Document Title: Function Group: Information Type: Date:

Description 200 Service Information 2014/4/16

Profile: CEX, EC45 [GB]

Description

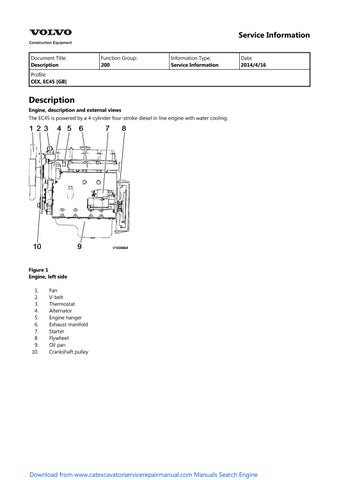

Engine, description and external views

The EC45 is powered by a 4-cylinder four-stroke diesel in line engine with water cooling.

Fan V-belt

Thermostat Alternator

Engine hanger

Exhaust manifold

Starter

Flywheel Oil pan

Crankshaft pulley

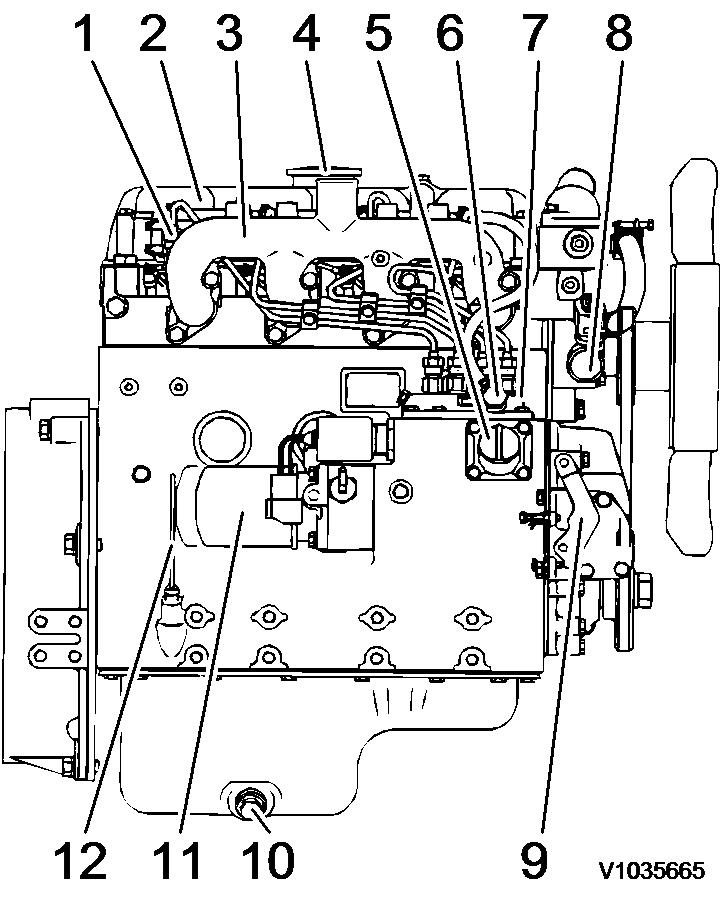

2 Engine, right side

Fuel injection nozzle

return

manifold

filler

filter Fuel inlet Injection pump Water pump Governor

drain plug Oil filter

Disptick

Document Title: Function Group: Information Type: Date: Precautions 200 Service Information 2014/4/16

Profile: CEX, EC45 [GB]

Precautions

Make preparation as follows before starting engine inspection and service.

Fix the engine on a horizontal base.

Remove the coolant hoses, fuel oil pipes, wire harness, control wires etc. connecting the driven machine and engine, and drain coolant, lubricating oil and fuel.

Remove soil, oil, dust, etc. from the engine by washing with solvent, air, steam, etc. Carefully operate so as not to let any foreign matter enter the engine.

Any part which is found defective as a result of inspection or any part whose measured value does not satisfy the standard or limit shall be replaced.

Any part predicted to dissatisfy the standard or limit before the next service as estimated from the state of use should be replaced even when the measured value then satisfies the standard or limit.

Service Information

Document Title: Function Group: Information Type: Date:

Troubleshooting chart 200

Profile:

CEX, EC45 [GB]

Troubleshooting chart

Service Information 2014/4/16

The following table summarizes the general trouble symptoms and their causes. If any trouble symptom occurs, take corrective action before it develops into a serious problem so as not to shorten the engine service life.

Engine troubleshooting chart

Trouble symptoms Causes

Engine does not start

Improper clearance of inlet/exhaust valve

Seizure of inlet/exhaust valve

Seized or broken piston ring

Worn piston ring, piston or cylinder

Seized crankpin metal or bearing

Foreign matter trapped in combustion chamber

Improper open/close timing of intake/exhaust valves

Improper properties of lubricating oil

Water entrance in fuel system

Clogged fuel filter

Air entrance in fuel system

Clogged or cracked fuel pipe

Insufficient fuel supply to fuel injection pump

Priming failure (foreign matter trapped in the valve inside the priming pump)

Starting motor defect

Alternator defect

Open circuit in wiring harness

Battery voltage drop

Engine starts, but stops soon.

Exhaust smoke none.

Engine starts, but stops soon.

Exhaust smoke excessive.

Improper clearance of inlet/exhaust valve

Seized crankpin metal or bearing

Improper arrangement of piston rings joint

Defective governor

Improper properties of lubricating oil

Insufficient lubricating oil level

Clogged fuel filter

Air entrance in fuel system

Clogged or cracked fuel pipe

Insufficient fuel supply to fuel injection pump

Seizure of inlet/exhaust valve

Seized or broken piston ring

Worn piston ring, piston or cylinder

Water entrance in fuel system

Corrective actions

Adjust the valve clearance

Correct or replace

Replace the piston ring

Perform honing and use oversize parts

Repair or replace

Disassemble and repair

Adjust the valve clearance

Use proper lubricating oil

Perform draining from the fuel filter

Clean or replace

Perform air bleeding

Clean or replace

Check the fuel tank cock, fuel tank, fuel pipe and fuel feed pump

Disassemble and clean

Repair or replace

Repair or replace

Repair

Inspect and charge the battery

Adjust the valve clearance

Repair or replace

Correct the ring joint positions

Make adjustment

Use proper lubricating oil

Add proper lubricating oil

Clean or replace

Perform air bleeding

Clean or replace

Check the fuel tank cock, fuel tank, fuel pipe and fuel feed pump

Correct or replace

Replace the piston ring

Perform honing and use oversize parts

Perform draining from the fuel filter

Insufficient engine output.

Exhaust color : ordinary

Insufficient engine output.

(Exhaust color : white)

Clogged air filter

Improper clearance of inlet/exhaust valve

Compression leakage from valve seat

Seizure of inlet/exhaust valve

Blowout from cylinder head gasket

Worn crankpin and journal bearing

Improper properties of lubricating oil

Improper properties of fuel oil

Clogged fuel filter

Air entrance in fuel system

Clogged or cracked fuel pipe

Insufficient fuel supply to fuel injection pump

Clogged strainer at fuel feed pump inlet

Seized or broken piston ring

Worn piston ring, piston or cylinder

Improper arrangement of piston rings joint

Reverse assembly of piston ring

Worn inlet/exhaust valve guide

Improper open/close timing of intake/exhaust valves

Timing of fuel injection pump too late

Improper properties of fuel oil

Water entrance in fuel system

Uneven injection volume of fuel injection pump

Poor spray pattern from fuel injection nozzle

Clean

Adjust the valve clearance

Lap the valve seat

Correct or replace

Replace the gasket

Measure and replace

Use proper lubricating oil

Use proper fuel oil

Clean or replace

Perform air bleeding

Clean or replace

Check the fuel tank cock, fuel tank, fuel pipe and fuel feed pump

Clean the strainer

Replace the piston ring

Perform honing and use oversize parts

Correct the ring joint positions

Reassemble correctly

Measure and replace

Adjust the valve clearance

Check and adjust

Use proper fuel oil

Perform draining from the fuel filter

Check and adjust

Check and adjust

Insufficient engine output.

(Exhaust color : black)

Poor exhaust color : white (During work)

Compression leakage from valve seat

Seizure of inlet/exhaust valve

Improper open/close timing of intake/exhaust valves

Insufficient cooling effect of radiator, Defective thermostat (kept opened) or slipping fan belt

Insufficient coolant level

Slackened fan belt

Defective thermostat

Timing of fuel injection pump too late

Improper properties of fuel oil

Uneven injection volume of fuel injection pump

Poor spray pattern from fuel injection nozzle

Clogged air filter

Engine used at high temperature or at high altitude

Clogged exhaust pipe

Seized or broken piston ring

Worn piston ring, piston or cylinder

Reverse assembly of piston ring

Improper open/close timing of intake/exhaust valves

Excessive cooling effect of radiator,

Lap the valve seat

Correct or replace

Adjust the valve clearance

Repair or replace thermostat and fan belt

Check leakage from cooling system

Adjust the belt tension

Check or replace

Check and adjust

Use proper fuel oil

Check and adjust

Check and adjust

Clean

Study output drop and load matching

Clean

Replace the piston ring

Perform honing and use oversize parts

Reassemble correctly

Adjust the valve clearance

Repair or replace

Poor exhaust color : black

(During work)

Defective thermostat (kept closed)

Defective thermostat

Timing of fuel injection pump too early

Timing of fuel injection pump too late

Improper properties of fuel oil

Water entrance in fuel system

Uneven injection volume of fuel injection pump

Poor spray pattern from fuel injection nozzle

Compression leakage from valve seat

Seizure of inlet/exhaust valve

Improper open/close timing of intake/exhaust valves

Timing of fuel injection pump too early

Timing of fuel injection pump too late

Improper properties of fuel oil

Uneven injection volume of fuel injection pump

Excessive fuel injection volume

Poor spray pattern from fuel injection nozzle

Clogged air filter

Engine used at high temperature or at high altitude

Clogged exhaust pipe

High knocking sound during compression

Abnormal engine sound

Uneven combustion sound

Timing of fuel injection pump too early

Improper clearance of inlet/exhaust valve

Compression leakage from valve seat

Seizure of inlet/exhaust valve

Seized or broken piston ring

Seized crankpin metal or bearing

Worn crankpin and journal bearing

Loosened connecting rod screw

Foreign matter trapped in combustion chamber

Excessive gear backlash

Improper open/close timing of intake/exhaust valves

Improper properties of fuel oil

Water entrance in fuel system

Uneven injection volume of fuel injection pump

Poor spray pattern from fuel injection nozzle

Clogged air filter

Clogged exhaust pipe

Hunting during idling

Seized or broken piston ring

Seized crankpin metal or bearing

Worn crankpin and journal bearing

Defective governor

Water entrance in fuel system

Uneven injection volume of fuel injection pump

Poor spray pattern from fuel injection nozzle

Check or replace

Check and adjust

Check and adjust

Use proper fuel oil

Perform draining from the fuel filter

Check and adjust

Check and adjust

Lap the valve seat

Correct or replace

Adjust the valve clearance

Check and adjust

Check and adjust

Use proper fuel oil

Check and adjust

Check and adjust

Check and adjust

Clean

Study output drop and load matching

Clean

Check and adjust

Adjust the valve clearance

Lap the valve seat

Correct or replace

Replace the piston ring

Repair or replace

Measure and replace

Tighten to specified torque

Disassemble and repair

Adjust gear and repair

Adjust the valve clearance

Use proper fuel oil

Perform draining from the fuel filter

Check and adjust

Check and adjust

Clean

Clean

Replace the piston ring

Repair or replace

Measure and replace

Make adjustment

Perform draining from the fuel filter

Check and adjust

Check and adjust

Hunting during work

Seizure of inlet/exhaust valve

Correct or replace

Large engine vibration

Seized crankpin metal or bearing

Worn crankpin and journal bearing

Defective governor

Water entrance in fuel system

Uneven injection volume of fuel injection pump

Poor spray pattern from fuel injection nozzle

Seizure of inlet/exhaust valve

Seized or broken piston ring

Seized crankpin metal or bearing

Worn crankpin and journal bearing

Loosened connecting rod screw

Defective governor

Timing of fuel injection pump too early

Uneven injection volume of fuel injection pump

Poor spray pattern from fuel injection nozzle

Repair or replace

Measure and replace

Make adjustment

Perform draining from the fuel filter

Check and adjust

Check and adjust

Correct or replace

Replace the piston ring

Repair or replace

Measure and replace

Tighten to specified torque

Make adjustment

Check and adjust

Check and adjust

Check and adjust

Difficulty in returning to low speed

Excessive fuel consumption

Excessive lubricating oil consumption

Defective governor

Compression leakage from valve seat

Excessive cooling effect of radiator,

Defective thermostat (kept closed)

Timing of fuel injection pump too late

Excessive fuel injection volume

Poor spray pattern from fuel injection nozzle

Engine used at high temperature or at high altitude

Seized or broken piston ring

Worn piston ring, piston or cylinder

Improper arrangement of piston rings joint

Reverse assembly of piston ring

Foreign matter trapped in combustion chamber

Worn inlet/exhaust valve guide

Improper properties of lubricating oil

Leakage from lubricating oil piping system

Excessive fuel injection volume

Lubricating oil diluted by fuel

Seizure of inlet/exhaust valve

Seized or broken piston ring

Worn piston ring, piston or cylinder

Lubricating oil mixed with water

Low lubricating oil pressure

Excessive blow-by gas

Blowout from cylinder head gasket

Cracked water jacket

Worn crankpin and journal bearing

Loosened connecting rod screw

Cracked water jacket

Improper properties of lubricating oil

Leakage from lubricating oil piping system

Insufficient delivery capacity of trochoid pump

Clogged lubricating oil filter

Defective pressure regulating valve

Insufficient lubricating oil level

Compression leakage from valve seat

Make adjustment

Lap the valve seat

Repair or replace

Check and adjust

Check and adjust

Check and adjust

Study output drop and load matching

Replace the piston ring

Perform honing and use oversize parts

Correct the ring joint positions

Reassemble correctly

Disassemble and repair

Measure and replace

Use proper lubricating oil

Repair

Check and adjust

Correct or replace

Replace the piston ring

Perform honing and use oversize parts

Replace the gasket

Repair or replace

Measure and replace

Tighten to specified torque

Repair or replace

Use proper lubricating oil

Repair

Check and repair

Clean or replace

Check, adjust or replace

Add proper lubricating oil

Lap the valve seat

Overheating of coolant

Seizure of inlet/exhaust valve

Seized or broken piston ring

Worn piston ring, piston or cylinder

Seized crankpin metal or bearing

Improper arrangement of piston rings joint

Reverse assembly of piston ring

Foreign matter trapped in combustion chamber

Worn inlet/exhaust valve guide

Improper properties of lubricating oil

Clogged lubricating oil filter

Excessive fuel injection volume

Blowout from cylinder head gasket

Seized or broken piston ring

Insufficient cooling effect of radiator, Defective thermostat (kept opened) or slipping fan belt

Insufficient coolant level

Cracked water jacket

Slackened fan belt

Defective thermostat

Excessive fuel injection volume

Engine used at high temperature or at high altitude

Correct or replace

Replace the piston ring

Perform honing and use oversize parts

Repair or replace

Correct the ring joint positions

Reassemble correctly

Disassemble and repair

Measure and replace

Use proper lubricating oil

Clean or replace

Check and adjust

Replace the gasket

Replace the piston ring

Repair or replace thermostat and fan belt

Check leakage from cooling system

Repair or replace

Adjust the belt tension

Check or replace

Check and adjust

Study output drop and load matching

Low coolant temperature

Air inlet pressure drop

Air inlet pressure rise

Exhaust temperature rise

Excessive cooling effect of radiator, Defective thermostat (kept closed)

Defective thermostat

Improper clearance of inlet/exhaust valve

Compression leakage from valve seat

Seizure of inlet/exhaust valve

Clogged air filter

Engine used at high temperature or at high altitude

Excessive fuel injection volume

Improper clearance of inlet/exhaust valve

Compression leakage from valve seat

Seized or broken piston ring

Insufficient cooling effect of radiator, Defective thermostat (kept opened) or slipping fan belt

Insufficient coolant level

Slackened fan belt

Timing of fuel injection pump too late

Uneven injection volume of fuel injection pump

Excessive fuel injection volume

Clogged exhaust pipe

Repair or replace

Check or replace

Adjust the valve clearance

Lap the valve seat

Correct or replace

Clean

Study output drop and load matching

Check and adjust

Adjust the valve clearance

Lap the valve seat

Replace the piston ring

Repair or replace thermostat and fan belt

Check leakage from cooling system

Adjust the belt tension

Check and adjust

Check and adjust

Check and adjust

Clean

Document Title: Function Group:

Engine trouble shooting 210

Profile:

CEX, EC45 [GB]

Engine trouble shooting

Information Type: Date:

Service Information 2014/4/16

Engine faults must be detected and rectified as quickly as possible in order to avoid more expensive repairs. The following table summarizes the most important faults and their rectification.

Problem/fault Possible cause of fault

Engine does not start

Starter switch defective

Starter power too low

Air in fuel system

Air filter dirty

Wrong oil viscosity

Engine too cold

Injection valves defective

Incorrect injection timing

Compression pressure too low

Engine shuts down automatically

Fuel tank empty

Air in fuel system

Fuel filter dirty

Fuel pump defective

Exhaust system clogged

Erratic running of engine

Fuel pump defective

Fuel filter dirty

Air filter dirty

Injection valves defective

Engine overheating

Cooling system elements defective

Fan not running

Lubrication system elements defective

Engine overheating

Incorrect injection timing

Oil level too low

Governor incorrectly adjusted

Coolant level not correct

Engine develops black smoke

Air cleaner soiled

Poor fuel quality

Fault remedy

Tighten connections. Replace the switch.

If the starter is OK, check condition of battery and electric connections.

Bleed the system.

Replace the air filter.

Check viscosity and fill in correct oil.

Check the function of the preheater plug.

Check and adjust the injection valves

Replace defective valves.

Adjust the injection timing. Check the valve clearance.

Check condition of cylinder head gasket, valves and piston rings.

Fill in fuel.

Bleed the fuel system.

Clean or replace the fuel filter.

Check connection of fuel pump or replace fuel pump.

Clear or replace the exhaust system.

Replace the pump.

Clean or replace the fuel filter.

Bleed the fuel system.

Clean the air filter. Check the intake air.

Check and adjust the injection valves

Replace defective valves.

Check elements (water pump, radiator, thermostat, cylinder head gasket, coolant hoses).

Check presence, tension and cleanliness of V-belt.

Check elements (oil filter, oil pump, suction filter) and replace defective parts.

Adjust the injection timing. Check the valve clearance.

Fill in oil. Check whether the oil in the engine meets the operating conditions.

Adjust the governor.

Correct the coolant level. Check whether the coolant meets the operating conditions.

Clean or replace the air filter.

Check quality of fuel and suitability for climatic

Irregular idle speed

Valve clearance and injection timing not correct

Compression pressure not O.K.

Injection pressure not O.K.

Injection pump defective

Engine control cable incorrectly adjusted

Poor engine oil quality

Poor fuel quality

Valve clearance and injection timing not correct

Opening pressure of injection valves not correct

Compression pressure not O.K.

Injection pump defective

Unusual engine noise

Poor fuel quality

Air cleaner soiled

Incorrect injection timing

Engine shut-down solenoid not O.K.

Injection pressure not O.K.

Compression pressure not O.K.

Injection pump defective

Oil pressure too low

Oil level and oil quality not correct

Oil pressure switch defective

Battery charge condition too low

Fan V-belt too loose

Generator defective

Battery defective

Wiring not O.K.

Regulator defective

Engine cannot be shut down

Starter switch defective

Engine shut-down solenoid not O.K.

conditions.

Adjust valve clearance and injection timing.

Check condition of cylinder head gasket, valves and piston rings.

Check and adjust the injection valves

Check injection pump, replace if necessary.

Adjust the control cable.

Fill in oil as required for the operating conditions.

Check quality of fuel and suitability for climatic conditions.

Adjust valve clearance and injection timing.

Check opening pressure and injection valves.

Check condition of cylinder head gasket, valves and piston rings.

Check injection pump, replace if necessary.

Check quality of fuel and suitability for climatic conditions.

Clean or replace the air filter.

Adjust the injection timing.

Check the engine shut-down solenoid.

Adjust the injection valves.

Check condition of cylinder head gasket, valves and piston rings.

Replace the injection pump.

Check oil level and oil quality and fill in specified oil.

Check and replace the oil pressure switch.

Tighten the V-belt or replace, if defective.

Check and replace the generator.

Replace the battery.

Check correct connection of cables.

Check regulator, replace if necessary.

Tighten connections. Replace the switch.

Check engine shut-down solenoid, replace if necessary.

Document Title: Function Group: Information Type: Date: Compression pressure inspection Service Information 2014/4/16

Profile:

CEX, EC45 [GB]

Compression pressure inspection

Compression pressure drop is one of major causes of increasing blow-by gas (lubricating oil contamination or increased lubricating oil consumption as a resultant phenomenon) or starting failure. The compression pressure is affected by the following factors:

Degree of clearance between piston and cylinder

Degree of clearance at intake/exhaust valve seat

Gas leak from nozzle gasket or cylinder head gasket

In other words, the pressure drops due to increased parts wear and reduced durability resulting from long use of the engine. A pressure drop may also be caused by scratched cylinder or piston by dust entrance from the dirty air cleaner element or worn or broken piston ring. Measure the compression pressure to diagnose presence of any abnormality in the engine.

Compression pressure measurement method

After warming up the engine, remove the fuel injection nozzle from the cylinder to be measured. Crank the engine before installing the compression gauge adapter.

Perform cranking with the stop handle at the stop position (no injection state).

Install the compression gauge and compression gauge adapter at the cylinder to be measured.

NOTE!

Do not forget to install a gasket at the tip end of the adapter.

Crank the engine by the starting motor until the compression gage reading is stabilized.

Standard compression pressure

Standard: 30 kgf/cm2 (427 psi)

Limit: 26 kgf/cm2 (370 psi)

Dispersion among cylinders: 3 kgf/cm2 (43 psi)

Document Title: Function Group: Information Type: Date: Valves, adjusting Service Information 2014/4/16

Profile: CEX, EC45 [GB]

Valves, adjusting

Adjusting the valves

1

nbr 21412

NOTE!

Clean the area around the rocker cover before starting adjustment work.

1. Pull off the hose for crankcase ventilation.

2. Remove the cylinder head cover.

3. Crank the engine until the valves are overlapping.

NOTE!

Overlapping of valves means: Exhaust valve not yet closed, intake valve starts to open. In this situation the push rods cannot be turned.

4. Adjust the valve clearance on the respective cylinder using a feeler gauge.

5. Tighten the counter nut. Check the adjustment again with the feeler gauge.

6. Attach the gasket to the rocker cover.

7. Install the rocker cover. Tighten the screws with a torque of 11.3 Nm.

8. Push on the crankcase ventilation hose.

Intake: 0.25 mm (0.01 in)

Exhaust: 0.25 mm (0.01 in)

Valve clearance values

Document Title: Function Group: Information Type: Date: Lubricating system, description 220 Service Information 2014/4/16

Profile:

CEX, EC45 [GB]

Lubricating system, description

The oil pump delivers pressurized engine oil to lubricate the contact faces of moving parts, such as crankshaft, camshaft, intake/exhaust valves, rockers and engine timing gears.

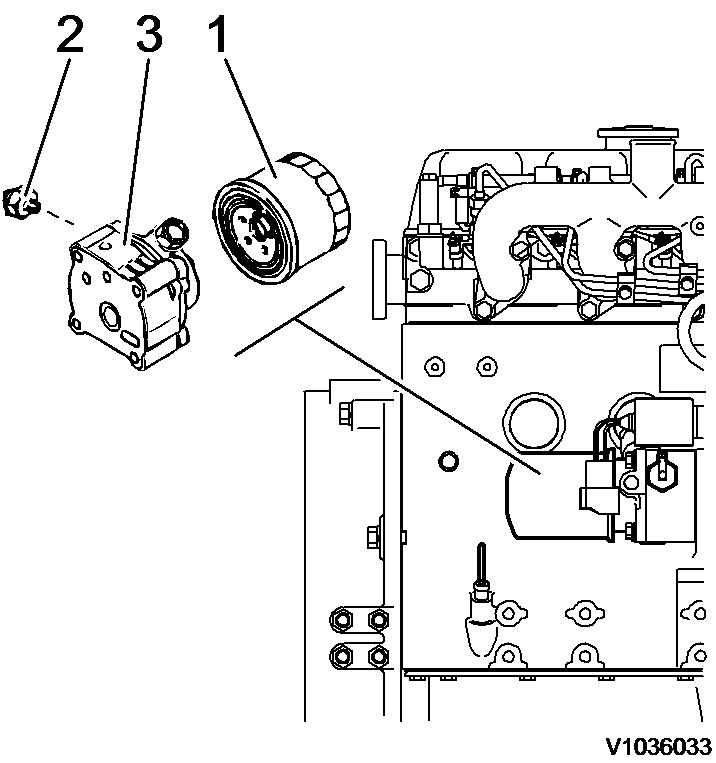

Document Title: Function Group: Information Type: Date: Removing the oil filter 222 Service Information 2014/4/16

Profile: CEX, EC45 [GB]

Removing the oil filter

Op nbr 22202

Filter wrench

Remove oil filter

1. Place a bowl under the oil filter to catch running out oil.

2. Unscrew the oil filter from the engine block using the filter wrench.

Document Title: Function Group: Information Type: Date:

Installing the oil filter 222 Service Information 2014/4/16

Profile: CEX, EC45 [GB]

Installing the oil filter

Op nbr 22202

1

1. Slightly oil the seal on the new oil filter with engine oil.

2. Screw on the new filter cartridge by hand. When the seal touches the contact face turn further for another 1/2 of a turn.

3. Fill in 0.5 litres of oil.

4. Start the engine and check for leaks in the vicinity of the filter.

5. Shut the engine down. Check the oil level, fill up oil if necessary.

Document Title: Function Group: Information Type: Date: Removing the oil pressure switch 222 Service Information 2014/4/16

Profile:

CEX, EC45 [GB]

Removing the oil pressure switch

Oil pressure switch

Op nbr 22205

Socket wrench for oil pressure switch

1. Unscrew oil pressure switch using a socket wrench for oil pressure switch.

Figure 1 remove oil pressure switch

Oil filter Pressure switch Oil pump

Oil pressure test

Op nbr

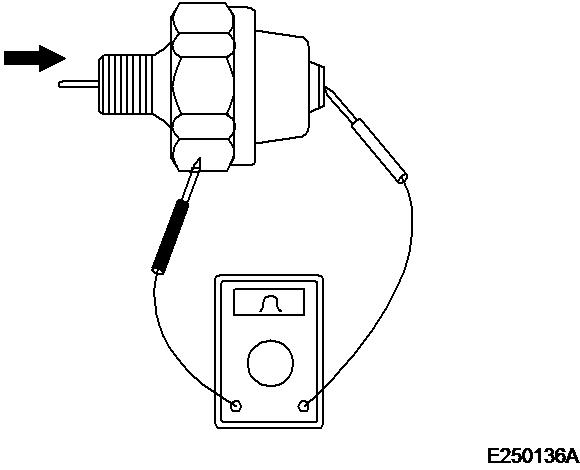

Ohmmeter

1. Check the current flow between terminal and housing with an ohmmeter, as shown in the illustration. If this current flow is not assured replace the pressure switch.

2. Insert a small diameter rod into the oil bore of the pressure switch and push slightly in to check, whether current flow is applied (see illustration). If this is the case, replace the pressure switch.

3. Blow with compressed air of 0.5 bar into the oil bore (arrow) to check whether current flow is present. If this is the case, replace the pressure switch. Check the switch also for air leaks. An air leak may be caused by a broken orifice. In this case the oil pressure switch must also be replaced.

Document Title: Function Group: Information Type: Date: Installing the oil pressure switch 222 Service Information 2014/4/16

Profile: CEX, EC45 [GB]

Installing the oil pressure switch

Op nbr 22205

Socket wrench for oil pressure switch

1. Cover the thread on the oil pressure switch with sealing compound. Turn in the oil pressure switch and tighten with the socket wrench to 10 ± 2 Nm.