Cordant™ by Baker Hughes delivers actionable insights through AI-enhanced workflows, helping industrial leaders improve reliability, reduce costs, and drive sustainability across operations.

Explore how Cordant™ can help your operations move faster, perform better, and adapt with confidence.

Managing

Director

Adam Soroka

Editor Mark Venables

The conversation around digital twins has shifted. Once regarded as experimental, they are now a central part of industrial strategy. At Future Digital Twin 2025 in Amsterdam, that transition is clear. The event brings together operators, technology leaders, and innovators who no longer ask if twins will reshape industry, but how fast and at what scale.

The challenge is not simply technical. It is cultural, organisational, and operational. Delegates this year will hear how agentic AI is transforming digital twins from static replicas into reasoning systems capable of decision-making. They will explore the thorny realities of data governance, where poor quality, fragmentation, and trust gaps remain some of the largest obstacles to scaling twin deployments. They will confront questions of diversity, workforce transition, and the changing role of fieldworkers as drones, wearables, and robotics redefine what it means to work at the sharp end of industry.

Future Oil & Gas

Group

Second Floor Front

116-118 Chancery Lane

London WC1A 1PP

Tel: +44 (0)203 675 9530

The programme reflects the urgency of these debates. AI-infused twins are emerging as orchestrators of complex ecosystems, from subsea engineering to the automated rig floor. They are being called on to manage not just machines, but the flow of insight that determines whether operations remain resilient in the face of pressure from markets, regulators, and the environment. Yet success is not guaranteed. Without clear frameworks for interoperability, governance, and trust, the risk of silos, inefficiencies, and over-promised outcomes remains real.

What stands out in the sessions ahead is the range of perspectives. Oil and gas executives will share how digital twins are redefining drilling strategy, shifting risk away from people and toward automated rig floors. Technology leaders will argue that agentic systems are the next leap, making twins active participants rather than passive models. Others will focus on the human dimension: the safety of fieldworkers, the cultural acceptance of AI-driven decision support, and the imperative to ensure that innovation does not leave segments of the workforce behind.

Future Digital Twin is not a conference about hypothetical futures. It is about the present pressures on asset integrity, safety, and sustainability, and the technologies being deployed today to address them. Attendees will not only hear about advances in AI and simulation, but also about the gritty realities of deploying them in complex, hazardous environments.

The twin has moved beyond the control room, into the field, into the cloud, and into the hands of workers who now operate as part of a digital ecosystem. The event in Amsterdam is a chance to step back and assess that journey, its opportunities, its risks, and its unfinished business.

Mark Venables Editor

Only digital twins can turn the AI-driven oilfield from hype into a business reality

Siloed data and rigid systems are still the biggest drag on progress across drilling, refining, and pipeline operations. Artificial intelligence has promise, but it cannot thrive on fragmented or incomplete information.

rig

Oil and gas drilling has embraced digital twins, seismic imaging, and AI-powered well planning, but the rig floor remains essentially unchanged. Automating this highrisk environment is the next lifechanging innovation needed to improve safety, efficiency, and resilience across the industry.

When machines learn to think alongside us in oil and gas

The oil and gas sector has never been short of complexity. It operates in some of the harshest environments on earth, under pressures both physical and financial, and with little margin for error. Against that backdrop, the arrival of digital twins infused with artificial intelligence feels less like a new gadget and more like a survival tool.

Drones, wearables and the new face of the industrial fieldworker

Oil and gas field operations have always pushed people to their limits. Workers climb flare stacks in brutal heat, wade through mud around leaking pipelines, and perform inspections hundreds of miles offshore where medical help is hours away. For decades, this resilience defined the industry. The individual fieldworker, often alone or with a small crew, carried the weight of asset integrity and operational safety.

Decarbonization of the UK’s energy system requires increased interaction and cooperation between all energy stakeholders. As DNV explains, alongside electrification, digitalization remains a key enabler in the pathway towards net zero against a backdrop of volatility, unpredictability, and complexity

Real-world applications and use cases have emerged beyond the buzz and hype of AI. According to Kongsberg, Natural language processing (NLP), large language models (LLM), hybrid machine learning (ML), generative and agentic AI, all represent a litany of transformational technologies.

Oil and gas companies are piling up data at unprecedented scale, yet the industry’s ability to turn this into trusted insight lags far behind the hype. Without robust governance and shared models, AI-driven twins risk becoming another layer of noise rather than a platform for real change.

Oil and gas companies are beginning to see generative AI evolve from experiment to operational tool. The emergence of agentic frameworks promises to turn asset performance management into a dynamic, adaptive system that improves efficiency, resilience, and decision-making at scale.

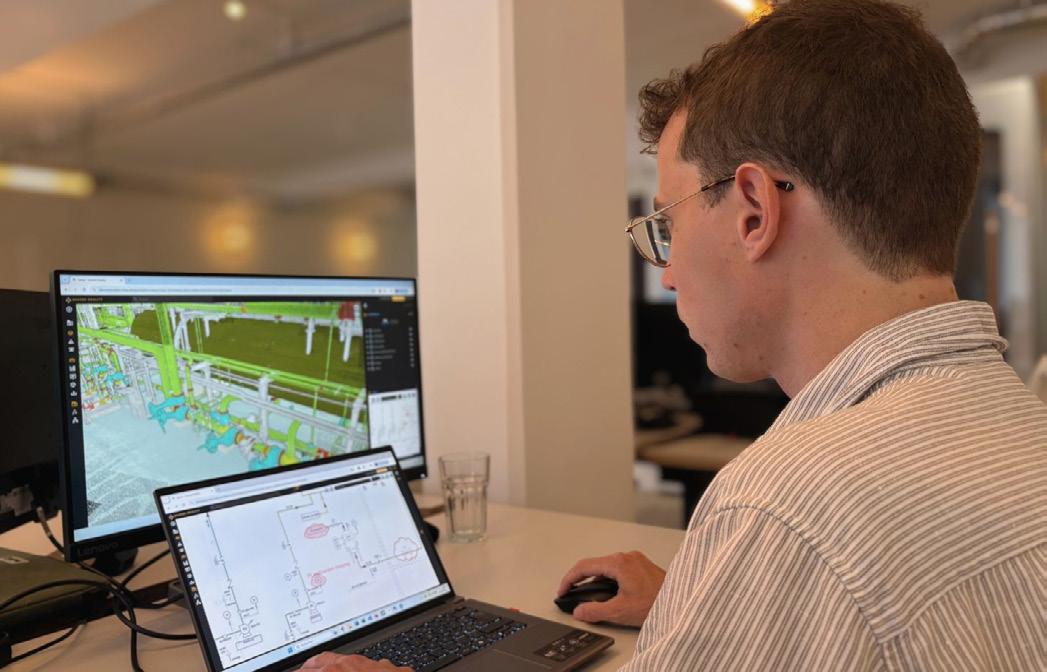

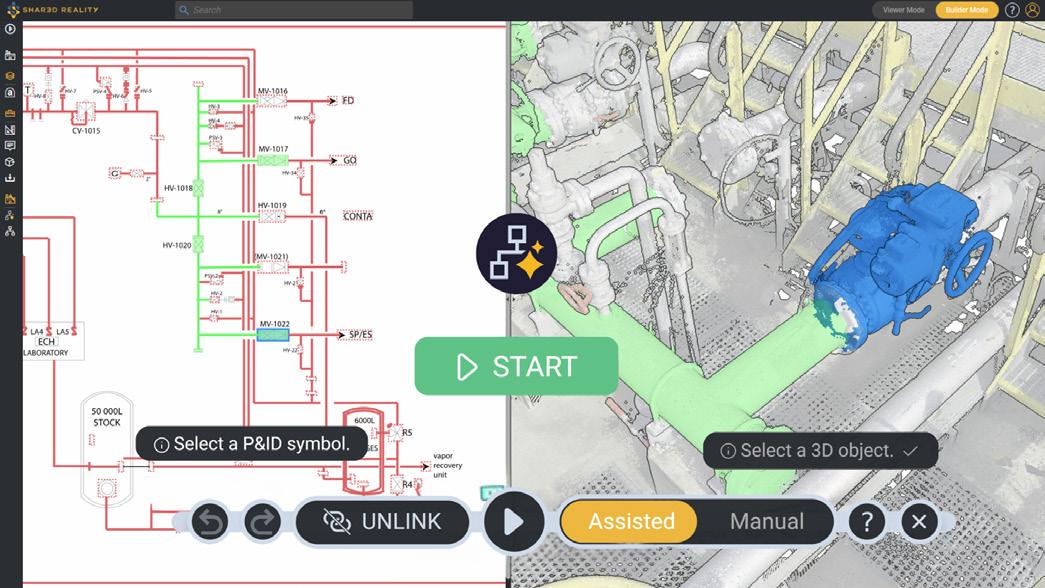

Oil and gas operators are investing heavily in digital tools, yet outdated field data continues to undermine safety, efficiency, and trust. A new generation of AI-powered platforms promises to close that gap by aligning documentation with the reality on site.

AI is reshaping the oil and gas sector, but the most significant challenge is not technical. It is human. Leading people through transformation requires systems of engagement designed for real users, a culture that prioritises participation and learning, and a commitment to diversity and inclusion as the foundation of sustainable change.

Outdated and unreliable field data remains one of the greatest risks in oil and gas, undermining safety and slowing critical decisions. By connecting documentation to real-world conditions, operators can restore trust between the physical and digital worlds and unlock safer, more efficient operations.

Siloed data and rigid systems are still the biggest drag on progress across drilling, refining, and pipeline operations. Artificial intelligence has promise, but it cannot thrive on fragmented or incomplete information. The digital twin is emerging as the unifying layer that brings strategy and operations into line, makes regulatory compliance routine, and creates a framework where generative AI can deliver value at scale rather than frustration

The modern oilfield generates torrents of information. Every hour, hundreds of thousands of sensors record pressure changes, vibration signatures, emissions levels, and flow rates. Geological models churn out their own data streams, as do maintenance records, financial systems, and control software. Yet despite this digital abundance, operators face a familiar obstacle: fragmentation. Different assets and systems often sit in isolation, stored in proprietary formats or locked inside legacy platforms. Rarely is that data contextualised across the asset lifecycle in a way that can drive decisions.

This lack of coherence limits what artificial intelligence can achieve. Machine learning models need structured and harmonised inputs to reach reliable accuracy. Generative AI is even more vulnerable, if it draws on inconsistent or incomplete data, the risk is that errors are amplified rather than solved. The digital twin steps into this void not as another database, but as a contextualising platform that brings order to complexity and translates it into usable intelligence.

A first principle for any AI-driven oilfield is interoperability. Assets last for decades and draw on equipment from multiple vendors. Unless information is structured according to common standards, every dataset becomes its own closed island, impossible to scale.

Industry initiatives have started to address this problem. The Open Subsurface Data Universe (OSDU) is building a platform where subsurface and well data can be accessed and shared across applications. The Digital Twin Consortium is pushing for similar levels of openness. Both efforts recognise that interoperability is not a luxury; it is the only way to make AI scalable rather than bespoke.

The advantages go beyond efficiency. A drilling optimisation model trained on one field should transfer to another. That is only possible if both datasets conform to a shared standard. Without that discipline, every deployment becomes a one-off, soaking up resources and undermining momentum.

The business benefits are clear. Unified datasets enable analytics to reduce downtime, enhance

throughput, and predict failures. Instead of reacting to problems in isolation, operators can orchestrate decisions across an entire value chain. The gains are financial, operational, and strategic.

Digital twins themselves have evolved dramatically. Their earliest uses were in design offices, simulating equipment layouts or testing conditions virtually. Today, they sit at the centre of business strategy. Twins no longer just reflect an asset, they orchestrate it.

Once underpinned by a standard data model, the twin becomes the operational fabric that links design, construction, and day-to-day performance. For executives, that alignment is not just a technical improvement but a shift in governance. It means digital strategy finally connects to operational reality.

Bp’s collaboration with Palantir in the Khazzan gasfields offers a glimpse of this trajectory. AIenabled twins there integrate drilling, production, and maintenance data into one seamless system. The outcomes are safer operations and more efficient performance, but just as important, the framework guards against the

risk of AI hallucination by embedding verification mechanisms into every workflow.

Shell has taken a similar line in refining, coupling predictive models with live process data. Operators can simulate adjustments before committing, striking a balance between output and emissions. What started as a technical exercise has become a board-level tool for managing risk, efficiency, and compliance.

Compliance as discipline Regulation and investor scrutiny on emissions are intensifying. Companies can no longer treat environmental reporting as an annual exercise. Progress must be visible, continuous, and credible. Digital twins provide the mechanism to meet that standard.

By linking live data from flaring sensors, methane monitors, and energy consumption trackers, the twin builds a real-time picture of environmental performance. AI benchmarks those readings against regulatory thresholds, runs scenarios of future emissions under different operating conditions, and recommends interventions. Compliance ceases to be a retrospective burden and becomes an operational discipline.

Equinor has tested this approach in the North Sea, using twins to monitor offshore emissions and energy use. The insights have allowed efficiency improvements that deliver both cost savings and lower carbon output. In this model, emissions management is no longer detached from business performance; it becomes integral to it.

The competitive impact is real. Companies demonstrating proactive compliance gain credibility with investors and stakeholders. The twin thus becomes not just an internal management tool but a visible signal of operational integrity.

No oilfield is static. Equipment changes, data sources expand, and operational priorities shift. A digital twin that is monolithic quickly becomes obsolete. Composable architectures, built on modular principles, avoid that trap.

With composability, operators can add or remove components as needed. New sources—whether seismic surveys, satellite images, or supply chain metrics—can be integrated without tearing down the whole system. This flexibility is a strategic advantage in a sector where conditions change faster than investment cycles.

Argentina’s Vaca Muerta basin provides a working example. Operators are plugging generative AI optimisation modules into existing twin platforms. These systems test scenarios in real time, adjusting pump speeds or valve pressures to boost energy efficiency without disrupting ongoing production.

The model extends across the value chain. Supply chain data can be integrated to improve logistics. Environmental monitoring can be strengthened with satellite feeds. Financial data can be layered into align operations with cost objectives. Modularity ensures that the twin remains relevant as technology and business requirements evolve.

Interoperability and modularity create the foundations. Generative AI adds the multiplier. Its strength lies in simulating, synthesising, and contextualising vast datasets, producing insights that reach far beyond conventional analytics.

In drilling, generative models can test thousands

of parameter combinations in silico, identifying strategies that reduce non-productive time. Reservoir management trials have already demonstrated recovery improvements of up to ten per cent while cutting water production significantly. Refining operations use generative modelling for continuous scenario planning, balancing throughput, energy costs, and emissions.

Pipeline integrity is another domain where generative models add value. By combining sensor readings with UAV imagery, AI-enhanced twins can simulate potential leak scenarios and recommend interventions before they escalate. Monitoring shifts from reactive detection to predictive prevention.

The effect is to turn static data into dynamic intelligence. These models do not replace human operators, but they amplify their decision-making power, providing context, options, and foresight that manual analysis could never deliver at speed.

Broader business implications

The AI-driven oilfield is not only about technology. It is about competitive positioning. Companies that succeed in unifying and contextualising their data will reshape how they are judged by regulators, investors, and employees alike.

Financially, the case is straightforward: downtime drops, maintenance becomes predictive, energy use is optimised, and costs fall. These improvements flow directly into earnings and asset valuations.

For the workforce, the change is cultural as well

as technical. Field staff must adapt from relying purely on hands-on experience to collaborating with AI systems. This demands new training programmes and a mindset shift towards datadriven practice. Trust in AI must be earned through transparency and explainability.

Strategically, composable twins guard against obsolescence. Digital strategies remain flexible, able to absorb new regulations, data streams, or market shifts. Companies that embrace this model are not locked into platforms—they are free to evolve.

The AI-driven oilfield is already taking shape. Advances in interoperability, modularity, and generative AI are turning aspiration into practice. The companies that treat digital twins as businesscritical, embed governance, and invest in cultural change will set the pace.

The rewards are clear: operational efficiency, real-time emissions control, and resilience against disruption. The risks are also clear: without standards, systems will fragment; without governance, trust will erode; without cultural readiness, adoption will falter.

The digital twin is no longer optional. It is becoming the backbone of an oilfield where intelligence, efficiency, and sustainability converge. The firms that master it will not only optimise assets but redefine their industry’s relationship with technology, stakeholders, and the environment.

At Baringa, we help organisations across Energy, Telecoms and the Public Sector transform asset performance, end-to-end. From design and capital delivery to handover and operations, we bring AI and digital innovation to every stage of the asset lifecycle.

Our focus? Driving reliability, boosting operational efficiency, and cutting lifecycle costs through:

• Intelligent Asset Management

• Digital Capital Projects

• AI-Enabled Field Services

With deep industry expertise and cutting-edge technology like digital twins and IoT, we deliver real results. With recent examples including AI-augmented understanding of major capital project risks, through to AI-optimised network asset availability and resilience, we are ready to help you stay ahead in a rapidly evolving landscape.

Oil and gas drilling has embraced digital twins, seismic imaging, and AIpowered well planning, but the rig floor remains essentially unchanged. Automating this high-risk environment is the next life-changing innovation needed to improve safety, efficiency, and resilience across the industry.

The oil and gas industry has a track record of turning technological ambition into operational reality. Digital twins are now optimising offshore facilities from remote operations centres. AI models have reduced well design cycles from months to days. Seismic imaging has delivered unprecedented clarity in the hunt for new reserves. Yet one of the most visible and hazardous parts of drilling has barely evolved in decades.

The rig floor, despite advances in automation elsewhere, continues to place people in the middle of high-risk operations. For Ann Davies, Senior Vice President, Wells at BP, this is where the next breakthrough must happen. She argues that the industry should commit to full automation of the rig floor, removing workers from danger and re-imagining drilling operations with the same ambition that once transformed subsea interventions.

Technology is already transforming drilling

BP is reshaping its upstream strategy with renewed investment in oil and gas. Davies explains that the Wells business is focused on exploration, infill drilling, and delivering higher reserves and margins, particularly in the US, where production is expected to rise from 740,000 barrels a day to one million by 2030. To achieve this, digital and technical capability must go hand in hand.

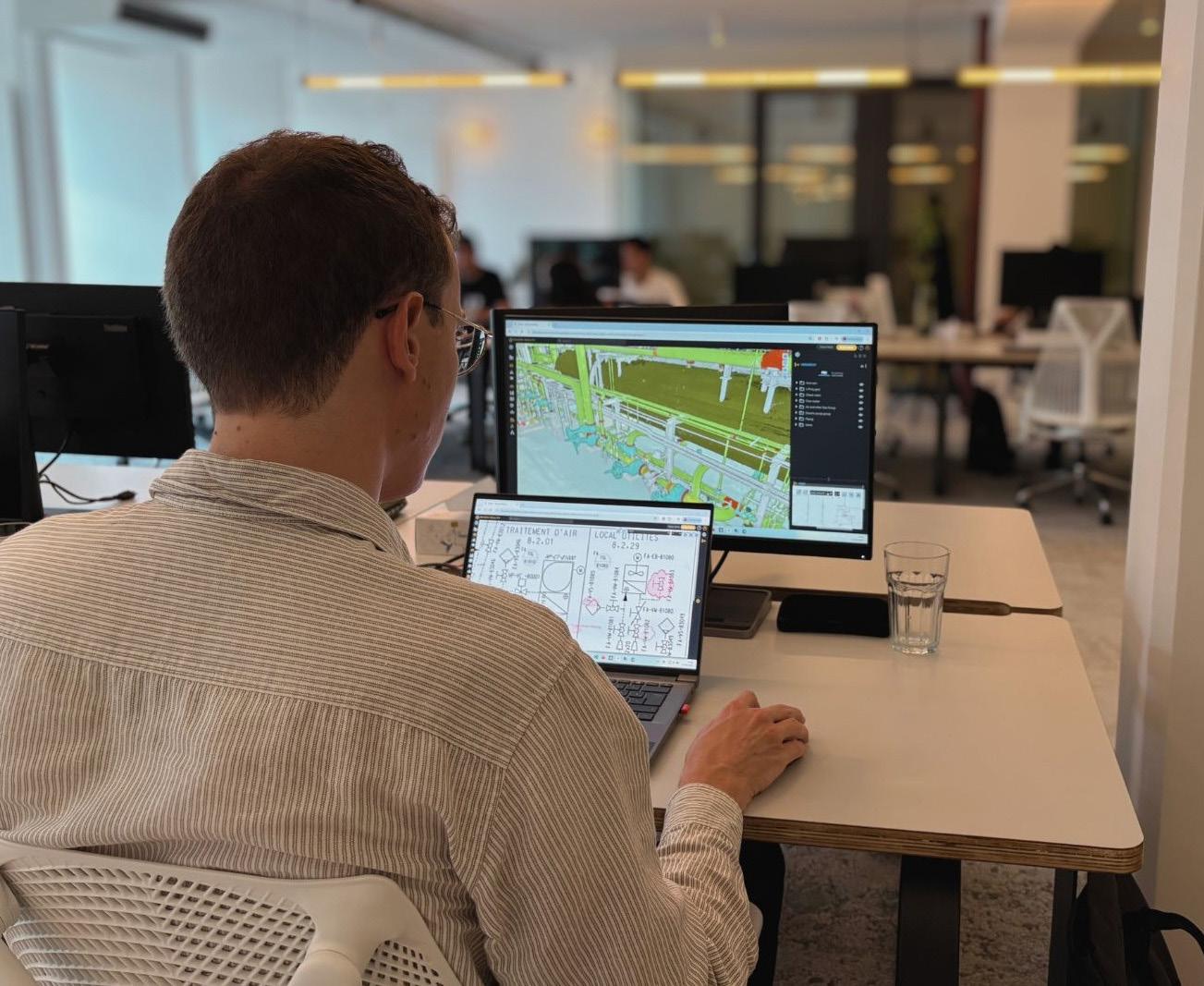

“Technical capability is a core strength for bp, and when we complement our strengths with technology and digital, we win. Today, we use digital twins of key facilities to help optimise operations remotely. We use AI to help us plan new wells, reducing well design time from months to a few days. We use cutting-edge seismic imaging to help us find the most profitable barrels,” Davies says.

The digitalisation of upstream operations has already demonstrated how rapidly technology can alter established practices. Remote monitoring has reduced travel to offshore facilities, while AI-driven well

planning has compressed timelines and reduced costs. These are not incremental changes but structural shifts in how the industry works.

Yet Davies identifies the rig floor as a striking exception. “Despite progress on safety, if you step foot on the floor of a drilling rig, it looks largely the same as it did 20 years ago, when I first set foot on one,” she says. “And, as we all know, the work on rig floors is not easy. We are drilling deeper and further than ever, with narrow drilling windows and harsh conditions. We are threading a needle miles away from that rig floor.”

The physical environment of the rig floor is as demanding as it is hazardous. Davies paints a vivid picture of what it means to step into this space. “Life on a rig floor is a high-stakes environment, where businesses are made, and a lot can go wrong,” she continues. “How you enter the rig floor, ready, as if you were competing in an extreme sport. But you are not dressed for flexibility and agility. Instead, you are head-to-toe in PPE. On the rig floor, there is a massive amount of activity, both on the surface and downhole. The smell hits you straight away. Tonnes of steel that move constantly, and in different directions. Entwined with human beings. Our people, amongst the machine.”

This collision of heavy machinery, unpredictable conditions, and human presence creates one of the most challenging working environments in the sector. Weather intensifies the risks, whether in extreme heat inside protective clothing or in the cold winds and horizontal rain of northern fields. For Davies, it is one of the most challenging jobs in the world, both physically and psychologically.

“That’s why working on a rig is, I believe, one of the toughest jobs in the world,” Davies explains. “But there is no question that you get an immense sense of satisfaction and achievement once you’ve completed the job. We are making history by delivering the energy the world needs. Energy that keeps people moving, helping fuel people’s lives. And if you believe, as I do, that everyone is entitled to a reliable supply of energy, then it makes it extra special. I have nothing but the utmost respect for those who do it.”

Respect, however, is not enough. The imperative is to rethink the design of the rig floor itself. “Now that I am in a leadership position, with responsibility for people and a business, the single most important part of my job is people’s safety,” Davies says. “And, of all the high-hazard aspects of the energy industry, we know, the rig floor is an area where most hazards are concentrated.”

For Davies, the conclusion is clear: the next wave of innovation must be full automation of the rig floor. “What I am proposing is that we take steps to fully automate the rig floor,” he continues. “Take people out of harm’s way. Remove people from inside the machine,” she says.

This ambition will require collective action. Rig assets change hands frequently, and ownership structures are often complex. To achieve automation, the industry will need cooperation across operators, drilling contractors, service providers, and technology partners. “If we are to automate, for greater safety and efficiency, we need everyone in

our industry to make it happen,” Davies explains. “To work together. Yes, there are hurdles to overcome. There is a need to retrofit ageing equipment and systems with new technology. And also, the elephant in the room, the idea that we would be pushing people out of work. The more automation, the fewer jobs, or the creation of different jobs. We will still need the expertise and experience of rig floor operators. But do we need to put them inside the machine? And we owe it to them to keep them as safe as possible.”

The precedent already exists. Divers once carried out inspection and repair work at great depth, a practice that exposed them to extraordinary risk. Today, remotely operated vehicles (ROVs) perform most subsea tasks, delivering improvements in precision, cost, and above all, safety. “The result is far safer, more efficient, precise and cost-effective subsea work,” Davies adds. “So, what I am advocating for is evolution. Where we raise the bar, together, as an industry. Like we have done before.”

Automation at scale is rarely straightforward. Retrofitting older rigs with robotics, sensors, and digital integration is a significant challenge. Standardisation will be required to ensure that technologies deployed on one operator’s rig can be maintained or upgraded under another. Investment cycles and regulatory requirements will influence adoption speed.

Yet the benefits are clear. Removing people from high-risk zones improves safety performance, reduces the likelihood of downtime caused by accidents, and accelerates operational efficiency. Advanced robotics and AI can bring greater precision to pipe handling, drilling, and tripping operations. Automation can also increase consistency, reducing the variability caused by fatigue or environmental stress.

The workforce dimension is equally important. As Davies notes, automation does not mean eliminating expertise but re-deploying it. Rig crews will be needed to supervise automated systems, interpret data, and manage exceptions. The skills required will evolve towards human-machine collaboration, digital literacy, and systems oversight. For executives, this implies investment not only in technology but also in training and workforce transition strategies.

Davies concludes with a call to action that emphasises both urgency and opportunity. “We are judged by our actions, not words and presentations,” she says. “Our

industry is focused on safety and efficiencies. And we find ourselves in the unique position this week where every person and company in this room can make so much happen. Operators, service companies, finance companies, digital companies. Remember, nothing new needs inventing. There is no technical reason we cannot automate rig floors. It is in our gift. And in our best interest. And it is the right time to get on with it.”

Her argument places rig floor automation in the lineage of past innovations. Just as air conditioning and space travel once transformed daily life, she positions automated rig floors as a life-changing step for oil and gas. “These are life-changing innovations,” he concludes. “This time, a life-changing innovation for our industry. So that when we look back in the future, we celebrate the people who drove our industry forward. But also struggle to imagine life before automated rig floors.”

For senior executives, the message is direct. The digital transformation of drilling cannot stop at design optimisation or facility monitoring. The physical interface of the rig floor remains the most visible test of safety culture, technological ambition, and industry collaboration. Full automation is not simply a technical challenge but a leadership decision about how the sector defines its future.

Automation of the rig floor is within reach. The technologies exist, the benefits are clear, and the urgency is growing. The question is no longer whether it can be done, but whether the industry has the will to do it together.

Bring accuracy, speed & trust back to the field

Discover Shared Reality, the AI-powered 3D workspace that connects your facility’s documentation, scans, and asset data into one visual source of truth.

Faster turnarounds, no surprises, finally, your site and systems in sync.

Join us for an exclusive webinar on 18 Sep, 2025

Samp is launching 3D BI, a powerful module of Shared Reality that allows you to display external metadata and analytics directly on 3D Reality Models.

The oil and gas sector has never been short of complexity. It operates in some of the harshest environments on earth, under pressures both physical and financial, and with little margin for error. Against that backdrop, the arrival of digital twins infused with artificial intelligence feels less like a new gadget and more like a survival tool.

Digital twins started life as digital blueprints, functional replicas of physical assets that could model stress, temperature, or performance. They were handy for training teams or testing ideas, but limited in scope. Over the last few years, though, something has shifted. When artificial intelligence is layered onto these models, the twin begins to do more than copy reality. It anticipates. It suggests. It adapts.

For operators, that shift is not a technical curiosity but a business necessity. A subsea pump that fails unexpectedly can shut down production, trigger a safety incident, or undermine

months of planning. A refinery struggling with fluctuating energy costs must balance output with emissions limits while staying competitive. In both cases, the idea of a system that can think ahead, rather than just report back, is a powerful proposition.

AI-enhanced twins are fed by relentless streams of data: vibration sensors, inspection logs, satellite readings, and weather forecasts.

Where human teams would once pore over spreadsheets for weeks, the system now ingests and interprets the lot in near real time. Machine learning finds the weak signals in the noise. Generative AI then builds scenarios, testing what might happen next and what levers could be pulled in response.

The result is less of a passive dashboard and more of a decision-making partner. Instead of simply showing a pressure reading, it can explain how that reading might evolve over the next 48 hours, whether it risks breaching safe thresholds, and what action would minimise both cost and emissions.

The most crucial point here is not replacing people but amplifying them. The machine does the heavy lifting on pattern recognition and forecasting. The human decides how to apply that knowledge in the messy, political, and highly contextual world of oil and gas operations.

Compliance as a built-in feature The growing weight of the energy transition has added another layer of urgency. Emissions, once treated as a side calculation, are now central to investor confidence and regulatory scrutiny. For operators, the challenge has been how to integrate this reality into day-to-day operations without paralysing output.

Digital twins offer one answer. Flaring events, methane leaks, or excess heat can be captured instantly, benchmarked against legal limits, and projected forward. Instead of compliance being an afterthe-fact box-tick, it becomes a real-time consideration. In some cases, the AI can even propose tweaks to process conditions that reduce emissions and save fuel at the same time.

That subtle change matters. It reframes compliance not as a drag on performance but as a driver of efficiency. When emissions management is embedded directly in operational models, sustainability and profitability begin to align.

Traditional automation has long underpinned the industry. Programmable logic controllers and deterministic systems do what they are told, and do it reliably. But they lack flexibility. They struggle when conditions fall outside predefined rules, which in oil and gas is a frequent reality. Reservoir behaviour, equipment wear, or erratic weather rarely obey tidy models.

Deep reinforcement learning offers an alternative. Within the safe confines of a digital twin, algorithms can play out thousands of scenarios, learn through trial and error, and refine their strategies. Over time, they become better at balancing competing objectives: maximising recovery, protecting equipment, and staying within environmental limits.

In a live operation, that means more robust decision support. The AI might not know precisely what will happen tomorrow, but it has experienced enough simulated tomorrows to offer guidance grounded in probability and learning, not just rules. The operator remains in charge, but with a richer map of options.

The technology story cannot be told without the human one. A twin powered by AI demands new skills, new trust, and new working cultures. A drilling engineer today must be as comfortable with algorithmic outputs as with pressure curves. A data scientist must learn why a marginal gain in throughput might not be worth the safety risk.

Reskilling programmes are already moving in that direction, but culture is harder to shift than capability. Trust is fragile. If teams see AI as a black box making opaque decisions, adoption stalls. If they can interrogate why a recommendation was made, what data was used, and what assumptions were fed in, then the machine becomes a colleague rather than a threat.

This is where explainability matters most. Operators do not need a lecture in machine learning theory, but they do need to see enough transparency to feel confident in the decisions they are approving. Without that cultural buyin, the promise of AI twins risks staying theoretical.

Oil and gas carry risks that few industries can match. An error can damage ecosystems, endanger lives, and carry reputational costs that last for decades. That reality makes responsible AI more than a slogan. It is a precondition.

Data must be representative and regularly audited to avoid bias. Models must be tested and retested, not just at launch but as they evolve. Transparent governance is needed so that responsibility never drifts between machine and human. These are not optional extras; they are the foundations of trust in a high-risk sector.

Machine learning sharpens prediction. Generative AI goes further, giving digital twins the ability to create and test new scenarios. That opens space for greater autonomy. A twin can take historical project records, combine them with real-time sensor data, and simulate the likely outcomes of maintenance or process changes before they are implemented.

The obvious benefit is speed. What once required weeks of manual study can be condensed into hours of machine-generated analysis. More importantly, safety improves. Teams can test interventions virtually without putting equipment or people at risk.

Genuine autonomy, where assets operate independently without human oversight, remains some way off. But generative AI moves the needle. It allows lower-risk, repetitive tasks to be automated, while preserving human judgment for the most consequential calls. Autonomy becomes a spectrum, not a switch.

Looking ahead, the convergence of AI and digital twins points towards a model of autonomous integrity management. In such a world, assets would monitor their own condition, predict their own needs, and adjust their own operations. The idea is no longer futuristic. Early steps are already visible.

The impact is hard to overstate. Unplanned downtime shrinks. Emissions management becomes embedded in daily practice. Human teams step away from repetitive firefighting and focus instead on strategy, creativity, and resilience.

That vision is not without risk. Overreliance on algorithms, poor governance, or cultural resistance could stall progress. But the opportunity is transformative. If approached deliberately, anchored in transparency, responsibility, and trust, the AI-powered digital twin could become more than just a tool. It could reshape the industry’s relationship with its assets, its workforce, and its future.

Oil and gas field operations have always pushed people to their limits. Workers climb flare stacks in brutal heat, wade through mud around leaking pipelines, and perform inspections hundreds of miles offshore where medical help is hours away. For decades, this resilience defined the industry. The individual fieldworker, often alone or with a small crew, carried the weight of asset integrity and operational safety.

That picture is now changing. The lone operator is giving way to a connected professional plugged into a web of digital tools. Drones hover overhead, capturing high-resolution images, wearables track fatigue and vital signs, and robotic crawlers move through spaces too dangerous for humans. All of it feeds into digital twins that no longer just sit in a control room

but extend into the field. The industrial worker becomes part of a real-time digital ecosystem where human expertise is reinforced by AI-driven intelligence.

This is more than a gadget story. It is a cultural and operational shift that redefines the meaning of asset integrity and reshapes the role of the worker.

Project Development & Innovation | Project Execution | World-Wide Operations

● Mooring Systems

● Fluid Transfer Systems

● Jetty-less solutions, including Ammonia

● Digital Products and Services

● Intelligent, AI driven Asset Management Solutions

Rethinking integrity at the sharp end

Asset integrity has always been a difficult promise to keep. Pipelines stretch for thousands of miles across deserts and tundra. Offshore platforms are battered by waves and salt. Equipment ages faster than planned, and inspection teams are asked to cover vast distances with limited resources. Traditionally, the solution has been physical inspections, where crews climb, measure, and report by hand.

The risks were obvious, and so were the limits. Manual checks are episodic; they capture conditions at a single moment in time. Failures often reveal themselves between inspections, leaving operators to react after damage has been done.

The arrival of digital twins connected to real-time data streams alters that equation. Instead of relying on inspection reports filed weeks apart, operators gain a real-time composite view built from drones, sensors, and wearables. The twin becomes a constantly updated mirror of the asset. It highlights emerging problems early, prioritises risks, and suggests where maintenance should be directed.

The philosophy changes, too. Integrity management stops being reactive and turns into a dynamic, ongoing process. Failures are prevented before they occur, interventions are more targeted, and the human inspector becomes a decisionmaker armed with a depth of information no clipboard could ever provide.

The connected twin represents the most crucial step in this evolution. Where early twins were confined to engineering teams and control centres, today’s versions extend directly into the field. They tie together workers, devices, and assets, creating a two-way flow of intelligence.

This distributed architecture is already altering day-to-day work. A wearable helmet can warn an operator if nearby

equipment drifts outside safe operating parameters. Drone imagery streamed live into the twin allows an engineer to “stand” on top of a flare stack without leaving the ground. Embedded twins within pumps or compressors can trigger alerts about subtle changes in vibration, pointing to degradation long before it becomes critical.

For the worker, these tools do not remove responsibility; they expand it. Instead of being limited to what they can see or touch, fieldworkers can draw on a broad digital context. They orchestrate multiple streams of information, validating what the system suggests and deciding how to act. Their role moves away from repetitive manual checks toward informed, proactive intervention.

Among all these technologies, wearables have the most direct impact on the daily life of workers. Smart helmets equipped with augmented reality overlays can project schematics or maintenance steps directly into the user’s vision. Instead of flipping through manuals or radioing for help, the worker sees the procedure unfold in front of them.

Remote collaboration is transformed. An expert in Houston can see precisely what a technician in the North Sea is looking at, providing guidance as if standing beside them. Training times shorten because less experienced staff can be guided step by step in real time.

Biometric monitoring adds a further layer. Sensors that track heart rate, stress, and exposure to toxic gases feed data into the twin alongside asset readings. The system recognises when fatigue is setting in or when environmental limits are being reached. Safety managers receive live alerts, enabling interventions before an incident occurs.

The effect is not simply efficiency. Workers who know that their health and safety are actively monitored—and that they can call on digital assistance instantly, tend to feel more supported, less isolated, and better able to focus on the task at hand.

All of this depends on communications. A drone capturing imagery of a flare stack is only valuable if the data arrives instantly where it is needed. A biometric alert is only helpful if it triggers in time to prevent an accident. In practice, latency makes the difference between a smooth operation and a serious incident.

The industry has begun to address this with private LTE networks, 5G deployments, and edge computing nodes close to critical assets. Processing data at the edge removes delays that would occur if everything had to travel back to a distant cloud. For wearables, this means an alert is delivered without hesitation. For drones, it ensures video feeds can be stitched into the twin without lag.

It is easy to overlook this hidden layer of infrastructure, but in high-risk environments, seconds matter. A digital twin that lags by even a minute is a liability. A twin that responds instantly becomes a trusted operational partner.

Drones, robotics and new eyes on assets

Drones and robotics demonstrate most vividly how the line between physical and digital is blurring. Unmanned aerial vehicles now handle flare stack inspections, rig surveys, and long pipeline patrols. Highresolution cameras and multispectral sensors capture details invisible to the human eye.

Once integrated into a digital twin, this data does more than create pretty images. It feeds into 3D visualisations, allowing engineers to rotate, zoom, and analyse assets in fine detail. Anomalies can be mapped against past records, and potential interventions can be rehearsed virtually before they are attempted in reality.

Robotics push this further into areas where human presence is impossible. Crawler units move through tanks, confined spaces, and subsea infrastructure. They identify cracks, corrosion, or leaks and relay the information directly to the twin. Gas-sensing drones can detect methane emissions too small to be seen, transforming environmental compliance into a live process rather than a retrospective exercise.

This is not about removing people from the picture. It is about ensuring they spend less time gathering data and more time making sense of it. The fieldworker remains the interpreter, the decision-maker, the one who decides whether to shut down, repair, or continue.

The bigger story is cultural. For generations, pride in oil and gas has been tied to physical toughness: the ability to endure weather, climb heights, and keep machinery running under brutal conditions. The digital shift does not erase that legacy, but it reframes it. The new measure of resilience encompasses not only physical endurance but also the ability to work fluently with digital systems.

That demands reskilling. Workers need to trust the data, understand the assumptions behind AI models, and know when to challenge the outputs. They must see technology not as a replacement but as an ally. Without that cultural buy-in, the promise of digital twins infused with drones and wearables risks stalling

at the pilot stage. Governance plays a role here. Responsibility must remain clear. The system may recommend, but the human approves. Data quality must be assured, and models must be transparent enough to interrogate. In a sector where mistakes carry huge environmental and human costs, those checks are not optional.

What emerges is a vision of the industrial fieldworker embedded within a human-digital ecosystem. Drones, wearables, robotics, and AIdriven twins combine to provide a constant stream of insight. Workers are safer because they no longer perform the most hazardous tasks. Assets are more reliable because problems are spotted earlier and addressed with precision. Operations are more efficient because decisions are made with live, contextualised intelligence.

The risks of over-automation remain. Blind faith in algorithms, poor governance, or underinvestment in training could easily erode trust. But if balance is maintained, the outcome is powerful: a workforce that is supported rather than replaced, more resilient assets, and an industry that moves forward without losing sight of its human core.

The oil and gas sector has always depended on people willing to take on harsh environments and unforgiving conditions. In the age of AI-enhanced digital twins, that dependence continues. But the role of the worker is evolving, from isolated problem-solver to orchestrator of a connected, intelligent system. That is not a loss of identity; it is an expansion of it.

At Marine Technical Limits, we envision an intelligent, proactive future for structural integrity. Our PYXIS platform, leveraging decades of expertise, is the definitive digital platform for your structural risk profile and integrity performance. By creating a dynamic digital twin of your FPSO hull, PYXIS acts as the fundamental AI enabler for predictive asset management. It centralises workflows in an immersive cloud environment, delivering real-time insights to empower truly predictive decisions, optimise efficiency, and safely extend asset lifespans. Partner with MTL to evolve your assets with digital intelligence.

See what’s possible at: technical-limits.com/pyxis

Decarbonization of the UK’s energy system requires increased interaction and cooperation between all energy stakeholders. As DNV explains, alongside electrification, digitalization remains a key enabler in the pathway towards net zero against a backdrop of volatility, unpredictability, and complexity

In the UK’s first Energy Digitalisation Strategy, the Government set out how only a digitalized energy system can withstand the distributed nature of low-carbon technologies connecting to the grid in the coming years. Several subsequent use cases - many now being realized as actual projectsare emerging across the UK energy sector. For example, the National Energy System Operator (NESO) is leading on the Virtual Energy System which aims to enable an ecosystem of connected digital twins. However, introducing digital technology, enabling data sharing, and increasing automation, inherently introduces additional risk into safety-critical systems.

How can the energy industry adopt digital technology, deploy sensor systems, share data and enable the introduction of computational models (including artificial intelligence and digital twins) to command their assets and be confident in their safe, secure and economical operation in addition to meeting the legal and regulatory requirements?

As we enter 2025, the energy industry stands at a pivotal moment in its history. Despite global economic headwinds and geopolitical uncertainties, we’ve witnessed unprecedented momentum in clean energy deployment and DNV forecasts that the world will hit peak emissions this year.

The UK’s energy landscape is transforming rapidly, with record-breaking renewable energy generation and falling costs of clean technologies setting new benchmarks for what is possible. The past year has demonstrated the UK’s potential on this transition journey. We’ve seen wind power generation reach historic highs, battery storage capacity expand significantly and Electric Vehicle (EV) adoption show signs of recovery. However, these achievements, while significant, are merely the initial steps toward the UK’s 2050 net-zero goal.

The ambitious new transition pathway mapped out by the UK government includes three critical milestones that will shape our journey towards net zero. DNV’s UK Energy Transition Outlook 2025 reveals a mixed picture of progress and challenges against these three targets:

First, by 2030, we expect to see a dramatic expansion of clean power infrastructure, with installed renewable capacity forecast to double, reducing our reliance on gas to less than 12%, but falling just short of the Clean Power 2030 target of 95%.

Second, DNV’s forecast of a 35% reduction of today’s emissions by 2035 highlights that progress is being made, but that the UK will still fall short of its new Nationally Determined Contributions (NDC) target of at least 81%.

Third, our forecast for 2050 sees the UK successfully decoupling economic growth from energy consumption, reducing the UK’s energy demand by 25% and emissions by 82% compared with 1990 levels. But clearly the UK is not reaching net zero.

Looking ahead, we see enormous opportunities in this transition. The green economy promises new jobs, reduced energy costs for consumers, enhanced

energy security, and technological leadership. However, these opportunities can only be realized through continued policy support, strategic investment, and strong collaboration across all sectors. The path ahead is challenging but clear: we must maintain our momentum while being agile enough to adapt to new technologies and opportunities. Together, we can build an energy system that is not just cleaner and more efficient, but also more equitable and resilient.

At DNV, we firmly believe that digital transformation is key to safeguarding energy supply in its current form; whilst at the same time helping to decarbonize and electrify society. We also expect our energy system to comprise connected digital twins, with AI baked into this smart, Cyber Physical Infrastructure (CPI). This will address the significant increase in complexity we foresee across the entire energy system which is becoming increasingly digitalized and connected. Only with trusted digital systems managing this complexity will the UK’s energy supply remain safe, secure and sustainable.

The chasm between theory and reality in terms of where the sector is today and where it needs to be to realise this digitalisation is significant but not unbridgeable. Through controlled research and testing, which includes stress testing the full envelope of potential future scenarios and demonstrating compliance, trust in digital assets can be gained: unlocking their investment and adoption across the energy industry.

Establishing trust in digital assets is vital for the industry, which is used to managing highrisk assets and critical infrastructure essential for society. As the energy sector transitions toward cleaner and smarter technologies, digital trust ensures seamless integration of these cross-vector systems to enable efficient energy production, distribution, and consumption. However, whilst digital technologies offer significant opportunities, they also introduce complexities and risks. Some examples include:

• Smart energy adoption: With the proliferation of smart energy technologies (such as smart grids, sensors, and IoT devices), there will be a substantial increase in the quantity of data produced and exchanged. Maintaining trust in the accuracy and validity of this data is paramount for reliable decision-making.

• Data management: Interoperability is essential for systems to facilitate new and existing data sources. Effective data handling through measurable data quality, secure storage and seamless exchange are critical for optimizing energy operations.

Cybersecurity: Operational technology must be robust against cyber threats which act as a significant hurdle for the adoption of digitalized assets on critical national infrastructure. It is therefore imperative that systems are rigorously tested against cyber threats, and that thorough cyber-security strategies with incident response plans are in place prior to adoption to instil trust that the energy system will remain safe, controlled and resilient.

Regulatory compliance: Trustworthy systems need to adhere to industry regulations and standards. Compliance builds confidence among stakeholders and ensures responsible energy practices.

In summary, digitalization is essential but it introduces new complexity and risks. Digital trust is paramount in underpinning a reliable and resilient energy system which supports a sustainable energy transition.

Bridging the gap to net zero

Awareness and reduction of digital technology risk is imperative to accelerating the energy transition. Without appropriate assurance of technical risk, new energy technologies – and specifically, digital and cyber-physical technologies – are, at best, expensive to scale, operate, insure and/or finance. Technical confidence is a critical building block for the deployment of energy technologies. Independent assurance can give investors the confidence needed to finance and ultimately deploy these technologies at scale.

According to DNV’s latest Energy Industry Insights report, a survey of over 1,000 C-level executives across power, renewables, oil and gas and industrial energy use sectors, a total of 91 % of respondents reported that they will increase or maintain investment in digitalization in the year ahead. Associated with that, 68% will focus on automation; whilst 71% report that improving data quality and ensuring data availability is high on the agenda. 60% of respondents suggest that they will use AI-driven applications in their operations.

The automation piece is of particular interest, as industry tells us that it is investing significant amounts into AI and other digital technologies but, according to the detail in our research, few can demonstrate the trustworthiness of these technologies to stakeholders for critical decision-making. Although only 12% of the industry’s C-level respondents say they are in an advanced stage of AI development – or have live AI projects – this is set to change with 73% stating they are piloting or planning activities for the future.

The struggle for many companies is the transition from pilot innovation projects and lab-based demonstrations to actual projects with business-as-usual implementation. DNV’s learnings, from assisting customers across the energy sector in this transition to implement trustworthy AI, can be summarised in three key highlights:

There needs to be a better understanding of how AI technology will deliver value by being sustainably integrated into work processes;

• Digital assets that are created require a structured change management approach throughout any digitalization process to ensure value is realized;

Given the different assurance requirements of digital technologies compared to physical assets, a comprehensive approach to data management and data quality is required to leverage sustainable value.

For many organisations in the sector, all three of those items remain challenges that need to be solved to ensure a more meaningful return on investment from assets. Establishing digital trust is vital to the future of the sector.

Oil and gas companies are piling up data at unprecedented scale, yet the industry’s ability to turn this into trusted insight lags far behind the hype. Without robust governance and shared models, AI-driven twins risk becoming another layer of noise rather than a platform for real change

The oil and gas industry has always been defined by scale. Pipelines stretch for thousands of miles. Offshore rigs operate in conditions few other industries would dare to approach. Refineries process millions of barrels with little margin for error. At the heart of all this sits a weight of information: engineering drawings, safety reports, compliance records, operational data. For decades, the instinct was to trap knowledge inside documents and manuals. It worked, after a fashion. Yet in today’s era of digital transformation, that legacy is starting to feel less like a foundation and more like a barrier.

The sector now collects more information than ever before. Sensors track every vibration, every temperature swing, every shift in pressure. Monitoring systems stream vast datasets to control rooms. Machine learning and generative AI promise to extract meaning from it all. Digital twins, dynamic and virtual counterparts of physical assets, offer the framework to bind them together. The promise is clear: prediction, optimisation, resilience. But the reality is messier. Without strong governance and a common way of modelling data, the value of these systems risks being smothered under the sheer weight of raw information.

This is not simply a technical puzzle. It is about how an industry steeped in engineering discipline can translate that discipline into the digital world. The question is not how much data can be captured, but whether it can be structured, trusted, and applied at the speed and scale modern operations demand.

Walk into many operational hubs today, and you will still see a reliance on PDF manuals and spreadsheets. The instinct to store everything as documents runs deep. For years, regulators, auditors, and engineers expected knowledge to take this form. The problem is that documents lock information away. They trap it in formats that machines cannot easily parse, leaving operators with archives instead of live intelligence.

Digital twins challenge that habit. A twin is only as useful as the data it can ingest, update,

and contextualise. That requires moving beyond documents into structured data environments. In practice, it means creating a shared digital language that allows sensor streams, engineering records, and operational inputs to coexist. It is not glamorous work, and it rarely makes the headlines, but this shift in mindset is what determines whether AI-enhanced twins succeed or fail.

Too often, early digital twin projects produced impressive 3D visualisations but offered little practical value. Operators admired them once, then left them to gather digital dust. The real progress comes when the twin is treated not as a picture but as a living system, one that grows, adapts, and feeds decisions across the asset lifecycle.

When IoT data flows into the twin, patterns of degradation can be spotted long before failure. AI models can run simulations, testing how equipment would behave under new load conditions or in harsher climates. Predictive maintenance stops being a slogan and becomes part of the daily workflow.

The key is continuity. Data cannot be allowed to fragment as an asset moves from design to build to operation. Every stage needs to feed the next, avoiding the silos that have plagued the sector for decades. Companies that manage this find their twins evolve with the asset, not against it. They remain accurate, relevant, and robust over time rather than degrading into static models.

The danger is clear: without common standards, the sector risks building a patchwork of proprietary twins that cannot talk to each other. That would recreate the same silos operators are trying to escape. This is where the idea of a standard data model becomes critical. Shared definitions, taxonomies, and structures for asset information mean twins can speak the same language. It also creates a base layer on which AI applications can thrive. Models trained on standardised, well-structured data perform better. They are easier to audit, more transparent, and far simpler to scale.

There are strategic implications here. Open architectures reduce the risk of vendor lock-in. They enable companies to introduce new tools without disrupting entire systems. They make digital transformation less of a gamble and more of a steady, cumulative journey. And perhaps most importantly, they enable collaboration across the value chain, from operators and suppliers to regulators and partners.

It is easy to think of digital twins as technical constructs, but they are only as valuable as the people who use them. Engineers, operators, and data scientists each have a different way of interacting with asset information. A governance model that ignores this diversity will fail, no matter how elegant the technology.

One way to close the gap is to design access and workflows around user personas. The maintenance team does not need the same dashboards as compliance auditors. Field engineers require alerts and contextual instructions, while data scientists need raw streams for model development. The more the twin reflects these realities, the more it becomes integrated into daily operations.

But this is also a cultural question. Trust in digital recommendations does not appear overnight. Workers need to understand how AI models reach their conclusions. They need training that builds fluency in interpreting data-driven insights. Transparency, accountability, and ownership of data quality are not optional extras; they are essential to adoption. Without them, twins risk being seen as remote, imposed systems rather than collaborative tools.

The best evidence of effective governance lies in what the twin can do. In refineries, twins that combine vibration data with historical baselines can flag mechanical anomalies before they escalate. Pipeline twins can integrate sensor streams with weather and environmental data to forecast risks of corrosion or leaks. Offshore, twins can align live monitoring with emissions models, giving operators real-time visibility of their environmental footprint.

These are not futuristic dreams but live examples of how twins translate governance into action. By creating a trusted data foundation, companies can build applications that move beyond proof of concept into daily use. Compliance becomes less about endless reporting and more about live assurance. Maintenance shifts from reacting to breakdowns to preventing them. Safety gains are measurable, not aspirational.

None of this works without connectivity. Low-latency communications are the invisible thread that ties the twin to the asset and the operator. In remote offshore fields or desert pipelines, transmitting vast data volumes is no small challenge.

Private LTE networks, edge computing nodes, and increasingly 5G are becoming the backbone of digital twin architectures. By processing data at the edge, companies cut latency and keep intel ligence close to the asset. A wearable alerting a worker to a pressure anomaly cannot afford a five-second delay. A drone surveying a flare stack needs its feed integrated instantly. In hazardous environments, real-time means precisely that.

The future of digital twins in oil and gas will not be shaped by visualisations or even by AI algorithms alone. It will be decided by governance. Without common standards and disciplined data models, twins cannot scale. They remain impressive pilots that fail to integrate into the broader enterprise.

With governance, however, the path to scalable automation opens up. AI-infused twins can move from individual use cases to enterprise-wide platforms. They can provide a single environment where safety, efficiency, and sustainability are managed in tandem. They can shift the industry away from document-heavy legacies into data-driven agility.

The competitive gap will widen. Companies that treat governance as an afterthought will be left behind. Those who see it as the enabler of innovation will find themselves with ystems that are flexible, trusted, and future-ready. The oil and gas sector has always thrived on engineering discipline. Assets are designed, built, and maintained to exacting standards. The same discipline now needs to be applied to data. Governance, structure, and culture are not glamorous, but they are the bedrock on which AI-driven twins will stand.

The industry’s next frontier is not collecting more data; it is making that data coherent, reliable, and usable at scale. If companies can achieve this, they will unlock digital twins that are not static models but living, breathing systems of intelligence. The fieldworker, the engineer, and the regulator will all find themselves working within environments where insight is immediate, decisions are informed, and operations are safer and more sustainable.

The challenge is immense, but so is the opportunity. Oil and gas have never shied away from complexity. The question now is whether it can bring the same rigour it applies to steel and concrete to the world of data. If it can, digital twins will move from promise to practice, and AI will finally have the disciplined foundation it needs to deliver at scale

Oil and gas companies are beginning to see generative AI evolve from experiment to operational tool. The emergence of agentic frameworks promises to turn asset performance management into a dynamic, adaptive system that improves efficiency, resilience, and decisionmaking at scale.

Generative AI has arrived in oil and gas with a mixture of enthusiasm and caution. The first wave of adoption resembled experiments in other industries, including drafting reports, generating synthetic training data, and automating translation tasks. Useful in their way, but hardly transformative. These early exercises rarely altered the fundamentals of how critical assets were managed or how operational performance was delivered. For some executives, the danger quickly became apparent. Without structural change, generative AI risked being written off as just another digital distraction, powerful in theory but peripheral in practice.

That perception is now starting to shift. Instead of treating generative AI as a stand-alone utility, attention is turning to agentic frameworks — systems that orchestrate multiple specialised AI agents into coordinated ecosystems. Rather than acting as passive mirrors of information, these agents interact with data, simulate operational scenarios, and even initiate actions. In asset-intensive industries such as oil and gas, where uptime is money and failure carries safety and environmental consequences, the implications are profound. Asset performance management, traditionally constrained by siloed systems and reactive processes, can now be reimagined around AI that is not only generative but also adaptive, collaborative, and deeply embedded into day-to-day operations.

No serious discussion of generative AI can ignore its flaws. The models can hallucinate, producing convincing but inaccurate outputs. They inherit biases from their training data, sometimes surfacing in subtle but dangerous ways. Their reasoning is opaque and complex, making it difficult to interrogate and trust in industries where safety and reliability are non-negotiable.

If left unchecked, these weaknesses would render generative AI unfit for asset performance management. Decisions in this environment directly affect production continuity, worker

safety, and environmental compliance. The task is therefore to design controls and governance frameworks that transform a general-purpose system into a dependable partner.

This is where agentic frameworks provide a breakthrough. By delegating responsibilities to specialised agents, validation agents to check data integrity, domain-specific agents to apply engineering logic, and compliance agents to measure against regulation, errors can be intercepted and corrected before they influence outcomes. For example, a generative model might draft a production optimisation plan. Still, before that plan reaches an engineer, it is scrutinised by validation agents to ensure the data inputs are accurate and the recommendations align with known constraints.

In practice, this layered system allows generative AI to uncover debottlenecking opportunities that human operators might miss. Instead of simply flagging anomalies, an orchestrated framework can map interdependencies across assets, identify precisely where throughput is constrained, and propose several possible resolutions. When domain-specific agents add their expertise and cross-check against historical data, the outputs gain credibility and practical value. What could have been a risky black-box recommendation becomes a transparent, auditable suggestion that a team can trust.

The technology alone is not enough. For agentic frameworks to

succeed in oil and gas, organisations must build ecosystems that integrate culture, talent, and partnerships. Without that, AI remains siloed, another pilot project, another innovation initiative, with little bearing on real operations.

Cultural readiness is often the most underestimated factor. Moving from document-driven workflows to AI-driven

insights requires a fundamental change in mindset. Engineers and operators must trust that insights generated by AI are not only technically correct but operationally meaningful. Data scientists, for their part, must accept that models cannot live in isolation from the field realities of extreme environments, unpredictable conditions, and human safety priorities. Success depends on blending these two worlds: embedding AI within operational contexts while ensuring human expertise remains central.

This cultural shift goes hand-in-hand with talent development. New skill sets are needed, combining domain knowledge with fluency in data and AI tools. Teams must learn to collaborate across disciplines that previously had little overlap. For many organisations, the greater challenge is not technical but human, building confidence, encouraging adoption, and fostering a sense of partnership between

human operators and their digital counterparts.

Strategic partnerships form the third leg of the ecosystem. Few oil and gas companies can build, validate, and maintain agentic frameworks on their own. Collaboration with technology providers, universities, and regulators accelerates development while embedding essential safeguards. Shared testbeds, joint research initiatives, and industry-wide standards provide the structure for trustworthy adoption. These partnerships are not about outsourcing responsibility but about distributing the heavy lifting of innovation while keeping governance at the centre.

The result of this ecosystem approach is more than risk reduction. It creates the conditions for accelerated value capture. Training datasets become richer, validation environments more rigorous, and deployment pathways clearer. In short, AI moves from an isolated experiment to a strategic asset.

Nowhere is the impact more evident than in the handling of asset information. For decades, asset records in oil and gas have been plagued by inconsistency: fragmented documentation, updates that lag reality, and knowledge buried in disconnected systems. These flaws compromise decision-making and reduce efficiency across maintenance, planning, and compliance.

Agentic frameworks allow generative AI to act as a living curator of asset data. Instead of passively storing records, the system continuously ingests, harmonises, and cross-references inputs ranging from engineering drawings and inspection reports to sensor feeds and historical performance logs. The result is not a static database but a knowledge base that evolves in real time.

The benefits of asset performance management are immediate. A scheduled maintenance task can be informed not only

by the equipment’s specifications but also by a complete history of interventions, likely risks, and recommended spare parts. When anomalies emerge, the system can simulate potential causes, compare them against historical precedents, and propose interventions with quantifiable probabilities. What was once a reactive maintenance regime becomes predictive, and predictive gradually matures into prescriptive.

The operational gains are tangible. Downtime is reduced. Throughput increases. Maintenance interventions become more targeted and less disruptive. Workers spend less time digging through inconsistent records and more time validating, interpreting, and executing high-value decisions. In an industry where uptime is measured in millions of dollars, these marginal improvements quickly compound into a competitive advantage.

The integration of real-time analytics and visualisation pushes this transformation further. In traditional settings, even when data is captured, the delay between collection, analysis, and response undermines its usefulness. Agentic frameworks embed AI agents directly into data streams, converting raw input into immediately actionable insight.

Consider an offshore facility where rotating equipment is tracked by IoT sensors. A vibration pattern shifts, subtly but significantly. A monitoring agent detects the anomaly, while a visualisation agent overlays the deviation onto a 3D digital model of the asset. A simulation agent then runs projections to assess potential outcomes under varying loads and conditions. Together, these agents provide operators with not just an alert, but a comprehensive package: what has happened, why it matters, and how it might unfold under different scenarios.

This orchestration transforms decision-making. Instead of waiting for periodic reports or relying on intuition, operators are presented with a clear, data-driven picture of risks and options. They can act earlier, faster, and with greater confidence.

The advantages extend beyond efficiency. Safety improves as emerging risks are identified before they escalate. Environmental performance benefits as leaks or emissions anomalies are flagged in their earliest stages. Visualisation tools ensure that insights are accessible not only to engineers but to managers, regulators, and stakeholders who need clarity without technical overload.

The arrival of agentic frameworks signals more than just another phase in digital transformation. It marks a structural shift in how asset performance management is conceived and executed. Where once performance was measured through retrospective reports and periodic inspections, it is now becoming a living process, continuously optimised through orchestrated AI.

Crucially, this shift does not diminish the role of human expertise. If anything, it magnifies it. Engineers interpret insights, validate recommendations, and ensure that AI-driven actions align with operational priorities. Managers set the cultural tone, shaping adoption and avoiding overreliance. Data scientists design frameworks that balance innovation with accountability. The power of agentic AI lies not in replacing people but in augmenting their ability to act with speed, accuracy, and foresight.

For oil and gas, the opportunity is significant. The industry operates some of the most complex, high-value assets in the world, in environments where safety and environmental standards are uncompromising. There is both a need and an incentive to harness AI responsibly. The companies that succeed will be those that treat AI not as a peripheral experiment but as a structural capability: governed responsibly, integrated deeply, and deployed strategically.

Asset performance management has always been about more than keeping equipment running. It is about resilience, adaptability, and continuity under pressure. With agentic frameworks, generative AI is stepping into this role not as a novelty but as a transformative force. The future of asset performance will not be determined by how much data is gathered but by how intelligently it is orchestrated, and in that lies the real promise of AI for oil and gas.

AI is reshaping the oil and gas sector, but the most significant challenge is not technical. It is human. Leading people through transformation requires systems of engagement designed for real users, a culture that prioritises participation and learning, and a commitment to diversity and inclusion as the foundation of sustainable change.

The conversation about digital transformation in oil and gas often gravitates towards infrastructure, automation, and efficiency. Yet many initiatives fail not because the technology underperforms but because the workforce is left behind. Suppose AI is to play a decisive role in reshaping asset management, operational decision-making, or process optimisation. In that case, it must do so in a way that respects and enhances the experience of the people who interact with it.

The oil and gas industry is entering an era where leaders are not only asked to implement systems but to guide people through cultural and psychological upheaval. The question is not simply whether AI works, but whether it works for everyone, whether employees trust it, feel empowered by it, and see themselves as part of the journey. That is where user experience, diversity, and inclusive leadership intersect with the broader themes of digital transformation.

Too often, technology is deployed in the hope that people will adapt around it. Experience shows the opposite is true. Workers on rigs, in control rooms, or in back-office functions do not want more systems, they want better systems. Engagement fails when tools are unintuitive, when outputs are opaque, or when the flow of work is interrupted by poorly designed interfaces.

Best practice in user experience demands more than technical usability. It requires empathy. AI-driven platforms must be co-designed with the people who use them, tested in live environments, and constantly

iterated with feedback loops. In practical terms, that means bringing operators, engineers, and fieldworkers into the development process, not as afterthoughts but as primary stakeholders.

Transparency is another pillar of engagement. If an AI system recommends an action, the user must be able to understand why. Explainability is not a luxury in high-risk environments—it is a prerequisite for trust. Without it, even the most accurate models will be sidelined as workers default to the methods they know. User experience in this sense is not cosmetic; it is central to whether AI becomes a trusted partner or a background distraction.

The temptation in any wave of technological change is to let the systems dominate the

narrative. Yet sustainable transformation begins with people. Employees must be active participants in AI adoption, not passive recipients of tools. Participation is not just about consultation; it is about creating pathways for workers at all levels to contribute ideas, test solutions, and influence outcomes.

Continuous learning is key to this process. AI systems will only improve with informed oversight, which in turn requires specific skills. That means re-skilling experienced workers who understand assets but not algorithms, and up-skilling younger recruits who may have data literacy but less operational context. Crucially, it also means creating a culture where experimentation is not punished. If employees are to learn continuously, they must be given permission to make mistakes, share insights, and iterate without fear.

Championing people over technology shifts the focus of transformation. Instead of chasing the latest platform or algorithm, the organisation builds capability from within. Workers see themselves reflected in the change, rather than displaced by it. The result is a culture where AI adoption feels less like imposition and more like collaboration.

AI does not remove the need for people, but it changes what people are asked to do. In the oil and gas industry, many roles are being redefined rather than eliminated. Engineers increasingly need to interpret model outputs as much as they operate machinery. Operators are asked to collaborate with systems that predict, visualise, and recommend. Managers are invited to integrate AI into decisionmaking processes that used to be instinctive or