INSIDE

Opinion

Is there a choice between being Legally Correct and Ethically Right?

Special Report

Achieving Safe & Secure Operations

Opinion

Is there a choice between being Legally Correct and Ethically Right?

Special Report

Achieving Safe & Secure Operations

Dear Readers,

This is the time where the intricacies of supply chains have become increasingly significant, with major thrust on ethics, governance, and sustainability. Through in-depth analyses and expert opinions, we explore how businesses can incorporate green practices, ensuring that the wheels of our supply chains move harmoniously with nature.

Our Cover Story in this issue dwells upon the necessity of constructing Sustainable Infrastructure. It is essential to mould an infrastructure that not only optimizes operational efficiency but also safeguards our environment. Responsible procurement is as important. The Perspective section unravels the threads of moral practices in sourcing, focusing on the symbiotic relationship between sustainable development and profitable operations. Industry leaders talk about how they have absorbed ethics into their sourcing strategies.

Furthermore, exploring Safety and Security in supply chain operations, we delve into protocols, technologies, and methodologies safeguarding assets, ensuring continuity in operations amidst the multiple challenges that globalization and geopolitics have introduced.

We hope that through our monthly publication, you have been exploring, learning, and transforming approaches that are not merely efficient and profitable but also ethical, safe, and environmentally consonant.

Thank you for your unwavering support and trust in our publication. Together, towards a sustainable, secure, and ethical future.

Warm Regards,

Charulata Bansal PublisherCharulata.bansal@celerityin.com www.supplychaintribe.com

Through this perspective story, sourcing & procurement leaders explore emerging approaches to measure, engage, and manage ethical sourcing, and supplier diversity that create sustained value.

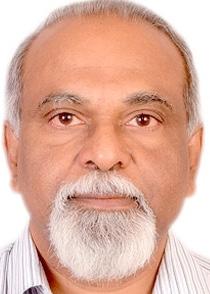

Lt Col Vijay Nair (Veteran), Founder and Consultant, Saarthak Solutions (ex VP-Reliance Retail), draws companies’ attention towards a very pertinent topic – Is there a choice between being legally correct and ethically right?

A sustainable world needs the industrial world to build more sustainable operations. As a result, it is prudent that future infrastructure development prioritizes Sustainable, Equitable, and Green Growth. Back home, the Central Government and industry stakeholders have been toiling hard to not only imbibe sustainable practices in their operations but are also devising ways to make sustainability a habit for every citizen. Our Cover Story this time explores ways to build sustainable practices that will ultimately help in conserving energy, reducing waste, optimizing the physical assets such as buildings & vehicles and highlights the efforts required to harness the potential of sustainability to garner economic value.

Our recently held panel discussion on ‘Achieving Safe & Secure Operations’ discussed the strategic priority of ensuring safety & security during cargo movement. Our expert panellists delved into the vital issue of addressing security concerns in today’s freight industry while highlighting the challenges faced and the strategies they employed to uphold safety standards. Excerpts…

This Reuters Events Supply Chain white paper in partnership with Maersk unearths the challenges & attempts at rewiring the global electronics supply chain…

Editor: Prerna Lodaya

Editor: Prerna Lodaya

DISCLAIMER: This magazine is being published on the condition and understanding that the information, comments and views it contains are merely for guidance and reference and must not be taken as having the authority of, or being binding in any way on, the author, editors, publishers who do not take any responsibility whatsoever for any loss, damage or distress to any person on account of any action taken or not taken on the basis of this publication. Despite all the care taken, errors or omissions may have crept inadvertently into this publication. The publisher shall be obliged if any such error or omission is brought to her notice for possible correction in the next edition.

The views expressed here are solely those of the author in his private/professional capacity and do not in any way represent the views of the publisher. All trademarks, products, pictures, copyrights, registered marks, patents, logos, holograms and names belong to the respective owners. The publication will entertain no claims on the above. No part of this publication can be reproduced or transmitted in any form or by any means, without prior permission of the publisher. All disputes are subject to the exclusive jurisdiction of competent courts and forums in Mumbai only.

In recent years, sustainability has become the front and the center for both consumers and brands in an effort to reduce the impact and effect of climate change. A big part of these sustainability initiatives includes imbibing Ethical Sourcing practices. According to a survey, 81% of customers value and prefer to buy from organizations who embrace sustainable and ethical sourcing. Several research have indicated that companies prioritizing social and sustainable procurement enjoy faster growth and higher valuations than other players in their sectors by a margin of 10%-20%. How can companies step up change, internally and in collaboration with partners, to ensure that responsible and sustainable procurement becomes the global norm? Through this perspective story, sourcing & procurement leaders explore emerging approaches to measure, engage, and manage ethical sourcing, and supplier diversity that create sustained value.

HIMANSHU MALOO NIKHIL PURI SAURABH PALSANIA Managing Partner, ImpactEazer Consulting Vice President – Sourcing & Planning, Yokohama Off-Highway Tires

HIMANSHU MALOO NIKHIL PURI SAURABH PALSANIA Managing Partner, ImpactEazer Consulting Vice President – Sourcing & Planning, Yokohama Off-Highway Tires

What are your views on ethical sourcing? Are there any success stories you would like to share on the front?

Saurabh Palsania, Joint President –Strategic Sourcing, Shree Cement: According to me, ethical sourcing is about bringing complete transparency and equal participation of all stakeholders while sourcing maximizes efficiency in the system. Wherever digitization and participative sourcing is being practiced,

this is being experienced. In my earlier experiences, I have come across many such experiences post implementation of complete transparency in sourcing through digitization of procurement to award of contract. We discovered new pricing benchmarks of spares and services, leading to accurate study of cost of manufacturing & delivery of sourced material & sourcing. Ethical sourcing is not only digitization, but also developing the system where equal opportunity

is provided to each stakeholder in the process of sourcing, which is key to achieve best results.

Nikhil Puri, Vice President – Sourcing & Planning, Yokohama Off-Highway Tires: Ethics have always been the part of sourcing, but it was never talked about so vocally before. But with the globalization coming up and supply chain getting moved out to various parts of the world, it started becoming more and more relevant. We

There is a clear sign that top class multinationals are moving the needle in the right direction, insisting on sustainable and ethical procurement practices with their major vendors, their tier-I and Tier-II suppliers. This is helping the organizations to change the mindset of consumers who are more aware and conscious of the brands they purchase. The young cohort (Gen X and Gen Y) make decisions that support environmental and sustainable enterprise in a serious manner. According to (SIG) Sourcing Industry Group Survey (2021), these are some of the interesting statistics.

67% of consumers prefer to work for socially responsible companies.

56% of consumers will pay extra for products and services from socially responsible companies.

52% of consumers made at least one purchase in the past six months from socially responsible companies.

52% of consumers check product packaging to ensure sustainable impact.

49% of consumers prefer to volunteer/ donate to organizations engaged in social and environmental programs.

are taking conscious efforts to create awareness among the buyers and customers on the ethical standards, be it labour laws, compliance, or sustainability concerns. There have been many success stories around it over the years. One of the cases, which come to top of my head, was regarding sourcing of one product. We have not awarded the business to the lowest supplier as the approach that he

followed was unethical. The buyer who brought this to the notice was awarded by the management, which also helped in setting up standards across the board.

What are the challenges that you foresee in monitoring sourcing practices?

Saurabh Palsania: Spent analysis is the heart of monitoring of sourcing

practices. The data availability is too much, while analytical reports available are too low for monitoring. When high volume of data is in the system in sourcing, it becomes more important to get the right insights at right time for timely & correct decisions. Also, it is important that the software pulls out exceptional information and sends it to the concerned person for timely action.

There may be two ways of utilizing the digitization –

• To highlight the exceptional things and

• The other way is to identify immediately & force corrective actions.

The challenge today in monitoring sourcing practices is thus the large data with no right tool to raise right exceptions & corrective action. With AI technology on board, we foresee right solution to be in place shortly.

Nikhil Puri: The challenge is the cultural difference. When we want to deploy ethical sourcing, it’s a completely uncharted territory, as soon as we start speaking with the teams, people get apprehensive and start thinking that their workload might increase. This thought has come up from the buyers. Such challenges stop us from implementing such practices. I firmly believe that there needs to be regulations to enforce the same, but before that, there needs to be adoption from the top management. If the culture change has to be brought in, it has to be a top-down approach. The same dilemma was there when we were in the digital transformation transition phase a decade back, but it has become the critical element for business survival. I am sure in a few years from now, ethical sourcing would also become an integral part of our businesses. The thrust is coming from the overseas players. They have a clear mandate to follow global ethical sourcing standards.

Himanshu Maloo, Managing Partner, ImpactEazer Consulting: Many of us have an intent to work towards achieving ethical sourcing practices. I feel somewhere government policies can be further strengthened in such a way that it pushes everyone to comply to the norms. Globally there are companies like EcoVadis, who has been doing a commendable job of monitoring such initiatives including sustainability practices. Still there is a long way to go in following such standards across industries. Another important element towards ethical sourcing is providing labor-friendly environment at workplaces

like at manufacturing sites, warehouses, etc. Earlier there used to be a 12-hours shift at workplaces, but now it has been reduced to an 8-hour shift. Additionally, workers today are demanding better conditions at workplace. If we want to retain the labor, it’s not just about the wages, it’s also about providing them better working conditions. Ethical sourcing is also about humanity and take care of people who are working for you.

What ethical sourcing can do to your brands? How does ethical sourcing build a brand and how do you communicate the same to your customers?

Saurabh Palsania: Ethical sourcing brings all competitive stakeholders on board and creates healthy competition. The opportunity with transparency creates a brand value through all stakeholders. Available time is invested in vendor & material / service development, which also adds to the brand value, otherwise would have been used in non-standard practices or manual interventions. The communication to customers is spontaneous & through various physical and digital platforms.

Nikhil Puri: Ethical Sourcing is becoming an important mandate for the overseas customers. Ethical Sourcing is also part of the sustainability itself. Customers are looking for the sustainable initiatives that their suppliers are providing. Sustainability has started becoming a vital criterion in supplier selection along with the standard parameters of Cost, Quality & Delivery. When discussing with the customers, you can always mention the practices that are followed in your organization, one being Ethical Sourcing. Policies & procedures should be in place for Ethical Sourcing, which

can be showcased to the customers. Customers are always looking for those partners, which are ethical in nature, and are in line with their values. If you have a written down procedure and policy and you are exercising the same, then the companies want to partner with you. As they are aware that come what may the buying decision will be taken on merit, and it will be ethical. It helps in strengthening the brand image.

Himanshu Maloo: Now-a-days overall consumer awareness also has been increasing. Thanks to social media, consumers are expecting brands to be more ethical and sustainable. There are several brands who are leveraging ethical sourcing to their advantages and building trust element with consumers. E.g., there are brands, who are using plastics taken out from Sea to make shoes. They are charging premium rates for such products and people are ready to pay for it. That shows how awareness is building up towards ethical and sustainable sourcing.

Kindly shed light on the e-waste policy being followed in the retail industry…

Nikhil Puri: In the electronics industry, at the retail store, they have dedicated places where consumers can deposit their mobiles / tablets / laptops for recycling. There has been an advent of recycling aggregators to collect these goods. They ensure to follow the compliances for e-waste disposal / recycling. If we talk about other wastes, there is an interesting concept emerging – zero waste to landfill. Every manufacturing company, irrespective of the industry they are operating in, is generating some kind of process waste. Out of this, most of the waste material is getting recycled, but some still remain as it is and can’t

Transparency and visibility are the outcomes of participative management of supply chain and high level of digitization. Building trust amongst all stakeholders by online sharing of information, more and more interaction, standard practices of sourcing and timely delivery of services, materials, payments, and acknowledgements will bring visibility and transparency across the supply chain.

be recycled and is hence sent away to landfill. In my previous organization, during the operational process, we used to generate glass as one of the wastes. Incidentally it was going to landfill for decades across the globe. We worked with cement industry and realized that the cement industry wanted that waste product for reinforcement. This way we were able to now recycle every waste byproduct. It became the biggest pitching point overseas as we were the only few companies globally who were not disposing any waste product to landfill.

Where is the line between being legally right and ethically right?

Nikhil Puri: There is a very thin line between being legally right and ethically right. There are numerous examples across the industries wherein they are legally right and following all the compliances. But are they ethically right, is a grey area. As an organization, you often see that there is a lot of impetus given on following all the legal obligations and compliances. But you will not find companies branding them as ethical. It is believed to be there. But are there are written down policies around it, so the answer is a big NO. In my opinion, “A legal entity may or may not be an ethical one, but an ethical one will always be a legal one.”

How can we start introducing transparency into the visibility of end-to-end supply chain?

Saurabh Palsania: Transparency and visibility are the outcomes of participative management of supply chain and high level of digitization. Building trust amongst all stakeholders

by online sharing of information, more and more interaction, standard practices of sourcing and timely delivery of services, materials, payments, and acknowledgements will bring visibility and transparency across the supply chain.

Nikhil Puri: Companies are taking conscious efforts to bring in transparency in the visibility of end-to-end supply chain. Today the customer is very intelligent, and he does not want to buy a product which is stained in any way. Traditionally, companies often check their tier I suppliers and are aware about what is going on there such as, are they following the ethical practices, are they following the labour laws, working conditions and so on. But are the companies going up to tier II & III & IV also. It was assumed that it is the responsibility of the tier I & tier II respectively. But the onus is on the company who is selling the end product. Organizations must start checking all the tier suppliers so that they are aware about the processes that they are following. Also, we are all aware that listed companies in India have started bringing their annual reports on sustainability. This report describes each and every activity that the business is conducting and the amount of discharge/waste getting generated out of each process. In lieu of this, they also showcase the efforts that the company has been taking to mitigate emissions and precisely reflecting their green practices. This helps in creating awareness among stakeholders / investors / global suppliers. The ethical practice should start from the RFP stage and not at the contract stage. Companies need to educate / train their suppliers in following ethical practices. Companies must have a separate sustainability

audit checklist than the regular audit list that they adhere to while finalizing a prospective supplier.

Himanshu Maloo: Building transparency towards sourcing practices today is voluntary for companies. There are very few companies who are ready to publish details about their sourcing practices, about their supplier qualification / management strategies, etc. This is doable for companies who are able to embrace ethical sourcing. But most companies who are yet to move is this direction, it is not doable in current environment. But slowly we will see a progress towards ethical sourcing, more and more companies will start getting more transparent. This will be important element to build trust for brands.

How do you foresee the scope & expanse of ethical sourcing growing from here on with companies waking up to the cause and taking pertinent measures?

Saurabh Palsania: There is a big shift now, which can be foreseen from traditional sourcing to ethical sourcing. This is possible because of the high availability of services providers and requirement of exchange of information to all stakeholders. Frequent requirement of audit trails of transaction, consistent uncertainty in the market also influenced by geopolitical matter, high competition within and across sector, continuous requirement of innovation for cost control, all the above is pushing for quick shift to ethical sourcing.

Nikhil Puri: Scope is immense of ethical sourcing. The important thing is to create awareness. Also there are no clear guidelines that are there on this topic. Every company proclaims and aspires to be an ethical company. Industries should come together and formulate the guidelines around this topic. It is not that companies do not want to do it. It is just that the rules of ethical sourcing are not defined properly. I foresee, that with so much globalization, companies will make it an important priority that is being discussed openly and widely so that it can be implemented.

Ethical sourcing brings all competitive stakeholders on board and creates healthy competition. The opportunity with transparency creates a brand value through all stakeholders. Available time is invested in vendor & material / service development, which also adds to the brand value, otherwise would have been used in non-standard practices or manual interventions. The communication to customers is spontaneous & through various physical and digital platforms.

Ethical sourcing is an approach to sourcing and supply chain management that considers the impacts of products on the people, communities, and environment who create them. It can help businesses improve their reputation, reduce risks, increase customer loyalty, and create positive social impact. Lt Col Vijay Nair (Veteran), Founder and Consultant, Saarthak Solutions (ex-VP-Reliance Retail), through this opinion piece, draws companies’ attention towards a very crucial topic — Is there a choice between being legally correct and ethically right?

ETHICAL sourcing is more than just a buzzword. It is a way of doing business that respects the people and the planet that make our products possible. Ethical sourcing means that businesses consider the social and environmental impacts of their sourcing decisions and take actions to ensure that their suppliers meet certain standards of responsible and sustainable practices. But ethical sourcing is not always easy or straightforward. Businesses often face complex and challenging situations that require them to balance their legal obligations, ethical values, and business interests.

While Ethical sourcing can have many economic benefits for businesses, such as enhancing their reputation, increasing customer loyalty, reducing operational risks, and improving supplier relationships, there is a cost associated with it and this could pose some challenges and dilemmas for businesses, such as balancing the costs and benefits of ethical practices, dealing with different cultural norms and expectations, and ensuring transparency and accountability throughout the supply chain, while it may be legally covered if it does none of this. For example, a business may comply with the minimum wage laws in a country, but still pay its workers less than a living wage. Or a business may source its products from a supplier that meets the legal environmental standards, but still causes significant harm to the environment.

Can we measure the performance?

Can we measure, where we stand in Ethical sourcing Index? While researching on this, I came across Dow Jones Sustainability Index. The Dow Jones Sustainability Index (DJSI) is a global index that assesses the environmental, social and governance (ESG) performance of companies based on various criteria such as climate strategy, human rights, corporate governance, innovation, and stakeholder engagement. The DJSI is composed of different regional and thematic indices, such as the DJSI World, DJSI Emerging Markets, DJSI Europe, and DJSI Asia Pacific. Was pleasantly surprised to find 12 Indian companies have been included in the DJSI Emerging Markets 2020 Index, which covers the top 10% of the largest 800 companies in 20 emerging markets based on their ESG performance, (viz., Mahindra & Mahindra Ltd, Tata Motors Ltd, Glenmark Pharmaceuticals Ltd, Havells India Ltd, and more).

It’s not that we, here in India, haven’t developed such indices. The SEBI has a report, the Business Responsibility and Sustainability Report (BRSR), that mandates the top 1000 listed companies (by market capitalization) to disclose their performance on environmental, social, and governance (ESG) aspects in their annual reports. BRSR is not merely presenting the data collected, but an approach to drive an organization’s commitment to sustainability and demonstrate it to the interested parties in a transparent manner.

As consumers become more aware and demanding and willing to pay for ethical standards, businesses will need to overcome the legal versus ethical dilemma of should they comply with the minimum legal requirements or go beyond them to meet the expectations of their stakeholders? Such answers are not always clear-cut, but one thing is certain, businesses have a responsibility to act ethically and transparently in their sourcing decisions, and to ensure that their suppliers do the same. By doing so, they can contribute to preserving ESG values (environmental, social, and governance) and creating a more equitable and sustainable world for everyone. Ethical sourcing is not a choice, it is a necessity.

In today’s fast shaping up global developments, self-reliance, sustainable infrastructure, and community support have become the critical pillars for India’s long-term prosperity and resilience. As per a recent IBEF report, self-sufficiency and deliberate investments in sustainable infrastructure will set the groundwork for a thriving and sustainable future. The good news is that globally we are witnessing a greater emphasis on sustainable investment, which considers Environmental, Social, and Governance (ESG) factors. A more sustainable world needs the industrial world to build more sustainable operations. As a result, it is prudent that future infrastructure development prioritizes Sustainable, Equitable, and Green Growth. Back home, the Central Government and industry stakeholders have been toiling hard to not only imbibe sustainable practices in their operations but are also devising ways to make sustainability a habit for every citizen. Our Cover Story this time explores ways to build sustainable practices that will ultimately help in conserving energy, reducing waste, optimizing the physical assets such as buildings & vehicles and also highlights the efforts required to harness the potential of sustainability to garner economic value.

Arecent Knight Frank report highlighted that the trend of using sustainable practices is gaining traction and is arguably the single most important theme that dominates dialogues across business lines and geographies. Even investment flows are now heavily influenced by how sustainable practices are being applied by potential prospects. This allpervasive theme has begun influencing the warehouse market with occupiers looking to reduce their carbon footprint and incorporate industry leading practices in the domain. With occupiers increasingly looking to outsource their logistics requirements and with end consumers demanding accountability, 3PLs and e-commerce players have begun to focus on this important aspect. Progress towards a greener warehouse can be measured in a tangible way by seeking building certifications that evaluate performance across metrics related to Environmental, Social, and Governance (ESG) criteria.

Our power-packed panel discussion on the sidelines of our annual awards ceremony harped on this very critical aspect. Let’s take a look at the thoughtprovoking insights of industry experts where they offer us a way ahead to achieve sustainable expanse…

What is Sustainable Smart Infrastructure? Also describe the top 4-5 Key drivers of these.

Dr. Mala Singh, Founder & MD, PEC Greening India: I believe Sustainable infrastructure is the amalgamation of architecture, engineering and ecology to create a symbiotic relationship of nature with human development. A smart & sustainable infra should be people and planet centric. It substantially optimizes utilization of scarce resources, reducing overall carbon emissions and sequestering carbon back into the earth. According to me, the key drivers for sustainable and smart infra are Green Buildings, Renewable Energy sources, Sustainable water and waste management and smart transportation systems. Green Buildings are energy and water efficient buildings which reduce waste. They encourage the use of sustainability from design stage till the final end use stage. They minimize

the adverse impact to biodiversity by preserving the local flora and fauna within the building site. They also reduce the demand for virgin raw materials by using more recycled and local materials in building construction. Since, most countries have committed to phase out the fossils fuel based energy sources, the demand for renewable energy sources has increase and will power the sustainable smart infra. The renewable energy systems must be integrated with the infrastructure. One of the best examples are the roof top solar plants. If we talk about water, then most of the Indian cities are vulnerable to water crises. Thus, sustainable water techniques like rain water harvesting, waste water recycling and reuse will drive the overall water smart infra. Waste management is again a major problem. The organic waste must be returned to the farmlands to close the nutrients loops. The inorganic waste should be segregated separately into hazardous and non-hazardous waste and must be treated by 3R principals. The smart and integrated mobility systems must reduce the dependence on privately owned vehicles and use more public transport. They must use clean fuels and build infra to sustain the growth.

Ravikant Parvataneni – CEO India, Argon & Co.: Some of the key drivers are –

• Use of A-grade warehousing: Initial cost could be high, but the life cycle cost is lower owing to higher life

• Use of non-polluting MHEs: Battery powered vs diesel engine powered

• Gold platinum ratings: Inculcate environment friendly best practices from the start

Vijay Ganesh, MD – Industrial & Logistics Services, Colliers India: Sustainability is a trending topic today where every organization is trying to adopt sustainable practices like reducing carbon footprint, reducing wastage, or conserving energy. Every organization needs to take a holistic approach towards it. Smart infrastructure plays a pivotal role in terms of tech-driven approach where we use data analytics and smart technologies to ensure the optimum utilization of assets and operations. Management commitment to sustainable

goals, government’s thrust on imbibing green initiatives, increased consumer awareness towards sustainability, Competitive advantage and brand value of the company are some of the driving factors behind the sustainability drive. Some of the notable trends include:

• Smart technology and resource efficiency – Sensors, IoT devices and data analytics platforms to monitor and optimise energy consumption, Water usage, Waste management etc.,

• Renewable energy

• Rooftop solar panel installation

• Solar powered Street Lights

• Circular economy- Reuse, Recycle and recovery of materials

• Standards and Certifications such as IGBD, LEED, BREEAM

India is a mix bag of rural & urban cities. What are the major challenges we will face while developing a sustainable, Smart Infrastructure, especially in the rural markets?

Dr. Mala Singh: On the contrary, I think it is much easier to implement smart and sustainable solutions in the rural areas as compared to urban areas. In many ways, our villages are already following sustainable practices. We have many examples of smart and sustainable villages across the country. But we hardly find a completely sustainable city in India. I think a little technological assistance and funding can make many of our villages smart and sustainable. Smart Infra will have multifold benefits for villages. As the rural areas transitions to smart infra, I believe that the socioeconomic impact would be really good. People would have access to affordable and renewable energy, clean and sufficient water, clean cooking fuel, access to affordable internet. This will improve the overall lives of the people in the rural villages. This also has a huge potential to stop the rural-urban migration which will ultimately reduce additional burden on the cities.

Arif Siddiqui, Founder & Director, Coign Consulting: For a very long time, this question of rural has been in the backyard, especially on the face

of technology, smart development, etc. However, if we see the growth of the Indian economy today, it is predominantly propelled from the rural regions. A lot of credit goes to internet penetration, which has gone up by over 50% of the country’s population. Let me reflect some of the challenges that we will still continue to face… first & foremost challenge that we need to deal with is bandwidth connectivity. The good news is that there has been continuous thrust being placed by the government and the private players to streamline the same. Another important concern that we must deal with on an urgent basis is the expectation differentiation between urban and rural customers. Rural customers are being governed by huge cultural value systems in the country whereas urban area has actually evolved

Every development on this planet has to be more inclusive, which not only just addresses the needs of business or the strategic goals, but also addresses the environmental goals and social requirements. To me, this will be truly a ‘Shashwat Vikas’ if we can achieve this. India aims to reach net zero by 2070. The Government has declared plan to add 50 GW of renewable energy capacity annually for the next 5 years to achieve the target of 500 GW by 2030. I am optimistic the way all the stakeholders are uniting to fight the climate change menace in the country and looking forward to a sustainable future for our next generations.

in terms of adopting both westernization and the Indian culture. These two cultural differences provoke a different customer behavior. We will have to look at the rural India from a completely different periscope to understand their behavior and the type of challenges those behavioral changes are going to face. Another important aspect is thrust on education and skill development.

Looking at creating infrastructure in the rural part of the country is going to be driven by three aspects – Affordability, Skill and the ability to maintain technology. It will be easy to invest in technology, equipment, all types of fit outs inside a warehouse, but it will be difficult to proactively maintain these technologies and keep the uptime high. They need to be able to have resources that are going to be used to operate these

smart warehouses or rather technologyaided warehouses. Maintaining business will be another big challenge. Therefore, the definition of smart will be completely different.

We need to relook at – is being smart always about hi-end technologies, hi-end equipment, and hi-end infrastructure? I think smartness is about defining what that specific infrastructure is serving. It’s not going to be one-size-fits-all solution. We will need to have warehouses catering to the needs of different customers. Infrastructure consultants need to study the specific demands of customers, the hierarchy of the warehouse in their overall supply chain, the segment they are catering to, etc. Post this analysis, they will need to develop the smart elements, which will be economical, which will make the supply chain resilient, and will also ensure that the personnel have the right skills to operate such warehouses.

Sanjay Desai, Co-founder & Regional Director, Humana International (S) Pte Ltd.: Yes, India is indeed unique in its mixed flavour of rural and urban cities and their differentiated infrastructure. Added to that complexity is India’s government set-up of Centre & State structures duplicating most of the efforts and costs. Here are some major challenges our MSMEs and Startup entrepreneurs in the rural regions will face while developing a sustainable smart infrastructure…

Education & awareness: Rural India needs to leapfrog in education & training programs like digital literacy, use of tech

gadgets in everyday life. Without these or due to low adoption rate, it will be very difficult to bring the awareness of the value of smart infrastructure in a sustainable manner across rural markets.

Lack of energy: Easy and reliable availability of energy resources is extremely critical to the development of smart infrastructure. It is a huge task to get power consistently across rural areas unless we built these energy resources first.

Unique nature of rural needs: It cannot be simply assumed that our prevailing smart solutions in urban markets will work seamlessly in rural markets. It will call for some customization to address specific challenges of rural communities.

Rural Skill set, maintenance & support: Typically, rural areas may lack certain modern skills to effectively maintain and support the smart infrastructure. In any technology dependent set-up, maintaining the infrastructure efficiently over a longer period is crucial from safety & security standpoint.

Cultural ethos and values: Relative to urban cities, communities in rural cities are much more closely associated with cultural ethos & values in their daily lives. Advancement in infrastructure and breaking some social beliefs is sensitive.

Circularity has been a powerful theme in the chemicals industry. As chemical reactions are carried out, there are invariably by-products or co-products that get generated along with the main product. AIL has pioneered the value addition or valorization of such streams. To share some examples, AIL was the first in India to use the byproduct hydrochloric acid to convert to calcium chloride and export this to various markets for oil & gas and other related applications. Similarly, the sulphuric acid streams are used to make a fertilizer - single super phosphate which is a great fertilizer for soil found in western India and also helps India reduce import dependency on fertilizers like diammonium phosphate. We are working with our suppliers to get recycled or bio-circular raw materials which will further boost this circularity.

Government and administrations need to be sensitive & respectful when they go about making the change.

How easy or difficult it is for SMEs/startups to embrace sustainable and smart asset management practices?

Dr. Mala Singh: I feel that the majority of our MSME sector is still widely using outdated technologies and processes, resulting in higher energy intensity. The MSME sector consumes about 25% of the total energy consumed by the industrial sector in India, and out of the total energy consumed, 15% is electricity consumption and 85% is thermal energy consumption. Smart Technology upgradation in the manufacturing process requires huge capital costs which may not be feasible for many SMEs and startups. Although, the Government of India has various schemes to lend money for technology and process upgradation of MSMEs, lack of awareness of existing financial mechanisms makes stakeholders sceptical to invest in low carbon technologies. One such government initiative is National Programme on Energy Efficiency and Technology Upgradation in SMEs undertaken by Bureau of Energy Efficiency (BEE). This program aims to strengthen the MSMEs by knowledge sharing, capacity building, and demonstrations of efficient technologies and adopt energy

efficiency measures and technologies to conserve energy in MSME sectors. Large companies and global organizations from different sectors can play a key role in financing as well as in providing technical assistance to small scale enterprises and startups. These funds must be mobilized to intensify the R&D for smart and green transition technologies. I think this will enhance the smart and sustainable asset management in SMEs and startups.

Ravikant Parvataneni: I believe that it’s easy to imbibe sustainability principles for SMEs/ startups rather than the large corporations. For big companies, the infrastructure has already been existing for years or decades and it takes whole lot of efforts for them to go back to the drawing board and start discussing where all they can bring in eco-efficient measures. While this is just one part of the puzzle, actually implementing the same would also take significant time. I am not considering the cost factor here. While for startups, they are just about building everything from scratch, so it’s practically easy for them to adhere to green norms right from the start. For bigger companies obviously, it becomes the CSR and ESG mandate and they have been taking efforts to imbibe green principles. One needs to be smart enough to gauge the impact and the criticality of the process and then adopt sustainable measures, be it big or small companies. It

can be incremental change as well.

Sanjay Desai: India holds 4th position in global rankings for number of MSMEs and their contribution to the Indian economy. India has roughly 62,000 registered startups and another 50,000 nn-registered family owned startups, which in total contribute 4% to India’s GDP. It has had an annual growth of 12-15% since the past three years and this is growing further. Securities and Exchange Board of India (SEBI) made ESG disclosures mandatory for the top 1,000 listed companies under its Business Responsibility & Sustainability Reporting (BRSR) initiative. While this is a great step forward, it puts a lot of stress on the top 1000 companies to be compliant. Let us look at some of the challenges that our SME/startup entrepreneurs will face in their endeavor to embrace sustainability and asset management consistently. We will also look at some of the mitigating factors that they can resort to as required…

Let’s talk about the challenges first…

• Resource crunch (men & materials): SMEs and startups often have limited materials and human resources availability, making it challenging to invest in sustainability initiatives and smart asset management efficiencies.

• Knowledge and cost of maintaining compliance: We all know that cost of implementing and then maintaining

asset management / ESG compliance can be high. Most SMEs and startups may not be able to afford these costs without a larger effort from their banks.

• Resilience to change / lack of awareness: Resistance from smaller businesses will affect India’s adoption in ESG compliance as well as new technologies. Global MNC or local giants will adopt ESG / Asset management over a period of time and be part of standard ecosystem. The resistance from MSMEs & startups is the result of lack of knowledge / low confidence in understanding ESG & its benefits.

• Challenge to scale up: MSMEs and startups who aim to move up the ladder for rapid growth may find it challenging to scale ESG and asset management practices in the same vein as their larger domestic partners. This is the phase where they would need help from Industry associations / respective state bodies.

Here are some of the mitigating factors…

• Take the first step, start small: These enterprises need to dare and take the first step to understand the path forward. Start making incremental progress one step at a time and keep the goal post moving ahead.

• Partner/collaborate within industry: Seek partnership or counselling with

industry associates, government bodies to see guidance, help and resources at a certain level.

• Train and leverage your employees: MSMEs and young entrepreneurs need to train their employees how to deal with ambiguity, complexity and advanced technology so that slowly they can learn and leverage their learnings eventually.

• Track your progress to seek financial assistance: Monitor and measure the impact of your initiatives and actions and how successful they are at implementation phase. Approach your anchor tenant or banks for financial assistance.

• Educate / upskill your employees: Train your team on the importance of ESG and asset management to involve them upfront in the process. This way you can keep your employees fully updated with new technologies and innovation in the marketplace.

Are there certain standards (or features) that companies can leverage while planning and designing a smart and agile distribution centre?

Arif Siddiqui: I completely agree that the government is really working hard in setting up policies. Owing to my intervention with the government, at different stages or at the current

Sustainability is a trending topic today where every organization is trying to adopt sustainable practices like reducing carbon footprint, reducing wastage or conserving energy. Every organization needs to take a holistic approach towards it. Smart infrastructure actually plays a pivotal role in terms of tech-driven approach where we use data analytics and smart technologies to ensure the optimum utilization of assets and operations. Management commitment to sustainable goals, government’s thrust on imbibing green initiatives, increased consumer awareness towards sustainability, Competitive advantage and brand value of the company are some of the driving factors behind the sustainability drive.

stage where I am a part of authoring a part of the National Logistics Policy and the handbook on the Warehouse Standardization, I have three things to say. We need to understand the context of the industry we are talking about. Currently the warehousing industry is not more than 7-8% is organized, which we call A-Grade Warehouse or best in breed infrastructure. Around 90% of the existing warehouses today were built more than two decades ago. Secondly, they are standalone facilities and were developed by farmers or conventional entrepreneurs and builders for whom every square foot of space matters because their entire business model runs on ground coverage. I have stated this to IGBC that we need to have a very special case and a policy or a methodology to grading or rating these warehouses. Rather than looking at platinum rating, we need to have basic entry level rating. Standards and features are so critical and important in operating a warehouse today. There is a study done by Gartner that in India not more than 9-10% of warehouses deploy a WMS. The very first important aspect is that we should first start walking the talk. WMS is such a primary requirement in any warehouse, be it a small or a large one. If we deploy WMS, then warehousing operators will be able to start analyzing data, which will help them in analyzing performance and would be in a better position to understand the gaps and work towards

I believe that it’s easy to imbibe sustainability principles for SMEs/ startups rather than the large corporations. For big companies, the infrastructure has already been existing for years or decades and it takes whole lot of efforts for them to go back to the drawing board and start discussing where all they can bring in eco-efficient measures. While this is just one part of the puzzle, implementing the same would also take significant time. I am not considering the cost factor here. While for startups, they are just about building everything from scratch, so it’s practically easy for them to adhere to green norms right from the start. For bigger companies obviously, it becomes the CSR and ESG mandate and they have been taking efforts to imbibe green principles. One needs to be smart enough to gauge the impact and the criticality of the process and then adopt sustainable measures, be it big or small companies. It can be incremental change as well.

them. Energy efficiency is one thing that we feel that by putting LEDs, we have achieved our carbon emission targets, but that’s just not true. It’s a small part of the change. We need to control the use of power, be it MHEs or any other operational area. Green is not only about the way you build your infrastructure; it is also about reducing the efforts of human beings. Sustainability is about reducing the efforts of warehousing operators so that they are able to do more with less efforts. Effort reduction is also part of sustainability.

Sanjay Desai: Smart distribution canters (SDCs) have their own standards (i.e. Class A, B), which organisations can leverage depending on the nature of their business and customer service criteria. These standards and features offer a certain efficiency and require process cadence and compliance standards which organisations need to adhere to. Here are some key standards and features which are available…

• Energy / utility efficiency: Class A/ B SDCs offer high utility or energy savings due to energy efficient lighting, a solar lighting footprint at lower cost and a structured warehouse layout, which allows a lot of natural light to come thru during daytime.

• Utilization of Warehouse space:

These SDCs are able to configure warehouse layout depending on the finished products to be stored. They offer solutions like narrow-aisle or mezzanines floors, slotted angles to maximize warehouse space.

• Warehouse management system: WMS is an integral part of inventory management operations (storage / retrieval and distribution operations). Organizations integrate the WMS with front-end (CRM) customer relationship management system to offer an end-to-end visibility to customers.

• Technology integration: SDCs operate with high level advanced technology like RFID, pick-pack RPA efficiencies to improve inventory handling / storage and distribution operations. For high volume small product footprint, we can set up an automatic storage and retrieval system (ASRS) to reduce downtime, provides reduced product handling and lesser damages.

• Safety and sustainable standards: SDCs are built in such a way that they comply with most safety standards (OSHA, REACH), which help organizations to protect their employees and assets. These SDCs incorporate sustainable design features like (LED lighting, Fire Security system, energy insultations).

What are the common obstacles that industries will face & what are the opportunities of a circular economy?

Dr. Mala Singh: I think this has been evolved from our great land itself. We can’t ignore that fact. Our ancestors have been following these sustainable practices since eons. When it comes to corporates imbibing the circular agenda, though at first sight, it looks like a challenge, it’s a great opportunity for them. They can start with waste minimization exercise. They must think of making the entire loop more inclusive. In doing so, MSMEs will play a major role. According to a study, 45% of carbon emissions are going to be reduced by MSMEs through circular economy principles. Scope 3 emissions mitigation will be a big challenge for companies, but if they can find a magic formula to curb the same wherein supply chain would play a catalytic role, then the ball will be in their court. The government is at the helm of change and has been laying immense thrust on imbibing green goals. We are already on the right track where consumers are eco-conscious and are driving the demand.

When we talk about industries, we must look at them from the sectors they serve. So we have service based industries and manufacturing based industries. The way these industries operate is different and hence the obstacles and opportunities in achieving circularity for both are different. Service industries includes IT industry, Hospitality, Healthcare, Tourism and

Transport, Banking and Finance, etc. In these industries, the people’s behaviour approach is a major challenge. But at the same times, it presents itself as a huge opportunity. Lack of sustainability awareness among the majority of employees and customers is a root cause of the problem. If service based companies would drive regular green awareness campaigns for its stakeholders though social media campaigns, it would bring drastic change in their behavior. We need to aware the masses that we are heading towards a climate catastrophe. How we are responsible and what can we do about it as an individual and as a collective group. I think our Prime Minister’s LiFE (Lifestyle of Environment) mission is a perfect example for this. If we could monitor and measure the negative impact of their daily activities thought the means of already available technologies and show the results to them, this would bring a sudden change in their behavior of consuming resources. The manufacturing industries have a unique opportunity to embrace circular economy. According to me, one of the major opportunities is through the design for circularity. The manufacturers can design out waste, conduct life cycle analysis in the product design phase and take responsibility at the end use of their products. This will not only reduce their need for virgin materials but will also help them to reduce cost and become more competitive in the market. They can also make consumers more aware on the ways to responsibly dispose their

products after consumption through smart labelling practices. The major challenge they are facing is that there lies a big gap between the supply and demand for raw materials, which are refurbished, remanufactured, and recycled. We need to build a cycle of green supply chain for the purpose of integrating circularity into manufacturing industries.

Mitesh Gangar, Head - Business & Supply Chain, Aarti Industries: Circularity has been a powerful theme in the chemicals industry. As chemical reactions are carried out, there are invariably by-products or co-products that get generated along with the main product. AIL has pioneered the value addition or valorization of such streams. To share some examples, AIL was the first in India to use the byproduct hydrochloric acid to convert to calcium chloride and export this to various markets for oil & gas and other related applications. Similarly, the sulphuric acid streams are used to make a fertilizer - single super phosphate which is a great fertilizer for soil found in western India and also helps India reduce import dependency on fertilizers like diammonium phosphate. We are working with our suppliers to get recycled or bio-circular raw materials which will further boost this circularity. For example, petrochemical crackers can take the waste plastic as feedstock and the products generated could be circular taking the mass balance approach (in proportion of the recycled feedstock).

We need to relook at – is being smart always about hi-end technologies, hi-end equipment, and hi-end infrastructure? I think smartness is about defining what that specific infrastructure is serving. It’s not going to be one-size-fits-all solution. We will need to have warehouses catering to the needs of different customers. Infrastructure consultants need to study the specific demands of customers, the hierarchy of the warehouse in their overall supply chain, the segment they are catering to, etc. Post this analysis, they will need to develop the smart elements, which will be economical, which will make the supply chain resilient, and will also ensure that the personnel have the right skills to operate such warehouses.

Ravikant Parvataneni: Changing the existing infrastructure ecosystem is going to be the single biggest challenge because there is a huge set of already available old infrastructure.

We are a growing nation, which means resource consumption, GHG emissions, new warehouses / transportation. How do we strike a balance with our ESG Goals?

Mitesh Gangar: Our feedstock comes from refineries, mines, or fertilizer companies. We do value addition over these and then supply our products to other chemical (active) manufacturers. While we do this, we, of course, consume a lot of carbon. We make derivatives of benzene, toluene, etc., and they inherently contain carbon. We consume more than 4.5 lakh metric tons of coal, which gives us electricity as well as steam, which is used for the processing of chemicals.

We have been working on multiple initiatives w.r.t. optimizing our consumption. We recently announced a hybrid power project to take care of almost 25% of our power needs in partnership with a service provider who is going to set up solar as well as wind capacities to help get us at least a particular portion of our electricity needs from renewable resources. For all our boilers which earlier were only coal-based boilers, we are converting them into dual feed boilers, which means we will be able

India is one of the few nations growing on all economic fronts. Striking a balance between economic development and achieving our ESG & sustainability aspirations is going to be the toughest challenge for all of us. It requires a structured and an e-to-e integrated approach across geography, industry segments & consumer dynamics. It also requires a massive effort in training / educating our industry professionals, consumers & MSME enterprises. Transparent and rigorous ESG reporting is the first step towards creating a harmonious and trustful environment pan-India amongst large and small enterprises. The Central Government needs to communicate and enforce ESG and CSR standards including auditing and periodical evaluations of industrial impacts to social and environmental factors.

to use biomass along with coal in various proportions.

There is an interesting case study that I’d like to share - for one of the products that we manufacture, the demand exceeded the capacity. This was a challenge thrown to the local site team to increase the production capacity. During the analysis, they highlighted the need for increasing the reaction & separation capacities and proportional addition of utilities. This was a simple scale-up in order to expand the capacity. When they raised this demand, we realized that we simply didn’t have enough space to be able to put all of these together. It was not possible to buy land adjacent to our site or take this additional capacity to another location. Then came an exciting revelation from a young engineer. He highlighted an entire product stream, which is coming out at an elevated temperature, and we were cooling it and such heat was lost to the utilities. He came up with an idea to utilize this excess heat for our raw materials. The moment we implemented this solution, the need for an additional utility went away. We were able to use this waste heat, make our process greener, and double our capacity with less than a 10% increase in the utility load. Such incidences only reflect that growth is possible even if we take the green route.

Ravikant Parvataneni: We should invest in developing logistics infrastructure

which will help reduce pollution and bring in efficiencies. Good roads, lesser traffic congestions, lower pollution, etc., are some examples. Similarly, there should be good warehousing infrastructure that leads to sustained reduced unit costs in the long run.

Sanjay Desai: Yes, this is a burning question, which will remain in our minds for some time in future. India is one of the few nations growing on all economic fronts. Striking a balance between economic development and achieving our ESG & sustainability aspirations is going to be the toughest challenge for all of us. It requires a structured and an e-to-e integrated approach across geography, industry segments & consumer dynamics. It also requires a massive effort in training / educating our industry professionals, consumers & MSME enterprises. Here are some of the primary considerations that we need to address consistently…

Nationwide (central) governance: We need a robust / nationwide standard policy framework, which will integrate ESG principles at the lowest levels of consumers with easy to understand awareness. These policies will address SMART goals, also detail their execution and how the success will look like across the end-to-end ESG deliverables.

Public-private partnerships: We need to

develop public-private partnerships to encourage investments in green / sustainable development across various industries. Such partnerships can offer incentives / subsidies including providing efficiency benefits like tax exemptions, incentives including penalties and fines if the ESG policies are executed as required.

Invest in technology and promote innovation: We need to invest in technology, clean energy and waste reduction using innovative solutions. Young MSMEs and startups need to work with the government to invest in sustainable agriculture practices like organic farming, water efficient irrigation systems aided by modern technology.

Circular product development: We need to inculcate a culture of circular product management whereby the industries are able to reuse and/ or scavenge 40-50% of the ‘used’ products, before the used products are dumped into landfills.

Transparency in ESG reporting: Transparent and rigorous ESG reporting is the first step towards creating a harmonious and trustful environment pan India amongst large and small enterprises. The Central Government needs to communicate and enforce ESG and CSR standards including auditing and periodical evaluations of industrial impacts to social and environmental factors.

What is the governing standard while engaging disposal/ containment of assets, especially in the chemical industry?

Mitesh Gangar: We continue to assess the useful life of our equipment. A lot of our chemicals are hazardous and therefore there can be safety issues even when discarding the waste equipment. We continually assess the residual useful life of the equipment and when that is reached, we move towards the replacement decision of that particular asset. It’s our responsibility to dispose of such assets in the right manner. Hazardous chemicals are sent to different processors depending on the suitable method to dispose of them –effluent treatment, incineration, or solid waste disposal. Metal would be sold to

another processor. There are challenges because the industry remains largely unorganized. Our teams handhold and educate them on proper handling. We also perform regular audits to ensure that the right practices are being followed.

Technology is there to help. But how do we use it to our advantage and not just for the sake of investment since everyone is doing ??

Sanjay Desai: Technology investment is a strategic decision, which is a senior leadership prerogative taking into considerations various parameters like future three years’ business growth / customer marketplace dynamics and changes in operational footprint. In this scenario, we need to leverage technology to create differentiation in marketplace. Let us understand factors how our technology investments can be purposeful…

Technology goes hand in hand with strategy: If technology investments are aligned to support business strategy (but not drive the strategy), the paybacks in this investment are long term.

Requirement assessment (needs): It is essential that we do a requirement analysis of our business needs and then design solutions using technology as a leverage to address the pain points or gaps to current processes.

Configure scale and flexibility: there is a need to choose right technologies which will scale and be flexible enough to accommodate changes in business dynamics, customer expectations over a longer period of time.

Integrate end to end capabilities: Select technologies that can seamlessly integrate with existing systems and processes. Avoid creating isolated technology siloes or solutions which are unique and highly customized.

Prioritize cybersecurity and data protection: Prioritize cybersecurity and data privacy using standard set of robust tools across entire organisation. Protect your organization and customer data from potential threats and exposures.

Re-train, re-skill users: Invest in training and skills development of your workforce to maximize the benefits of technology investments.

How much of a role does a SC consultant really play in the design phase today in helping the client manage the assets smartly? Ravikant Parvataneni: I would like to turn this question and ask ourselves – are we playing an enabling role? May be not! Our roles especially on the downstream supply chain has been limited to helping companies reduce the cost per unit. We are as good as the clients. When we suggest solutions, it is always specific

to our customers’ requirements. The moment we try to bring in sustainability into operations, that will first increase the consulting cost. It is good to see that whenever it is strategic consulting, customers have started requesting to bring in sustainability aspect as well. It is just not about warehousing or transportation cost or the total supply chain cost reduction, but it is also about carbon footprint. For us, it is much easier to get involved at the design stage, rather than doing retrofit for clients.

Considering the current challenges of climate change, how can India transform into a sustainable / infra environment? Can you provide a view of some of the best practise here?

Dr. Mala Singh: We were already smart & sustainable if we trace the ancient history of India. We were developing structures that were inherently sustainable in nature. We were sourcing materials locally; we were using indigenous techniques to develop the infrastructure and we were addressing the aspect of biodiversity. In short, we were actually developing the infrastructure in harmony with nature. However, owing to the exploitation of resources, all thanks to rapid industrialization, exploding populations, sustainable infrastructure development took a complete backseat. Green today has become the need of the hour. Now a days, climate change, global warming, resource depletion, have become a great threat for all of us. We don’t have any option left but to bring back our culture of being in sync with the ecology. It’s startling to state that each year, Earth Overshoot Day marks the date when we have used all the biological resources that the Earth can renew during the entire year. This means that humanity currently uses 75% more than what the planet’s ecosystems can regenerate. From Earth Overshoot Day until the end of the year, humanity operates on ecological deficit spending. We are already sitting at the tipping point. In this context, developing smart & sustainable infrastructure becomes pertinent, which is fundamentally based on the principles of green. Smart is no more sufficient, which we achieve through the deployment of new age

technology tools. Bringing back the ancient culture & heritage values has to be an integral part of the development. When we talk about People, Planet and Profit together, results in the sustainable development. Every development on this planet has to be more inclusive, which not only just address the needs of business or the strategic goals, but also addresses the environmental goals and social requirements. To me, this will be truly a ‘Shashwat Vikas’ if we can achieve this. India aims to reach net zero by 2070. The Government has declared plan to add 50 GW of renewable energy capacity annually for next 5 years to achieve the target of 500 GW by 2030. I am optimistic the way all the stakeholders are uniting to fight the climate change menace in the country and looking forward to a sustainable future for our next generations.

Mitesh Gangar: India has always had the opportunity to leapfrog across technologies. So, like with the example of almost skipping landlines in every household to now having mobile phones for each user, there is an opportunity to directly adopt sustainable and smart infrastructure. We see this happening in automobiles, and we are actively evaluating using electric-powered vehicles even for heavy cargo transport. We are taking the IGBC green certification for newer offices/ buildings. We are actively working on route optimization and reducing the fuel intensity of logistics by transporting the optimal volumes per trip.

Sanjay Desai: India is one of the fastest growing economies in the world since the last decade because of its own domestic economy / high consumption supported by its ever growing middle class and its increasing regional and cross border trade. However, a consistent growth of this magnitude has its own challenges. And one of them is achieving ESG compliance for all industry sectors. It requires a multifaceted approach involving government policies, industry initiatives and stakeholder collaborations. A few of the strategic best practices are covered below…

• Energy efficiency solutions like energy

efficient smart buildings, green standards in building technologies in office as well as homes, introduction of electric vehicles and extensive use of hydrogen as a fuel.

• Waste management and recycling practices like converting waste into energy, encourage use of biodegradable and eco-friendly packaging materials, improving training and awareness for recycling practices across industry segments.

• Water conservation via day-today practices like reducing water wastages, averting leakage & promoting organic farming, reducing use of chemicals/ fertilizers and finally encourage crop diversification supported by sustainable farming.

• Encourage industries to adopt circular product development strategies with closed-loop production process and re-use and/ or scavenge finished and semi-finished goods as much as possible before they go landfill.

• Resilience in disaster recovery and preparedness plans to withstand weather disruptions or other extreme conditions like deluges or wildfires. There is also a need to verify their feasibility and robustness.

• India’s agricultural throughput contributes 15% to India’s US$3 trillion economy. It also employs close to 45% of the total working population and covers 40% of country’s land mass. India needs to adopt organic farming to reduce the use of chemicals and fertilizers, invest in techniques of sustainable land management practices including preserving rainwater (water harvesting).

In the fast-paced realm of new age freight movement, ensuring safety has become a nonnegotiable imperative. Within the intricate ballet of shipping, be it domestic or global, cargo security is a pivotal act that requires precision, planning, and a meticulous approach. Protecting shipments from a spectrum of threats demands a cohesive strategy built upon a foundation of essential components. Companies that implement effective safety programs stand to gain a significant return on their investment. Our recently held panel discussion on ‘Achieving Safe & Secure Operations’ discussed the strategic priority of ensuring safety & security during cargo movement. Our expert panellists delved into the vital issue of addressing security concerns in today’s freight industry while highlighting the challenges faced and the strategies they employed to uphold safety standards. Excerpts…

“AsIndia prepares to become a US$5 trillion economy, there are varied challenges that need to be ironed out when it comes to supply chain. The two important ones involve Security and Safety. Whenever we discuss about security, it always implies chemical transportation security owing to the hazardous nature of the product. It also involves other products as well but what is less understood is the security aspect in the supply chain. It is no longer the safeguarding business that we have deployed some guards for a facility, it’s all about securing our assets or our products, making sure that goods are not hijacked while in-transit. The other day someone was talking to me with an apprehension if the goods would reach the destination. As startling as it may sound about a decade back or so, 15% of the truck moving on Indian roads not do not know where they disappeared. If that persists, it is now increasingly

becoming a major security threat owing to reasons such as counterfeit, kidnapping, terrorist activity, to name a few.” With these remarks, RG Panicker, MD, Dangerous Goods Management India, moderator of the panel set the tone in the right direction.

The evolving landscape of freight transportation brings with it a unique set of security challenges. From cargo theft to cyber threats targeting digital systems, the industry’s vulnerabilities are multifaceted. The increasing complexity of supply chains, often spanning multiple countries and modes of transport, amplifies these risks. Cargo security encompasses a spectrum of measures and practices to safeguard shipments against various threats. These threats go beyond the traditional notion of theft and extend to tampering, unauthorized access, and transporting hazardous or contraband materials.

However, the industry is rising to the occasion. Triumphs in the realm

of freight transportation security are characterized by innovative solutions and collaborative efforts. The objective is clear: to ensure that the integrity of cargo remains intact throughout its journey, preserving its value, reliability, and safety. Government, industry associations, and private enterprises are collaborating to establish best practices and regulations that enhance security across the supply chain. Employing advanced technologies such as IoT sensors, blockchain, and realtime tracking, companies are bolstering security measures to monitor cargo conditions and thwart unauthorized access. Here’s an insightful take on companies’ innovative strategies to tackle safety & security while in-transit…

What are the most important critical safety risk and challenges that the industry is facing?

Arush Kishore, VP - Integrated Operations (Liquid & Gas), Reliance Industries: I think the risks are pretty

much well known, if we can start with environment, health, financial and not limited to risk to reputation. At RIL, we are at a curve where every safety initiative that we take releases efficiency and therefore leads to cost competitiveness vis-à-vis competition. During the initial days, people would consider this as the cost factor. It forces you to look at minute tasks in 3P triangle – People, Process and Platform. For us as business entity, safety is linked to business efficiency.

Dhritiman Chakraborty, Director Operations, Ingram Micro: In the IT distribution landscape, while the nuances may vary, many safety and security aspects are fundamentally shared across industries. At the heart of our operations lies the trust of numerous OEMs, for whom we manage the distribution. Ensuring data security is paramount, as it upholds the integrity and reputation of both our partners and us. Beyond data, there’s also the tangible aspect, which is safeguarding the high-value inventory in our warehouses. The financial metric aside, any compromise on this front can severely dent the trust OEMs have on us and that we’ve built over the years.

RG Panicker: Supply chain security is critical concern for organizations as it encompasses the protection of goods, information, and processes throughout the supply chain. Couple of key issues that are of concern and needs to be addressed are

• Counterfeit product: Counterfeit product being of inferior quality can be dangerous to consumers as they

don’t meet any safety standards or undergo quality checks. Fake pharmaceuticals, electronics or cosmetic products can have severe health and environmental issues. They can undermine legitimate business resulting in significant economic loss and even brand reputation losses if consumer associated it with the company without understanding that they are counterfeit products.

• Physical safety of the people when transporting dangerous goods if they are not packed appropriately and in accordance with the regulations.

• If security is weak, it can lead to pilferage, theft and tampering of goods.

• Cyber security is another area of concern, as the virus attack can immobilise the organisation as today almost every system is IT enabled and interconnected

How would you carry out risk assessment for your organization?

Arush Kishore: We have a wellorganized, cadence-based system of risk assessment – identification, assignment, and classification. We have a risk register at various levels of our organization and again a risk mitigation cadence of platforms that meet regularly to flag of concerns and expedite mitigation efforts.

Dhritiman Chakraborty: A robust risk assessment hinges on diligent identification of all possible risk areas. It’s vital to consider every facet of our operations, while assessing risks - from human assets and physical inventory to data and our corporate

reputation. Following identification, a comprehensive mitigation strategy is to be crafted. Parallelly, contingency or ‘Plan B’ scenarios are to be prepared to handle any possible exposure. Every organization, especially in our fast-paced industry, should also have a Business Continuity Plan (BCP) that seamlessly merges with risk assessment. The cornerstone, however, remains employee training. An organization’s frontline should be well-equipped and aware of their roles in risk scenarios and hence they need to be frequently trained.

What are the requirements or steps you follow when you are selecting your third-party vendors when it comes to safety & security?

Arush Kishore: The Covid disruption threw up many insights into day to day operations. One of the insights was the need for management of vendor quality. one of the learnings we immediately implemented was a vendor capability audit for both entry of new players and standardization of desirable practices among existing associates. This coupled with a data derived performance measure is proving to be a great tool in capability building and enhancement of our vendors, thus improving our ability to service the demands of a dynamic business environment.

Dhritiman Chakraborty: Safety and security are paramount in our vendor selection process. The steps we typically follow include:

Background Checks: Assess the vendor’s reputation, previous collaborations, and any recorded breaches or issues.

I think safety is a hygiene factor. It’s not good enough being agile or quick. Supply chain is nothing if you are unsafe. This understanding of safety has to be owned by the entire organization and not just supply chain. Only then will the efficiencies flow. The Covid disruption threw up many insights into day to day operations. One of the insights was the need for management of vendor quality. One of the learnings we immediately implemented was a vendor capability audit for both entry of new players and standardization of desirable practices among existing associates. This coupled with a data derived performance measure is proving to be a great tool in capability building and enhancement of our vendors, thus improving our ability to service the demands of a dynamic business environment.