Dear seafarers,

Dear seafarers,

Unfortunately, COVID-19 is still playing a major role in determining the conditions under which we are currently working. This is reflected both directly and indirectly in some of the articles in this issue of Wavelength.

While the pandemic has had a negative impact on certain industries to such a degree that they are facing crippling losses, others have benefited from the so-called ‘new normal’. In the latter category, there are those that have reaped financial reward and those that have exhibited a high degree of resilience by recognizing the potential of placing an emphasis on the human element in these trying times. This has been borne out in the two SQE contributions which show how the Company’s response to the virus has mitigated feelings of isolation within our seafaring community.

The Safety First article clearly illustrates how some of the disadvantages of hierarchical structures, which are fundamental in shipping, can be overcome through a noblame culture and the ability of a ‘subordinate’ to draw attention to an unsafe work practice. These two features, among others, open new channels of communication that can break down detrimental barriers. The Company News section also shows the importance of communication with those on board to establish a rapport that strengthens relationships and acknowledges the invaluable contributions those at sea make day in, day out.

The Manning & Training submission highlights the issue of bullying and harassment that can be readily exacerbated under adverse conditions. Again, this insidious

problem can be confronted by raising awareness of how communicating and behaving inappropriately can harm others and how a defence mechanism can be implemented. At this point, it must be stressed that the Company had already embarked on a path to redefining relationships with and among our Seafarers prior to the pandemic through the introduction of ‘Goal Zero’, vessel visits and the adaptation of leadership to be as far away from authoritarian as possible.

The articles from both the Technical Department and Marine Operations focus on safety and how fundamental procedures in the engine room and on the bridge can never be compromised. Indeed, the second article points out how timely actions that are made possible by adhering to proper procedures can prove vital in protecting lives, property and the environment.

I would like to thank the new contributors, Dimitris Fakiris (Deputy DPA), Christina Toki (Technical) and Captain Athanasios Spanelis (Marine Operations) for their participation in compiling this issue. I would also like to express my gratitude to Cmdr Nicholas Iliopoulos, the founder and former editor of Wavelength for his contribution. The value he places on staying in touch with former colleagues and maintaining a relationship with the Company can only be described as admirable.

I sincerely hope you enjoy this issue of Wavelength. If you have comments, suggestions or questions regarding the content, please do not hesitate to contact me at comment@wavelength.gr.

Best wishes, Nick Seaman

Read about The Coral Sea on page 18.

Ten of the Company’s seamen were promoted during the second quarter of 2020. The list of promotees in chronological/ alphabetical order together with their vessels and promotion details is shown in the table.

Congratulations are due to all the promotees, especially in these most challenging of times.

John Evan

Erickson

Redentor

Gerico

Aditya

Yevhen

STOIAN Hryorii

Cherwin

We are delighted to welcome a new addition to our fleet. M/V DUKE (ex-BW EINKORN) is a kamsarmax bulk carrier built in Japan in 2010, and was delivered to her new owners at Manila on 24 September 2020. The ship marks the first bulk carrier

It should also be pointed out that the "THANK YOU!!" message on the cover of this issue is even larger this time around. This is intended to show that the gratitude the Company would like to express to all our Seafarers for their outstanding work ethic is as profound as ever, if not at an all time high.

addition since 2016, and will be trading worldwide. May we wish safe seas and good fortune to her Master Capt. Kole and his officers and crew.

Introduction

The Engine Room is a complex space accommodating the majority of the most crucial pieces of machinery for the vessel’s operation such as the main engine, diesel generators, boilers, air compressors, coolers and pumps. Taking into consideration that every part of the Machinery equipment is also intertwined with piping systems, tanks, cabling, lifting arrangements and various tools, it is evident that works in the Engine Room can prove challenging. Therefore, when planning and executing maintenance or repairs on machinery, the crew must always take into consideration all the safety guidelines provided by the equipment Makers as well the precautions based on the nature of the work to be done e.g. welding, electrical works etc.. The following guidelines include crucial points to ensure safe and efficient work for machinery-related items onboard.

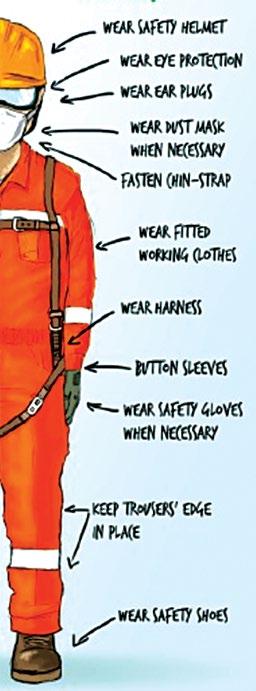

Maintenance jobs shall be carried out exclusively by qualified personnel using the necessary Personal Protective Equipment (PPE). Attention must be paid to the following:

• Safety shoes, hearing protection, work gloves and protective headwear must be worn when there is risk of falling objects, loud noises and sharp edges or oily surfaces.

• Safety googles must be used when working with compressed air, hydraulics and grinders, or when there is risk of getting foreign objects in the eyes.

• A fall protection harness and arrestor equipment is recommended when working in places on the engine where there is risk of falling or slipping.

• Gloves made of neoprene or PVC shall be used when removing O-rings and other rubber/plastic-based sealing materials which have been subjected to abnormally high temperatures and may have a caustic effect when touched directly.

• Jewelry, wrist bands or rings must be removed before work as these can put the worker at risk, especially when working with rotatory tools or performing electrical work.

• When working in groups, always discuss the procedure, action plan and hazards of the jobs prior to initiating the work.

By Christina Toki

In all cases, without exception, please consult the PPE Matrix that is included in FIM, with instructions on what PPE is required for each task. Also, never forget two of the strongest tools you have to stay safe during work: the Daily Work Planning Meeting (DWPM) and your LMRA cards (doing your Last Minute Risk Assessments BEFORE commencing any task). Follow them wisely and consistently, and stay safe!

b) Special Dangers

A number of situations may lead to risk of serious injury to the body. The following recommendations must always be observed:

- Opening cocks may cause discharge of hot liquids or gases

- Dismantling parts may cause the release of springs

- Do not stand near turbochargers in case of any abnormal running

- Do not stand near crankcase doors or relief valves nor in corridors near doors to the engine room if an alarm is set off for:

• oil mist

• high lube oil temperature

• no piston cooling oil flow

• or a scavenge box fire

c) Cleanliness

The engine and engine room must always be kept clean, with floors and surfaces free of oil, soil and dirt.

• Gloves must always be used when working on or near hot surfaces.

• All crew members must ensure that their uniforms are clean, dry and properly cover the whole body.

Oil spills shall be immediately removed and oily rags shall be collected and stored by the crew to avoid risks of accidents due to slippery floors and fire incidents.

The exterior of the engine should be kept clean, and the paintwork maintained so that leakages can be easily detected. Bilges are to be painted a light color to assist in visually identifying a fresh leak and their chemical cleaning is to be completed periodically.

Preventing oil leaks is one half of the problem; the other being effective cladding or shielding of hot surfaces so that they do not present a source of ignition if an oil leak occurs. It is a SOLAS requirement that surfaces, which are at temperatures above 220°C that might come into contact with oil as a result of system failure, are properly insulated.

If there is a risk of grit or sand blowing into the engine room, stop the ventilation and close the ventilating ducts, skylights and engine room doors.

Welding or other work that causes the spread of grit and/ or swarf must not be carried out near the engine unless it is closed or protected and the turbocharger air intake filters are covered.

i. Fuel leaks

According to reports, approximately 50-60% of engine room fires are attributed to fuel leaks. Loosening joints, fractured pipes and mechanically damaged pipes on both high and low pressure fuel lines, pipe unions that are over or under tightened, the use of unsuitable seals or gaskets which deteriorate due to the effects of heat are some of the reasons that trigger an oil fire.

To avoid oil spraying on hot surfaces and electrical installations, the flanged connections must be guarded using anti-splashing tape.

In the case of the anti-splashing tape being temporarily removed for maintenance or repair, it must be reinstalled upon the completion of the relevant work.

The crew must regularly check the integrity of the insulating materials and rectify any gaps identified. Significant attention shall be paid to equipment of complex design such as turbochargers or bents and flange joints on pipelines. For those areas, routine surface temperature measurements are also suggested. Insulation contaminated by oil or other flammable products must be renewed and insulation removed during maintenance must always be fully restored.

Welding shall be carried out only after ensuring that there are no naked lights and no explosive gases, vapors or liquids present in the engine room. The surrounding area must always be inspected prior to welding to make sure that no flammable item is in the vicinity.

Before carrying out any kind of hot work, make sure that the hot work checklist and risk assessment forms have been duly filled. It is of the utmost importance to ensure that the requirements in FIM Chapter B for hot work and entry into enclosed spaces (if applicable) have been followed, including obtaining the required authorization and issuance of permit, be it from the shore management or on board according to the relevant matrix. All safety procedures must be strictly followed while carrying out such jobs in enclosed spaces.

Attention is also drawn to the danger of fire when using paint and solvents with a low flash point. Porous insulating material soaked with oil from leakages is flammable and should be renewed.

Before engaging the turning gear, make sure of the following:

1. The starting air supply is shut off.

2. The main starting and slow turning valves are blocked.

3. The indicator cocks are open.

The turning gear must be operated by the remote control and only by the person working on the engine. The remote control should always be kept in optimal working condition and any fault in the device or cable must be rectified before use.

Warnings must be given before each turning. Operation of the turning gear from the switchboard must not take place while maintenance work is in progress inside the engine.

11: Guidelines for engaging/ disengaging the turning gear must be thoroughly followed.

When the turning gear is engaged, check that the indicator lamp ‘Turning gear in’ has switched on. It is also suggested that warning placards with the words ‘Turning gear engaged’ are made and hung at all maneuvering stations whenever the turning gear is engaged, irrespective of whether the safety devices are functional. These placards should be removed only after disengaging the turning gear.

If the crankcase is opened before the engine has cooled down, welding and the use of naked flames will result in the risk of explosions and fire.

Prior to entering the crankcase, the crew must check that the starting air supply to the engine and the starting air distributor are shut off and that the main starting valve is locked. Before entering, ventilate the crankcase for about 30 minutes after stopping the engine.

When working in the crankcase, a safety harness and fall arrestor equipment is strongly recommended.

The turning gear should always be operated exclusively by the personnel who enter the crankcase or cylinders. Work in the crankcase is a minimum two-man job and requires good communication that must be maintained at all times.

Prior to any use, lifting appliances/tools must be visually inspected for cracks, corrosion, excessive wear, loose fasteners, deformations and damage.

Unidentified or damaged tools and tools not clearly marked with Safe Working Load (S.W.L.) or Work Load Limit (W.L.L.) must not be used.

Figure 14: The S.W.L. must not be exceeded under no circumstances.

When using lifting appliances make sure the following guidelines are taken into consideration:

Table 1: Guidelines for planning & executing lifting operation

1 Keep clear of the space below a crane with load.

2 Never exceed the lowest Safe Working Load (S.W.L.) of the lifting equipment in the lifting chain.

3 Plan lifting of engine components through all steps of the lifting procedure.

4 Only use designated lifting points.

5 Use tackles between the engine room crane and component, when lifting loads below 500 kg.

6 Make sure the lifting attachments are tightened into full contact with the component to be lifted.

7 Make sure to attach the load correctly on the crane hook.

8 Keep the lifting equipment clear of sharp edges.

9 Carefully inspect the wire rope before starting the work and identify any defects.

Wire ropes must not be used when the following defects are identified.

15: When wire rope defects are identified, no lifting operation shall take place.

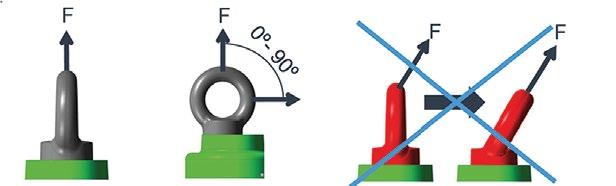

When using chain tackles , be aware of the lifting angle.

When using hooks , keep in mind that only hooks with safety latches are allowed for lifting.

When using eye screws/eye nuts , be aware of the loading direction, as lateral loading is prohibited.

h) Electric Shock Hazards

Electric shock is the physical stimulation or trauma caused by the flow of electricity through the human body that can occur during contact with or by being near live (energized) electrical parts.

Electrical Shock hazards may occur due to:

• Defective electrical tools: Untrained or unqualified personnel attempt electrical power connections

• Improper electrical phasing: Damaged wire insulation as a result of hot work processes

• Corroded connectors: Attributed to saltwater intrusion or contact

• Worn or frayed electric cables: Inadequate electrical isolation, failure to test for de-energization, and improper lockout/tags-plus application

• Electric cables pinched in hatches/doors: Tools and equipment not properly grounded

• Electric cables struck by grinders/saws: Blind-side drilling into electrical conductors

An electric shock can occur without direct contact with electricity and is the predominant root cause of burn injuries

Safeguards against common causes of electrical hazards are:

1. Using appropriate PPE (rubber gloves, rubber boots) and using appropriate insulating rubber mats when required

2. Testing and regular maintenance of equipment

3. Regular testing of overload devices

4. Checking that insulation is in good condition

5. Checking connections are made properly

19: Always wear protective clothing, rubber gloves, rubber knee pads and safety shoes to avoid risk of shock.

Further instructions on the use of PPE for Electrical hazards can be found in FIM Chapter B.

i) Alarms

It is important that all alarms lead to prompt investigation and remedy of the error. No alarm is insignificant. Never cancel an alarm (even a repetitive / annoying one) without first investigating it thoroughly and establishing for yourself the

actions to be taken. Always remember that Risk Normalization is to be avoided, and cancelling alarms without checking is a common mistake – it has to stop! The most serious alarms are equipped with slow-down and/or shut-down functions. It is, therefore, important that all engine operation personnel are familiar and well- trained in the use and importance of the alarm system.

j) Lighting

Ample working light should be permanently installed at appropriate places in the engine room spaces, and portable working lights should be obtainable everywhere.

24V safety lamps must be available for use inside the engine.

Figure 20: Working lamps to be properly stored for cable protection

k) Storing and Securing

Large spare parts should, as far as possible, be placed near the area of use, well secured and accessible by crane. Under no circumstances should the engine parts be stored on engine galleries while the engine is running.

All spares should be protected against corrosion and mechanical damage. The stock should be checked at intervals and replenished in good time.

If paints and thinners are carried onboard, they should be stored in their original container, protected from direct sunlight in a dry, cool and well ventilated space, away from incompatible materials, hot areas and exhaust gases or vapours.

Hand tools should be securely fastened and placed on easily accessible tool panels. Special tools should be securely fastened close to the area of use in the engine room.

Oxygen and acetylene bottles must be stored outside the engine room and accommodation areas. They must not be stored together but kept apart and securely lashed. Lockers containing gas bottles must be properly identified and marked accordingly.

Conclusion

Nobel Prize winner poet Pablo Neruda introduced us to his poem titled ‘The Sea’ with the verse saying ‘I need the sea because it teaches me, I don’t know if I learn music or awareness’. And even though music is an enjoyable companion of many seafarers, awareness is an imperative necessity in order to safeguard human life and the integrity of the vessel.

It is essential to apply the same watchkeeping principles either for en route navigation or when the ship is anchored according to the Company’s Safety Management System. Constantly monitoring the surroundings of the vessel drastically decreases the risk of collision in today’s ever congested anchorages. Serious accidents, collisions or groundings can be avoided with the following practices:

By

- Having a proper lookout who relies on all senses (visual scanning @ 360 degrees, hearing, feeling, even smell)

- Consulting all the available electronic aids (radar, AIS, radio traffic etc.)

- Constantly monitoring the position of the vessel to determine the onset of any dra

- Closely observing the movements of other vessels

- Ensuring that the watchkeeping officer is able to immediately call upon a lookout, e.g. in the case of deteriorating visibility

- Calling for help. Do not hesitate to call the Master when the operating conditions are deteriorating

- Having well-rehearsed contingency plans for weather deterioration or imminent collision

- Having watchkeepers properly rested, according to rest time requirements, so that they have a clear mind and exhibit resilience during an incident

- Fully concentrating on Watchkeeping and avoiding any form of distraction like paperwork

- Avoiding complacency is imperative. Casualty records show that humans underestimate the potential consequences of developing situations. Accident studies demonstrate that signals and indications that something wrong is happening are constantly ignored by watchkeepers. Recognising and appreciating such signals and indications is the first step towards avoiding a casualty.

If another vessel is approaching on a collision course and avoiding action cannot be taken,

• a warning must be given immediately – light and sound.

• the engines must be brought on standby.

• the Master must be called.

• the anchor crew has to be mustered.

To illustrate the above and give emphasis to the importance of maintaining a proper lookout at all times, we would like to

M/T CE-Niriis was safely anchored at Hong Kong South Lamma Dangerous Goods anchorage, laden with 101,778 tons of fuel oil. An oil products tanker of 47,278 mt DWT, also in laden condition, was anchored nearby M/T CE-Niriis.

On the afternoon of August 22nd, the 47,278 mt DWT tanker commenced heaving up her anchors in order to leave the anchorage.

The Master of CE-Niriis, who was on the bridge at the time, observed that there was neither any trace of smoke from the funnel of the 47,278 mt DWT tanker nor any propeller wake.

Once both of her anchors were in secure position, it was noticed that the 47,278 mt DWT tanker was approaching CENiriis due to the strong prevailing current. Apparently, the Main Engine of the 47,278 mt DWT tanker was not operational and the vessel was most probably facing a black out.

The Master of CE-Niriis acted swiftly:

- The crew was alerted and placed on standby.

- The anchor crew mustered to heave up the anchor.

- The engine was started.

- The Hong Kong Marine Department was notified about the developing situation.

- Suitable evasive manoeuvres were carried out (engine to Half Ahead, steering wheel to Hard Starboard).

- The vessel was re-anchored safely.

A collision between two laden tankers with all the possible grave consequences was avoided due to the following factors:

- There was a proper lookout and early recognition of a developing situation.

- Clear orders were given by the Master of CE-Niriis to his crew.

- The well-trained and resilient crew acted promptly and effectively.

- All the essential ship's equipment operated as required in this emergency situation (diesel generators, main engine, windlass, auxiliary machinery), which was a result of proper maintenance procedures and sound technical management.

We would like to take this opportunity and congratulate the Master of M/T CE-Niriis, Captain Dimitrios Dimarakis, and his crew for their continuous efforts, excellent seamanship, alertness and resilience despite the serious current challenges of COVID-19 pandemic and security issues in piracy infested waters.

During April 2020 the first Health & Safety Campaign (01/2020) was forwarded to all vessels of the fleet on the topic of Bullying and Harassment. The campaign lasted until 31/5/2020, when all vessels submitted their evaluation, with comments and suggestions. The Health & Safety Campaign was received with enthusiasm and was rated with a grade of 4.7 (5 being the highest score). Therefore, it was considered a successful campaign. It was explained that bullying and harassment at sea can have serious consequences for the physical and emotional health of a ship’s crew, such as decreased motivation, increased absenteeism and a fall in productivity . What is more, bullying and harassment can also have negative effects on the companies themselves, resulting in a deterioration of working conditions with huge organisational, economic and potential legal consequences, too.

By Chara Markatzinou, Training Coordinator

Given the serious consequences of bullying and harassment, it is shocking that according to research carried out by Nautilus International, almost 50% of seafarers have personally experienced bullying, harassment or discrimination at sea: this is a common problem

Harassment and bullying can take a wide variety of forms, ranging from verbal aggression, ill-treatment, cyberbullying or sexual discrimination through to various forms of physical aggression resulting in serious injuries.

The Seamen were requested to share their own experience, if any, and provided that they felt comfortable to do so, and to discuss the contents of the campaign during the health and safety meetings held on board.

Bullying and harassment were defined, and their characteristics as well as practical examples were presented to our Seamen on board. What is more, the Seamen were also introduced to the notion of mindfulness and were presented with various mindfulness techniques (i.e. breathing) as a means to cope with bullying and harassment episodes.

It was reported by a series of vessels that the specific campaign had raised the Seamen’s awareness on more flexible ways of communicating with others. The Officers and crew on board were reminded that everyone has the right to be treated with dignity and respect. Moreover, there was a request by most vessels to provide them with more information on mindfulness as well as how to practise mindful techniques. So as to cater for this specific request, the second Health & Safety Campaign, which was launched in May 2020 and was titled Steps to Positive Mental Health , included among other information, training on mindfulness as well as 1-minute mindfulness exercises, mindfulness techniques for anger, anxiety and addictions (i.e. smoking, sugar, etc.). All vessels of the fleet also received a DVD with useful videos regarding mindful breathing and meditation. Shortly, when the specific campaign also concludes, we will revert with a brief review of it.

Bully-Bullied illustration showing how bullying behaviour can be offset by a person’s superpowers of self-love, love, meditatio n and mindfulness.

The following is an extract from the writings of Don Miguel Ruiz, which can provide a further way to mitigate any negative effects of bullying in addition to the protective superpowers in the diagram: Give us the courage to love our family and friends unconditionally, and to change our relationships in the most positive and loving way. Help us to create new channels of communication in our relationships so there is no war of control, there is no winner or loser. Together let us work as a team for love, for joy, for harmony.

Since the beginning of 2020 COVID-19 has been in our lives, testing our endurance and changing our way of living. As the world was not prepared to deal with the virus, our only weapons were our personal hygiene, through washing hands, using specific protective equipment and social distancing. During the first few months, it was difficult for everyone to comply with the new requirements and specific procedures that WHO, flags and other national organizations had set in place. This was, and still is, especially the case for the crew members on board our vessels, who are trying to continue their hard work through these difficult times.

By Dimitris Fakiris, Deputy DPA

Now after eight months, we can share with confidence that with your efforts, we have minimized the number of virus cases on board our fleet. With the Company's Outbreak Management plan and your personal endeavour to adapt the vessels in order to comply with the latest requirements for COVID-19, you showed to all of us that with personal responsibility, it is

possible to be protected against the Coronavirus. As a Company, we would like to thank you for all of your efforts and make an earnest request for you to continue complying with the COVID-19 restrictions, to protect yourselves on board, to familiarize the new crew with the precautions, and to continue being an example for each and every one of us.

Finally, we wish to add that we had great feedback from many of our crews regarding the Company’s attitude towards this unprecedented virus.

One of the best quotes that should represent our mental state is the one received from Bosun Eric Sibulo on board M/T Merbabu:

“Think positive, stay negative!”

Dear seafarers,

Having been a member of a shipping company for a number of years, I have come to realize that learning how work is done onboard is very difficult. Work as imagined and work as done are not the same. Seafarers are the experts onboard and the written systems and procedures are only a mirror of their successful work. And here comes the oxymoron: “The higher up and the further away you are from an awareness of workplace hazards – the lower down and the further away you are from influencing the work systems”.

So, can these systems protect you? If your expertise feedback is available on how to improve the processes and what safeguards are needed, then yes!

On the other hand, learning your work systems is your most powerful tool for safety & reliability, but it is something that takes effort. The enemy of learning is knowing – when you think you know a task, you will not ask important, relevant questions. Be curious, be smart, be humble.

Waiting for failure to occur is too late – learn while operations are normal.

But failures at some point are inevitable... Error is normal. People make mistakes; they are not machines. We all need to strive for a work environment where it is safe to fail and learn. This can be achieved by asking what failed instead of who failed.

Sometimes we think we can fix the problem by fixing the person who failed by blaming them. But blame is the opposite of encouragement. No one can improve in this way because mistakes are not choices and errors are not a conscious decision to fail –error is an unintended deviation from an expected outcome.

The Company’s NO BLAME culture is something that we all need to work on and constantly try to improve. As a result of this effort, we have launched our recent campaign: changing SWA to SWO. Changing just one word? Can Authority becoming Obligation actually make a difference? Words are powerful and it’s important for us all to be aware of how we use them. Using the right words, being clear, positive, polite and humble, not only improves communication but also safety. Such a seemingly small change can have a tremendous impact on your onboard relations.

NO BLAME behaviour always starts at the top, it encourages good relations and creates clear lines of communication:

• Leaders of all levels shape how the organisation learns by their reaction to failure. All eyes are on them.

• Be ready to receive feedback even when it is bad.

• Communication at all levels is important and it can only be achieved with good relationships.

• If you don't know what's wrong, it can't be rectified.

ALWAYS REMEMBER: You can blame and punish or you can learn and improve, but you can't do both

I wish you calm seas and safe voyages, Elli Moretti

We wish to thank ALL fleet vessels for embracing Health and Safety campaigns and for providing feedback of their onboard implementation with such enthusiasm! As there is no space to address each and every one of you separately for your efforts in the SWO campaign, this time we chose M/T MIKELA P

So thank you Cpt. Leonid Yelenchu k for sending us this great “time out” photo!

A Japanese bulk carrier that ran aground on a reef in Mauritius last month threatening a marine ecological disaster around the Indian Ocean island has broken apart, authorities said on Saturday.

The vessel struck a coral reef on July 25, spilling about 1,000 tonnes of fuel oil and endangering corals, fish and other marine life in what some scientists have called the country’s worst ecological disaster.

The press revealed that the 58-year-old captain of the ill-fated newcastlemax Wakashio could face negligence charges after it emerged the crew were celebrating a crewmember’s birthday and had headed nearer towards the Mauritius coastline to get a wifi signal just prior to the bulk carrier’s grounding on the reef!

The Flag Administration, Panama Maritime Authority, had earlier suggested the ship ran into difficulty because of bad weather, although data providers have shown there was no inclement weather around southern Mauritius at the time of the accident.

Thereafter, Panama Maritime Authority’s preliminary investigation into the grounding of the bulker vessel Wakashio off Mauritius says it deviated from its course to pick up an internet connection relating to an onboard celebration. The Panama authorities say the statement is ‘not designed to apportion blame’.

Keep your Behavoural Barriers STRONG!

Barriers prevent the Hazard from becoming an Incident

When all your barriers don’t work properly at the same time... the holes line up... then the hazard passes through and results in an incident!

TRUST:

T EN Really Useful Safety Tips PROMOTE YOUR MENTAL HEALTH!

This is as much as the seafarer can do for themselves. Always pay attention to the signals your mind and body are giving you and ask for help if you are in a crisis situation. Your safety is the number one priority.

1. Socialize: Take time for regular tours round the ship and have informal chats. Spend time with others and participate in the social life onboard.

2. Don’t keep problems to yourself: Share your problems with a person close to you, on board or ashore. If you feel lonely, reach out to others, do something together. This can give anyone a sense of time out and can be a good distraction.

3. Do not neglect the importance of physical wellness:

-Eat well: A healthy diet is the A and Z to a sense of wellbeing.

-Get a quality sleep: Set an alarm at a regular time each day, avoid the computer when you go to bed, and use your bed mainly for sleep.

-Exercise: Exercise can clear your thoughts and get you into a better state of mind to deal with your problems.

4. Identify the source of your stress: Make a list of the things worrying you or talk them over with someone you trust to identify the main causes of stress. Then plan your action.

TRUST: Ten Really Useful Tips STRONG Behavioural Barriers

1. Chronic Unease: worry about what can go wrong

5. Engage with others in a respectful way: A key component of wellbeing is a harmonic coexistence with others. Be respectful and this respect will be reflected back. If there are any problems, deal with them as soon as possible. Do not tolerate bullying and harassment.

2. Avoid complacency: do not let your guard down

3. Observe differently: spot weak signals.

6. Do not underestimate the impact of details: You may feel broken down, but even small things like having an open door to your cabin or watching a movie in the common areas can make a difference to your mental health after a while.

4. Situational Awareness: be aware of your surroundings

7. Be present: Train yourself in the practice of mindfulness meditation to bring attention to whatever is happening in the present moment. This helps you to manage your stress and find inner peace.

5. Safety Intervention: act during unsafe situations

8. Take initiatives: Encourage social activities on board, don’t wait for others to think of all the good ideas!

6. Alert others to follow safe practices

7. Adopt a no blame behaviour

9. Take care of others: Reach out to any of your colleagues who seem to be feeling down. Even the smallest act can count, whether it's a smile, a thank you or a kind word.

8. Teamwork: Proper DWPM and tool box talks are vital.

10. Remain vigilant: Look out for the warning signs in yourself and others. The following factors may indicate a mental health problem:

9. Don’t be afraid to voice your opinion.

• Changes in behaviour or mood

• Changes in effectiveness at work

• Inability to focus/make decisions

• Changes in eating habits

10. Show that you care when someone is having a hard time.

• Use of alcohol/ drugs.

Welcome to yet another Nostalgia article! We hope you enjoy the journey into the past and that it motivates you to recall your experiences and share them amongst your colleagues in order for them to live on.

In this edition, we will start off with the engine room and take a look at some photos of our team of technical superintendents on board during dry dock repairs back in the day. Then we will take a look at one of our previous vessels in the Company’s fleet, which justifies the motto “impossible is nothing”.

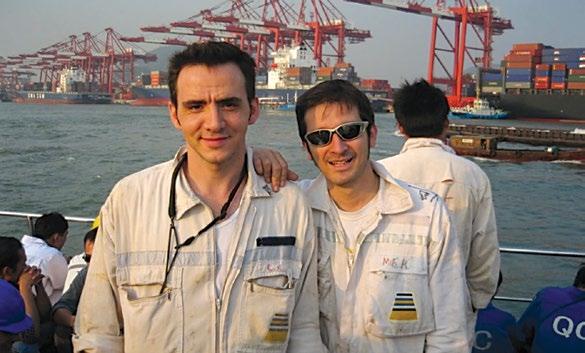

So let’s start off with some photos taken during 2007. These are of the dry dock/ conversion to double hull carried out on board the m/t CE-Ulsan at Shekou, China. Shown right are superintendent engineers, Mr. Michalis Maritsas and Mr. Christos Kartsonas, in their early years with the Company on the morning service boat, excited to be participating in the dry dock works of the CE-Ulsan.

The CE-Ulsan was an aframax tanker, originally 115k deadweight, built in Hyundai Heavy Industries, Korea in 1990. She was one of the largest aframaxes of her era. She joined our fleet in 2004 and was sold in 2012. In the meantime, she was converted to a double-hull tanker with a reduced deadweight of 107k.

They may look like the ghostbusters but in fact, they are the "repair-busters", our team of superintendents, Mr. Yannis Fassoulis (ex super/nt eng), Mr. Christos Kartsonas (super/nt eng), Mr. Christos Chatzigiaksoglou (super/nt eng) and Mr. Paul Birleanu (super/nt eng).

Below, the director of Marine Operations, Mr Michalis Kapsorrachis, Marine superintendent, Captain Yannis Papageorgiou and superintendent engineer, Mr. Christos Kartsonas, are working in adverse weather conditions but still enthusiastic.

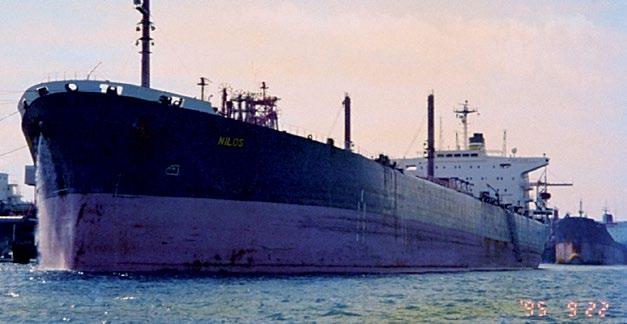

Moving on,let us take a closer look at m/t Nilos, a 89k dwt single hull aframax tanker, built in Imabari, Japan in 1981.

Bonding over lunch after a hard day’s work!

From left to right : Mr. Paul Birleanu (super/nt eng), Mr. Yannis Fassoulis (ex super/nt eng), Mr. Antonio Magtagol (C/E), Mr. Andaya Zosimo (ex C/E), Mr. Christos Kartsonas (super/nt eng), Captain Andaya Emeterio (ex Capt, the most senior Master of the Company at the time and the first Philippino Master to take command of a Company vessel - M/T APNOIA in 1996), 2/E, Mr. Antonio Magtangol (C/O) and Mr. Mei – Ship Repair Manager.

She was sold and converted to a semi-submersible heavy load carrier in 2006, and is still active today at the age of 39!

Let’s see if you can guess who this charismatic, young, safety cultured girl is.

Find the answer on page 19.

F inally, don’t forget that we depend on your participation to provide past photos of your adventures at sea! So, keep sharing your collection of photographs by e-mail to contact@ wavelength.gr. Make sure you add a note for each photo, stating the name of the ship, date, location and the names of any seafarers in the photo. Looking forward to seeing you in the editions to come!

Calm seas and safe travels,

The 99-year-old four-masted steel bark Sedov is sailing home by an unusual route. She is sailing North from Vladivostok and transiting the Arctic by the Northern Sea Route to reach her home port of Kaliningrad. Crossing the Arctic will be the culmination of a grand voyage of more than 25,000 nautical miles sailed by the Sedov since November 1, 2019.

“Following a detailed study of possible alternatives for the bark’s continued sailing, we consider it relevant to propose that the Sedov completes its expedition with a voyage across the Northern Sea Route from the east to west,” said Ilya Shestyakov, the head of Russia’s Federal Agency for Fishery, which operated the ship. “We believe that such a voyage will have a great symbolic and practical effect.”

Itis widely believed that Moussaka originated as a result of Arabs bringing the eggplant/aubergine to the Mediterranean region. It was a significant introduction, not only because it led to the dish that has become synonymous with Greek cuisine but also because eggplants have a wide variety of nutritional benefits. Firstly, they are high in fibre and low in calories. Secondly, they contain important minerals in fair quantities such as manganese, potassium and iron as well as traces of magnesium and copper. Thirdly, they possess vitamins K, C and B6 together with high levels of antioxidants.

Initially, the dish appeared in Greece in the form of a baked casserole, and it continued to be served in this way for about 100 years. Then, in the 1920s, Nikos Tselementes, a Greek chef from Sifnos who has to become known as the moderniser of Greek cuisine, made some changes to the dish. These changes allowed Greek cuisine to embark on its own path without being constrained by Turkish influences. Moussaka became strongly layered, allowing

The ship is expected to reach its homeport of Kaliningrad on November 15 this year. On its Arctic expedition, the vessel is due to visit the ports of Pevek, Sabetta, and Murmansk. It is also expected to make a halt in the archipelago of Novaya Zemlya. An icebreaker will accompany the ship to ensure its safety during its voyage through the Arctic.

Sedov was built as the Magdalene Vinnen II in 1921. She is one of the largest traditional sailing ships in operation. Today, Sedov is a sail training vessel, training cadets from the universities of Kaliningrad, Saint Petersburg, and Astrakhan, Russia.

Traditional Greek Moussaka Courtesy of: www.mygreekdish.com

it to be served in distinct portions rather than as a kind of ‘stew’. Although there are several layers, there are two distinct sections: the bottom part centred around the sliced eggplant and the topping consisting of béchamel. Ingredients include lamb or a mixture of lamb and beef mince, onion, garlic, oregano, mint, bayleaf, cinnamon, chopped tomatoes, salt, olive oil and, of course, eggplants. To cater for vegetarians, chefs can replace the meat with a mushroom-based sauce. As regards the béchamel, this is made from unsalted butter, flour, milk, salt, egg yolks and cheese. Moussaka, served in its modern form thanks to chef Nikos Tselementes, may be regarded as a symbol of Greek independence from occupying forces. It may also be viewed as a Greek dish that has been elevated to international cuisine with award-winning restaurants in such countries as the USA, Australia, Singapore, Israel and Hungary serving it to discerning diners, and onboard cooks serving it to hungry seafarers on the high seas.

Sources: www.theculturetrip.com, www.tasteatlas.com, www.bonapetit.com, www.onedishcloser.com

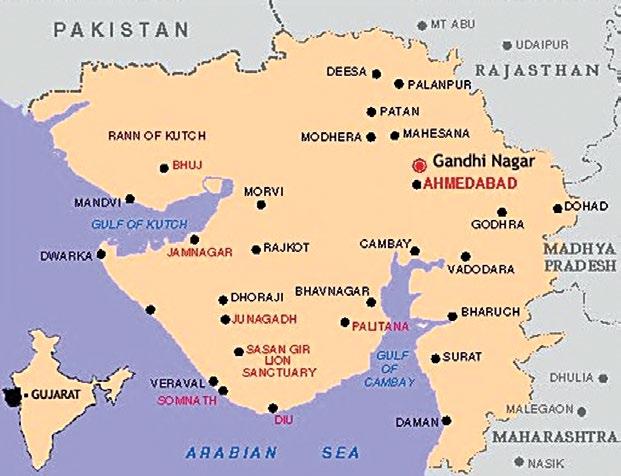

M

andvi, which was founded by Rao Khengarji I, King of Kutch, in the late sixteenth century, is now the dhow building centre in India. At the time of its establishment, Mandvi was ideally located to become a thriving port. Facing the Sea of Oman on the Gulf of Kutch, Mandvi lay on the intersection of the spice and camel caravan routes. Therefore, it was inevitable that its access to West Asia and Africa together with its proximity to these two great trade routes would lead Mandvi to gain prominence as a maritime link. As such, Mandvi was home to a large majority whose livelihoods were dependent on mercantile, sailing and boat-building activities.

By all accounts, Mandvi became more and more prosperous as both exports and imports increased. Indeed, by the eighteenth century, Mandvi merchants operated about 400 vessels that sailed on trade routes with East Africa, the Persian Gulf and the Malabar Coast in India. The burgeoning maritime trade bode well for the boatbuilding activities that took place on the banks of the River Rukmavatu, which flows south through Western Gujarat. Nowadays, however, Mandvi’s importance as a port has diminished greatly, but its 400-year-old dhow building tradition lives on despite the order books being much thinner.

Building materials and methods have changed somewhat over the centuries, yet there are some practices that have not altered. First and foremost, the basic construction material, wood, is no longer the same. Once sourced locally, it is now imported from Malaysia. More specifically, the timber used nowadays is ‘sal’ wood (Shorea robusta), which is an ideal choice due to its durability and water resistance. The first step in any dhow building project, which is overseen by a senior craftsman and requires some 30 labourers working for around two years to complete, is the laying of a single curved beam of approximately 20m in length.

Around the base of the hull or spine, bent ribs are attached. To these, long planks are fixed from stem to stem using steel bolts. The woodwork is often accomplished by cutting, planing, chiselling and drilling by hand, although power tools can be used whenever necessary. As regards the steel bolts, these have replaced the original hand-forged iron spikes that once

held the ships together. Making the dhows watertight is still a traditional process in which thin cotton cord is soaked in oil before being wedged into the seams between the planks with a hammer and chisel.

wood using long steel bolts.

Source: www.caravanmagazine.in

The dhows built at Mandvi range in capacity from 300 to 1500 tonnes with the majority falling in the higher categories. The largest can reach four storeys in height and require a crew of around thirty to operate them. Unlike the dhows of the past that relied on their lateen sails for power, modern ones are towed out at high tide into the Gulf of Kutch and then to dockyards on the Arabian Penninsula to be fitted with diesel engines and registered by the buyer.

So far, boatbuilding at Mandvi has survived many challenges. Fortunately, today there are still buyers, many of whom are from Dubai, willing to maintain demand. Additionally, the traditional building methods still used in the construction of dhows have attracted a few tourists who wish to witness firsthand, skills that have been handed down for generations and that continue to provide livelihoods for the artisans of Mandvi.

Sources: www.caravanmagazine.in, www.visura.co, www.gujarat-travels.com www.economictimesofindia.com, www.travelswithsheila.com

The Coral Sea is a sea of the south-west Pacific Ocean off the east coast of Australia. Extending 1400 miles (2250km) from north to south and around 1500 miles (2414km) east to west, this unique sea has an area of some 1,850,000 square miles (4,800,000 square km). The Coral Sea merges with the Solomon Sea to the north, the Tasman Sea to the south and is connected to the Arafura Sea via the Torres Strait. North of latitude 20oS the sea floor is abundant with coral. This area is called the Coral Sea Plateau. As regards depth, this reaches 24,002 ft (7,316m) in the South Solomon Trench and 25,134ft (7,660m) in the New Hebrides Trench.

The Coral Sea, which incorporates the Great Barrier Reef that extends 1200 miles (1900km) down the Australian coast, is universally recognised as a region of astonishing biodiversity. It encompasses 49 different habitats that support more than 300 threatened species and are home to endangered species, including hawksbill and green turtles, several species of whales and dolphins together with 27 species of seabirds. The richness of marine life also attracts large predators like sharks, tuna, marlin, swordfish and sailfish, some of which provide jobs for those tourists who visit the area for its renowned sport fishing.

It has long been obvious that the Coral Sea’s biodiversity is unique and exists because a delicate balance has been preserved. In 1981, the Great Barrier Reef was added to the World Heritage List, and nine years later the IMO designated this amazing ecological site as a particularly sensitive sea area (PSSA), thereby recognising the area’s vulnerability to the potential negative impacts of international shipping activities.

With hindsight, it could be claimed that these two landmark moments formed the basis of all the work that has been done to conserve the biodiversity in the Coral Sea while allowing for the sustainable use of natural resources wherever possible. The accomplishment of this aim bears testament to the cooperation between the Australian Government and the IMO. Over the years the former has defined the Coral Sea Commonwealth Marine Reserve, an area covering approximately 382,180 square miles (989,842 square km), passed the Biodiversity Conservation Act (1999) and formulated a Management Plan (2014), taking into account the social, cultural and economic values of the Coral Sea. The latter has introduced Associated Protective Measures within the Great Barrier Reef, including compulsory pilotage in the northern part of the Reef inner shipping route. Furthermore, in 1997, the IMO approved a mandatory ship reporting system to reduce the probability of navigational errors.

Both the Australian Government and the IMO have followed closely activities in the area and have taken proactive measures to strengthen their commitment to minimizing potential environmental impacts on the sensitive areas in the region. Stringent management of shipping activities has been introduced by a collaboration among the Great Barrier Reef Marine Part Authority, the Australian Marine Safety Authority and Safety Queensland. For their part, the IMO has imposed additional protection measures to mitigate the risks posed by an increasing volume of marine traffic. These include a 2015 extension of the area covered by previous measures to encompass another area of the south-west Coral Sea. Additionally, two more associated protective measures (APMs)

were introduced in the Torres Strait. Firstly, a two-way route was introduced in the Great North East Channel. Secondly, there was an extension of Australian’s system of pilotage to the Torres Strait and Great North East Channel. These two APMs have successfully improved navigational safety, reduced the risk of collision and grounding and allowed more time to intervene when a situation like a mechanical breakdown occurs. Other protective measures are designated shipping areas, ship routing systems, a network of visual and electronic aids to navigation, the Great Barrier Reef and Torres Strait vessel traffic service, the implementation of no anchoring areas and emergency response assets.

Source: Wikipedia.org

One of the APMs introduced by the IMO

Source: www.imo.org

Source: www.wikipedia.org

Given the wide range and number of stakeholders in the Coral Sea and its sensitivity to human activity, the task of conserving this region of outstanding maritime beauty and biodiversity has been monumental. Thanks to exceptional management practices and a willingness to cooperate for the benefit of the environment, though, much has been achieved. Indeed, the Coral Sea has been able to cater as far as possible for the needs of the shipping industry, the tourist industry, the fishing industry, indigenous peoples, recreational users and scientific researchers while keeping their environmental impacts to a minimum. In view of the pressure placed on the region and the degree of environmental integrity that it still retains, the stringent management of Coral Sea resources may well be regarded as a model for other similarly sensitive marine areas at risk from the negative effects of human activities.

Sources: www.un.org, www.gbrmpa.gov.au, www.britannica.com, www.environment.gov. au, www.sunshinecoastdaily.com

1. Make the names of two countries using all the letters in the following sentence: READ ‘RACE AN OGRE’.

2. The chemical symbols for antimony, sodium and uranium can be rearranged to form the name of the largest port in an Asian country. What is the name of the port?

3. My name rhymes with what you do on a bike, and when I go out, sea birds can eat what they like. My name is a brand of washing powder anyone can buy, and some ships can sail only when I’m high. What am I?

4. Which four-letter word can be used to complete the following words? UNB_ _ _ _ ED, C_ _ _ _ WORK, LAND_ _ _ _ ED, _ _ _ _ DOWN.

5. A woman lives twice as far away from her parents as her brother does. They both live due west of their parents. She moves 50 miles south-west and now she lives one and a half times further away from her parents than

1. Which of the following is the northernmost port?

A. Helsinki, Finland B. Keflavik, Iceland

C. Murmansk, Russia D. Valdez, USA

2. Which of the following is the oldest IMO member country?

A. Egypt B. Romania

C. Spain D. Chile

3. In which country was the Queen Mary built?

A. England B. Wales

C. Northern Ireland D. Scotland

her brother does How far away from their parents does her brother live?

6. Which four-letter word can be placed after the words to the left and before the words to the right?

DINNER FRAME DOWN TRAVEL

REACTION CHARTER

7. In 5 steps, change the word WILD to TAME by changing one letter at a time to form intermediate words.

8. Valentina prefers stores to shops, cameras to mobiles, skaters to surfers and piglets to calves. She likes exhibitions just as much as presentations. By the same token what does she prefer: apples or oranges? Why?

6. Which of the following is not a problem usually encountered in atmospheric condensers?

A. blocked tubes B. excessive marine growth

C. burst discs D. tube corrosion

7. What is the minimum period an Oil Record Book must be kept for after the final entry has been made in it?

A. 9 months

4. Cadmium and cadmium compounds are considered hazardous materials. What is the chemical symbol for cadmium?

A. Cd B. Ca

C. Cm D. Cu

5. What principle of physics do Flettner rotors use to function on vessels?

A. Bernoulli effect B. Magnus effect

C. Rebound effect D. Doppler effect

B. 2 years

C. 3 years D. 5 years

8. From which country did the Kon-Tiki expedition begin in 1947?

A. Chile B. Sweden

C. Norway D. Peru

9. In which year was the first version of SOLAS adopted?

A. 1908 B. 1914

C. 1924 D. 1929

10. Tandoori chicken is a popular dish worldwide. How did the dish get its name?

A. from a region B. from a cook

C. from a cooking vessel D. from an ingredient

Find a keyword associated with at least one article in this issue by solving the clues and rearranging the letters in the boxes with black borders.

1. Significant ship in Welsh history (6)

2. Coral Sea predator (6)

3. Basic ingredient in Moussaka (8)

4. These are congested nowadays (10)

5. Part of the Company’s culture (2,5)

6. This cannot be tolerated (8)

7. Where Empire Windrush was built (7)

8. Dhow building centre (6)

9. No flammable items around during this work (7)

Hint: health and happiness

Built in Aberdeen by Alexander Hall and Sons at a cost of just under £6000, Mimosa was launched on 21st June 1853. Weighing in at 447 tons, Mimosa was 139.9ft (42.6m) long and had a beam of 25.5ft (7.8m). The tea and cargo clipper, with her three masts, plied her trade in relative obscurity for nearly 12 years prior to becoming a very important part of Welsh history. In the middle of the nineteenth century, many Welsh people had become disillusioned with the imperialistic policies of Victorian Britain. So, they formed their Emigration Committee, whose aim was to establish a pacifistic democratic community at a location where they would be freed from being bombarded by the English language. The place selected to achieve this aim was the Chubut Valley in Patagonia, Argentina, and the ship that would deliver them to their chosen land was Mimosa. Of course, being a cargo clipper, she was not built to carry passengers and, therefore, had to be converted at a cost of £2500, which included the charter and supply of provisions, before beginning the transatlantic voyage.

Source: Wikipedia.org

On 28th May 1865, Mimosa, under Captain George Pepperell, set sail from Liverpool with 153 passengers on board. Hundreds of wellwishers gathered on the banks of the River Mersey to say goodbye. The Welsh banner was proudly raised, and as recorded by a passenger called Thomas Jones “.., the anchor was raised and we bade farewell to the land of our birth.” Unfortunately, Mimosa had to wait on the Mersey for three days before the winds became favourable for the voyage.

The passengers who had paid £12 or £6 (children) had to endure storms either side of the Atlantic, so the vast majority of their voyage occurred in calm waters. The biggest problems the passengers had to face were boredom, poor food and

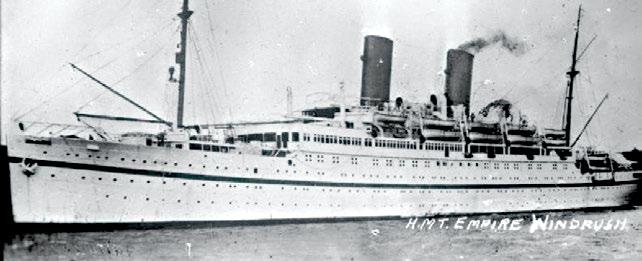

The Empire Windrush was the name given to a vessel captured by the British at Kiel at the end of WWII. Having been built in Hamburg by Blohm & Voss in 1930, she alternated between transporting immigrants to South America and operating as a cruise ship. The 500ft (152.48m) long, 8,530DWT vessel that could achieve a speed of 14.5 knots took up military duties during the war, serving as a barracks ship, a troop ship, an accommodation recreational ship and as a vessel to transport deportees. She survived several attacks during this period, but managed to complete her last duty, which was to carry German refugees away from the Red Army. After being renamed in January 1947, HMT Empire Windrush functioned as a troop transporter. On one of her voyages from Australia to Britain, she stopped over at Kingston, Jamaica to pick up British servicemen who were on leave and take them back to the UK. Apart from these servicemen and those who had left Australia, there were 66 Poles who had boarded in Mexico with the aim of making the UK home under the Polish Resettlement Act. Since there was still plenty of space left on the vessel, a decision was taken to advertise passage to the UK at a transit cost of either £44 or £28 depending on accommodation. At that time, in 1948, the British Nationality Act, which would allow residents of any British colony to be granted UK citizenship, was on the way to being passed in parliament. In anticipation of the Act being passed, the number of West Indians applying for transit far exceeded the number of available spaces on board.

The successful applicants, the vast majority of whom were from either Jamaica or Bermuda, took with them a wide range of skills.

cramped accommodation, but they gained relief by playing games, singing together and sharing stories. Their monotony was also broken during the crew’s celebration of crossing the equator on 28th June. Almost a month later, on 26th July, Mimosa arrived at New Bay and on the following day, the immigrants took their first steps on Patagonian soil. The colony they developed, which was centred on Gaiman, Trelew and Trevelin, was known as Y Wladfa (The Colony).

Today, there are an estimated 50,000 Patagonians of Welsh descent, around 5,000 of whom are Welsh speakers. Many of these descendants live in Welsh cottages that despite seeming somewhat incongruous, are a proud reminder of those intrepid emigrants who left their beloved homeland in search of a better future.

Source: www.casgliadwerincymru.co.uk, www.clwydfhs.org, www.wikipedia.en Davies, JD. Britannia’s Dragon: A Naval History of Wales (2013)

Source: www.wikipedia.org

There were mechanics, carpenters, electricians, civil servants and even a judge seeking a new life in the UK. This was to be the first voyage in the wave of migration from the Caribbean to Britain between 1948 and 1971. Those who remained in the UK were named the “Windrush Generation” after the vessel responsible for taking the first West Indians to the UK.

HMS Empire Windrush continued her service, which included the transportation of the last troops stationed in Greece back to the UK. Four years after this, HMS Empire Windrush began her final voyage in February 1954. After leaving Yokohama in Japan, she suffered a huge explosion in the engine room that resulted in her being abandoned. An effort was made to tow her to Gibraltar, but this failed and she sank off the coast of Algeria.

Like Mimosa, HMS Empire Windrush has become part of national history. Their voyages have become symbols of the Welsh and Caribbean spirit to seek out the best for their progeny without compromising their cultural heritage following integration.

Source: www.bbc.com, www.en.wikipedia.org