We have a motto “If you see something, say something!” And on 25-26 November 2024, we saw a lot and said a lot! We all witnessed another great event held by CENMAR Manila for Filipino Officers and Ratings at Makati, Manila.

By Andreas Chandris

The tradition continued without surprises and more than 120 seafarers gathered for a two-day event with various topics presented by the Head Office attendees and external guests. As part of the Forum Committee, we are excited that this event continues to grow in so many ways every year. Indeed, it is becoming a trend and a common request for many Seafarers and Head Office personnel to attend and live the experience. RISQ, Planning of Bunkering Operations, Working at Heights, Spark Erosion in M/E Bearings, Life Saving Tools, ShaPoLi, Speak Up, Ordering and Provisions Management were only few of the topics presented this year at the Manila Forum. One of the best moments of the Forum, was the Basketball game where the “Alligators” won the mini-tournament in front of colleagues, friends and families. All the games were intense and the final between the “Alligators” and the “Tigers” was exciting throughout. Final outcome: CENMAR ONE TEAM!

Last but not least, I want to personally thank each and every one of you who has worked for this and all similar events in order to ensure they run smoothly both on and off stage. Please remember, we are, all of us, a team, on board and ashore. So BE AWARE, TAKE CARE, EVERY TIME, EVERYWHERE and IF YOU SEE SOMETHING, SAY SOMETHING!

Adequate control of oxygen and pH levels is, therefore, essential for magnetite formation.

6Fe + 2O2 → 2Fe3O4 : Magnetite

Poor Oxygen Control-Hematite layer

Oxygen Pitting

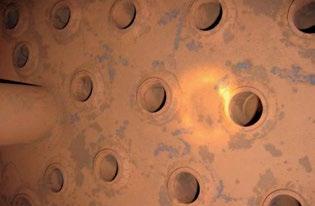

Boiler: Appearance of Good Magnetite formation

Hematite layer and Blister Corrosion

Sulphate Ion Corrosion

Good Oxygen ControlMagnetite layer

Boiler: Appearance of Good Magnetite formation

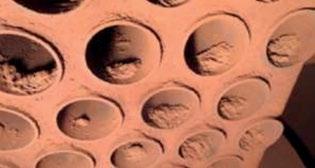

Mishandling of sodium sulphate generates sulphate ions, leading to corrosion as depicted in the photo.

Corrosion of lower tube plate caused by sulphate ions

Caustic Attack

Caustic corrosion can be formed on high heat transfer surfaces as

a result of water evaporation, since concentrated NaOH (caustic soda) solution dissolves the metal. Prevention of caustic attack can be achieved by correct phosphate treatment levels and avoidance of a caustic solution. Both the phosphate levels and pH need to be monitored.

These salts are normal substances that can be found in the sea water used for fresh water distillation on board. Hardness salts create scale, which obstructs the heat transfer in the Boiler, increases the water flow resistance inside the tubes and can cause tubes to overheat. In addition, the fuel consumption when firing the auxiliary Boilers can be increased as a result of heat loss.

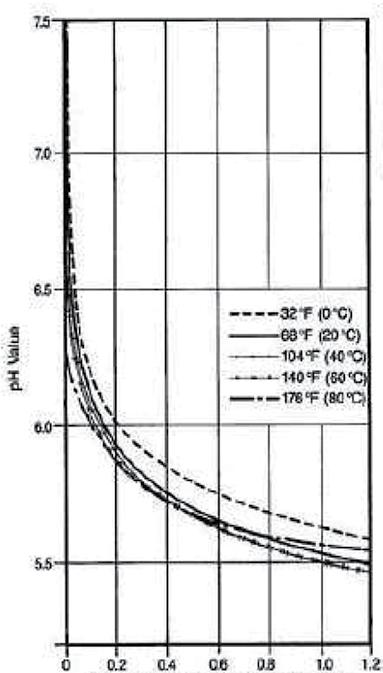

These substances are a result of the chemical decomposition of gases or from various contaminants such as carbon dioxide, which forms carbonic acid. 1 ppm CO2 in the steam can reduce the condensate pH from 7.0 to 5.5. This decrease in the pH value can result in corrosion, “Acid Attack”, of the tubes, especially at bends and threaded joints. The metal surfaces are subject to pitting and a reduction in thickness. This type of corrosion occurs very quickly and leads to steam leakages.

CO2 + H2O → H2CO3 : Carbonic Acid

Concentration of Carbon Dioxide related to pH value & temperature

As a rule of thumb, below are mentioned the basic solutions that can be applied to avoid or absorb the different types of corrosion and malfunctions mentioned previously.

Problem

Dissolved Gases

Hardness Salts

Solution

Increase hotwell temperature

Chemical treatment

Use of good quality water

Chemical treatment

Frequent water analysis

Frequent blow down

Acidic Substances Chemical Treatment

Table 1: Summary of Types of Corrosion and their Solutions

Makers’ Recommendations about Water Quality

The following tables present the required characteristics of the water as specified in the manuals for the Main Engines, Diesel Generators and Boilers used in our fleet vessels. These parameters should be always monitored and be within the recommended limits.

Hardness (ppm CaCO 3) 10 max.

Sulphate (mg/L)

Silicate (mg/L)

max.

*water to be free of ammonia

Table 2: Characteristics of the cooling water used in Main Engines MC-C, ME-B & ME-C

CaCO 3)

(mg/L)

Table 3: Characteristics of the cooling water used in Diesel Generators

(ppm CaCO 3)

(ppm CaCO 3)

Alkalinity (ppm CaCO 3)

Hydrazine (ppm) - 0.1-0.2 - -

Phosphate (ppm) - 20-50 - 20-40

Specific density (kg/m 3) - 1.003 max.

Conductivity (μS/ cm) - 2000 max. - -

Oil Content 0 0 0 0

Table 4: Characteristics of the water used in Boiler Plants

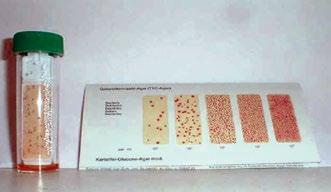

Boiler water treatment can be achieved with the use of liquid chemicals, in order to maintain the proper composition of the water and minimize the presence of oxygen.

Whenever needed, chemicals have to be injected into the Boiler water, in order to meet the maker’s recommendations and control its alkalinity, hardness, sludge and condensate pH.The chemical used must contain neutralizing volatile amines to bring the pH level of the condensate and steam system to a non-corrosive pH level of about 8.3–9.0. These alkaline compounds raise the Boiler

water pH and create the proper environment for the phosphates to react with calcium salts. The phosphates precipitate the dissolved calcium salts that cause hardness and converts them into a non-adherent calcium sludge which can be easily removed by blow down and a coagulant which keeps the sludge dispersed in small particles and conditioned to be removed by normal blow down. An example of a suitable chemical for this process is “Autotreat” manufactured by Wilhelmsen (or equivalent).

Control of oxygen present in the water

The minimization of the presence of oxygen in the Boiler water system is very important in order to protect the Boiler from several types of corrosion. This can be achieved by the use of liquid chemicals that act as oxygen scavengers. These are used more or less on a daily basis by all vessels in order to keep the oxygen at low levels and maintain the Boiler in good condition. “Oxygen Scavenger Plus” or “DEHA” manufactured by Wilhelmsen (or equivalent) can serve this purpose.

The main issues that have to be dealt with in order to maintain efficiency and proper water quality in a cooling system are scale formation on heat transfer surfaces, bacteria contamination and metal corrosion. The use of the appropriate chemicals, that can increase the pH value of the water in order to neutralize any acidic substance and create a thin coating on all metal surfaces to protect them against corrosion, is the most effective way to avoid the aforementioned issues.

Prevent and rectify oil contamination

A major issue that is very likely to occur is water contamination with oil due to damaged heating coils, heat exchangers or other metal surfaces between steam/water and oil. The presence of oil in the Boiler will cause many problems like the creation of sludge deposits that could clog and damage tubes and instruments, the acceleration of corrosion and creation of an oil film on the heat exchanging surfaces, which reduces heat transfer. The conductivity of oil is very low (0.1 W/m2°C, 20 times less than the conductivity of scale), which results in the isolation of heat on the surface of Boiler tubes, overheating of the tubes and finally to their failure. An oil film with a thickness of 0.5mm can reduce the strength of the metal surface by 1/3.

The first line of defence to avoid such an issue is to make sure that the heating coils and heat exchanging surfaces are free of damage and corrosion. Upon identifying that the Boiler water has been contaminated with oil, which can be done through the cascade or hot well tanks, there are several steps that have to be followed such as frequent surface blowdowns of the Boiler, inhibition of chemicals (coagulants) and continuous monitoring of the water to make sure that no oil deposits have remained.

Oxide

Nitrite inhibition in the cooling water system at appropriate/high levels gives complete protection against corrosion by forming a protective oxide film on the metal surfaces. In this case the metal surfaces of the system are protected against pitting, cavitation and erosion. “Rocor NB” produced by Wilhelmsen (or equivalent) is an example of a chemical that can serve this purpose.

The nitrites, phosphates and emulsifying oils that can be found in closed cooling water systems are good nutrient media for bacteria that can cause many corrosion problems as they produce a variety of acids while they grow . The use of biocides such as “MAR-71” produced by Wilhelmsen (or equivalent) can prevent and combat bacterial growth and guard the system against corrosion.

Pressure surge, or hydraulic shock, occurs when the kinetic energy of a flowing liquid is suddenly disrupted, generating a shockwave that travels through the pipeline. These pressure spikes can damage equipment, disrupt loading and pose serious safety risks. Understanding the causes, consequences, and preventive measures is essential for safe cargo operations.

• Rapid Valve Operations: The quick opening or closing of valves causes abrupt pressure fluctuations. Sudden closures create pressure spikes, while rapid openings lead to uncontrolled surges.

• High Flow Rates: Sharp increases in loading rates without gradual adjustments cause turbulence and unstable pressure variations.

• Tank Changeovers: Poorly coordinated transitions between tanks disrupt pressure stability, leading to localized pressure surges.

• Ineffective Relief Systems: Bypass valves or surge relief systems that fail to activate can result in excessive pressure build-up and system failure.

• Incorrect Pump and Valve Operations: Improper handling can generate severe pressure surges, damaging pipelines, hoses, or Marine Loading Arms (MLAs).

• Ship/Shore Connection Risks: These are one of the most vulnerable points in the system, where excessive pressure can occur if valves are closed too quickly.

• Pipeline and Elevation Factors: Long pipelines, high flow rates and significant elevation differences between the ship and shore tank increase surge severity.

• Ship/Shore Coordination: A lack of proper communication and planning can lead to uncontrolled flow rates and valve closures, increasing surge risks. A written agreement covering these aspects should be part of the pre-transfer conference and documented in the Ship/Shore Safety Checklist.

A product tanker commenced loading at a controlled rate of 500 m³/hr as per standard operating procedures. After confirming stable conditions, the crew gradually increased the rate to 2,200 m³/hr, with six cargo tanks open. The manifold pressure remained steady, and no back pressure was observed.

Approximately 20 minutes into full-rate loading, the Chief Officer decided to redistribute cargo among the tanks for even loading. To do so, he simultaneously opened four new tanks and closed four existing tanks without adjusting the pumping rate or coordinating with the terminal.

Within minutes, the Emergency Shutdown (ESD) system was activated, bringing loading operations to an abrupt halt. Upon investigation, the terminal found that the pipeline pressure had surged to 18 kg/cm² due to the sudden shift in flow dynamics. The

bypass relief valve failed to activate, leading to valve damage and triggering the ESD system.

The aftermath of the incident was significant:

• Financial Losses & Delays: The vessel incurred a substantial demurrage claim, and the terminal suffered additional delays that impacted subsequent vessel operations.

• Operational Impact: The need for repairs on the damaged valves led to further setbacks in loading schedules.

• Pollution Risk: The abrupt stoppage of loading introduced a potential risk of pollution, as uncontrolled pressure fluctuations could have led to leaks at the ship/shore interface.

This case highlights the critical importance of controlled valve operations and coordinated tank changeovers to prevent sudden pressure surges. Proper communication between the vessel and terminal, along with adherence to structured loading procedures, could have mitigated the risks associated with abrupt cargo redistribution.

• Equipment Damage: High-pressure spikes can rupture hoses, damage valves, and compromise the ship/shore connection.

• Operational Delays: Unexpected shutdowns require troubleshooting, leading to costly loading delays.

• Environmental Hazards: There is an increased risk of oil spills due to sudden cargo flow interruptions.

• Safety Risks: Pressure surges can endanger crew members near the cargo manifold.

• Avoid Downstream Valve Closure: Valves should not be closed against the liquid flow except in emergencies.

Shore leave plays a crucial role in maintaining the health and wellbeing of seafarers. While the Maritime Labour Convention (MLC) 2006 recognizes this by stating:

"Seafarers shall be granted shore leave to benefit their health and well-being, consistent with the operational requirements of their positions",

there are no specific guidelines on how to protect or promote it.

In recent years, factors such as COVID-19, supply chain disruptions, and conflicts have reduced shore leave opportunities for many seafarers. To ensure health and safety, shore leave should be granted only after assessing the risks to seafarers' health, including the infection rates in the local area, port, or country.

While the Master of the ship grants shore leave, every seafarer is entitled to it under the MLC.

Our company understands the significant health benefits shore leave offers and is concerned about the barriers many seafarers face. Shore leave depends on various factors like:

• Health and safety at the port

• Immigration requirements

• Port authority regulations

• Accessibility of the port

Here are a few tips to help you make the most of your time ashore:

• Share Notes with Fellow Seafarers – Learn from shipmates who have visited the port before. They can guide you on places to avoid and provide tips for a smooth shore leave experience.

• Carry Proper Documentation – Always bring your

shore leave pass, seaman’s book, or copies of these documents. Many places do not accept foreign currency, so carry local money or cards.

By Nasos Skouras

• Save Key Contact Numbers – Before heading ashore, make sure you have important numbers saved, such as: Ship’s agent, Ship contact details, Terminal gatekeeper’s number

Locals may be cautious of outsiders. A friendly and respectful attitude helps build rapport, especially when asking for directions or assistance.

• Avoid close contact with anyone showing symptoms of illness.

• Wash hands regularly using soap and water for at least 20 seconds.

• Disinfect commonly touched surfaces.

• Stay away from crowded areas with poor airflow. Reminder

We enforce a zero-alcohol policy. Please enjoy your shore leave responsibly and return to the vessel safely.

Stay Safe, Enjoy Your Time Ashore!

In the fourth quarter of 2024, there were thirty two promotions. The list of those ratings and officers who were promoted along with their vessels and promotion details in chronological/alphabetical order appears in the table below.

John NAMRATTA OS to ASD

Jayvee NAMRATA C/Tr. to A/C

TAYA John Rafael MERBABU OS to AB

AHUMADA Alphonse SUNDORO OS to ASD

18.11.24 PELAEZ Jorence Cj AMALIA M. C/Tr. to A/C

The majority of those promoted are younger crew members who have obviously shown their eagerness to learn and, therefore, improve their performance. Hopefully, they will continue to show their willingness to progress and have a rewarding career with the Company. We are looking forward to seeing those Seafarers’ names again on future promotions lists. In the last quarter of 2024, there were no advancements to the

18.11.24 VALLES Accel Gay AMALIA M. OS to ASD

19.11.24 CALUAG Ian Jhenielle CASTA DIVA OS to AB

20.11.24 CABRERA Carl Axl SUNDORO OS to AB

01.12.24 ROSALES Harvey CALLIOPE P. 3/E to 2/E

01.12.24 SISON Arvin Abe CE-BERMUDA OS to AS

RIYAJ Ahmad AMALIA M. 3/M to 2/M

PAGENTE Stephen CE-BERMUDA C/Tr. to A/C 08.12.24 JEROTA Edjon ALEXIA C/Tr. to A/C 10.12.24 LAGAMON Denis DINO OS to AB 12.12.24 DURILAG John Cloyd DANAE D/Tr. to OS 13.12.24 BISO Joefrey Jr. CAPTAIN A. STELLATOS OS to AB 13.12.24 CONDES Jestoni KAPSALI ASE to FTR 13.12.24 TABULIN Vladyslav NAMRATA 4/E to 3/E

18.12.24 PUMARES Henry ALLIANCE 4/E to 3/E

25.12.24 SINHA Ashish Kumar COSTAS P. 3/M to 2/M

30.12.24 DE CHAVEZ Bryant Ernest POPI P. C/Tr. to A/C

top rung of the ladder. However, there were two promotions to Second Engineer. These were given to Alex Alborote (Nilos) and Harvey Rosales (Calliope P.), who now have the esteemed position of Chief Engineer as their next goal.

Warmest congratulations are due to each and every one of our Seafarers. You have all contributed greatly to the smooth running of the vessels that you proudly sail on. Thank you.

In this installment the second of our Seafarers, Captain Anil Kumar, has stepped up to provide further insights into life on board by offering solutions to the challenges that need to be addressed at sea. I would like to relate to him my profound gratitude for his contribution to this initiative.

How do you foster an inclusive and supportive environment on board, ensuring that crew members from diverse backgrounds feel valued and respected?

Below are methods to foster an inclusive and supportive environment on board, ensuring that crew members from diverse backgrounds feel valued and respected

• The Master should model inclusive behaviour and respectful communication.

• Encourage crew members to approach the Master with concerns or suggestions.

• Listen actively and empathize with crew members from diverse backgrounds.

• Conduct anonymous surveys to gauge crew satisfaction and identify areas for improvement.

• Monitor crew performance and provide constructive feedback.

• Thoroughly investigate any incidents of harassment, bullying, or discrimination.

• Ensure all crew members understand that harassment, bullying, or discrimination will not be tolerated.

• Encourage respectful communication among crew members, avoiding stereotypes or biases.

• Involve crew members from diverse backgrounds in decisionmaking processes.

• Address any microaggressions or unintentional biases promptly and constructively.

• Ensure all crew members understand the importance of diversity, equity, and inclusion.

• Provide training for all crew members on cultural differences and nuances.

• Develop and communicate policies that promote equality and respect.

Can you share an experience where embracing diversity among your crew contributed to better teamwork, problemsolving, or overall operations?

• While transiting through high-risk waters, a piracy drill was conducted. The crew consisted of Indian and Filipino members. Instead of following a rigid, one-size-fits-all approach, I encouraged input from both nationalities based on their past experiences. The Filipino crew members shared insights into real piracy tactics, while the Indian crew members proposed practical defence measures. The result was a well-rounded anti-piracy strategy that incorporated the best practices from different parts of the world, ensuring everyone was well-prepared for a real threat.

• Diverse crews often face challenges related to different religious practices, food preferences, and work styles. Once I noticed a decline in morale due to misunderstandings about meal choices during long voyages. I worked with the Chief Cook (Filipino) and crew representatives to implement a rotating meal plan that accommodated different cultural preferences. Small changes like celebrating major cultural holidays and events featured traditional foods, music, and dances from various countries significantly improved crew morale, leading to better teamwork and overall efficiency.

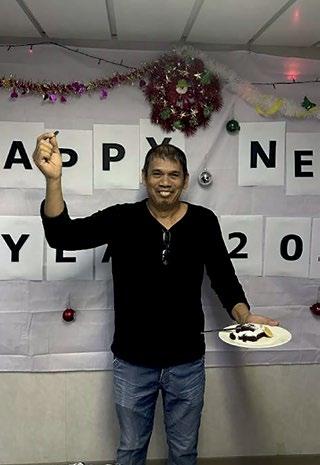

Judging from the photos received from numerous vessels, the solutions proposed by Captain Anil Kumar and implemented across the fleet have had a positive impact on our Seafarers. You can see for yourselves how well they have incorporated events and celebrations into their routines. Enjoy looking at the images of the lucky coin and games winners as well as those of crew members celebrating the New Year.

MESSAGE FROM THE DPA:

Dear seafarers, from the

I am happy to commend you and your colleagues on board the vessels mentioned below, who kept their safety intact and their safety culture on the rise:

- On board 10 of our vessels since their delivery

- On board 23 of our vessels within year 2024 (compared to 18 in year 2023)

M/T COSTAS P

M/T DIMITRI

M/T DINO

M/T MERAPI

M/T POPI P

M/V ANDONIS

M/V DUKE II

M/V GUARDIAN

M/V PHILIPPOS A.

M/V SMYRNA

The Company recognizes and rewards the crew that contributed to this great safety record.

ALMOST 80% OF OUR FLEET REMAINED INCIDENT FREE FOR YEAR 2024!! CONGRATULATIONS TO ALL OUR SEAFARERS!

M/V PHILIPOS A. – Incident free since 2011: Our fleet champion!

M/T AG.NIKOLAOS

M/T ALEXIA

M/T APANEMO

M/T APNOIA

M/T CAPTAIN A. STELLATOS

M/T CE-HAMILTON

M/T LENI P.

M/T MIKELA P.

M/T NAMRATA

M/T PSERIMOS

M/T SEMERU

M/T YANNIS P.

M/V APAGEON

M/V CALLIOPE P.

M/V CASTA DIVA

M/V DANAE

M/V EVGENIA P.

M/V NILOS

M/V POLYMNIA

M/V RUBY

M/V STEFANOS

M/V VENTURE

AWARD : Internet cards for all crew on board

M/T MERBABU – Incident Free during 2024

Keep up the “SAFE” work! I wish you safe voyages and a safe return home, Elli Moretti

Source: Britannia P&I

At midnight on 20 September 2021, the 2/O relieved the Master to take over the 0000 to 0400 navigational watch. However, contrary to the SMS and international regulations, no additional lookout was assigned for the night watch. The BNWAS, designed to alert the crew if the officer on watch becomes incapacitated, was turned off. During the night, the ship proceeded on autopilot. The 2/O conducted his watch normally. However, between 0345 and 0355, he briefly sat on the bridge couch and fell asleep. At 0353, the ship failed to execute a planned turn to join the TSS and continued a straight course towards the shoreline. Coastal authorities monitoring the ship attempted to call on Very High Frequency (VHF) radio when it did not alter course, but the 2/O failed to respond. At around 0413, the ship ran aground at a speed of 7.8 knots in the Yailata Protected Area, causing extensive hull damage. Water entered several ballast tanks through breaches in the hull, but there was no immediate fuel leakage. The impact rendered the ship immobile, and the rocky bottom complicated subsequent refloating efforts.

Following the grounding, the 2/O was awakened by the loud noise of the ship grounding. He stopped the engine and alerted the rest of the crew, including the Master and Chief Officer (C/O). Upon arriving at the bridge, the Master ordered the crew to refrain from responding to VHF calls and initially instructed the crew to turn off the Automatic Identification System (AIS). These decisions delayed emergency response efforts and raised questions about the Master’s judgment during the critical moments following the grounding.

The Master attempted to use the main engine to reverse the ship off the rocks, despite objections from the C/O and other crew members, who feared that further damage to the hull might result. At 0512, the ship finally established radio contact with VTS-Varna and reported the grounding. Fortunately, no injuries were reported among the crew, and there was no immediate pollution. However, the delay in communication hampered early response efforts.

The investigation identified several procedural lapses that contributed to the grounding. The most significant failure was the deactivation of the BNWAS system, which would have alerted the crew when the 2/O became incapacitated. The SMS procedures required the BNWAS to always remain active, but the system was manually turned off, and no record of its deactivation was made in the ship’s logbook. Another critical error was the absence of a lookout during the watch. The SMS required an additional lookout to be present during the hours of darkness, but the Master released the lookouts from their duties, assigning them to general deck work during the day instead. This decision left the 2/O alone on the bridge during a critical phase of navigation, increasing the risk of human error.

The Master’s oversight of the voyage was also called into question. The passage plan prepared by the 2/O was neither reviewed nor approved by the Master or C/O. Furthermore, the Master altered the ship’s course to sail closer to the coast but this deviation from the original route was not documented or properly communicated.

The 2/O’s fatigue was also identified as a key contributing factor to the incident. He was repeatedly summoned by the Master for various tasks, including administrative duties and translations. The investigation revealed that the Officer had not been able to sleep adequately since the ship’s departure from Ukraine, undermining his ability to remain alert during his watch.

Fatigue remains a critical issue in the maritime industry, and this case underscores the need for effective fatigue management.

Seafarers often hesitate to use support lines due to a variety of concerns.

One major barrier is the stigma and cultural perceptions surrounding mental health. Many come from backgrounds where discussing personal struggles is seen as a weakness, making them reluctant to reach out for help. They may also fear being judged by colleagues or superiors.

Another significant concern is job security. Some seafarers worry that seeking support could be perceived as an inability to handle stress, which might affect their career prospects. There is also a fear that reporting mental health concerns could lead to termination or forced repatriation, further discouraging them from using these services.

Lack of awareness and accessibility also plays a role. Not all crew members are informed about the availability of support lines,

how they work, or whether they can access them while at sea. Connectivity issues, including poor internet access and restricted phone use, make it even harder to reach out when needed.

By Chara Markatzinou

Even when support is available, distrust and concerns about confidentiality prevent many from using it. Some fear that their conversations may not remain private and that information might be shared with their employer or colleagues. This uncertainty makes them hesitant to open up about personal or work-related issues.

Additionally, many seafarers feel that their struggles are not serious enough to warrant seeking help. The tough, self-reliant nature of life at sea leads many to believe they should handle problems on their own. They may compare their challenges to those of others and decide that their situation does not justify using a support service.

Language and communication barriers also create obstacles. Not all helplines offer support in multiple languages, making it difficult for non-native speakers to express their emotions clearly. Even when language is not an issue, some seafarers may struggle to articulate their feelings, especially over the phone.

Lastly, there is skepticism about the effectiveness of support lines. Many believe that simply talking to someone won’t change their circumstances, particularly if they are facing long-term stress, isolation, or difficult working conditions. This sense of helplessness discourages them from reaching out, as they see no tangible benefit in doing so.

Our company utilizes two support lines: Mindcall and MHG, which any Seafarer can contact 24/7, 365. Those answering the phone calls or replying to chat/e-mails speak a variety of languages, so it is highly likely you will be able to speak in your mother tongue. They are all professionals and maintain confidentiality.

Addressing these barriers requires education, clear assurances of confidentiality, accessible multilingual services, and strong leadership support to create a culture where seeking help is seen as a sign of strength, not weakness.

Here are some practical tips to build trust in support helplines:

1. Start Small: Begin by making a brief call to ask general questions about the services they offer. This allows you to get familiar with how the helpline works and helps build comfort without diving into personal details.

2. Talk to Others: Reach out to fellow seafarers who have used support lines. Their first-hand experiences can offer valuable insights and reassurance, helping you understand the confidentiality and genuine support these services provide.

3. Stay Open-Minded: Approach each call with an open mind and be prepared for a supportive, non-judgmental conversation.

Remember that the people on the other end are trained to listen and offer assistance so that you can feel more at ease.

4. Ask Questions: During the call, feel free to ask any questions that help clarify how the service works such as what information is required, who has access to the information, and how your privacy is protected.

5. Use the Helpline Regularly: Even if you don’t have an immediate problem, occasionally calling the helpline can help you get accustomed to the process and reinforce the notion that it’s a safe space.

6. Observe Their Responsiveness: Pay attention to how the helpline staff respond to your inquiries. Are they respectful, empathetic, and willing to help? Positive interactions can go a long way to building trust.

7. Take Your Time: Don't feel rushed during the conversation. It’s okay to take a pause, think about what you want to say, or ask for clarification if needed.

The goal is to make sure you’re comfortable with the process.

By gradually building familiarity with the helpline and engaging with it at your own pace, you’ll be able to build trust and confidence in the service over time.

Proper hydration is essential for seafarers working on board vessels, especially during the summer months when high temperatures and physical exertion increase the risk of dehydration. However, staying hydrated is equally important throughout the year as long working hours, exposure to varying climates, and demanding tasks can lead to fluid loss, affecting health and performance.

Why Hydration Matters

Water plays a crucial role in regulating body temperature, maintaining energy levels, and supporting overall well-being. Dehydration can cause fatigue, dizziness, headaches, and reduced concentration, which can increase the risk of accidents and impair decision-making—serious concerns for those working in a maritime environment.

Seafarers should be aware of the early signs of dehydration, which include:

• Dry mouth and excessive thirst

• Dark-colored urine or decreased urination

• Dizziness or lightheadedness

• Fatigue and muscle cramps

• Difficulty concentrating or headaches

Ignoring these signs can lead to severe dehydration, which may cause heat exhaustion or heat stroke, particularly in hot weather conditions.

1. Drink Plenty of Water – Aim for at least 2–3 litres of water daily, increasing intake in hot or physically demanding conditions.

2. Avoid Dehydrating Beverages – Minimize consumption of caffeine, alcohol, and sugary drinks, as they can contribute to fluid loss.

3. Eat Hydrating Foods – Include water-rich fruits and vegetables like cucumbers, oranges, and melons in your diet.

4. Carry a Water Bottle – Keep a bottle nearby and take regular sips throughout the day.

5. Monitor Urine Colour – Light-colored urine indicates good hydration, while dark urine suggests you need to drink more fluids.

6. Adjust for Climate & Activity – Increase water intake in hot environments or during physically strenuous work.

Even in cooler temperatures, dehydration remains a risk due to indoor heating, air conditioning, and physically demanding tasks. Maintaining hydration habits year-round ensures optimal health, alertness, and performance at sea.

Prioritizing hydration is a simple yet effective way to stay healthy, energized, and safe on board. Drink water regularly and encourage fellow crew members to do the same. Stay hydrated, stay alert, and stay safe!

It is the turn of the Marine Operations Department to take centre stage in this section. So, let’s hear from eight members of this team along with a colleague from the ICT Department.

My name is George Karathanos, and I currently work as a Tanker Operator for the Company. Prior to this role, I gained valuable experience as a seaman, which has provided me with a strong foundation in maritime operations. In my current position, I’m responsible for overseeing tanker vessel operations so as to ensure smooth and safe management throughout the entire process. A key part of my role involves reviewing and checking CP (Charter Party) terms and negotiating with charterers to secure favourable conditions for the Company. I collaborate closely with the Chartering, Technical, and Purchasing Departments to ensure seamless coordination in scheduling, logistics, and maintaining compliance with safety regulations. I'm grateful for the opportunity to be part of this team and contribute to its success while continuing to grow professionally.

Andreas Chandris

I am happy to have been part of the Centrofin Family since 2011, mainly as a link in the Marine Operations chain. I started as an Operator for both Tankers and Bulk Carriers, and now I currently stand as Fleet Supervisor for the Bulk Fleet. Indeed, Operations has been my passion due to its difficulties, responsibilities and new daily experiences. Part of our daily routine as Operators is to organize the vessels next fixture and port calls, making each voyage as competitive as possible. Our Bulk Fleet Operators team has been growing over the past few years, which has elevated my job satisfaction because I always find it exciting to welcome the new vessels and Seafarers to the Fleet, while trying to make our Bulk Team one of the strongest. In 2018 it was with great joy that I became the Forum Committee Chairman, organizing the events along with a skillful team of people from Head Office and the CENMAR offices in other countries. This role has given me chances to be creative and communicate more with Seafarers of all rankings, and not only Senior Officers. I see with great joy that our Forum is not only a KPI target but an event that people seek to attend and be part of. This brings us the motivation to look for ways to take the events to a whole different level.

Maria Gonata

My name is Maria Gonata, known to most of you as MG.

My journey in the shipping world started back in 1995, when I was recruited by the Company in the Operations Department as Administrator. I will never forget the feelings I had the very first times, when every simple discussion between the master mariners in the office was completely foreign to me. However, every year my knowledge of the shipping industry grew along with my responsibilities. Some of my responsibilities are the following: •Follow up/update Danaos operation application •Purchase/follow up Charts - Publications •E-Books •Purchase/follow up sea stock Paints •Arrange and Follow up with Security Guards •Drug & Alcohol procedures

After three decades, I have felt thankful to be working for the Company, which is a significant part of my life.

And, of course, I will never forget my mentors, Captain Alexandros Stellatos & Babis Trantas who were always beside me, coached me and assisted me in gaining deep knowledge throughout the years I worked with them.

I am truly grateful to be part of the Company and greatly appreciate the collaborative efforts of both the office and onboard teams.

Wishing you calm seas, fair winds and safe voyages.

Hello to you all!

My name is Cpt. Efstathios Angeletos, I had the privilege of joining the company in December 2024 as a Marine Superintendent, overseeing the Bulk Carriers fleet. I hold a Master Mariner A’ class license and served as Master on board Panamax, Ultra-Handymax, and Supramax bulk carriers from 2018, demonstrating extensive expertise in the operation and management of these vessels.

As an accomplished maritime professional with extensive experience as a Master, I have successfully overseen vessel operations, managed diverse crews, and ensured strict compliance with international maritime regulations. Throughout my career, I have developed exceptional leadership abilities, mastered crisis management, and honed my skills in operational planning while thriving in challenging environments. These experiences and competencies have equipped me to transition seamlessly to a shore-based role, bringing valuable expertise and a dynamic perspective to the maritime and logistics industry.

As a Marine Superintendent, I am responsible for monitoring and enforcing safety policies to ensure full compliance with international regulations, including ISM, SOLAS, and MARPOL.I oversee vessel operations, managing cargo handling, navigation, and logistical processes to maintain efficiency and safety. Additionally, I coordinate and supervise maintenance activities to ensure vessels remain operational and reliable. My role also involves conducting regular ship visits and inspections, preparing for external audits by flag states and port authorities, and addressing any non-conformities with proactive solutions. Being part of this organization fills me with gratitude, as I greatly value the synergy between our office and onboard teams. It is through our shared commitment and teamwork that we consistently achieve excellence and uphold the highest standards in everything we do.

May every voyage be a safe and successful one.

Laura Kazazis

My name is Laura and I am lucky to have been part of the Cenmar family since 2018. As the daughter of a C/E, I have the thrill of shipping "running in my veins", as we say.

I am the Vetting Officer of the Company and closely collaborate with all Departments to ensure that vetting processes align with the overall safety protocols of the organization. I also liaise with Oil Majors to ensure that our Vessels meet the required criteria for selection.

I feel grateful to be working for this Company and being part of its growth and success, a common vision that I am sure that we all share.

Here's to the milestones yet to come!

Lucas Pikazis

Hello, my name is Lucas and as a dedicated IT engineer and a new addition to the Company, I bring with me a passion for continuous learning and problem-solving in the ever-evolving tech landscape. With a background in computer science and hands-on experience in various IT projects, I am continuously seeking opportunities to enhance my skills and stay updated with the latest technological advancements. My primary goal is to enhance expertise, tackle complex challenges, streamline processes, and contribute to innovative solutions that drive efficiency and performance. I am also committed to professional development and a proactive approach to overcoming obstacles in any tech-driven environment.

Wishing you all safe travels and calm seas

Is enjoying the sweet, simple things in life a key to happiness ?

1. Make the names of two Company vessels using all the letters in the following sentence: RING EL IN PADUA.

4. . Which six-letter word can be placed after the words to the left and before the words to the right?

2. The letters in the chemical symbols for astatine, boron, neon and strontium can be rearranged to form the name of a sea. What is the name of the sea?

3. Which three-letter word can be used to complete the following words?

ST_ _ _ Y, SH _ _ _ LINE, REST_ _ _ and F _ _ _ CASTLE

1. What does the ‘C’ in STCW stand for?

A. Competence B. Convention

C. Capability D. Certification

5. In 5 steps change the word POST to SEND by changing one letter at a time to form intermediate words.

6. What is the next number (X) in the following sequence? 2, 10, 24, 44, 70, X

A. carbon dioxide B. carbon monoxide

C. methane D. sulphur dioxide

2. Which port was forced to close for 7 days when Hurricane Sandy struck in 2012?

A. New Orleans B. Virginia

C. New York/ New Jersey D. Charleston

3. Which of these Company vessels was built in Japan?

A. M/V Guardian B. M/T Popi P

C. M/V Danae D. M/T Agios Nikolaos

4. What kind of vessel does the dangerous situation known as ‘girting’ involve?

A. a barge B. a tug C. a coastguard vessel D. a barque

5. Which gas will the EU Emissions Trading System be including from 1st January 2026?

6. During an emergency response, how should communication between the bridge and engine room teams be conducted?

A. with constant updates B. with a calm demeanour

C. in their mother tongue D. with only vital information

7. Which of the following waterways has the narrowest point?

A. Sunda Strait B. Malacca Strait

C. Magellan Strait D. Lombok Strait

8. According to informed estimates, approximately how many million pieces of plastic go into our seas every day?

A. 2 B.4 C. 6 D.8

On 28th 1973 Roger Mallinson, a 35-year old engineer and senior pilot formerly with the Royal Navy, spent most of the day repairing a broken manipulator on a Vickers Oceanics submersible called Pisces III. In addition to making the repairs, he replaced the oxygen tank with a full one.

During the early hours of the following day, Mallinson, accompanied by Roger Chapman, a 28-year-old pilot who had also served with the Royal Navy, began a routine dive. Their job aboard the submersible was to lay a section of transatlantic telephone cable about 150 miles (240km) southwest of Cork in Ireland. At the end of their uneventful shift, they headed for the surface, and at just after 9 am their submersible was in position to be raised onto a ship with a towline.

During the lift, a water alarm went off. It signalled a massive water ingress into the aft sphere after the towline had become entangled on the aft sphere hatch and opened it. At first, Pisces III sank about 160ft (47m). It was held briefly by the line but the excess weight of 1 tonne of water caused the line to snap. Then the submersible inverted and sank to the seabed at a depth of 1575ft (480m).

When Pisces III reached the bottom, Chapman and Mallinson had to organize themselves as the submersible was upside down. They estimated that they had about 64 hours of oxygen left and ensured there were no leaks. They realised they had to limit their movements to conserve their oxygen as much as possible. They also decided to let the CO2 concentration build up higher than normal so as to reduce the rate of oxygen consumption. This decision caused them to feel sleepy and lethargic.

Above the surface, the rescue teams were well aware that they were in a race against time. So, a coordinated rescue mission was organised. A company vessel, Vickers Venture, with another submersible, Pisces II, on board headed for the nearest port so that it could be flown to Ireland. The Royal Navy vessel, HMS Hecale, went to the location of the stricken Pisces III with special ropes on board. Assistance was provided by the US in the form of a Controlled Underwater Recovery Vehicle (CURV), and Canada dispatched a Coast Guard vessel called John Cabot that happened to be berthed in Swansea, Wales.

On the morning of 30th August, the Vickers Voyager arrived in Cork, where it loaded the submersibles Pisces II and Pisces V that had been flown in overnight. The vessel reached the rescue site in the early hours of 31st August. Pisces II was launched but the lifting rope detached from the manipulator arm and Pisces II had to surface to be repaired. The other submersible, Pisces V, also had to return to the surface as it ran out of power before locating Pisces III. A second attempt to locate the stricken submersible succeeded but there was an unsuccessful attempt to attach a rope. So, Pisces V stayed on the sea bed with Pisces III. Then another attempt to get Pisces II down had to be abandoned because of a leak. Even the US submersible had problems of an electrical nature that prevented a launch. At this point Pisces V came back to the surface.

Pisces III with Chapman and Mallinson aboard were now alone again. On board, their oxygen was running out and the system to remove carbon dioxide from the craft was not working efficiently. Both pilots developed severe headaches and felt very cold.

On 1st September, Pisces II was launched and a tow-rope was attached to the rear sphere of Pisces III. Then the CURV assisted by attaching a second towrope, and the lift began. During the 1st phase of the lift the CURV had to be disentangled from Pisces III, causing further delay. Then, at a depth of 100ft (30m), there was a second pause as divers attached heavier lifting cables to the submersible.

About 9½ hours after the rescue launch of Pisces II, Pisces III reached the surface, but this did not bring about a sigh of relief because there was still work to be done. Divers took another nailbiting 30 minutes to open the hatch so that fresh oxygen could replace the stale air in the submersible.

It was estimated that when the hatch was opened, there was only twelve minutes of oxygen left. The crew, Chapman and Mallinson, required assistance to exit Pisces III. Their exit marked the deepest successful submarine rescue in history. The story, which was plagued by setbacks, has been featured both on radio and television broadcasts as well as in books and magazines.

Sources: en.wikipedia.org, www.bbc.com/news, www.submersiblewrist.substack.com, www.newsweek.com