Deere Harvester W orks

Introduction

Foreword

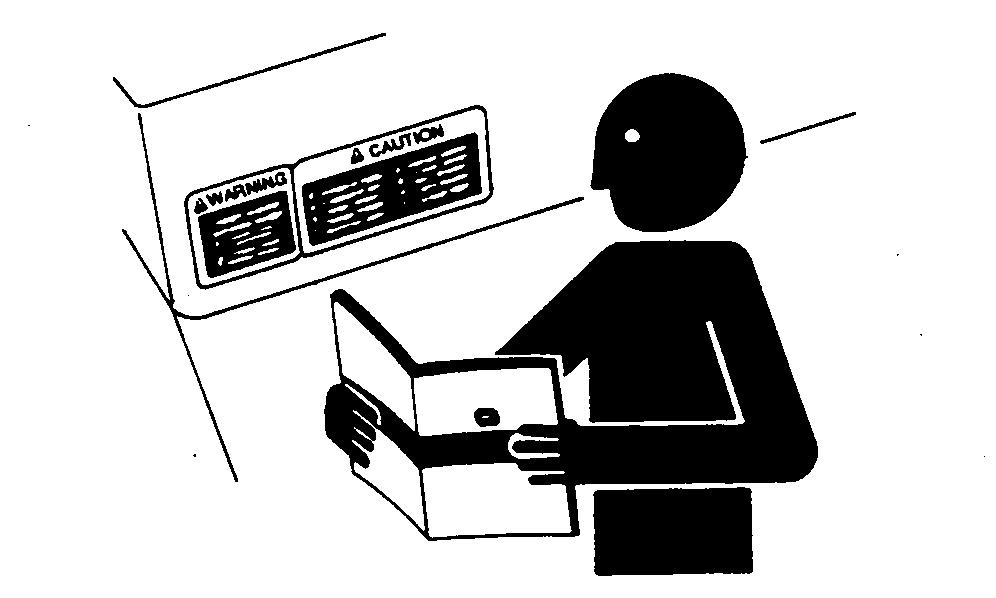

This manual written for experienced Essential tools required performing certain service work are identified this manual and are recommended for

Live with safety: Read the safety messages the introduction this manual and the cautions presented throughout the text the

This the safety alert When you see this symbol the machine this alert the potential for personal injury

T echnical manuals are divided two parts: repair and operation and tests. Repair sections tell how repair the Operation and tests sections help you identify the majority routine failures quickly

Information organized groups for the various components requiring service the beginning each group are summary listings all applicable essential tools, service equipment and tools, other materials needed the job, service parts wear and torque

T echnical Manuals are concise guides for specific They are the job guides containing only the vital information needed for diagnosis, analysis, testing, and repair

Fundamental service information available from other sources covering basic theory fundamentals general and basic type failures and their causes.

Contents

Section

Group

Group and Component Identification

Group Specifications

Group and T esting Procedures

Section T rouble Codes

Group 1 Diagnostic Codes and Addresses

Group 2 Armrest Display Unit

Group 3 Control Unit CAB and Cab Power

Module Diagnostic T rouble Codes

Group 4 Cornerpost Display Unit

Group 5 Control Unit ECU Diagnostic T rouble Codes

Group 6 Display W arning Messages and Fault Codes

Group 7 KeyCard and Data Storage Card W arning Messages

Group 8 Mobile Processor W arning Messages

Group 9 VEST DOC W arning Messages

Group Harvest Moisture Meter

Group 1 1

Control Unit LC1 and Left Power

Module 1 Diagnostic T rouble Codes

Group Control Unit LC2 and Left Power

Module 2 Diagnostic T rouble Codes

Group Calibration Codes

Group Control Unit PTP Diagnostic T rouble Codes

Group Control Unit RCU and Right Power

Module Diagnostic T rouble Codes

Group Control Unit SFC Diagnostic T rouble Codes

Group Control Unit SSU Diagnostic T rouble Codes

Group Last Exit Codes

Group StarFire Receiver 300 Diagnostic T rouble Codes

Group Receiver (iTC and 3000) Diagnostic T rouble Codes

Group Receiver W arning Messages

Group errain Compensation Module Diagnostics T rouble Codes

Group Control Unit VCM Diagnostic T rouble Codes

Group Universal Row Guidance Diagnostic T rouble Codes

Group i GreenStar Display 2100/2600

Section Symptoms

Group 220 System

Group 230 Intake and Cooling Systems

Group 240 System

Group 250 T rain System

Group 255 Wheel Drive System

Group 260 System

Group 270 System

Group 275 Gearcase System

Group 280 System

Group 290 —Heating, V entilating and Air Conditioning System

Group 300 System

Section 220—Engine System

Group Information

Group est Procedures and Adjustments

Group 15A T ype Identification

Group 15B Diagnostics T ype A

Group 15C Diagnostics T ype B

Group 15D Diagnostics T ype C

Group Identification and Location

Section 230—Air Intake and Cooling System

Group Information

Group est Procedures and Adjustments

Group 15A Intake System Diagnostics

Group 15B Package T ype Identification

Group 15C Package Diagnostics T ype A

Group 15D Package Diagnostics T ype B

Group Identification and Location

Section System

Group 5 T o Use This Diagnostic Information

Group 10A Diagnostic T rouble Codes and Addresses

Group 10B Addresses Controller

Group 10C Setting Addresses

Group 10D T rouble Codes, W arning Messages and Fault Codes

Group 10E Procedures

Group 15A Header Height Control T ype Identification

Group 15B Header Height Diagnostics T ype A

Group 15C Header Height Diagnostics T ype B

Original All illustrations and specifications this manual are based the latest information available the time The right reserved make changes any time without notice.

Continued next page

Group 15D

Header Height Diagnostics T ype C

Group 15E

Group 15F

Header Height Diagnostics T ype D

Header Height Diagnostics T ype E

Group 15G Header Height Diagnostics T ype F

Group 15H

Group 15I

Header Height Diagnostics T ype G

Header Height Diagnostics T ype H

Group 15J Seat Diagnostics

Group 15K and Battery Diagnostics

Group 15L Counter Diagnostics

Group 15M Display Unit Overall Diagnostics

Group 15N Power Strip Outlet Diagnostics

Group 15O Alarm T ype Identification

Group 15P Alarm Diagnostics T ype A

Group 15Q Alarm Diagnostics T ype B

Group 15R Bus Diagnostics

Group 15S T ilt Diagnostics

Group 15T Raise/Lower T ype Identification

Group 15U Raise/Lower Diagnostics T ype A

Group 15V Raise/Lower Diagnostics T ype B

Group 15W Speed Sensor Diagnostics

Group 15X V ane Angle Diagnostics

Group 15Y Grain Elevator Speed Sensor Diagnostics

Group 15Z Fan Speed Adjust Diagnostics

Group 15AA Fan Speed Display Diagnostics

Group 15AB Unit CAB/CPM Overall Diagnostics

Group 15AC Unit CDU Overall Diagnostics

Group 15AD Unit ECU Overall T ype Identification

Group 15AE Unit ECU Overall Diagnostics T ype A

Group 15AF Unit ECU Overall DiagnosticsT ype B

Group 15AG Unit LC1/LPM1 Overall Diagnostics

Group 15AH Unit LC2/LPM2 Overall Diagnostics

Group 15AI Unit PTP Overall Diagnostics

Group 15AJ Unit RCU/RPM Overall Diagnostics

Group 15AK Unit SFC Overall Diagnostics

Group 15AL Unit SSU Overall Diagnostics

Group 15AM Unit VCM Overall Diagnostics

Group 15AN Auger Speed Sensor Diagnostics

Group 15AO Head Chopper Speed Sensor Diagnostics

Group 15AP Pressure Adjust Diagnostics

Group 15AQ Plate Adjust T ype Identification

Group 15AR Plate Adjust Diagnostics T ype A

Group 15AS Plate Adjust Diagnostics T ype B

Group 15A T Plate Display Diagnostics

Group 15AU Plate Resume Diagnostics

Group 15A V Beater Speed Sensor

Diagnostics

Group 15A W Cutterbar T ilt Adjust Diagnostics

Group 15AX Deck Shift Diagnostics

Group 15A Y Frame Float Adjust Diagnostics

Group 15AZ Speed Adjust T ype Identification

Group 15BA Speed Adjust Diagnostics T ype A

Group 15BB Speed Adjust Diagnostics T ype B

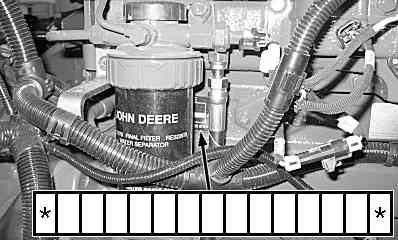

Group 15BC Fuel Pump T ype Identification

Group 15BD Fuel Pump Diagnostics T ype A

Group 15BE Fuel Pump Diagnostics T ype B

Group 15BF Fuel Pump Diagnostics T ype C

Group 15BG Air Filter Sensor Diagnostics

Group 15BH and Fuel Control T ype Identification

Group 15BI and Fuel Control DiagnosticsT ype A

Group 15BJ and Fuel Control DiagnosticsT ype B

Group 15BK and Fuel Control DiagnosticsT ype C

Group 15BL Coolant T emperature Sensor

Diagnostics

Group 15BM Oil Pressure Sensor Diagnostics

Group 15BN Accelerator Speed Sensor

Diagnostics

Group 15BO House Filter Switch T ype

Identification

Group 15BP House Filter Switch Diagnostics

T ype A

Group 15BQ House Filter Switch Diagnostics

T ype B

Group 15BR House Pressure Sensor

Diagnostics

Group 15BS House Reverse Diagnostics

Group 15BT House Speed Adjust T ype

Identification

Group 15BU House Speed Adjust Diagnostics

T ype A

Group 15BV House Speed Adjust Diagnostics

T ype B

Group 15BW House Speed Display

Diagnostics

Group 15BX Corn Head Diagnostics

Group 15BY Wheel Drive Diagnostics

Group 15BZ Level Display Diagnostics

Group 15CA Plug Diagnostics

Group 15CB Level Switch T ype Identification

Group 15CC Level Switch Diagnostics T ype A

Group 15CD Level Switch Diagnostics T ype B

Group 15CE Loss Monitor Diagnostics

Group 15CF T ank Cover Diagnostics

Group 15CG Data Card T ype

Identification

Group 15CH Data Card DiagnosticsT ype A

Group 15CI Data Card DiagnosticsT ype B

Continued next page

Group 15CJ Display T ype Identification

Group 15CK Display Diagnostics T ype A

Group 15CL Display Diagnostics T ype B

Group 15CM Display Diagnostics T ype C

Group 15CN Documentation T ype

Identification

Group 15CO Documentation Diagnostics T ype A

Group 15CP Documentation Diagnostics T ype B

Group 15CQ Mobile Processor

Diagnostics

Group 15CR R T ype Identification

Group 15CS R Diagnostics T ype A

Group 15CT R Diagnostics T ype B

Group 15CU R Diagnostics T ype C

Group 15CV StarFire Receiver T ype

Identification

Group 15CW StarFire Receiver

Diagnostics T ype A

Group 15CX StarFire Receiver

Diagnostics T ype B

Group 15CY StarFire Receiver Diagnostics T ype C

Group 15CZ

StarFire Receiver

Diagnostics T ype D

Group 15DA StarFire Receiver

Diagnostics T ype E

Group 15DB StarFire Receiver Diagnostics T ype F

Group 15DC Steering Auto T ype

Identification

Group 15DD Steering Auto Diagnostics

T ype A

Group 15DE

T ype B

Group 15DF

T ype C

Steering

Auto Diagnostics

Steering Auto Diagnostics

Group 15DG Steering Auto Diagnostics T ype D

Group 15DH Steering Auto Diagnostics T ype E

Group 15DI Steering

Identification

Group 15DJ Steering

Manual T ype

Manual

Diagnostics T ype A

Group 15DK Steering Manual

Diagnostics T ype B

Group 15DL Speed Display Diagnostics

Group 15DM Monitor Diagnostics

Group 15DN Engage T ype Identification

Group 15DO Engage Diagnostics T ype A

Group 15DP Engage Diagnostics T ype B

Group 15DQ Identification Diagnostics

Group 15DR Raise/Lower Diagnostics

Group 15DU Oil T emperature Sensor

Diagnostics

Group 15DV Charge Pressure Switch

Diagnostics

Group 15DW Drive Control DiagnosticsAutomatic Feed Rate T ype Identification

Group 15DX Drive Control DiagnosticsAutomatic Feed Rate T ype A

Group 15DY Drive Control DiagnosticsAutomatic Feed Rate T ype B

Group 15DZ Drive Control Diagnostics

Manual

Group 15EA T ilt Automatic Diagnostics

Group 15EB T ilt Display Diagnostics

Group 15EC T ilt Manual Diagnostics

Group 15ED Beacon Lights Diagnostics

Group 15EE Dome Light Diagnostics

Group 15EF Draper T ransport Diagnostics

Group 15EG Engine Service Lights

Diagnostics

Group 15EH Field Lights T ype Identification

Group 15EI Field Lights Diagnostics T ype A

Group 15EJ Field Lights Diagnostics T ype B

Group 15EK Field Lights Diagnostics T ype C

Group 15EL Field Lights Diagnostics T ype D

Group 15EM Gullwing Service Lights

Diagnostics

Group 15EN Hazard Lights T ype

Identification

Group 15EO Hazard Lights DiagnosticsT ype A

Group 15EP Hazard Lights DiagnosticsT ype B

Group 15EQ Marker Lights T ype

Identification

Group 15ER Marker Lights DiagnosticsT ype A

Group 15ES Marker Lights DiagnosticsT ype B

Group 15ET Panel Lights Diagnostics

Group 15EU Road Lights T ype Identification

Group 15EV Road Lights DiagnosticsT ype A

Group 15EW Road Lights DiagnosticsT ype B

Group 15EX Road Lights DiagnosticsT ype C

Group 15EY Shoe Service Lights

Diagnostics

Group 15EZ Side Finder Lights Diagnostics

Group 15F A Unloading Auger Light

Diagnostics

Group 15FB W ork Lights Diagnostics

Group 15DS V entilating and Air Conditioning

Diagnostics

Group 15DT Diagnostics

Group 15FC Link System CAB/CPM

Diagnostics

Continued next page

Group 15FD Link System LC1/LPM1

Diagnostics

Group 15FE Link System LC2/LPM2

Diagnostics

Group 15FF Link System RCU/RPM Diagnostics

Group 15FG Flow Sensor Diagnostics

Group 15FH Gearcase Filter Switch Diagnostics

Group 15FI Gearcase Pressure Sensor Diagnostics

Group 15FJ Gearcase T emperature Sensor Diagnostics

Group 15FK System Aiming Diagnostics

Group 15FL System Heater Diagnostics

Group 15FM Sensor Diagnostics

Group 15FN Brake Alert T ype Identification

Group 15FO Brake Alert Diagnostics

Group 15FP Distribution Fuse Center Diagnostics

Group 15FQ Distribution W ake Power Diagnostics

Group 15FR Stop Diagnostics

Group 15FS Diagnostics

Group 15FT Fore/Aft Adjust T ype Identification

Group 15FU Fore/Aft Adjust Diagnostics T ype A

Group 15FV Fore/Aft Adjust Diagnostics T ype B

Group 15FW Raise/Lower T ype Identification

Group 15FX Raise/Lower Diagnostics T ype A

Group 15FY Raise/Lower Diagnostics T ype B

Group 15FZ Raise/Lower Diagnostics T ype C

Group 15GA Raise/Lower Diagnostics T ype D

Group 15GB Resume Fore/Aft Diagnostics

Group 15GC Resume Raise/Lower Diagnostics

Group 15GD Reverse Diagnostics

Group 15GE Speed Automatic Adjust Diagnostics

Group 15GF Speed Manual Adjust Diagnostics

Group 15GG Chaf fer Adjust DiagnosticsT ype Identification

Group 15GH Chaf fer Adjust DiagnosticsT ype A

Group 15GI Chaf fer Adjust DiagnosticsT ype B

Group 15GJ Sieve Adjust Diagnostics T ype Identification

Group 15GK Sieve Adjust Diagnostics T ype A

Group 15GL Sieve Adjust Diagnostics T ype B

Group 15GM Diagnostics

Group 15GN Speed Limit T ype Identification

Group 15GO Speed Limit Diagnostics T ype A

Group 15GP Speed Limit Diagnostics T ype B

Group 15GQ Guidance T ype Identification

Group 15GR Guidance Diagnostics T ype A

Group 15GS Guidance Diagnostics T ype B

Group 15GT Leveling Diagnostics

Group 15GU Engage Diagnostics

Group 15GV Brake Charge Pressure

Diagnostics

Group 15GW Spreader Speed Adjust

Diagnostics

Group 15GX Spreader Speed Sensor

Diagnostics

Group 15GY Aid Diagnostics

Group 15GZ Diagnostics

Group 15HA ailings Elevator Speed Sensor

Diagnostics

Group 15HB ailings Monitor Diagnostics

Group 15HC Clearance Adjust Diagnostics

Group 15HD Clearance Display

Diagnostics

Group 15HE Speed Adjust Diagnostics

Group 15HF Speed Display Diagnostics

Group 15HG ransmission Dif ferential Lock

Diagnostics

Group 15HH ransmission Parking Brake Engage

Diagnostics

Group 15HI ransmission Speed Limit Diagnostics

Group 15HJ ransmission T Range Automatic Diagnostics

Group 15HK ransmission Shift Lock Diagnostics

Group 15HL Auger Engage Diagnostics

Group 15HM Auger Fold Diagnostics

Group 15HN Auger Swing Diagnostics

Group 15HO W asher/Wiper Diagnostics

Group 20A Code Listing

Group 20B Information

Group 20C Repair Procedures

Section T rain System

Group Information

Group est Procedures and Adjustments

Group 15A Drive Diagnostics

Group 15B ransmission T ype Identification

Group 15C ransmission Diagnostics T ype A

Group 15D ransmission Diagnostics T ype B

Group 15E Drive T ype Identification

Group 15F Drive Diagnostics T ype A

Group 15G Drive Diagnostics T ype B

Group 15H Drive Diagnostics T ype C

Group Identification and Location

Section

255—Four

Wheel Drive System

Group Information

Group est Procedures and Adjustments

Group 15A Speed Four Wheel Drive T ype

Identification

Group 15B Speed Four Wheel Drive Diagnostics T ype A

Group 15C Speed Four Wheel Drive Diagnostics T ype B

Group Identification and Location

Section

260—Brake

System

Group Information

Group est Procedures and Adjustments

Continued next page

Group 15A Brake T ype Identification

Group 15B Brake Diagnostics T ype A

Group 15C Brake Diagnostics T ype B

Group 15D Brakes T ype Identification

Group 15E

Brakes Diagnostics T ype A

Group 15F Brakes Diagnostics T ype B

Group Identification and Location

Section System

Group Information

Group est Procedures And Adjustments

Group 15A

Hydraulic System T ype

Group 15B Hydraulic System DiagnosticsT ype A

Group 15C

Hydraulic System DiagnosticsT ype B

Group 15D Pickup Drive T ype Identification

Group 15E Pickup Drive Diagnostics T ype A

Group 15F Pickup Drive Diagnostics T ype B

Group 15G Pickup Drive Diagnostics T ype C

Group 15H T ilt Diagnostics

Group 15I Pressure Adjust Diagnostics

Group 15J Plate Adjust Diagnostics T ype Identification

Group 15K Plate Adjust Diagnostics T ype A

Group 15L Plate Adjust Diagnostics T ype B

Group 15M Auger Drive Diagnostics

Group 15N Belt Drive T ype Identification

Group 15O Belt Drive Diagnostics T ype A

Group 15P Belt Drive Diagnostics T ype B

Group 15Q Cutterbar Pressure Diagnostics

Group 15R Cutterbar T ilt Diagnostics

Group 15S Frame Float Diagnostics T ype Identification

Group 15T Frame Float Diagnostics T ype A

Group 15U Frame Float Diagnostics T ype B

Group 15V House Gearcase Cooler Diagnostics

Group 15W House Reverser Shift Diagnostics

Group 15X House Speed Adjust T ype Identification

Group 15Y House Speed Adjust Diagnostics T ype A

Group 15Z House Speed Adjust Diagnostics T ype B

Group 15AA Corn Head Diagnostics

Group 15AB Raise/Lower Diagnostics

Group 15AC System Overheating Diagnostics

Group 15AD T ilt T ype Identification

Group 15AE T ilt Diagnostics T ype A

Group 15AF T ilt Diagnostics T ype B

Group 15AG coupler Diagnostics

Group 15AH Drive T ype Identification

Group 15AI Drive Diagnostics T ype A

Group 15AJ Drive Diagnostics T ype B

Group 15AK Fore/Aft T ype Identification

Group 15AL Fore/Aft Diagnostics T ype A

Group 15AM Fore/Aft Diagnostics T ype B

Group 15AN Raise/Lower T ype Identification

Group 15AO Raise/Lower Diagnostics T ype A

Group 15AP Raise/Lower Diagnostics T ype B

Group 15AQ Raise Lower Diagnostics T ype C

Group 15AR Raise/Lower Diagnostics T ype D

Group 15AS System T ype Identification

Group 15A T Diagnostics T ype A

Group 15AU Diagnostics T ype B

Group 15A V Speed Adjust Diagnostics

Group 15A W Auger Swing Diagnostics

Group 15AX Raise/Lower Diagnostics

Group Identification and Location

Section 275—Main Gearcase System

Group Information

Group est Procedures and Adjustments

Group 15A Gearcase Overall Diagnostics T ype Identification

Group 15B Gearcase Overall Diagnostics T ype A

Group 15C Gearcase Overall Diagnostics T ype B

Group 15D Gearcase Filter Restricted Diagnostics

Group 15E Gearcase Pressure Low Diagnostics T ype Identification

Group 15F Gearcase Pressure Low Diagnostics T ype A

Group 15G Gearcase Pressure Low Diagnostics T ype B

Group 15H Gearcase T emperature High Diagnostics

Group 15I Engage Diagnostics

Group 15J Auger Engage Diagnostics

Group Identification and Location

Section 280—Steering System

Group Information

Group est Procedures and Adjustments

Group 15A System T ype Identification

Group 15B Diagnostics T ype A

Group 15C Diagnostics T ype B

Group Identification and Location

Section V entilating and Air Conditioning

System

Group Information

Group est Procedures and Adjustments

Group —Heating, V entilation and Air Conditioning Diagnostics

Group Identification and Location

Section System

Group Information

Group V ibration Diagnostics

Group Identification and Location

Group

9570 STS

Operating Speeds 9670 STS and 9770 STS Combines

Specifications 9670 STS

Specifications 9770 STS Combine

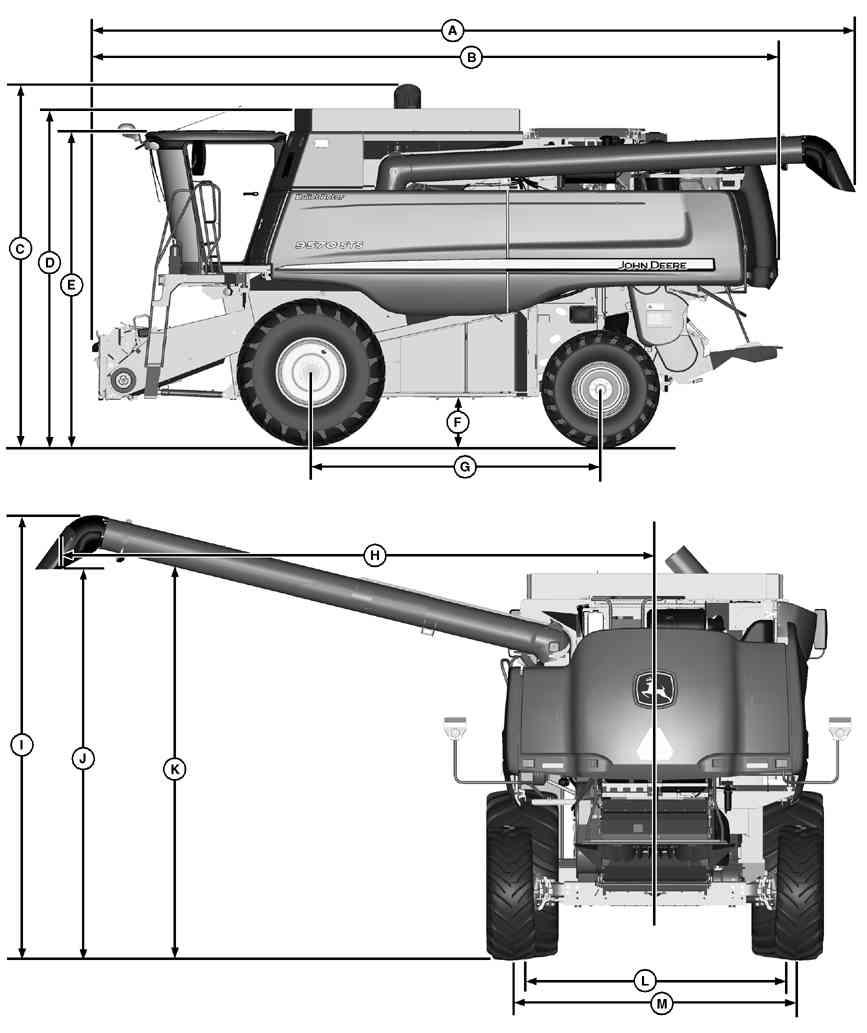

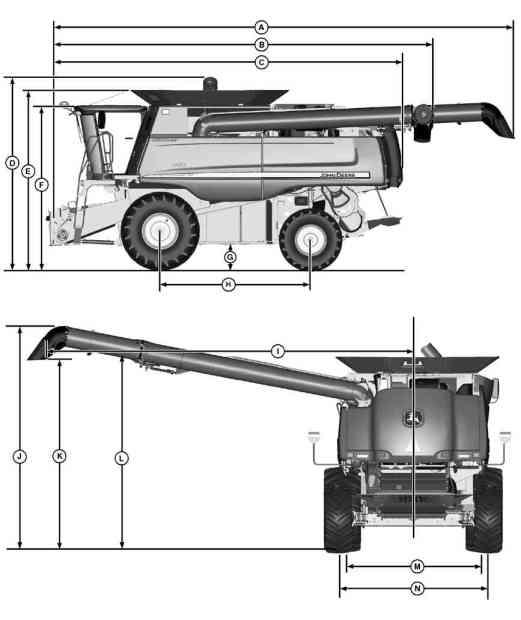

Dimensions 9670 STS and 9770 STS Combines

Dimension Reference Points 9670 STS and 9770 STS Combines

Operating Speeds 9870 STS

Specifications 9870 STS Combine

Dimensions 9870 STS Combine

Recognize Safety Information

This a safety alert

When you see this symbol your machine this alert the potential for personal injury

Follow recommended precautions and safe operating practices.

Handle Fluids

Fires

When you work around not smoke work near heaters other fire hazards.

Store flammable fluids away from fire not incinerate puncture pressurized

Make sure machine clean trash, grease, and debris.

not store oily rags; they can ignite and burn spontaneously

Prepare for Emergencies

prepared a fire

Keep a first aid kit and fire extinguisher handy

Keep emergency numbers for ambulance and fire department near your

Prevent Battery Explosions

Keep lighted and open flame away from the top battery Battery gas can

Never check battery charge placing a metal object across the posts. Use a volt meter hydrometer . not charge a frozen battery; may W arm battery 16°C (60°F).

Prevent Acid Burns

Sulfuric acid battery electrolyte strong enough burn skin, eat holes clothing, and cause blindness splashed into

A void the hazard by:

Filling batteries a well ventilated area. W earing eye protection and rubber gloves.

A voiding breathing fumes when electrolyte

A voiding spilling dripping

Use proper jump start

you spill acid yourself:

Flush your skin with water

Apply baking soda lime help neutralize the Flush your eyes with water for Get medical attention immediately

acid swallowed: not induce

Drink large amounts water but not exceed 2 L Get medical attention immediately .

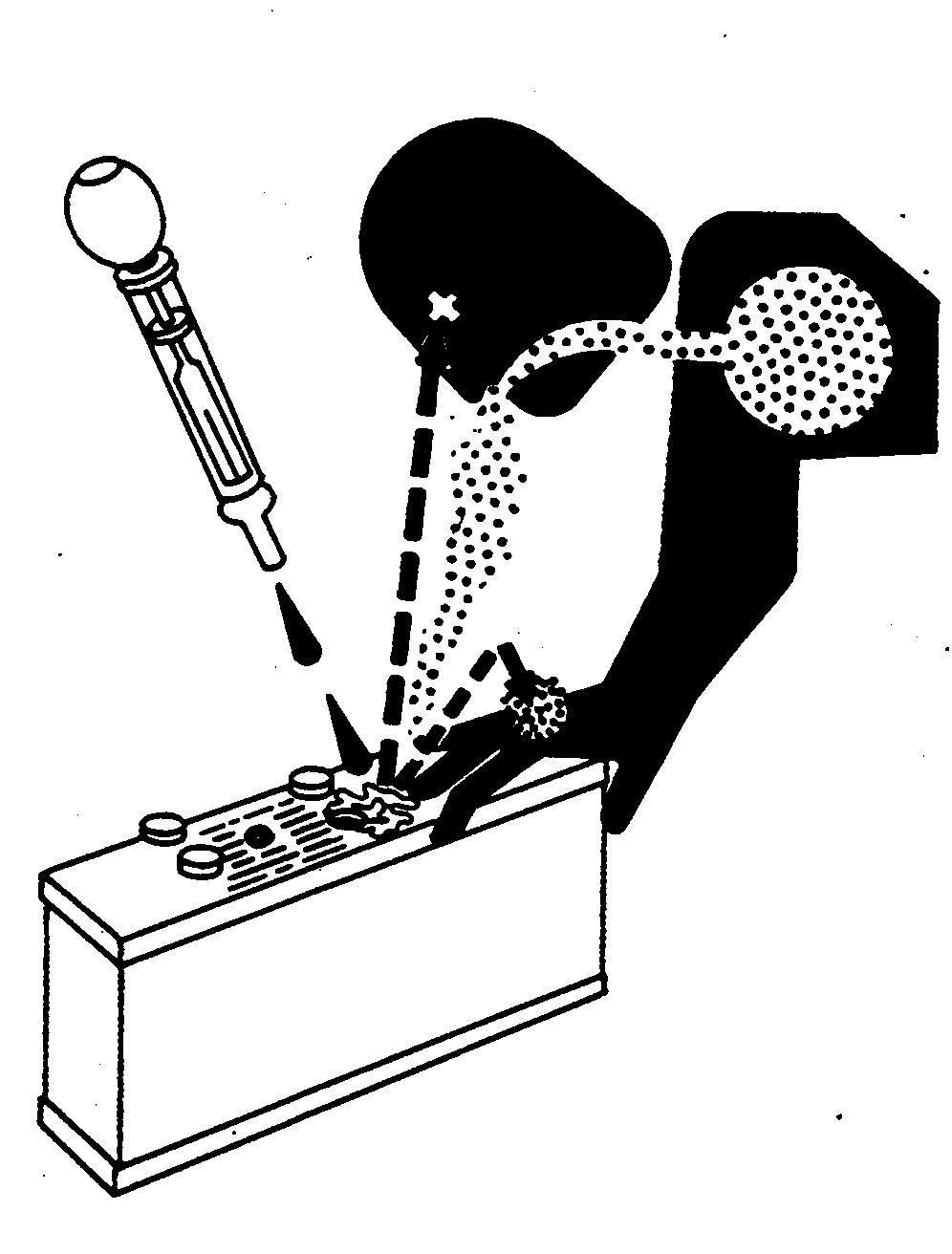

Handle Chemical Products Safely

Direct exposure hazardous chemicals can cause serious injury Potentially hazardous chemicals used with John Deere equipment include such items and

A Material Safety Data Sheet (MSDS) provides specific details chemical products: physical and health safety and emergency response

Check the MSDS before you start any job using a hazardous chemical. That way you will know exactly what the risks are and how the job safely . Then follow procedures and recommended

(See your John Deere dealer for MSDS’ s chemical products used with John Deere

Handle Starting Fluid Safely

Starting fluid highly

Keep all sparks and flame away when using Keep starting fluid away from batteries and cables.

T o prevent accidental discharge when storing the pressurized keep the cap the container , and store a protected not incinerate puncture a starting fluid container .

A void

Fluids

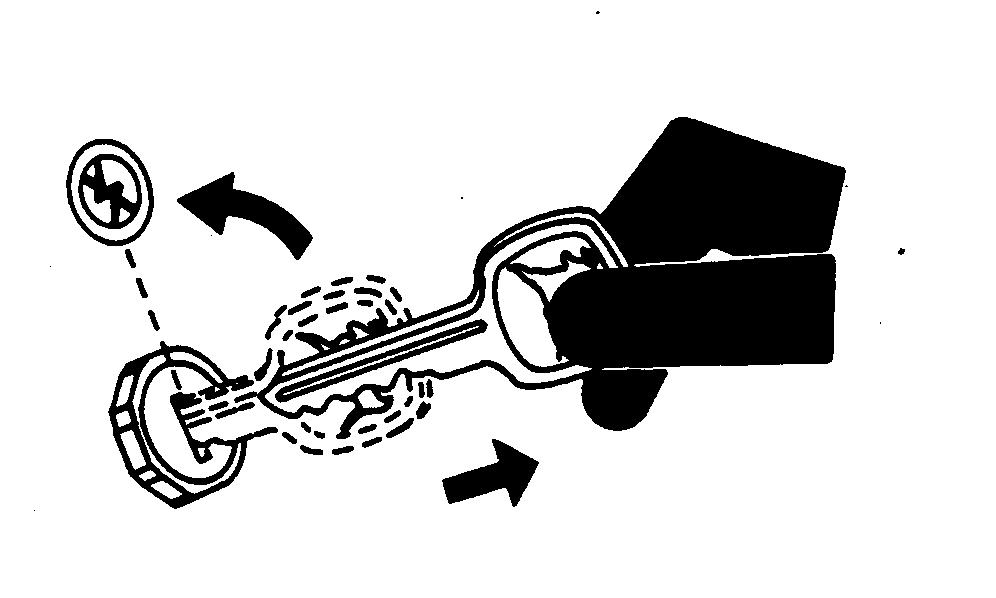

Escaping fluid under pressure can penetrate the skin causing serious injury

A void the hazard relieving pressure before disconnecting hydraulic other T ighten all connections before applying pressure.

Search for leaks with a piece Protect hands and body from high pressure accident see a doctor immediately Any fluid injected into the skin must surgically removed within a few hours gangrene may result. Doctors unfamiliar with this type injury should reference a knowledgeable medical Such information available from Deere & Company Medical Department calling 1 800 822 8262 309 748

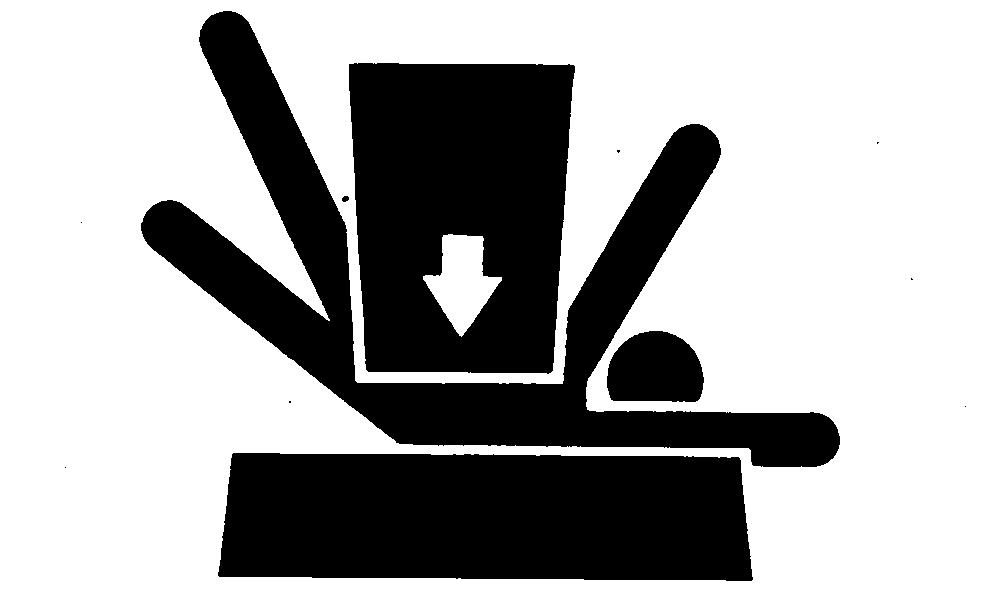

Park Machine Safely

Before working the machine:

• Lower all equipment the

• Stop the engine and remove the key

• Disconnect the battery ground strap.

• Hang a "DO NOT OPERA TE" tag operator station.

Support Machine Properly

Always lower the attachment implement the ground before you work the machine. the work requires that the machine attachment provide secure support for left a raised hydraulically supported devices can settle leak not support the machine cinder hollow props that may crumble under continuous load. not work under a machine that supported solely a Follow recommended procedures this

When implements attachments are used with a always follow safety precautions listed the implement attachment operator ’ s manual.

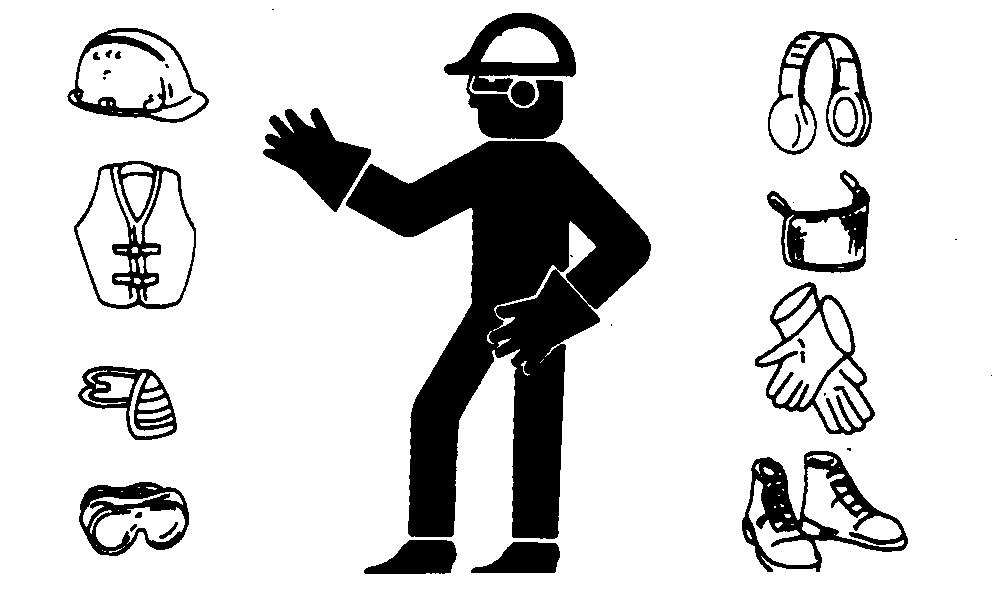

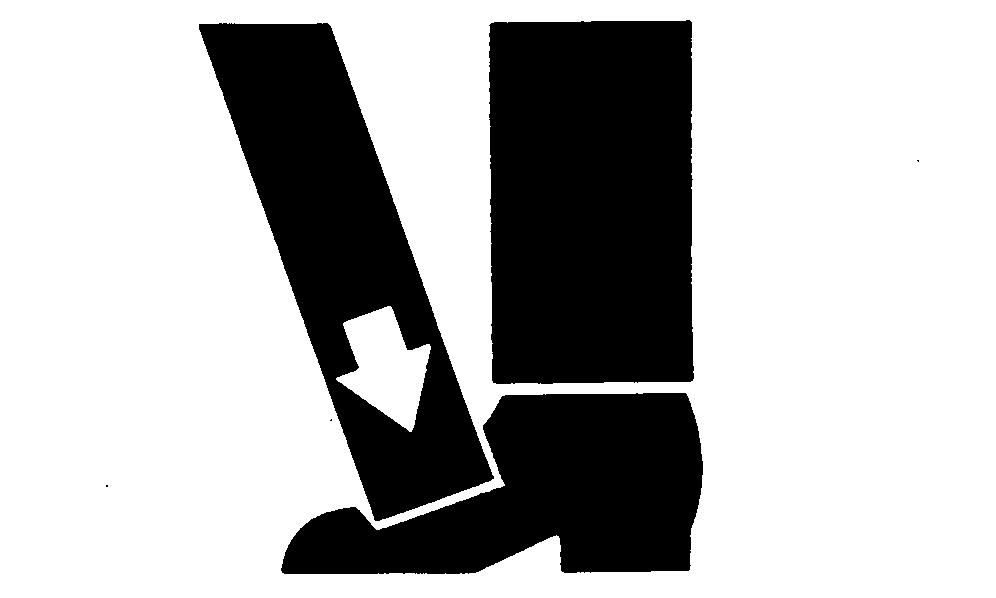

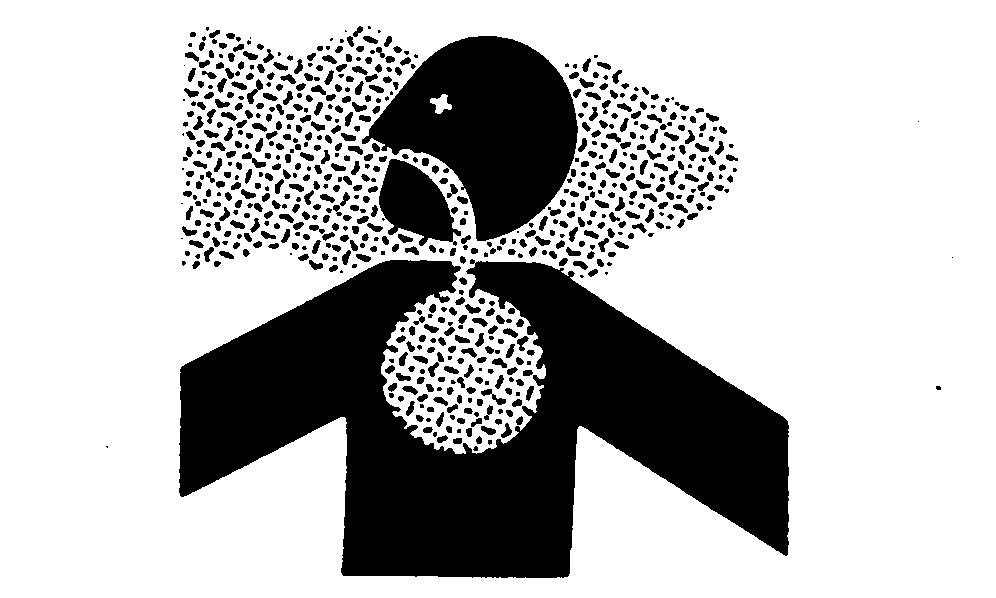

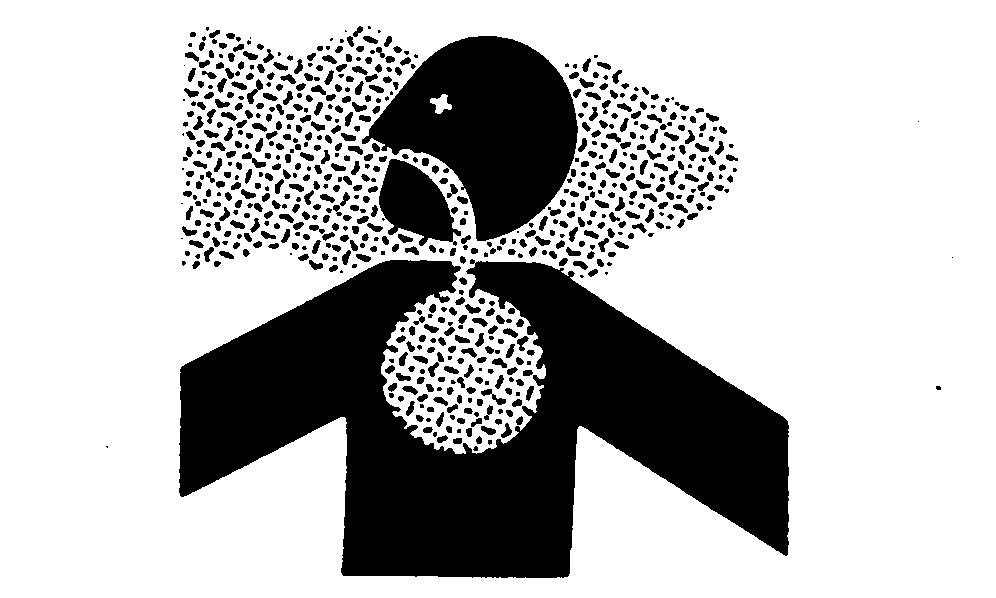

W ear Protective Clothing

W ear close fitting clothing and safety equipment appropriate the

Prolonged exposure loud noise can cause impairment loss

W ear a suitable hearing protective device such earmuf earplugs protect against objectionable uncomfortable loud noises.

Operating equipment safely requires the full attention the operator not wear radio music headphones while operating

Protect Against Noise

Prolonged exposure loud noise can cause impairment loss

W ear a suitable hearing protective device such earmuf earplugs protect against objectionable uncomfortable loud noises.

W ork Clean Area

Before starting a job:

• Clean work area and

• Make sure you have all necessary tools your

• Have the right parts

• Read all instructions thoroughly; not attempt

W ork V entilated Area

Engine exhaust fumes can cause sickness necessary run engine enclosed remove the exhaust fumes from the area with exhaust pipe extension.

you not have exhaust pipe open the doors and get outside air into the

Illuminate W ork Area Safely

Illuminate your work area adequately but safely Use a portable safety light for working inside under the Make sure the bulb enclosed a wire The hot filament accidentally broken bulb can ignite spilled fuel oil.

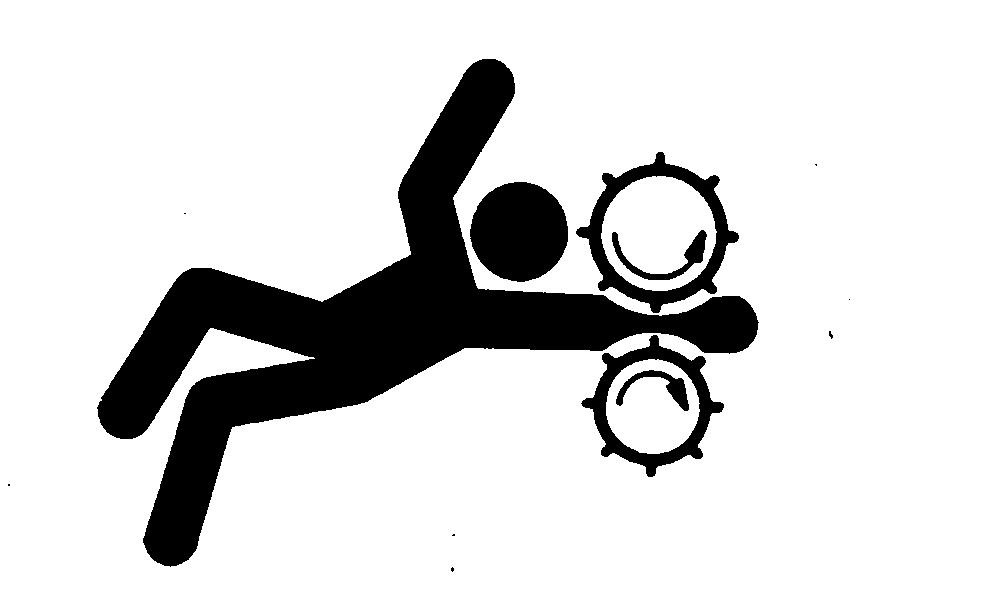

Service Machines Safely

T long hair behind your not wear a scarf, loose clothing, necklace when you work near machine tools moving these items were get severe injury could

Remove rings and other jewelry prevent electrical shorts and entanglement moving

Construct DealerMade T ools Safely

Faulty broken tools can result serious injury When constructing use proper , quality and good not weld tools unless you have the proper equipment and experience perform the

Service Cooling System Safely

Explosive release fluids from pressurized cooling system can cause serious

Shut f Only remove filler cap when cool enough touch with bare hands. Slowly loosen cap first stop relieve pressure before removing completely .

Service Accumulator Systems Safely

Escaping fluid gas from systems with pressurized accumulators that are used air conditioning, hydraulic, and air brake systems can cause serious injury Extreme heat can cause the accumulator and pressurized lines can accidentally not weld use a torch near a pressurized accumulator pressurized

Relieve pressure from the pressurized system before removing accumulator

Relieve pressure from the hydraulic system before removing accumulator Never attempt relieve hydraulic system accumulator pressure loosening a

Accumulators cannot

High pressure fluid remaining fuel lines can cause serious injury Only technicians familiar with this type system should perform Before disconnecting fuel lines, sensors, any other components between the high pressure fuel pump and nozzles engines with High Pressure Common Rail (HPCR) fuel wait a minimum minutes after engine

Replace Safety Signs

Replace missing damaged safety See the machine operator ’ s manual for correct safety sign

Use Proper Lifting Equipment

Lifting heavy components incorrectly can cause severe injury machine damage.

Follow recommended procedure for removal and installation components the

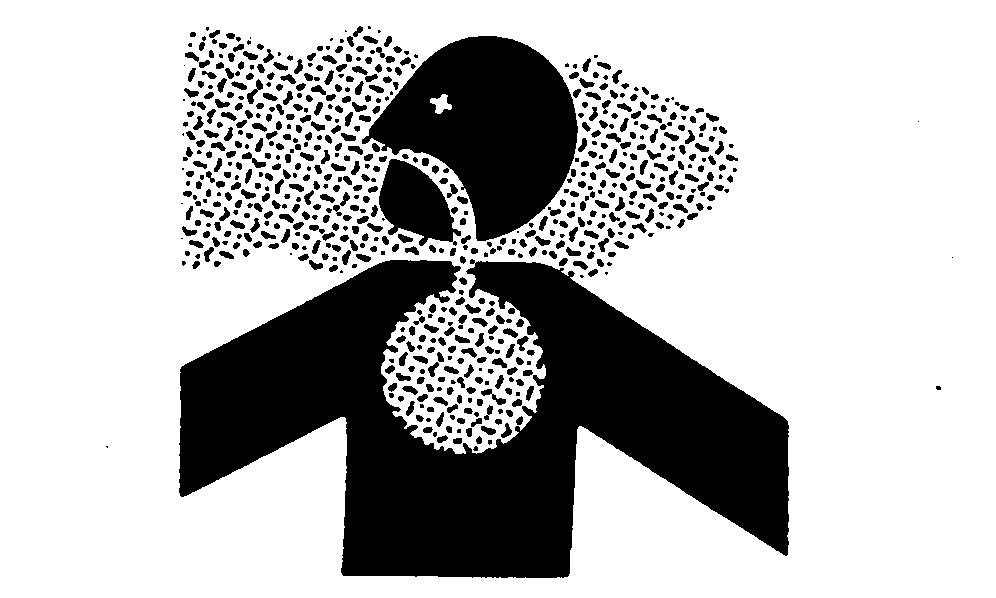

Remove Paint Before W elding Heating

A void potentially toxic fumes and Hazardous fumes can generated when paint heated welding, soldering, using a torch.

Remove paint before heating:

• Remove paint a minimum 100 from area fected paint cannot wear approved respirator before heating welding.

• you sand grind avoid breathing the W ear approved respirator

• you use solvent paint stripper , remove stripper with soap and water before Remove solvent paint stripper containers and other flammable material from area. Allow fumes disperse least minutes before welding

not use a chlorinated solvent areas where welding will take

all work area that well ventilated carry toxic fumes and dust away

Dispose paint and solvent properly

A void Heating Near Pressurized Fluid Lines

Flammable spray can generated heating near pressurized fluid resulting severe burns yourself and not heat using a torch near pressurized fluid lines other flammable materials. Pressurized lines can accidentally burst when heat goes beyond the immediate flame area.

Service T ires Safely

Explosive separation a tire and rim parts can cause serious injury death.

not attempt mount a tire unless you have the proper equipment and experience perform the

Always maintain the correct tire pressure. not inflate the tires above the recommended pressure. Never weld heat a wheel and tire assembly The heat can cause increase air pressure resulting a tire W elding can structurally weaken deform the

When inflating tires, use a clip chuck and extension hose long enough allow you stand one side and NOT front over the tire assembly Use a safety cage

Check wheels for low damaged rims missing lug bolts and nuts.

A void Harmful Asbestos Dust

A void breathing dust that may generated when handling components containing asbestos Inhaled asbestos fibers may cause lung cancer

Components products that may contain asbestos fibers are brake pads, brake band and lining assemblies, clutch and some The asbestos used these components usually found a resin sealed some way Normal handling not hazardous long airborne dust containing asbestos not

A void creating dust. Never use compressed air for A void brushing grinding material containing When wear approved respirator

A special vacuum cleaner recommended clean not apply a mist oil water the material containing asbestos.

Practice Safe Maintenance

Understand service procedure before doing Keep area clean and dry

Never lubricate, service, adjust machine while Keep feet , and clothing from power driven Disengage all power and operate controls relieve Lower equipment the Stop the Remove the key Allow machine

Securely support any machine elements that must raised for service

Keep all parts good condition and properly Fix damage immediately Replace worn broken Remove any buildup grease, oil, debris.

self propelled disconnect battery ground cable ( ) before making adjustments electrical systems welding

towed implements, disconnect wiring harnesses from tractor before servicing electrical system components welding

Use Proper T ools

Use tools appropriate the Makeshift tools and procedures can create safety

Use power tools only loosen threaded parts and fasteners.

For loosening and tightening use the correct size NOT use measurement tools metric A void bodily injury caused slipping

Use only service parts meeting John Deere specifications.

Dispose W aste Properly

Improperly disposing waste can threaten the environment and ecology . Potentially harmful waste used with John Deere equipment include such items brake and

Use leakproof containers when draining not use food beverage containers that may mislead someone into drinking from them. not pour waste onto the down a into any water

Air conditioning refrigerants escaping into the air can damage the s atmosphere. Government regulations may require a certified air conditioning service center recover and recycle used air conditioning

Inquire the proper way recycle dispose waste from your local environmental recycling center , from your John Deere dealer .

Live W ith Safety

Before returning machine customer , make sure machine functioning properly , especially the safety systems. Install all guards and shields.

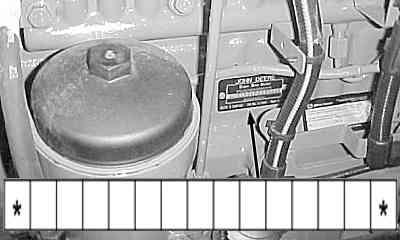

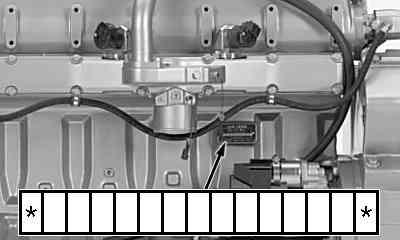

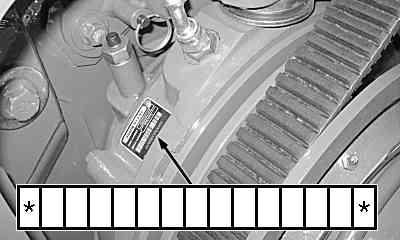

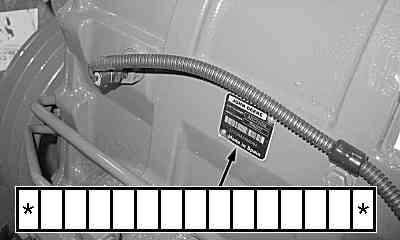

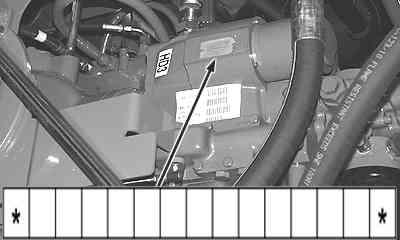

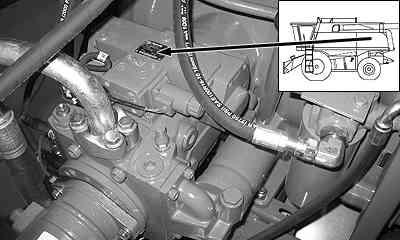

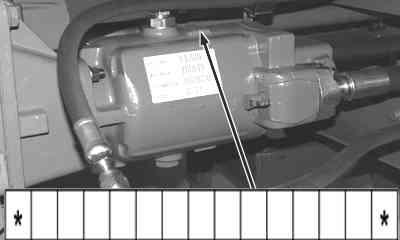

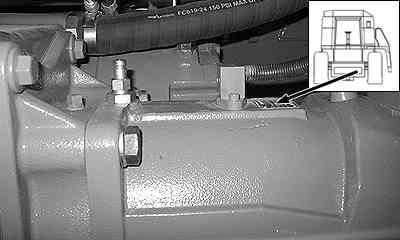

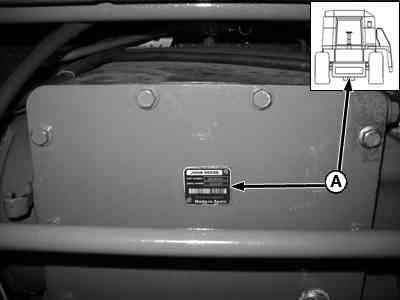

Identification Plates

Each combine has identification plates similar the one The letters and numbers stamped these plates identify a component assembly

ALL these characters are needed when ordering parts identifying a combine component for any John Deere product support they are needed for law enforcement trace the combine ever

side

Feeder House Reverser Gearcase

Operating Speeds — 9570 STS Combine

Speeds shown are average and can vary from machine Speeds are rated high idle with separator engaged, load.

speeds specifications and design subject change without

Chopper/Discharge Beater Jackshaft 2002 rpm

Chopper Speed) 1600/2500 rpm

Dimensions 9570 STS Combine NOTE: Dimension specifications subject change

(13

(13

(14

(13

(14

• For 18.4R38*** Duals and 480/80R38 (149A8) R1, subtract 141

• For 20.8R38** Duals and 520/85R38 (155A8) subtract 103 (4.1 in.)

• For 14PR subtract 1 1 1 • For 30.5L 14PR R2, subtract (3.2 in.)

• For 30.5LR32*** subtract 1 • For 800/65R32 (172A8) R1W , subtract a Dimension measured m from the grain spill This represents the unloading auger when centered over the grain

Dimension Reference Points — 9570 STS Combine

Operating Speeds — 9670 STS and 9770 STS Combines

Speeds shown are average and can vary from machine machine. Speeds are rated high idle with separator

specifications and design subject change without notice.

Speeds

Unloading V ertical Auger

Unloading Outer Auger

Grain T ank Horizontal Augers

Chopper Speeds

Chopper/Discharge Beater Jackshaft

Chopper Speed)

Dimensions 9670 STS and 9770 STS Combines

Operating Speeds — 9870 STS Combine

Speeds shown are average and can vary from machine Speeds are rated high idle with separator Operating speeds specifications and design subject change without notice.

Chopper/Discharge Beater Jackshaft 2002 rpm

Chopper Speed) 1600/2500 rpm

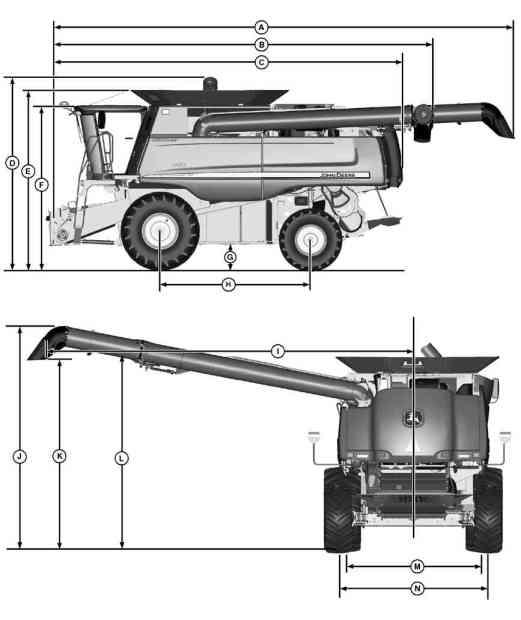

Dimensions — 9870 STS Combine

NOTE: Dimensions are approximate and subject change without

(14 6

(14 6

Refer Ground Drive and Rear Axle Section Refer Ground Drive and Rear Axle Section

Refer Ground Drive and Rear Axle Section Refer Ground Drive and Rear Axle Section

• For 18.4R42 *** Duals (480/80R42), add 2 (0.1 in.)

• For Duals subtract

• For Duals add

• For 20.8R42 Duals, add (2.8 in.)

• For 30.5L 14PR R1, subtract (0.7 in. )

• For 14PR add 1 1

• For *** subtract • For 35.5L 12PR R2, add 101 (4.0 in.)

• For 900/65R32 (172A8) R2, add (3.0 in.)

• For 800/70R38 (173A8) R1W , add

• For 76X50 16PR HF3, add (3.0 in.)

a Dimension measured m from the grain spill This represents the unloading auger when centered over the grain

T orque values listed are for general use only , based the strength the bolt screw NOT use these values a dif ferent torque value tightening procedure given for a specific For plastic insert crimped steel type lock for stainless steel for nuts U see the tightening instructions for the specific Shear bolts are designed fail under predetermined Always replace shear bolts with identical

a Grade 2 applies for hex cap screws (not hex bolts) (152 mm)

Replace fasteners with the same higher higher grade fasteners are tighten these the strength the Make sure fastener threads are clean and that you properly start thread When lubricate plain zinc plated fasteners other than lock wheel bolts wheel unless dif ferent instructions are given for the specific

Grade 1 applies for hex cap screws over 6 (152 mm) and for all other types bolts and screws any

b means coated with a lubricant such engine fasteners with phosphate and oil 7/8 and larger fasteners with JDM F13C zinc flake

c means plain zinc plated without any 1/4 3/4 fasteners with JDM F13B zinc flake

T orque values listed are for general use only , based the strength the bolt screw NOT use these values a dif ferent torque value tightening procedure given for a specific For stainless steel fasteners for nuts U see the tightening instructions for the specific T ighten plastic insert crimped steel type lock nuts turning the nut the dry torque shown the unless dif ferent instructions are given for the specific

Shear bolts are designed fail under predetermined Always replace shear bolts with identical property Replace fasteners with the same higher property higher property class fasteners are tighten these the strength the Make sure fastener threads are clean and that you properly start thread When lubricate plain zinc plated fasteners other than lock wheel bolts wheel unless dif ferent instructions are given for the specific

a ???Lubricated??? means coated with a lubricant such engine fasteners with phosphate and oil M20 and larger fasteners with JDM F13C zinc flake

b ???Dry??? means plain zinc plated without any M18 fasteners with JDM F13B zinc flake

Face Seal Fittings Assembly and Installation—All Pressure Applications

Face Seal ORing Stud End Installation

Inspect the fitting They must free dirt and/or defects.

Inspect the O must free damage and/or

Lubricate O rings and install into groove using petroleum jelly hold place.

Push O ring into groove with petroleum jelly O ring not displaced during assembly

Index angle fittings and tighten hand pressing joint together insure O ring remains place.

T ighten fitting nut torque value shown the chart per dash size stamped the NOT allow hoses twist when tightening

Face Seal Adjustable Stud End Installation

Back f lock nut (jam nut) and washer full exposed turned down section the fitting.

Install a thimble over the fitting threads protect the O ring from

Slide the O ring over the thimble into the turned down section the fitting.

Remove

Face Seal Straight Stud End ORing Installation

Install a thimble over the fitting threads protect the O ring from nicks.

Slide the O ring over the thimble into the turned down section the

Remove

Fitting Installation

Install fitting hand until snug.

Position adjustable fittings unscrewing the fitting more than one

Apply assembly torque per

Assembly T orque

Use one wrench hold the connector body and one wrench tighten

For a hydraulic may necessary use three wrenches prevent twist; one the connector body , one the nut, and one the body the hose fitting.

External Hexagon Port Plug T orque Chart

Port Stud End Thread Size a

M10 x 1

M12 x

M14 x

M16 x

M18 x

M20 x

M22 x

M27 x 2

M30 x 2

M33 x 2

M42 x 2

M48 x 2

M60 x 2

ORing Boss Fitting T orque Chart

Straight Fitting

Inspect O ring boss seat for dirt defects.

Lubricate O ring with petroleum jelly Place electrical tape over threads protect O ring groove

Remove

Angle Fitting

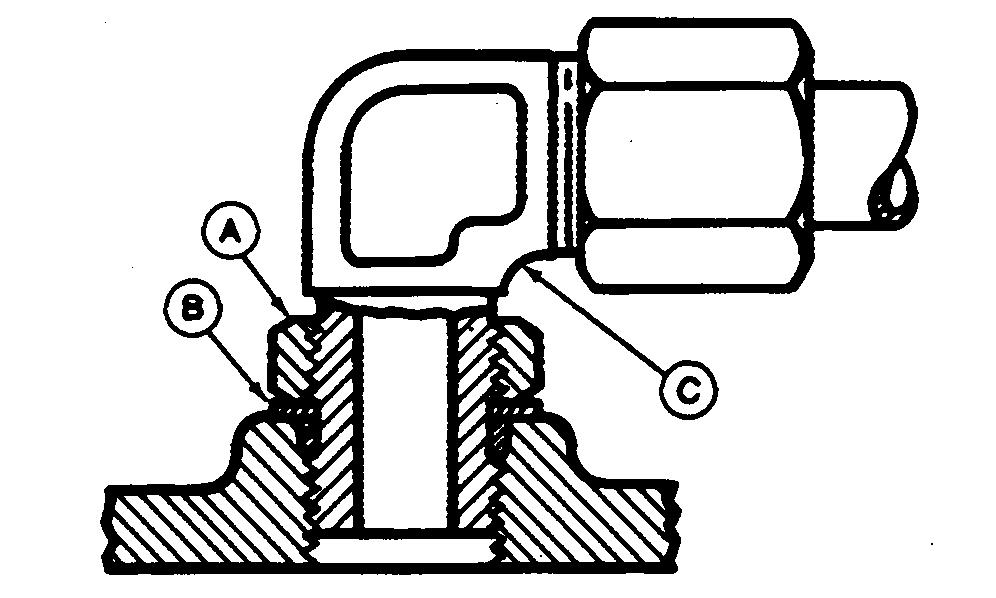

Back f nut (A) and back washer (B) completely head end (C)

T urn fitting into threaded boss until back washer contacts face boss.

T urn fitting head end counter clockwise proper index (maximum one

Hold fitting head end with a wrench and tighten lock nut and back washer proper torque value.

NOTE: not allow hoses twist when tightening

ORQUE V ALUE CHART

3/8

7/16

1/2 UNF (12)

9/16 UNF (18)

3/4 UNF (34)

7/8 UNF (46)

1 1/16 102 (75)

1 3/16 122 (90)

1 5/16 142 (105)

1 5/8 190 (140) 1 7/8 217 (160)

NOTE: T orque tolerance ±

SAE Four Bolt Flange Fitting T orque Chart

Inspect the sealing surfaces for nicks roughness out flat

Scratches cause Roughness causes seal wear Out flat causes seal these defects cannot polished out, replace the component.

Install the correct O ring (and backup washer required) into the groove using petroleum jelly hold

For Split flange; loosely assemble split flange halves, being sure that the split centrally located and perpendicular the Hand tighten cap screws hold not pinch O

For single piece flange; put hydraulic line the center the flange and install four cap screws. With the flange centrally located the port, hand tighten cap screws hold not pinch O

For both single piece flange and split sure the components are properly positioned and cap

screws are hand T ighten one cap screw , then tighten the diagonally opposite cap screw T ighten the two remaining cap T ighten all cap screws within the specified limits shown the

NOT use air wrenches. NOT tighten one cap screw fully before tightening the NOT over

a T olerance ± The torques given are enough for the given size connection with the recommended working T orques can increased the maximum shown for each cap screw size Increasing cap screw torque beyond this

result flange and cap screw bending and connection

b SAE Grade 5 better cap screws with plated

c Metric

T roubleshooting

T o prevent unnecessary loss time and productivity , please use the following procedure a guideline handling machine issues.

Identify the system systems that are not functioning properly

Many failures can present multiple symptoms.

Identify all the systems that are currently experiencing

T alk the customer and the operator , they may have some insight what going wrong.

Find out any yourself ’ service was Customer additions the machine attempted self service can sometimes the primary cause the

Pick the most critical system that not working and diagnose

Diagnosing and resolving the most critical system failure first may solve problems occurring with other systems.

Use Service ADVISOR your diagnostic support and information delivery tool for the system you have

Make sure you are using the latest data. Choose the correct machine model and serial number range

Understand the operation the system that you have

T s systems interact are dependent many other systems provide our s unique

careful normal abnormal operation usually caused improper improper conditions, and on.

A void mistakes caused improperly operating something skipping a required step for proper

Refer the Operator ’ s Manual Diagnostic Theory Operation for

Run the diagnostic routine for the system that you

all the things that the diagnostic routine asks you the order they are

Confirm that proper operation the system has been fully

Confirm the proper operation the other systems that were not working properly there are still back step 2 and pick the next most critical system and run the list