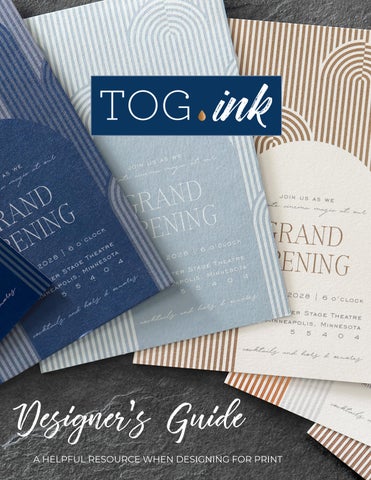

A HELPFUL RESOURCE WHEN DESIGNING FOR PRINT

to specialty print of the finest quality made possible for everyone!

Welcome, Graphic and Stationery Designers!

We are so excited to partner with you, and we can’t wait to see your art running through our presses!

As part of a nation-wide network of printers that has been specializing in fine stationery since 1948, TOG.ink has more than 70 years of stationery design and printing experience. We have mastered presses, perfected processes and learned new, technically advanced print methods.

In 2018, we opened our largescale services to a small-scale market — local stationers, freelance designers and artists. Our offering is expertly curated with you in mind, so you can create stationery your clients love.

Our goal is to simplify your life by offering all the print processes you want in one location with 24/7 access to easy online ordering. With TOG.ink, growing and scaling your business is a breeze.

Together, we will make beautiful things!

Sincerely,

The TOG.ink Team

Explore custom printed products, including custom napkins, letterpress invitations, gifts & more!

3. Upload and Place Order

Verify your specs per product, save as a PDF, and upload it. Then select your material and quantity, add to cart.

Design your artwork, secure final approval, and ensure everything is set for the finished product.

4. Print, Ship, and Relax

Your artwork is being printed and shipped with care. Now, relax - your part is done.

TOG.ink offers more specialty print processes and pairings than any other custom print service in the industry. Not to mention, we offer low minimums and competitive pricing to make specialty print accessible for all whether you’re part of a large business or moonlighting as a freelance designer.

When you’re looking to expand your offering to include custom print with foil and digital, we’ve got you covered. We also offer a variety of other print combinations you would never expect! So you can experiment with custom print combinations like letterpress and foil or thermography and die cutting to impress your clients.

Let’s take a look at each of the print processes you’ll find at TOG.ink.

The Occasions Group is a subsidiary of Taylor Corporation. To follow Taylor Corporation’s progress on sustainable practices, please visit taylor.com/sustainability

When digital print technology emerged in the market, it rocked the print industry and its full-color capabilities opened up an entirely new world of opportunity for designers. Today, digital print is everywhere but using our state-of-the-art presses means your digital art will print better than the rest.

Outstanding features:

- State-of-the-Art Equipment

- Vibrant Color with Sharp Detail

- G7® Master - Color Quality Certification

Most often used for:

Everything! Digital is extremely versatile and opens up lots of possibilities for today’s stationery designers.

Our presses:

The state-of-the-art presses we use are widely regarded as the best in the industry for high resolution, full-color printing. Guess what we have? A whole fleet of them!

Pairs beautifully with:

Foil printing, which is offered by many of our competitors but unlike our competitors, we offer other print pairings like digital + letterpress and digital + thermography.

The crown jewel of print processes, foil printing adds instant star power to any design! At TOG.ink, we use a few foil printing methods to ensure the best results based on your design, bringing a luxe, high-shine finish to every piece.

Perfect for:

Holiday cards, wedding invitation suites, baby announcements, boutique greeting cards, and graduation announcements.

How we print:

We select the best foil printing method for each design to ensure crisp, eyecatching results. Every detail matters, and we make sure your work shines—literally!

Pairs beautifully with:

Digital printing, letterpress, thermography, and die cutting.

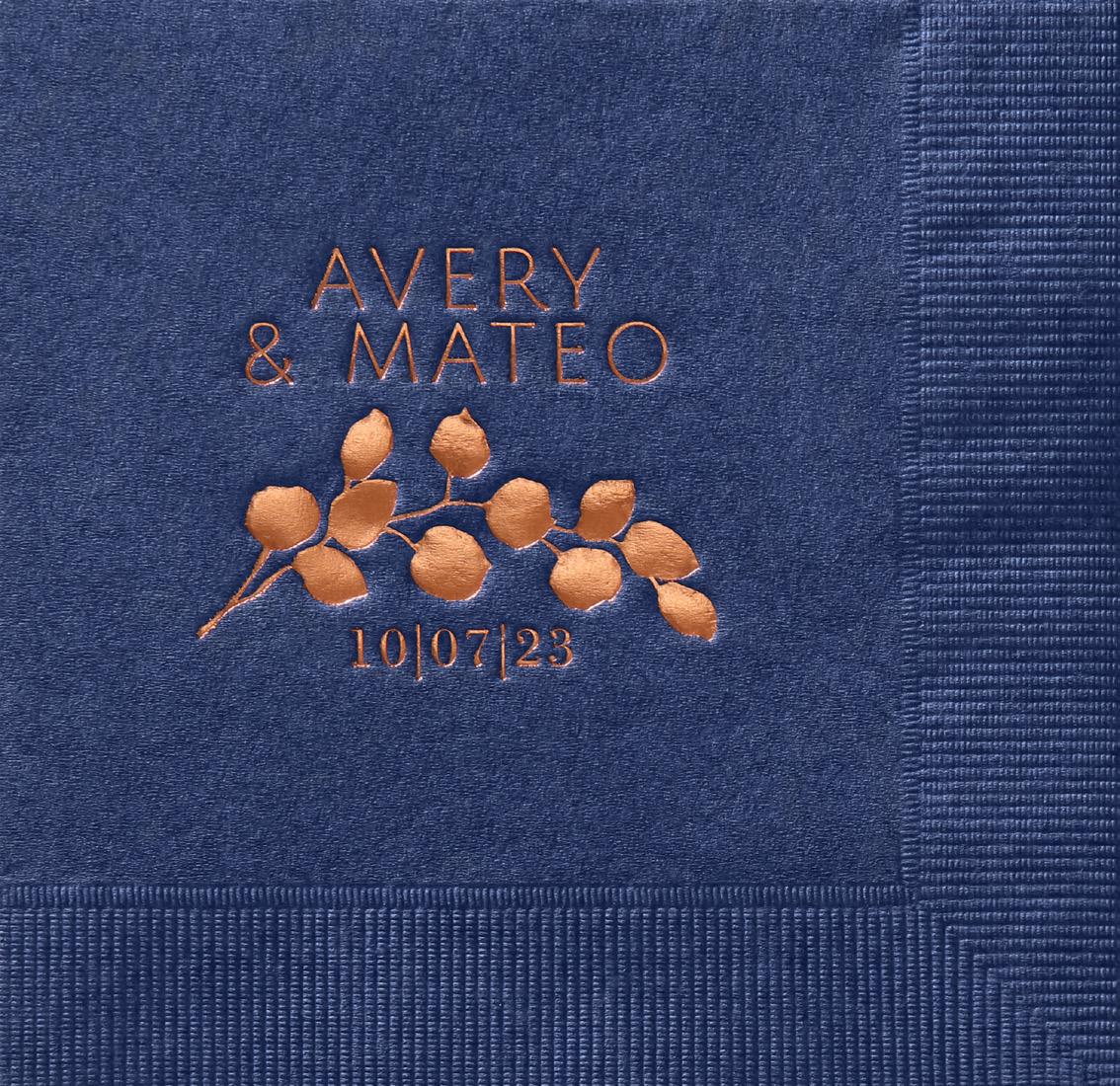

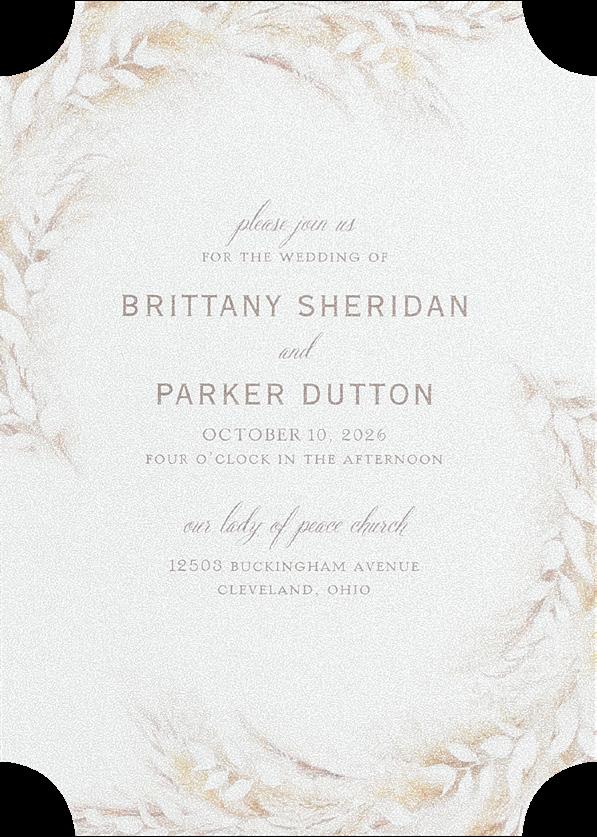

Shown: digital printing + foil printing

Classic and affordable. When a piece of stationery is printed, resin is sprinkled on the wet ink and exposed to heat. The resin and ink fuse together, raising the lettering in an effect that’s similar to engraving for a fraction of the cost. We offer 1- and 2-color thermography.

Outstanding features: - Finish with Subtle Sparkle - Distinct, Raised Texture - 2-Color Thermography Available

Most often used for: Wedding invitations! Although thermography also looks quite nice on boutique greeting cards, personal stationery and business cards.

Our presses: Thermography is printed on offset printers, which require a beautiful balance of manual and automated tasks to achieve the signature look and feel of thermography printing.

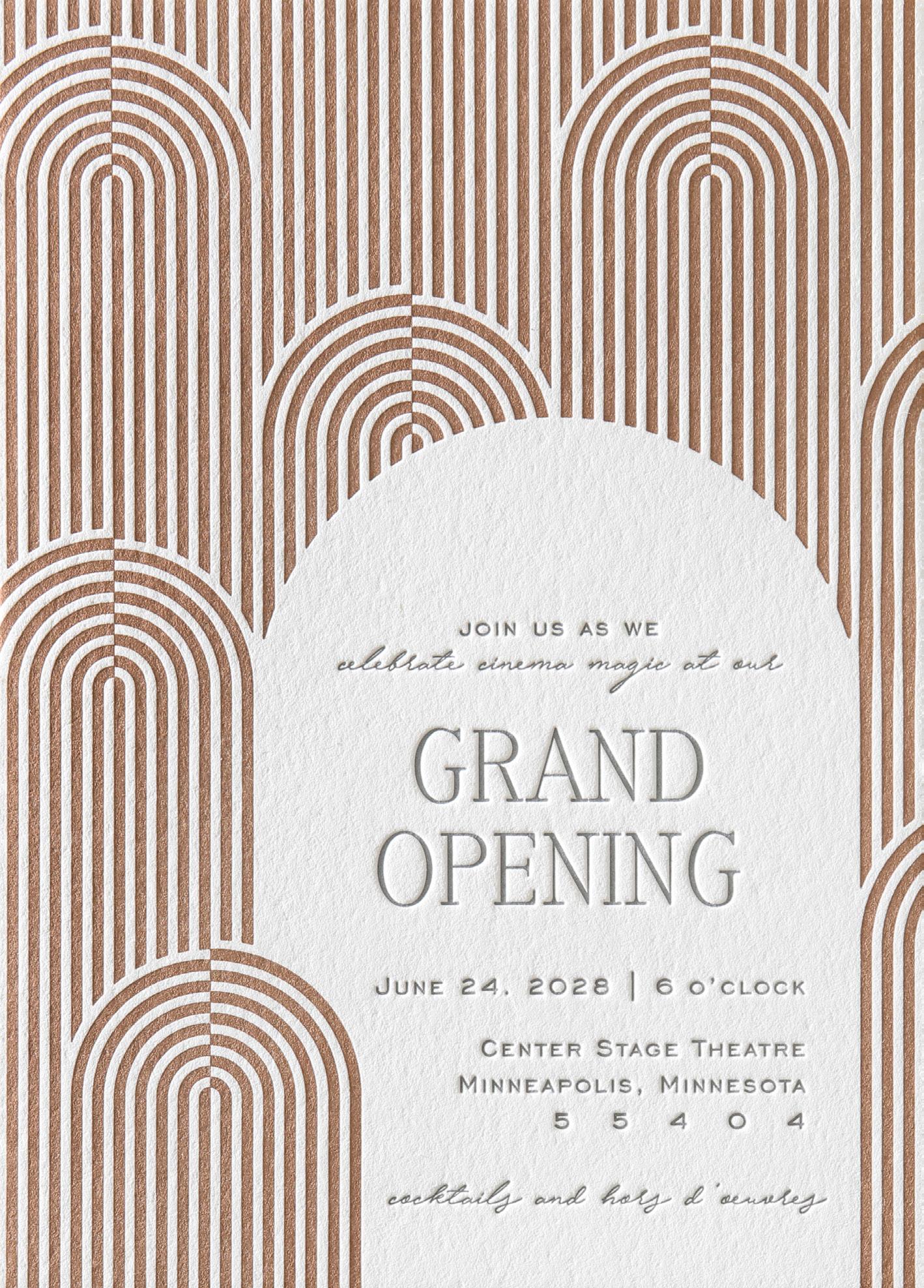

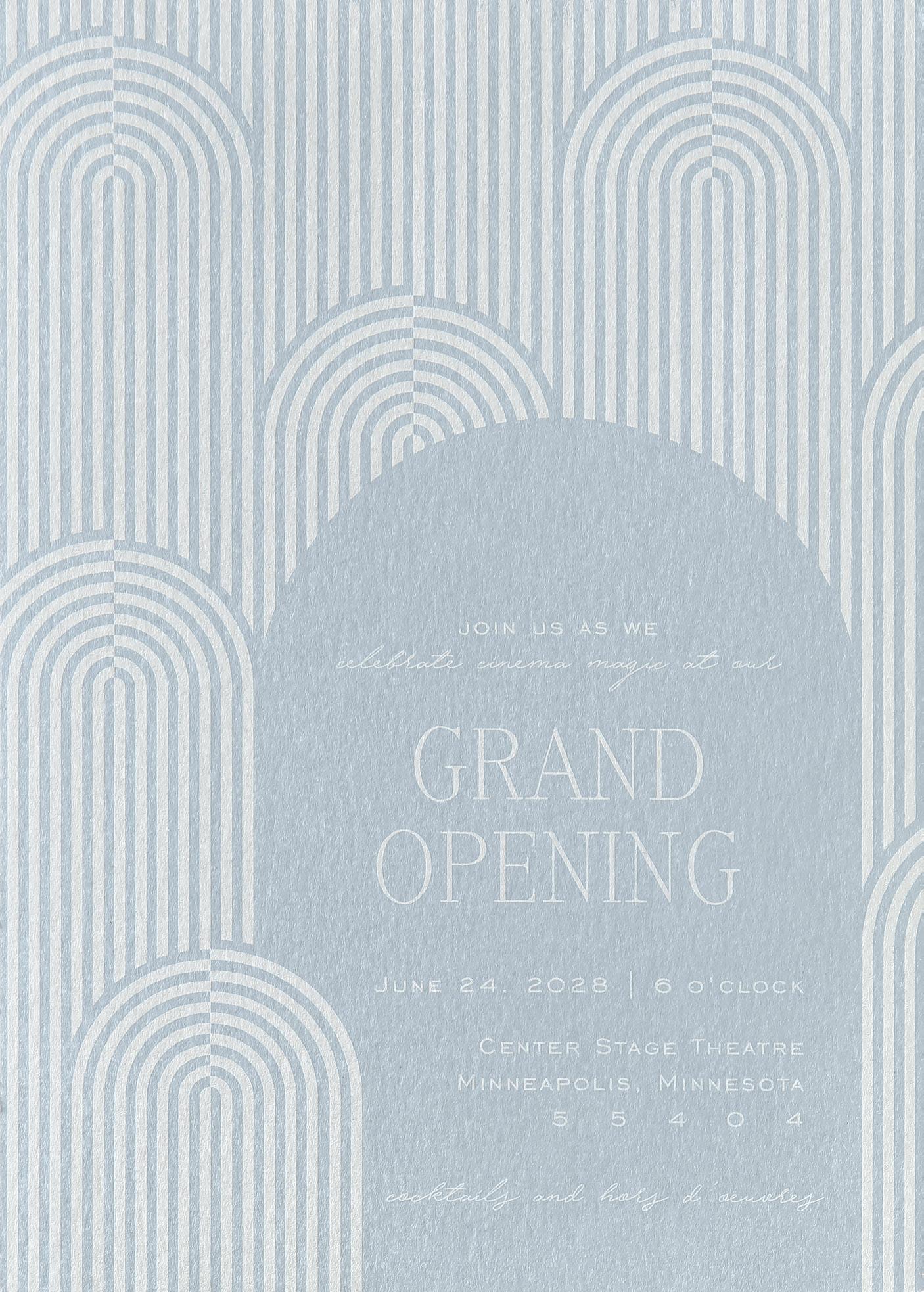

Letterpress printing is really old...but in a good way! It begins as a digital design, which is sent to film as a negative and then exposed to a plate. The plate is then pressed to individual sheets of paper. A heavily impressed image on thick paper leaves the design and wording crisp and sharp.

Outstanding features:

- Deep Impression, Luxe Feel - Premium Cotton Papers - 1- and 2-Color Available

Most often used for: Formal invitations for special events like weddings or corporate fundraisers. Also a popular choice for personal stationery and boutique greeting cards.

Our presses: Heidelberg presses are legendary in the print industry for their strength, accuracy and ease of operation. Fine stationery printers still use these presses today due to the distinct beauty and character they produce.

Pairs well with: Digital or foil printing.

Shown: letterpress printing

White Ink printing uses white toner instead of your run-of-the-mill white ink. White Toner Printing technology has taken years to develop, but now designers like you can get the vibrant white print you crave at the quantities you need for a price that fits your budget.

Outstanding features:: - Full, Saturated White - Richly Colored Papers - Also Available on Envelopes

Most often used for: Social stationery such as wedding invitations, Mitzvah invitations, event invitations, personal stationery, holiday cards and more.

Our presses: Our state-of-the-art presses use White Toner Printing technology to make bright, highly saturated white possible on our carefully chosen collection of richly colored papers.

Shown: White Ink printing

Enhanced raised foil is a digital print finishing process that adds luxurious shine and texture to your piece for a great price! Liquid polymer is applied to achieve the raised foil finish for a luminous look and tactile experience. This unique process also results in highly accurate artwork and foil alignment.

Outstanding features:

- Foil Is Raised Off the Paper

- Available on Front and Back

- More Foil for Half the Price

Most often used for:

Everything! Lower cost means foil is no longer reserved for high-end stationery or once-in-a-lifetime events. We see it used most often for graduations!

Our presses:

Enhanced Foil printing is a UV-based process. The raised effect is created by a liquid polymer, which is applied and partially cured with UV lights. Then foil is applied and cured.

Available only with:

Printing on acrylic requires a unique printing process to ensure a quality result that stands the test of time. UV Printing is a form of digital printing that uses ultra-violet lights to dry or cure ink as it is printed. UV cured inks are weather-resistant and offer increased resistance to fading.

Outstanding features: - Crystal Clear Acrylic - Crisp White Printing - Luxurious and Durable

Most often used for:

Formal event stationery like wedding invitations and gala invitations. Custom acrylic is available in smaller stocks to create a perfectly coordinated invitation ensemble. Acrylic is also used for indoor and outdoor signage.

Our presses:

Our large-scale UV printers are actually flat-bed presses, which print directly onto clear stocks. These presses are capable of both short- and long-run capabilities.

Pairs well with:

Not available to pair.

More details to note:

Custom printed acrylic is shipped with protective adhesive sheets covering both sides. Avoid scratches when removing any adhesive residue left behind by washing gently in warm soapy water with a soft cloth. Then handle the printed piece by the edges to avoid fingerprints.

Shown: UV printing

Digital sublimation printing is a print-and-transfer method of printing, which provides exceptional print quality in tonal transitions for premium results on a variety of product from ceramic mugs to satin ribbon.

Sublimation’s precise heating technology is designed for excellent color brilliance and ensures accurate, consistent alignments.

Outstanding features:

- Vibrant Color

- Highly Accurate Alignment

- Easy Product Diversification

Most often used for:

Personalized gifts and embellishments. Sublimation is often used on ceramics, resins, fabrics and signage.

Our presses:

We house an extensive line of sublimation equipment perfect for printing on hard and soft surfaces. This top-of-the-line equipment provides brilliant, high-quality color on every item.

Pairs well with: Not available to pair.

We offer a large selection of wholesale napkins available with digital printing and Foil Stamping, and both are available in long and short runs! Our patented process for digital napkin printing produces vibrant color and detailed artwork. Our napkin foil stamping follows the very same process as our gorgeous foil stationery!

Outstanding features:

- Premium Quality 3-Ply Paper Napkins

- Multiple Napkin Colors and Foil Colors

- Crisp and Vibrant Full-Color Printing

Most often used for:

Special events, celebrations and parties! Branding and promotion for large and small businesses. Fundraising events, personalized gifts and so much more.

Our presses:

Foil stamped napkins are printed on the ever-impressive Heidelberg presses; the very same machines that print our letterpress stationery.

Our digital napkin printing process is a patented technology, which allows us to print larger volumes of custom print napkins featuring vibrant fullcolor printing in less time than our competitors.

Because paper is the canvas for your masterpiece.

We know what papers work best with what print processes. We experiment with every paper we offer for proven performance and we have carefully considered what designers like you want. Almost all of our papers are made in the U.S.A. and many contain recycled content. Learn more about our papers and choose the right fit for your artwork.

Most of our products are available in both white and ecru. White paper is bright, clean and crisp. Ecru paper is cream-colored paper, slightly darker than ivory. Both white and ecru are smooth and even with no variations in color — perfect for digital printing! We also offer colored paper stocks for foil printing and White Ink.

The paper weight you choose won’t affect the quality of your artwork but it can enhance the overall piece. A heavier paper has a more luxurious feel. We offer a wide range of paper weights so you can choose the right one for the job.

We offer three main finishes: smooth, shimmer and texture. Each finish will enhance your artwork in a different way: a smooth finish is classic and elegant, a shimmer finish lends a nice glow, and textured adds depth and interest

SMOOTH 111 lb. | 15 pt. thickness

I 10.5 pt. thickness

100 lb. I 14 pt. thickness SPICE

100 lb. I 14 pt. thickness

lb. | 10.5 thickness

100 lb. I 14 pt. thickness

I 14 pt. thickness

93 lb. I 14 pt. thickness

100 lb. | 13 pt. thickness 30% recycled

100 lb. I 14 pt. thickness

Excellent quality for an excellent price, this paper is the most commonly used paper in printed stationery. A soft, smooth finish is the distinguishing characteristic and it’s available in white, ecru, and a variety of beautiful colors.

SHIMMER

105 lb. | 16.2 pt. thickness 30% recycled

SHIMMER

105 lb. | 16.2 pt. thickness 30% recycled

CORAL SHIMMER

105 lb. | 14 pt. thickness

105 lb. | 10.5 pt. thickness

SHIMMER DOUBLE THICK

210 lb. | 32.4 pt. thickness

SHIMMER

lb. | 13.3 pt. thickness

lb. | 16.2 pt. thickness

recycled

| 16.2 pt.

| 14 pt.

We offer a luminous shimmer paper! Paper with a hint of shimmer gives your design an elegant glow without being over the top. Shimmer papers are available in white, ecru and select colors.

Cotton paper provides the impeccable quality that makes letterpress and other specialty print methods so distinct and highly sought after. These 100% cotton papers are soft to the touch and look extra luxurious.

The slightly rough feel and grainy look of textured paper adds depth and interest to any design. The paper is still soft with smooth, beautiful color but adding a slight texture creates a uniquely rich appearance.

Clear stocks are unique and allow for fun, creative interpretations as various event invitations and business materials. Clear acrylic has a luxe look and substantial feel while translucent vellum creates an elegant layer or invitation accent.

We have done our best to accurately represent each color, but please note that colors may vary slightly depending on print process and paper.

We have done our best to accurately represent each color, but please note that colors may vary slightly depending on print process and paper.

Dress up the design with a stylish trim option. A new shape can create a brand-new look and feel. Watch for the icons below to indicate if trim options are available and which options are available per item.

CORNERS

We are happy to accept custom print requests! See below for the most common requests we receive. As you’re reviewing the questions below, you can visit Designing for Print for more helpful information. When you’re ready to submit your request, please fill out our Custom Quote Form and we’ll respond with the possibilities and an estimate.

Do you offer 2-color letterpress?

Yes, you can find 2-color letterpress items when you shop all letterpress. Look for items with L + L listed on the card image. Save and upload artwork as instructed in the product detail bullets. We recommend reading Designing for Print (linked above) before creating your artwork.

Do you offer blind letterpress?

Yes, choose any letterpress item, and choose the “debossed” option in the color selection when ordering.

Do you offer 2-color thermography?

A second color can be added to any thermography item. Upload a separate PDF for each ink color. There is a minimal extra charge applied after the second PDF is uploaded. We recommend reading Designing for Print (linked above) before creating your artwork.

Do you offer 2-color foil printing?

Yes, we can do two foil colors. Submit a Custom Quote Form (linked above) and please read Designing for Print (linked above) before creating your artwork.

Do you offer blind embossing?

Yes, we offer blind embossing. Please submit a Custom Quote Form (linked above) and our Customer Care Team will get back to you. Please note: blind embossing is not available on cotton papers. However, you can achieve a similar look with blind letterpress (which is debossed instead of embossed).

Can I add additional print processes?

You may request additional print processes. Please note that adding a second, third or fourth print process is dependent on the other print process(es) you want. Please submit a Custom Quote Form (linked above) and our Customer Care Team will get back to you.

Do you offer more stocks than what’s available online?

Yes, we can access more stocks upon request. We recommend calling the Customer Care Team at 866-708-0177 to inquire about specific stocks or to see what’s available.

A10 = 5.75 x 9.25 (Flat)

A9 = 5.5 x 8.5 (Flat)

A8 = 5.25 x 7.875 (Flat)

A7 = 5 x 7 (Flat + Folded)

A6 = 4.625 X 6.25 (Flat + Folded)

A2 = 4.25 x 5.5 (Flat + Folded)

A1 = 3.5 x 4.875 (Flat + Folded)

R11 = 4.25 x 11 (Folded)

R4 = 4.8125 x 6.8125 (Flat)

R5 = 4.5625 x 6.5625 (Flat)

R7 = 3.5 x 6.125 (Flat)

R6 = 3.5 x 5.5 (Flat)

R9 = 2 x 3.25 (Flat)

R8 = 1.75 x 3 (Flat)

Business Card = 3.5 X 2 (Flat)

We offer a variety of custom printed envelopes and blank envelopes. Check out the sizes and printing options below, and don’t forget to take a look at our Envelope Embellishments like address labels, liners and self-inking stamps.

Outer (Mailing) Envelope Size Guide

Standard Flap

Square Flap

Digital Printing

Digital Variable Print

Foil Printing

Offset Printing

White Ink Printing

White Ink Variable Print

White Envelope

Ecru Envelope

Envelope Colors

Variable print describes the process of printing different sets of data in one order. Usually this refers to envelope addressing where customers upload a list of guest addresses, which are then professionally printed on the envelopes.

We offer variable print on flat cards, folded cards and art prints as well. We recommend reading How to Set Up a Multipage PDF for Variable Print in preparation for your first order.

A1 Envelope

A1 Euro Envelope

A7 Euro Envelope

A9 Outer Double Envelope

A8 Inner Envelope, Ungummed

A2 Square Flap Envelope

A10 Inner Envelope, Ungummed

A8 Outer Single Envelope

A2 Euro Envelope

A6 Envelope

A7 Envelope

A8 Outer Double Envelope

A9 Inner Envelope, Ungummed

A9 Outer Single Envelope

A10 Outer Single Envelope

A10 Outer Double Envelope

S1 Outer Double Envelope

A1 Square Flap Envelope

A7 Euro Envelope, White Ink

A2 Square Flap Envelope, White Ink

A1 Euro Envelope, White Ink A2 Envelope

Find more helpful content on the TOG.ink Blog!

When you want to use multiple print processes on one piece, we suggest checking out the very helpful Print Processes & Pairings Cheat Sheet to help you choose. You can also refer to the print processes featured on our homepage.

Once you’ve chosen a print pairing, review the design guidelines for each print process on the Product Details page or in the Art Specs Grid (see page 52). When designing for multiple print processes, it is important to remember that the rules for each print process still apply.

Take note! Digital print works with just about every print process. Digital is a flat printing method so there are fewer limitations. The remaining steps we will cover are geared toward other specialty print processes.

When designing for print pairings involving letterpress and thermography, designers need to take into account the slight movement of the press during the run because this is what causes registration issues. Learn more about this in our blog post, When Does Registration Become a Problem?

The Art Specs Grid will help guide you but remember that you will need to include at least 1⁄8" between each process. The 1⁄8” guideline also applies to specialty print processes in two colors, like 2-color letterpress or 2-color thermography.

Before you upload your artwork, convert it to 100% black. Why? Although digital presses print color by mixing a combination of four ink colors — cyan, magenta, yellow and black (CMYK) — other print processes use a premixed ink or foil color and die. Your artwork PDFs are sent to a special die maker, which reads the 100% black artwork to create a raised surface on the die. The ink or foil is then applied to the die for printing.

The file will need to adhere to the following rules:

• Choose the “high quality” option.

• Name your file with letters and numbers only (no special characters).

• Uncheck “preserve editing capabilities” (if using Adobe Photoshop or Illustrator).

• Hide all non-art and template layers.

You will need to upload one PDF for each process. Each PDF will need to be vector or 600 dpi and 100% black. We suggest separating each process into its own layer in your file so you can easily separate the colors after they are converted to black.

You will select the desired ink or foil color (unlike digital) and the site will generate a preview for a final check before it is sent off to press. You’re going to love the end result!

Confirm art is complete before creating PDF to upload. We are not able to create or modify your art file. Therefore, artwork must be complete before creating your final PDF for upload.

Review our artwork specifications and product templates. We have provided the file requirements necessary for a successful upload and printed piece.

• View Artwork Specifications: tog.ink/custserv_content.jsp?pageName=artwork_specifications

• Review the product’s template, which is available on each product’s detail page.

Verify the file is in a PDF format. You will not be able to select other file types (like .jpg, .png, .tiff, .psd or .indd) when ready to upload.

Review Art Size vs. Finished Size.

The Art Size is found within the product template or on the product detail page. Our Art Size is not the same as the product’s finished size.

• “Art Size” includes bleeds if bleeds are required.

• “Finished Size” indicates size of final printed product.

• “File Size” indicates how large the file is in terms of kilobytes (KB) and megabytes (MB).

Did you receive this error? Your artwork is sized incorrectly. Check the product’s detail page and/or template for the correct art size. TIP: Quickly check the art size by hovering in the bottom left of Adobe Acrobat. Art Size should match the PDF’s page size.

Check the size of your file.

For fastest upload times and best results, avoid large file sizes. TIP: Removing “Preserve Editing Capabilities” when saving will result in a smaller file size with high resolution for printing.

• We recommend a file size of 5MB or under.

• Our system can accept up to 50MB but the file will take longer to upload and may error out.

Check your color type based on your print processes. An incorrect color type setting will result in poor print quality.

• Digital and Sublimation Printing files should be set to “process”.

• Files for Thermography, Foil Printing, Letterpress, Enhanced Foil, White Ink and UV Printing (clear stock) should be set to 100% black.

Create a file for each printing process. Items with two printing processes require two files for upload.

• Create one PDF per print process.

• Reference the product’s template when creating each PDF.

Check if your file names contain special characters. Any character other than a letter or number will cause the following error:

professional

TOG.ink offers a simple, upload-your-artwork user interface. We accept PDF files only, which means following the artwork specifications and file requirements for each product is essential to a successful ordering process.

Below you will find an easy-to-use grid with art specs and file requirements needed per print process. You will find these same details listed on each product detail page as you’re shopping. We also recommend reviewing the File Upload Troubleshooting Checklist (see pages 50-51) either before uploading your PDF or after if you’re receiving errors.

digital artwork layer is required. Please refer to digital art specs above.

Templates are available to help you create a flawless design every time! We offer templates for most of our products to make sure your designs you create fit beautifully and will print perfectly on our various card sizes and product types. Check back often because we regularly update our product offering which means we’re continuously adding new templates too. Not to mention the ones we’re reviewing and changing based on customer requests.

Extra small text may cause registration and quality issues. As many of you probably know, different fonts can appear drastically different even at the same point size. Since we are an upload-your-artwork print service, we don’t limit the fonts you can use, which means we can’t curate a list of fonts and provide guidelines for font sizes. Print design best practices would state anything under 6 pt. is not readable but “readable” is also dependent on the font. Certain script fonts at 8 pt. might be unreadable while certain block fonts at 6 pt. will be perfectly readable. Please be mindful of this while designing for print.

Fine lines of less than 1 pt. thickness are not recommended for letterpress and foil stamped artwork in order to maintain quality consistency. You may choose to experiment with fine lines of less than 1 pt., but we cannot guarantee the results and may not cover the cost of a reprint.

Heavy coverage is not advised on thermography items, letterpress items and foil stamped napkins. Please do not attempt to fill large spaces or “flood” an area. Heavy coverage is also not advised on Variable Print Envelopes with designs intended to bleed. Our press operators define “heavy” coverage as anything greater than one square inch. Thermography borders more than 1⁄4" wide can also be problematic for consistency.

Be aware that all letterpress items and many of our foil items utilize handcrafted print processes with a 1⁄16" tolerance, which means movement of 1⁄16" may occur from piece to piece. We recommend designing with a 1⁄8" space between two ink colors for thermography and letterpress. We recommend 1⁄8" space between two foil colors as well. Designing for movement is the best way to ensure success! Check out Custom Quotes on page 36 to see how you can order the above mentioned processes in two colors.

Our press operators are highly skilled and capable of hitting tighter registration, depending on the design. However, since we don’t have eyes on your design, we can’t guarantee success. You may choose to experiment with registration tighter than 1⁄8" but we cannot guarantee the results and may not cover the cost of a reprint.

Border artwork is probably the trickiest artwork to print and cut down accurately. We highly recommend utilizing product templates and designing for the movement that may come from the printing process.

The Designer Tool Kit is meant to be both inspirational and a helpful reference when meeting with clients, which is why we made sure form and function are spot on. All featured swatchbooks are removable and easy to flip through. Just $35 per kit. Sold out! New release date to be determined.

Your complete satisfaction with our products and print services is important to us. With this in mind, we have compiled a list of frequently asked questions from customers just like you! If you don’t find what you’re looking for, we encourage you to call our knowledgeable Customer Service Team (see last page).

Cheat Sheets are here to help you navigate all of the product and print services TOG.ink has to offer. You’ve seen several of our most popular Cheat Sheets throughout this guide. All Cheats Sheets are available as downloadable PDFs. Save them in a folder on your desktop or print them for your workspace.

The TOG.ink Blog provides helpful tips and inspiration straight from print experts, so designers like you can create successful printed pieces and explore new opportunities. You’ll find print processes explained, new product alerts, print design tips, professional design inspiration, a gallery of printed sample photography and more.

Available Monday - Friday 9am-4pm CST 866.708.0177 EMAIL

Available Monday - Friday 8am-5pm CST customercare@tog.ink CHAT

Available Monday - Friday 8am-5pm CST