by construction industry in June 2023”.

The Wacker Neuson Group once again posted dynamic growth in the first half of 2023. As a result, the company raised its full-year guidance when it published its preliminary figures for the first half of the year on 13 July.

Group revenue increased by 27.4% to €1,365.9m year on year (H1 2022: €1,072.5m) and earnings before interest and taxes (EBIT) were 101.9% higher at €176.7m (H1 2022: €87.5m). At 12.9%, EBIT margin was significantly above the previous year (H1 2022: 8.2%).

Dr Karl Tragl, CEO of the Wacker Neuson Group said: “We continued to develop positively in the second quarter despite the ongoing tense environment. This underlines the fact that we are increasingly succeeding in coping with the numerous challenges we face. Against the backdrop of this positive development, we raised our full year guidance in mid July. Nevertheless, we remain cautious for the second half of the year in order to be able to respond to a potential economic slowdown at any time.”

Continued strong demand, particularly in the core markets of Europe and North America, contributed to the significant revenue growth in the first half of the year. In the EMEA region, revenue grew by 23.9% to €1,023.5m (H1 2022: €826.3m).

After a weaker development in southern Europe last year, there was a noticeable increase in demand here in the first half of 2023. By contrast, the market in the United Kingdom, which was still characterised by double-digit growth rates in 2022, showed restrained development.

Demand remained high, particularly for wheel loaders and telehandlers. Demand for compact equipment for the agricultural sector under the Kramer and Weidemann brands also remained high, with revenue in the Agriculture segment rising significantly by 51.9% to €315.1m (H1/2022: €207.4m).

The positive trend also continued in the Americas region. Revenue in the region grew by 48.3% to €300.7m (H1 2022: €202.8m). As part of its continued diversification of its sales strategy, Wacker Neuson continued to attract additional authorised dealers in North America in the first half of 2023.

Revenue in the Asia-Pacific region declined slightly in the first half of the year, falling by 3.9% to €41.7m. As in previous quarters, the Australian market showed clear double-digit growth rates, with the company’s strategy of systematically expanding the dealer network and adapting the product portfolio to local needs continuing to be successful. However, the other markets in the region as well as China and southeast Asia, which in total contribute significantly less revenue than the Australian market, declined in the first half of 2023.

At 31.6%, the net working capital ratio at the end of the first half was above the target range of around 30%. In absolute terms, net working capital amounted to €883.6m, an increase of 31.1% compared to the previous year (30 June 2022: €673.9m, 31 December 2022: €718.9m).

Against the backdrop of the positive business performance, gross cash flow also improved by 63.7% year on year to €200.2m (H1 2022: €122.3m). At €-30.5m, free cash flow was also significantly higher than in the previous year (H1 2022: €-123.8m, before effects from the reversal of a fixed-term deposit in the first half of 2022). At €352.9m, net financial debt showed a significant increase compared with year-end 2022 (H1 2022: €234.5m). Free cash and cash equivalents amounted to €33.7m at the reporting date (31 Dec 2022: €53.7m).

XCMG Construction Machinery Co Ltd reported 38.2bn Chinese Yuan (£4.11bn) in first-half revenue of as of 30 June, a 28.23% decrease year-on-year, a smaller drop compared to the industry average. XCMG’s revenue from export amounted to 12.488bn Yuan (£1.34bn), a 157.28% increase year-on-year.

Per the simulated financial statements after the completion of material assets reorganisation, “New XCMG” ranks number one in China’s construction machinery industry in terms of total revenue and net profit. In addition, XCMG’s interim dividend plan has a proposed dividend of 2.3 Yuan per 10 shares (tax included).

After five years of rapid growth, the construction machinery industry has shown a downward trend starting from Q2 of 2021 that continues to this day, and China’s domestic market is going through a cyclical adjustment. Facing the challenges, XCMG has mapped a new industry layout of “Five pillars and 10 emerging strategic industries” with a continuous focus on primary businesses:

• The hoisting machinery BU continues to lead in the highly competitive market with a 3.1% increase in market share and sales breakthroughs of all-terrain cranes in the high-end European/American markets,

• The market share of crawler cranes has increased by 8.1%. XCMG has expanded the business scope of truck cranes and explored new opportunities for profitable growth,

• XCMG Fire-fighting Safety Equipment maintained the top position in lifting fire trucks and boom-type aerial work platforms and launched construction for the second phase of its new base,

• XCMG Environment Technology has increased market share and gross profit margin,

• The revenues from small construction machinery, maintenance machinery, forklift and information industry have increased by 100.3%, 18.3%, 89.5% and 23.4% respectively year-on-year.

In the first half of 2022, XCMG’s overseas entities delivered outstanding performance, with revenues increasing by

71.8%. XCMG Brazil’s first-half revenue has exceeded that of the annual total of 2021 and achieved a significant increase in profit and overall indicators. Company registration and site selection for XCMG’s North American projects have been completed and German Schwing’s revenue has turned the tide, while India Schwing has become a benchmark of collaborative development with a 68.5% increase in revenue. XCMG India is officially in operation and the group’s subsidiary in Uzbekistan has reported revenue growth of 69.1% year-on-year.

Lu Chuan, President of XCMG, said: “The ‘New XCMG’ will adhere to achieving transformation, upgrade, and high-quality development; continue to advance digital technologies supported by world-class software platforms; and strengthen the R&D of information technologies such as big data, AI, 5G, industrial IoT, and digital twin; while further expanding and stabilising the innovation chain, industry and supply chain to build core competitive advantages for growth and profit.”

Epiroc hydraulic attachment tools enable all types of demolition projects to be handled faster, with less noise and lower overall cost. Our crushing and screening machines enable valuable waste materials to be retrieved from the demolition waste to be recycled and re-used.

For construction projects, our rig mounted attachments enable rapid, efficient site clearance and preparation. Epiroc equipment for trenching and foundation work gets the job done faster and more easily.

Caterpillar Inc. announced second-quarter 2023 sales and revenues of $17.3bn, a 22% increase compared with $14.2bn in the second quarter of 2022. The increase was primarily due to higher sales volume and favourable price realisation.

• Operating profit margin was 21.1% for the second quarter of 2023, compared with 13.6% for the second quarter of 2022,

• Adjusted operating profit margin was 21.3% for the second quarter of 2023, compared with 13.8% for the second quarter of 2022,

• Second-quarter 2023 profit per share was $5.67, compared with secondquarter 2022 profit per share of $3.13,

• Adjusted profit per share in the second quarter of 2023 was $5.55, compared with second-quarter 2022 adjusted profit per share of $3.18. Second-quarter 2023 and 2022 adjusted operating profit margin and adjusted profit per share excluded restructuring costs. Second-quarter 2023 adjusted profit per share also excluded a discrete tax benefit to adjust deferred tax balances.

For the first half of 2023 enterprise operating cash flow was $4.8bn, and the company ended the second quarter with $7.4bn of enterprise cash. In the quarter, the company repurchased $1.4bn of Caterpillar common stock and paid dividends of $0.6bn.

Jim Umpleby, Chairman and CEO said:

Jim Umpleby, Chairman and CEO said:

“I’m proud of our global team’s strong operational performance in the second quarter. Our results reflect continued healthy demand as we achieved doubledigit top-line growth and record adjusted profit per share while generating strong Machine, Energy and Transportation (ME&T) free cash flow.

“Our team remains committed to serving our customers, executing our strategy and continuing to invest for longterm profitable growth.”

THE NEW V7 & V7-HW

They may be the smallest machines in our range but with smooth, powerful, electronically controlled drives, front oscillation and P-kinematics parallel lifting, our new compact wheel loaders have the capability to take on the big jobs with ease.

The Construction Plant-hire Association (CPA) has announced the speaker lineup and agenda for the CPA Conference, which is taking place on Thursday 9 November 2023.

The theme of the one-day event is Facing the Challenges in the Plant-hire Sector and the conference is being hosted at the Heart of England Conference and Events Centre in Fillongley, near Coventry. Delegate tickets can be booked online at www.cpa.uk.net/events/cpaconference-2023 for £75 plus VAT per person, including lunch. The event is open to both CPA members and non CPA members.

The CPA Conference 2023 is being held in association with headline sponsor Point of Rental Software and it will be the eighth CPA Conference. Over the years, the event has become established as an essential entry in the calendar for senior figures in the plant-hire sector.

Former BBC news presenter and journalist Merryn Myatt will host four panel debates covering The Plant-hire Sector in 2023, Fuelling the Future, Focus

on CPA Special Interest Groups and Challenges and Combatting Plant Theft and Fraud, featuring experts from the construction plant hire sector.

Panel speakers include Asif Latief, Managing Director of Boels Rental; Mark Anderson, Managing Director North of GAP Group; James Atkinson, Vice President UK and Europe of Rouse Services; Jim Haigh, Chairman/ CEO of Eagle Platforms; Joel Babb of Falanx Cyber; Kirsty Archbold-Laming, Director of Southern Hoist Services; Adam Nicholson, Managing Director of Eagle Platforms; Alasdair Reisner, Chief Executive of the Civil Engineering Contractors Association (CECA); Chris Gill, Director of L Lynch Plant Hire and Haulage; Peter Gibbs, Chief Operating Officer of Ainscough Crane Hire; and Kevin Howells, Managing Director of Datatag ID.

CPA Chief Executive Stu McInroy said: “This year’s conference agenda addresses some of the most important issues faced currently by CPA members and the wider construction industry.

Topics such as future fuels and plant theft and fraud are of significant concern to many of our members, and the event will provide delegates an opportunity to develop a greater understanding of the challenges they face currently and how they may be addressed.”

The conference will run alongside a small, targeted exhibition. Confirmed exhibitors at the event include Point of Rental Software, Genquip Groundhog, Thomas Group, Nexus Vehicle Rental, Plant Planet, Scottish Qualifications Authority (SQA), Capja, MHM Group, Tobin Plant/LiuGong Machinery (UK), NOCN Group, Prolectric, CITB, Rouse Services, Go Plant Ltd and CESAR Powered by Datatag.

The exhibitor packages also include attendance at a pre-conference networking dinner on the evening of Wednesday 8 November. Only a very limited number of exhibition spaces remain available.

For more information regarding exhibiting or attending, please contact Lisa Collins on 07968 840 390 or email: lisa@lisacollinscommunications.co.uk.

We offer the world‘s best-selling quick coupler system. We are the original and have decades of experience and testing behind us. Our solutions work and you get an outstanding combination of quality, performance and safety. There‘s only one OilQuick!

• Lightning fast change of hydraulic, electrical and mechanical attachments from inside the cab.

• Always the right attachment for the job.

• Distributes oil, grease, water and electricity.

• No staff around the machine during tool changes.

• Improved safety.

• Meets and exceeds safety standards globally.

• Increased productivity.

• Increased profitability.

• Reduce the number of machines on the site.

• Reduced transport costs.

• Eliminates oil spills.

• Protected hose run.

• Less dirt in the cab.

• For machines 1-120 tonnes.

Interviewee: Antti Anttila

Role and company: CEO, Lekatech

Sector: Electric hammers

Established: 2018

Employees: 11

Geographical reach: Global Prior roles/positions in career: Business development, CEO, supply chain

I have been working in manufacturing industry in a variety of functions and organisations since graduating with an MSc Industrial Engineering in 2002. The roles started with supply chain and quality and evolved to business development and general management. The companies have been from tiny companies to multinationals located in Finland and Germany. My passion is in developing innovation-intensive new business and doing that with exceptional teams.

Lekatech was founded in 2018 to electrify the hammering industry. The exceptional deep technology development by a startup has proven to be viable for rock breaking. It brings the performance of hammers to a new level, addresses major environmental issues and enables the Industry 4.0 transition.

I am one of the founders so I have been fortunate to be able to build the team around us together with the other founders. We have succeeded in putting on track an excellent and committed culture with a lot of joy at work. So yes, I think I fit in well in the Lekatech team.

The major focus of Lekatech development has been and continues to be around the technology and product development. But that is nothing without a lot of things around it. My main duty is to make sure the technical development is utilised in a maximum potential way. This includes

functions from business development, funding development, marketing to administration and HR. It is important to keep the different development activities in balance between each other.

QTell us about the balance between your expertise in your sector and your role in business

I have been in manufacturing industry with a B2B model all my career. The products I have worked on varied a lot but the majority have been machines or partial machines on a significant scale. That provides a good understanding of general rules of the game when it comes to Lekatech’s business. The hammer industry as such is new to me, which feels nice since there is something to learn, while I can bring my experience from other sectors to it.

QWhat is it about your role and the sector that attracts you?

We can change the world for the better. We have a technology at hand that can really make a big difference on the environmental level as well as personal and customer business success level. Furthermore, we see a long development path of the ecosystem ahead that will have a dramatic impact on efficiency and safety of mining and demolition.

I enjoy the success of the team. We are making progress all the time and the team is really committed to achieving our ambitious goals. Every day is energising in Lekatech.

QHow do you think your colleagues see you (or you would like them to)? Good question! I hope they see me as an enabler to realise their personal ambitions rather than someone controlling and limiting their space.

QTell us more about Lekatech’s history and development as a company

Founded in 2018 with three part time founders, we have gone through a lot of development, prototyping and testing phases up to now. The technology risk has been great in the past, but we have overcome it by now. There is a multitude of expertise areas that we have had to cover internally and externally and we feel we have succeeded well.

QBriefly sum up what Lekatech does, in particular for our readers in Diggers LIVE

Our electric hammers for rock breaking and demolition are the choice for an electric carrier, excavator, boom or mining machine. It is simply a much better choice for the electric carrier than a hydraulic one. More power, accuracy and versatility, with a lower environmental burden.

QTell us about Lekatech’s growth path. How will it be expanding into Europe and potentially worldwide and how will you be involved in that?

Lekatech hammers are attached to the carrier typically by the carrier machine providers or their dedicated dealers. The carrier must be equipped accordingly to ensure safe attachment. That’s why Lekatech works closely with carrier machine providers.

We are addressing European markets first, through carrier machine providers in Europe. They may also make Lekatech hammers available for customers outside Europe. Wherever electric carrier machines are used for hammering, that’s where the Lekatech electric hammer is the choice. Once the experience is strong enough in Europe, we will expand to address carrier machine providers in other countries, too.

QTell us about your relationship with customers and potential customers. What does a Lekatech customer look like?

There are different reasons to be a Lekatech customer. Some value the lower total cost of ownership. For some the high performance combined with compactness is key. Others may put the environmental benefits as the highest priority. And there are surely some that simply want to be pioneers and discover by themselves what Lekatech can bring them. In any case, the customer is running or is going to run his/her machines with electric drives. The customer is following the changing expectations of society. Typically, the Lekatech customer is also concerned about environmental matters.

QWhat are Lekatech’s USPs, as a product and a company? How can these benefit customers?

Greater performance, lower environmental burden, IIoT (Industrial Internet of Things)/Industry 4.0-readiness. Performance comes in more output and more adjustability, making it possible to address effectively different type of tasks with only one hammer. It also means lower energy and maintenance costs etc. Environmental benefits are especially important for the image of the customer. In some cases that can be a qualifying criterion or a differentiating factor among the competition.

The IIoT-readiness is currently only in its infancy. For many this is not yet of great value, but the importance of this will grow every year as the ecosystem evolves.

QTell us about your team and working culture

The company has a strong team spirit and culture. The culture is described by humble positiveness combined with passion to achieve high goals. The environment is supportive towards one another. Fairness is also a fundamental value that is valued and employed by every member of the team.

QDoes Lekatech face any issues with the availability of labour, experienced and inexperienced? Is there a good pool of potential new recruits? Lekatech is situated one and a half hours away from the capital region of Finland, in the middle of the woods. It is not exactly a hotspot of skilled personnel. On the other hand we are still in the southern part of Finland with a large amount of skilled persons within an hour’s reach. We are recruiting people for different roles requiring different levels of experience and expertise. Lekatech has been very flexible on working times, working locations and we have people from many nationalities. English is the only common language within the company.

QHow do you see Lekatech in five or ten years?

Lekatech will be a well known brand in the industry. It is the electric hammer and Lekatech technology is the industry benchmark.

QAnd how about yourself?

I hope to be part of the Lekatech success story in one or another form. If the role needs to change for the benefit of the company, I’d go for it.

Who/what would you be in an alternative life?

I like practical life and nature. I would like to be born in a remote area and live from nature.

Who is your favourite artist?

I like the business books of Jim Collins. Jukka Jalonen is my favourite coach (Finnish national hockey team). Music preference is mood dependent – from classical through pop to melodic heavy is in the range.

Who do you most admire?

Many different people in different areas of life. President Obama is one of them.

What would be your desert island luxury? A summer house.

What gets you out of bed in the morning? Excitement for the day’s challenges.

What do you do for fun?

Construct or spend time with friends and family.

When and where are you happiest?

When the team has achieved something great and I was not involved.

Bobcat has extended the company’s R2-Series of mini-excavators with the launch of the new E88 8-t Stage V compliant model, replacing the previous E85 M-Series machine. The E88 delivers outstanding performance from a compact dimension machine, superb operator comfort and excellent stability with high digging output.

The E88 provides the operator with the full experience expected of an R2Series excavator, adding new features and options such as an optional fourth AUX4 auxiliary tilt coupler line, a fifth AUX5 hydraulic coupler line as standard and a longer undercarriage. Bobcat´s acknowledged productivity is coupled with smooth controllability thanks to low effort joysticks and intuitive five or seveninch displays, class-leading visibility and exceptional transportability for its weight class. Large, easy opening covers provide convenient, ground level access to all service points and for maintenance checks.

The proven Bobcat D24 Stage V 4-cylinder engine offers a maximum power output of

48.5 kW and ensures the highest performance and maximum reliability. To meet Stage V emission levels, the engine uses diesel oxidation catalyst (DOC) and a diesel particulate filter (DPF), replacing selective catalytic reduction to achieve maximum reliability, efficiency and environmental protection.

Like previous Bobcat R2-Series machines such as the E60, the new E88 continues to develop the philosophy of “built around the operator”. The spacious cab with plenty of headroom and legroom retains

the proven design of the cab in the E60. Easy and safe to get in and out of thanks to the wide doors, unique 3D handle, antislip step on the undercarriage and foot space above the track, the cab makes the daily life of the operator an easier one.

Panoramic visibility at the top of its class

Unparalleled visibility improves job site awareness, making the machine more precise, easier and more productive to use, while keeping the job site safe. The new E88 excavator is engineered with narrower, but solid cab pillars and ample glass surface area.

Buckets: 0.7 m3

Operating weight (inc cab, tracks, standard arm): 8,994 kg

Digging depth: 4,859 mm (with long dipper stick)

Digging reach: 7,549 mm (with long dipper stick)

Engine: Bobcat D24 4 cylinder 2.4 L Stage V 48.5 kW at 2,100 RPM

DEVELON, formerly Doosan Construction Equipment, has launched the new DX140LC-7K 14.6-t crawler excavator, replacing the company’s successful DX140LC-7 model. While the performance and working range are the same as the DX140LC-7, the new machine incorporates many improvements that enhance safety and convenience both for the operator and for working on site, together with a better operator experience, particularly from a maintenance point of view.

The main improvements on the new DX140LC-7K model include:

• Better maintenance access

• Safer access to the upper structure

• Better rear visibility

• Better right-side visibility

• New dashboard with tablet design, offering faster response

The upgraded serviceability of the DX140LC-7K includes better access to the DEF tank and the fuel refilling hose. This is combined with a much easier approach for the operator to the engine

compartment via new anti-slip steps and handrails positioned behind the cab. The anti-slip steps are protected and secured by a new door on the side of the excavator. The DX140LC-7K also has a new flattened engine cover design that has reduced the maximum height of cover components on the back of the machine from 1,285.5 mm and 1,320 mm down to a uniform 1,070 mm across all of the back of the machine. This now offers much better visibility for the operator both to the rear and to the right-hand side of the machine.

Specifications

Hyundai has updated its mid-weight compact excavators, with the introduction of the HX65A crawler model and the HW65A wheeled machine. The two excavators replace the popular R55-9A and R55W-9A, boasting a revised design, new technologies and upgraded features.

The operating weight has been increased to 6-6.5 tonnes, depending on specification, and both machines are now powered by Hyundai’s own Stage V diesel engine. This 2.4-litre motor delivers a maximum power rating of 48.5 kW, with 248 Nm of torque available and it drives a proven Bosch-Rexroth open centre hydraulic system, with Parker main control valves and an Eaton swing motor.

The hydraulic system is equipped with proportional joysticks as standard, with a ram lock switch mounted on the left-hand lever head. Double-acting breaker piping is also standard equipment and rotation piping is available as an option from the factory. The excavators feature an improved swing motor, offering increased operating speed and torque, boosting productivity in

digging and loading operations.

The new cab design delivers improved space for the operator, with increased visibility and a fully adjustable, heated operator seat. A revised air conditioning system provides optimised airflow within the cab and there are lower noise levels inside and externally. Bringing technology from larger Hyundai excavators, the compact machines now feature a seveninch touchscreen monitor. This can be used to set auxiliary hydraulic flows for attachments.

Cabin working lights have been improved and there is now the option of full FOGs (Falling Object Guard) at the front and top of the cabin, to provide additional protection on demolition and other hazardous operating sites. Rear and side view cameras provide improved visibility all around the machines.

In response to customer demand, the wheeled HW65A will be offered with a choice of single or twin tyres, available from the factory, to allow the machine to better adapt to a range of job site

requirements, delivering optimal traction and stability.

Both the wheeled and tracked machines have wide opening engine hoods, providing easy access to regular maintenance items. All filters are placed within the engine compartment, with ground level access and a toolbox mounted within the cowl. A double-layer air cleaner delivers prolonged service life and Hyundai’s Hi-MATE telematic system is available to provide remote monitoring of machine working and performance.

JCB’s 245XR combines minimum swing with maximum space, delivering compact operating dimensions with no compromise in performance or productivity. With best-in-class cab space and comfort, impressive stability and productivity, a highly efficient driveline and excellent serviceability, the 245XR sets a new standard in the reduced swing 22 to 26-tonne excavator sector.

At just 1,720 mm, the 245XR has a tail swing that is 40% shorter than the conventional 220X model, with which it shares many features. This offers contractors a highly effective excavator for use in confined site works.

The 245XR can be ordered with a choice of monoboom or a TAB triple articulating boom and there is a choice of 2.4-m and 3-m dipper arms, for increased breakout or maximum reach. Maximum digging reach with the monoboom is 9,952 mm, with a maximum digging depth of 6,627 mm.

With a choice of 600-900 mm heavy-duty track pads, the 245XR offers exceptional stability, for digging across track and for lifting duties on site while an optional dozer blade is offered, for maximum versatility.

The 245XR uses the proven one-metrewide cab featured on X-Series machines, which is 15% larger than the cab on the previous JS generation excavators. With an internal volume of 2.86 m3, it is the largest cab in the sector, delivering maximum comfort throughout the working day for operators.

The cab has an internal noise level of just 69 dBa, among the quietest in the sector and boasts a range of seating options, developed with Grammer, to deliver maximum support and comfort. Standard specification includes climate control, a factory-fit Bluetooth radio, window blinds, refuelling pump and tool kit. Specific packs to suit individual regions will also be offered.

The 245XR is powered by a highly efficient EU Stage V-compliant JCB Dieselmax 448 engine, delivering 129 kW. The 4.8-litre engine uses a Selective Catalytic Reduction Filter (SCR-F) that comprises a combined SCR, Diesel Particulate Filter (DPF) and Diesel Oxidation Catalyst (DOC) with a large ash holding capacity. There is no requirement for Exhaust Gas Recirculation (EGR) and the system has been removed

from the new inlet manifold, resulting in a cleaner burning engine.

Despite the compact rear bodywork, JCB has installed large service doors, providing easy access. Air filter and hydraulic filter life is up to 2,000 hours, while engine oil changes intervals are set at 500 hours. There are wide, well-spaced steps and grab rails for upper structure access, reducing maintenance times and increasing safety.

A brand at the global forefront of design and innovation, Mecalac is renowned for its pioneering products. The 15MC brings class-leading power to an excavator that is compact enough to fit within a single traffic lane.

Its unique design integrates the counterweight and equipment just against it to ensure optimum compactness with enhanced stability. It uses this to great effect, offering manoeuvrability and versatility with unmatched stability regardless of the upper carriage’s rotation angle.

Powered by a turbocharged Deutz TCD 3.6 L4 water-cooled diesel engine, the 15MC delivers 100 kW at 2,300 RPM. It also achieves significantly reduced emissions with an exhaust gas recirculation (EGR) valve, catalytic converter (DOC) and selective catalytic reduction (SCR) system. The clever design allows easy access for refuelling from the ground, with a tank capacity of 150 L (plus 30 L reserve tank) for extended operation.

The excavator’s hydrostatic transmission works with the Central X chassis and a pair of two-speed travel motors for effortless movement over difficult ground. A cockpit selector allows the operator to easily and immediately switch between standby, eco and power modes. The hydraulic system uses a variable displacement pump to generate a maximum flow rate of 270 L/min and a 330 bar working pressure, delivering smooth and precise control.

An innovative three-section boom with an integrated offset allows the excavator to operate against the track in all upper frame positions, while also reaching out to a maximum and unmatched working range of 8.8 m. When fitted with Mecalac’s two-piece boom attachment, the 15MC can dig to a depth of 4.98 m and delivers 8,170 daN breakout force / 6,200 daN tear out (penetration) force.

Mecalac’s patented CONNECT

hydraulic quick coupler ensures simple and safe equipment changes direct from the cab. Integrated directly into the dipper, it is perfectly reversible and works efficiently in all positions – from digging to working with loader buckets and handling pallet forks more safely or a ripper tooth.

Additional benefits include easy cab

access, ROPS and FOPS protection, front and rear working lights, air conditioning, heated pneumatic seat and a state-of-theart telematics system. The 15MC can also be specified with a wide selection of work tools to ensure complete job site suitability.

For more information about the 15MC, or Mecalac’s full range of classleading compact equipment, visit www.mecalac.com.

Finance for business purposes only. Subject to acceptance and affordability checks. Applicant must be 18 or over. Promotion valid from 17th July 2023 to 30th September 2023 on selected new machines. Minimum finance term of 12 months. The finance product available under this promotion is Hire Purchase. Full VAT, deposit, and a document fee of £195 are all due on signing. An option-to-purchase fee of £150 (plus VAT) will be collected with the final payment. The customer will own the machine when all payments have been made. Alternative finance options are available, terms and conditions apply. UK Customers only. Images are for illustrative purposes only. Finance provided by BNP Paribas Leasing Solutions Limited, Northern Cross, Basingstoke, RG21 4HL. Registered in England N° 9012255.

For more information contact us today:

by Alex Cox, Marketing and Communications Officer, SMT GB

by Alex Cox, Marketing and Communications Officer, SMT GB

dust suppression solution. Equipped with a 30 LPM hydraulic lifting pump that deliver water to four nozzles, fitted in tandem to both sides of the boom, the fine mist produced by these nozzles negates the need for a separate truck for pumping water, and can also be used for cleaning the machine with a high pressure water gun mounted behind the cab of the machine.

Representing the perfect partnership for the construction industry, SMT GB offers the full purpose-built Volvo demolition specification excavator range, as well as services and solutions designed to keep efficiency, productivity and uptime maximised.

Volvo’s demolition specification excavators offer unparalleled levels of protection to both the machine and its operator, thanks to an extensive list of factory-fitted protective features. One such feature is a reassuringly comprehensive chassis-mounted FOPS cage, ensuring the operators are fully protected against falling debris. The front door of the FOPS cage is also openable, distinguishing it from third party cab-mounted FOPS systems that other manufacturers are heavily reliant on. Additionally, a substantial boom bash plate offers excellent protection to the HRV valves and lift cylinders, with the cylinders themselves being more substantial than those fitted to competitor machines, while ram-guard protection keeps to the bucket ram in perfect working order.

Other protective features of a Volvo demolition specification excavator are factory-fitted slew ring guards, segmented side-impact protection and extra duty belly plate protection. Additionally, more robust side doors are also fitted to the machine, complete with fly screens, fins fitted to the inside of the door and a reversible fan to help keep machines dust-free even in the worst operating conditions.

However, demolition specification Volvo excavators represent far more than a heavily armoured excavator for customers. All Volvo demolition specification excavators are also equipped with a broad range of features designed to ensure that these are the most productive machines on site.

A hammer shear rotate circuit delivers 40 to 60 litres of hydraulic oil per minute, while twin pumps provide extra flow to ensure all machine attachments can be utilised to their full ability. What’s more, a return filter for the hammer shear rotate circuit keeps machine hydraulic systems free of any potential contaminants.

Demolition specification Volvo excavators are also equipped with a complete

Volvo’s patented modular boom system also provides ultimate versatility for demolition fleets. The innovative modular joint uses a hydraulic locking mechanism to release digging equipment and change from Volvo-manufactured high reach demolition booms to straight or standard configuration booms with both ease and speed. Additionally, boommounted cameras fitted to high reach equipment provide operators with a clear working view.

The undercarriage of the Volvo demolition specification excavator is also hydraulically extendable and contractable. Not only does this make machine transportation simple, but also ensures that demolition specification Volvo excavators are a stable and secure platform to work from.

As standard, the warranty on a Volvo demolition specification excavator is 12 months or 2,500 hours, but this can be extended to five years or 10,000 hours optionally. In addition to SMT GB’s inclusive range of customer support agreements, customers can rest assured that their machine investment is fully protected and are provided with financial peace of mind from knowing that machine maintenance costs remain fixed.

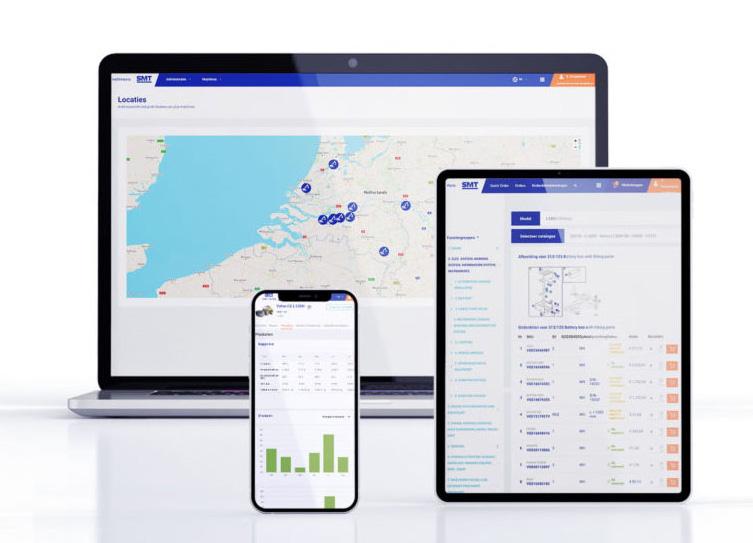

Additionally, the secure web-based MySMT portal is freely available to all SMT customers, greatly simplifying fleet management. Through MySMT, customers are able to access the Volvo CareTrack telematics system, SMT ProCare advanced machine monitoring system and online parts store.

From fuel consumption data, to location and machine usage reports, Volvo CareTrack gives customers a wealth of information to make informed decisions for their Volvo fleets. Additionally, CareTrack access is provided with all SMT Level 2 Customer Support Agreements.

For additional insight, SMT ProCare provides customers with the reassurance that professionally trained SMT analysts are monitoring the health and performance of their Volvo machines remotely. The team can then provide bespoke recommendations if a machine intervention is required. This proactive approach helps to prevent breakdowns and provides customers with more time to focus on core operations. A dedicated technical support team is also on-hand to answer any customer enquiries relating to their Volvo excavators.

Through the online parts store, accessible via MySMT, customers are able to order the parts they need on a 24/7 basis. Additionally, free standard delivery is available to all orders places from an online parts account. Together with the products, services and solutions SMT GB provides, we aim to build lasting relationships with all our customers.

Powered by a Stage V Yanmar diesel engine and featuring a fuel efficient Casappa hydraulic system, the 1.9-t zero tailswing mini excavator is a real powerhouse that delivers outstanding performance in the most compact spaces.

Weighing in at just 1,925 kg and with a height of just 2,370 mm, the SY18U is easy to transport and manoeuvre on site. In addition to its zero tailswing

• ROPS/FOPS certified canopy

• LED work lights for maximum versatility in low light conditions

• Battery disconnect switch, emergency stop button and seat belt

• Travel alarm and rotating warning beacon to increase visibility and attract attention

All SANY excavators are also registered and protected with the CESAR Datatag

to a minimum thanks to the quiet and low vibration of the Yanmar engine.

All maintenance and service parts are easily accessible from the ground level saving time and money during regular inspections and all maintenance work.

Like all SANY excavators, the SANY SY18U comes with an industry leading

to the UK in what we see as the right manner, with Brexit and then Covid delaying our entrance.

When the market was recovering in 2021 we began directly contacting big players to garner their feedback regarding our machines, including quality, setup and specifications etc. This feedback from our partners was invaluable.

could service our customers more effectively.

XCMG began life in China in 1943 as Huaxing Iron Factory and has developed into the third largest construction machinery manufacturer in the world, and China’s number one. Xuzhou Construction Machinery Group was officially established in 1989 and in 1992 it became the first Chinese company in its sector to obtain the right to export independently.

The company formed a joint venture with Caterpillar in 1994 – Caterpillar (Xuzhou) Co. Ltd. – building Cat machines under licence for more than 20 years. It also formed a joint venture with Liebherr in 1995 – Xuzhou Liebherr Concrete Machinery Co., Ltd.

We have built on our roots from the 1940s to improve and give value, teaming with the likes of Caterpillar to build to a high standard and then more recently improve and evolve further to where we are with the very latest Stage V machinery.

In 2013 XCMG established its largest research and development hub outside of China, the European Research Centre in Düsseldorf, Germany, and in 2014 its first overseas wholly-owned subsidiary was put into production in Brazil. That same year the XCMG American Research Center was established in Minnesota, USA.

It’s been an adventure bringing XCMG

We went back and improved performance, fuel burn and operator comfort and then remerged with our new Stage V, fourth generation of European machines ready for action.

We knew from looking at competitors, especially other Chinese brands, that how we entered the market was very important. It was for this reason that we established our head office in High Wycombe on the M40 and close to other arterial roads near London. We located our 8,000 m3 of workshops and storage premises in Lambourn on the M4, again placing it on the major arterial routes so we

We knew from our customers that backup was paramount so we have focused on the service side first, with new engineers and product specialist being the first members of the team. Setting up the parts centre came next, stocking all parts directly not through Europe or China but here in the UK. Our parts team are hugely experienced from the industry so know what it takes to keep our customer working.

The company is now introducing itself to the UK market, with a range of machines from 1.5 to 100-t, including excavators, wheeled loaders from 12 to 34-t and a full range of access platforms and booms. Skid steers, compaction rollers, mobile cranes, ADTs etc will all come later.

We have several electric machines but XCMG foresees the future being with the development of hydrogen engines. Watch this space!

“Solid

Every year too many workers are killed or injured through unnecessary contact with plant and machinery on construction sites and beyond.

Zonr plant proximity solution has been designed and built using Pathfindr’s technology expertise in collaboration with construction safety experts. It uses Ultra-Wideband (UWB) signals to create a virtual barrier around dangerous plant and equipment.

• Super simple and quick to deploy.

• Base easily transferable between vehicles.

• Logs and locates all identified incursions.

• No hard wiring for exterior equipment.

For a free, no obligation demo go to Zonr.com

The Wacker Neuson EW100 wheeled excavator is unique in its class and sets new benchmarks in design, with its development focused on user-friendliness and efficiency.

The construction site 4.0 was the focus while developing the machine – intelligent Attachment Management, a well thoughtout Human Machine Interface and preparation for diverse assistance systems and interfaces are just a few examples.

To select a new attachment the driver simply picks the one they need on the 10-inch touchscreen display and presses save. In the future, all the driver has to do is press a button and the EW100 automatically adjusts to the selected attachment, dynamically regulating the flow of hydraulic oil, for example.

The system is very userfriendly, with individual drivers able to

enter and save their preferred settings. The excavator excels in the area of safety, with good visibility thanks to the flattened engine hood. Alongside the rear view camera, this ensures a comprehensive view all around the machine. The excavator is

extremely stable even when rotating 360 degrees with a lifted load.

Thanks to the powerful drive hydraulics and the high basic work performance, the EW100 can be used to complete tasks that would otherwise require a 14-t excavator.

Yanmar Compact Equipment EMEA

(Yanmar CE)’s B110W wheeled excavator (11,000 kg operating weight) perfectly balances the equilibrium between speed, stability and outstanding productivity. With a digging force of 72.0 kN (arm) and 58.5 kN (bucket), and a digging depth of 4,300 – 4,650 mm, this machine is the perfect solution for urban jobsites, infrastructure projects and landscaping. More commonly seen on heavy excavators, the B110W’s articulated boom radically improves performance in lifting, moving and placing loads. This comes from the added articulation, which offers the greatest possible working range. The two-piece boom is suited to highperformance digging work, transport and precise positioning of heavy loads. You have two options: a two-piece

articulated boom with 2,000 mm dipperstick – for digging work and precise movement of heavy loads – and a twopiece articulated boom with 2,350 mm dipperstick, for even greater reach and excellent working range.

Logistics when getting to the next site can be expensive and result in downtime. But with the B110W, moving on is painless. You’ll hit the road at up to 36 km/h in option and your journey will be effortless thanks to the variable drive system and comfortable cab. A hydrostatic travel drive also works to make the operators life easier, which simultaneously functions as an additional braking system and an additional accelerator pedal for delicate machine movements.

You can also feel assured knowing that the B110W does its bit for the planet,

with an engine that reduces emissions by up to 90%, including nitrogen oxides, hydrocarbons and fine dust. The EU Stage IV/EPA Tier 4 Final engine achieves this through an improved combustion and injection system, a diesel-oxidation catalyst (DOC) and selective catalytic reduction. The B110W will also cut fuel costs with an auto-idle function, helping with your overhead.

Yanmar CE is currently working on the production of a custom-painted Navy Grey B110W excavator in Crailsham, Germany, but that isn’t the only thing that sets this unit apart. Marking a momentous milestone, this particular tailor-made model is the 16,000th wheeled excavator to be produced by Yanmar CE. Its completion is scheduled for next month and it will be adorned with an exclusive ‘16k’ celebration panel to mark the very special occasion.

Combining Japanese know-how with European manufacture, Yanmar Compact Equipment delivers a full portfolio of state-of-the-art machines that are specially designed for a wide range of applications; including infrastructure, drainage, landscaping, demolition and civil engineering.

David Kocurek, once described as local eccentric businessman, has been at the helm of Kocurek Excavators for 40 years. From an early age he demonstrated a natural skill and passion for engineering and to this day still continues to solve a myriad of mechanical and technical problems on a daily basis – always the first to be at the factory, always dressed in his overalls ready to take on whatever the day throws at him.

QTell us about the history and development of Kocurek

I’ve never actually worked for anyone other than myself. Well, there was a very short period where I worked for my father, but it quickly came apparent that wasn’t going to work. Initially I went in all guns blazing and my business grew. We were undertaking engineering work in local factories, being young and perhaps somewhat naive lead me to have to file for bankruptcy in 1981, something which at the time carried a lot more stigma than today. In the end all our local suppliers and creditors were paid in full but I was left with nothing.

Not to be deterred, and with a bit more of an idea how to do things right, the present business was started with the help of my late mother Rita. While I was busy doing the hands-on work, mother would be sorting all day-to-day business like invoicing and answering the phone. She continued working full time until she was 78 years old, still answering the phone and connecting calls.

One of my suppliers from my previous business very kindly let me squat in a small corner of his factory and use some of his equipment, for which I will always be grateful. We often used to have a brew together in the late

Interviewee: David Kocurek Role: Managing Director/co-founder Company: Kocurek Excavatorsafternoon when his factory was quiet and he would give me sound advice on how to run a business properly. John White was a good man and a real gentleman.

I am often asked how the present company started and became so prominent in the modification business. In reality it was almost by accident. The old engineering services business had almost the first three tonne mini excavators in the UK.

We had seen the seeds of our new business in the form of rental of these excavators. The new business purchased these three machines from the receivers of the old business and we had the nucleus of a rental fleet. The problem was that I did not have any real customers and no track record of being a rental company. Looking round I approached the local rivers authority and the engineer there told me he already had offers of these new and innovative machine – ie minis – from other established companies. “What can I do to get in with you?” was my question.

Well these machines were great but very limited in terms of reach. They needed to be longer. So I went straight back to my squat and cut the booms and dippers in half added some plate and counterweight and had a brilliant a long reach 3-t machine. This was the foundation of our rental and manufacturing business. We built on this and it has given us 40 years in business. In the early years it was mostly renting our modified machines and in the last 25 years it has turned exclusively to manufacturing.

We currently employee around 70 people and these range from university graduates who have joined our design team to skilled tradesmen such as electricians, welders and machinists. Also, those individuals who have joined us straight from school and have worked their way up the ranks to now hold manager and supervisory positions. However, one of my greatest joys has been to see my family join the company; we now have nine family members in the workforce. I consider our whole workforce as a family, looking out for one another and all pushing towards the same goal, that is to create a machine to be truly proud of.

QWhat makes Kocurek different?

Tell us about your company’s relationship with its customers

Our expertise in what we do and the fact we are not afraid to develop new products. It is somewhat incredible that customers put their faith (and hard earned cash) in us to deliver a product that in some cases can be the first of its kind. In 40 years, it is sometimes easy to forget what has been achieved in terms of the product we have produced and while often it is still based on the original concept we continually refine and learn from each machine delivered. Our customer base is worldwide and the fact we are often dealing with the same longstanding

customer gives us the benefit of knowing that we’re doing something right.

Personal relationships are important, building a rapport with the customer so you know their likes/dislikes and how their company operates. I like to think our customers know we will support our product if they do encounter any issues and this applies to those on the other side of the world too.

The ordering process can be a long one especially for large conversions, we can be in talks with customers for up to 24 months before the quote becomes an official order. At that point the real work can start, our supply contracts can now be up to 20 pages long, the devil is in the

detail, a lesson we have learned along the way. Before anything is cut designs will be approved by the customer and then it’s all go. Being bespoke and in control of nearly all of the parts and components that go into the machine means we can make changes mid-build if required.

QTell us about Kocurek’s recruitment, or any apprenticeships/ trainee schemes it runs

A lot of our employees have been with the company for years, a sign we hope means we can’t be that bad to work for. We do find that the nature of our work means people are either completely invested or quite simply it’s not for them. Everything here is on another scale size wise and that is what can either intimidate or inspire new employees.

With our family ethos it is great when you see that we have four sets of father and sons working here, encouraging the next generation is so key now. We do have an incredibly skilled workforce and we aim to ensure we keep them by offering good wages, good working conditions and possible opportunities to grow and develop.

QHow about Continuous Professional Development or ongoing training?

I have personally come to realise how important CPD is in more recent times, probably because it was something that I never had or ever felt the need for but having now implemented many things into Kocurek for our staff I can see the benefits.

To name a few we carry out staff appraisals, regular supervisor training and of course the staple health and safety training, all of which help engage our staff and provide us valuable feedback as well. We want our employees to feel valued and realise what part they play in our success.

QWhat can we do to attract young people into the plant industry, design and engineering?

Offer them opportunity. We want to encourage all our staff to grow, flourish and develop in their job roles, and progress where possible too. Our design engineers are a classic example of being able to offer the chance and responsibility to help design and create whole projects and feel the pride when you see that

design brought to life and go to work. When our machines are built up for final testing in the yard it’s a great sight to see everyone come out and see what they have helped build, from the smallest of machined components to huge assemblies welded all by hand by skilled individuals.

QHow do you see the outlook for the plant industry, engineering and Kocurek?

For Kocurek, a problem I foresee will be finding the workers. As a company we do still rely heavily on skilled workers to carry out the work – which is no bad thing. There is little opportunity for the ingression of AI or robotics as human skill is required to really get a feel of the work, quality required and problem-solve on jobs which, are in essence, prototypes. The bespoke nature of our work means that full automation is not a possibility as you would spend just as much, if not more time calibrating and setting machines. A skilled welder can just spark up and crack on. The building of a mini excavator has the potential to be fully automated as it is the repetition of the work that makes it possible. That’s not us though.

QWhat will Kocurek’s focus be on in the medium term?

Continual development and refinement of our current product portfolio while still maintaining the search for new products.

QWhat are the biggest technological developments you have seen in the industry? What has allowed you to develop to manufacture the unique products you do?

The changeover to fly by wire hydraulics. Originally a joystick in the cab functioned through a low-pressure hydraulic system to control the main valve blocks. This is now rapidly being replaced by an electric joystick that controls the main valve block via electrical signals. While this has many advantages, from a cost and mass production point of view it makes it more difficult for bespoke modifiers to undertake our work. This causes increased time and costs which all have to be factored into sale prices to customers. Customer acceptance and the confidence of our customers to place orders with us for machines that are at the drawing board stage.

QAnd what do you envisage will be the future game changers?

The lemming-like rush to electrics, while commendable from a climate change point of view, in many cases products have been rushed to market and the customers are not enjoying the benefits they should be.

QAre there any other critical factors in your business/design/ engineering model? What does a company like Kocurek need from the business, economic and social environment to be successful?

It would be easy to become complacent as we have very few direct competitors, so it is important to stay relevant and in customers minds. We ensure we attend, where possible, industry events as well as entering our machines into industry awards. Like any business we feel the effects of global difficulties within the industry. For us it is important to stay current and keep looking for the next opportunity, we are not afraid to try something new.

QWhat is Kocurek doing with regard to sustainability? What challenges and opportunities does it present you?

It is a challenge for manufacturers. There is no easy way to change everything you do to become green. For us it is small

changes that by themselves don’t sound a lot but hopefully do help play a part in the wider scheme of things. The skill of the worker should never be overlooked or underestimated, often technological solutions aren’t the be all and end all, you cannot automate everything.

QTell us about one of your key products

Telescopic demolition

QOutline the key functions of the product

Enabling the safe and controlled demolition of high structures by a machine that can still be transported easily. One machine can be utilised at multiple heights meaning full versatility for a single machine. Our telescopic demolition ranges from 21 m to 76 m maximum pin heights.

QHow are these products critical for potential users?

Everyone wants value for money, to have equipment and machines that can be utilised on multiple jobs and enable customers to bid for a variety of contracts. For example, a Kocurek 51 m telescopic demolition rig can potentially operate a three-tonne tool at a max height of 51 m but it can continue to be worked down to 22 m, the scope this offers is excellent for customers. A simple but superb solution. Not to detract from the

telescopic demolition as that is the focus, but with the Kocurek modular joint this single machine could in fact demolish a whole building from top to bottom by way of swapping equipment back to standard or if the customer has brought the whole package, another demolition arm.

QCan you quantify any of these benefits?

I like to think that our customers would be best placed to answer that question. The fact that we are still selling this product shows there is the demand and what is out there in the field working proves that point. The first telescopic rig was built in 2001 and it is still earning its owner money – the key point for anyone looking to invest in equipment is the return they will see.

QTell us about the development of these products. Was it revolution or evolution?

Most of the Kocurek products are born as

finding a solution to a customer’s problem. The telescopic demolition equipment was designed to solve the problem of how to demolish tall structures where refinement and precision was required. People often ask why you can’t just blow it down with explosives. The UK is a good example of where space is not abundant. Often structures requiring demolition are so close to other buildings that it is just not an option. The telescopic demolition equipment solves that problem and to this day the fundamentals of the design have barely altered, which proves it was a good design and product from the outset.

QHow will Kocurek be developing this product range?

We are currently looking to develop our own quick coupler system. While the modular joint works well, it is still necessary for the driver/fitter to manually attach each hydraulic line. For speed and ease we need to update to a fully automated system.

equipment sold with it including our highest telescopic demolition arm to date – 76m.

QTell us about the different aspects of your work (after 40 years at Kocurek). What range of tasks do you undertake? In a day I can go from making serious financial decisions to welding on the shopfloor to problem solving with our design engineers to unblocking the drains in the employee restrooms.

QWhat do you find most rewarding in work? Which parts of work are most challenging?

Seeing people grow and learn within the company, having employees who have been with the company since leaving school. We have seen how the company has helped them not only to provide for themselves but then be able to support their new families.

Dealing with people and the new constraints and rules that employers must follow. While there have been some good things come out of these changes for employees, it does create more work for the employer and often expense.

For example, I can no longer speak frankly to a person whose work falls below standard, now I have to document and implement a PIP (Performance Improvement Plan) and this creates more work for others who have to mange them.

QWhat would you like to achieve before retirement (if retirement is a thing for you)?

No retirement! As the elder statesman of the company I’m constantly looking to bring new products to the company, which will then lead to a profitable and long term future for our next generations.

Brunel

What do you do for fun? Woodwork

Who do you most admire? Brunel

What would be your desert island exile luxury? Woodworking tools

What gets you out of bed in the morning? Going to work

When and where are you happiest? In my factory

What’s the most expensive non-essential thing you’ve ever bought?

My lawnmower (it’s a big one)

What’s your bucket list activity? Make another ground-breaking machine

What’s your ideal weekend? Working in my home workshop

What would you do for a company excursion/treat, money no object? Visit The SS Great Britain

Autumn, winter, spring or summer? Spring

What’s your favourite food? Nuggets and chips

What’s your tipple of choice? Teetotal!

Be or do? Which represents you best? Do

This year, Epiroc’s Hydraulic Attachment Tools (HAT) division will be celebrating 60 years of technology leadership and manufacturing in the Epiroc factory in Essen. The hydraulic breaker was originally developed in 1963 by the German company Krupp Berco Bautechnik, which became part of Atlas Copco in 2002. In 2018 they split off their mining and attachment businesses and created Epiroc, a company in its own right. The product range today includes 100 different hydraulic attachment tools, such as hydraulic breakers, cutters, pulverisers, bucket crushers, shears, grapples and magnets. With production facilities in Essen and Dermbach (Germany) and

Kalmar (Sweden), the division develops and manufactures market leading attachment tools for use in deconstruction, demolition, recycling, rock excavation, direct mining and secondary breaking in rock, reinforced concrete, steel and other materials.

The original Krupp rig-mounted hydraulic breaker was developed and patented in 1963. The first machine, the HM 400, attracted huge interest at the Hannover fair in 1967 and more than 2,000 units were sold.

The aim was to save time and labour in demolition and mining operations where, at that time, pneumatic tools were widely used and the new concept was highly successful. It meant that one person

operating a rig-mounted hydraulic breaker could do the same amount of work as several operators with pneumatic tools. The current range includes the HB 10000, the largest serial hydraulic breaker in the world – every punch equals the weight of 130 elephants.

This innovation was the start of a major transformation in the construction and mining industries. Today, hydraulic breakers are in general use and dozens of manufacturers around the globe produce machines of this type under a large number of different brands. Tens of thousands of machines are sold around the world each year.

Epiroc’s subsequent innovations over the years include the groundbreaking SB or “solid body” concept for hydraulic breakers. The slim, lightweight solid body design delivers outstanding durability and reliability, easier handling, lower fuel consumption and other benefits that make

the SB Hydraulic Breakers leaders in a competitive market.

Epiroc’s innovative VC drum cutters take demolition and digging to the next level. Thanks to the arrangement of its cutting heads in a V formation, it achieves pioneering performance such as higher efficiency and cost-effectiveness, as well as protection of operators, the environment and carriers.

Mounted on excavators, Epiroc hydraulic attachments enable all types of demolition projects to be handled faster, with less noise and lower overall cost. Their crushing and screening machines enable valuable waste materials to be retrieved from the demolition waste to be recycled and reused.

For construction projects, the rig mounted attachments enable rapid, efficient site clearance and preparation. Epiroc equipment for trenching and foundation work gets the job done faster and more easily, and this also applies to pipelaying for utilities and other purposes.

In the UK and Ireland, Epiroc has partnered with well-established and respected attachment dealers to ensure its products are backed up by great service and support. Each dealer has a good knowledge of customer needs in their geographic territory and is well placed to commission and service attachments locally:

• London, West Midlands, southern and south-east England – Coyle Equipment Services

• South-west England – Plant & Engineering Services Ltd

• East of England – Ernest Doe & Sons Ltd

• East Midlands and northern England – Trojan Plant Equipment Ltd

• South Wales – Mason Bros

• Scotland – Rockbreakers UK Ltd

• Northern Ireland and Eire – WAC McCandless (Engineers) Ltd

of Hydraulic Equipment Sales, Approved Hydraulics

of Hydraulic Equipment Sales, Approved Hydraulics

and started selling Bakker BV clamshell buckets to the civil industry and Baltrotor Hydraulic rotators with some success.

This very quickly led to us being asked for log grapples also for the forestry industry. We then became the UK agent for Intermercato log grapples from Sweden. These have now become the market

leader in the UK due to their large range of forestry attachments and tree shears, and more importantly the company’s dedication to the best quality available.

The Intermercato range is ever growing, and it is about to release its latest range of the grapples in the coming weeks – The GRX range from size 15 to 25 – this range

will be lighter, stronger and have more of an excavator grab design then its previous models. Models above 25 will remain the same.

As our journey in the attachment market continued to grow, we were looking to expand our range and after discussions with many suppliers we signed up the UK dealership for Minelli SRL attachments based in Italy. Minelli is well known in Europe for its quality and strength of grabs due to its use of HARDOX material. We were now able to offer a full range of material handling

attachments to the crane and excavator market for machines up to 80 t, including, polyp grabs, clamshell bucket grabs, selector grabs, rail grabs and more.

The last part of our search for quality suppliers in Europe led us to CMB SRL, a large demolition manufacturer also based in Italy. CMB produces a heavyduty range of demolition attachments for machines from 5 to 50 t. Again, its use of HARDOX and WELDOX is justified through the use and ability of its attachments. Completing the range this gave us the opportunity to offer new and existing customers steel shears, pulverisers, crushers, demolition grabs and more.

Approved

Hydraulics is always looking to supply the best quality equipment and keep prices at a respectable level. With our great success over the past years and continued growth, we hope