Since its inception in 2002, Countlab® has been at the forefront of providing distinctive solutions tailored to the unique needs of various industries. Our unwavering commitment to quality, excellence, and innovation has not only set us apart but has also empowered our customers to adapt seamlessly to ever-changing market dynamics.

Designed specifically for the Pharmaceutical & Nutraceutical Markets but suitable for all:

• Tablet (coated / uncoated)

• Capsules

• Hard / soft gel

Also suitable for candies and other small components

(Applicable to all MF & SF platforms)

Driven by a passion for precision, Countlab® crafts machinery that embodies reliability and efficiency. Every piece we design reflects our deep understanding of industry demands, ensuring our clients stay ahead in their sectors.

Countlab® brought the most compact and fastest electronic counter to the market.

Compact yet powerful, Countlab®’s tabletop solutions redefine efficiency and precision in packaging.

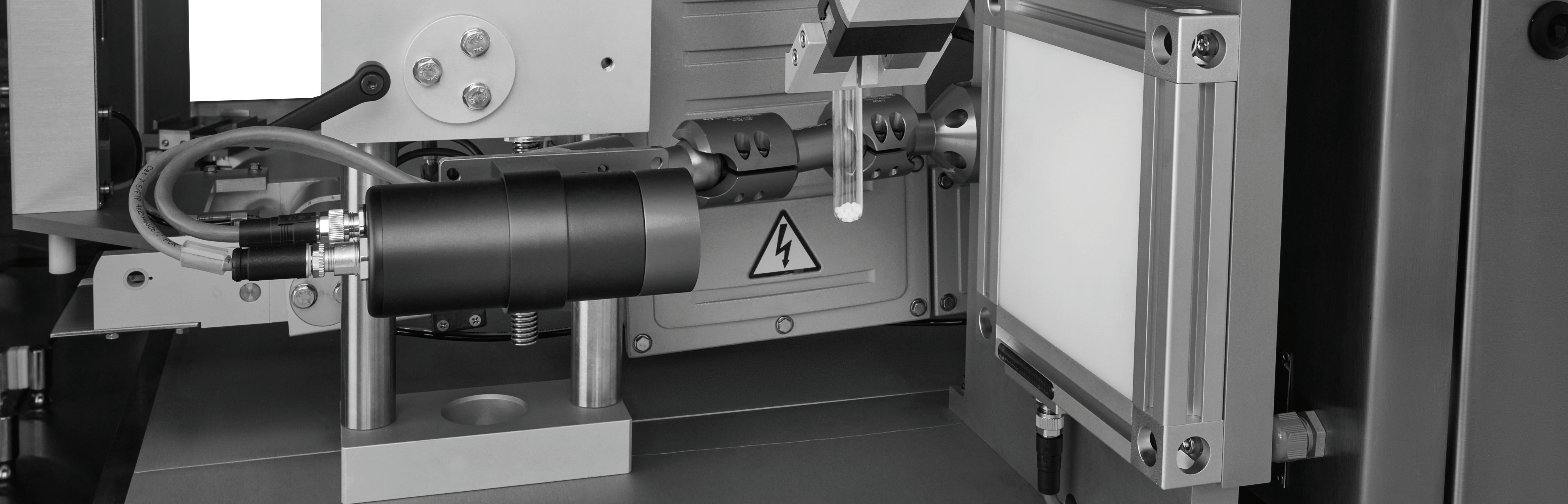

At the center of Countlab®’s innovative technology are our Ultra High-Speed Optical Sensors (at 2500 scans/second), capable of monitoring components as small as Ø1 mm (0.039”), while also being able to detect broken tablets or capsules to be rejected. Countlab®’s sensor technology and assembly also eliminate blind spots for even higher count accuracy than existing solutions.

Monoblock Solutions:

• Patriot SF-1

• Patriot SF-2

• Patriot SFX

• Intrepid SF

• MF

• Galaxy Semi-automatic precision counting units:

• Conquest SF

• MF Plus

Stand -Alone Solutions:

• SF-1

• SF-2

• SF-100

• SF-200

• SF-100-IPC

The Mini Fighter™ (MF) is a tabletop tablet and capsule counter used as a validation tool that aids in Quality Assurance (QA) procedures.

It simplifies and accelerates verifying the count accuracy of filled containers on the packaging line, maintaining high reliability.

When integrated as part of the Countlab® tablet and capsule packaging line, this system can be used manually or automatically for count validation.

• Following cGMP design recommendations

• Only FDA-approved pharmaceutical grade materials:

◊ Tempered glass

• Data report capability

• GAMP Documentation

(Applicable to all MF & SF platforms)

The MF being a validation system, the MF+ is a small batch counting, production unit benefiting from the same features with the addition of a gate block utilized to perform pre-counts for production output purposes during actual production runs.

Base Features:

• Specialized trays for single or very low count

• Dust compensation

◊ Assuring the sensors do not get obstructed view due to dust

• Dust vacuum recuperation for uncoated tablets

• Universal filling nozzle ensuring compatibility with various container sizes and shapes, with limited change parts

• Vibratory tray with variable frequency and amplitude range

◊ To accommodate various tablet shapes while facilitating sliding down the vibratory plate, optimizing production throughput

(Applicable to all MF & SF platforms)

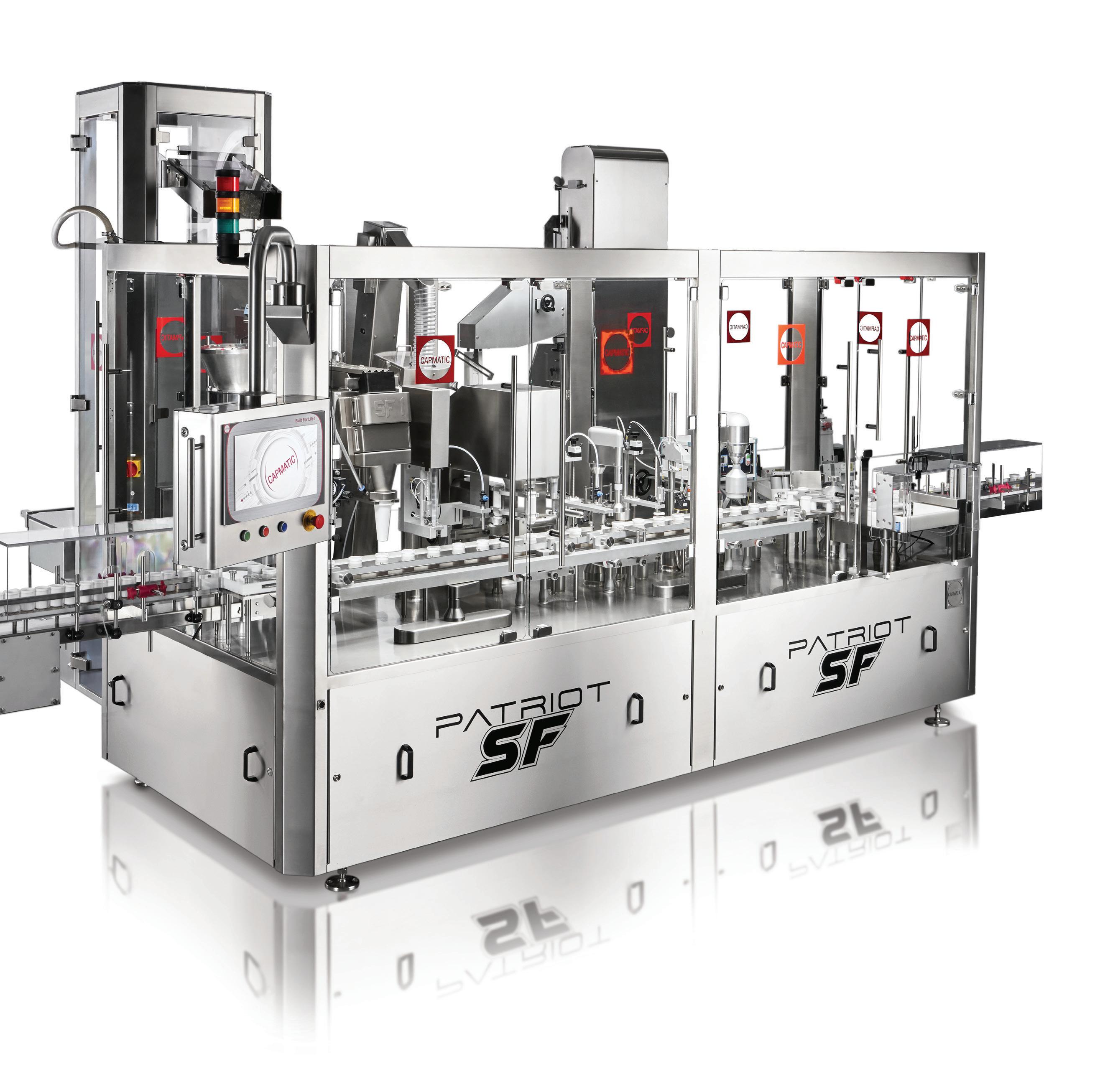

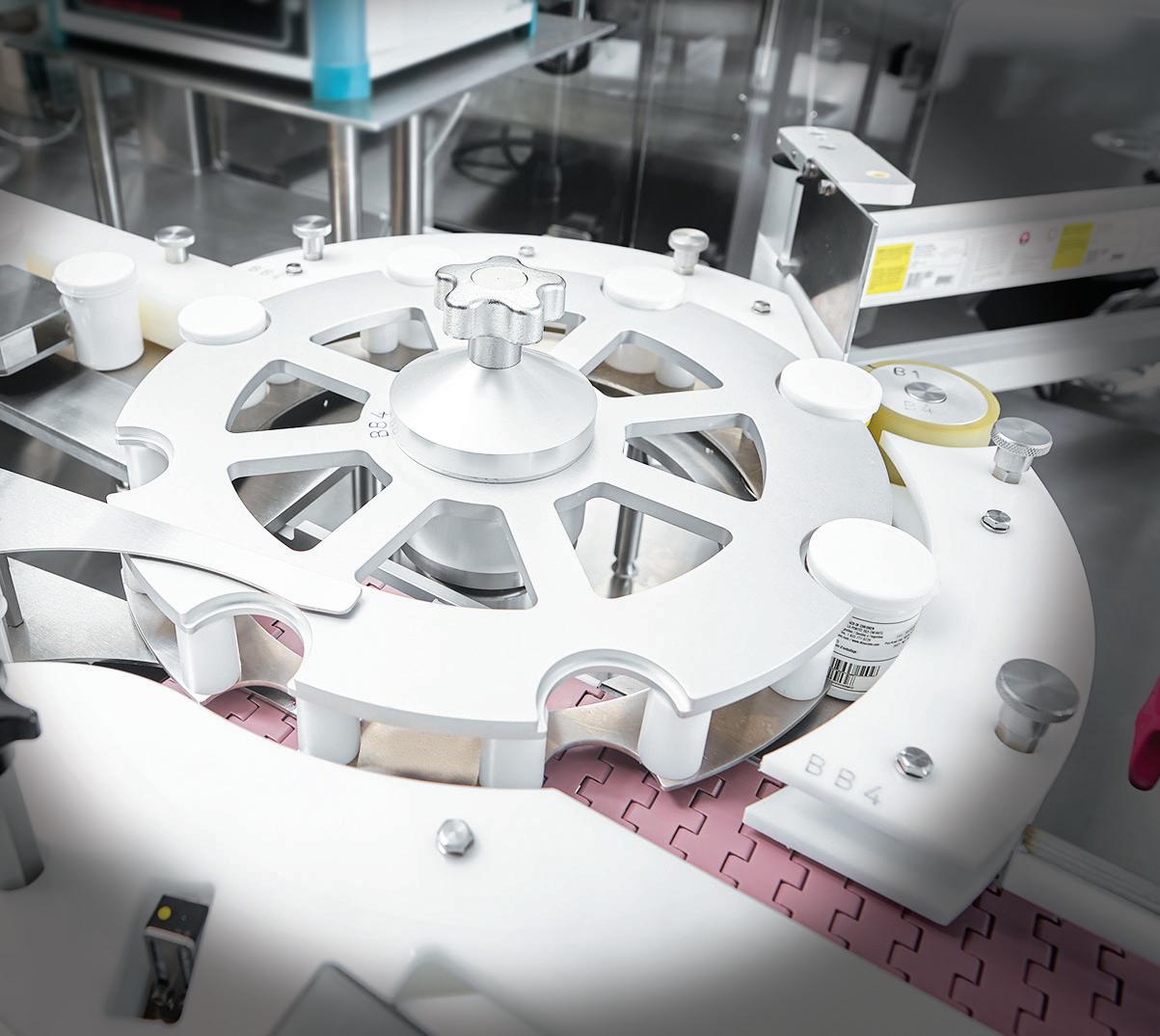

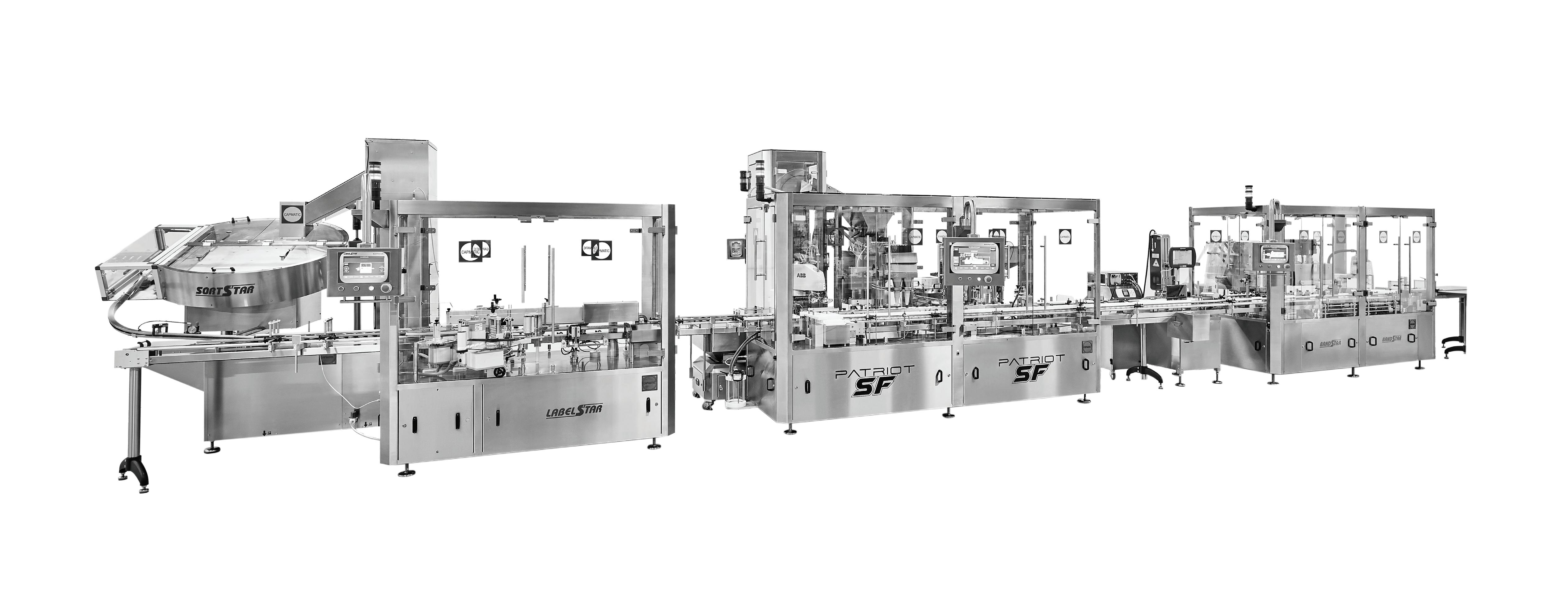

Revolutionizing counting with Monoblocks – A seamless blend of elegance, speed, versatility, accuracy, and compactness, taking advantage of the latest technologies in one fully integrated package.

Since 1964, Capmatic has revolutionized the packaging industry by introducing Monoblock’s to the market, where multiple operations will be performed within a single platform, reducing the packaging line footprint and the number of operators required. True to our origins, Countlab® is now pursuing the same success with the following:

Monoblock Solutions:

• Patriot SF-1

• Patriot SF-2

• Patriot SFX

• Intrepid SF

• Conquest SF

• Galaxy

Base Features:

• Bigger hopper capacity

• Two steps vibratory plates reducing the traveling distance

• Longer vibratory plates for higher throughput

• Four (x4)/ Eight (x8)/ Twenty (x20) counting channels

• One (x1)/ Two (x2)/ Four (x4)/ Five (x5) funnel(s)

The STREET FIGHTER SF-1 is an automatic precision counter with an integrated reject station and optional advanced features for enhanced quality control.

SF-1 Module:

• Four (x4) counting channels

• One (x1) funnel

• 30 BPM

Can be operated as:

• Stand - alone

• Integrated within a packaging line

• Integrated within a Countlab® Monoblock solution (Applicable to all SF modules)

*Speed and performance criteria are subject to testing with actual samples.

**BPM = Bottle(s) Per Minute

The STREET FIGHTER SF-2 is an upgrade to the SF-1; with the same features, but incorporating dual funnels to handle two (x2) bottles at a time.

SF-2 Module:

• Eight (x8) counting channels

• Two (x2) funnels

• 60 BPM

Additional features

• Fully integrated electrical cabinet

• NEMA 4x electrical and HMI enclosure

ensuring dust and liquid protection

• Color touchscreen HMI

• Pneumatic gating or servo-driven feedscrew

• Limited maintenance requirements

◊ Wipe down

(Applicable to all SF modules)

*Speed and performance criteria are subject to testing with actual samples.

**BPM = Bottle(s) Per Minute

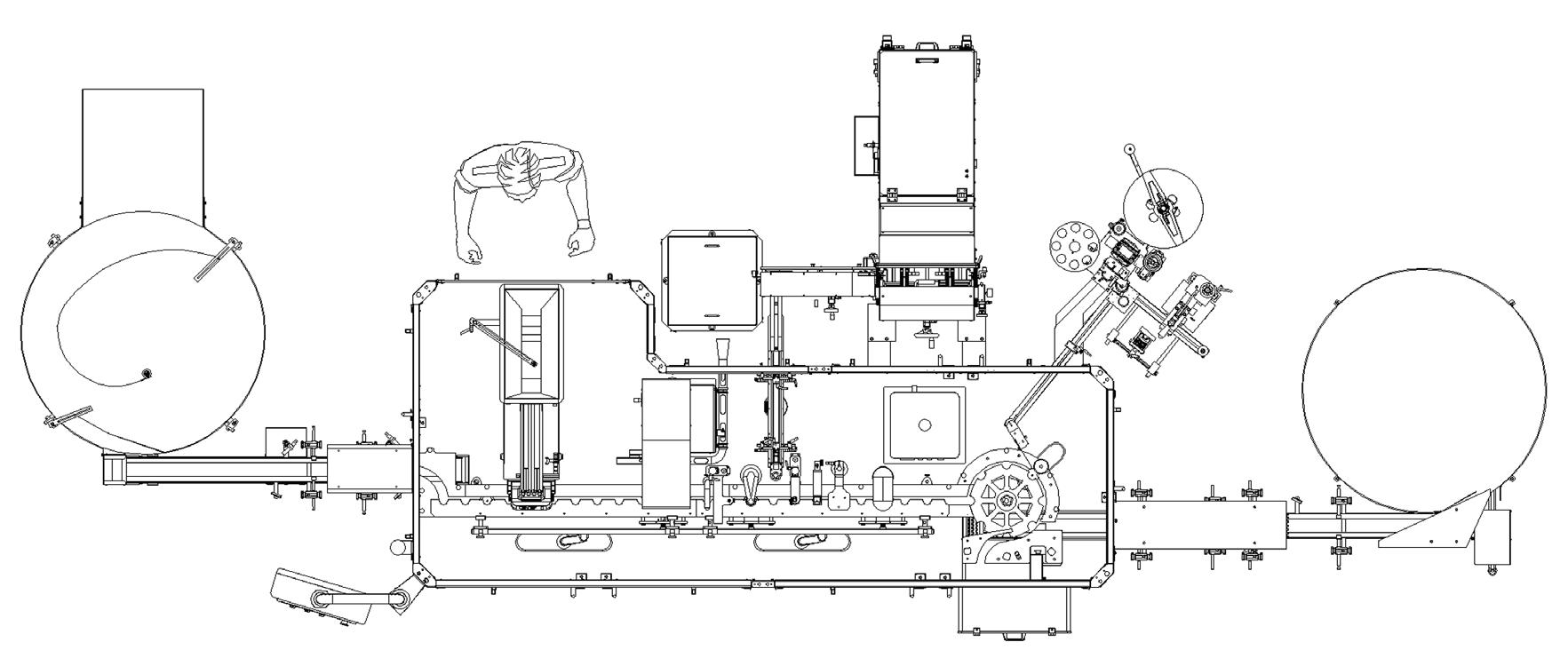

The PATRIOT SF-1 is a compact Monoblock solution designed for precise tablet and capsule counting. Incorporating an SF-1 electronic counting module, the Patriot SF-1 was specifically tailored to ensure accurate counts.

Base Features:

• One (x1) operator required

• Compact, balcony-style design facilitating maintenance and access

• Recipe-driven, quick and repeatable changeovers

• Servo-driven single indexing

• One electronic counter module model SF-1

• One automatic cap feeding system with CapSort Elevator

(Applicable to all MF & SF platforms)

SF-1 Module:

• Four (x4) counting channels

• One (x1) funnel

• 30 BPM

• One cap pick and place station with pre-tightening device

• One final servo-driven tightening station

• One reject station

• Machine controlled with Industrial PLC

• 255mm (10’’) multi-color touchscreen HMI

• Three (X3) colors status beacon light

• Euroguard system with tempered glass interlocked doors

The PATRIOT SF-2 is the next level in advanced counting Monoblock. Maintaining the elegant design and features of the Patriot SF-1, but integrating the SF-2 electronic counting module with dual funnels for increased throughput.

Base Features:

• Servo-driven dual indexing

• Servo-driven capping with torque feedback

• One electronic counter module model SF-2

• Suitable for Pharmaceutical, Healthcare, Nutraceutical Industrial, and cosmetic products

(Applicable to all SF platforms)

SF-2 Module:

• Eight (x8) counting channels

• Two (x2) funnels

• 60 BPM

Regulatory Agencies:

• FDA

• cGMP

• OSHA

• UL

• NEMA

• GAMP

• NEC

*Speed and performance criteria are subject to testing with actual samples.

**BPM = Bottle(s) Per Minute 60BPM**

The INTREPID SF is the culmination of Countlab®’s Monoblock evolution. Cutting edge double index Monoblock solution equipped with two (x2) SF-2 electronic counting modules for optimum speed and efficiency.

Base Features:

• Servo-driven dual indexing

• Servo-driven capping with torque feedback

• Two electronic counting modules model SF-2

(Applicable to all SF platforms)

Two SF-2 Modules:

• Sixteen (x16) counting channels

• Four (x4) funnels

• 120 BPM

Options to all Patriot SF & Intrepid SF:

◊ Bottle cleaner

◊ Desiccant inserter (pouch, canister)

◊ Cotton inserter

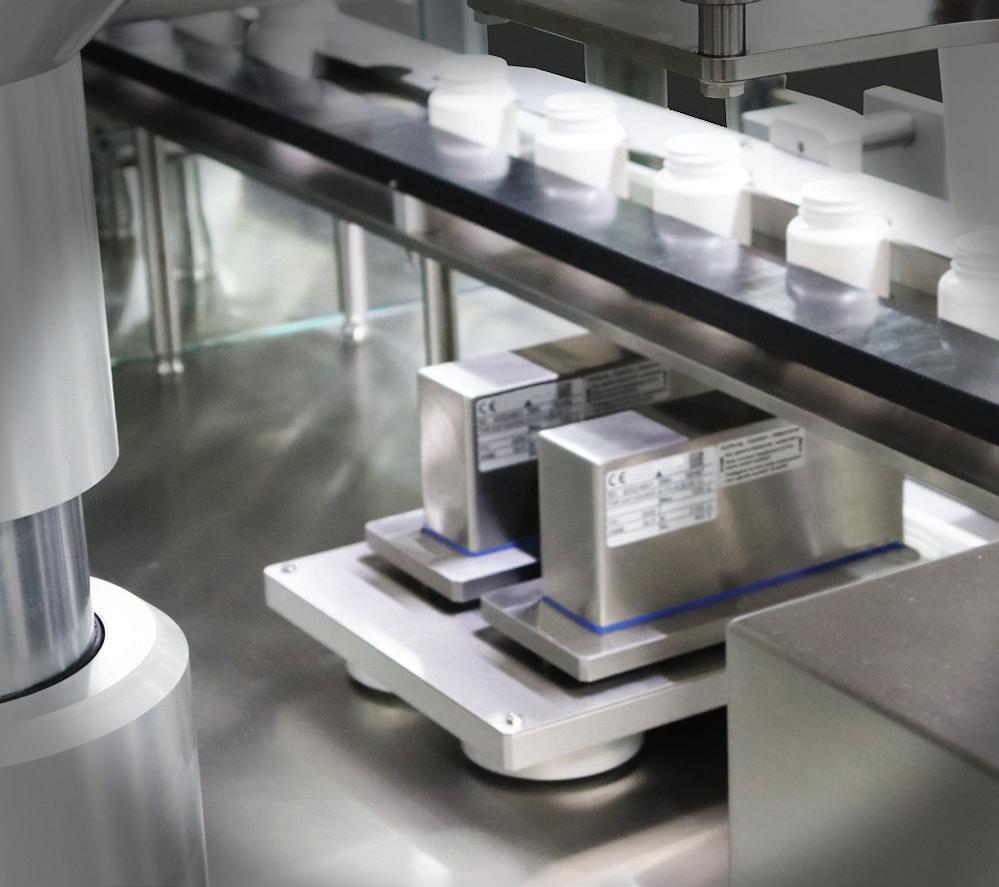

◊ Weight Check

◊ Induction sealing

◊ Torque feedback sensor

◊ Labeling

◊ Coding & vision inspections

◊ Metal detector

The STREET FIGHTER-100 (SF-100), is the pinnacle in tablet & capsule counting. Boasting the highest speed and accuracy within the smallest footprint.

Base Features:

• Handling five (x5) bottles at a time

• Servo-driven indexing feedscrew

• Servo-driven vacuum reject starwheel

• Euroguard system with tempered glass interlocked doors

• Fully integrated electrical cabinet

(Applicable to all Patriot SF & Intrepid SF Monoblocks)

SF-100 Counter:

• Twenty (x20) counting channels

• Five (x5) funnels

• 150 BPM

SF-100-IPC:

• In Process Checkweighing with data management

Additional Features:

• No air required for normal operations

• NEMA 4x electrical and HMI enclosures ensuring dust and liquid protection

• Color touch screen HMI

• Limited maintenance requirements

◊ Wipe down

The STREET FIGHTER SF-200 is a dual electronic counter, optimizing speed, accuracy, and versatility. Integrating two SF-100 modules, offering up to 300 BPM, ensuring high-speed performance in a unified design.

Base Features:

• Handling ten (x10) bottles at a time

• Servo-driven indexing feedscrew

• Servo-driven vacuum reject starwheel

• Integrated Design: Features motorized conveyor feeding systems linked to a single reject station

(Applicable to all Patriot SF & Intrepid SF Monoblocks)

SF-200 Counter:

• Forty (x40) counting channels

• Ten (x10) funnels

• 300 BPM

Additional Features:

• Tablet’s size:

◊ Ø2 mm to Ø22 mm

◊ Thickness: 3 mm to 22mm

◊ Length: 3mm to 25mm

• Capsule’s size:

◊ 5 to 000

◊ Thickness: 3 mm to 22mm

◊ Length: 3mm to 25mm

•

•

•

Advancing oncology product packaging while ensuring utmost safety, reliability, and state-of-the-art performances. One of the benefits of the Monoblock packaging solutions is the ability to be integrated with a RABS (Restricted Access Barrier Systems) enclosure.

This upgrade is used to not only protect the product from outside contamination but also to protect the operators from potent active pharmaceutical ingredients, which may adversely affect them.

Restricted Access Barrier Systems (RABS) are used to contain Active Pharmaceutical Ingredients (API). it protects operators from potentially harmful effects of the product and protects the products from exterior contaminants.

Countlab®’s advanced packaging solution offers a sealed, negative pressure environment for safely handling of potent APIs, ensuring maximum protection up to OEB Level 3.

Customizable Options:

• Tablet elevator

• Tablet/Capsule integrity inspection

• Metal detector

• In Process Check Weigher (IPC)

• Desiccant inserter (roll fed, individual sachet or canister)

(Applicable to all Patriot SF & Intrepid SF Monoblocks)

• Servo-driven capping with numerical feedback

• Vision inspection for cap and label integrity

• Industrial PC with data storage and management

• GAMP-style documentation is written internally

• Patriot SFX: Upgradable to the SF-1, allowing the packaging of tablets, but also liquid within the same platform

Storage and Transport

Countlab®’s solutions leave no place for guesswork; hence, it is a clean solution to organize all required contact and change parts.

Lift Fighter Pharmaceutical Grade Tablet / Capsule

Elevator

• No air requirement

• Magnetic lift

• Integrated Dust Collection

• Touchscreen control

Countlab®’s tablet vision inspection system is an advanced solution designed to detect discrepancies in tablets, ensuring only good product is packaged.

It identifies color, size, and broken tablets with precision.

Base Features:

• Designed to prevent cross-contamination

• Stand-alone / Easy to fit

• High-resolution color cameras

• Lighting system optimized to minimize reflections allowing the highest efficiency in defect detection

• Centralized reject bin / Reject confirmation

Another feature to alleviate your quality control department: IPC (In Process Check Weighing). Automatically calculate the bottle’s net weight. No need for a bulky external checkweigher providing gross weight.

100% Inspection of:

• Size

• Shape

• Damaged / Chipped / Cracks

• Color deviation

• Print / Embossed

Fully integrated inspection and reject. the solution ensure the end user’s safety and the integrity of the product being packaged. These metal detectors make compliance easier and detect metal less than 0.3 mm in diameter. The compact footprint and low-profile design enable it to seamlessly integrate with a robust, quality build for long-term reliability.

Strive for total control with limited operator intervention. Countlab® offers softwarebased solutions for storing and managing your crucial production information. While providing you with complete the audit trail meeting FDA regulation and complying with 21 CFR, Part 11.

Make sure your product is being packaged in a contaminant-free container. As you are unpacking your containers, particulates such as plastics, cardboard, or even wood can be introduced. Clean, ionized, compressed air filtered at 0.2UM will be pushed through the nozzles, removing static charge and contaminants to be recuperated by a heavy-duty aspirator in stainless steel with HEPA filter.

Utilizing a powerful knife to cut and not tear the material. Capable of handling natural cotton as well as synthetics (Polyester/ Rayon). Produces cotton length from 70 to 150 mm to be inserted in an inverted “ U ”, as recommended by cGMP for the Pharmaceutical industry to avoid loose filaments. Also capable of inserting multiple cotton strips as required, with insertion confirmation.

Your package would not be complete without identification. Product name, ingredients, how to use, logo, package date, expiration date, LOT number, bar codes and more can be printed/or pressure sensitive label can be applied; all within the Monoblock confinement. inkjet, thermal transfer, laser, or hot stamp, all with vision inspection are available options.

Protecting the end user is always in mind, hence the reason for having a properly sealed container off the shelf. No need for additional equipment or more floor space. Countlab® made sure to be able to integrate these solutions within our Monoblocks. Integrated induction seal head with Cap Retorque to avoid loosen Caps.

You also require desiccant to be incorporated within your package; Pouch on a roll, individual sachets, or canister, they all can be handled. Single or multiple packet insertion can be programmed into the recipe, with insertion confirmation.

Another quality control tool is making sure that each bottle gets the appropriate capping force. Record the information and monitor it over time to be pro-active instead of reactive to potential sealing issue.

Countlab® is continuously innovating.

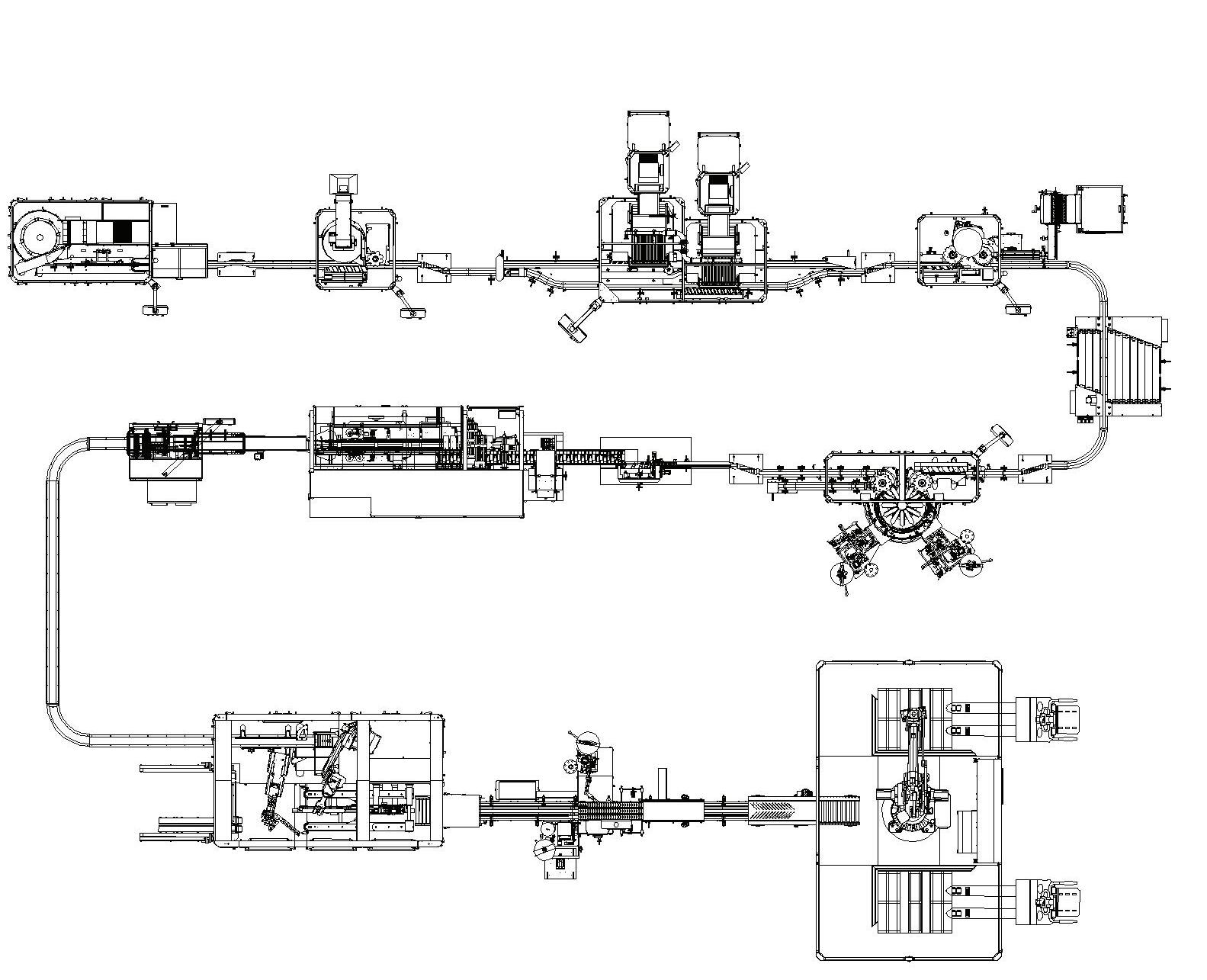

Now that the Patriot SF & the Intrepid SF are well-established Monoblock solutions on the market, be ready to be introduced to the Galaxy.

Harnessing the future with our robotic and chainless transport solutions – A fusion of cuttingedge technology, precision, and adaptability for unparalleled packaging prowess.

A perfect symbiosis between operators and automated equipment.

• Magnetic shuttle transport system

• Grouped or individually controllable shuttles

• Collision avoidance & precision shuttle control features

• Shuttle traceability at all times during operation

This all-in-one solution will provide you with the flexibility of processing various products within different sizes and shaped containers and output a final package containing bottles, leaflets, swabs, sticks, and more, all within the one enclosure.

Reach out to Countlab® to learn more about how the Galaxy can fit your production objectives.

Great for asynchronous conveyance, where filling, sealing, capping, labeling, inspections and other applications may have various processing times. The shuttles will be programmed to dwell for the required amount of time at each processing station or for operator interactions without ever worrying about the shuttles colliding or moving during a manual operation as they advance in or out of operations.

• Scalable modular system

• Low noise

• Low maintenance with very few moving parts

• Limited wear & tear

• Liquid, powder, and or tablet handling –Individually or combined

• Sealing, capping, labeling, ultrasonic welding, coding & verification

• Pick and place carton packing with leaflet or other odd component insertion

• Inspections (torque, weighing, vision)

• Assembly

The world of product transport has never seen flexibility like that offered by the Galaxy. Out of four basic elements, the Galaxy track configuration can morph into any shape and arrange any combination of open and closed track circuits to match the needs perfectly.

• Conceptual design with zero programming

• Accurate simulation and testing in 3D

• Shuttles can be equipped with

◊ Shelves

◊ Pucks

◊ Shuttle combination to act as a gripper

Countlab® will help users check the fundamental feasibilities, forecast throughput, and rule out potential hazards right from the start; By accurately simulating the entire track system in order to test and evaluate countless different layouts and scenarios to identify which configuration is the most efficient. The entire conceptual design will be completed in a single user-friendly tool without any programming. Once the configuration is complete, it can easily be exported to Automation Studio for further development.

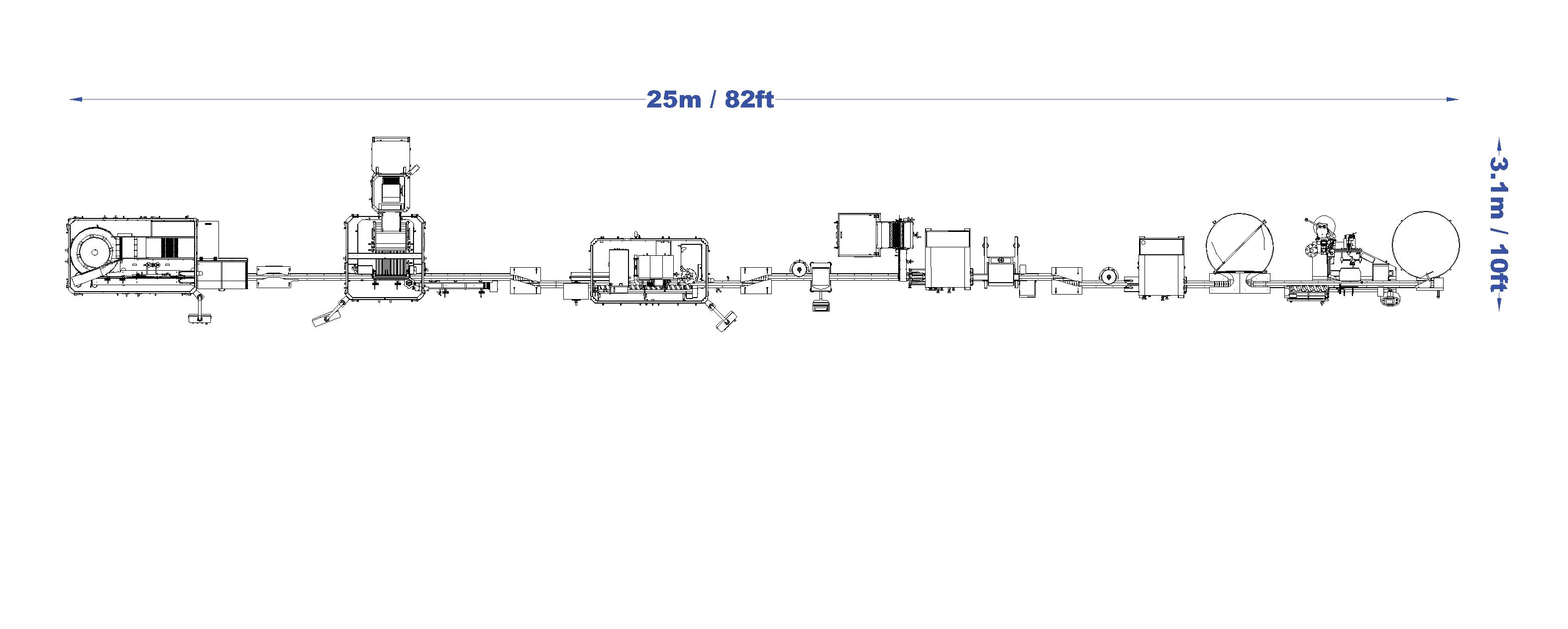

Streamlining processes with our line integration solutions –a harmonious blend of efficiency, connectivity, and seamless production flow. LINE SYNCHRONY