REP

Basic instructions

T echnical Information

This manual has been produced a new technical information This new system designed deliver technical information electronically through CDROM and paper A coding system called ICE has been developed link the technical information other Product Support functions W arranty

T

echnical information written support the maintenance and service the functions systems a customers When a customer has a concern his machine usually because a function system his machine not working all, not working ficiently , not responding correctly his commands. When you refer the technical information this manual resolve that customers you will find all the information classified using the new ICE according the functions systems that Once you have located the technical information for that function system then you will find all the electrical hydraulic nents, assemblies and sub for that function system. Y will also find all the types information that have been written for that function the technical data the functional data (how the diagnostic data (fault codes and troubleshooting) and the service data install

integrating this new ICE coding into technical information , you will able search and retrieve just the right piece technical information you need resolve that customers concern his This made possible attaching 3 categories each piece technical information during the authoring

The first category the Location, the second category the Information T ype and the third category the Product:

• LOCA TION the component function the that the piece technical information going describe Fuel

• INFORMA TION TYPE the piece technical information that has been written for a particular component function the machine Capacity would a type T echnical Data that would describe the amount fuel held the Fuel

• PRODUCT the model that the piece technical information written for

Every piece technical information will have those 3 categories attached Y will able use any combination those categories find the right piece technical information you need resolve that customers concern his

That information could be:

• the description how remove the cylinder head

• a table specifications for a hydraulic pump

• a fault code

• a troubleshooting table

• a special tool

How Use this Manual

This manual divided into Each Section then divided into Contents pages are included the beginning the then inside every Section and inside every Chapter alphabetical Index included the end a Chapter . Page number references are included for every piece technical information listed the Chapter Contents Chapter

Each Chapter divided into four Information types:

• (D) T echnical Data (specifications) for all the mechanical, electrical hydraulic devices, components and,

• (C) Functional Data (how works) for all the electrical hydraulic components and

• (G) Diagnostic Data (fault codes, electrical and hydraulic troubleshooting) for all the electrical hydraulic components and

• (F) Service data (remove disassembly , install) for all the electrical hydraulic components and

Sections

Sections are grouped according the main functions a systems the Each Section identified a letter C The amount Sections included the manual will depend the type and function the machine that the manual written for Each Section has a Contents page listed alphabetic /numeric order This table illustrates which Sections could included a manual for a particular

SECTION

A Distribution Systems B Power Production C

Power T rain D

T ravelling E Body and Structure F Frame Positioning G

T ool Positioning H W orking Arm J T ools and Couplers K Crop Processing L Field Processing

PRODUCT

T ractors

V ehicles with working arms: backhoes, skid

equipment and

Chapters

Each Chapter identified a letter and number combination Engine The first letter identical the Section letter Chapter inside Section Power CONTENTS

The Chapter Contents lists all the (D) technical data (specifications), (C) functional data (how works), (F) service data install and (G) diagnostic data (fault codes and troubleshooting) that have been written that Chapter for that function system the

Contents

INDEX

The Chapter Index lists alphabetical order all the types information (called Information Units) that have been written that Chapter for that function system the machine.

Index

Information Units and Information Search

Each chapter composed information units. Each information unit has the ICE code shown parentheses which indicates the function and the type information written that information Each information unit has a page erence within that Chapter The information units provide a quick and easy way find just the right piece technical information you are looking for .

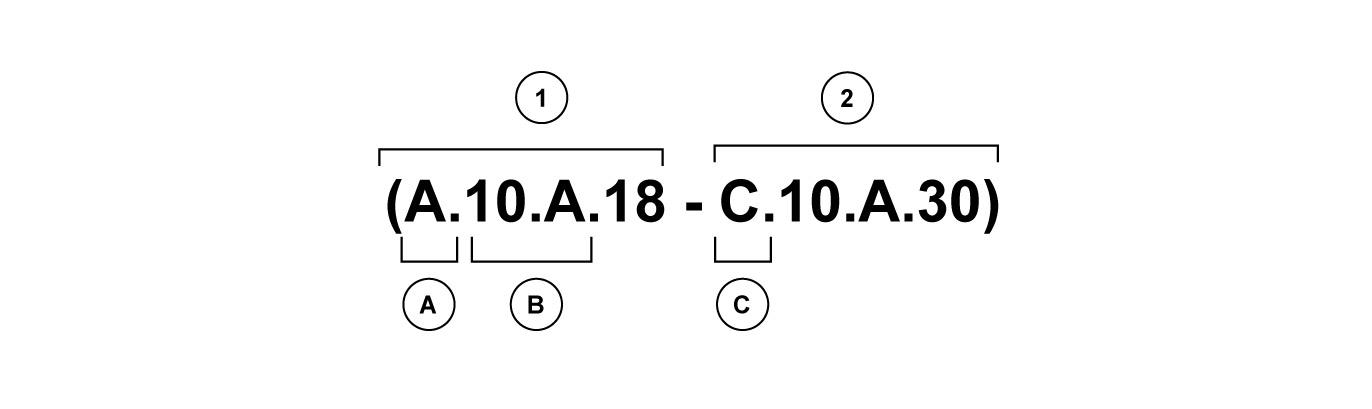

example information unit Stack valve Sectional V iewInformation Unit ICE code A C ICE code classification Distribution systems Primary hydraulic power

1

Navigate the correct information unit you are searching for identifying the function and information type from the ICE

• (1) Function and (2) Information

• (A) corresponds the sections the repair manual. (B) corresponds the chapters the repair (C) corresponds the type information listed the chapter (D) , T echnical (C) , Functional (G) , and (F) , (A) and (B) are also shown the page numbering the page footer THE REST THE CODING NOT LISTED ALPHA NUMERIC ORDER THIS

• Y will find a table contents the beginning and end each section and chapter Y will find alphabetical index the end each chapter .

• referring (A) , (B) and (C) the you can follow the contents index (page numbers) and quickly find the information you are looking for

CRIL03J033E01

Page Header and Footer

The page header will contain the following references:

• Section and Chapter description

The page footer will contain the following references:

• Publication number for that Section Chapter

• V ersion reference for that publication.

• Publication date

• chapter and page reference / 9

General specification

BOL T T ORQUE INFORMA TION

DECIMAL HARDW ARE

Fasteners should replaced with the same higher higher grade fasteners are these should only tightened the strength the

Make sure the fasteners threads are clean and that thread engagement This will prevent them from failing when being

T ighten plastic insert crimped steel lock nuts approximately % the dry applied the not the bolt head. T ighten toothed serrated lock nuts the full torque value.

The (Alloy) fasteners torque values are for a and two

When using (Alloy) not use the values this table for tapped

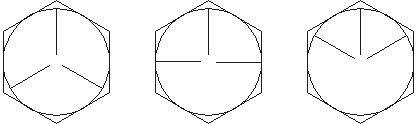

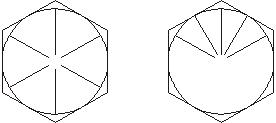

SAE Markings for Bolts and Cap Screws

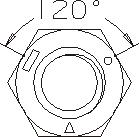

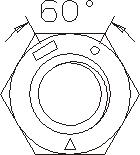

SAE Markings for Hex Nuts

IMPOR T ANT : NOT use these values a different torque value tightening procedure given for a specific T orque values listed are for general use only Check tightness fasteners periodically Shear bolts are designed fail under predetermined Always replace shear bolts with identical

NOTES

• * Grade 2 applies for hex caps (not hex bolts) 152 ( 6 ) Grade 1 applies for hex cap screws over 152 ( 6 ) and for all other types bolts and screws any

• means coated with a lubricant such engine fasters with phosphate and oil means plaind zinc plated without any

T ORQUE SPECIFICA TIONS METRIC HARDW ARE

Use the above torques when specifications are not

These values apply fasteners with both coarse and fine threads received from supplier , plated unplated, when lubricated with engine These values not apply graphite Molydisulfide grease oil

Use a click type torque better

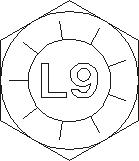

Grade and Studs

Usually torque values specified grade fasteners can used satisfactorily grade

O Face Seal End

O Boss End Fitting Lock Nut

NOTE: Apply sealant /lubricant male pipe threads. The first two threads should left uncovered avoid system Screw pipe fitting into female pipe port the finger tight Wrench tighten fitting the propriate turns from finger tight (TFFT) shown table making sure the tube end elbow tee fitting aligned receive incoming tube hose

Conversion factors

U.S.

Hydraulic contamination

Contamination the hydraulic system a major cause the malfunction hydraulic components. Contamination any foreign material the hydraulic Contamination can enter the hydraulic system several (A) When you drain the oil disconnect any (B) When you disassemble a (C) From normal wear the hydraulic components.

(D) From damaged worn (E) From a damaged component the hydraulic

All hydraulic systems operate with some contamination. The design the components this hydraulic system mits ficient operation with a small amount increase this amount contamination can cause problems the hydraulic The following list includes some these (A) Cylinder rod seals

(B) Control valve spools not return (C) Movement control valve spools dif (D) Hydraulic oil becomes too (E) Pump gears, housing, and other parts wear rapidly . (F) Relief valves check valves held open (G) Quick failure components that have been (H) Cycle times are slow; machine does not have enough power

your machine has any these check the hydraulic oil for There are two types microscopic and

Microscopic contamination occurs when very fine particles foreign material are suspension the hydraulic These particles are too small see Microscopic contamination can found identification the following problems testing a laboratory Examples the problems:

(A) Cylinder rod seal

(B) Control valve spools not return NEUTRAL.

(C) The hydraulic system has a high operating

V isible contamination foreign material that can found odor V isible contamination can cause a sudden failure components. Examples visible contamination: (A) Particles metal dirt the (B) Air the

(C) The oil dark and (D) The oil has odor burned (E) W ater the

you find use a Portable Filter clean the hydraulic

REP AIR MANUAL

DISTRIBUTION SYSTEMS

PRIMAR Y HYDRAULIC POWER SYSTEM

750L , 850L

750L , 850L

750L , 850L

SECONDAR Y HYDRAULIC POWER SYSTEM

ELECTRICAL POWER SYSTEM

LIGHTING SYSTEM

750L , 850L F AUL T CODES

750L , 850L

DISTRIBUTION SYSTEMS A

PRIMAR Y HYDRAULIC POWER SYSTEM10.A

Inlet section Disassemble

V isual inspection

Assemble

Inlet section Assemble

Install

Hydraulic pump

Flow test

Remove

Disassemble without O

V isual inspection without O

Assemble without O

Disassemble with O

V isual inspection with O

Assemble with O

Preliminary test

Install Reservoir

Apply vacuum

DIAGNOSTIC

Sensing system

Filter restriction sensor T esting

PRIMAR Y HYDRAULIC POWER SYSTEM Special tools

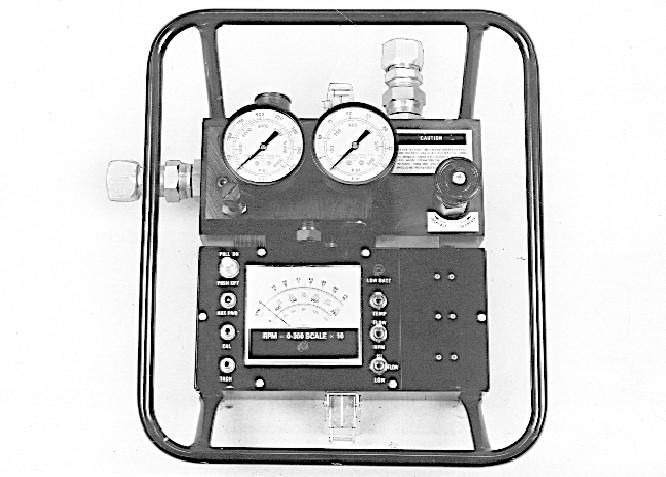

1 CAS1804 PRESSURE TEST KIT

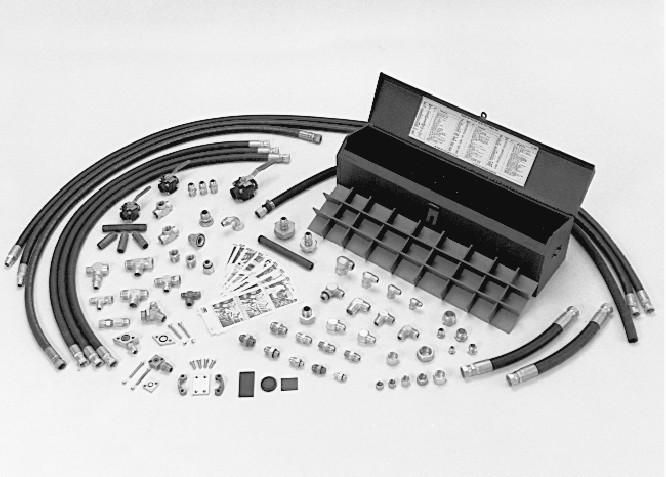

CAS1808 2 CAS1808 FLOWMETER FITTING KIT

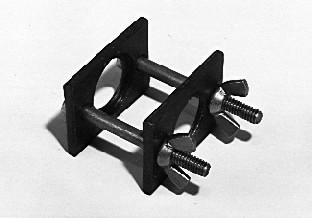

CAS10090 3 CAS10090 HAND PUMP

SYSTEM

Stack valve T orque

Stack valve Special tools

Stack valve Calibration

Stack valve General specification