5090R, 5100R, 5115R, 5115RH and 5125R (FT4/

Stage IIIB) Tractors Repair

REPAIR TECHNICAL MANUAL

5R Series Tractors

TM143519 01DEC18 (ENGLISH)

John Deere Augusta Works

Foreword

The diagnostic technical manual is written for an experienced technician. Essential tools required to perform certain type of work are identified in Section 300, and are recommended for use. Live with safety: Read the safety messages in the introduction of this manual and the cautions presented throughout the text.

CAUTION:

This is the safety-alert symbol. When the symbol is shown on the equipment or in a manual, be alert to the potential for personal injury.

Introduction

Diagnostic technical manuals are comprised of general information, checks, theory of operation, schematic and diagnostic procedures. Sections in a diagnostic technical manual help quickly identify the likely cause of routine failures. Component sections include images of the component or connector and location on the equipment.

The diagnostic technical manual references component manuals and repair technical manuals. Repair technical manuals are organized for various components requiring service instruction

Both diagnostic and repair technical manuals are concise guides for specific equipment. They are on-the-job instructions containing vital information to diagnose, analyze, test, and repair the equipment.

DX,DIAGTM,IFC-19-20111208

TM143519 (01.12.2018) 5R Series Tractors

Section 10 - General Information

Group 05 - Safety

Group 10 - General Specifications

Group 15 - Fuels and Lubricants

Group 20 - Serial Number Locations

Section 20 - Engine

Group 05 - Engine

Section 30 - Fuel, Air Intake, Exhaust, and Cooling

Group 05 - Fuel System

Group 10 - Air Intake System

Group 15 - Exhaust System

Group 20 - Cooling System

Section 40 - Electrical

Group 05A - Fuses and Relays

Group 05B - Ground Points

Group 05C - Connectors

Group 05D - Wiring Harnesses

Group 05E - Electrical Components

Section 50 - Drive Systems and Transmissions

Group 05 - Separation

Group 10 - PPST Transmission

Group 15 - Clutch Assembly

Group 20 - Differential

Group 25 - Control Valves

Group 30 - Final Drive

Group 35 - Rear PTO

Group 40 - Front PTO

Group 45 - Mechanical Front-Wheel Drive

Group 50 - Suspended Front Axle

Group 55 - Creeper Assembly

Group 60 - Transmission Lube Pump

Section 60 - Steering and Brakes

Group05- Steering

Group 10 - Brakes

Section 70 - Hydraulics - Open Center

Group 05 - Pumps and Filters

Group 15 - Hitch Valve

Group 20 - Rear Selective Control Valves

Group 25 - Mid-Mount Selective Control Valves

Section 71 - Hydraulics - Closed Center

Group 05 - Pumps and Filters

Group 10 - Rear SCVs

Group 25 - Mid-Mount SCV Valves

Section 72 - Hydraulics - Common

Group 10 - Hydraulic Controls

Group 15 - Rear Hitch

Group 20 - Front Hitch

Section 80 - Miscellaneous

Group 10 - Rear Hitches

Group 15 - Fenders

Group 20 - Hood

Group 25 - Step Assemblies

Group 30 - Wheels

Section 90 - Cab and Open Operator`s

Station

Group 05 - Seat and Support

Group 10A - Control Console

Group 10B - CommandARM™

Group 20 - Cab Components

Group 30 - Air Conditioning System

Group 35 - Heating System

Section 99 - Special Tools

Group 05 - Dealer Fabricated Tools

Group 10 - Service Tools

TM143519 (01.12.2018) 5R Series Tractors

Contents

10-1 TM143519 (01.12.2018) 5R Series Tractors Contents Page Section 10 General Information Page Group 05 - Safety Work In Ventilated Area 10-05-1 Recognize Safety Information 10-05-1 Avoid Backover Accidents 10-05-1 Prevent Machine Runaway...........................................10-05-2 Avoid Contact with Agricultural Chemicals 10-05-2 Clean Vehicle of Hazardous Pesticides 10-05-2 Use a Safety Chain 10-05-3 Work in Clean Area .......................................................10-05-3 Decommissioning - Proper Recycling and Disposal 10-05-3 of Fluids and Components ............................ Avoid Harmful Asbestos Dust 10-05-4 Use Electronic Display Properly 10-05-4 Avoid Hot Exhaust 10-05-4 Clean Exhaust Filter Safely ..........................................10-05-5 Exhaust Filter Cleaning 10-05-6 Handle Fuel Safely-Avoid Fires 10-05-6 Prepare for Emergencies 10-05-6 In Case of Fire................................................................10-05-6 Handle Fluids Safely-Avoid Fires 10-05-7 Avoid High-Pressure Fluids 10-05-7 Use Foldable ROPS and Seat Belt Properly 10-05-7 Avoid Static Electricity Risk When Refueling..............10-05-8 Install All Guards 10-05-8 Use Proper Lifting Equipment 10-05-9 Illuminate Work Area Safely 10-05-9 Live With Safety..............................................................10-05-9 Service Machines Safely 10-05-9 Support Machine Properly 10-05-10 Protect Against Noise 10-05-10 Remove Paint Before Welding or Heating...................10-05-10 Park Machine Safely 10-05-11 Stay Clear of Rotating Drivelines 10-05-12 Follow Safety Instructions 10-05-12 Use Proper Tools............................................................10-05-13 Service Tires Safely 10-05-13 Keep ROPS Installed Properly 10-05-13 Stay Clear of Rotating Drivelines 10-05-14 Construct Dealer-Made Tools Safely............................10-05-14 Practice Safe Maintenance 10-05-15 Understand Signal Words 10-05-15 Replace Safety Signs 10-05-15 Protect Against High Pressure Spray..........................10-05-16 Store Attachments Safely 10-05-16 Avoid Heating Near Pressurized Fluid Lines 10-05-16 Wear Protective Clothing 10-05-16 Precautions for Welding ...............................................10-05-17 Service Accumulator Systems Safely 10-05-17 Handling Batteries Safely 10-05-17 Handle Agricultural Chemicals Safely 10-05-18 Service Cooling System Safely 10-05-19 Wait Before Opening High-Pressure Fuel 10-05-19 System .............................................. Service Front-Wheel Drive Tractor Safely 10-05-19 Use Steps and Handholds Correctly 10-05-20 Handle Electronic Components and Brackets 10-05-20 Safely .............................................. Transport Tractor Safely................................................10-05-20 Deliver Safely 10-05-20 ServicingElectronic Control Units 10-05-21 Welding Near Electronic Control Units 10-05-21 Keep Electronic Control Unit Connectors Clean ........10-05-22 Group 10 - General Specifications Regions and Country Versions 10-10-1 Features and Accessories 10-10-2 Machine General Specifications 10-10-4 Drain and Refill Capacities........................................... 10-10-4 Service Recommendations for O-Ring Boss 10-10-5 Fittings........................................................... Service Recommendations For Flat Face O-Ring 10-10-6 Seal Fittings .................................................. . Metric Bolt and Screw Torque Values 10-10-7 Unified Inch Bolt and Screw Torque Values 10-10-8 Glossary of Terms 10-10-9 Trademarks 10-10-10 Group 15 - Fuels and Lubricants Alternative and Synthetic Lubricants 10-15-1 Transmission and Hydraulic Oil 10-15-1 Diesel Engine Coolant (engine with wet sleeve 10-15-2 cylinder liners) Operatingin WarmTemperature Climates 10-15-2 John Deere COOL-GARD™ II Coolant Extender 10-15-3 Water Quality for Mixing with Coolant 10-15-4 Concentrate................................................... Testing Coolant Freeze Point 10-15-4 Diesel Exhaust Fluid (DEF) - Use in Selective 10-15-5 Catalytic Reduction (SCR) Equipped Engines ......................................................... Disposal of Diesel Exhaust Fluid (DEF) ..................... 10-15-5 Refilling Diesel Exhaust Fluid (DEF) Tank 10-15-5 Storing Diesel Exhaust Fluid (DEF) 10-15-6 Testing Diesel Exhaust Fluid (DEF) 10-15-6 Diesel Engine Oil Service Interval for Operation at 10-15-6 High Altitude Diesel Engine Oil - Interim Tier 4, Final Tier 4, 10-15-7 Stage IIIB, and Stage IV................................ Engine Oil and Filter Service Intervals - Interim 10-15-8 Tier 4, Final Tier 4, Stage IIIB, and Stage IV Engines ......................................................... John Deere Break-In Plus™ Engine Oil - Interim 10-15-8 Tier 4, Final Tier 4, Stage IIIB, and Stage IV. Oil Filters 10-15-8

10-2 TM143519 (01.12.2018) 5R Series Tractors Fuel Filters Diesel Fuel............................................................ Handlingand Storing Diesel Fuel Lubricity of Diesel Fuel ......................................... Testing Diesel Fuel BioDiesel Fuel Page 10-15-9 10-15-10 10-15-10 10-15-11 10-15-11 10-15-12 Page Transmission, Steering, Brake, Hydraulic, and 10-15-15 Gear Case Oil ............................................... Oilscan™ and CoolScan™ 10-15-15 Minimizing the Effect of Cold Weather

Diesel 10-15-13 Engines ......................................................... Supplemental DieselFuelAdditives Grease.................................................................. Mixing of Lubricants.............................................. Lubricant Storage 10-15-13 10-15-14 10-15-14 10-15-14 Group 20 - Serial Number Locations Serial Numbers 10-20-1 Product Identification Number 10-20-2 Engine Serial Number 10-20-3 Transmission Serial Number ........................................10-20-4 Suspended Front Axle Serial Number 10-20-4 Mechanical Front Wheel Drive (MFWD) Serial 10-20-4 Number ......................................................... Cab Serial Number 10-20-5

on

Work In Ventilated Area

TS220-UN: Engine exhaust fumes

Engine exhaust fumes can cause sickness or death. If it is necessary to run an engine in an enclosed area, remove the exhaust fumes from the area with an exhaust pipe extension. If you do not have an exhaust pipe extension, open the doors and get outside air into the area.

DX,AIR-19-19990217

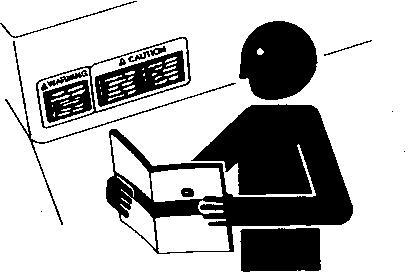

Recognize Safety Information

T81389-UN: Safety-alert symbol

This is a safety-alert symbol. When you see this symbol on your machine or in this manual, be alert to the potential for personal injury.

Follow recommended precautions and safe operating practices.

DX,ALERT-19-19980929

Avoid Backover Accidents

PC10857XW-UN: Avoid Backover Accidents

Before moving machine, be sure that all persons are clear of machine path. Turn around and look directly for best visibility. Use a signal person when backing if view is obstructed or when in close quarters.

Do not rely on a camera to determine if personnel or obstacles are behind the machine. The system can be limited by many factors including maintenance practices, environmental conditions, and operating range.

DX,AVOID,BACKOVER,ACCIDENTS-19-20100830

Safety 10-05-1 TM143519 (01.12.2018) 5R Series Tractors

Group 05 Safety

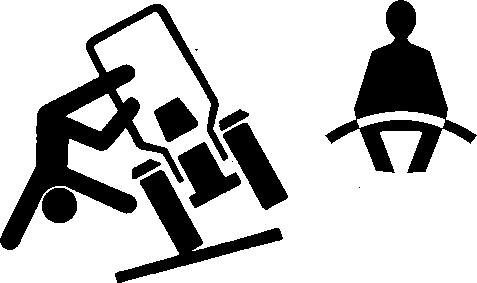

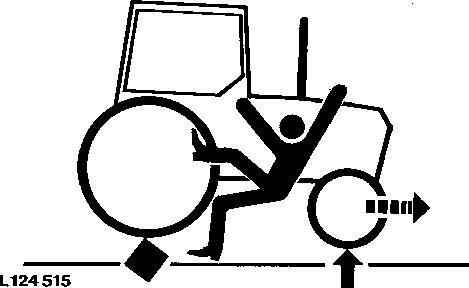

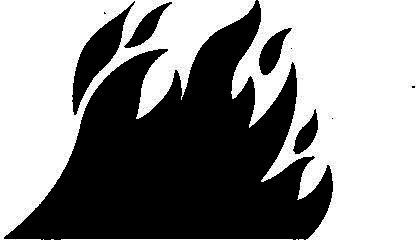

Prevent Machine Runaway

TS177-UN: Machinery Runaway

Avoid possible injury or death from machinery runaway. Do not start engine by shorting across starter terminals. Machine will start in gear if normal circuitry is bypassed.

NEVER start engine while standing on ground. Start engine only from operator’s seat, with transmission in neutral or park.

DX,BYPAS1-19-19980929

Avoid Contact with Agricultural

Chemicals

TS272-UN: Pesticide Use

CAUTION:

This enclosed cab does not protect against inhaling vapor, aerosol or dust.

1. When operating in an environment where pesticides are present, wear a long-sleeved shirt, long-legged pants, shoes, and socks.

2. If pesticide use instructions require respiratory protection, wear an appropriate respirator inside the cab.

3. Wear personal protective equipment as required by the pesticide use instructions when leaving the enclosed cab: into a treated area to work with contaminated application

TS220-UN: Harmful Pesticides equipment such as nozzles which must be cleaned, changed or redirected to become involved with mixing and loading activities

4. Before re-entering the cab, remove protective equipment and store either outside the cab in a closed box or some other type of sealable container or inside the cab in a pesticide resistant container, such as a plastic bag.

5. Clean your shoes or boots to remove soil or other contaminated particles prior to entering the cab.

DX,CABS1-19-20090325

Clean Vehicle of Hazardous Pesticides When exposed to hazardous pesticides, clean exterior and interior of vehicle daily to keep free of the accumulation of visible dirt and contamination.

CAUTION:

During application of hazardous pesticides, pesticide residue can build up on the inside or outside of the vehicle. Clean vehicle according to use instructions of hazardous pesticides.

Sweep or vacuum the floor of cab. Clean

and inside cowlings of

Wash entire exterior of

Dispose of any wash water with hazardous concentrations of active or non-active ingredients according to published regulations or directives.

DX,CABS2-19-20010724

Safety 10-05-2 TM143519 (01.12.2018) 5R Series Tractors

1. 2. 3. 4.

headliners

cab.

vehicle.

Use a Safety Chain

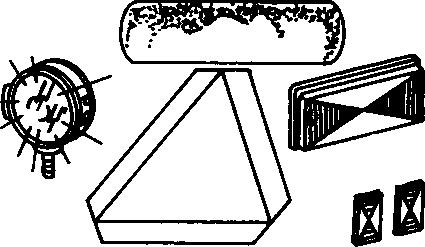

Work in Clean Area

Decommissioning — Proper Recycling and Disposal of Fluids and Components

TS217-UN: Safety Chain

A safety chain will help control drawn equipment should it accidentally separate from the drawbar.

Using the appropriate adapter parts, attach the chain to the tractor drawbar support or other specified anchor location. Provide only enough slack in the chain to permit turning.

See your John Deere dealer for a chain with a strength rating equal to or greater than the gross weight of the towed machine. Do not use safety chain for towing.

DX,CHAIN-19-19930303

TS1133-UN: Recycle Waste

Safety and environmental stewardship measures must be taken into account when decommissioning a machine and/or component. These measures include the following:

Use appropriate tools and personal protective equipment such as clothing, gloves, face shields or glasses, during the removal or handling of objects and materials.

Follow instructions for specialized components. Release stored energy by lowering suspended machine elements, relaxing springs, disconnecting the battery or other electrical power, and releasing pressure in hydraulic components, accumulators, and other similar systems.

T6642EJ-UN: Clean Work Area

Before starting a job:

Clean work area and machine. Make sure you have all necessary tools to do your job. Have the right parts on hand. Read all instructions thoroughly; do not attempt shortcuts.

DX,CLEAN-19-19900604

Minimize exposure to components which may have residue from agricultural chemicals, such as fertilizers and pesticides. Handle and dispose of these components appropriately.

Carefully drain engines, fuel tanks, radiators, hydraulic cylinders, reservoirs, and lines before recycling components. Use leak-proof containers when draining fluids. Do not use food or beverage containers.

Do not pour waste fluids onto the ground, down a drain, or into any water source.

Observe all national, state, and local laws, regulations, or ordinances governing the handling or disposal of waste fluids (example: oil, fuel, coolant, brake fluid); filters; batteries; and, other substances or parts. Burning of flammable fluids or components in other than specially designed incinerators may be prohibited by law and could result in exposure to harmful fumes or ashes.

Service and dispose of air conditioning systems appropriately. Government regulations may require a certified service center to recover and recycle air conditioning refrigerants which could damage the atmosphere if allowed to escape.

Evaluate recycling options for tires, metal, plastic, glass, rubber, and electronic components which may be recyclable, in part or completely.

Contact your local environmental or recycling center, or your John Deere dealer for information on the proper way to recycle or dispose of waste.

Safety 10-05-3 TM143519 (01.12.2018) 5R Series Tractors

DX,DRAIN-19-20150601

Avoid Harmful Asbestos Dust

Avoid breathing dust that may be generated when handling components containing asbestos fibers. Inhaled asbestos fibers may cause lung cancer.

Components in products that may contain asbestos fibers are brake pads, brake band and lining assemblies, clutch plates, and some gaskets. The asbestos used in these components is usually found in a resin or sealed in some way. Normal handling is not hazardous as long as airborne dust containing asbestos is not generated.

Avoid creating dust. Never use compressed air for cleaning. Avoid brushing or grinding material containing asbestos. When servicing, wear an approved respirator. A special vacuum cleaner is recommended to clean asbestos. If not available, apply a mist of oil or water on the material containing asbestos.

Keep bystanders away from the area.

Use Electronic Display Properly

Electronic displays are secondary devices intended to aid the operator in performing field operations, increase comfort and provide entertainment. Displays offer a wide range of functionality, are used in many different machine system applications and can be used with other secondary devices such as handheld electronic devices.

A secondary device is any device that is not required to operate your machine for its primary use. The operator is always responsible for safe operation and control of the machine.

To prevent injury while operating the machine:

Position the display according to the installation instructions. Ensure that the device is secured and does not obstruct the driver’s view or interfere with the machine operating controls. Do not become distracted by the display. Stay alert. Pay attention to the machine and surrounding environment.

Avoid Hot Exhaust

DX,DUST-19-19910315

Do not change settings or access any functions that require prolonged use of the display controls while machine is moving. Stop the machine in a safe location and place in park position before attempting such operations.

Never set the volume so high that you cannot hear outside traffic and emergency vehicles.

To promote safe operation, certain functions of displays may be disabled unless the machine movement is restricted and/or has been placed in the park position. Overriding this safety feature may violate applicable law and can result in damage, serious injury, or death.

Only use available display functionality when conditions permit you to do so safely and in accordance with instructions provided. Always observe safe driving rules, state, or local laws and traffic regulations when using any secondary device.

DX,ELEC,DISPLAY-19-20150113

RG17488-UN: Safety Hot Parts

Servicing machine or attachments with engine running can result in serious personal injury. Avoid exposure and skin contact with hot exhaust gases and components.

Exhaust parts and streams become very hot during operation. Exhaust gases and components reach temperatures hot enough to burn people, ignite, or melt common materials.

DX,EXHAUST-19-20090820

Safety 10-05-4 TM143519 (01.12.2018) 5R Series Tractors

TS220-UN: Asbestos Dust

Clean Exhaust Filter Safely

TS1695-UN:

During exhaust filter cleaning operations, the engine may run at elevated idle and hot temperatures for an extended period of time. Exhaust gases and exhaust filter components reach temperatures hot enough to burn people, or ignite or melt common materials.

Keep machine away from people, animals, or structures which may be susceptible to harm or damage from hot exhaust gases or components. Avoid potential fire or explosion hazards from flammable materials and vapors near the exhaust. Keep exhaust outlet away from people and anything that can melt, burn, or explode.

Closely monitor machine and surrounding area for smoldering debris during and after exhaust filter cleaning.

Adding fuel while an engine is running can create a fire or explosion hazard. Always stop engine before refueling machine and clean up any spilled fuel.

Always make sure that engine is stopped while hauling machine on a truck or trailer.

Contact with exhaust components while still hot can result in serious personal injury.

Avoid contact with these components until cooled to safe temperatures.

If service procedure requires engine to be running:

Only engage power-driven parts required by service procedure

Ensure that other people are clear of operator station and machine

Keep hands, feet, and clothing away from power-driven parts. Always disable movement (neutral), set the parking brake or mechanism and disconnect power to attachments or tools before leaving the operator’s station.

Shut off engine and remove key (if equipped) before leaving the machine unattended.

Safety 10-05-5 TM143519 (01.12.2018) 5R Series Tractors

TS227-UN: Fire Safety

TS271-UN: Hand Over Flame

TS1693-UN: Moving Parts

Stop

DX,EXHAUST,FILTER-19-20110112

Exhaust Filter Cleaning

RG17488-UN: Safety Hot Parts

Servicing machine or attachments during exhaust filter cleaning can result in serious personal injury. Avoid exposure and skin contact with hot exhaust gases and components.

During auto or manual/stationary exhaust filter cleaning operations, the engine will run at elevated idle and hot temperatures for an extended period of time. Exhaust gases and exhaust filter components reach temperatures hot enough to burn people, or ignite, or melt common materials.

DX,FILTER-19-20100120

Handle Fuel Safely Avoid Fires

Handle fuel with care: it is highly flammable. Do not refuel the machine while smoking or when near open flame or sparks.

Always stop engine before refueling machine. Fill fuel tank outdoors.

Prevent fires by keeping machine clean of accumulated trash, grease, and debris. Always clean up spilled fuel.

Use only an approved fuel container for transporting flammable liquids.

Never fill fuel container in pickup truck with plastic bed liner. Always place fuel container on ground before refueling. Touch fuel container with fuel dispenser nozzle before removing can lid. Keep fuel dispenser nozzle in contact with fuel container inlet when filling.

Do not store fuel container where there is an open flame, spark, or pilot light such as within a water heater or other appliance.

TS202-UN: Avoid Fires

Prepare for Emergencies

TS291-UN: First Aid Kit

Be prepared if a fire starts.

DX,FIRE1-19-20111012

Keep a first aid kit and fire extinguisher handy. Keep emergency numbers for doctors, ambulance service, hospital, and fire department near your telephone.

DX,FIRE2-19-19930303

In Case of Fire

TS227-UN: Flames

CAUTION:

Avoid personal injury.

Stop machine immediately at the first sign of fire. Fire may be identified by the smell of smoke or sight of flames. Because fire grows and spreads rapidly, get off the machine immediately and move safely away from the fire. Do not return to the machine! The number one priority is safety.

Call the fire department. A portable fire extinguisher can put out a small fire or contain it until the fire department arrives; but portable extinguishers have limitations. Always put the safety of theoperator andbystanders first. Ifattempting toextinguish afire,

Safety 10-05-6 TM143519 (01.12.2018) 5R Series Tractors

keep your back to the wind with an unobstructed escape path so you can move away quickly if the fire cannot be extinguished. Read the fire extinguisher instructions and become familiar with their location, parts, and operation before a fire starts. Local fire departments or fire equipment distributors may offer fire extinguisher training and recommendations.

If your extinguisher does not have instructions, follow these general guidelines:

Handle Fluids Safely Avoid Fires

1.

2.

3.

4.

Pull the pin. Hold the extinguisher with the nozzle pointing away from you, and release the locking mechanism.

Aim low. Point the extinguisher at the base of the fire.

Squeeze the lever slowly and evenly.

Sweep the nozzle from side-to-side.

TS227-UN: Avoid Fires

Avoid High-Pressure Fluids

X9811-UN: High Pressure

Inspect hydraulic hoses periodically – at least once per year –for leakage, kinking, cuts, cracks, abrasion, blisters, corrosion, exposed wire braid or any other signs of wear or damage.

Use Foldable ROPS and

Properly

DX,FIRE4-19-20130822

When you work around fuel, do not smoke or work near heaters or other fire hazards.

Store flammable fluids away from fire hazards. Do not incinerate or puncture pressurized containers.

Make sure machine is clean of trash, grease, and debris.

Do not store oily rags; they can ignite and burn spontaneously.

DX,FLAME-19-19980929

Replace worn or damaged hose assemblies immediately with John Deere approved replacement parts.

Escaping fluid under pressure can penetrate the skin causing serious injury.

Avoid the hazard by relieving pressure before disconnecting hydraulic or other lines. Tighten all connections before applying pressure.

Search for leaks with a piece of cardboard. Protect hands and body from high-pressure fluids.

If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically removed within a few hours or gangrene may result. Doctors unfamiliar with this type of injury should reference a knowledgeable medical source. Such information is available in English from Deere & Company Medical Department in Moline, Illinois, U.S.A., by calling 1-800-822-8262 or +1 309-748-5636.

DX,FLUID-19-20111012

Seat

Belt Avoid crushing injury or death during rollover.

If this machine is equipped with a foldable rollover protective structure (ROPS), keep the ROPS in the fully extended and locked position. USE a seat belt when you operate with a ROPS in the fully extended position. Hold the latch and pull the seat belt across the body.

Insert the latch into the buckle. Listen for a click.

Tugontheseat belt to make surethat thebelt is securely fastened.

Snug the seat belt across the hips.

TS1729-UN: Fasten Your Seat Belt

If this machine is operated with the ROPS folded (for example, to enter a low building), drive with extreme caution. DO NOT USE a seat belt with the ROPS folded.

Safety 10-05-7 TM143519 (01.12.2018) 5R Series Tractors

Return the ROPS to the raised, fully extended position as soon as the machine is operated under normal conditions.

Avoid Static Electricity Risk When Refueling

RG21992-UN: Static Discharge (Fuel Nozzle)

The removal of sulfur and other compounds in Ultra-Low Sulfur Diesel (ULSD) fuel decreases its conductivity and increases its ability to store a static charge.

Refineries may have treated the fuel with a static dissipating additive. However, there are many factors that can reduce the effectiveness of the additive over time.

Static charges can build up in ULSD fuel while it is flowing through fuel delivery systems. Static electricity discharge when combustible vapors are present could result in a fire or explosion.

Therefore, it is important to ensure that the entire system used to refuel your machine (fuel supply tank, transfer pump, transfer hose, nozzle, and others) is properly grounded and bonded. Consult with your fuel or fuel system supplier to ensure that the delivery system is in compliance with fueling standards for proper grounding and bonding practices.

DX,FUEL,STATIC,ELEC-19-20130712

Install All Guards

TS677-UN: SafetyFan

Rotating cooling system fans, belts, pulleys, and drives can cause serious injury.

Keep all guards in place at all times during engine operation. Wear close-fitting clothes. Stop the engine and be sure fans, belts, pulleys, and drives are stopped before making adjustments, connections, or cleaning near fans and their drive components.

DX,GUARDS-19-20090818

Safety 10-05-8 TM143519 (01.12.2018) 5R Series Tractors

DX,FOLDROPS-19-20130822

RG22142-UN: Explosion

Use Proper Lifting Equipment

TS226-UN: Proper Lifting Equipment

Lifting heavy components incorrectly can cause severe injury or machine damage.

Follow recommended procedure for removal and installation of components in the manual.

DX,LIFT-19-19900604

Illuminate Work Area Safely

TS223-UN: Work Area Safely

Illuminate your work area adequately but safely. Use a portable safety light for working inside or under the machine. Make sure the bulb is enclosed by a wire cage. The hot filament of an accidentally broken bulb can ignite spilled fuel or oil.

DX,LIGHT-19-19900604

Live With Safety

TS231-19: Safety Systems

Before returning machine to customer, make sure machine is functioning properly, especially the safety systems. Install all guards and shields.

DX,LIVE-19-19920925

Service Machines Safely

TS228-UN: Moving Parts

Tie long hair behind your head. Do not wear a necktie, scarf, loose clothing, or necklace when you work near machine tools or moving parts. If these items were to get caught, severe injury could result.

Remove rings and other jewelry to prevent electrical shorts and entanglement in moving parts.

DX,LOOSE-19-19900604

10-05-9 TM143519 (01.12.2018) 5R Series Tractors

Safety

Support Machine Properly

TS229-UN:Support Properly

Always lower the attachment or implement to the ground before you work on the machine. If the work requires that the machine or attachment be lifted, provide secure support for them. If left in a raised position, hydraulically supported devices can settle or leak down.

Do not support the machine on cinder blocks, hollow tiles, or props that may crumble under continuous load. Do not work under a machine that is supported solely by a jack. Follow recommended procedures in this manual.

When implements or attachments are used with a machine, always follow safety precautions listed in the implement or attachment operator′s manual.

Protect Against Noise

TS207-UN: Noise Exposure

There are many variables that affect the sound level range, including machine configuration, condition and maintenance level of the machine, ground surface, operating environmental, duty cycles, ambient noise, and attachments.

Exposure to loud noise can cause impairment or loss of hearing. Always wear hearing protection. Wear a suitable hearing protective device such as earmuffs or earplugs to protect against objectionable or uncomfortable loud noises.

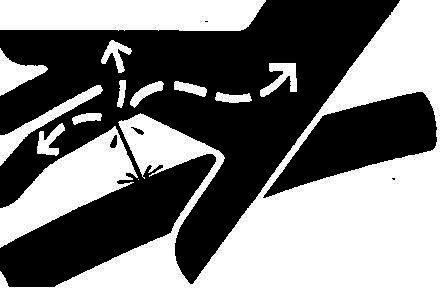

Remove Heating Paint Before Welding or Remove paint before heating:

Remove paint a minimum of 100 mm (4 in.) from area to be affected by heating. If paint cannot be removed, wear an approved respirator before heating or welding.

If you sand or grind paint, avoid breathing the dust. Wear an approved respirator.

If you use solvent or paint stripper, remove stripper with soap and water before welding. Remove solvent or paint stripper containers and other flammable material from area. Allow fumes to disperse at least 15 minutes before welding or heating.

Do not use a chlorinated solvent in areas where welding will take place.

TS220-UN: Toxic Fumes

Avoid potentially toxic fumes and dust.

Hazardous fumes can be generated when paint is heated by welding, soldering, or using a torch.

Do all work in an area that is well ventilated to carry toxic fumes and dust away.

Dispose of paint and solvent properly.

Safety 10-05-10 TM143519 (01.12.2018) 5R Series Tractors

DX,LOWER-19-20000224

DX,NOISE-19-20171003

DX,PAINT-19-20020724

Park Machine Safely

TS230-UN: Remove the Key Before working on the machine:

Lower all equipment to the ground. Stop the engine and remove the key. Disconnect the battery ground strap. Hang a "DO NOT OPERATE" tag in operator station.

Safety 10-05-11 TM143519 (01.12.2018) 5R Series Tractors

DX,PARK-19-19900604

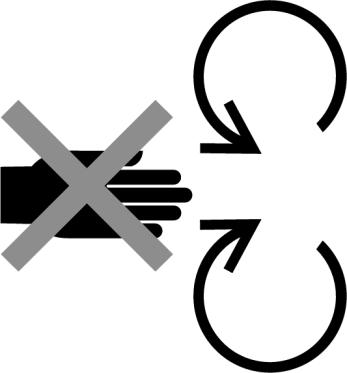

Stay Clear of Rotating Drivelines

Entanglement in rotating driveline can cause serious injury or death.

Keep tractor master shield and driveline shields in place at all times. Make sure rotating shields turn freely.

Only use power take-off driveshafts with adequate guards and shields.

Wear close fitting clothing. Stop the engine and be sure that PTO driveline is stopped before making adjustments, connections, or cleaning out PTO driven equipment.

Do not install any adapter device between the tractor and the primary implement PTO driveshaft that will allow a 1000 rpm tractor shaft to power a 540 rpm implement at speeds higher than 540 rpm.

Do not install any adapter device that results in a portion of the rotating implement shaft, tractor shaft, or the adapter to be unguarded. The tractor master shield shall overlap the end of the splined shaft and the added adaptor device as outlined in the table.

The angle at which the primary implement PTO driveshaft can be inclined may be reduced depending on the shape and size of the tractor master shield and the shape and size of the guard of the primary implement PTO driveshaft.

Do not raise implements high enough to damage the tractor master shield or guard of primary implement PTO driveshaft. Detach the PTO driveline shaft if it is necessary to increase implement height. (See Attching/Detaching PTO Driveline)

When using Type 3/4 PTO, inclination and turning angles may be reduced depending on type of PTO master shield and coupling rails.

Follow Safety Instructions

TS201-UN: Follow Safety Instructions

Carefully read all safety messages in this instruction. Read the product operators manual for operating instructions and safety messages. Do not let anyone operate without instruction. (A copy of the operators manual may also be available from the Service ADVISOR™ application.)

Service ADVISOR is a trademark of Deere & Company DX,READ,INS-19-20090623

Safety 10-05-12 TM143519 (01.12.2018) 5R Series Tractors

TS1644-UN: Rotating Drivelines

H96219-UN: Drivelines

PTO Type Diameter Splines n ± 5 mm (0.20 in.) 1 35 mm (1.378 in.) 6 85 mm (3.35 in.) 2 35 mm (1.378 in.) 21 85 mm (3.35 in.) 3 45 mm (1.772 in.) 20 100 mm (4.00 in.) 4 57.5 mm (2.264 in.) 22 100 mm (4.00 in.)

DX,PTO-19-20170228

Safety 10-05-13 TM143519 (01.12.2018) 5R Series Tractors

Use Proper Tools

TS779-UN: Proper Tools

Use tools appropriate to the work. Makeshift tools and procedures can create safety hazards.

Use power tools only to loosen threaded parts and fasteners. For loosening and tightening hardware, use the correct size tools. DO NOT use U.S. measurement tools on metric fasteners. Avoid bodily injury caused by slipping wrenches.

Use only service parts meeting John Deere specifications.

DX,REPAIR-19-19990217

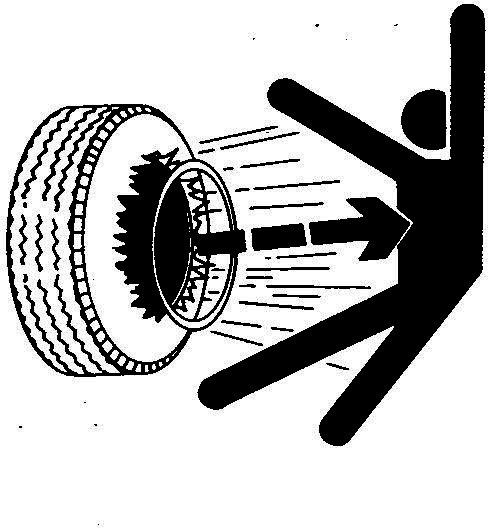

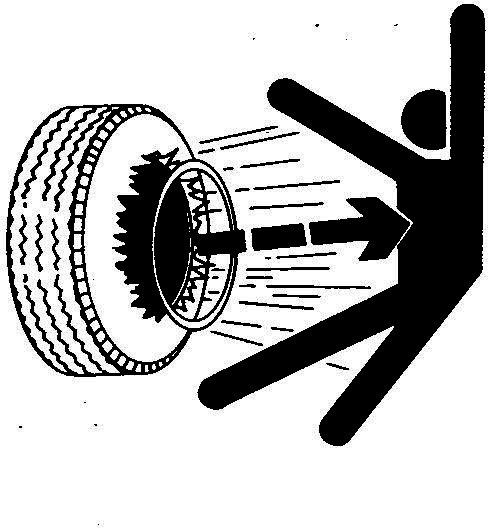

Service Tires Safely

TS211-UN: Explosive Tire and Rim Parts

CAUTION:

Explosive separation of a tire and rim parts can cause serious injury or death. Do not attempt to mount a tire unless you have the proper equipment and experience to perform the job.

Always maintain the correct tire pressure. Do not inflate the tires above the recommended pressure.

Never weld or heat a wheel and tire assembly. The heat can cause an increase in air pressure resulting in a tire explosion. Welding can structurally weaken or deform the wheel.

When inflating tires, use a clip-on chuck and extension hose long enough to allow you to stand to one side and NOT in front of or over the tire assembly. Use a safety cage if available.

Check wheels for low pressure, cuts, bubbles, damaged rims or missing lug bolts and nuts.

DX,RIM1-19-20081027

Keep ROPS Installed Properly

TS212-UN: Roll-Over Protective Structure

Make certain all parts are reinstalled correctly if the roll-over protective structure (ROPS) is loosened or removed for any reason. Tighten mounting bolts to proper torque.

The protection offered by ROPS will be impaired if ROPS is subjected to structural damage, is involved in an overturn incident, or is in any way altered by welding, bending, drilling, or cutting. A damaged ROPS should be replaced, not reused.

The seat is part of the ROPS safety zone. Replace only with John Deere seat approved for your tractor.

Any alteration of the ROPS must be approved by the manufacturer.

DX,ROPS3-19-20111012

10-05-14 TM143519 (01.12.2018) 5R Series Tractors

Safety

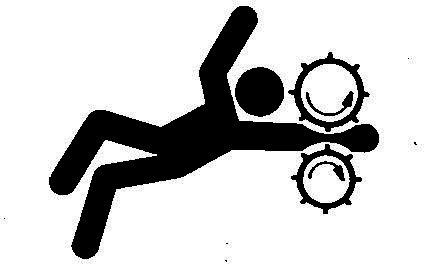

Stay Clear of Rotating Drivelines

Entanglement in rotating driveline can cause serious injury or death.

Keep tractor master shield and driveline shields in place at all times. Make sure rotating shields turn freely.

Only use power take-off driveshafts with adequate guards and shields.

Wear close fitting clothing. Stop the engine and be sure that PTO driveline is stopped before making adjustments, connections, or cleaning out PTO driven equipment.

Do not install any adapter device between the tractor and the primary implement PTO driveshaft that will allow a 1000 rpm tractor shaft to power a 540 rpm implement at speeds higher than 540 rpm.

Do not install any adapter device that results in a portion of the rotating implement shaft, tractor shaft, or the adapter to be unguarded. The tractor master shield shall overlap the end of the splined shaft and the added adaptor device as outlined in the table.

The angle at which the primary implement PTO driveshaft can be inclined may be reduced depending on the shape and size of the tractor master shield and the shape and size of the guard of the primary implement PTO driveshaft.

Do not raise implements high enough to damage the tractor master shield or guard of primary implement PTO driveshaft. Detach the PTO driveline shaft if it is necessary to increase implement height. (See Attching/Detaching PTO Driveline)

When using Type 3/4 PTO, inclination and turning angles may be reduced depending on type of PTO master shield and coupling rails.

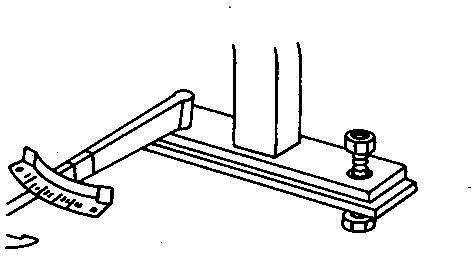

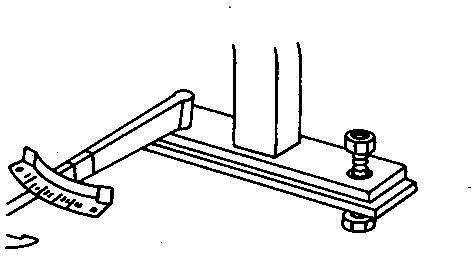

Construct Dealer-Made Tools Safely

LX1016749-UN: Construct Dealer-Made Tools Safely

Faulty or broken tools can result in serious injury. When constructing tools, use proper, quality materials, and good workmanship.

Do not weld tools unless you have the proper equipment and experience to perform the job.

DX,SAFE,TOOLS-19-19971010

Safety 10-05-15 TM143519 (01.12.2018) 5R Series Tractors

TS1644-UN: Rotating Drivelines

H96219-UN: Drivelines

PTO Type Diameter Splines n ± 5 mm (0.20 in.) 1 35 mm (1.378 in.) 6 85 mm (3.35 in.) 2 35 mm (1.378 in.) 21 85 mm (3.35 in.) 3 45 mm (1.772 in.) 20 100 mm (4.00 in.) 4 57.5 mm (2.264 in.) 22 100 mm (4.00 in.) DX,PTO-19-20170228

Practice Safe Maintenance

TS218-UN: Keep Area Clean

Understand service procedure before doing work. Keep area clean and dry.

Never lubricate, service, or adjust machine while it is moving. Keep hands, feet, and clothing away from power-driven parts. Disengage all power and operate controls to relieve pressure. Lower equipment to the ground. Stop the engine. Remove the key. Allow machine to cool.

Securely support any machine elements that must be raised for service work.

Keep all parts in good condition and properly installed. Fix damage immediately. Replace worn or broken parts. Remove any buildup of grease, oil, or debris.

On self-propelled equipment, disconnect battery ground cable () before making adjustments on electrical systems or welding on machine.

On towed implements, disconnect wiring harnesses from tractor before servicing electrical system components or welding on machine.

Falling while cleaning or working at height can cause serious injury. Use a ladder or platform to easily reach each location. Use sturdy and secure footholds and handholds.

DX,SERV-19-20170228

Understand Signal Words

DANGER ; The signal word DANGER indicates a hazardous situation which,if not avoided,will result indeath orserious injury. WARNING ; The signal word WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION ; The signal word CAUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate injury. CAUTION may also be used to alert against unsafe practices associated with events which could lead to personal injury.

A signal word DANGER, WARNING, or CAUTION is used with the safety-alert symbol. DANGER identifies the most serious hazards. DANGER or WARNING safety signs are located near specific hazards. General precautions are listed on CAUTION safety signs. CAUTION also calls attention to safety messages in this manual.

TS187-19: Signal Words

Replace Safety Signs

TS201-UN: Safety Signs

DX,SIGNAL-19-20161005

Replace missing or damaged safety signs. See the machine operator’s manual for correct safety sign placement.

DX,SIGNS1-19-19900604

Safety 10-05-16 TM143519 (01.12.2018) 5R Series Tractors

Protect Against High Pressure Spray

TS1343-UN: High Pressure Spray

Spray from high pressure nozzles can penetrate the skin and cause serious injury. Keep spray from contacting hands or body.

If an accident occurs, see a doctor immediately. Any high pressure spray injected into the skin must be surgically removed within a few hours or gangrene may result. Doctors unfamiliar with this type of injury should reference a knowledgeable medical source. Such information is available from Deere & Company Medical Department in Moline, Illinois, U.S.A.

DX,SPRAY-19-19920416

Store Attachments Safely

TS219-UN: Stored Attachments

Stored attachments such as dual wheels, cage wheels, and loaders can fall and cause serious injury or death.

Securely store attachments and implements to prevent falling. Keep playing children and bystanders away from storage area.

DX,STORE-19-19930303

Avoid Heating Near Pressurized Fluid Lines

TS953-UN: Flammable Spray

Flammable spray can be generated by heating near pressurized fluid lines, resulting in severe burns to yourself and bystanders. Do not heat by welding, soldering, or using a torch near pressurized fluid lines or other flammable materials. Pressurized lines can accidentally burst when heat goes beyond the immediate flame area.

DX,TORCH-19-20041210

Wear Protective Clothing

TS206-UN: Protective Clothing

Wear close fitting clothing and safety equipment appropriate to the job.

Prolonged exposure to loud noise can cause impairment or loss of hearing.

Wear a suitable hearing protective device such as earmuffs or earplugs to protect against objectionable or uncomfortable loud noises.

Operating equipment safely requires the full attention of the operator. Do not wear radio or music headphones while operating machine.

DX,WEAR-19-19900910

Safety 10-05-16 TM143519 (01.12.2018) 5R Series Tractors

Precautions for Welding

Remove paint before welding or heating (see Safety Section in this manual for more information on paint removal and highpressure lines).

CAUTION:

Avoid potentially toxic fumes and dust. Hazardous fumes can be generated when paint is heated by welding, soldering, or using a torch. Do all work outside or in a well ventilated area. Dispose of paint and solvent properly. If you sand or grind paint, avoid breathing the dust by wearing an approved respirator. If you use solvent or paint stripper, remove with soap and water before welding. Remove solvent or paint stripper containers and other flammable material from area before welding. Allow fumes to disperse at least 15 minutes before welding or heating.

IMPORTANT:

Welding on the engine is NOT ALLOWED. If welding must be performed on the machine, follow these precautions.

IMPORTANT: High currents or electrostatic discharge into electronic components from welding may cause permanent damage.

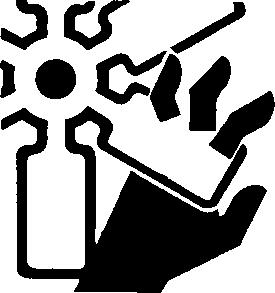

Service Accumulator Systems Safely

TS953-UN: Welding Precaution

1. Remove paint from the area to be welded and ground cable clamp location.

2. Disconnect the negative (-) battery cable(s) or open battery (-) switch if equipped.

3. Disconnect the positive (+) battery cable(s) or open battery (+) switch if equipped.

4. Clear or move any wiring harness sections away from the welding area.

5. Welding on engine components is not allowed.

6. Never connect the welder ground to any engine component or engine driven components that may be connected to the engine.

7. After welding, reverse steps 2 3.

DX,WELDING,PRECAUTIONS-19-20101206

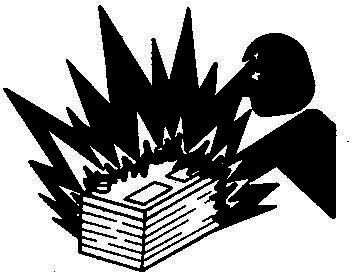

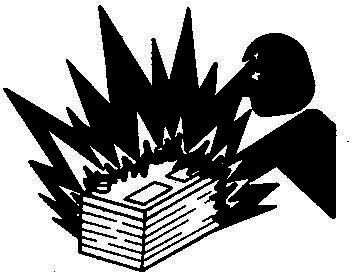

Handling Batteries Safely

TS281-UN: Hydraulic Accumulator

Escaping fluid or gas from systems with pressurized accumulators that are used in air conditioning, hydraulic, and air brake systems can cause serious injury. Extreme heat can cause the accumulator to burst, and pressurized lines can be accidentally cut. Do not weld or use a torch near a pressurized accumulator or pressurized line.

Relieve pressure from the pressurized system before removing accumulator.

Relieve pressure from the hydraulic system before removing accumulator. Never attempt to relieve hydraulic system or accumulator pressure by loosening a fitting. Accumulators cannot be repaired.

DX,WW,ACCLA2-19-20030822

TS204-UN: Caution

Safety 10-05-17 TM143519 (01.12.2018) 5R Series Tractors

TS203-UN: Caution

Battery gas can explode. Keep sparks and flames away from batteries. Use a flashlight to check battery electrolyte level.

Never check battery charge by placing a metal object across the posts. Use a voltmeter or hydrometer.

Handle Agricultural Chemicals Safely

Always remove grounded (-) battery clamp first and replace grounded clamp last.

Sulfuric acid in battery electrolyte is poisonous and strong enough to burn skin, eat holes in clothing, and cause blindness if splashed into eyes.

Avoidhazardsby:

Filling batteries in a well-ventilated area

Wearing eye protection and rubber gloves

Avoiding use of air pressure to clean batteries

Avoiding breathing fumes when electrolyte is added

Avoiding spilling or dripping electrolyte

Using correct battery booster or charger procedure.

If acid is spilled on skin or in eyes:

Flush skin with water.

Apply baking soda or lime to help neutralize the acid. Flush eyes with water for 15 30 minutes. Get medical attention immediately.

If acid is swallowed:

Do not induce vomiting.

Drink large amounts of water or milk, but do not exceed 2 L (2 qt.).

Get medical attention immediately.

WARNING: Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to cause cancer and reproductive harm. Wash hands after handling.

DX,WW,BATTERIES-19-20101202

can be harmful to your health or the environment if not used carefully.

Always follow all label directions for effective, safe, and legal use of agricultural chemicals.

Reduce risk of exposure and injury:

Wear appropriate personal protective equipment as recommended by the manufacturer. In the absence of manufacturer′s instructions, follow these general guidelines:

Chemicals labeled ′Danger′ : Most toxic. Generally require use of goggles, respirator, gloves, and skin protection.

TS220-UN: Safety

Chemicals labeled ′Warning′ : Less toxic. Generally require use of goggles, gloves, and skin protections.

Chemicals labeled ′Caution′ : Least toxic. Generally require use of gloves and skin protection.

Avoid inhaling vapor, aerosol or dust. Always have soap, water, and towel available when working with chemicals. If chemical contacts skin, hands, or face, wash immediately with soap and water. If chemical gets into eyes, flush immediately with water.

A34471-UN: Safety

Chemicals used in agricultural applications such as fungicides, herbicides, insecticides, pesticides, rodenticides, and fertilizers

Wash hands and face after using chemicals and before eating, drinking, smoking, or urination. Do not smoke or eat while applying chemicals. After handling chemicals, always bathe or shower and change clothes. Wash clothing before wearing again.

Safety 10-05-18 TM143519 (01.12.2018) 5R Series Tractors

Seek medical attention immediately if illness occurs during or shortly after use of chemicals. Keep chemicals in original containers. Do not transfer chemicals to unmarked containers or to containers used for food or drink. Store chemicals in a secure, locked area away from human or livestock food. Keep children away.

Service Cooling System Safely

Always dispose of containers properly. Triple rinse empty containers and puncture or crush containers and dispose of properly.

DX,WW,CHEM01-19-20100824

Wait Before Opening High-Pressure Fuel System

TS281-UN: Cooling System

Explosive release of fluids from pressurized cooling system can cause serious burns. Shut off engine. Only remove filler cap when cool enough to touch with bare hands. Slowly loosen cap to first stop to relieve pressure before removing completely.

DX,WW,COOLING-19-20090819

Service Front-Wheel Drive Tractor Safely

TS1343-UN: High-Pressure Fuel Lines

High-pressure fluid remaining in fuel lines can cause serious injury. Only technicians familiar with this type of system should perform repairs. Before disconnecting fuel lines, sensors, or any other components between the high-pressure fuel pump and nozzles on engines with High-Pressure Common Rail (HPCR) fuel system, confirm that the fuel pressure is relieved.

DX,WW,HPCR2-19-20140909

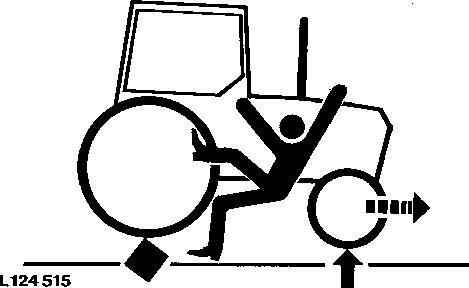

L124515-UN: SafetyTractor Rolling Forward

When servicing front-wheel drive tractor with the rear wheels supported off the ground and rotating wheels by engine power, always support front wheels in a similar manner. Loss of electrical power or transmission hydraulic system pressure will engage the front driving wheels, pulling the rear wheels off the support if front wheels are not raised. Under these conditions, front drive wheels can engage even with switch in disengaged position.

DX,WW,MFWD-19-20090819

Safety 10-05-19 TM143519 (01.12.2018) 5R Series Tractors

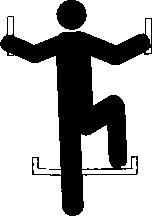

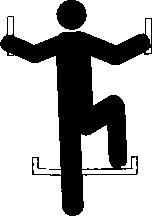

Use Steps and Handholds Correctly

T133468-UN: Use Handholds and Steps

Prevent falls by facing the machine when getting on and off. Maintain 3-point contact with steps, handholds, and handrails.

Use extra care when mud, snow, or moisture present slippery conditions. Keep steps clean and free of grease or oil. Never jump when exiting machine. Never mount or dismount a moving machine.

DX,WW,MOUNT-19-20111012

Handle Electronic Components and Brackets Safely

TS249-UN: falling hazard

Falling while installing or removing electronic components mounted on equipment can cause serious injury. Use a ladder or platform to easily reach each mounting location. Use sturdy and secure footholds and handholds. Do not install or remove components in wet or icy conditions.

If installing or servicing a RTK base station on a tower or other tall structure, use a certified climber.

If installing or servicing a global positioning receiver mast used on an implement, use proper lifting techniques and wear proper protective equipment. The mast is heavy and can be awkward to handle. Two people are required when mounting locations are not accessible from the ground or from a service platform.

DX,WW,RECEIVER-19-20100824

Transport Tractor Safely

RXA0103709-UN: Transport Tractor Safely

A disabled tractor is best transported on a flatbed carrier. Use chains to secure the tractor to the carrier. The axles and tractor frame are suitable attachment points.

Before transporting the tractor on a low-loader truck or flatbed rail wagon, make sure that the hood is secured over the tractor engine and that doors, roof hatch (if equipped) and windows are properly closed.

Never tow a tractor at a speed greater than 10 km/h (6 mph). An operator must steer and brake the tractor under tow.

DX,WW,TRANSPORT-19-20090819

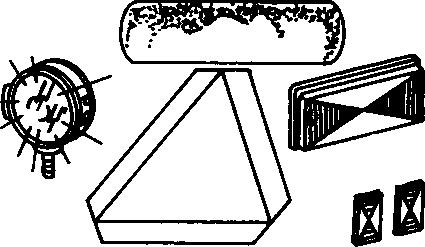

Deliver Safely

TS217-UN: Safety Chain

TS949-UN: Safety Lighting and Markings

The best method for delivering tractors, self-propelled equipment, and most implements or attachments is on a flatbed truck or trailer. Secure loads with tie down chains, straps, and binders.

Safety 10-05-20 TM143519 (01.12.2018) 5R Series Tractors

Be aware of height and width restrictions to avoid collision with overpasses, bridge abutments, or other road users. Check with local authorities regarding oversized load transport restrictions and requirements.

When towing, remember that towed loads can swerve, upset or cause loss of control when towed with an oversized towing unit. Never tow an implement behind a truck or other motor vehicle. The ability to maintain control and brake the implement and vehicle mass is compromised. The ability to properly attach the implement hitch and safety chain to the motor vehicle may be marginal. With most motor vehicles it is not possible to properly operate the warning, tail and turn signal lights on the implement, and in most cases the implement tires are not rated for highway speeds.

Tow drawn implements only with a properly sized and weighted tractor equipped with a stationary drawbar. (See tractor operator′s manual for ballast requirements.)

Integral and semi-integral implements should be attached to a tractor with a three-point hitch as specified in the implement operator′s manual. The tractor should have the proper size rear tires and the sway blocks should be in the down position. Do not transport unless the tractor front end is ballasted to the weight levels specified in the tractor operator′s manual for the correct implement code.

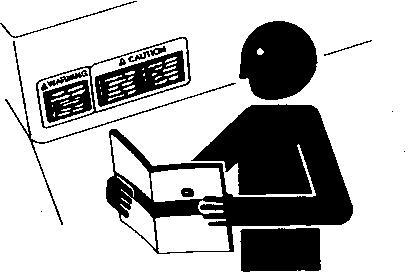

Servicing Electronic Control Units

IMPORTANT:

1. Do not open control unit and do not clean with a highpressure spray. Moisture, dirt, and other contaminants can cause permanent damage.

Control units are not repairable; replace only if indicated in the diagnostic procedure.

2. Since control units are the components LEAST likely to fail, isolate failure before replacing by completing the diagnostic procedure.

Welding Near Electronic Control Units

Before transporting, attach a properly sized safety tow chain between the implement and tractor.

Stopping distance increases with speed and weight of towed loads, and when transporting on slopes. Observe these recommended maximum road speeds, or local speed limits that may be lower:

If towed equipment does not have brakes, do not transport at speeds above 32 km/h (20 mph) and do not tow loads that weigh more than 1.5 times the weight of the tractor.

If the towed equipment has brakes, do not transport at speeds above 40 km/h (25 mph) and do not tow loads more than 4.5 times the weight of the tractor.

Use additional caution and reduce speed when towing under adverse surface conditions, when turning, and when on inclines. Attach the implement lighting harness to the tractor and make sure that the warning and taillights on both the tractor and implement are on and functioning properly.

Make sure that the SMV and other markings on the implement are clean and visible.

3. The wiring harness terminals and connectors for electronic control units are repairable.

4.

IMPORTANT: If an electronic control unit is not programmed identical to the original control unit, misleading diagnostic messages and poor performance will occur.

Before putting back into service, verify that the control unit is programmed identical to the original control unit.

DX,WW,ECU01-19-20151002

IMPORTANT:

1. Do not jump-start engines with arc welding equipment. Currents and voltages are too high and may cause permanent damage.

Disconnect the negative (-) battery cable(s). Disconnect the positive (+) battery cable(s). Connect the positive and negative cables together. Do not attach to vehicle frame.

Clear or move any wiring harness sections away from welding area.

Connect welder groundclose to weldingpoint and away from control units.

TS953-UN: Welding Graphic

6. After welding, reverse Steps 1 5.

DX,WW,ECU02-19-20090814

Safety 10-05-21 TM143519 (01.12.2018) 5R Series Tractors

2.

3.

4.

5.

DX,DELIVER-19-20010419

Keep Electronic Control Unit 3. Connectors Clean 4.

IMPORTANT:

1. Keep terminals clean and free of foreign debris. Moisture, dirt and other contaminants may cause the terminals to erode over time and not make a good electrical connection.

Observe the locking mechanism of the connector when disconnecting and reconnecting. Do not pull on wires to disconnect. Before reconnecting:

Look for bent terminals; do not force connectors into each other.

Replace any terminal where corrosion exists. Clean the connector of any foreign debris. Dry the connector of any moisture.

If a connector is not in use, put on the proper dust cap 6. When reconnecting, make sure seals around the connector or an appropriate seal to protect it from foreign debris and pairs are functional. moisture.

DX,WW,ECU03-19-20090611

IMPORTANT:

2. Do not probe through the wire insulation or through the back of the connector. Do not insert items such as paper clips or wires into connector terminals.

Make measurements on a connector terminal using JDG10466 Flex Probe Kit in SERVICEGARD.

Safety 10-05-22 TM143519 (01.12.2018) 5R Series Tractors

5.

Group 10

General Specifications

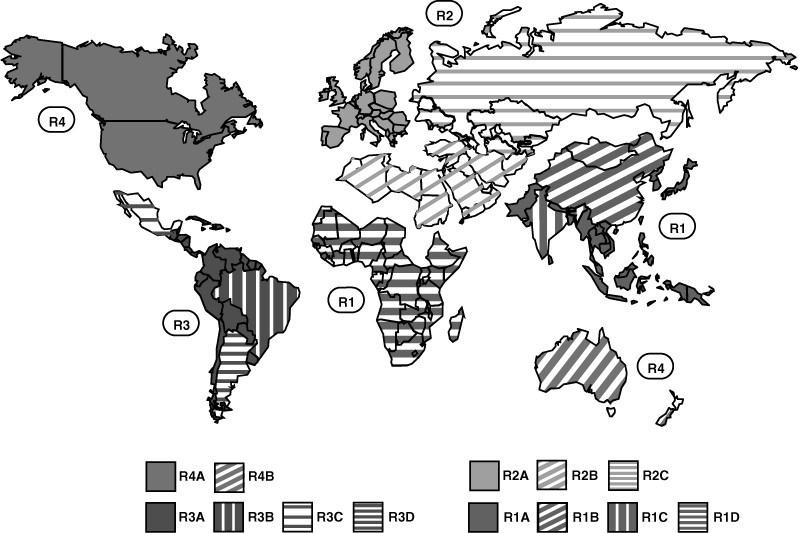

Regions and Country Versions

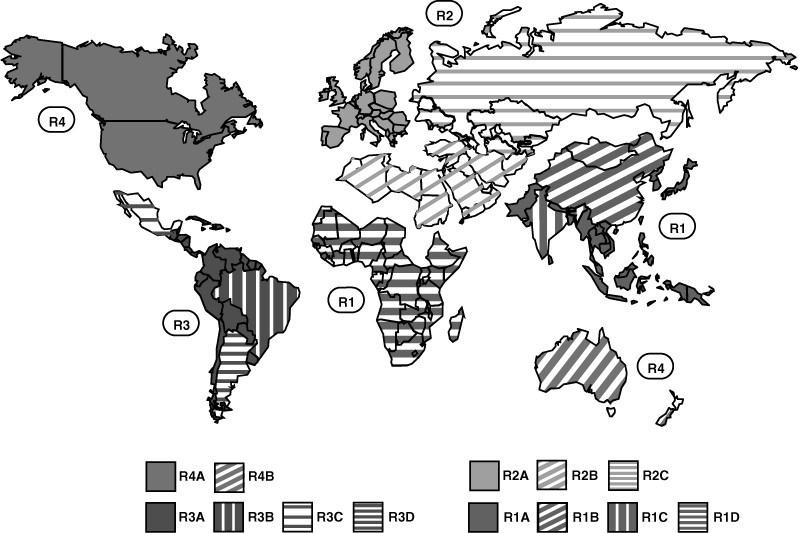

RXA0150915-UN: Region Map

LEGEND:

R1-Asia and Sub-Saharan Africa

R1A-Far East, Sri Lanka and Pakistan

R1B-China

R1C-India

R1D-Sub-Saharan Africa

R2-Europe, North Africa, Mid East, CIS

R2A-European Union (EU 28+)

R2B-North Africa and North Middle East (NANME)

R2C-Common Wealth of Independent States (CIS)

R3-Central and South America

R3A-Latin America (JDLA)

R3B-Brazil

R3C-Mexico

R3D-Argentina

R4-North America

R4A-USA and Canada

R4B-Oceania (Australia and New Zealand)

Regions 1, 2 and 3 equipment is traditionally manufactured with Economic Commission for Europe (ECE) features or systems.

Drive and signal lighting, traffic signs, safety signs, and braking features are some of the systems that differ between ECE and SAE. For example, Text-Free (pictorial only) safety signs are used for ECE while Text with Picture safety signs are used on SAE. Use information above, if equipment information is identified by regions, countries, trade federations, industry standards, or governmental regulations.

NOTE:

Australia and New Zealand (R4B) are available as either region 4 and/or region 2 configurations, only using text-free safety signs.

PB32103,00004BF-19-20170608

General Specifications 10-10-1 TM143519 (01.12.2018) 5R Series Tractors

Region 4 equipment is traditionally manufactured with Society of Automotive Engineers (SAE) features or systems.

Features and Accessories

The information covered in this block pertains to the features of the machines covered in this Technical Manual. It can be used in addition to the normal advertising literature or may help in determining which specific feature requires service.

NOTE:

Design, features, accessories, and specifications are subject to change without notification.

Features marked ”X” are available for that particular model number vehicle. Features marked ” ” are NOT available for that particular model number vehicle. Not all features are available on all vehicles or markets. Some features are dependent on other features being installed on the vehicle. For example, air conditioning and heating can only be on a cab equipped vehicle.

10-10-2 TM143519 (01.12.2018) 5R Series Tractors Features and Accessories (European and European Export Version) 5090R5100R5115R5125R Standard Cab with Right Hand Console Controls X X X X Standard Cab with CommandARM X X X X Premium Panorama Roof Cab with Right Hand Console Controls X X X X Premium Panorama Roof Cab with Command Arm (Requires PFC hydraulics and EH SCVs) X X X X Narrow Cab X X X X Air Conditioning and Heater X X X X Standard Cloth Air Suspension Seat X X X X Premium Cloth Air Suspension Seat X X X X Less Instructional Seat X X X X Instructional Seat with Seatbelt X X X X 16F/16R CommandQuad Manual (40k) X X X X 16F/16R CommandQuad (40k) X X X X 32F/16R Command8 (40K) X X X X 32F/16R Command8 (40K) w/ Creeper X X X X 4 Cylinder IT4 Engine X X X X 4 Valve High Pressure Common Rail Fuel Injection X X X X Turbocharger with Intercooler X X X X Turbocharger with Wastegate X X X X Water Separator X X X X Fuel Filter X X X X Air Cleaner X X X X Air Conditioner Condenser (Cab) X X X X Engine Oil Cooler X X X X Transmission Hydraulic Oil Cooler X X X X Cold Weather Start Aid (Air Intake Heater) X X X X Cold Weather Start Aid (Glow Plug) X X X X Engine Coolant Heater X X X X Wet Traction Clutch X X X X Creeper X X X X Open Center Hydraulics X X X X Close Center Hydraulic X X X X Tandem Gear Pump 25.6 GPM (96.7 LPM) X X X X Steering Pump 6.3 GPM (23.7 LPM) X X X X Implement Pump 19.3 GPM (73.0 LPM) X X X X Flanged Rear Axle Planetary Final Drives X X X X MFWD Front Axle X X X X MFWD Front Axle with Suspension X X X X Electrohydraulic Differential Lock X X X X Features and Accessories (North America and North America Export Version) 5090R5100R5115R5125R Standard Cab with Right Hand Console Controls X X X X Standard Cab with CommandARM X X X X Premium Panorama Roof Cab with Right Hand Console Controls X X X X Premium Panorama Roof Cab with Command Arm X X X X Narrow Cab X X X X Air Conditioning and Heater X X X X Standard Cloth Air Suspension Seat X X X X Premium Cloth Air Suspension Seat X X X X Instructional Seat With Seatbelt X X X X 16F/16R CommandQuad Manual (40k) X X X X 16F/16R CommandQuad Manual (40k) w/ Creeper X X X X 32F/16R Command8 (40K) X X X X 4 Cylinder FT4 X X X X 4 Valve High Pressure Common Rail Fuel Injection X X X X Turbocharger with Intercooler X X X X Water Separator X X X X Fuel Filter X X X X Air Cleaner X X X X Air Conditioner Condenser (Cab) X X X X Engine Oil Cooler X X X X Transmission Hydraulic Oil Cooler X X X X Cold Weather Start Aid (Air Intake Heater) X X X X Cold Weather Start Aid (Glow Plug) X X X X Engine Coolant Heater X X X X Wet Traction Clutch X X X X Creeper X X X X Open Center Hydraulics X X X X Close Center Hydraulics X X X X Tandem Gear Pump 25.6 GPM (96.7 LPM) X X X X Steering Pump 6.3 GPM (23.7 LPM) X X X X Implement Pump 19.3 GPM (73.0 LPM) X X X X Flanged Rear Axle Planetary Final Drives X X X X

General Specifications

Electrohydraulic MFWD X X X X Electrohydraulic Rear Power Take-Off (PTO) X X X X Wet PTO Clutch X X X X Dual (540/540E) Speed PTO X X X X Front PTO X X X X Front Loader Compatible X X X X Front 3-Point Hitch X X X X Mechanical Rear 3-Point Hitch X X X X Electronic Rear 3-Point Hitch X X X X Wagon Hitch Automatic X X X X Pickup Hitch Mechanical X X X X Drawbar Pickup Hitch X X X X 2 Mechanical Stackable Rear SCVs X X X X 3 Mechanical Deluxe Stackable Rear SCVs X X X X 2 Proportional EH Stackable Rear SCVs X X X X 3 Proportional EH Deluxe Stackable Rear SCVs X X X X Less Mid SCV X X X X 2 Standard Stackable Mid SCV with Mechanical Joystick Control X X X X 3 Deluxe Mid SCV with Mechanical Joystick Control X X X X 3 Deluxe Mid EH SCV with Electronic Joystick Control X X X X Pneumatic Trailer Brake X X X X Hydraulic Trailer Brake X X X X

General Specifications

10-10-3 TM143519 (01.12.2018) 5R Series Tractors PB32103,00004CA-19-20170612 2 Mechanical Stackable Rear SCVs X X X X 3 Mechanical Deluxe Stackable Rear SCVs X X X X 2 Proportional EH Stackable Rear SCVs X X X X 3 Proportional EH Deluxe Stackable Rear SCVs X X X X Less Mid SCV X X X X 2 Standard Stackable Mid SCV with Mechanical Joystick Control X X X X 3 Deluxe Mid SCV with Mechanical Joystick Control X X X X 3 Deluxe Mid EH SCV with Electronic Joystick Control X X X X MFWD Front Axle X X X X Electrohydraulic Differential Lock X X X X Electrohydraulic MFWD X X X X Electrohydraulic Rear Power Take-Off (PTO) X X X X Wet PTO Clutch X X X X Dual (540/540E) Speed PTO X X X X Triple (540/540E/1000) Speed PTO X X X X Front Loader Compatible X X X X Mechanical Rear 3-Point Hitch X X X X Electronic Rear 3-Point Hitch X X X X