Withcorrectmaintenanceandproperuse,Gehlskid-steerloaderswillgiveyearsof dependableservice.Thisservicemanualisintendedtobeaguideintheassemblyand disassembly,installationandremoval,adjustmentandtesting,troubleshootingand replacementofcomponentsthattogethermakeuptheGehlSL7610andSL7810skid-steer loaders.

ForSL7710(EU)serviceinformation,followproceduresforSL7610 skid-steerloaders,exceptwherenotedseparately.

Inmanyoftheproceduresfoundwithin,theinstallationstepsaretheexactoppositeofthe removalstepsandviceversa,andtherefore,theoppositeprocedureisnotwritten.Instead,a notetoreversetheprocedurewillbestated.Thisreducesredundancyandexcessivepagesin themanual.Incasesthough,wheretheassemblyanddisassemblyorremovaland installationproceduresdifferandadditionalstepsorsafetyconcernsareparamount,the entirereverseprocedurewillbewrittenouttoincludethenewinformation.

TheTableofContentsandIndexcanbeusedtomaketheprocedureyouneedtofindan easierprocess.Also,thereareblacktabsextendingoffthepageshighlightingthechapters forthosewhoprefertothumbthroughthemanual.Manyschematics,photographs,andline artdrawingsareusedtohelpperformthenecessaryrepairs,tests,oradjustmentsthatthe 7010Seriesskid-steerloaderneedstokeepitingoodrunningcondition.

Ifyouhaveanyadditionalquestions,pleasecontactyourauthorizedGehldealerorcallthe GehlServiceDepartmentforassistance. GehlisaregisteredtrademarkoftheGehlCompany.

7610/77107810

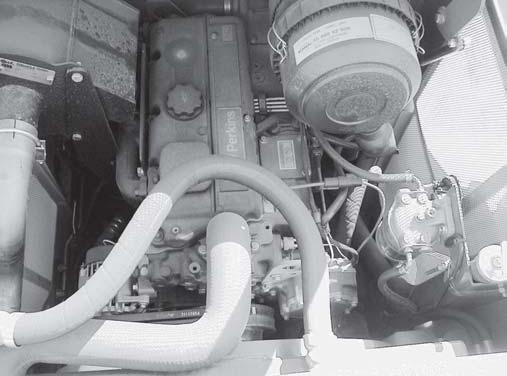

MakeofEnginePerkinsPerkins(Turbo)

Model1104C-441104C-E44T

FuelDieselDiesel

Displacement269CID(4,41L)269CID(4,41L)

Horsepower-Net86hp (64kW)@2400rpm

PeakTorque223lbf-ft (302N•m)@1400rpm

115hp (86kW)@2400rpm

291lbf-ft (394N•m)@1400rpm

*SAERatedOperatingLoad3400lbs(1542kg)3675lbs(1724kg)

OperatingWeight10180lbs(4618kg)10260lbs(4654kg)

ShippingWeight8980lbs(4073kg)9060lbs(4110kg)

Specificationsbelowapplytoall7610,7710and7810models

Capacities

HydraulicReservoir18.5USgal(70L) Chaincases(each)3USgal(11,4L)

EngineOil8.9USqts(8,4L)

FuelTank28.9USgal(109,4L)

Electrical

Battery12voltDCwith950CCA Starter12voltDC(3kW) Alternator85A

HydraulicSystem

HydraulicSystemPressure3300psi(228bar) StandardAuxiliaryFlowRate(Single)2-29gpm(8-110L/min) High-FlowAuxiliaryFlowRate(Dual)40gpm(151L/min)

TravelSpeed-SingleSpeed0to8.0mph(0to13km/h)

TravelSpeed-Two-Speed(optionalon7610/7710)0to14mph(0to22,5km/h)

TireOptions

14x17.5-14plyFoam-Filledtires 14x17.5-14plyHighClearanceFlotationtires 14x17.5-14plySevereDutytires 15x17.5-14plyFoam-Filledtires-SevereDuty 33x15.5x16.5-12plyExtraWideHeavyDutytires 12x35SolidRubbertires

BucketsandCapacities

Width-inches(millimeters)BucketDescriptionCapacity(Heaped) 84inches(2083mm)Dirt/Construction22.0cubicfeet0,62cubicmeters 84inches(2083mm)Dirt/Construction28.0cubicfeet0,79cubicmeters 90inches(2286mm)Dirt/Construction29.3cubicfeet0,83cubicmeters 48inches(1219mm)PalletForkN/AN/A

*Operatingloadratedwitha84inch(2134mm)dirt/constructionbucketinaccordancewithSAEJ818.

1.0cu.yd.bkt.w/14x17.5tires inchesmillimetersinchesmillimeters

A Overalloperationheight-fullyraised185.54719187.84770

B Heighttohingepin-fullyraised14236071423607

C Overallheight-topofROPS81205781.12060

D Overalllength-bucketdown15940391614089

E Dumpangle@fullheight38°38°

F Dumpheight109.527811072718

G Dumpreach-bucket(fullheight)36.893538.2970

J Rollbackatground28.5°28.5°

M Rollbackangleatfullheight85°85°

O Seat-to-groundheight411041411041

PWheelbase-nominal551397551397

Q Overallwidth-lessbucket812057812057

ROverallbucketwidth842134842134

S Groundclearancetochassis(betweenwheels)9.12319.1231

UMaximumbackgradingangle81.5°81.5°

VDepartureangle21°21°

WClearancecircle-front(withbucket)98.52502101.72583

XClearancecircle-front(lessbucket)60.6153960.61539

YOveralllength(lessbucket)30°30°

ZClearancecircle-rear80.5204580.52045

Theabovesafetyalertsymbolmeans:ATTENTION!

BECOMEALERT!YOURSAFETYISINVOLVED! Itstressesanattitudeof“HeadsUpforSafety”andcan befoundthroughoutthisservicemanualandonthe decalsonthemachine.

Beforeoperatingorworkingonthismachine,readand studythefollowingsafetyinformation.Inaddition,be surethateveryindividualwhooperatesorworkswith thisequipmentisfamiliarwiththesesafetyprecautions. Itisessentialtohavecompetentandcarefuloperators, whoarenotphysicallyormentallyimpaired,andwho arethoroughlytrainedinthesafeoperationofthe machineandthehandlingofloads.Itisrecommended thattheoperatorbecapableofobtainingavalidmotor vehicleoperator’slicense.

Theuseofskidsteerloadersissubjecttocertainhazards thatcannotbeeliminatedbymechanicalmeans,butonly byexercisingintelligence,careandcommonsense. Suchhazardsinclude,butarenotlimitedto,hillside operation,overloading,instabilityoftheload,poor maintenanceandusingtheequipmentforapurposefor whichitisnotintendedordesigned.

TheGehlCompanyALWAYSconsiderstheoperator’s safetywhendesigningitsmachineryandguards exposedmovingpartsfortheoperator’sprotection. However,someareascannotbeguardedorshieldedin ordertoassureproperoperation.Furthermore,the Operator’sManualandthedecalsonthemachinewarn ofadditionalhazardsandshouldbereadandobserved closely.

Thissectionofthemanualincludesprocedures,which whenfollowed,willallowsafeperformanceofservice procedures:MandatorySafetyShutdownProcedure, LiftCylinderLiftarmSupportDevice,RollOver ProtectiveStructure(ROPS)/FallingObjectProtective Structure(FOPS)LockMechanism,LoaderRaisingand LoweringProcedures,andRelievingHydraulic Pressure.

“DANGER”indicatesanimminently hazardoussituationwhich,ifnotavoided, willresultindeathorseriousinjury.

“WARNING”indicatesapotentially hazardoussituationwhich,ifnotavoided, couldresultindeathorseriousinjury.

“CAUTION”indicatesapotentially hazardoussituationwhich,ifnotavoided, mayresultinminorormoderateinjury.May alsoalertagainstunsafepractices.

ReadandunderstandtheServiceManual andalldecalsbeforemaintaining,adjusting orservicingthisequipment.

Doors,GuardsandShields -Somephotographsinthis manualmayshowdoors,guardsandshieldsopenor removedforillustrativepurposesonly.BESUREall doors,guardsandshieldsareintheirproperoperating positionsBEFOREstartingenginetooperateunit.

DamagedorWorn-outParts -Forsafeoperation, replacedamagedorworn-outpartswithgenuineGehl serviceparts,BEFOREoperatingthisequipment.

Attachments -Gehlloadersaredesignedandintended tobeusedonlywithGehlCompanyattachmentsor approvedreferralattachments.TheGehlCompany cannotberesponsibleforoperatorsafetyiftheloaderis usedwithanon-approvedattachment.

BatterySafety -Toavoidinjuryfromasparkorshort circuit,disconnectthenegativebattery cable(-)beforeservicinganypartofthe electricalsystem.Donottipthebattery morethan45ºtoavoidspilling electrolyte.

LoaderStability -Aloader’sstabilityisdeterminedby itswheelbase.Thefollowingelementscanaffect stability:terrain,enginespeed,loadbeingcarriedor dumped,andsuddencontrolmovements.

Therefore,ALWAYShavetheoperatorrestraintbar loweredandweartheseatbelt.Operatethecontrolsonly fromtheoperator’sseat.Operatethecontrolssmoothly andgraduallyatanappropriateenginespeedthat matchestheoperatingconditions.

DONOTexceedtheratedoperatingloadofthe machine.Foradditionalstabilitywhenoperatingon inclinesorramps,ALWAYStravelwiththeheavierend oftheloadertowardthetopoftheincline.

ALWAYSlooktotherearbeforebackingup.

Whenparkingmachine,beforeleavingseat,check restraintbarforproperoperation.Therestraintbar, whenraised,appliesparkingbrakeanddeactivates lift/tiltcontrolsandauxiliaryhydraulics.

Keyswitch -NEVERattempttobypassthekeyswitchto starttheengine.Usethejump-startingprocedure detailedinthe Service chapterofyourOperator’s Manual.

HydraulicFluidLeaks -NEVERusehandstosearch forhydraulicfluidleaks.Instead,usepaper orcardboard.Fluidunderpressurecanbe invisible,penetratetheskinandcausea seriousinjury.Ifanyfluidisinjectedinto skin,seeadoctoratonce.InjectedfluidMUSTbe surgicallyremovedbyadoctororgangrenemayresult.

WearSafetyGlasses -ALWAYSwearsafetyglasses withsideshieldswhenoperatingthe machineorstrikingmetalagainstmetal.In addition,itisrecommendedthatasofter (chip-resistant)materialbeusedtocushion theblow.Failuretoheedcouldleadtoseriousinjuryto eye(s)orotherpartsofthebody.

ALWAYSwearsafetyglasseswhensearchingfor hydraulicleaksorwhenworkingnearbatteries.

LoadedBucket/Fork -DONOTraiseordropaloaded bucketorforksuddenly.Abruptmovementsunderload cancauseseriousloaderinstability.

NEVERpushtheliftcontrolintothe“float”position withthebucketorattachmentloadedorraised,because thiswillcausetheliftarmtolowerrapidly.

DONOTdrivetooclosetoanexcavationorditch.BE SUREthatthesurroundinggroundhasadequate strengthtosupporttheweightoftheloaderandtheload.

DONOTsmokeorhaveanyspark producingequipmentintheareawhile fillingthefueltankorwhileworkingonthe fuelorhydraulicsystems.

ExhaustGases -Exhaustfumescankill.DONOT operatethismachineinanenclosedareaunlessthereis adequateventilation.

Engine -NEVERuseetherorstartingfluid.

People -NEVERcarryriders.DONOTallowothersto rideonthemachineorattachment,becausetheycould fallorcauseanaccident.

BESUREallpersonsareawayfromthemachineand giveawarningbeforestartingtheengine.

ALWAYSfacemachineandusehandholdsandsteps whengettingonoroff.DONOTjumpoffmachine.

Wearappropriateearprotectionfor prolongedexposuretoexcessivenoise.

ALWAYSperformadailyinspectionofthe machineBEFOREusingit.Lookfor damage,looseormissingparts,leaks,etc.

Removetrashanddebrisfromthemachineandengine compartmenteachdaytominimizeriskoffire.

NewoperatorsMUSToperateloaderinanopenarea awayfrombystanders.Practicewithcontrolsuntil loadercanbeoperatedsafelyandefficiently.

BEFOREcleaning,adjusting,lubricating,servicing theunitorleavingitunattended:

1.Movethedrivecontrolhandle(s)tothe NEUTRALposition.

2.Lowertheliftarmandattachmentcompletely. Also,seeStep4below.

3.Movethethrottletothelowidleposition,shutoff theengineandremovethekey.

4.IftheliftarmMUSTbeleftinthe“raised” position,BESUREtoproperlyengagetheliftarm supportdeviceinsteadofperformingStep2.

Onlyaftertheseprecautionscanyoubesureitis safetoproceed.Failuretofollowtheabove procedurecouldleadtodeathorseriousinjury.

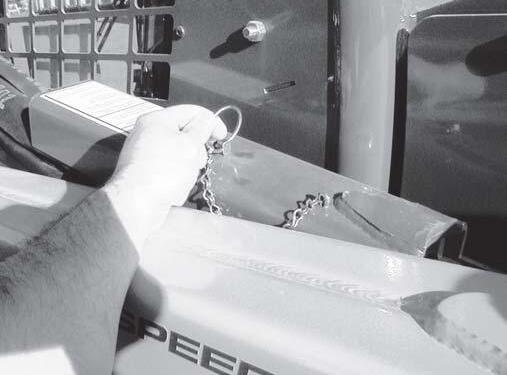

Fig.2-1 Thelockpinsecurestheliftarmsupportdevice ontherearlinkoftheliftarm.

Fig.2-2 Pressinandholdthelockpinbuttonandpullit outoftherearlink.

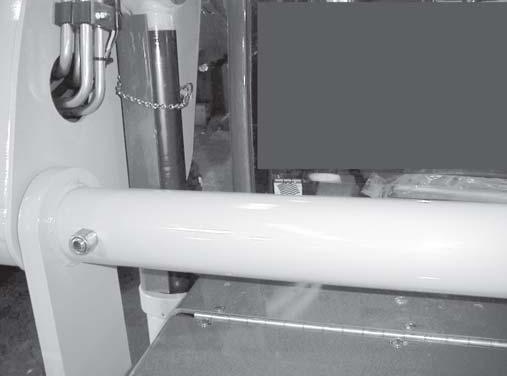

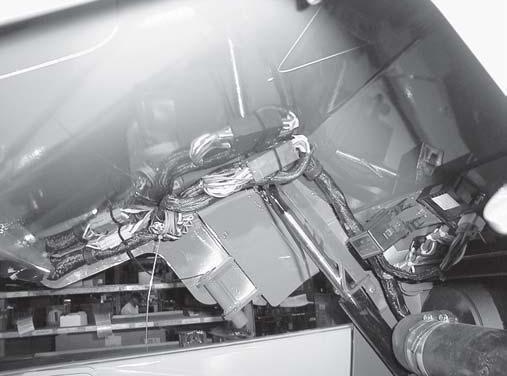

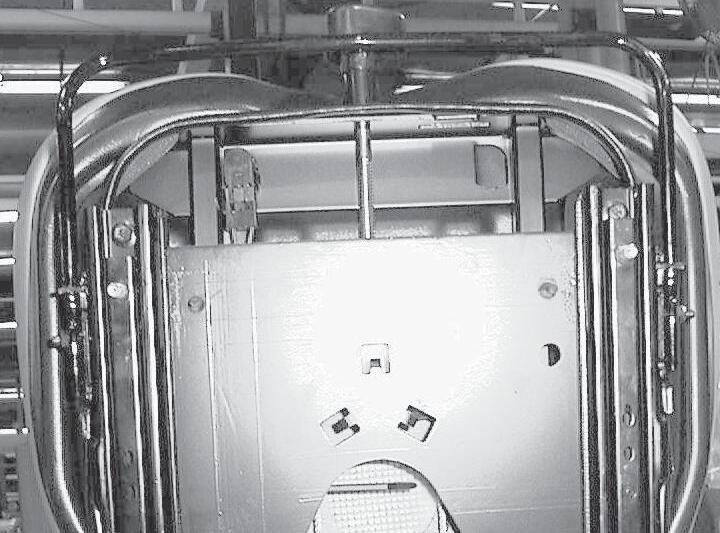

Fig.2-3 Theliftarmsupportdevicerestsontopofthelift cylinderbaseononeend.Notethesecuringlatch wrapsaroundliftcylinderrodandsecuresto supportdevicetab.

BEFOREleavingtheoperator’scompartment toworkontheloaderwiththeliftarmraised, ALWAYSengagetheliftarmsupportdevice. TurnthekeyswitchtoOFF,removethekey andtakeitwithyou.

Manyserviceproceduresrequirearaisedliftarmto alloweasieraccesstoloadercomponents.Foroperator andservicepersonnelsafety,aliftarmsupportdeviceis standardonGehlskid-steerloaders.Usedasacylinder block,ithelpspreventaraisedliftarmfrom unexpectedlylowering.

BESUREtoengageliftarmsupportdevicewhenever theliftarmisraised.Whenthedeviceisnotbeingused, secureittoleftsideofthetiminglinkusingthelockpin andcradleprovided.

Theliftarmsupportdeviceisasafetydevicewhichmust bekeptinproperoperatingconditionatALLtimes.

Thefollowingproceduresoutlinethecorrectwayto engageanddisengagetheliftarmsupportdevice.

1. Lowerliftarmuntilcontactwithloaderframe.

2. TurnthekeyswitchtotheOFFpositiontostopthe engine.

3. Leaveoperator’scompartment.Pressinandhold lockpinbuttontoreleaseitslockingmechanism. Removelockpinholdingsupportdeviceagainst liftarmhoses.Removesupportdevice. Figs.2-1, 2-2

4. Returntooperator’scompartmentandrestart engine.Useliftcontroltocompletelyraiseliftarm. TurnkeyswitchtotheOFFpositiontostopengine.

5. Leaveoperator’scompartment.Verticallyinstall supportdevicearoundliftcylinderrodwith u-shapedendupandout.Securesupportdeviceto liftcylinderrodwithattachedlockpin. Fig.2-3

6. Returntooperator’scompartmentandrestart engine.Lowerliftarmagainstsupportdevice.Then, stoptheloaderengine,removethekeyandleavethe operator’scompartment.

NEVERleaveoperator’scompartmentto disengageliftarmsupportdevicewithengine running.

Toreturntheliftarmsupportdevicetoitsstorage position,proceedasfollows:

1. Raisetheliftarmcompletely.

2. TurnthekeyswitchtotheOFFpositiontostopthe engine,removethekeyandtakeitwithyou.

BEFOREtestingthemachine,ALWAYSclear peoplefromthearea.

3. Beforeleavingtheoperator’scompartment,check tobesuretheliftarmisbeingheldintheraised positionbythesolenoidvalve(SeeNOTE).

NOTE: WithkeyswitchOFF,andsolenoidvalve functioningproperly,liftarmwillnotmovewhenlift controlismovedforward.IfvalvedoesNOThold liftarm,doNOTleaveoperator’scompartment.Instead, havesomeonestoresupportdeviceforyou.Then, contactyourGehldealertodeterminereasonwhy liftarmlowerswhilekeyswitchisinOFFposition.

4. Tostoreliftarmsupportdevice,removesupport devicefromliftcylinderrodandplaceinstorage cradleonliftarmhoses.Insertlockpinthroughpost goingthroughsupportdeviceandpressringflat.

Fig.2-1

Forservice,theROPScanbeunboltedandtiltedback.A ROPSliftassistpumphelpstotilttheROPSback.A self-actuatinglockmechanismengagestolockthe ROPSinarolled-backposition.

1. Theliftarmshouldbeloweredorlockedintheraised positionperthe“LiftarmSupportDevice Engagement”procedureinthischapter.

2. TurnkeyswitchtoOFFpositiontostopengine. Removekeyandtakeitwithyou.

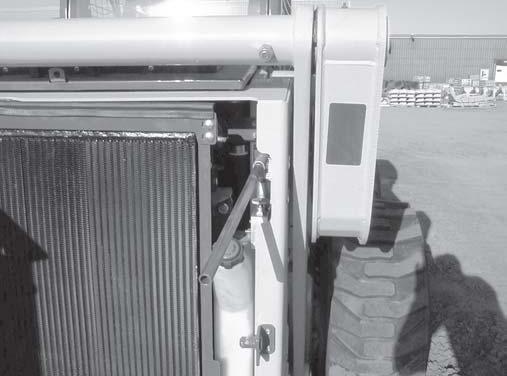

Fig.2-7 Tightenthepumpneedlevalvebeforeraisingthe ROPSandslowlyloosenthepumpneedlevalve tolowertheROPS.

Fig.2-8 Strokingthepumphandleupanddown,raisethe ROPSuntiltheROPSlockautomatically engages.

Fig.2-9 ROPSlockmechanismengaged.

3. Leavetheoperator’scompartment.

DONOTleaveoperator’scompartmentwith enginerunning.Beforeleaving,shutoff engineaccordingto“MandatorySafety ShutdownProcedure”describedinthis chapter.

4. Removeonecapscrew,threeflatwashers,andone locknutoneachsideoftheROPS. Figs.2-4,2-5

5. OpenreargrilletoexposeROPSliftassistpumpand itshandle.Inserthandleintopump. Fig.2-6

6. Besureneedlevalveonpumpistightened (clockwise).Raiseandlowerpumphandletobuild pressureandbeginraisingROPS. Figs.2-7,2-8

7. Pumphandleupanddownuntilself-actuatinglock mechanismunderROPSengages.Thelock mechanismlocksROPSinarolled-backposition whenitfallsinfrontofcylinder. Fig.2-9

1. OpenreargrilleandputROPSliftassistpump handleintopump.Besureneedlevalveisstill tightened.PumphandleuntiltensiononROPSlock mechanismreleases. Fig.2-9

2. EngageROPSliftlockbaronself-actuatinglockso thatlockispositionedtoslideabovecylinder. Fig. 2-10

Fig.2-10 ROPSliftlockbarpositionsthelocktoslide abovethecylinderallowingtheloweringofthe ROPS.

3. ReleasepressureinROPSliftassistpumpby turningneedlevalvecounterclockwise.Slowly lowerROPSuntilitcomesincontactwiththe chassis. Fig.2-7

BESUREthecontrolhandlesandhand throttlecleartheROPS.

4. Reinstallthetwocapscrews,sixflatwashersand twolocknutsthatattachtheROPSfrontuprightsto thechassis. Figs.2-4,2-5

Thefollowingprocedureshouldbeusedtorelieve pressureinthehydraulicsystempriortoperforming serviceproceduresonhydraulicsystemcomponents.

1. Completelylowerthebucketorattachment.

2. TurnkeyswitchtoOFFpositiontoshutdown engine.

3. Withtheoperatorintheseatandtherestraintbar lowered,turnthekeyswitchtotheONpositionbut DONOTstarttheengine.

4. Movethelift,tiltandauxiliaryhydraulicscontrols throughseveralcycles. Figs.2-11,2-12,2-13

5. TurnthekeyswitchtotheOFFposition.

OnHand/Footmodels,theliftandtiltfunctions arecontrolledwiththefootpedalsonthefloorof theROPS.Theauxiliaryhydraulicsare controlledintherightcontrolhandle.

OnDualHandmodels,liftandtiltfunctionsare controlledbytheleftandrightcontrolhandles. Theauxiliaryhydraulicsarecontrolledwiththe leftfootontheauxiliarypedalassembly.

Fig.2-13

OnT-Barmodels,liftandtiltfunctionsare controlledwiththerightcontrolhandle.The auxiliaryhydraulicsarecontrolledwiththeleft footontheauxiliarypedalassembly. AuxiliaryHydraulics LiftandTilt

Thefollowingprocedureisusedtoraisetheskid-steer loadersothatallfourtiresARENOTcontactingthe ground.

BEFOREservicingthemachine,exercisethe “MandatorySafetyShutdownProcedure” describedinthischapter.

DONOTrelyonajackorhoisttomaintainthe “raised”positionwithoutadditionalblocking andsupports.Seriouspersonalinjurycould resultfromimproperlyraisingorblockingthe skid-steerloader.

1. Toraiseandblocktheloader,obtainfourjackstands orwoodenblocksofsufficientstrengthtosupport theloader.

2. Usingajackorhoistcapableofraisingthe fully-equippedloader,liftrearofloaderuntiltires areoffground. Fig.2-14

3. Placetwojackstandsunderflatpartofloader chassis.Placethemparallelwith,butnottouching, thereartires. Fig.2-15

4. Slowlylowerloadersoitsweightrestsonjack standsorthewoodenblocks.

5. Repeatsteps2-4forthefrontend.Whenthe procedureisfinished,allfourtiresareoffthe ground,andtheycanberemovedasnecessary.

Whenserviceproceduresarecomplete,theskid-steer loadercanbetakendownfromthe“raised”position.To lowertheloaderontoitstires:

1. Usingajackorhoist,raisefrontofloaderuntilits weightnolongerrestsonthejackstands.

2. Carefullyremovejackstandsorwoodenblocks underfrontofloader.

3. Slowlylowerloaderuntilfronttiresareonground.

4. Repeatsteps1-3forrearofloader.

Hydraulicoillevelindicatorlocatedinfrontof reargrille.

Fig.3-2 Hydraulicoildrainplugaccessedfrom underneathloaderthroughsmallaccesspanel.

HydraulicSystem Reservoir

UseaMobilDTE15M,or Petro-CanadaPremium HVI60,orequivalent whichcontainsanti-rust, anti-foam,and anti-oxidationadditives &conformstoISOVG46.

Capacity: 18.5Gallons(70L)

Chaincases

Usehydraulicsystemoil orSAEgrade15W-40 motoroil.

Capacity(eachside): 3Gallons(11,4L)

GeneralInformation

NEVERservicethisunitwhenanypartofthe machineisinmotion.ALWAYSBESUREto exercisethe“MandatorySafetyShutdown Procedure”(see Safety chapter)BEFORE servicingthisequipment.

Routinelubricationisanimportantfactorinpreventing excessivepartwearandearlyfailure.Loaderandengine operationdependsonusingcorrectgrade,high-quality lubricatingoilsandanti-freezecoolant.Thischapterand thechartbelowlistlocations,temperaturerangesand typesofrecommendedlubricantstobeusedwhen servicingthismachine.Inaddition,refertotheengine

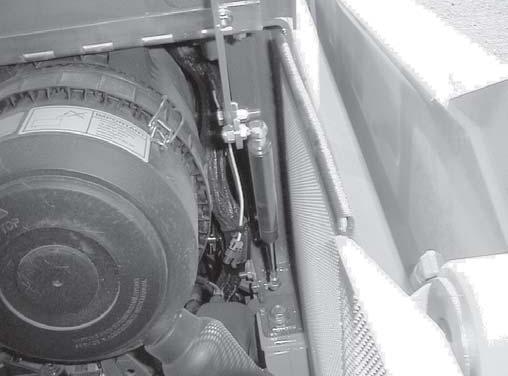

Fig.3-3 Remoteengineoildrainlocatedbehindtheleft reartire,underneaththeloader.

Grease Fittings

Uselithium-based grease

CrankcaseOil (DieselEngine)

Below32°F(0°C)use SAEGrade*10or 10W-30

Above32°F(0°C)use SAEGrade*15W-40

*ServiceClassification: API-CF-4/CG-4

Capacity: 8.9Quarts(8,4L)

Anti-freeze CoolantSystem

Addamixtureof50% water,50%ethylene glycoltotherecovery tankifcoolantlevelin recoverytankislow.

manualforspecificgradesandratingsasspecifiedby theenginemanufacturer.

NOTE: Wheneverserviceisperformedonhydraulic components(valves,cylinders,hoses,etc.),fueltanks andlines,caremustbetakentopreventdischarging fluidontotheground.Catchanddisposeoffluidper localwastedisposalregulations.

Theoilreservoirforhydraulicandhydrostaticsystems hasacapacityof18.5U.S.gallons(70liters).Avisual oillevelindicator(Fig.3-1)islocatedinfrontandabove theleftreartireforconvenientmaintenanceofthe hydraulicoillevel.

Thehydraulicoilreservoirshouldbedrained(Fig.3-2) andfilledafterevery1000hoursofoperationor annually(whicheveroccursfirst).UseMobilDTE15M orPetro-CanadaPremiumHVI60hydraulicoil(orISO VG46equivalent)whichcontainsanti-rust,anti-foam andanti-oxidationadditives.Hydraulicoilfilter elementshouldbereplacedwhenindicatoronright instrumentpanelshowsred.Fordetails,referto “HydraulicOilFilterElementReplacement”procedure inthe Hydraulic chapter.

ThePerkinsdieselenginecrankcasehasacapacityof 8.9quarts(8,4liters).Thechartbelowlists recommendedoilviscosityfortheengine.

Engineoilshouldbechangedandthefilterelement replacedevery500hoursofservice.Aremoteengineoil draincanbefoundbehindtheleftreartire.Refertothe engineoperator’smanual(seeNOTE, Fig.3-4)for detailsonchangingoilrefertothe“OilFilterRemoval” and“OilFilterInstallation”procedures.

NOTE: Refertoengineoperator’smanualfor additionalinformationonoilchangeintervals, includingthe50-hourinitialoilchangeinterval.

Below32°F(0°C)SAE10or10W-30

Above32°F(0°C)SAE15W-40

Serviceclassification:API-CF-4/CG-4

(2)onleftsideofengine.

Locationofengineoilfill(1),engineoildipstick (2)andhydraulicoilfilltube(3).

Fig.3-7 Locationofchaincasecheckplug(1)anddrain plug(2)atlowerrightfrontofchaincase.Left sidesame.

Fig.3-8 Locationoftheleftchaincaseoilfillplug.This filllocationalsoservesasabreathervent.Fender coverhasbeenremoved.Rightsidesame.

Eachchaincaserequires3gallons(11,4L)ofmotoroil. Thisquantityofoilshouldbemaintainedatalltimes. Theoilinbothchaincasesshouldbedrainedandrefilled every500hoursofoperationorannually,whichever occursfirst.

1. Removedrainplugonchaincaseanddraintheoil. Fig.3-7

2. Reinstallthedrainplug.

3. Removebothoilfillandoillevelcheckplugs. Figs. 3-7,3-8

4. Addoilthroughthefillpluguntiltheoilstartsto flowoutofthecheckplug. Figs.3-7,3-8

5. Reinstallthecheckplug,thenthefillplug.

Uselithium-basedgreaseonallgreasefittings. Figs. 3-9,3-10

GreaseEvery10hoursofoperation(ordaily)

1. Greaseliftarmpivots

2. Greasetiltcylinderpivots

3. GreaseAll-Tach™attachmentpivots

Gehl7010Seriesskid-steerloadersuseasplitradiator designtohelpkeeptheengine(withanti-freezecoolant) andhydraulicoilfromoverheating.Manyproceduresin thisServiceManualrequireyoutopartiallyorfully drainoneorbothtoperformthoseprocedures.

BEFOREbeginningthisserviceprocedure, performthefollowingSAFETYprocedure:

Shutofftheengineandallowtocool. (Fordetailedinstructions,refertothe Safety chapterofthismanual).

Anti-freezeCoolantDrainProcedure(Fig.3-12)

1. Openreargrilleandlockopen.

2. Removetheradiatorcap.

3. Adraincockislocatedatbottomcenterofradiator. Opendraincockanddraincoolantintoasuitable container.

4. Closedraincock.

1. Removesmallrearaccesspanelunderneathloader neartheleftreartire.

2. Placea15gallon(56,8L)catchpanunderthe hydraulicoildrainplug.

3. Removethedrainpluganddrainoil.

4. Replacethedrainplug.

Gehl7010Seriesskid-steerloadershaveaweldedsteel chassis.Maintenance,serviceandrepairmaybe performedthroughstandardaccesspanels.

Twosidecasesprovidemountingforthedrivemotors andforthefrontandrearaxles.Thesidecasesalsoserve assealedhousingsforthedrivechainsandsprockets. Oilisusedinsidethesecasestoensurethechainsalways receiveproperlubrication.

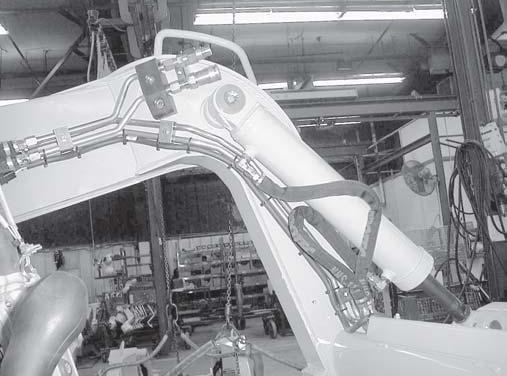

Theliftarmandtheliftandtiltcylindersaremounted withpivotpins.Capscrewsareusedtosecurethepivot pins.ARolloverProtectiveStructure/FallingObject ProtectiveStructure(ROPS/FOPS)isstandardfor operatorsafety,andboththeseatandrestraintbar includeinterlockswitches.

Installation

BEFOREbeginningthisserviceprocedure, performthefollowingSAFETYprocedure:

Shutofftheengine.

(Fordetailedinstructions,refertothe Safety chapterofthismanual).

RemovalProcedure

1. Opentheengineaccesscoveruntilthegasspringis completelyextended.

2. Removetheenginesidecoversbylooseningone locknutsecuringsidecoverstoframe.Liftuponthe sidecoverstoremovethem. Fig.4-1

3. Disconnectthegasspringfromtheengineaccess coverbyremovingthegasspringclipattheaccess coverendofthegasspring,thenpullthegasspring offtheballstudontheaccesscover. Fig.4-2

4. Removefourcarriageboltsandlocknutsonthe pianohingesecuringtheaccesscovertothehinge andremovethecover. Fig.4-3

InstallationProcedure-FollowallWARNINGS first,thenreversetheremovalsteps

cover,pullretainingclipoutandusingasmall flat-headscrewdriver,popgasspringofftheball stud.

Rollover&FallingObject-ProtectiveStructure(ROPS/FOPS)Components

1FITTING/STR 2FITTING/STR 3WASHER/FLAT 4NUT/HEX

5NUT/LOCK 6NUT/LOCK

7NUT/LOCK 8NUT/LOCK 9WASHER

10MOUNT 11PIVOT/ROPS

12TUBE/HANDLE 13HOSE

14BAR/LOCKLIFT

15PIN/CLEVIS 16CYLINDER

17ASSEMBLY/LOCK 18ROPS 19PUMP 20HOSE

21SCREW/CAP

22SCREW/CAP

23SCREW/CAP

24SCREW/CAP

25SCREW/CAP

26PIN/COTTER

Fig.4-4 AssemblyviewofROPS/FOPScomponents.

Rollover&FallingObject-ProtectiveStructureInteriorComponents

Fig.4-5 AssemblyviewofROPS/FOPSinteriorcomponents.

1NUT/SPEED 2GROMMET 3NUT/LOCK 4PAD/SEAL 5PAD/SEAL 6PAD/SEAL 7WINDOW 8CLAMP 9WINDOW 10CLAMP 11WINDOW 12HEADLINER 13CONSOLE 14CONSOLE

15DECAL 16CONSOLE 17WINDOW 18WASHER 19COVER/BOX 20LOUVRE 21LOUVRE 22SUPPORT 23HINGE/PIANO 24SCREW/MACH 25SCREW/MACH 26COVER/DECK 27SCREW/PHIL

1NUT/HEX

2SCREW/CAP

3NUT/HEX

4NUT/LOCK

5NUT/HEX

6NUT/HEX

7SCREW/CAP

8PIN/LOCK

9SCREW/CAP

10SPRING

11STUD/BALL

12SLEEVE/CRIMP

13WIRE

14WASHER

15WASHER/SHIM

16PLUG

17MOUNT/LATCH

18ROD/LATCH

19NUT/LOCK

20BUMPER

21BUSHING

22SPRING/GAS

23BRACKET

24CLIP/GASSPRING

25COVER/TOEPLATE

26NUT/LOCK

27NUT/LOCK

28SPACER

29COVER/CHAINCASE

30PLATE/FLOOR

31STOP/SPROCKET

32SUPPORT/BAR

33SUPPORT/BAR

34CROSSMEMBER

35HINGE/PIANO

36BREATHER

37COVER/FRONT

38COVER/FRONT

39PLATE/COVER

40PLUG

41LINK/PIVOT

42CAP/FUEL

43CHASSIS

44MOUNT/FRONT

45COVER/ENGINE

46COVER/ENGINE

47BACKEND

48TANK/FUEL

Fig.4-6 Assemblyviewofthechassiscomponents.

49COVER/FRONT

50COVER/FRONT

51STRIKER

52STEP

53BUMPER

54GRILLE/REAR

55LATCH

56SEAL/SHROUD

57SEAL/SHROUD

58GRILLE

59HANDLE/GRAB

60SCREEN

61COVER/BUMPER

62COVER/BUMPER

63BRACKET/PUMP

64STRIP/TRIM

65MOUNTING/FILTER

66SEAL/SHROUD

67BRACKET

68COVER/SIDE

69COVER/SIDE

70NUT/HEX

71SCREW/THDCUT

72SCREW/CAP

73SCREW/CAP

74SCREW/CAP

75SCREW/CAP

76BOLT/CARRIAGE

77BOLT/CARRIAGE

78BOLT/CARRIAGE

79BOLT/CARRIAGE

80BOLT/CARRIAGE

81BOLT/CARRIAGE

82SCREW/MACHINE

83SCREW/MACHINE

84SCREW/PHILLIPS

85SCREW/CAP

86SCREW/MACHINE

87WASHER/FLAT

88SCREW/CAP

89NUT/HEX

90NUT/JAM

91WASHER/FLAT

92WASHER/FLAT

93WASHER/FLAT

94NUT/HEX

95SCREW/CAP

Fig.4-7 AssemblyviewoftheT-BarandDualHandcontrolcover.

AssemblyviewoftheHandandFootcontrolcover.

1SCREW/CAP

2MAT/FLOOR

3RETAINER/PANEL

4PLATE/COVER

5ASSEMBLY/FLOORPLATE

6COVER/BATTERY

7RECEPTACLE/CLIP-ON

8STUD/BAIL-STYLE

9SCREW/MACHINE

10NUT/HEX

11SCREW/CAP

12SCREW/CAP

1SCREW/CAP

2RETAINER/PANEL

3COVER/BATTERY

4ASSEMBLY/FLOORPLATE

5MAT/FLOOR

6PLATE/COVER

7RECEPTACLE/CLIP-ON

8STUD/BAIL-STYLE

9SCREW/MACHINE

10NUT/HEX

11SCREW/CAP

12SCREW/CAP

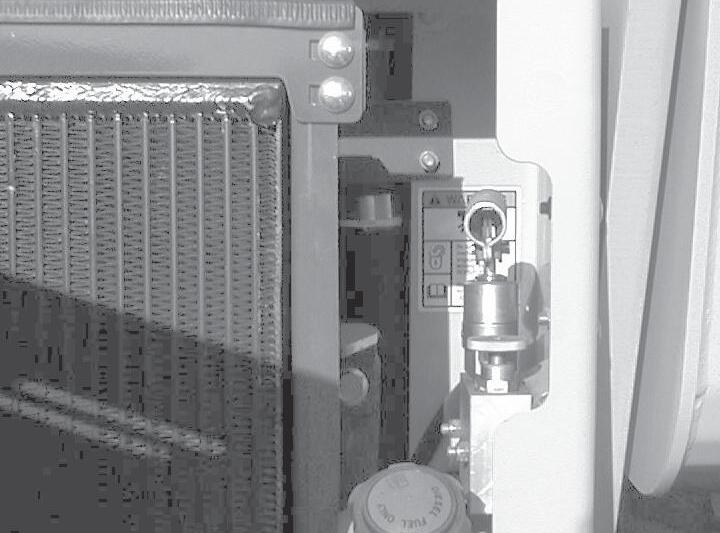

Fig.4-9 Locationofenginedisconnectswitchonleftside ofradiator.

Fig.4-10 Oneoftwo(1of2)nutssecuringthefusepanelis foundinsidetheROPS.Itcanbeaccessedby pullingbacksomeoftheinteriorpaneling.

Fig.4-11 Locationofoneoftwo(1of2)capscrews securingtheROPSelectricalpanelunderneath theROPS.Bothcapscrewsalsosecurerear portionoftherestraintbarpivotbracket.

ROPS/FOPSRemovalandInstallation

WARNING BEFOREbeginningthisserviceprocedure, performthefollowingSAFETYprocedure: Shutofftheengine.

(Fordetailedinstructions,refertothe Safety chapterofthismanual).

1. Openthereargrille.Switchtheauto-engine disconnectswitchtotheOFFposition. Fig.4-9

2. Removetheengineaccesscoverspertheprocedure inthischapter.

3. InsidetheROPS,pullsomeinteriorpanelingupand removenutsecuringfusepaneltoROPS. Fig.4-10

NOTE: Removingthesidesupporttubeaidsinthe removalofthefusepanel. Fig.4-10

4. RaisetheROPSpertheprocedureinthe Safety chapter.

5. WiththeROPSrolledandlockedback,attacha hoistsothatitissupportingtheweightoftheROPS.

HoistMUSTBEsituatedpreciselyabove ROPSorelseperformingfollowingstepsmay causeROPStoswingasboltsareremoved. Thiscouldcauseseriousbodilyinjuryand/or damagetheloader.

6. Disconnectfourelectricalconnectionsbundledto the"back"oftheROPS:a24-pin(useAllen wrench),a12-pin,a5-pinanda2-pinconnector. Fig.4-13

7. Removetwocapscrewsandwashers(alsousedfor therestraintbar)securingelectricalpanel underneathROPS. Fig.4-11

8. UnderneaththeROPS,removethesecondlocknut securingthefusepanel(step3)andremovefuse panel. Fig.4-14

9. RemoveROPSlockmechanismcylinderfrom ROPSbyremovingacotterandclevispin. Fig.4-12

LocationofclevispinsecuringtheROPSlock mechanismtotheROPS.

Fig.4-13 Locationofelectricalconnectionsbundledat rearoftheROPS.

Fig.4-14 Locationofsecondlocknutsecuringthefuse panelfromunderneaththeROPS.

10. Removetwolocknutsandcapscrewswhichattach therearoftheROPStothechassis. Fig.4-15

11. LifttheROPSofftheloader.

InstallationProcedure-FollowallWARNINGS first,thenreversetheremovalsteps

Fig.4-15 Locationofcapscrewandlocknutsecuringone sideoftheROPStothechassis.Othersideisthe same.

Locationoffourhexnutssecuringtheseattothe seatpan.

Fig.4-17 Thiswiringharnessmustbedisconnectedfrom theseatswitchtoremovetheseatfromthe ROPS.

Fig.4-18 Frontslidescrewsshown.Rearslidescrews becomevisibleaftermovingtheseatslide forward.

SeatRemovalandInstallation WARNING

BEFOREbeginningthisserviceprocedure, performthefollowingSAFETYprocedures: Shutofftheengine.

RollROPSbackuntillockengages. (Fordetailedinstructions,refertothe Safety chapterinthismanual).

RemovalProcedure

1. Removefournutsfromextendingstudsattaching seattoseatpanunderneathROPS. Fig.4-16

2. ReleaselockmechanismandlowerROPS. Disconnectseatswitchfromwiringharness. Fig. 4-17

3. Lifttheseatfromtheseatpan.

InstallationProcedure-FollowallWARNINGS first,thenreversetheremovalsteps

SeatSlideReplacement(Fig.4-18)

ReplacementProcedure

1. Removetheseatpertheprocedureinthischapter.

2. Removefourscrewsattachingseatslidestoseat.

3. Replacewithnewslidesusingexistingscrews.

AirDuctRemovalandInstallation

AirductsintheROPSarestandard,andutilizedwhen heaterorairconditioningoptionsareinstalled.

RemovalProcedure

1. OntheoutsideoftheROPSremovefourscrews securingtheairductstotheROPS. Fig.4-19

2. Slidethebackoftheairductoutfirst,thenslidethe frontout.RemoveairductfromROPS. Fig.4-20

InstallationProcedure-Reversetheremovalsteps

AirDuctLouverReplacement(Fig.4-21)

ReplacementProcedure

1. On3”roundlouvers,openlouvers,insertfingers andpopoutlouver.Onrectangularrollnozzle louvers,unscrewtwoscrewssecuringnozzlelouver toairduct.

2. On3”roundlouvers,popnewlouverintoexisting bezeluntilclicksoundtellsyouitisseated.Onroll nozzlelouver,dropitinrectangularspaceand securewithtwoscrews.

ROPSRearWindowRemovaland

Installation

BEFOREbeginningthisserviceprocedure, performthefollowingSAFETYprocedure:

Shutofftheengine.

(Fordetailedinstructions,refertothe Safety chapterofthismanual).

RemovalProcedure

1. Unlatchtwolatchesatbottomofwindowandpush windowoutapproximatelyhalfway. Fig.4-22

2. Grablatchlockwiththumbandindexfinger.Pullup onlatchlocktodisengagetwopins. Fig.4-22

3. Pressdownonlatchuntilitpopsoffbottomportion screwedintoROPS. Fig.4-23

4. Withanassistanttocatchwindow,pushwindowout to90°oruntilitdropsoutofchannel. Fig.4-24

Fig.4-22 Slidethisportionofrearwindowlatchupon bothlatches.

Fig.4-23 Pressdownandbackonlatchuntilitpopsoffthe steelaxle.

Fig.4-24 Assistantcatchestherearwindowafterbeing pushedoutwardapproximately90°fromthe ROPS.Slidewindow’shingeassemblyinto channeltoreinstalltheROPSrearwindow.

1. Fitwindow’shingeassemblywindowupandinto channelonoutsideofROPS.Windowshouldhang fromchannelifseatedproperly. Fig.4-24

2. FrominsideROPSreattachbothlatchestotheir respectivelatchbase.Pressupfromunderneath latchuntillatchseatsoverbar. Fig.4-23

3. Presslatchlocksdownuntilthepinsseatoverbar. Thewindowcannowbeclosed. Fig.4-22

4. Testwindowforsecurityandmatingofallseals.

1. Openreargrilleandraiseengineaccesscover.

2. Removetwocapscrewsandwashersunderneath reardeckofROPSsecuringtherearoftherestraint bar. Fig.4-25

NOTE: Bothofthesecapscrewsandwashers,instep2, alsosecuretheROPSelectricalpanelunderneaththe reardeckoftheROPS.

3. InROPS,removetwoPhillipsscrewssecuring restraintbarcoversoneachsideofdeck.

4. Disconnectrestraintbarswitchfromwireharness locatedaboverestraintbaronrightside. Fig.4-27

5. Removetwocapscrewsandwashersatfrontof restraintbarfromreardashandremoverestraintbar.

Fig.4-27

NOTE: Forrestraintbarswitchremoval,refertothe Electrical chapter.

InstallationProcedure-Reversetheremovalsteps

Fig.4-25 Locationofrearcapscrewandwashersecuring therearoftherestraintbarunderneaththedeck oftheROPS.Rightsidesame.

1RING/RETAINING 2NUT/LOCK

3SPRING

4ACTUATOR

5SWITCH

6BEARING/BRONZE

7BUMPER

8PIN/PIVOT

9PIN/PIVOT

10ROD/SPRING

11NUT/HEX

12CLIP/RETAINING

13BAR/RESTRAINT

14BRACKET/PIVOT

15BRACKET/PIVOT

16BRACLET/PIVOT

17BRACKET/PIVOT

Fig.4-26 Assemblyviewoftherestraintbar.

Locationofrestraintbarswitchwireconnected towireharness.

18COVER/RESTRAINT

19COVER/RESTRAINT

20SCREW/CAP

21BOLT/CARRIAGE

22SCREW/CAP

23SCREW/PHILLIPS

24WASHER/FLAT

25NUT/JAM

26WASHER/FLAT

27WASHER/FLAT

28WASHER/FLAT

Threepersidecapscrewssecuringthegreasecap totheliftarm.

Fig.4-30 Onepersidecapscrewandwashersecuring All-Tach™pivotpintoliftarm.

RemovalProcedure

1. Lowertheliftarmsandslightlyextendthetwotilt cylinders. Fig.4-28

2. Whilesupportingthetiltcylinder,removetwo capscrewsandlocknutssecuringthelowertilt cylinderpivotpins,anddrivethelowerpivotpins outoftheirmounts. Figs.4-25

3. Removesixcapscrewssecuringthegreasecapsto theliftarm.Removethegreasecaps. Fig.4-29

4. Removetwocapscrewsandwasherssecuringthe pivotpinstotheAll-Tachassembly. Fig.4-30

NOTE: SupporttheAll-Tachwithsuitablehoisting equipmentbeforeperformingthenextstep.

5. Power-A-TachHitchOnly: Unplugtheelectrical connectorattheleftkneejointoftheliftarm.Clip plastictiesonleftliftarmkneejointuntilpower harnessisfreeofliftarm. Fig.4-31

6. Inserta5/8”x6”capscrewintoeachpivotpinand forcethepinoutbyhammeringonthecapscrew.

InstallationProcedure-Reversetheremovalsteps

Fig.4-31 Locationofelectricalconnectoronleftliftarm kneejoint.Notetheseveralplastictiesthat securethepowerharnesstotheliftarm,too.

1SCREW/CAP

2NUT/HEX

3WASHER

4WASHER

5WASHER

6PIN

7PIN

8SHIM

9SHIM

10ALL-TACH™

11HANDLE

12LINK/STOP

13LINK/SLIDE

14LINK/END

15LINK/PIN

16LINK/LATCH

17PIN/LATCH

18CAP/GREASE

19PLATE/PIN

20PIN/SPRING

21PIN/SPRING

22PIN/SPRING

23FITTING

24SCREW/CAP

25SCREW/CAP

26SCREW/CAP

27SCREW/CAP

28SPRING

Fig.4-32 AssemblyviewofthemanualAll-Tach™hitch.

1WASHER/FLAT

2HANDLE

3LINK/SPRINGSTOP

4LINK/SPRINGSLIDE

5LINK/END

6PLATE/PIN

7PIN/SPRING

8PIVOT/HANDLE

9STOP/PIN

10SCREW/CAP

11SPRING

Fig.4-33 AssemblyviewofthemanualAll-Tach™actuatorgroup.

INSERT30AMPFUSE LOCATIONISSHOWNON DECALLOCATEDONTHE FUSECOVER

HARNESSROUTING:

138848:INSIDEFRAME-ALONGHYD.TUBESANDHOSES-ALONG TIMINGLINKANDTOWER(SEEDETAILA).

138849:INSIDELEFTBEAMOFLIFTARM-CONNECTIONSFRONTAND REARASSHOWN.NOTEACCESSHOLESINLIFTARM.

138850:ALONGHYD.TUBESDOWNLEFTLIFTARMBEAM(FRONT) -OVERTOANDTHRUCLAMPONCROSSTUBE-THRUALL-TACHPIVOT.

1TIE/WIRE 2NUT/HEX 3TIE/NYLON 4CLAMP/HOSE 5NUT/LOCK 6COVER/MULTI-TACH™ 7ACTUATOR 8ASSEMBLY/SWITCH 9HARNESS/POWER 10HARNESS/POWER 14LINK/EXTENSIONLEFT 15LINK/EXTENSIONRIGHT 16SCREW/SELF-TAPPING 17SCREW/CAP 18BOLT/CARRIAGE

Fig.4-34 AssemblyviewoftheelectricaPower-A-Tach™hitch.

NOTEA:LATCH(LOCK)-UNLATCH(UNLOCK)FUNCTIONSMUST BEVERIFIEDWHENINSTALLATIONISCOMPLETEAND PRIORTOLOADERBEINGPUTINTOSERVICE.

NOTEB:MINIMUMTIEPOINTSASSHOWN.ALLHARNESS ASSEMBLIESTOBEROUTED,TIEDANDCLAMPED TOAVOIDSHARPEDGES,WEARPOINTS,ANDPIVOT POINTS.TRIMEXCESS/ENDOFCABLETIES.

NOTEC:SWITCHTOBEINSTALLEDINLEFTCONSOLE BESIDEBRAKESWITCH.SWITCHASSEMBLY MOUNTED/INSTALLEDASSHOWNWITHSHROUD TYPECONNECTORUP.PLUGSWITCHINTO CONNECTORSBEHINDTHELEFTCONSOLEPANEL.

ControlsChapter

AuxiliaryHydraulicsCableAdjustment-Hand/Foot ................... 6-29

AuxiliaryHydraulicsCableAdjustment-T-BarandDualHand ............. 6-27

AuxiliaryHydraulicsCableRemovalandInstallatin-T-BarandDualHand 6-26

AuxiliaryHydraulicsCableRemovalandInstallation-Hand/Foot 6-28

ControlHandleRemovalandInstallation ..........................6-6

FootThrottleAdjustment-T-BarandDualHand ..................... 6-39

FootThrottleRemovalandInstallation-T-BarandDualHand 6-36

PivotTubeRemovalandInstallation-T-Bar,Hand/FootandDualHand

EngineComponents-SL7610/SL7710Models ...........................9-3

EngineComponents-SL7810Models ................................9-4

EngineDisconnectSwitch-RemoteBatteryTerminalRemovalandInstallation 10-24

ENGINEIDLE/HIGHIDLERPMCHART 6-40

EngineRemovalandInstallation................................... 9-21

ExhaustAssemblyRemovalandInstallation

FuelTankRemovalandInstallation 9-24

G

GreaseFittingLocations

HHandThrottleAdjustment-Hand/Foot

Hand/FootControlHandleAssembly 6-11

HydraglideAccumulatorRemovalandInstallation 8-46

HydraglideRideControlComponents-EarlierVersion ...................... 8-46

HydraglideRideControlComponents-NewerVersion 8-47

HydraulicOilFilterElementReplacement 8-19

HydraulicOilReservoir ........................................3-2

HydraulicSystem-HighFlowAuxiliaryComponents-Liftarm ..................8-9

HydraulicSystem-LiftarmComponents ...............................8-8

HydraulicSystem-StandardAuxiliary-MainControlValveComponents .............8-7

InterlockControlModuleTest

Lift/TiltControlAdjustment

Rollover&FallingObject-ProtectiveStructure(ROPS/FOPS)Components

Rollover&FallingObject-ProtectiveStructureInteriorComponents

ROPSRearWindowRemovalandInstallation