Dear seafarers,

Although the topics covered in this issue seem to be varied, there are some themes that are highlighted in several contributions. One of these is effective communication, without which the efficient operation of any organisation is impossible.

The importance of communication is brought out in no uncertain terms in the Safety First section, in which talking openly, sharing feelings and asking questions are clearly shown to be some of the prerequisites for the enhancement of resilience and the formulation of best practices. What is more, this section contains a stark warning in the form of a case study involving a fatality that occurred due to a total breakdown in communication during a toolbox talk. Likewise, the Manning and Training article points out how strong relationships, whose very nature requires good communication, can reinforce resilience. Moreover, this article pinpoints the need for requesting support to maintain wellbeing and keep the potentially negative effects of stress at bay.

Another article that covers the need for communication is that provided by Marine Operations via a new contributor, Alkividis Polychronakis. In his review of a Search and Rescue drill, there is reference to the uninformed and unprepared who are at most risk during helicopter operations. Such individuals, who have not engaged in effective communication prior to one of these operations, cannot be mindful of their situation, a state that may easily result in serious injury or worse to either themselves or a fellow seaman. The Culture Corner

section also reveals how communication with at-risk youth in Canada through a shared maritime heritage can offset the dangers of marginalisation and increase connectivity. Similarly, in the Bodies of Water section the need for a number of agencies to work together to preserve the integrity of the Great Lakes is highlighted. Again, effective communication is shown to be key to achieving any goal.

On a different tack, the Technical article reports the welcome and uplifting news of the Company’s newbuilding orders. The news is a clear indicator of the Company’s commitment to saving energy, reducing emissions, enhancing safety and providing better accommodation in the face of potentially disruptive forces. It is, therefore, a prime example of resilience.

Please remember that without communication we isolate ourselves and become exposed to physical and mental threats. Conversely, communicating effectively by clarifying messages and asking questions (communication is a two-way process) until the communicator and the recipient are ‘on the same wavelength’ enhances connectivity and resilience, both of which function as barriers to such threats.

I sincerely hope that you enjoy this issue of Wavelength. If you have comments, suggestions or questions regarding the content, please do not hesitate to contact me at comment@ wavelength.gr. Last, but certainly not least, I would like to thank those who have taken the time and trouble to send pictures of their vessels to Athens to be included in Wavelength. Please keep them coming.

Best wishes, Nick Seaman

The two photos below of the M/T Niriis show the adverse conditions seafarers can face. Read more on this in the Nostalgia section on page 14.

A total of twenty of the Company’s seafarers gained a promotion in the third quarter of 2020. The list of those promoted in chronological/alphabetical order along with their vessels and promotion details is shown in the table.

The sustained efforts of those on the list are very much appreciated and worthy of the Company’s warmest congratulations. Their commitment to furthering their careers, irrespective of the pressures they, along with their colleagues, are under bears testament to their integrity and willingness to live up to their responsibilities. With vaccines on the horizon, it is hoped that at least one of the pressures faced will be alleviated. Until then, all our Seafarers, who are deserving of the highest praise, should maintain their focus on what is most important to them and strive to reach their goals with whatever support they require to ensure their well-being.

By Ioannis Pantos, Technical Director

Nine years after the delivery of the vessels Pserimos, Kapsali and Leni P. from “Samsung Heavy Industries”, the Company has decided to proceed with a newbuilding order for three (3) Suezmax tankers that will be constructed in the same Shipyard and will be delivered during the 3rd and 4th quarters of 2022.

The vessels, which will be provided with machinery and systems of the latest technology, are energy efficient, environmentally friendly and will comply with the upcoming requirements of IMO MEPC 75 for the reduction of Greenhouse Gases (expected entry into force: 1st January 2023).

The principal dimensions, tank capacities and basic machinery particulars are as follows:

Main Engine MAN B&W 6G70 ME-C10.5

Ultra long stroke, electronically controlled engine

DMCR: 16,400KW x 75.4 RPM NCR : 11,209KW x 66.4 RPM

Compliance with NOx Tier III with LP SCR Triton Engine Control System

Diesel generators STX-MAN B&W 7L23/30H 3x1,150 kW

Compliance with NOx Tier III with LP SCR

Aux. Boilers Oil fired, water tube Boilers 2 x 35,000 kg/h

Composite Boiler Vertical, cylindrical Boiler Steam production: 1,500kg/h (oil fired section) 450kg/h (exhaust gas section

Cargo pumps Steam turbine driven 3 x 4,000 m3/h

Ballast pumps Electric motor driven 2 x 2,000 m3/h - one (1) pump provided with VFD

Main air compressors Control air compressor Service air compressor Topping up air compressor

2x285m3/h

400m3/h

200m3/h 50m3/h

F.O. Purifiers L.O. Purifiers 2 x 3,800L/h 2 x 3,000L/h

Compliance with Rules, Regulations and other Requirements

Vessels will be classed with the American Bureau of Shipping (ABS) with the following Class notations:

+A1(E), Oil Carrier, +AMS, +ACCU, ESP, CSR, AB-CM, UWILD, TCM, CPS, VEC-L, BWT, ENVIRO, IHM, RRDA, SPMA, CRC (SP, SC-PL), BWE, ESA, SMART (INF).

It is worth mentioning the importance of the following Class notations:

-AB-CM: Construction Monitoring: During the vessel’s construction, special attention will be paid to critical areas i.e. fit-up inspections, alignment etc.

-ENVIRO: Vessels will comply with all of the applicable environmental regulations/requirements of MARPOL Annexes I, II, IV, V and VI.

-ESA: Enhanced Shaft Alignment – This notation is assigned to vessels designed, constructed and operated in compliance with shaft alignment procedures in the ABS Guide for Enhanced Shaft Alignment.

-SMART (INF): This notation is assigned to vessels which have hardware and software that accomplishes certain data handling functions.

The vessels will also comply with the following requirements:

-OCIMF, Mooring Equipment Guidelines, 4th Edition, 2018

-New Panama Canal requirements

-ExxonMobil, Marine Environmental, Safety and Quality Assurance Criteria, 2017 Edition “MUST” and “Strongly Preferred” items

Hull Form – Hydrodynamic improvements

The remarkable improvement of energy efficiency is achieved by the optimization of hull design in forward and aft parts.

In addition, the following energy saving devices are provided:

-SAVER Fins (Samsung Advanced Vibration & Energy Reduction Fins)

-SAVER Stator D (Partial Duct)

-SARB (Samsung Advanced Rudder Bulb)

-The “SAVER Fins” result in increased power efficiency through flow improvement and improvement of the hull vibration level by mitigating propeller pressure fluctuation with equalized inflow.

-The “SAVER Stator D” results in power savings due to net thrust produced by the enclosed duct.

-By providing the “SARB” , the flow separation behind the propeller cap is improved and the propulsion efficiency is increased by reducing the hub vortex.

-Finally, the highly efficient “STAR” propeller (Samsung Tip Advanced Raked Propeller) creates a lower propeller excitation force, and the propulsion efficiency is improved.

-The estimated fuel savings by combining all of the Energy Saving Devices above is approximately 5%.

-The vessels comply with the “Energy Efficiency Design Index” (EEDI) Phase 2 requirements.

The Energy Efficiency Design Index (EEDI), formulated for new ships, estimates the quantity in grams of emitted CO2 per transport work (g of CO2 per tonne-mile).

A MAN B&W “G” ME-C electronically controlled (without camshaft) Main Engine is provided.

The “G” prefix stands for “Green-ultra long”.

A G-type engine’s longer stroke results in a lower rpm for the engine driving the propeller.

This lower optimum engine speed allows the use of a larger propeller and is, ultimately, significantly more efficient in terms of engine propulsion. Together with an optimized engine design, this reduces fuel consumption and CO2 emissions.

The Main Engine particulars are as follows:

Maker/Type: MAN B&W 6G70ME-C 10.5

Derated Maximum continuous rating (DMCR): 16,400Kw x 75.4rpm

Normal continuous rating (NCR, 68.35% DMCR): 11,209Kw x 66.4rpm

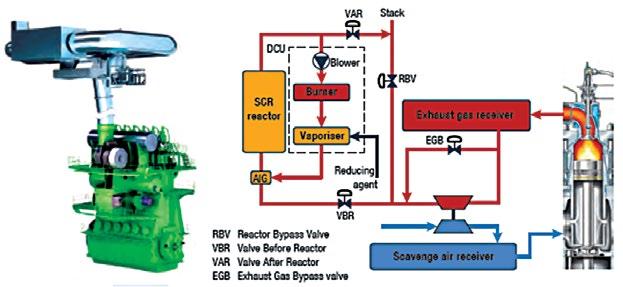

The Main Engine shall comply with MARPOL 73/78 Annex VI Reg.13 (NOx emissions) and shall satisfy IMO NOx Tier III requirements with LP SCR (Low Pressure Selective Catalytic Reduction)

Figure 7: LP SCR Technology for the IMO NOx Tier III requirements

Selective Catalytic Reduction (SCR) is an exhaust gas temperature method by which the NOx generated in a marine diesel engine can be reduced to a level in compliance with the NOx Tier III requirements.

The NOx reduction is obtained by a catalytic process in an SCR reactor installed in the exhaust gas line after the combustion process. In the SCR reactor, the NOx is reduced catalytically to nitrogen and water by adding ammonia as a reducing agent.

The catalyst in the reactor consists of blocks with a large number of channels, providing a large surface area on which the catalytic process takes place.

The Main Engine is provided with the following systems/ accessories:

-Alpha cylinder lubricators (integrated)

-a Local Operating Panel (LOP)

-a Hydraulic Power Supply (HPS)

-a Hydraulic Cylinder Unit (HCU)

-an Engine Control System (ECS)

-PMI online with an auto-tuning system

-a bearing wear down monitoring system

-a water in oil monitoring system

-an exhaust gas by-pass system

-a load dependent cylinder liner (LDCL) cooling water system

-CoCoS-ESD ME Basic

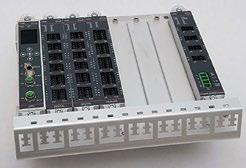

The Engine Control System is based on the new generation ‘‘Triton’’ Controller Platform.

The new controller platform is characterized by its:

-increased engine flexibility for improved performance due to higher computational power and more advanced control functions.

-advanced controls for increased fuel flexibility and emission reduction.

-modular architecture for future upgrades.

-preparation for simple interfaces towards other ship automation systems.

-enhanced digital offerings.

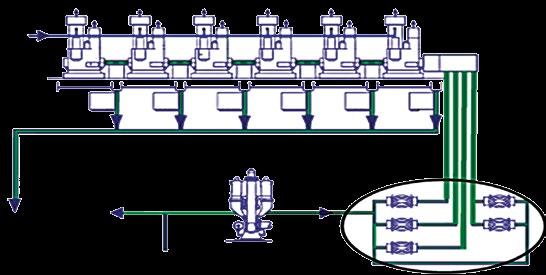

Cargo oil tanks are grouped into three (3) segregations.

Double-valve segregation is maintained throughout the whole discharge operation, including stripping and COW operations.

The maximum loading rate shall be 16,200m3/h through three (3) cargo manifolds when two (2) cargo tanks are engaged in each segregation.

The vessels are provided with three (3) steam turbine driven cargo pumps of 4,000m3/h capacity each, one (1) cargo stripping eductor of 600m3/h capacity and one (1) stripping pump of 240m3/h capacity.

An Automatic Unloading System (AUS) is provided for cargo stripping.

The main suction and discharge valves are of the proportional type with an intermediate position indication.

A Linked Emergency Shut Down system for cargo handling system should be provided according to OCIMF Recommendations for Oil Tanker Manifolds and Associated Equipment 2017.

Heating coils of aluminized steel, Sch 80 are provided for Cargo and Slop Tanks.

A cargo tank level gauging system of the radar beam type is provided.

An independent high (95%) and high-high (98%) cargo tank level gauging system is provided.

Three (3) temperature sensors are provided in each cargo tank.

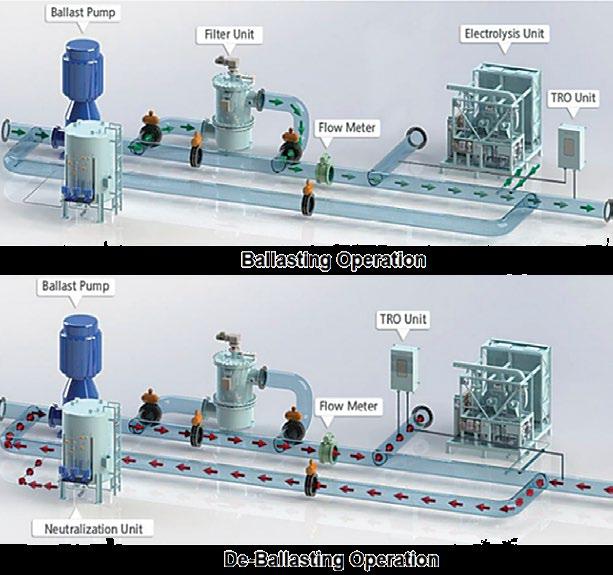

Ballast Water Treatment System (BWTS)

Samsung’s “Purimar” BWTS, which is based on filtration and side stream electrolysis is provided.

Figure 12: Process flow of operation

At ballasting, the ballast water treatment process performed comprises two main unit operations:

-Mechanical separation (filtration 50pm)

-Disinfection

At de-ballasting, a neutralization unit decreases the total residual oxidant (TRO) concentration before discharge is required.

Ship’s equipment and outfit

Steering gear: One (1) electro-hydraulic, 2-ram 4-cylinder type steering gear will be installed in the steering gear room.

A rudder of the full spade type will be provided to improve speed performance.

Electro-hydraulic driven (high pressure type) mooring winches will be provided.

The brake drum surface material will be stainless steel.

Single point mooring (SPM) fittings will be provided in accordance with the OCIMF recommendation i.e. two (2) bow chain stoppers of 350 tons SWL, two (2) bow chocks of 600x450m.

An emergency towing system combined with an escorting pull back system for tugs will be provided on the poop deck. Emergency towing fittings on the forward deck will be commonly used with SPM fittings.

The vessels will be equipped with two (2) cargo hose handling cranes with a lifting capacity of 20.0 tons SWL for compliance

with Basrah/Iraq and Al Shaheen/Qatar oil terminal requirements.

Both cranes will also be certified for personnel transfer (SWL 1.0 ton).

Two (2) lifeboats of the totally enclosed type with a capacity of 30 persons each will be provided.

Firefighting Systems

The following firefighting systems will be provided:

-Engine Room and Pump Room: High expansion foam

-Deck area of Cargo tanks: Low expansion foam

-Vest mast riser: Independent high pressure local CO2 system

Citadel

The steering gear room will be used as a citadel with the following provisions:

-Two (2) steel doors (from steering gear room to engine room and at the steering gear room entrance from the upper deck) and one (1) hinged hatch with an antipiracy device.

-A manual damper and redundancy ventilation

-A public toilet

-One (1) set of Iridium telephones, one (1) VHF radio telephone and one (1) remote Inmarsat FB500 telephone

Accommodation

The “Captain class” and “Senior Officer class” cabins are provided with a day room and a bedroom.

All cabins are provided with a private lavatory.

A lift for six (6) persons (500kg) is provided.

Separate air conditioning systems are provided for the Galley and Wheelhouse.

Two (2) laundries for the Officers and Crew and one (1) ship’s laundry are provided.

A garbage compactor will be installed in the garbage store.

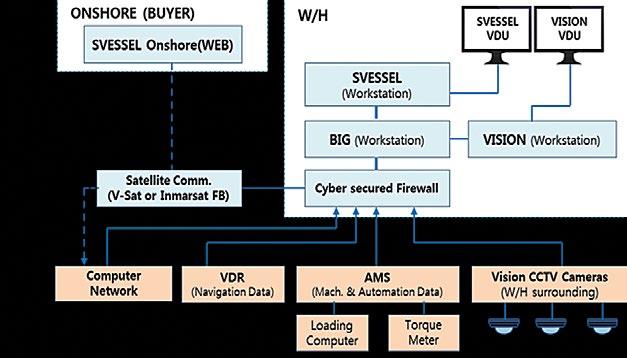

Samsung Smart Ship Solution

1) SVESSEL

SVESSEL provides an enhanced smart-ship solution –“Intelligent and Life-cycle Managed Ship”, which was developed through the Builder’s own ship-building ICT technologies, comprising monitoring, planning, reporting and managing functions.

The system shall consist of the following three sub-systems:

-BIG: An onboard integrated data gathering & communication platform

-SVESSEL Onboard: An onboard enhanced safety & operability solution platform

-SVEEEL Onshore: An onshore web-based vessel & fleet monitoring platform

2) BIG

BIG is a data gathering & communication platform interfacing with VDR (for navigation), AMS (for automation, loading) and ship network (for weather forecasting supplied by buyer) that can gather and transfer the data to the Buyer.

3) SVESSEL Onboard

SVESSEL Onboard is a software platform which displays onboard voyage planning, monitoring, reporting and various functions as follows:

a) Basic functions:

-An optimum voyage recommendation with fuel savings through optimized trim, route and speed condition according to SEEMP guidance

-Route monitoring, time-series trend analysis and daily reports

-Visual energy monitoring such as the energy consumption of machineries (M/E, generator engine and auxiliary boiler) according to SEEMP guidance and estimated CO2/SOX/NOX emissions calculations

-EU-MRV or IMO-DCS reporting certified by ABS and DNV GL

-Ready for onshore remote monitoring of SVESSEL via satellite

b) Ship performance monitoring: shaft RPM & torque measurement

c) Ship motion risk assessment & guidance: based on shipmodel database and real-time heading/speed/roll/pitch through weather forecast data

d) VISION guidance

One (1) set of a VISION guidance system shall be provided with a dedicated VDU with workstation in the W/H.

The system shall provide the following functions on the VDU with a control keyboard:

-A distance guideline to the operator promptly during berthing or sailing at a strait

-An augmented obstacle view on around-view (bird’s-eyeview) for safe voyages

4) SVESSEL Onshore

SVESSEL Onshore is a Web-based warranty service used by onshore managers for real-time vessel, fleet and claim tracking.

5) Hardware for SVESSEL

-One (1) 27’’ VDU with two (2) sets of Workstations (1-BIG, 1-SVESSEL Onboard) located in the W/H

-One (1) Workstation for VISION with a 27’’ VDU and three (3) cameras located in W/H front and bridge wings outside

-One (1) Firewall switching Hub

-AC220V power from the ship’s AMS UPS

-A standard interface with a VDR, AMS and torque meter

-An Interface with Computer Network System. The Buyer shall provide weather forecasting through the Computer Network System.

Design improvement items

- The complement will be increased from “27+6” to “30+6” persons.

- A citadel will be provided in the Steering Gear Room.

- The lifting capacity of the cargo hose handling cranes is to be 20 tons SWL.

- The capacity of the P/R fans will be increased from 2x50% to 2x100%.

- The P/R Bilge direct suction valve will be operated remotely.

- Sliding pads will be provided between the pipes and supports for the transversely installed pipes.

- Zinc anodes of the bolted type will be provided in the Ballast tanks.

- A gas detection system at the Accommodation A/C inlet will be installed.

- The maximum loading rate will be increased from 12,000 m 3/h to 16,200m 3/h.

- A linked emergency shut down system will be provided for cargo pumps.

- There will be an axial movement trip/alarm for the Cargo pump turbines.

- Two (2) Inert Gas fans of 100% capacity each are to be provided for redundancy.

- One (1) ballast pump with VFD (Variable Frequency Drive) will be provided for economic operation.

- A distance ring for aft stern tube seals will be provided.

- The Aux. Boilers steam production was increased from 2x30 tons/h to 2x35 tons/h

- Fuel transfer, circulating and supply pumps are to be provided with magnetic couplings (leak free pumps).

- A bursting disc will be installed in the vacuum condenser.

- An Integrated Bilge Water Treatment System will be provided.

- A M/E bearing temperature monitoring system will be provided.

Helicopters are frequently used for various maritime operations including crew changes, pilot embarkation/ disembarkation and emergency medical lift offs. Modern day, powerful and reliable helicopters can save lives as they can be used to conduct speedy medical evacuations.

Helicopter operations can also cause damage to equipment and injury to the unprepared and the uniformed. One should never underestimate the power of the helicopter’s downdraft. Loose equipment near the landing / winching area is a great hazard to the ship’s crew and to the helicopter itself. There have been cases of loose equipment damaging the rotor blades of the helicopter. With reference to the very important circular by Rightship, “RS-01:2019 Helicopter Operations High Potential Near Miss Incidents’’ , we have noted an increase in near misses caused by unsecured items in the vicinity of the helicopter landing area. One such example is a loose and unpressurised fire hose picked up by the helicopter’s downdraft.

One case of a successful helicopter operation was the Search & Rescue drill conducted jointly by the Maritime Rescue Coordination Center (MRCC) of Almeria, Spain and M/V Coral Island.

M/V Coral Island was contacted by the MRCC, Almeria on October 5th, 2020 at 15:30 UTC and requested to carry out a Search and Rescue drill. The ship was in laden condition and underway to the discharging port of Tema, Ghana.

Captain Willie G. Mendones, the Master of M/V Coral Island, contacted the Head Office to advise about the proposed drill and accepted the invitation of the Almeria MRCC.

All preparations were made according to the Emergency Response Plan and the Master gave the green light to proceed with the drill.

The drill scenario involved an injured crew member in need of immediate evacuation and health care. The ship’s crew was requested to be ready to participate as required. The engine crew were placed on standby in the engine room for the required maneuvering.

The helicopter approached the vessel on the port side of the main deck and commenced the winching operation by lowering the guide line rope. The rescuer landed on board the vessel to secure the stretcher with the dummy. The rescuer was thereafter lifted by the helicopter which cleared the vessel.

MRCC Almeria contacted the vessel to advise that the drill was completed successfully and to extend their congratulations to the ship’s crew for their professional assistance.

We would like to take this opportunity to congratulate Captain Willie G. Mendones and his crew for the professionalism and resilience that they exhibited during the Search & Rescue drill and wish all ships calm seas & safe voyages.

Stress can be a blessing in disguise. Even though a certain amount of pressure can be quite helpful and motivating, if we have too much pressure for a long time, we run the risk of a more severe stress reaction. Stress is hidden in most of our everyday activities, so it can easily build up. Therefore, when there is no stress relief, it affects both our physical and mental health, and causes the quality of our life to decline.

Below, you will find some useful tips on how to manage your stress, either when you are working on board or when you are ashore with your family and loved ones. Remember, relieving stress can grow into a very pleasant habit and become part of our everyday life.

Health and self-care are very important in managing stress. Look after your health. Try to plan breaks throughout the year with a change in activities and surroundings where possible. Make looking after yourself top priority.

Organize yourself as best as you can. Being organized will help reduce your stress levels. If you don’t cram too much into the day, you will be able to deal with crises if they arise.

W ork may be the problem. If so, what aspects are stressful? Could better time management help? What are your priorities? Could you delegate? Could you get more support? Do you need some training? Should you speak to your manager?

Try not to take on too much. Be realistic about what you can achieve, so set yourself reasonable goals.

O wn up to yourself that you are feeling stressed – half the battle is admitting it!

Be in the moment where possible. Focus on the here and now. Don’t dwell on past or future worries as this will increase your stress levels.

E at a balanced diet. Eat slowly and mindfully, allowing at least half an hour for each meal. Don’t eat on the run or whilst doing another activity.

A lcohol does not help stress. Reduce your alcohol intake if you feel you are drinking as a way to cope with stress.

T ime for things you value is vital, including time for yourself. Plan some valued activities in your life. Stress can make us lose sight of what is most important. Make time for what matters most and you will manage your stress better.

S olve problems rather than burying your head in the sand. Write down the problems in your life that may be causing stress, and as many possible solutions as you can. Make a plan to deal with each problem.

T alk things over with a friend or family member or someone else you can trust and share your feelings with. Relationships are key to our resilience.

R elaxation or leisure time each day is important. Use recommended relaxation techniques, or try some new ways to relax such as aromatherapy or reflexology.

E xercising regularly is a great stress buster. At least 30 minutes of moderate exercise on five or more occasions per week is excellent for stress control. Walking, running, cycling, dancing, yoga, tennis… It doesn’t matter what the exercise is, but it helps if you enjoy it!

S ay no and don’t feel guilty.

S eek professional help if you have tried these things and your stress is still a problem.

Source: www.nhs.gov.uk

By Chara Markatzinou, Training Coordinator

During office meetings, it was decided that presents would be delivered to Company vessels that called at Piraeus over the festive season. This token of appreciation took the form of traditional festive season gifts. The boxes with presents, which were packaged for us by Fresh Pastry Shop, included the following:

Traditional Greek sweets (i.e. melomakarona & kourampiedes).

Cookies decorated with sugar paste Christmas patterns and truffles.

Gifts also included lucky charms with the traditional Greek Christmas symbol of a boat. These were prepared by Floga, the association that provides both help and support for children with cancer and their families.

A ‘’Pick your Wish’’ purse, in which small pieces of wood with a wish written on one side, was sent to each vessel . Every Seaman was able to pick his own wish. The wishes were Love, Health, Happiness, Joy & Prosperity.

The presents were greatly appreciated and the Seamen were quick to share their feedback with us.

M/T CE-Bermuda

Please be informed that all crew received their Greek Xmas sweets and "Pick your wish" bag on 01.01.2021 We collect all crew in Mess Room and give this presents from our Company and "Floga" association in traditional Ukrainian/Russian manner. All crew enjoy of this presents and send best wishes to all. Thank you to make this holiday more bright to us. Please find below photo received from the vessel.

M/V Nilos

Confirm safe receipt for gifts and appreciate.

M/T Pan.Armata

Kindly be informed that all crewmembers were very grateful for this unexpected presents and sweets. The "Pick your wish" bag was met with big enthusiasm and crew was happy to receive such "prediction" for following year. This event raised our spirit and make us feel festively. We wish to thank you for your support and beautiful mood.

M/T CE-Hamilton

Thanks a lot for pleasant gifts received in Greece. - It's very valuable to all us! The team is sending warm greeting from our hearts. We are surprised and very appreciated! Hope this action can support children in needs and everyone who involved.

The specific vessel also prepared a handmade thank you card, as seen below:

M/T Captain A. Stellatos

On behalf of entire crew we are humbled and grateful for Greek Christmas Sweets and other goodies including "PICK YOUR WISH BAGS". Your thoughtful gesture behind the gifts has been highly Appreciated. We are truly touched beyond word.

Once again a big THANKYOU to make our Christmas and New Year Bright and Beautiful.

from the SQE Department

Dear seafarers,

The pandemic that came into our lives during 2020 has created change and raised concerns for not only our own health, but also for the health of our colleagues and our loved ones.

However, our concerns are not only about health issues. The economic impact of these unprecedented events will be felt for some time to come.

Under the circumstances, being resilient will help us to adapt. Enhance your resilience by talking openly, something that seems more essential now than ever.

Ask yourself and your colleagues:

How is life onboard for you and the team?

What is morale like on board?

Are you receiving enough information and support regarding the COVID19 pandemic?

Are you getting the necessary provisions?

Is there anything more the shore team can do to support you and your team’s wellbeing?

Do you have enough PPE to keep the crew safe and healthy?

Have you had any difficulties with visitors complying with our procedures to keep the vessel a safe place to live and work?

Do you feel our people are still 'switched on' to the possibility of accidents and incidents? Do you feel their safety vigilance and reporting is strong?

While serving on board during these weird times I urge you more than ever to discuss issues amongst yourselves and convey your opinions to head office without any hesitation.

Talk to, listen to and learn from each other; RESET safety!

I wish you safe voyages and a safe return home.

Over the past few years, the Shipping Industry has considered the process of collecting and circulating Best Practices to be a vital tool for continuously improving Company Safety Culture. Thus, our Company has recently launched a Health & Safety campaign on the topic of Safety Best Practices in common areas of Risk Assessment across the Fleet.

The purpose of this campaign is to identify areas for improvement and to increase Safety Awareness on this important issue and thus ensure the Continuous Improvement of Safety Onboard.

Masters are asked to inform and motivate their Officers and Crew on how to report best practices with cases from their daily routine on which safe practices can be improved. Even though this is a voluntary effort , crews should be vigilant in reporting any practices that may enhance crew safety & welfare, improve onboard living standards, or provide environmental protection that could also be adopted by other

fleet vessels. The goal is to receive ONE Best Practice from each vessel per month. With this practice, we will gradually collect a large pool of safety ideas that can be implemented across the Fleet and meet relevant Shipping Industry requirements. All Best Practices will be recorded at Head Office and will be evaluated by the corresponding Office Staff. The ones that are considered to be the most beneficial will be circulated to the Fleet. Where appropriate, best practices will also be incorporated into our Company SMS. Finally, we wish to reward this voluntary effort every 6 months as follows:

• The Top 5 Best Practices will be published in our Wavelength Safety Bulletin by nominal recognition.

• The whole crew of the vessel with the BEST of the Top Best Practices will also be awarded free internet or calling cards as a token of appreciation / recognition of their efforts in this Campaign.

Hong Kong Marine Department (MARDEP) shared lessons from an incident onboard a Hong Kong-flagged container ship

When the vessel was anchored at Western Anchorage No.3 in Hong Kong, the crew transferred some spare main engine exhaust valves on the aft deck to the engine room with a monorail hoist through a skylight hatch, and then moved them to a designated position with an engine room overhead crane.

At that time, a fitter was working alone under the skylight hatch. The fitter temporarily lowered an exhaust valve on a removable floor plate (RFP) and released it from the hook of the monorail hoist.

Soon after the release of the hook, the exhaust valve toppled and crushed the fitter on the left side of his abdomen, resulting in his death.

Probable cause

The investigation identified that the main contributory factor to this incident was the overloading of the RFP by the exhaust valve as it could not support the 3-tonne weight of the exhaust valve.

As a result of the overloading, the RFP deformed and the exhaust valve toppled, crushing the fitter to death.

The investigation also identified the following safety issues:

•The crew should have worked as a group rather than leaving one crew member to handle the exhaust valve transfer operation alone.

•During the toolbox talk, there was neither any discussion nor risk assessment made regarding the operation necessary for the receipt of heavy machinery parts.

Lessons learned

1. Senior ship officers should carry out proper risk assessment and/or a toolbox talk to all crew members concerned in order to identify any potential safety hazards and implement appropriate safety measures to eliminate the risk of dangers when handling heavy machinery parts.

2. Ship crews should maintain good housekeeping of the engine room in accordance with the “Code of Safe Working Practice for Merchant Seafarers”, i.e. floor plates or gratings should be properly secured.

When an undesirable event doesn’t result in harm because barriers were in place and worked as intended

1. Consider failing safely in toolbox talk discussions

2. For each task, ask what can go wrong and seriously injure the people involved.

3. For each task, ask if everyone is wearing full protection.

4. For each task, ask if everyone feels comfortable enough to speak up. Find out!

5. For each task ask: When mistakes are made, what will keep you safe?

6. But is that enough? If it is not enough, what else is needed? Can the job be done a different way?

7. In your team, YOU know how the work is actually done and YOU have the best solutions.

8. Prepare for the unexpected!

9. Keep your Behavioural Barriers STRONG! (the sketch of these barriers apply on every occasion, and that is why it is repeated in most of our “Safety First” sections of Wavelength)

10. Mistakes should not be life changing. Mistakes will happen BUT when we do make mistakes, no one should get hurt! That is what it means to fail safely!

When all your barriers don’t work properly at the same time... the holes line up... then the hazard passes through and results in an incident!

In the Nostalgia section of this issue of Wavelength, we will continue our virtual journey in the past through the magical sea borne voyages of both current and previous fleet vessels. While the land personnel’s work environment is the stable workplace of an office, the officers and crew on board experience a different adventure every day with new ports, sea passages and ever-changing conditions such as the weather making their working environment a little more interesting!

In a previous installment of Nostalgia, as you may recall, we saw the fascinating photos of M/T Leni navigated by Captain Michail Michail passing through the Panama Straits! Navigating in restricted waterways and canals was even more difficult back in those days before the evolution that technology brought to navigation through the use of GPS, ECDIS etc.

Below we can see the original M/T Georgios S. back in November 2002 conducting a ship-to-ship lightering operation to discharge part of the cargo on board. She needs to lighter some cargo in order to meet the air draft restriction in place, due to navigating under a bridge, and reach her discharge port in the US.

The Georgios S. was the company's second newbuilding project and first suezmax ever ordered. She was built by DSME (Daewoo Heavy Industries at that time) to a very high specification and was delivered in June 2001, flying the Greek flag as can be seen in the photo. Her deadweight was 159,885 MT and she was operated in the spot market with the Company until 2007. The vessel was named in honour of the company's first Technical Manager and Director, George Stavrakis, who had served the Company since its inception in the 1970s and until his passing in December 1999. His nephew Nikos Stavrakis joined the Company in 2001 and is presently in the Chartering Dept., fittingly responsible for fixing the suezmaxes.

The life of seafarers is such that they must overcome all sorts of difficulties, including the weather. However, modern shipbuilding has progressed and the ships are designed to survive in the harshest environments.

Below M/T CE-Shilla facing the bad weather of Typhoon Bolaven in August 2012 with winds up to 10-11 on the Beaufort scale and a swell of 7-8 m.

Adverse conditions are not found only at sea, though. They can also be encountered ashore as can be seen in the following two photos:

And for our ‘guess who’ section of Nostalgia’, please see right a person who has quite a bit of work experience both as a navigating officer and a recruiting officer in the office. Below he is in the Cargo Control Room of M/T Panagia Armata serving as 2nd Officer back in 2012. Can you guess who this young and enthusiastic professional is?

Find the answer on page 19.

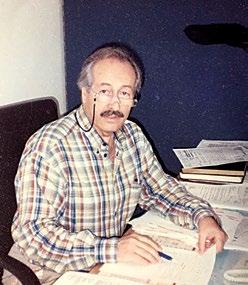

TAs already mentioned, the work environment of onboard and office staff differ significantly but just as conditions onboard have changed over time so has the office work environment. Take a look at the photo below taken before flat screens and open space work areas. Mr. Likourgos Soulimiotis from the Accounts Department is eagerly settling invoices, without the worry of GDPR.

hank you to those of you who have shared your experiences in your work environment by sending in photos. I encourage the rest of you to also participate by sending in your photos and not to miss out on the chance for your moment of publicity! We’d also be glad to receive photos of yourselves when you were much younger to see if people can correctly guess the person in the photo.

Calm seas and safe travels,

Since 1870 there has been a great deal of interest in the mystery of a lost ship thought to be located in the Salton Sea in California. Dubbed the ‘Ship in the Desert’ because California’s largest lake is shrinking and is completely surrounded by desert, the story of the sunken vessel has appeared in newspapers and magazines for more than a century. It has also featured in poetry and television documentaries.

Due to the lack of progress in finding this vessel, many people have given up on the story. That changed over a decade ago, though, when a 500-year-old Portuguese ship was discovered by miners in the Namibian desert. The vessel in question is Bom Jesus, which set sail from Lisbon in 1533. On her voyage to India, she disappeared near the Namibian mainland and was lost until she was found in the pit of a drained lagoon.

Among the wreckage of the Portuguese vessel, gold worth an estimated 9 million was recovered. In addition, well preserved cannons, swords, astrolabes, muskets, chain mail and pottery were retrieved. These, together with other finds, have given historians an invaluable insight into daily life on board a sixteenth-century ship. Like the lost ship in the Californian desert, the existence of Bom Jesus in the Namibian desert had

ne of the most popular Filippino dishes is sisig, whose name derives from an old Tagalog word, “sisigan”, which translates as “to make it sour”. The dish dates back to at least 1732, when its existence was first recorded in a dictionary compiled by the Spanish missionary, Diego Bergaño. In the dictionary, the dish, which originates from the Pampanga region on Luzon Island, is described as “a salad in a green papaya/guava and a dressing of salt, pepper, garlic and vinegar”. This definition reveals that it was most probably a side dish that accompanied roast meats.

Today, the dish has achieved an elevated status thanks to the inventiveness of Aling Lucing and Benedicto Pamintuan. The former, who had a street food stall or ‘carinderia’ in Angeles City, literally reinvented sisig by utilising parts of the pigs’ heads that were discarded by the kitchens at Clark Airbase. Later, Benedicto Pamituan began serving sisig on a sizzling plate, an idea that was readily allowed taken up by Aling Lucing. These two culinary innovations allowed the side dish to first become a beer food and

Remains of 500-year-old shipwreck that contained gold and artefacts

Source: www.historycollection.com

been just a story. However, treasure hunters would have had great difficulty in searching for the lost treasure in Namibia as the ship was located near the diamond mining town of Oranjemund, which is heavily guarded as the sands contain diamonds. Moreover, the Namibian government had lain claim to the gold haul, which is perfectly normal in such circumstances. What is ironic about the Portuguese vessel being blown off course almost five centuries ago is that the castaways on board who were seeking fortune ended up on diamond rich sands, but had no way of returning with the previous stones. Indeed, not one of the crew survived the grounding.

The discovery of Bom Jesus has given impetus to the efforts of those who seek the lost ship of the Salton Sea. Their task will not be hindered by the presence of heavily-armed security personnel, but it will not be plain sailing either as the Salton Sea has relatively high levels of toxic substances. This is a further reminder that while hunting treasure on sunken vessels is exciting, it can also be fraught with danger even when the ships are not at the bottom of the sea.

Sources: www.indipendent.co.uk, www.nationalgeographic.com

Courtesy of: www.thehungryexcavator.com

then a dish in its own right that has achieved both national and international acclaim.

A typical sisig, if there is such a dish, is made by removing the fleshy portions of a pig’s head after it has been boiled until tender, chopping them up and either grilling them or broiling them. They are then seasoned with salt, pepper and vinegar or calamansi juice before being fried with chopped onions and chicken livers. Last, but not least, a raw egg is added. Of course, there are numerous variations or additions possible. For instance, chicken, tuna and even squid can substitute for pork and ox brains or pork cracklings can be incorporated into the dish.

Sisig has been widely described as a uniquely Filippino dish. However, this staple of Kapampangan cuisine can now be enjoyed across the globe thanks to the inventiveness of two food stall owners who plied their trade in Angeles City.

Source: www.foxyfolksy.com, www.pepper.ph, www.kapampagnan.org

V

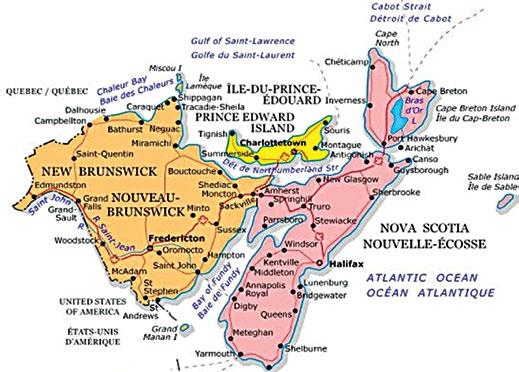

essel building in the Maritimes, which is the name given to the three eastern provinces of New Brunswick, Nova Scotia and Prince Edward Island in Canada, began in the 17th century. Throughout that century and the beginning of the next, building vessels was relatively small scale, but that changed around the middle of the 18th century, when there was shipbuilding boom in the Maritimes.

The growth of the shipbuilding industry, which was led by New Brunswick, was driven primarily by the opportunity to export the region’s abundant resources of timber and fish. Moreover, shipbuilding in the Maritimes was incentivised by Governor Cornwallis, who offered a bounty of ten shillings per ton for every new vessel constructed in the region. As a result, larger vessels were built, and settlers arrived to provide employees for the shipbuilding firms in New Brunswick, St. Martin’s, St. John and Nova Scotia.

By the middle of the 19th century, there were 176,000 tons of registered shipping in Nova Scotia alone. Then, over the next two decades, this figure rose sharply to around one million tons, a pattern that was being replicated across the three provinces. During the 1850s and 1860s, the introduction of iron steamships had barely any impact on the building of wooden vessels as they could be built relatively cheaply. Among the types of vessels built in the Maritimes were sloops, schooners, brigs and barks. The majority of these were designed by the foreman or a master builder at the shipyard rather than a naval architect. During the design phase, a model of the ship would be created as a reference for the builders at the yard. The actual site on which the ship was constructed was very close to a slope leading to the water’s edge so that a gravity launch could be deployed over logs and planking that prevented ships from sinking into the mud.

The hardwood keel was constructed with local yellow or black birch. After the skeleton was completed, the ship was planked from the keel upwards. In order to shape the planks, a steam box was used. After exposure to the steam, the planks were pliable enough to be twisted and bent before being attached with copper or iron bolts or treenails or a combination of bolts and nails. During the golden era of shipbuilding in the Maritimes (1850-1870s), the region’s shipyards were brimming with activity, but when supply overtook demand, freight rates plummeted and the decline began. Another blow to the industry came when the government introduced a policy to encourage the transportation of fish and timber to central Canada by rail.

Despite the decline, which forced many vessel building facilities to close, there were shipyards that continued producing wooden vessels well into the 20st century. These were limited in number and were often located far apart. For instance, in Lunenburg, Nova Scotia, there was just one pioneer shipbuilder, David Smith, who managed to keep the craft alive.

Throughout the 20th century and the beginning of the 21st century, the industry has gone through ups and downs.

Currently, the Maritimes boat yards are operating at close to full capacity as they rush to meet the demand for lobster fishing boats in the midst of the booming lobster industry. This development has even encouraged people who left the region to seek work elsewhere to return as the yards struggle to cope with the labour shortage. In addition to providing boats for lobster fishing, the Maritimes’ boatbuilding community is using the culturally important craft of constructing boats for a completely different purpose. Thanks to an innovative idea that aims to use a traditional craft to prevent at-risk youth from being marginalised, programmes run by museums, historical societies, boatyards, community non-profits and universities have been established throughout the Eastern Seaboard.

One such programme is run by the Maritime Museum of the Atlantic (MMA) situated on the Halifax waterfront in partnership with Mont Saint Vincent University’s Child and Youth Studies department. This particular programme, which is run several times a year, involves groups of youths attending a three-day boatbuilding class during which each group builds a 12-foot rowboat under the tutelage of a master boatbuilder. At the beginning of the course, most of the participants are frightened that they will make mistakes, but when they realize that mistakes are not frowned upon and are actually used to teach, their apprehension fades. During the course, they also learn how to sand, plane, drill, use instruments and boatbuilding mathematics and tell the difference between woods. In short, they absorb the concept of boatbuilding and gain confidence in their abilities. On the final day their efforts are rewarded as they take out the boat they have built onto the water.

These programs, which facilitate a sense of belonging in the participants, instil the values of patience and hard work so that their risk of being marginalised is greatly reduced. In short, they are able to connect their identity to a shared maritime heritage with the rest of society. The laudable move to utilize culture in this way has rightfully been highlighted and celebrated in Canada’s Culture Days’ 2020 event under the aptly named theme, ‘Unexpected Intersections’.

Sources: www.part.ns.ca, www.cbc.ca, www.archives.novascotia.ca, www.culturedays.ca

The Great Lakes is the name given to a chain of five freshwater lakes that form the largest combined area of fresh water on the planet. The basins that accommodate the water in the lakes were created by the action of huge glaciers passing through the region. When the glaciers receded around 14000 years ago, the basins began to fill with water. This process continued until the water reached its present levels between 3000 and 10000 years ago.

The lakes in descending order of size are Superior, Huron, Michigan, Eerie and Ontario. They form the St. Lawrence hydrographic system that extends from the St. Louis River through to the Atlantic Ocean via the Gulf of St. Lawrence. As the lakes drain roughly from west to east, the discharge rates increase from 75,600 cubic feet per second (Lake Superior to Lake Huron via St. Marys River) to 242,000 cubic feet per second or 6,853 m3/sec (Lake Ontario into the St. Lawrence River). Most of the water supply comes from precipitation, which ranges from 30-36 inches (760-916mm) annually in the region.

Escanaba’s

By Recomposemedia, https://commons.wikimedia.org

As the Great Lakes are so large, accounting for approximately 20% of the world’s fresh surface water supply, their area of 94,250 square miles (244,106 square kilometres) allows them to shape the climate by absorbing heat in the summer and releasing it during the winter months. They are also a vital source of drinking water for around 148 million residents of the US and Canada, including the 30 million who call the Great Lakes Basin home.

In addition to human inhabitants, the region supports more than 3,500 plant and animal species. More specifically, aquatic species include algae, microscopic crustaceans, plankton, clams and shrimp. There are also species such as lake trout, whitefish, salmon, bass and catfish that are fished for small-scale commercial and recreational purposes. Unfortunately, the waters have also become home to invasive species like the notorious zebra mussel that have not only threatened native species but have also clogged pipes and fouled hulls.

The latter impact has had an adverse effect on the companies who operate commercial vessels on the Great Lakes. These companies, of which there are around twenty-five, are vital to the area as there are 44,000 jobs related to maritime transport and a further 54,000 mining jobs dependent on

them. Indeed, mining low grade iron ore, for example, may not be economically feasible without the savings that are made by using lake freighters to transport such cargoes instead of trains or trucks. These savings are estimated a staggering $3.6bn annually, a figure achieved in view of the fact that the largest vessels can carry the same amount of cargo as can 700 rail cars or 2800 trucks. Most vessels operating on the Great Lakes confine their voyages to lake ports, but some do have overseas destinations which they reach via the St. Lawrence Seaway. Last, but not least, lake freighters have facilitated the establishment of large industries and, therefore, cities around the lakes.

All in all, the lakes generate over 5 million jobs and $60bn in wages. Apart from shipping and mining together with industries like iron and steel that are directly dependent on them, employment opportunities exist in agriculture, timber and power, which is generated by hydroelectric stations as well as coal-fired power stations and nuclear power plants that rely on the lakes as a source of cooling water. Tourism also offers employment to the local population.

Although the Great Lakes occupy a vast area, they are sensitive to pollutants as the outflows are small compared to the total volume of water. As such, the cleansing ability of the lakes is low, which means that pollutants in the form of farm chemicals, city waste, industrial discharges and atmospheric pollution become more and more concentrated. This leads to water quality problems as oxygen levels drop, a phenomenon experienced in the lakes that has resulted in fish and birds succumbing to their polluted habitats.

Fortunately, since the 1950s and particularly since the 1970s major efforts have been made to control pollution. Lakewide management plans have been drawn up based on toxicity data to improve water quality standards. Despite the enormity of this task, there has been some success as the actions of concerned parties such as the Great Lakes Initiative have led to the resurgence of some fish populations. Additionally, federal programs for the restoration and management of the Great Lakes supported by county and local governments as well as councils from tribal nations have afforded environmental protection for the region, thereby safeguarding a vital resource for all life forms that depend on it for their survival.

Source: www.britannica.com, www.glc.org, www.epa.gov, www.boatnerd.com

1. Make the names of two countries using all the letters in the following sentence: I WANT A TANGO.

2. The chemical symbols for aluminium, neon, oxygen, rhenium, tin and tungsten can be rearranged to form the name of a ‘southern’ port. What is the name of the port?

3. My name rhymes with a single piece of snow, and what you release before you can go. I am made by movement of the sea or a lake. So, if you’re sailing, look behind you; I am the ____. What am I?

4. Which three-letter word can be used to complete the following words? MI _ _ _ E, STO_ _ _ E, D_ _ _ GED and F_ _ _ MENT.

5. Alfredo prefers Parmesan to Gouda. He likes slippers but not sandals, and he prefers ships to boats. He would like to visit both Liverpool and Plymouth. By the same token, which fruit does he prefer: peaches or pears?

1. Which of the following vessels visited the World’s Columbian Exposition in Chicago in 1893?

A. Tilikum

C. Viking

B. Kon-Tiki

D. Mayflower

2.The Torres Strait links the Arafura Sea with which other sea?

A. Coral Sea

C. Timor Sea

6. Which five-letter word can be placed after the words to the left and before the words to the right?

GREEN BAR PARKING _ _ _ _ _ TRAVEL PERSONAL RACE

7. In 6 steps, change the word LIFT to DROP by changing one letter at a time to form intermediate words.

8. There are 8 marbles of identical size and weight in a black bag. There are 4 red ones and 4 orange ones. If someone draws out 4 marbles, one by one, the probability of drawing 4 red marbles can be expressed as: 1 in X. What is X?

B. Tasman Sea

D. Java Sea

3.Which former Company vessel is still active as a semi-submersible heavy load carrier at the age of 39?

A. Ruby

C. Ulsan

B. Wave

D. Nilos

4.According to reports, approximately what percentage of engine room fires is attributed to fuel leaks?

A. 75-80%

C. 50-60%

B. 65-75%

D. 40-50%

5.What is the maximum current velocity at which a windlass is designed to operate when a vessel is temporarily moored in a harbour or sheltered with no waves?

A. 0.5m/s B. 1.5m/s C. 2.5m/s D. 3.5m/s

at the foot of the page

6.The world’s largest floating liquefied natural gas platform is called Prelude. How long is this platform?

A. 396m B. 420m C. 452m D. 488m

7.Which of the following ports does not operate a ferry service across the Irish Sea?

A. Bristol B. Stranraer C. Dún Laoghaire D. Holyhead

8.According to records, where was Lloyd’s, the world’s first classification society, established in 1760?

A. at a bank B. in a warehouse

C. at a port D. in a coffee shop

9.Having kidney stones is a health problem faced by seafarers, especially in the engine department. Which of the following is a primary cause of this condition?

A. lack of protein B. dehydration C. lack of vitamin C D. stress

10.Which of the following pairs of neighbouring countries has the highest combined number of ports?

A. Argentina & Brazil B. Norway & Sweden C. Germany & Holland D. Australia & New Zealand

at the foot of the page

Find a keyword associated with at least one article in this issue by solving the clues and rearranging the letters in the boxes with black borders.

1. Great Lakes port (6)

2. Company that delivered Leni P. (7)

3. Smallest of the Great Lakes (7)

4. Portuguese treasure ship found here (7)

5. Being this helps us adapt (9)

6. A technique used to relax (11)

7. Sea where Search and Rescue drill was conducted (7)

Hint: Being this is beneficial

Answers

7.Alboran. Keyword: MINDFUL GUESS WHO: The mystery person is the ever enthusiastic Panagiotis Bartzis.

Built at a cost of $7 million by the Great Lakes Engineering Works of River Rouge, Michigan, the SS Edmund Fitzgerald underwent her maiden voyage in September 1958. At 729ft (222m) in length and with a beam of 75ft (23m), she was the first lake freighter to be built to the maximum of St. Lawrence Seaway size. As such, it was only natural that she was dubbed “Queen of the Lakes”, and became a firm favourite for vessel spotters and watchers.

Despite her grandiose nickname, she had less than an auspicious launch ceremony. It took three attempts to break the champagne bottle on her bow, the keel blocks stubbornly resisted release and her sideways launch led to spectators being soaked and her crashing into the pier. During her operation by the Oglebay Norton Corporation, she had further ‘mishaps’, including a collision with the SS Hochelaga, a grounding and scrapes with lock walls. Conversely, in 1969, she received a safety award for completing eight years’ service without a worker taking time off through injury.

By 1975, the SS Edmund Fitzgerald had completed 748 round trips from Duluth, Minnesota loaded with iron ore to iron works in such cities as Detroit and Toledo.

Named after a 16th-century Genoese admiral, the SS Andrea Doria was built at Ansaldo Shipyards in Genoa, Italy. At 213m (701ft) in length and with a maximum speed of 23 knots, she was neither the largest nor the fastest liner on the Atlantic route, but her passengers were treated to the most luxurious of crossings. The SS Andrea Doria’s first Atlantic voyage began on 14th January 1953. This was preceded by her first cruise that commenced on 23rd December 1952. Both occasions saw her being given a magnificent send-off by huge crowds.

The well-designed passenger areas made her one of the most beautiful post-war liners. This, together with the impeccable service, excellent cuisine, artistic décor and open air lido areas with three swimming pools put her at the pinnacle of the hospitality industry at the time.Thus, she attracted passengers of international fame, including actors Cary Grant, Spencer Tracy, Joan Crawford and Kim Novak. Among other big names that enjoyed her luxury were Orson Welles, Robert Guggenheim and General George C. Marshall. By the time the SS Andrea Doria was ready to leave Italy on 17th July 1956 on a nine-day voyage to New York with

On 9th November 1975, she set sail for Zug Island near Detroit under Captain Ernest M. McSorley. The forecast for inclement weather was nothing out of the ordinary for November, so it gave no cause for concern. However, the meteorologists revised their forecast to a gale warning and then to a storm warning. They were right, as the SS Edmund Fitzgerald did indeed encounter a winter storm on 10th November, reporting winds of 52 knots and 10ft (3m) high waves.

Mighty Fitz, another of her nicknames, was not alone in the storm as the SS Arthur M. Anderson under Captain Bernie Cooper was some 10 miles (16km) behind her. During the communication between the two vessels, Captain McSorley revealed that late on the afternoon of 10th November the SS Edmund Fitzgerald had started taking on water, lost two vent covers and experienced radar failure. He also stated that his vessel was being subjected to one of the worst seas had had ever been in.

During the storm, the USCG advised vessels to seek safe anchorage. Without radar this may have proved virtually impossible, which may explain why Captain Cooper reported that the SS Edmund Fitzgerald passed too close to Six Fathom Shoal, a dangerous area of shallow water.

1,134 passengers and 572 crew, she had completed 100 return crossings. Nobody expected the 101st to be any different, but on the 25th July she entered the heavy traffic sea-lane of the North-East coast under the cloak of dense fog. As she disappeared in the fog, she was to experience something that would end her service. Cloaked in fog, heading in the opposite direction was the passenger liner, MS Stockholm, whose officer on watch picked up the blip on the radar from the Andrea Doria shortly after 10:45, the time at which the Andrea Doria became aware of the presence of the Stockholm heading towards her. As the situation was far from unprecedented, there was no cause for concern. However, both ships misidentified each other’s location and despite last ditch efforts to avoid a collision, Stockholm’s icebreaker bow struck the SS Andrea Doria

At around 7 pm, approximately 17 miles (27km) from Whitefish Bay, the main hatchway caved in and shortly afterwards, the stricken vessel sank. There were no survivors as all 29 aboard were lost. Four days later, the wreck was located amidst conjecture as to why the vessel had disappeared below the waves. No firm conclusions regarding the sinking of the SS Edmund Fitzgerald have been reached, but the disaster has led to changes in shipping practices on the Great Lakes. These include a pre-November inspection to check hatch and vent closures, lifesaving equipment and watertight integrity. There is now additional crew training, too. Sources: www.cimss.sec.wisc.edu, www.shipwreckmuseum.com, www.michiganseagrant.org, www.wikipedia.en

on the starboard side. The impact killed 5 people on the Stockholm and caused the SS Andrea Doria to list 20o to starboard, making her eight portside lifeboats impossible to use. Her bulkhead had been snapped as the Stockholm had penetrated 30ft (10m) into her hull, leaving a gaping hole when the two vessels broke free of each other.

The Andrea Doria’s distress call received a response from the Stockholm, a light freighter, two American Navy vessels and finally, a huge French liner, Ile de France. The responding vessels kept loss of life to minimum as 46 souls perished in addition to the five killed on impact. At 10:09 am the following day, the SS Andrea Doria capsized and sank in 240ft (73m) of water in the North Atlantic, where she still rests. The collision between the two liners led to rule changes with regard to the use of radar to avoid collisions. In this case, the radar available to the two ships was poorly handled, whereas in Edmund Fitzgerald’s case there was radar failure. So, it may be concluded that an inability to utlize technology efficiently can equate to having no technology at all.

Sources: www.italianliners.com, www.history.com, www.wikipedia.en