Ben Chambers

ben@globalnews.media

01903 952 648

EDITOR

Toby Wilsdon

toby@globalnews.media 01903 952 645

TO ADVERTISE

john@globalnews.media 01903 952 640

Ben Chambers

ben@globalnews.media

01903 952 648

Toby Wilsdon

toby@globalnews.media 01903 952 645

john@globalnews.media 01903 952 640

Nicki Chambers

nic@globalnews.media 01903 952 640

Global News Media Ltd

Suites 5 & 6, Chapel House

1-6 Chapel Road

Worthing West Sussex BN11 1EX

Asbestos Hub is in media association with UK Asbestos Training Association (UKATA)

Asbestos Hub is published four times a year. Subscription records are maintained at Global News Media Ltd, Suites 5 & 6, Chapel House, 1-6 Chapel Road, Worthing, West Sussex BN11 1EX.

Articles and information contained in this publication are the copyright of Global News Media Ltd and may not be reproduced in any form without the written permission of the publishers. The publishers cannot accept responsibility for loss of, or damage to, uncommissioned photographs or manuscripts.

Welcome

issue

I think it is safe to say that the Asbestos Hub team has fully immersed itself in your world over the past 12 months.

We want to continue to evolve and use our growing knowledge and input from industry experts to put together a magazine that the industry reads, respects and can learn from.

We recently returned from the European Asbestos Forum in Amsterdam (extensive coverage from page 28) and are already booked in for next year’s forum, to be held in Brussels. We will also be heading to the Belgian capital in 2023 for the second Asbestonomy event, having been proud media partners to its debut in London last summer. The event is now sure to grow on the international asbestos industry scene.

We put our money where our mouth was in September, hosting the first ever British Asbestos Awards, sponsored by Empire Asbestos, at the King Power Stadium in Leicester. It was an awesome event bringing the closely linked asbestos and demolition industries together.

We are going bigger in every sense of the word for year two. The 2023 event will be held at the world’s most technologically advanced stadium, the Tottenham Hotspur Stadium in London, booked for 1 September with a host of new awards up for grabs.

Empire Asbestos is again the principal sponsor and I must offer a huge thank you to Jaime and her team for their support this year and next, buying into what we are doing.

As we close out 2022, I want to thank those who have worked with us on interviews, case studies and events, those who have advertised with us and those who have sent over supportive emails or LinkedIn messages saying how they are enjoying what we are doing.

I am proud to publish this go-to magazine for the industry, but most importantly this is your magazine. If you like it, great, but if you don’t, that’s just as important so please do let us know. Equally if you want to get involved in any capacity, you know where my brilliant team and I are.

Here’s to a successful 2023 to you all – Merry Christmas.

Publisher, Asbestos Hub ben@globalnews.media

UKATA: All the latest news and information from the industry body

NEWS: All the latest asbestos news from around the world

• OSHA convicts two contractors for asbestos hazards after platform collapse

• Johnson & Johnson to face UK class action lawsuit over talc asbestos claims

• How much asbestos is there still in Italy?

• Offanengo – the Italian municipality with zero asbestos

• Further €6.3m aid for asbestos removal in Catalonia

• What is the current condition of asbestos in UK buildings?

• Brazil: Tugboat carrying asbestos banned from docking in Pernambuco

• Spain: Beyond a compensation fund for asbestos victims

• Belgium: Real estate market threatens to come to a standstill due to shortage of asbestos experts

• South Africa: “No money” to replace potentially harmful asbestos roofs in Eastern Cape schools

• Australia: 6,000 t of asbestos illegally disposed of every year

• Place of reflection for thousands of Canberrans hit by Mr Fluffy asbestos crisis

• Canada: Prime minister’s official residence closed for renovation including asbestos removal

• Northern Ireland government pays out more than £40m in compensation since 2011

• DMD Environmental becomes the latest UKATA Accredited Training Centre

Asbestos Hub attends the 5th European Asbestos Forum in Amsterdam

• Introduction by Ben Chambers

• Campaigning for improved asbestos management in the UK, by Charles Pickles

• INASCO Asbestos Converting AB, by Rikard Högberg

• The importance of measuring asbestos fibres: Impact on determinations of definitions and tools, by Sean Fitzgerald

Over the past 12 months, despite challenging circumstances for all businesses, UKATA has gone from strength to strength, unveiling new courses, creating, maintaining relationships with industry, and attending several of the biggest events the sector has to offer.

At the start of the year, UKATA partnered and exhibited at The Health & Safety Event, the UK’s largest gathering of those responsible for running a safe and efficient workplace. At the event, UKATA staff raised asbestos and mesothelioma awareness and promoted asbestos training and UKATA membership.

UKATA representative, Emma Willey was part of a panel debate on the “Role of the modern-day health and safety professional” in front of a packed theatre. Discussing the importance of asbestos training and highlighting the effects poor health & wellbeing can have on operatives and her own experiences in the health and safety sector.

April, saw the launch of the Mavis Nye Foundation Cycle Club (MNFCC), a charity fundraising initiative for the Mavis Nye Foundation. I was overwhelmed by the amount of support UKATA received from industry and thrilled to have sold all sponsorship packages within days of the announcement

UKATA auditor and team leader, Ab Woolass, and his team have completed the challenge, riding for 144 hours and 2,368 miles. The total amount raised for The Mavis Nye Foundation will be announced next year at the UKATA AGM and 15th Anniversary Awards evening I would like to thank Ab, Toni Purvis, Marnie Owen, and James Griffiths for donating their time and effort to help raise asbestos and mesothelioma awareness throughout the year and representing the association and the MNFCC sponsors proudly and professionally.

Emma Willey speaks at The Health & Safety Event

Emma Willey speaks at The Health & Safety Event

The association partnered and attended many other exhibitions this year including the inaugural Safety, Health & Wellbeing Live event in Manchester and Farnborough and the Contamination & Geotech Expo which took place at the NEC, Birmingham

The association reached new heights by exhibiting and supporting the brand new Asbestonomy conference, an event that brought together on an international scale, key players in the asbestos industry UKATA also sponsored the European Asbestos Forum conference, another event to help promote the association, asbestos training, and UKATA membership on a global scale.

UKATA was shortlisted and commended at the East Midlands Chamber Derbyshire Business Awards for the Commitment to People Development Award. The award recognises our firm commitment to people development, implementation, and promotion of a learning and development culture, as well as how our staff’s wellbeing is supported

To round-off the year, the UKATA brand refresh was launched with a brand-new training certificate that is currently in circulation. Over the last couple of years, we have researched security methods to help protect the UKATA brand and its members which has been incorporated into the new design

Looking forward to 2023, UKATA will mark 15 years in business, with a celebratory awards ceremony taking place 7th July at The Radisson Blu, East Midlands. A formal invitation and further information will be shared in the new year

UKATA will also be exhibiting at several events during 2023 including Safety, Health & Wellbeing Live North and South, the Health & Safety Event, the Contamination Expo with more events yet to be confirmed, raising the profile of the association and its members UKATA will continue to forge new corporate partnerships and relationships with likeminded associations and organisations to benefit the industry and UKATA members

Finally, I would like to thank all UKATA members, industry associates, and corporate partners for their continued support throughout the year and wish all Asbestos Hub readers a Merry Christmas and a Happy New Year.

EAF Conference 2022

EAF Conference 2022

With the aim to simplify, strengthen and protect the brand, The UK Asbestos Training Association –UKATA officially launches its brand refresh including a new training certificate design.

Officially launched on 21st November, new logos for UKATA members, industry associates and corporate partners are now in use

A new training certificate was launched on the same day which boasts several new security features and a brand-new design, changes which indicate a transition into the next generation

Over the last couple of years, UKATA has researched security methods to support the development of a new certificate which will help protect the UKATA brand and its members. The new certificate, in portrait, as opposed to the former landscape design includes a QR code, which can be scanned by a mobile device to validate the authenticity of a certificate. In addition, to help raise brand awareness for UKATA members, their logo’s and contact information are now larger and more prominent.

The new training certificate uses a licensed font and hosts other security features making it unalterable, thus preventing fraudulent certificates.

Speaking on the launch of the brand refresh, UKATA Chief Operating Officer, Craig Evans said:

“I am very excited to roll out our brand refresh and new training certificate on Monday 21 November. A lot of work internally has been carried out to simplify and modernise the UKATA brand, moving the association forward into a new era, as we approach 15 years of business.

The new certificate provides another mark of quality to the association with it’s use of new security features.

UKATA members, industry associates and corporate partners can now use the new logos on their website and promotional material, whilst training delegates will start to receive the new UKATA certificate as of the launch date.”

The designs alongside this piece, featuring the new logo show the old style certificate which will be out of circulation by the end of 2023 (all UKATA certificates are valid for 12 months, any certificates issued in December will bear the new design. Certificates issued prior will show the old design and remain valid for 12 months) certificate validation is available 24/7 on www.ukata.org.uk.

Following a successful partnership in 2022, UKATA returns to Safety, Health & Wellbeing Live (SHW Live) taking place in Manchester 14 – 15 February 2023 and Farnborough 27 – 28 September 2023.

SHW Live reaches an audience of highly engaged buyers and senior OSH professionals. Launched and firmly established during 2021/22, the show boasts a dual-event regional platform which perfectly balances affordability and quality.

Safety, Health and Wellbeing Live will bring the local OSH community together for two days of essential educational, networking and procurement opportunities, designed to help shift the dial on health and safety culture in the workplace.

Speaking on forthcoming shows, Craig Evans, UKATA Chief Operating Officer said:

“We are delighted to have been invited to return as partners for the Safety, Health and Wellbeing Live shows. If you didn’t manage to attend SHW Live in 2022, I would urge you to put the dates in your diaries for the 2023 shows.

We look forward to exhibiting at both shows and continuing to raise awareness of the dangers of asbestos, silica, and other construction dusts. UKATA staff will be on stand 47 to provide information on UKATA membership and support with the training needs of delegates.”

Registration is now live for SHW Live North, 14 – 15 February, Manchester Central, bringing a whole host of new and returning exhibitors, new line up of conference sessions, numerous networking opportunities and an award-winning venue.

Established in 2008, UKATA is a highly respected, leading authority on asbestos training. Its passion is to both maintain and improve asbestos training, ensuring the highest standards are upheld by means of continual quality assessment.

UKATA continuously works within current legislation as a minimum, whilst collaborating with industry partners to ensure that the UK has the highest standards of asbestos safety.

UKATA freely shares knowledge and information both online and across social media, demonstrating that education remains their top priority.

A mezzanine platform at an old Boston power plant collapsed during asbestos removal operations in May. Three workers were wounded and one lost his legs.

As a result, the two subcontractors involved were fined $700,000 USD for serious violations of workplace safety standards in November.

Several months ago, Johnson & Johnson was fined more than $4bn USD for having commercialised

products containing asbestos fibres causing ovarian cancer to 22 women. Since then, products have been withdrawn in the US and Canada and will be soon in the UK.

Recently, the famous lawyer, Mark Lanier, opened a new law firm and launched a British class action against Johnson & Johnson for all the cancers caused to British consumers.

He calls on anyone suffering from ovarian cancer or mesothelioma who believes that talc products caused their illness to contact him.

Just 30 years after the ban on asbestos in Italy, it is almost impossible to know how many sites are still contaminated and need to be reclaimed.

Asbestos is still present in Italy and yet the Ministry of Ecological Transition (MITE), initially responsible for collecting and publishing

data, has not published any since 2020. Some regions have not published figures for five years or more.

According to the National Asbestos Victims Fund, the country would have about 1m infested sites, 10 times more than the figures presented in the National Asbestos Plan.

OSHA convicts two contractors for asbestos hazards after platform collapse

Johnson & Johnson to face UK class action lawsuit over talc asbestos claims

Offanengo, a Northern Italian municipality, has finally completed the asbestos removal work that started a few months ago on all its properties. The total cost of the work stood at €80,000 (£69,000) and was supported by a grant from the Lombardy region.

The removal of asbestos from municipal buildings was carried out in two phases and in full conformity with safety regulations. Offanengo is now an asbestos-free city, in line with environmental and health requirements.

The ARC (Waste Agency of Catalonia) has increased by €6.3m (£5.42m) the amount of aid (initially set at €1m) intended to help owners of properties containing asbestos.

This aid targets asbestos removal, transport, management, and treatment of asbestos

for individuals or legal entities, public or private, and neighbourhood communities.

This decision is in line with the European regulation to remove asbestos safely and to eliminate the four million tonnes remaining in Catalonia.

ATaC (Asbestos Testing and Consultancy) and NORAC: National Organisation of Asbestos Consultants analysed a million lines of data. Their findings are:

• Over 70% of all asbestos materials have some level of damage

• Of these, 30% are in the highest risk category

The report was launched in parliament in November and generated a lot of reactions from the industry.

It shows that a national asbestos database is achievable and how it could lead to a pragmatic removal plan in the UK.

What is the current condition of asbestos in UK buildings?

Offanengo: the Italian municipality with zero asbestos

On Wednesday 9 November, the Federal Court of Pernambuco (Brazil) banned the mooring of a tugboat from Turkey carrying an old aircraft carrier and fixed a daily fine of R$ 100,000 for noncompliance with the decision.

According to the government of Pernambuco, the ship's mooring represents a health and environmental risk, carrying about ten tonnes of asbestos and other toxic and radioactive waste. The ship had already been complained of for illegal export of asbestos.

As recently mentioned, the law 21/2022 for the creation of a compensation fund for asbestos victims has been approved. This fund will make it easier and faster to collect compensation for victims.

A month after the approval of the law, some grey areas remain to be clarified for union mobilisation and victims' associations, especially the question of the amount received by victims and the tax brackets. The clarification steps will

also focus on the need for post-professional medical surveillance, the acceleration of the asbestos removal plan in the country, the evolution of the European strategy. While the creation of the compensation fund is good news, a regulatory evolution is awaited.

From 23 November, anyone selling a house built before 2001 is required to provide an asbestos certificate. This document indicates to the buyer how asbestos-safe is the property.

Only certified asbestos experts can produce the certificate, however, faced with a high demand an expert shortage is reported. This a worrying situation for private individuals trying to sell their property quickly.

According to the OVAM (Public Waste Agency of Flanders), the situation should be regularised as many diplomas will be issued to increase the workforce.

Belgium: real estate market threatens to come to a standstill due to shortage of asbestos experts

Five years after the court case ordered the Eastern Cape Education departments to accelerate improvements of school infrastructure, there is still no programme to remove asbestos.

According to figures, about 1,075 schools in the Eastern Cape have asbestos roofs. The estimated

budget is around R15bn (£700,000) to be removed and replaced. However, the department claims not to have the financial resources to undertake such work. Improving school infrastructure and bringing it up to minimum standards remains a preoccupation for the region.

The Australian government launched a new campaign during the National Asbestos Awareness week to enhance good practices with asbestos waste among smallscale demolition projects and DIY activities.

The waste illegally dumped in Australia costs around AUD 11.2m (£6.2m) each year to be cleaned up – with the cost borne by the taxpayer. More than the financial cost, lives are at risk due to those bad practices, including those who dump or clean the asbestos waste themselves.

Mr Fluffy loose-fill asbestos insulation was widely used in the Canberra region during the '60s and '70s in thousands of houses exposing both workers and building owners/workers. It is part of the Australian asbestos legacy. A “place of reflection” will be hosted at the National Arboretum, accessible to all Canberrans.

South Africa: “No money” to replace potentially harmful asbestos roofs in Eastern Cape schools

Australia: 6,000 t of asbestos illegally disposed of every yearPlace of reflection for thousands of Canberrans hit by Mr Fluffy asbestos crisis A forest shelter at the National Arboretum will be dedicated to the Mr Fluffy families.

It has been seven years since 24 Sussex Drive hosted a prime minister –and Stephen Harper was the last one. That is mainly due to the poor conditions of the 1868 building. A few employees with their offices located in the house have been relocated to ease the refurbishment works.

The asbestos

abatement of this Classified Heritage Asset should start next year after the Canadian winter.

Greg Hopkins worked in a number of factories and industries before his death from mesothelioma aged 60.

His son Chris and his family received some compensation through one of the government-run

asbestos compensation schemes available in Northern Ireland.

Chris said: "When you look at the amount of money that has been paid in compensation, it shows the scale of the problem."

Canada: Prime minister’s official residence closed for renovation including asbestos removal

Northern Ireland government pays out more than £40m in compensation since 2011

Canada: Prime minister’s official residence closed for renovation including asbestos removal

Northern Ireland government pays out more than £40m in compensation since 2011

Norwich-based asbestos removal and survey company, DMD Environmental is proud to announce their SHEQ Director, Chris Cato has successfully secured his UKATA Professional Trainer Membership.

This latest UKATA-accredited training centre in Norwich is a welcomed hub to provide quality training, as DMD is the only training facility offering licensable asbestos works training within 50 miles of Norwich.

Providing Licensed and NonLicensed Asbestos Works Training and Asbestos Awareness training, this service line expansion is providing an opportunity for both DMD Environmental and the delegates within their area who will benefit from the training.

Chris Cato, SHEQ Director at DMD Environmental comments: “UKATA is instantly recognised and respected for the exacting standards in asbestos training, and it is an honour to be able to offer this UKATA approved training to members of the public who need the differing levels of knowledge and practical skills. Here at DMD Environmental, we endeavour to increase the level of asbestos awareness within the region, and offering this new service is a great step towards that.”

The success of UKATA has been driven by the industry, which acknowledges that the standards delivered by UKATA Members offer assurance that delegates have received quality training from a provider who has proven competency at the highest level.

Chris Cato, SHEQ Director at DMD Environmental

Chris Cato, SHEQ Director at DMD Environmental

“We are extremely pleased to have reached the 1 year mark on our flagship project, and we are even more proud to say, that to date, we are accident/incident free. The total man hours worked to date equates to an incredible 64,405 hours!

This is a fantastic accomplishment, which has been achieved due to the high standards set by the management, supervision and site team as a whole.

A big thanks to everyone involved in the project, here’s to the next 12 months!”

For the next few issues we will be taking excerpts from magazine friend and mesowarrior Mavis Nye’s blog to see what exactly she has been up to with the trials and tribulations of living with mesothelemia

For the full blog please go to: rayandmave. wordpress.com

14 October 2022

The MesoUK Patient Carer Day and now we have a Positive Covid Test

I thought September was madness, but October is even more maddening.

COVID has struck our house. We went to MesoUK’s Patient Carers Day last week and had a great time. It was so lovely meeting up with all our friends and really had a ball.

We travelled up a day earlier to Nottingham to miss out on a train strike. That meant we had the Belfrey Hotel to ourselves, and the staff were so friendly, so we spent a pleasant time there.

So many friends arrived the next day it was great catching up with everyone’s news.

A lovely meal out in the restaurant next door only we didnt know that but found out by calling for a taxi then found all we had to do was to walk through a hedge and past Lidil’s and we are there.

After an educational day the next day where we learnt so much it was time to change and enjoy a

Gala evening.

Then a huge surprise in the awards was one for me

It was a great success and next day saw us travel home.

Then we started sneezing and feeling a cold coming on. Tested and yes we have COVID.

I must admit that the GP and hospital swung into action fast and

we soon had the antivirus drugs delivered to us and we are on Molnupiravir.

We have had to cancel my Chemo treatment and other appointments to attend conferences until we can get a negative reading and self-isolate.

Oh dear does nothing run smooth in this house.

So after dodging COVID for years we got caught and got through it.

When it came to it though we had to work through it on our own as there is so much information and yet not a lot for COVID and Cancer.

Our GP was great in helping with medication.

We had the antiviral drug and that got us to a clear 10 days of feeling very low,

I had decided to contact my Oncologist through my Meso Nurse and ask to come off Chemo.

I had messed about for so long with Bloods being out 3 times and delayed treatment I was in such a muddle to where I was.

Then I checked and it said to stop Chemo until well clear of COVID.

But I have been so low and felt so grotty that Im pleased I put a halt on everything. We have Isolated for 10 days and will

continue.

The coughing has stopped, the house is quiet again at night.

The site where we found the most help https://www.macmillan. org.uk/coronavirus/cancer-andcoronavirus

It meant I had to cancel FAAM one of my favourite conferences, but I will use this time to get back strong again and hope that 2023 will be a better year.

What started off as a joke

has grown to a serious Group thanks to Greg Bryne

The Venue was at the Van der Valk Hotel Oostzaan, the Netherlands.

We had travelled to my family in Luton to stay the night before and our son drove us to Luton Airport.

We had planned on driving up there, but the protesters were being silly again at Dartford at the Dartford Crossing, we gathered everything up, called a taxi and got to the station in time for a train to London then Luton.

We got to the airport in plenty of time and was already to fly to Schiphol Airport.

We had a easy flight on Easy Jet and arrived at the hotel in the evening.

The room was very nice and we soon settled in and went to bed.

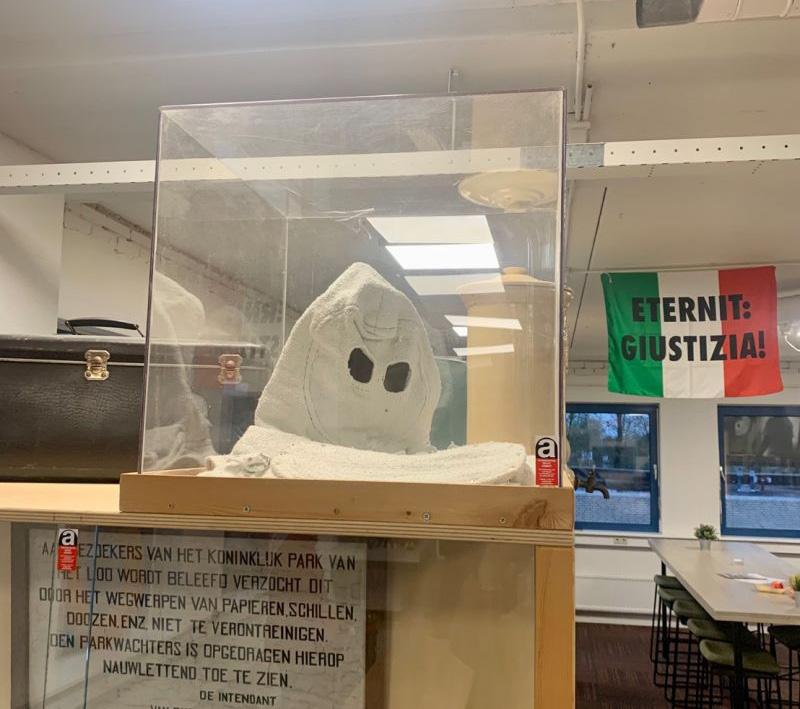

The next day after breakfast we met up with old friends and new and was soon nattering away, but the time went quickly and then it was lunch and wait for the coach and guided visits to the Asbestos Museum and the Asbestos denaturation plant.

The EAF conference hosted an exclusive, guided tours to the unique and fascinating Dutch Asbestos Museum first which was somewhere I always wanted to visit as I had been friends with Harry Honk for many years. We were shown around and my whole childhood was in front of me, my Ironing board I had as a child, a steam train my hair curlers, kettles just so many items that I had used or played with all containing asbestos.

Then we visited the Asbestos denaturation plant where asbestos is destroyed (‘denatured’) using two different, state of the art methods (industrial waste acid and, of all things, water!

It is all very experimental, but they are working hard to get it in to production.

We came home and Yvonne had laid on a wonderful evening meal.

11 November 2022: classic conference

The EAF conference excels in providing the opportunity to meet relevant specialists from around

the globe, learn and share state of the art science and innovations of every conceivable field relating to asbestos and to build lasting, helpful networks.

There was such a lot of wonderful and interesting information shared that even Ray kept awake and has been talking about it all ever since.

Thank you, Yvonne, for all you did to make us so welcome well done another conference successfully completed.

Another great meal was served, and drinks drunk we were all very mellowed.

Getting up this morning and having a quick breakfast we

travelled by taxi to the airport, and I asked if we could have assisted travel as the airport is huge and so much walking.

The people were so nice and a lady booked us in. We chatted to other travellers until two lovely young girls came with wheelchairs for us. My first ride in a wheelchair ever.

famous Tony Rich It was lovely catching up and he asked me for my Autograph on a magazine that had my story in!!

TheWe went through security and my pusher had to be search like us. She said every time they take someone through, they are searched as they could take a bomb through, and security is very strict.

We then went through to the waiting area for the flight.

Another young girl came to take us to the plane on a electric cart we really had a laugh as she shouts out greetings to all her friends in shops and others transporting passengers.

We arrived at the gate but no plane as it hadn’t landed.

Then the plane arrived, and I expected to have to go in a queue but no! We go down in a wheelchair in the lift walk to a van, as I thought but the driver lined it up with a door above us in the plane and the whole body lifts up and a door in the plane opened and we walked in, but our seat was right at the back of the plane. People were looking at us like passengers do when you’re on a coach and you are last back.

Two young lads were in our seat, and I said, I bet you thought you was going to get away with that, they said yes, and everyone laughed.

In no time we were on lift off and a really great flight again.

Arrived at Luton and it all went wrong. Only 1 wheelchair I walked; Ray had a ride.

We then walked to get the bendy bus to the station, but it was bus replacement to Hitchen. Two lovely ladies pushed us to the front of the queue and then carried my case everywhere. We finally get a train to London, and we got home. We were shattered but so happy we really had had a very interesting few days thanks to so many wonderful people –Thankyou every each and one of you.

On Monday, the two leading asbestos management industry bodies will present evidence in Parliament that the Health and Safety Executive’s (HSE) policy of managing asbestos in situ is failing badly.

The report has been produced by Asbestos Testing

and Consultancy (ATaC) and the National Organisation of Asbestos Consultants (NORAC). It will be published at an event in Parliament hosted by the Chairman of the Work & Pensions Select Committee, Sir Stephen Timms, who led an inquiry into asbestos management in the UK during

2022.

An embargoed copy of the report is attached.

It is the first annual analysis of consolidated data on the presence of asbestos in UK buildings. It has been produced in response to the Work and Pensions Committee’s report, which concluded that

A new report by leading asbestos industry organisations highlights the repeated failures of the Health & Safety Executive’s asbestos management system and continuing presence of lethal asbestos in public building

too little is known about the current extent and condition of asbestos in UK buildings.

The new report finds that a high proportion of the asbestos materials in UK buildings presents a risk to public health, and that it needs urgent remediation or removal.

• Of the 128,761 buildings inspected, 100,660 (78%) were found to contain asbestos

• Within those 100,660 buildings, 710,433 items of asbestos were found

• Out of the 710,433 items of asbestos, 507,612 (71%) were recorded as having some level of damage

• Of the 507,612 damaged items, only 120,629 (24%) would be classed as “licensable” work and require a specialist contractor

• Conversely, a significant proportion of damaged items can be classified as ‘high risk’ — the worst category of damage demanding amelioration or removal.

• Some of this material will have been inspected previously, meaning that it has been noticed and left unaddressed

The report’s clear conclusion is that asbestos management in these premises is failing. The authors state that existing datasets need expanding and standardising in order to be able to identify different types of buildings that pose a risk, such as social housing, hospitals, schools, etc.

This would be necessary for the development of a national database, one of a number of measures called for by the Work & Pensions Committee but dismissed by both the HSE in its submissions and by the Government in its

response to the Committee. Says Work & Pensions Committee chairman, Sir Stephen Timms MP:

‘Asbestos remains the single greatest cause of work-related fatalities in the UK, with more than 5,000 deaths in 2019. I welcome the ATaC/NORAC report, showing that a large amount of data is readily available. With further development, it could form the basis of a national database, supporting safe management of asbestos, and helping to prioritise buildings for phased removal. I hope Ministers will rethink their opposition to a database‘

The report is welcomed by the campaign group Airtight on Asbestos, which has long argued for a proactive programme of phased asbestos removal.

Says Airtight on Asbestos founder, Charles Pickles:

‘These findings by ATAC and NORAC show just how patchy the current regulatory regime for managing asbestos is. For years, the HSE has said that removal is far more dangerous than management in situ, and that a national database for monitoring the location and condition of the substance would be too difficult to implement. In short, the policy has been to sit back and do nothing while buildings decay and become more hazardous for occupants. Now the data is in: either we act to remove the threat, or we ignore it and watch as the crisis deepens.’

Says Head of Health and Safetyat the Institution of Occupational Safety and Health, Ruth Wilkinson: “Asbestos is the biggest cause of occupational cancer, claiming hundreds of thousands of lives a year worldwide. It remains a global challenge to both occupational and public health, and simply must be addressed. Sadly, as a result of this unmanaged situation, many people, and workers in particular, will continue to become seriously ill and die prematurely”.

The analysis by ATAC/NORAC is the first of what will be an annual report into the condition of asbestos in UK buildings. It is a response to a 10-month inquiry by the Work and Pensions Select Committee, which was set up in September 2021 after considerable pressure from Airtight on Asbestos and other consumer representatives. The W&P Committee found that the HSE could provide no evidence about the condition of asbestos in public buildings.

The Committee said the HSE should:

• Create a ‘National Asbestos Database’ to record all asbestos currently remaining in public buildings – including type, quantity, risk factor, etc.

• Change the current policy of ‘management in-situ’ to one of a prioritised, scheduled removal of asbestos from ‘atrisk’ buildings.

• Develop a National Asbestos Strategy with the Government, which would coordinate efforts to remove asbestos from highrisk settings.

• Create a robust research framework into the measurement of asbestos exposure using more advanced techniques than are currently practiced.

In its submissions, the HSE response resisted these areas – and flatly rejected proposals for a national database and the phased removal of asbestos from UK buildings. It said a new central register would merely duplicate existing information and undermine the requirement on duty holders to manage asbestos.

John Richards, Spokesperson for Asbestos Testing and Consultancy (ATAC) and the National Organisation of Asbestos Consultants (NORAC), was scathing about the Government’s response: ‘We understand why the Government has chosen to reject calls for a national database in addition to mandatory accreditation for asbestos surveyors as this would highlight the full extent of the problem facing the UK, one which has been ignored for decades. The Government responded positively following the 74 deaths that tragically occurred at Grenfell Tower with the establishment of a dedicated regulator, yet with almost 100 deaths occurring weekly as a result of past asbestos exposure and little understanding on the long term consequences of low level exposure, the Government chooses to ignore the recommendations of the Works and Pensions committee.’

Airtight on Asbestos’s Charles Pickles says that ATAC/ NORAC’s new findings compel the Government/HSE to act:

‘In light of this new data, Airtight on Asbestos is renewing its call for the HSE to implement a national asbestos database, which can then be used as a base to drive a programme of phased removal. Doing so would take the UK one step closer to safe, asbestosfree public buildings – and could potentially save thousands of lives in the future. The time to act is now’.

A leading asbestos management consultancy is urging retailers to put the safety of their staff and customers first following a steep rise in the number of high street stores failing to manage asbestos in their premises.

As the busiest time of the year approaches, Acorn Analytical Services is urging retailers to protect the safety and wellbeing of those around them by checking for the presence of asbestos in any sites built before 2000. In premises where asbestos has been found, surveys should be carried out

regularly to ensure it has not been damaged or fractured.

A report published by the Asbestos Testing and Consultancy Association (ATaC) has highlighted the enormous scale of the asbestos problem facing the UK.

Of more than 128,000 buildings surveyed between October 2021 and March 2022, a staggering 78% were found to contain asbestos. In total more than 700,000 individual items of asbestos were found and 71% of those were damaged, potentially posing a significant threat to health.

Director of Acorn Analytical Services, Neil Munro said: “The UK is in the middle of an asbestos epidemic and the statistics released by ATaC are frightening.

“Asbestos is all around us – in our offices, factories, hospitals, schools and our high streets –and a number of retailers have received hefty fines recently for not managing their duty of care around asbestos management.

“Many of our towns and cities are dominated by units which were built well before the ban on asbestos was introduced in 1999 and it is essential that retailers and landlords check for the presence of asbestos if they are not sure.

“Failure to do so could be deadly, putting staff or customers at risk of mesothelioma, a cancer caused by

prolonged exposure to asbestos fibres, as well as costly fines.

“We’ve already seen an increase in the number of big businesses getting in touch with us to discuss the need for asbestos surveys and anticipate that number will increase throughout 2023.”

With the cost-of-living crisis heaping financial pressure on many small businesses, Neil also warned against putting off asbestos surveys because of the additional cost.

He said: “Where asbestos exists, it is a legal requirement for it to be managed safely and within the latest regulations. Not doing so could lead to significant fines which could cause even more harm to your business and its reputation.”

Acorn Analytical Services is fully accredited by the UK Accreditation Services (UKAS).

ACORN Analytical Services is an award-winning asbestos management consultancy based in Northampton and Cleckheaton.

Founded in 2000, Acorn Analytical Services works with clients across the UK, including major household names, local authorities, housing partnerships and schools, specialising in asbestos management and compliance, asbestos removal management, asbestos surveys, air testing, sample testing and four stage clearances. The company’s team of experts also offer UKATA asbestos awareness training to companies nationwide.

As well as offering guidance on a practical level, the team at Acorn Analytical Services is passionate about raising awareness of the dangers

of asbestos and has worked closely with charities including Mesothelioma UK on a number of national campaigns. As a member of the Asbestos in Schools Steering Group, director, Ian Stone, has lobbied MPs and Peers on this important issue.

Over the years, the company has continued to grow and now has offices in London and Wolverhampton, employing 80 staff.

In November, in front of the biggest names in construction, Acorn Analytical Services was named as one of the best consultancies in the UK at the National Building and Construction Awards.

For more information about Acorn Analytical Services visit www.acorn-as.com or call 01604 648928.

Toby and I attended our first and the fifth EAF conference representing Asbestos Hub, which we (as well as everyone else we spoke to) agreed was an amazing success.

We were among more than 150 delegates from 15 countries and five continents. To quote organiser Dr Yvonne Waterman “It’s so heart-warming with so much knowledge and experience being shared that even I look back at this event with some astonishment.”

Not withstanding a meagre 45-minute flight from Gatwick, logistics still played a negative part and we missed day one’s tour of the National Asbestos Museum, which was a shame, but the real deal and our goal was always day two and the conference proper.

Having said that Yvonne has already invited us back to visit the museum in April 2023. An apparently an easy flight from London City Airport direct to the Hague and a tour will await. We shall certainly participate in that with Yvonne in 2023.

The conference began early at the rather splendid Van der Valk Hotel, where the networking area was just about the right size to house all the delegates for coffee and a chat. Along the perimeter was a variety of stands allowing us to engage with suppliers to the

industry some of whom we had never seen before.

As is common at such events seeing old faces is always a good start. We were greeted by Yvonne and we also bumped into Charles Pickles, Mavis and Ray Nye, the team at Casella, Mesothelioma UK’s Liz and many more, that deadlines do not allow me to mention.

The packed day of speakers split into two sessions in separate rooms for the afternoon.

Toby and I had to pick carefully though fortunately as we came as a pair we could allow ourselves full coverage and cover both rooms.

We have heard back from most of the speakers and you can read what some of them had to say further along in this feature, with more to follow in subsequent issues of Asbestos Hub

You can find articles based on speakers' presentations at EAF from page 36.

We used the EAF to debut Asbestos Hub TV, where over the past week we have slowly been releasing our interviews from the event via social media to our home YouTube channel.

In his interview with us, Ray Nye, husband of Mavis Nye, was effusive in his praise of this year's European Asbestos Forum, saying it was the very best asbestos conference he had been to.

Everyone here at Asbestos Hub is looking forward to the 6th EAF conference, which is being held in Brussels next year and we have no doubt that it will be a resounding success.

Formulated to support the reduction in human and environmental impacts associated with the management of hazardous materials.

TriMax™ has been formulated to increase its effectiveness on particulate containment when combined with our patented foam delivery system.

CapSure Pure™ is proven to be significantly more effective in reducing atmospheric particulate release when assessed against the traditional containment products and techniques.

CapSure Dissolve™ has been specially formulated to safely and efficiently remove bitumen adhesives, coatings, and residual contaminants without the need of mechanical aid.

CapSure Dissolve site trials courtesy of Thermac BEFORE AFTER

safety and that employers must ensure there is no better practical means to keep employees and the public safe and demonstrate this. So the question is, are we safe and are we using the best techniques and practices to ensure and demonstrate our collective safety, with regard to asbestos?

I was honoured to be able to talk about the Airtight on Asbestos Campaign at the European Asbestos Forum on 11 November 2022. I founded this campaign in late 2019, with the aim of bringing about improvements in the management of asbestos here in the UK. Generally health and safety here is excellent, however when it comes to asbestos, we imported more asbestos per capita and more brown and blue asbestos per capita than any other

country. Historical exposure during both direct work and incidental association to these fibres and the materials they were made into, has today produced the highest rates of asbestos related disease anywhere in the world here in the UK.

Our policy for asbestos is one of, “management in-situ”, so much of the asbestos we imported remains in-situ. Our law is that workplaces should be safe, the HSE should make adequate arrangements to enforce

When you compare our practices here to the best of international standards, our management practices, policy and ability to demonstrate our safety are all deficient. While we have a policy of management in-situ, others have accepted asbestos in-situ is a clear risk and adopted 40-year National Asbestos Strategies, with clear time frames for the removal of the highest risk asbestos. To ensure safety during this process considerably higher standards of air monitoring are employed, using modern microscopy and sampling techniques. Asbestos is a zero threshold carcinogen and our number one occupational killer and yet here in the UK, the air monitoring threshold known as the “Clearance Indicator” used to declare areas suitable for normal occupation is set at an acknowledged dangerous level. Clearly this dated practice needs to be called out and improved urgently.

The UK has the worst asbestos legacy, much asbestos in-situ and is dangerously behind on best practice. This is why after 20 years working in asbestos consultancy, I determined to campaign for improved asbestos management.

For the last three years The Airtight on Asbestos Campaign has engaged directly with politicians with the aim of educating them

of the actual risks from our asbestos today and how to improve its management with the best policies, practices and techniques currently in use elsewhere. The campaign was instrumental in persuading Sir Stephen Timms to set up the 2022 Work and Pension Select Committee Enquiry into the HSE’s Management of Asbestos.

Generally, it is now accepted that UK asbestos management is not sufficiently robust to curtail the risks from asbestos in-situ. The enquiry report largely rejected the status quo and accepted many of the recommendations for improvements suggested by Airtight on Asbestos, BOHS, FAAM, ATAC, NORAC and others. However, the two major recommendations of a National Asbestos Database and a 40-year UK Asbestos Strategy were rejected by the HSE. Although the HSE is currently considering improvements to air monitoring, it is vital to keep campaigning for improvement here, in order that these much needed improvements are enacted.

In terms of prioritising certain buildings for wholesale demolition, CLASP primary schools should be replaced first.

A child exposed to asbestos has five times the likelihood of contracting mesothelioma as an adult teacher of 35. Amosite / brown asbetsos common in CLASP schools has 100 times the potential for causing mesothelioma as chrysotile and children are at least twice as likely to disturb asbestos as adults. Multiply 5 x 100 x 2, the actual risk is 1,000 times higher than chrysotile asbestos cement roofing sheets on a

factory for example.

By correcting the algorithm to the known risk factors, the risk is clearly off the scale. Such buildings should be prioritised for demolition therefore: write to your MP and demand this.

By definition all our amphibole asbestos is now more than 40 years old, with the majority being over 50 years old. All chrysotile containing materials are now at least 20 years old, with the majority being more than 30 years old. The ageing of ACMs and the buildings erected in the post war period is now advanced. Many are beyond their design and economic lifespans, with maintenance bills and asbestos risks ever rising. It is a matter of fact that the majority of the asbestos containing materials we have in the UK, will either fail or be demolished within the next 15 years. Given this, and given that having a plan informed by data will enhance asbestos safety, minimise unplanned expenditure from phantom asbestos being discovered and enable demolition and refurbishment works to adhere to schedule, a National Asbestos Database and National Asbestos Eradication Plan are now considered cost saving, life saving, time saving measures.

In this and in previous years,

the EAF continues to showcase best practice in air monitoring, data management, asbestos policy, asbestos denaturation and many other topics. These practices show that management of asbestos can be much improved and the materials destroyed. From this optimism confidence can be drawn, for if shown the way our illustrious political leaders will surely continue to see the light and adopt best practice, in line with our law and curtail future deaths from asbestos disease amongst today’s school children.

Asbestos is emblematic of industrial practices and exposures from the last century. Should any future government be committed to a programme of national social, economic and political renewal, such measures would embody these goals and be a fundamental prerequisite for any building work, refurbishment demolition or environmental / insulative programmes undertaken at scale. As such, the Airtight on Asbestos Campaign will continue to fight for:

• Improved asbestos air monitoring

• A National Asbestos Database

• A 40-year National Asbestos Eradication Plan

You are more than welcome to lend your support.

I have worked for a company called “INASCO Asbestos Converting AB” since 2016. I come from a different background. I was the Managing Director and Publisher for the Swedish business newspaper “Dagens Industri” in Russia for 14 years. “Dagens Industri”, called “Delovoy Peterburg” in Russia, was

the largest and most successful business newspaper in St. Petersburg at that time. I managed to put about 200 Russian mafia leaders in jail. I had to flee from St. Petersburg when my former Russian wife and the Russian mafia wanted to kill me.

Thus, I turned to something less

dangerous. Asbestos converting –how to find a way of making use of recycled asbestos.

Together with insight from the Technological University in St. Petersburg and Norwegian consultants we developed the INASCO blend.

We all know about the problems that asbestos gives. The official figure in Sweden is 400,000 tonnes of different kinds of asbestos waste. That figure is from the 1980s. It is an old figure. We argue that this figure is more likely to be two million tonnes or above. We base this figure on the production figures from different asbestos producing factories in Sweden and importation statistics.

Early in the process, we took the INASCO blend to The National Swedish Authority for Testing) and it confirmed that there are no asbestos fibres left in the INASCO blend.

INASCO Asbestos Converting AB continued to work with the Cement and Concrete Institute (CBI – Cement och Betong Institutet) at the Royal Technological Institute of Sweden (KTH – Kungliga Tekniska Högskolan), now called Research Institute of Sweden (RI.SE).

It also worked with RENOVA, the largest waste company in Gothenburg; with SÖRAB, one of the waste companies in Stockholm; with Laser Machining Inc. (LMI AB) in Nås in the County of Dalarna, which specialises in lasers; and Librixer in Mölndal, south of Gothenburg, which in a chemical free process can mechanically liberate spinel, perovskite, calcium aluminate in the finished product from the INASCO process.

The funding for project development for “INASCO Asbestos Converting AB” was provided by the Swedish Energy Agency.

We have developed a process

on how to convert both general asbestos wastes as well as old used eternite plates. The latter has historically been used as both roofing and outside house wall coverings.

The INASCO process safely converts these old grey boring boards and other asbestos based waste products, now temporarily stored, to safe valuable raw materials such as refractory materials, or other usable raw materials such as spinel, perovskite and calcium aluminate, making these ready for new applications.

The goal of the present project was to present a potential process for converting asbestos waste into attractive saleable residual

products, with an all-cost benefit. The fully developed process must be able to demonstrate profitable “productification” of, for instance, hazardous constructions materials. This can partly be accomplished through the sale of valuable result materials using INASCO asbestos neutralisation system starting with energy-efficient laser combustion of the asbestos contaminated hazardous waste.

Asbestos samples were obtained both from the Swedish waste companies “RENOVA” and "SÖRAB". Stockholm has analysed and identified the different types of asbestos based composites now stored in hazardous landfills. This analysis was done by“A-Analys”

and “ALS Scandinavia” analysis companies. All samples were carefully enclosed in plastic bags during all handling.

For the experimental process only chrysotile asbestos was chosen. Chrysotile is the most used asbestos.

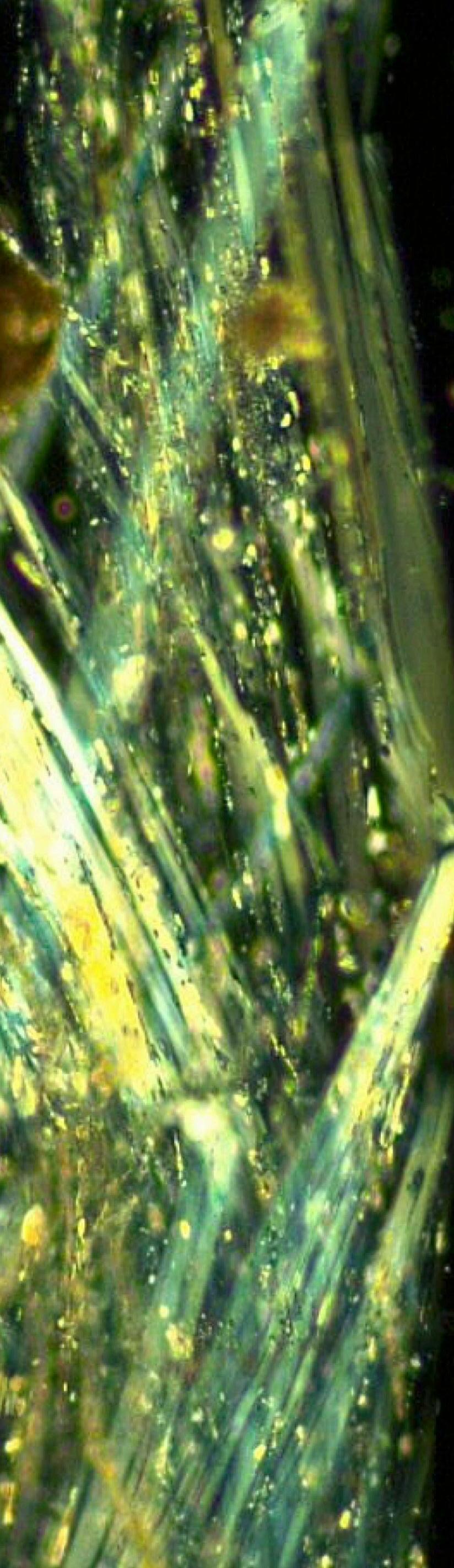

The procedure of grinding, mixing and combustion in a hightemperature furnace was carried out three times, as well as the analysis of the residual product. The residue materials were analysed in stereo microscopes, SEM and in XRD, by Dr Lars Kraft, CBI.

We have later continued and have done hundreds of burnings. We have an estimated volume of 8.5 kg of ready material. The research work was paused during the COVID pandemic.

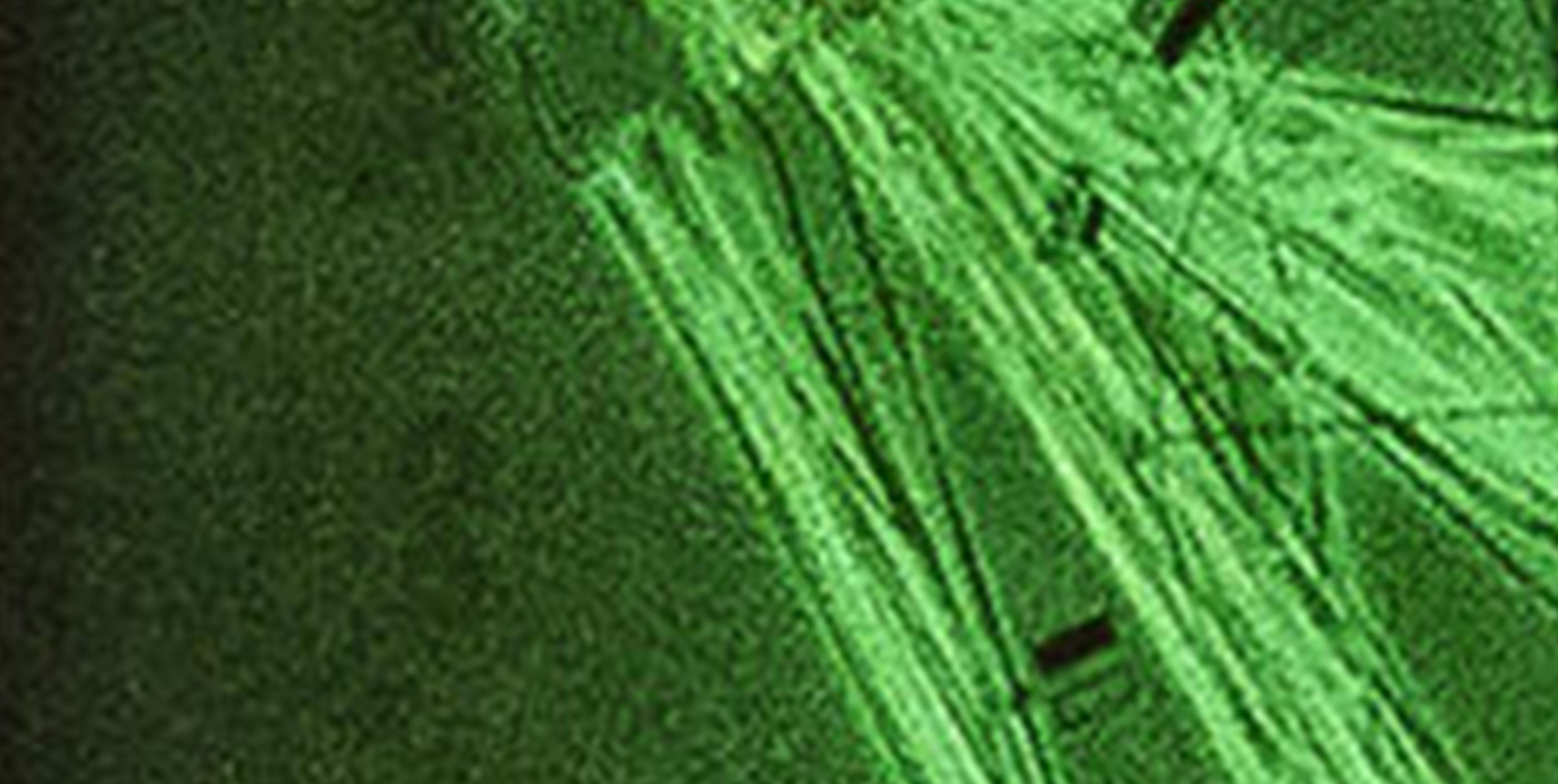

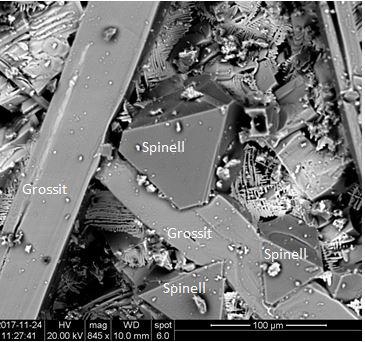

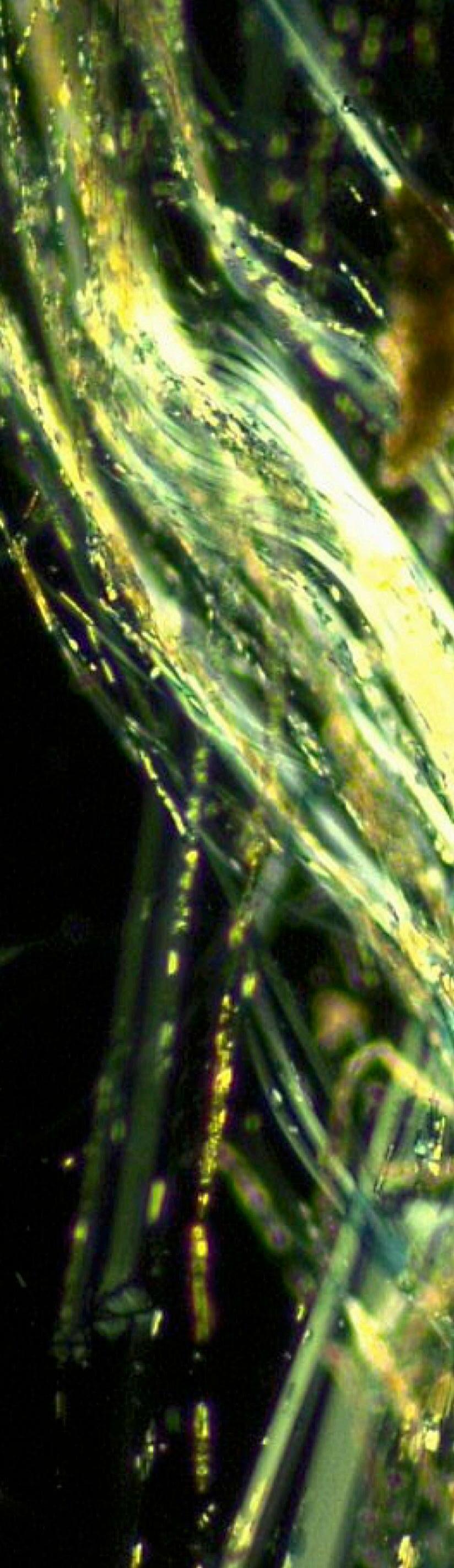

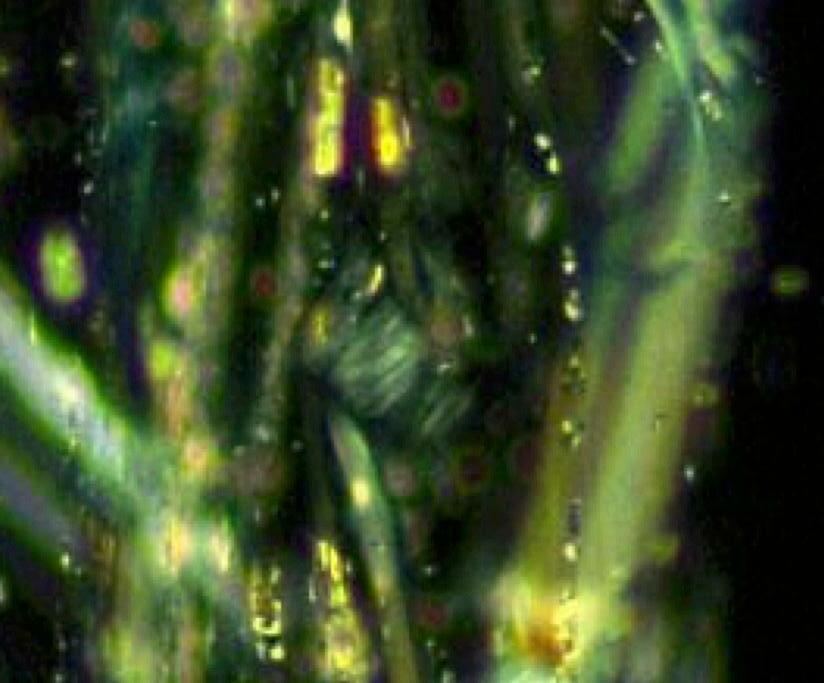

FIGURE 4. Three spinel grains surrounded by grossite bars and white structures in the background

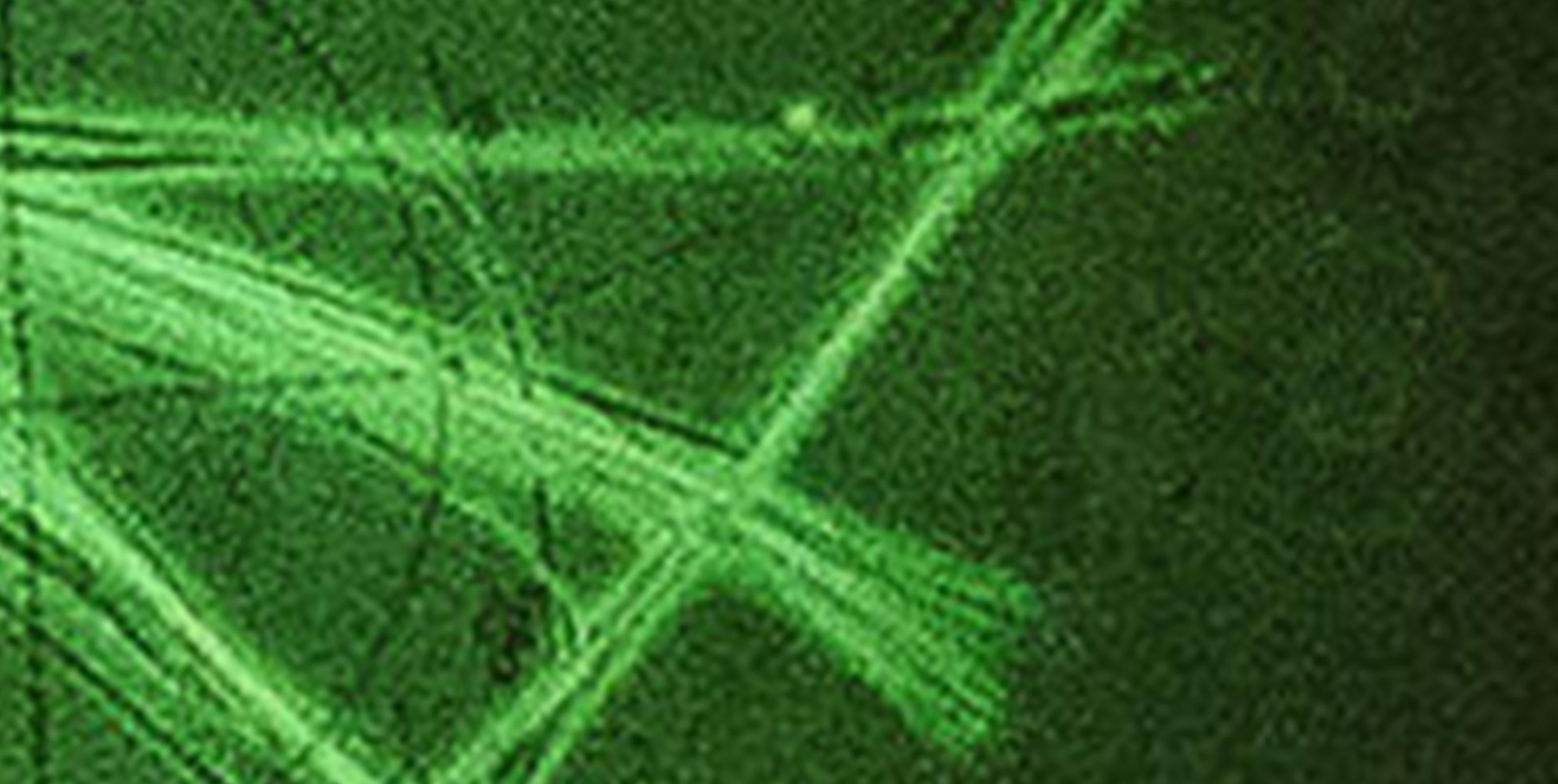

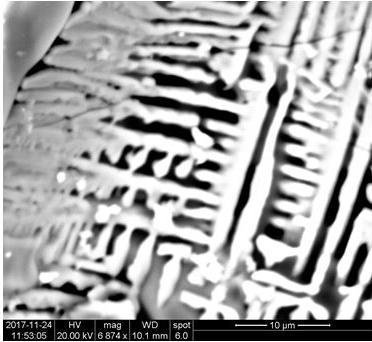

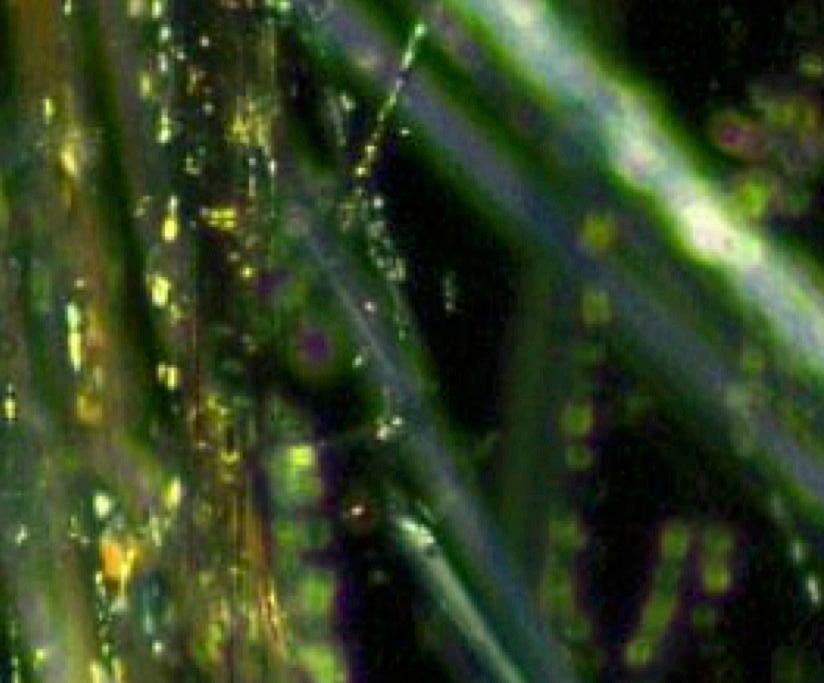

FIGURE 5. Close-up of the structure of the white background. The white patterns consist mainly of perovskite

In all cases, the studies of the residue in both SEM/EDS and XRD have confirmed the formation of spinel. However, the spinel grains were significantly smaller in all three cases compared to the grains in the reference sample examined in 2016, which were produced in St. Petersburg. Certain modifications to the combustion cycle and the mixing procedure were therefore made in subsequent tests two and three.

The test two was partially unsuccessful, because the asbestos mixture had boiled over the edges of the crucible, probably due to overfilling of material in the crucible. However, the sample still showed formation of spinel, although to a lesser extent compared to test one. In test three, however, the spinel grains were again abundant, albeit still of small size.

One significant challenge associated with converting asbestos into safe materials is the high energy cost of traditional lasers. INASCO solved the problem of radically

decreasing energy consumption by new laser technology provided by Laser Machining INC AB in Dalarna Sweden. The company has more than 40 years' experience using fibre laser and has done 640 applications of lasers worldwide.

Together with Laser Machining we made a test using new fibre laser process, concluded in its laboratory. We exposed the INASCO blend for a short time and we had a documented reaction – the INASCO blend material.

Together with Laser Machining's CEO, Tim Hamblin-Smith, we have worked out a continuous fibre laser converting process, that we call the Fibre Laser Waterfall process. This gives us the possibility to convert tonnes of asbestos material in a short time and at a very low cost.

In order to separate or free the outcome of the INASCO blend, we have used a new unique proprietary method and technology called Librixer Liberation/ Micronisation headed by the Inventor Erik Lundgren.

Instead of grinding the material they pull the groups of homogenous structures apart

along natural composite materials

boundaries using high frequency resonance forces, instead of crushing or shearing the material with brute force, which otherwise would render these materials less valuable.

The Librixer technology radically lowers the operating costs as well as improving the purity of the resulting materials. Librixer has examined the INASCO blend and concluded that the individual components can be efficiently liberated and separated from each other.

Spinell is used to make spinell bricks for steel plants. Spinell withstands 2,472° C and these bricks are usually used to produce slag line bricks. The slag line takes the heat of the hot iron from 1,600 to 1,800° C.

Perovskite can be used for refractory material.

Calcium Aluminate/Grossite: There is a high demand for cement in Sweden as the cement company Slite will be closed. There is lack of about 2m tonnes of cement per year. As this recycled material has saved 702 kg per tonne, it has a great advantage.

Högberg(NES) Asbestos Ltd are a family run company set up in 2011, with over 25 years’ experience within the industry. This proves an invaluable source of knowledge for us to draw upon. With an excellent management structure and dedicated staff, we are able to cater for every client requirement nationwide.

Our growing reputation for providing a friendly and professional service within the asbestos removal industry demonstrates our lasting relationship with our existing and new clients with repeat works. Our number one priority is the need of our clients and to carry out the safe removal of asbestos always.

What is asbestos? This is perhaps the most difficult question to answer, depending on which definition we use and what tools we are using to determine that something is asbestos.

Unfortunately, we are more often than not stuck with the definition for asbestos as published in the regulations. For example, the US Federal Register CFR 40 763.80: The asbestiform varieties of chrysotile (serpentine); crocidolite (riebeckite); amosite (cummingtonite grunerite); anthophyllite; tremolite; and actinolite.

This definition was based not on health risk but on the primary minerals that were harvested as useful fibrous minerals from the earth, that is, the fibrous minerals dominant in the mines where asbestos was historically produced. Approximately 98% of this material was from large serpentine deposits where chrysotile asbestos was the target and primary mineral.

For decades asbestos, predominately chrysotile from serpentine, was mined and processed into different grades of fibre for a myriad of applications such as brakes, pipe and boiler

lagging, insulation, asbestos siding, and cement asbestos products.

In most of the industrial developed world, asbestos in building materials has been reduced or phased out. However, asbestos in friction products (such as brakes) and cement asbestos products (such as water piping and corrugated roofing; CAB) have been slower to be phased out, or still present significant human health risks from asbestos materials in place.

In many countries, especially the less developed ones, the legacy of asbestos use has been largely ignored or underreported. This is especially true in countries like Colombia, Indonesia, and Mexico, to name a few. In ongoing investigations of CAB roofing and its environmental impact, I am currently working with government authorities and universities in these areas, where we are still seeing abundant asbestos products being eroded and contributing fibres, especially chrysotile and crocidolite, into the air.

In searching for asbestos labs in Latin America, I saw two laboratories offering asbestos fibre counts in Argentina, only one in Brazil and two in Columbia. Only one lab (in Brazil)

had international accreditation, and one of the Colombian labs had a national accreditation. All the LA labs were doing PCM analysis only. There are no labs using electron microscopy (SEM or TEM) for asbestos anywhere in Latin America.

This brings us to the different analytical tools commonly used to determine asbestos presence and to quantify it with various methods. For air testing, we have two basic tools: Phase Contrast Microscopy (PCM), and Transmission Electron Microscopy (TEM).

PCM is used for abatement, monitoring air sample analysis and most clearance samples outside of schools (unless otherwise regulated). Analysis at 400x magnification, documents fibrous concentration trends only, as the light microscope cannot resolve the different mineral types or smaller fibres.

TEM is required in the US for the analysis of final clearance samples in schools (AHERA); occasionally used for private sector testing. TEM air testing is conducted at 20-25,000x and can determine the chemistry and atomic structure of mineral crystals through Energy-Dispersive Spectrometry (EDS) and Selected Area Electron Diffraction (SAED).

Bulk testing can also employ PLM and TEM to determine asbestos content, with X-Ray Diffraction (XRD) and Scanning Electron Microscopy (SEM) also routinely used. Each of these tools has its advantages and disadvantages. PLM can identify various minerals to some extent based on interactions with fibres and can also look at the gross morphology to determine consistency with the asbestiform

growth habit. But PLM cannot necessarily determine the chemistry or structure of crystals and therefore cannot definitively identify minerals beyond consistency with optical characteristics like refractive index, retardation, sign of elongation, and birefringence. Further, PLM cannot resolve the finer fibres that constitute the majority of most asbestos fibre populations. Most distributions of fine asbestos dust produce less than one in 20 fibre structures large enough to be seen by PLM.

XRD is limited in that it is not a microscopic technique, has lots of interferences and relies on prior data to identify consistency of response in the sample to reference minerals. Further, XRD has a limit of detection around 1% for the asbestos-forming minerals and cannot differentiate fibrous from nonfibrous varieties of the same minerals.

Electron microscopy (SEM and TEM) has the advantage of being able to see the very finest fibres, and when equipped with EDS, the chemistry of those fine crystals as well. Crystalline structure can be determined by diffraction, which can only be facilitated with the electron beam transmitted through the crystals rather than scanned on the surface. Hence, TEM is capable of providing the crystal structure through SAED, which is not possible with SEM.

Both types of electron microscopes are limited however in the amount of time to prepare the samples, the level of expertise required by the analyst, the lengthy time required to analyse each sample and the relatively small amount of material tested because of the higher magnification.

Mineralogy can also play an interesting role in the determination of asbestos in various materials. In the geologic sense, each asbestos mine was considered a source of a primary type of asbestos, like chrysotile (white asbestos; the most common), crocidolite (blue; the third most common), or amosite (the second most common; brown asbestos – not actually a mineral but an acronym for the asbestos mines of South Africa).

When we look at the myriad mineral types found in these deposits, however, we find that rarely if ever is a mineral resource just one mineral. For instance, the asbestos mines in Canada were predominately chrysotile, but if you look closely you will find many other minerals both fibrous and nonfibrous, including antigorite and lizardite polymorphs of serpentine, as well as anthophyllite, tremolite,

and actinolite, occasionally in the asbestiform habit in the same bags/ materials/products into which the labels only mentioned chrysotile.

This is true for many other mineral resources, including vermiculite and talc, both of which have been found to contain significant amounts of asbestos. In fact, chrysotile, vermiculite and talc are both predominantly formed from the metamorphism of other rocks, and those other rocks are often the asbestos-forming minerals. For example, amphiboles can be altered by heat, pressure, water and time to form serpentine, vermiculite or talc.

Because of this close relationship between talc and its potential asbestos-forming protoliths (parent rocks), talc has often been found to contain asbestos fibres sometimes well below the resolution of analytical tools and protocols designed to identify asbestos in building materials (PLM; XRD).

Sporadic investigations over the decades have found asbestos in talcbased commercial products, but the lack of specific testing to safeguard talc has resulted in thousands of products all over the world where recent testing has determined asbestos is being sold to be aerosolised to unwitting consumers. My own finding of asbestos in play clays, children’s toys and cosmetics has led to repeated publications in the peer-reviewed literature, news stories and investigations. Most recently, the FDA has recognised the need to develop more sophisticated protocols whereby no talc should be deemed “asbestos free” without confirmation by TEM.

In school buildings, the most common uses of asbestos were in:

• Insulation lagging, particularly around pipework, boilers and ducts

• Insulating boards, particularly ceiling tiles

• Asbestos cement products

The HSE has confirmed that they will be assessing how schools are managing the risks from asbestos within schools and are meeting the ‘duty to manage’ requirements under Regulation 4 of the Control of Asbestos Regulations 2012. The HSE will be carrying out a programme of inspections in primary and secondary schools in England, Scotland and Wales from September 2022 onwards.

One of the main issues with regards to asbestos exposure in schools is that many of the buildings in use in the UK were constructed before the year 2000. With this in mind, the use of asbestos was rife across the building industry between the 1930s and 1980s. Therefore, more than 75% of Britain’s state schools have been found to contain asbestos.

• Bitumen

• Floor tiles

• Textured paints and coatings.

The Health and Safety at Work Act 1974 and Management of Health and Safety at Work Regulations 1999 place a legal duty on employers to prevent exposure and assess the risks posed by asbestos. The Health and Safety Executive has estimated that asbestos may still be present in 300,000 nondomestic buildings and many more homes, despite the long-term efforts to remove it. With this in mind, MPs have now called for a 40-year deadline for all asbestos to be removed from public and commercial buildings, including schools.

More specifically, The Control

of Asbestos Regulations 2012 states that the responsibility for maintaining premises that may contain asbestos lies with the duty holders. In schools, this can be classed as the employer or the governing body or the responsibility may be shared. Duty holders must:

• Confirm what you already know about the ACMs on your premises, and review how you are currently managing them

• Prevent work on your premises that may disturb the fabric of the building until measures to control the risks have been implemented

• Carry out regular inspection for damage and disturbance of materials and take immediate action to control these

• Develop a strategy for compliance

• Carry out a risk assessment of your ACMs to set priorities for management

• Develop a site-specific asbestos management plan

• Monitor and review the asbestos management plan every 12 months

Under the Control of Asbestos Regulations 2012, the primary responsibility to manage asbestos in a school lies with the duty holder. This is defined as anyone who has the responsibility for the maintenance and/or repair of the building. The duty holder has a legal responsibility for the safe management of any asbestos-containing materials that are present in a school, and is also liable for prosecution if the regulations are breached.

In order to manage the presence of asbestos in buildings, duty holders are expected to survey their building, create a register of ACMs and write an asbestos management plan that details the procedures for monitoring the condition of ACMs. The assessments that HSE inspectors will be carrying out will require a copy of the asbestos management plan.

The asbestos management plan is a vital document that registers and outlines the ways in which asbestos will be managed across a particular property, and how

people using the site will be kept safe from exposure to the fibrous mineral. It should be clear, simple and easily accessible, and duty holders will need to ensure that it is reviewed regularly. The HSE also states that all schools must have a site-specific asbestos management plan, and that key stakeholders should be familiar with it.

The most likely way that ACMs will create a risk in schools is when they are disturbed or damaged through maintenance, repair or construction activities. With this in mind, school caretakers are considered to be at high risk of asbestos exposure due to the nature of their work. If asbestos is disturbed during any of these activities, there is a risk that the fibres will be released and create a risk to other occupants of the building, such as teachers and students.

In addition, within a school environment, asbestos can be disturbed through activities of the students, such as the movement of table and chairs (rubbing against walls for example), kicking and

throwing balls and in some cases vandalism. Given the age of many school buildings, the passing of time also increases the possibility of the general degradation of building materials.

If asbestos is in a good condition and is unlikely to be disturbed or damaged, it will not pose a significant risk to health as long as it is properly managed. It is, however, strongly recommended that teachers and children should not undertake activities that damage ACMs, such as pinning or tacking work to insulating boards or ceiling tiles.

Asbestos awareness training

Asbestos awareness training is vital for both school staff and contractors. As aforementioned, caretakers are often the most at risk, so asbestos awareness training would be a requirement for them, particularly as they carry out small maintenance jobs and activities that could potentially disturb and damage the fibrous mineral. All third-party contractors undertaking building and refurbishment works that could disturb ACMs should also be asbestos awareness trained, with the school instructing these works being required to check this as part of their engagement process.

How can SOCOTEC help?

SOCOTEC offers UKAS-accredited asbestos surveying and testing services, accompanied by asbestos management and consultancy services, giving those in the education sector expert advice to ensure asbestos is being managed properly in schools. Our highly experienced consultants offer independent advice and flexible solutions, which are supported by our own in-house UKAS-accredited testing and inspection schedules No.0148 and No.1089.

Would you benefit from an independent asbestos healthcheck, ahead of the HSE led audit?

Get in touch.