Since 1964, Capmatic has consistently innovated and made a strong impression. Introducing the next-generation Peristaltic Pump: Capmatic’s patented and trademarked SteelHeart®.

Like Countlab, LabelStar, CPM Innovations, WCM Manufacturing, Robotika, and SteelHeart® have been part of the Capmatic family since 2002, creating a vertically integrated engineering group focused on automated packaging machinery.

Capmatic’s SteelHeart® is celebrated for its flexibility, precision, and userfriendly operation. Its most sought-after feature is the disposable fluid path, designed to prevent cross-contamination. In auto-calibration mode, this system can periodically sample via the integrated load cell to automatically adjust the flow rate and volume of fluid, ensuring consistent filling accuracy and compensating for any deviations from the target weight.

Applications:

• Pharmaceutical and Diagnostic

• Life Science

• Personal Care and Cosmetic

• Food and Beverage

• Industrial and Chemical

Maximize your production capabilities with SteelHeart®— a state-of-the-art filling solution that redefines industry standards. For over 61 years, the Capmatic family has consistently provided excellence. Discover unparalleled efficiency, dependability, and top-notch product quality.

STEELHEART - SH 1

STEELHEART - SH 2

MICRO STEELHEART

STEELHEART PUMP CART

AXY

STEELFLOW IV BAGS

ROTARY BAMBINO

SYNERGY PATRIOT

SYNERGY INTREPID

CONQUEST PHARMA FCL - FPC

INTREPID FC 44 - 66 - 88

CONQUEST FPC & AC/DC

BCT PACKAGING LINE

ROAD RUNNER PL

FLOWSTAR

ROAD RUNNER

MONOSTAR PHARMA

ROBOFLEX TL

UNIQUE SOLUTIONS

BAMBINO - S

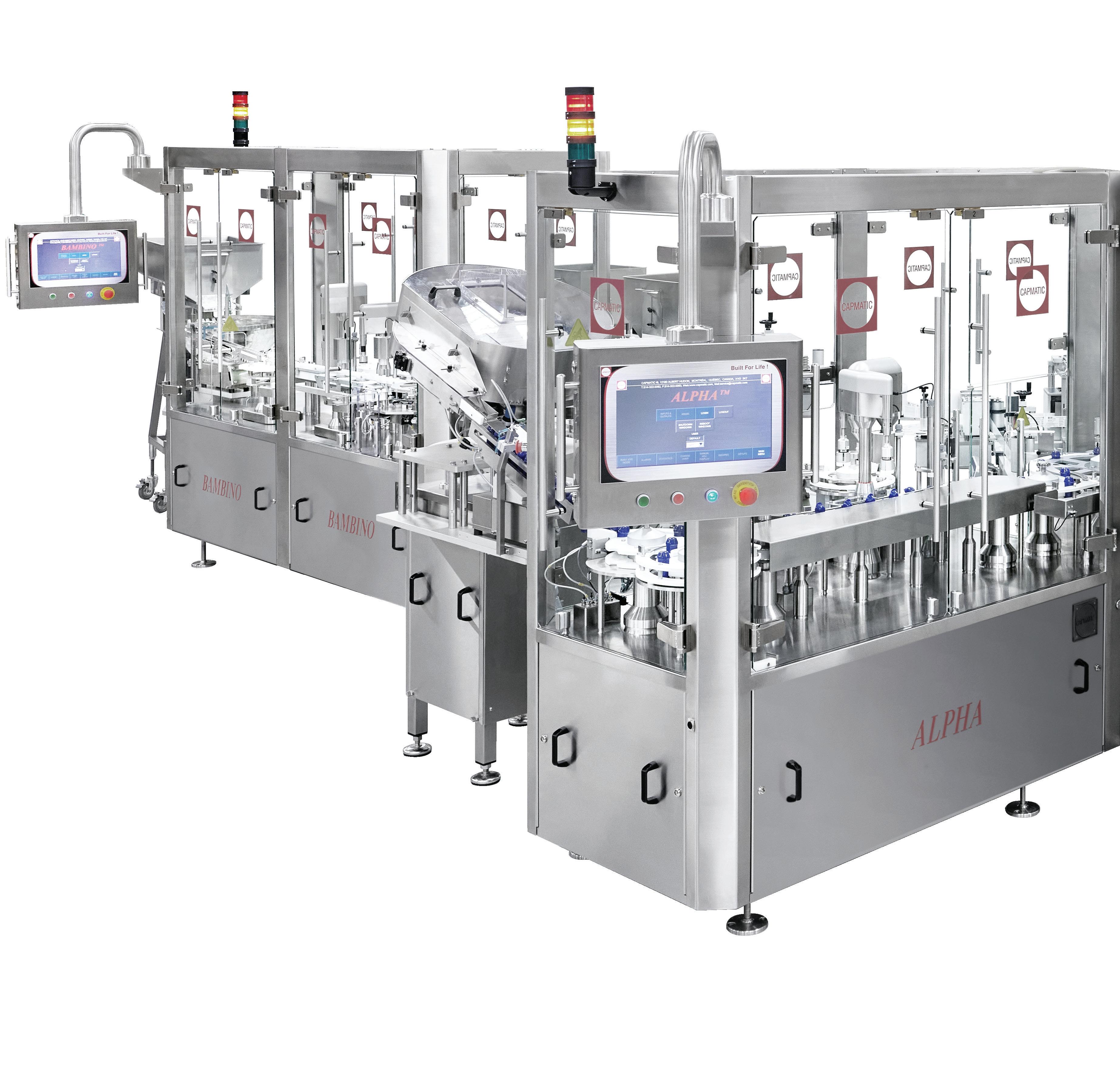

SYNERGY ALPHA

BANDSTAR

POWDER PATRIOT

COMPLETE BOTTLE FILLING LINE

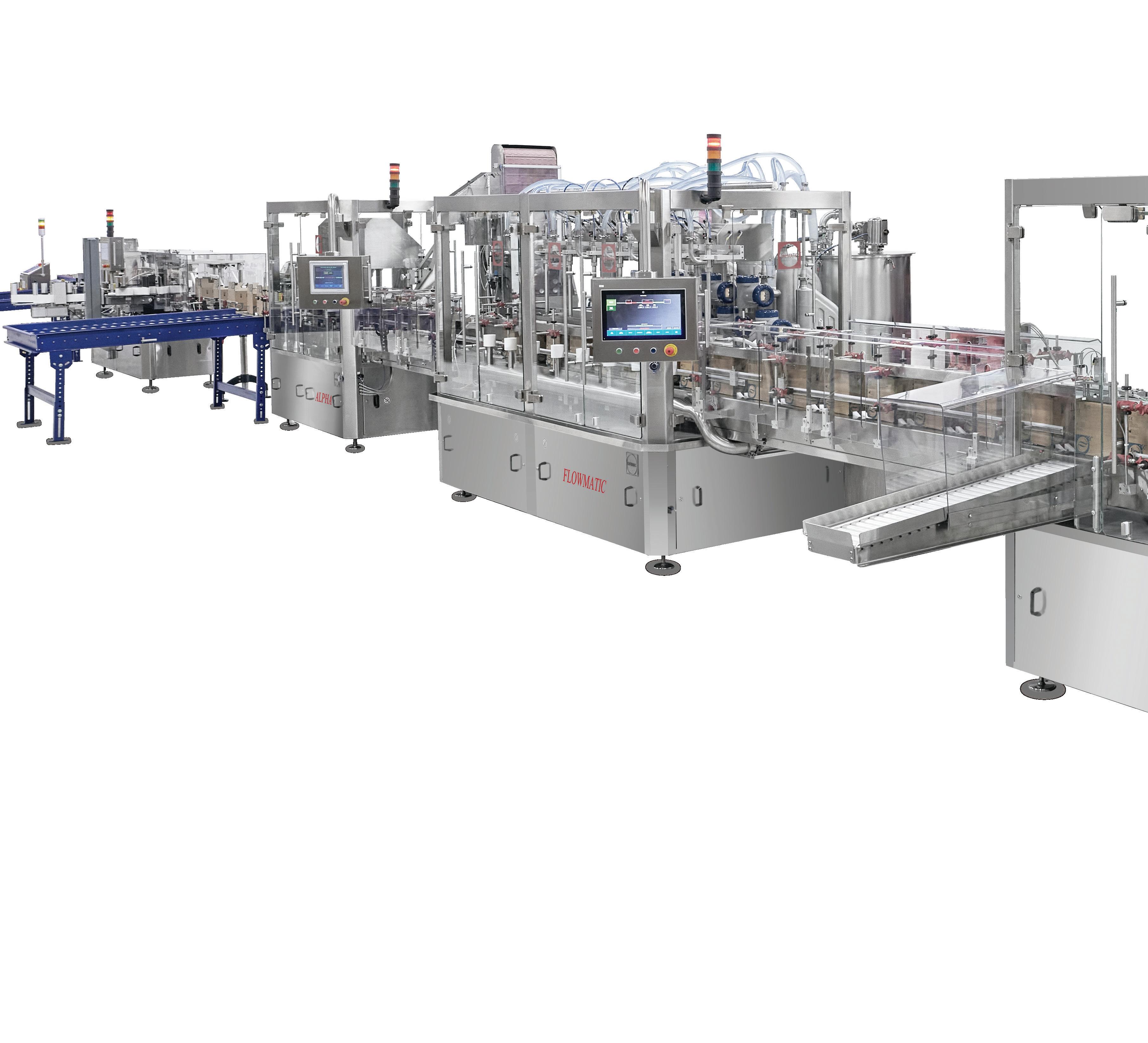

FLOWMATIC

BELTSTAR

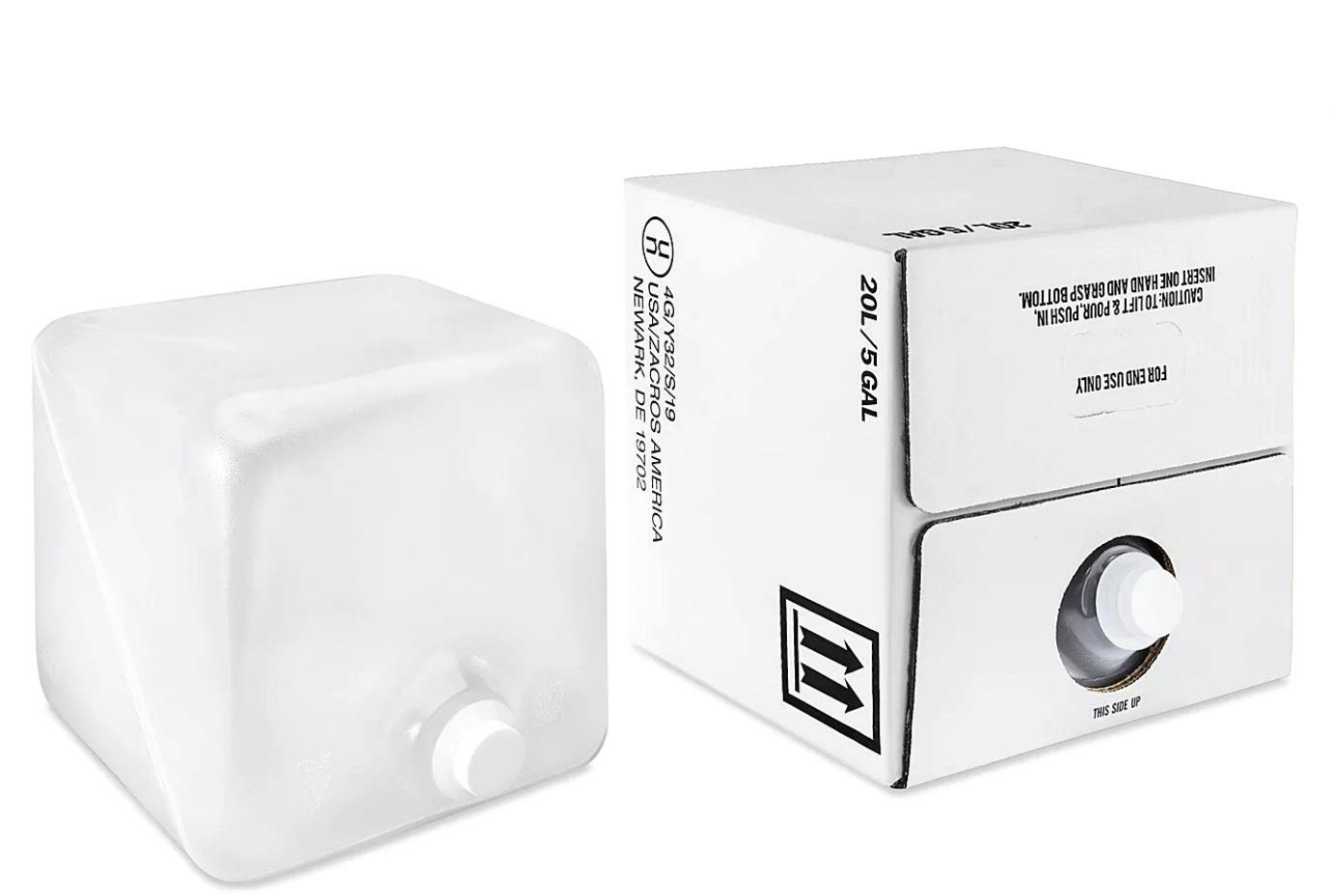

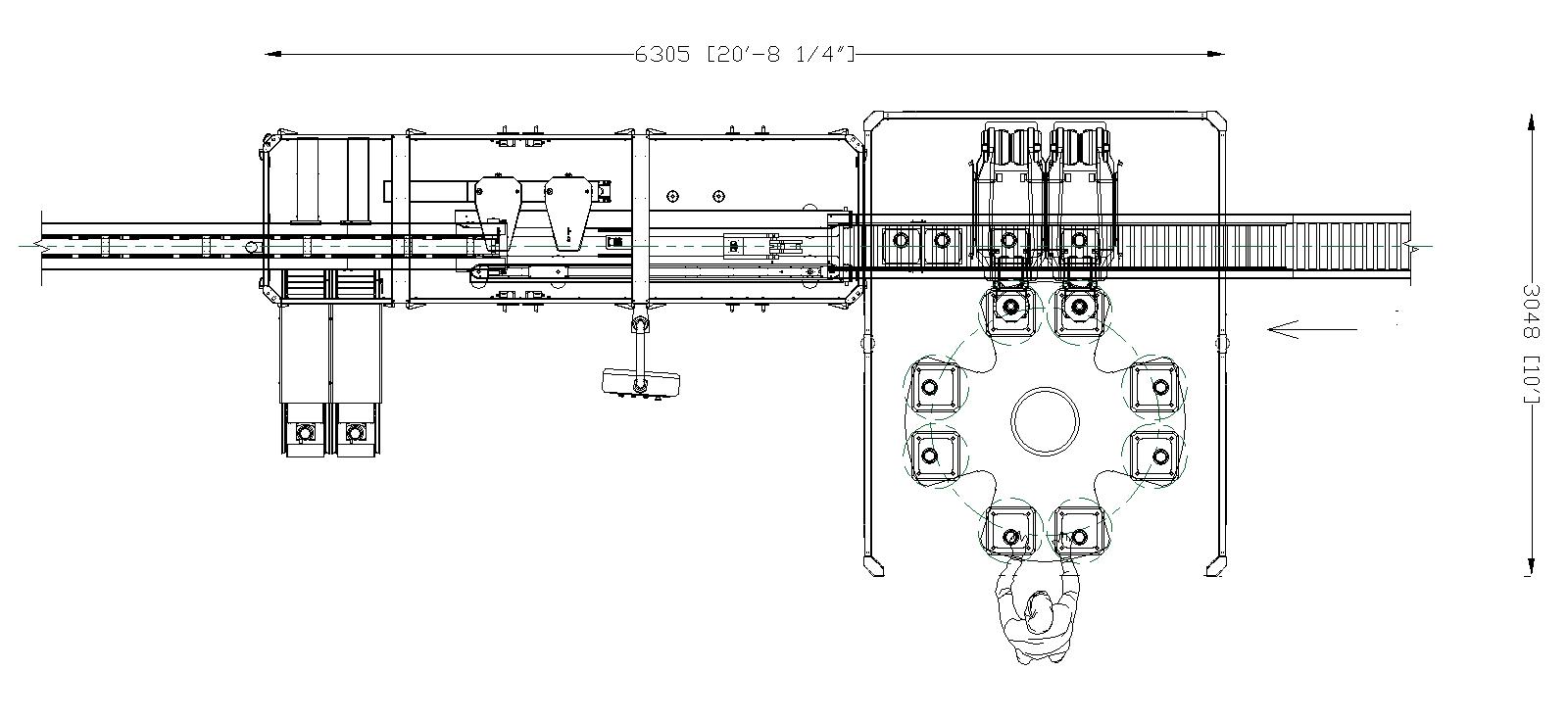

CUBITAINER PACKAGING LINE

ROBOFLEX - S

FLOWMATIC

ALPHA - X GALAXY

Line Integration

The SH-1 single-head peristaltic pump can be supplied as a stand-alone, semi-automatic tabletop filling unit or integrated into a fully automated packaging system.

Base Features:

• Hose sizes from 0.5 mm ID to 8 mm ID

• Recommended fill volume ranges from 1ml to 500ml

• Flow rates up to 4 liters/minute

Additional Features:

• User-Friendly Design: Designed ergonomically for ease of use.

• Fast Pump Access: Easy-release cover featuring a large grip.

• Cleanroom Prepared: Completely suited for sterile environments.

• Enhanced Safety: Pump functions are interlocked with cover.

• High Precision: Filling accuracy of ± 0.5% (application dependent).

• Rapid Pump Speed: Up to 650* RPM**.

• Adjustable Nozzle Positioning: Offers flexible freestanding design support.

• GMP & FDA Compliant.

*Speed and performance criteria are subject to testing with actual samples. **RPM = Rotation Per Minute

• Enhanced Operational Control:

◊ Industrial PC & Touchscreen HMI with secure user access and programmable recipes.

◊ Automated batch control (fill count & interval) set via HMI.

• Superior Product Handling & Accuracy:

◊ Servo-driven for precise and repeatable fills.

◊ Gentle on products: no significant shear forces due to dual offset rollers.

◊ Anti-drip “suck-back” feature ensures clean operation.

• Rapid Changeover & Flexibility:

◊ Quick product changeover (1 minute for a single-head machine).

◊ Supports various single-use tubing configurations, and multiple tubing materials/brands.

• Robust & Cleanroom Ready:

◊ Durable 316 stainless steel pump head and 304 stainless steel frame construction.

◊ Easy-to-clean design suitable for cleanroom environments.

◊ HMI or foot-pedal operation for flexibility.

These fills were using water at 20° C. The values shown are approximate as viscosity and the handling properties of the product e.g. foaming, splashing often dictate what rpm the pump is to run at.

These fills were using the “oversize” pump cap

The SH-2 dual-head peristaltic pump configuration retains all the features of the SH-1 and provides double the capabilities. It enables the operator to simultaneously manage two (2) containers from different product sources if needed.

Base Features:

• Versatile Design: Use as a standalone benchtop unit or integrate with gating systems and conveyors for full automation.

• Dual Head Power: Features two peristaltic pump heads (from the SH1 range), each delivering up to 4 L/min for high-performance throughput.

• Product Protection: Besides its no-cross-contamination feature, the SteelHeart® offers gentle filling with dual offset rollers, reducing pulsation and shear forces.

• User-Friendly Control: Adjust fills through HMI, which allows for simple automation of batch sizes and intervals.

SteelHeart Automation Kit

If you’ve outgrown your SH-2 and want to reduce operator involvement, there’s no need to purchase an entirely new system. Our Automation Kit Upgrade enables you to automate the feeding and filling of vials and bottles, and it includes the following features:

• Infeed & accumulation turntable.

• Programmable Logic Controller.

• Touch screen HMI with Ethernet connection.

• Motorized sanitary conveyor.

• Stainless steel base cabinet.

• Pneumatic gating system.

• Programmable servo driven bottom-up fill.

• Safety interlocked perimeter guarding.

Peristaltic Performance in Relation to Viscosity*

1000

Viscous products may perform satisfactorily by using increased bore size tubing and accepting less fill accuracy.

Capmatic’s Micro SteelHeart® (SH—Micro pump head) greatly improves your low-end fill range capabilities. It is designed for accurate dispensing in the 10-1,000 µL range, merging intelligent control algorithms with a user-friendly design.

Base Features:

• Same design and performance, but more compact.

• Hose diameters vary from 0.5 mm ID to 0.8 mm ID.

• Recommended fill volume ranges from 10 µl (0.01 ml) to 1,000 µl (1 ml).

Capmatic’s SteelHeart® Pump Cart is a portable, standalone dosing unit that’s compatible with existing equipment as well as our Capmatic base machines. The cart can accommodate 4 to 24 peristaltic pumps or volumetric pistons, all servo motor-driven and programmable via the cart’s HMI.

Base Features:

• From 1-24 SteelHeart Peristaltic pumps

• Programmable servo-driven pump system

• Stainless steel enclosure

• Equipped with wheels for mobility

• Compliant with cleanroom standards (ISO 5)

• HEPA-filtered laminar airflow for sample protection

Options:

• Auto-calibration using a connectable scale

• Automatic fill weight compensation

• Complete validation documents

• Dosing nozzles (lure fastening needle, plain tube, check valve, 316ss, plastic, etc.)

• Dosing tubes with a thickness of 2.4 mm and inner diameters of 0.5, 0.8, 1.6, 3.2, 4.8, 6.4, and 8 mm.

Monoblock or Inline filling system integration

Quickly Interchangeable Cart (featuring volumetric pistons, flowmeters or peristaltic pumps)

Capmatic’s Monoblock solution offers precise filling, capping, labeling, and automated handling for centrifuge micro-tubes used in medical, scientific, and industrial fields. It includes features for quality control and cleanroom options.

• Secure Handling: Ensures positive control for even the most unstable micro-tubes.

• Precision Filling: Accurate to 10 µL with automatic volume compensation. A non-metallic fluid path is available.

• Integrated Quality: Includes in-process check weighing for accurate fills.

• Reliable Capping: Offers precision capping with application force feedback.

• Comprehensive Labeling: Utilizes a distinct system featuring coding and inspection, encompassing 2D/3D barcodes.

• Automated Workflow: Employs robotic tray infeed and outfeed, eliminating the need for component changeover.

• Clean Environment: An optional laminar flow hood guarantees compliance with ISO 5 standards.

• Adaptable Design: Provides versatility and effortless portability.

Capmatic’s SteelFlow IV Bags is a compact, semi-automatic filling and closing machine designed for the precise and aseptic handling of flexible IV bags. This equipment eliminates inconsistent sealing and component jamming while simplifying cleaning and changeovers.

Base Features:

• Versatile: Capable of filling and sealing a wide range of bag sizes (50mL to 5L+), and accommodates various connector types and sealing methods like stopper, thermal, US, and RF.

• Precise: Achieve high-precision filling (±0.5%) using either a peristaltic pump or a mass flow meter.

• Efficient: Offers semi-automatic operation (manual loading, automated processing) with quick changeovers, leading to high output capabilities (up to 6,000 bags per hour).

• Compliant: Built with FDA-approved, aseptic-ready materials and adheres to stringent standards including GAMP5, UL/CE, and CFR 21 Part 11.

Additional Features:

• Compatible with all bag types (EVA, PVC, PP).

• Suitable for various connector types with multiple sealing options, including stopper insertion, thermal, ultrasonic, and radio frequency (RF) sealing.

• Suitable for bags with one or two open fill tubes sealed by the insertion of a stopper.

• Data storage & management

• Automated Loading

Flow metering Fill Volume Confirmation System

placing IV Bags into bag positioning grippers IV Bags grippers index to needle Filling Station

For more than 61 years, the Capmatic Rotary Bambino has offered a dependable automated solution for filling, plugging, capping, and labeling. This compact Monoblock, featuring rotary indexing, embraces the latest innovations. Furthermore, don’t hesitate to inquire about the linear Synergy Bambino for containment related applications.

• Consistent Product Handling: Servo-driven rotary system indexing.

• Single Index Precision.

• Customizable Filling: Standalone servo pumps (peristaltic/volumetric).

• Minimized Foaming: Programmable bottom-up filling.

• Multiple Closure Options: Supports orifice reducers and screw caps.

• Professional Labeling: Wrap-around application.

• Filling for Micro to Small Volumes: Ranges from 1µL to 200 mL capacity.

• Compact Design: Accommodates Ø25-50mm vials or bottles (up to 100mm).

• Efficient Production: Up to 40* BPM.

*Speed and performance criteria are subject to testing with actual samples. **BPM = Bottle(s) Per Minute

Capmatic’s Synergy Patriot is a streamlined, inline indexing rake packaging solution. Similar to the previous model, the Rotary Patriot, Synergy efficiently manages plastic or glass containers: it fills, plugs, caps/crimps, and labels, all within one containment area. This machine is perfectly designed for isolator and Rab integrations.

• Comprehensive Integrated Solution: Optimize your workflow by effectively managing filling, plugging, capping, and wrap-around labeling all within one platform.

• Servo-Driven Accuracy: Guarantees accurate operations with a complete servo-driven design and linear indexing system.

• Broad Versatility: Accommodates micro-volume filling (0.001 mL) up to 1 Liter, handling bottles/vials from Ø25mm to Ø95mm (up to 300mm high).

• Efficient Throughput: Delivers speeds up to 60*BPM.

*Speed and performance criteria are subject to testing with actual samples. **BPM = Bottle(s) Per Minute

Building on the proven success of the Synergy platform, the Synergy Intrepid effectively doubles your production capacity for filling, orifice reducer placement, and screw capping. It serves as a strong, high-speed solution for challenging pharmaceutical and industrial settings.

• Double Speed Performance: Reaches speeds of up to 120* BPM using an advanced, programmable servo-driven dual indexing system.

• Core Processing Power: Combines filling, orifice reducer placement, and screw capping, all utilizing established Synergy platform technologies. (Note: Labeling is handled externally to this Monoblock.)

• Containment-Focused Design: A favorite in the pharma/biotech markets, this system provides excellent containment capabilities for sensitive environments.

• Precision & Versatility: It accommodates a wide range of fill volumes (1 µL to 1,000 mL) and various container sizes from Ø25 mm to Ø85 mm, with heights up to 200 mm.

• Rugged & Compact: Engineered for continuous 24/7 use in cleanrooms or challenging industrial environments, this product boasts a sleek and compact design with an integrated electrical cabinet for easy installation.

*Speed and performance criteria are subject to testing with actual samples. **BPM = Bottle(s) Per Minute

Experience the exceptional speed and dependable handling with Capmatic Conquest Pharma. This fully servo-driven, continuous-motion rotary Monoblock is designed to efficiently process small, delicate components such as syringes and ampoules at extremely high speeds—ideal for demanding pharmaceutical, cosmetic, and food applications.

Base Features:

• Continuous Motion Speed: Achieve up to 300* BPM for maximum efficiency.

• Customizable Options: Adapt the system to suit your requirements by incorporating filling, plugging, capping, over-capping, and labeling stations within the Monoblock.

• Manages Unstable Components: It excels at processing small-format containers (Ø10-55mm, up to 150mm tall), including traditionally challenging items.

• Precise Dosing: This entirely servo-driven system provides options for peristaltic or volumetric piston pump (1µL —250mL) of liquids and semi-viscous materials.

• Proven Across Industries: Trusted technology for the pharmaceutical, cosmetic industries requiring speed and precision.

*Speed and performance criteria are subject to testing with actual samples. **BPM = Bottle(s) Per Minute

Meet demanding production targets with Capmatic’s Synergy Intrepid series. The INTREPID FC series by Capmatic is a compact, sequential inline system featuring the FC 44 indexing X4. It utilizes Synergy technologies for fast, efficient, and highly accurate product handling and processing, especially filling, making it particularly well-suited for Tare/Fill/Weight processes. It is specifically designed for production in ISO 5 clean room environments and IPC (Process Check Weighing/Inline Process Control).

Base Features:

• Available Configurations: Designed FC (44 – 66 – 88) / FPC (444 – 666 – 888)

• Optimized for Tare/Fill/Weight: Designed for applications requiring high filling precision, incorporating 100% IPC (Inline Process Control) as standard.

• High-Efficiency Inline Design: Process up to 250 units per minute*, indexing multiple components simultaneously.

• Servo-Driven Accuracy: Utilize a comprehensive servodriven system featuring a programmable filling station with bottom-up capability, adaptable to various dosing methods.

• Fast, Recipe Driven Changeovers: Switch formats quickly and precisely using pre-programmed recipes via the industrial PLC interface.

• Integrated Safety: Features a complete security perimeter with interlocked tempered glass doors for operator safety and process containment.

Powder

*Speed and performance criteria are subject to testing with actual samples. **BPM = Bottle(s) Per Minute

Get the positive handling and accuracy of the Conquest series in a high-speed linear platform. The Capmatic Linear Conquest (Conquest FPC) is designed for speed and precision in filling, fitment placement and capping operations.

Base Features:

• Continuous Motion Speed: Achieve up to 300* BPM for maximum efficiency.

• Flexible Configurations: Customize the system to meet your needs – integrate filling, plugging, capping, over-capping, and labeling stations within the Monoblock.

• Handles Unstable Components: Excels at processing small format containers (Ø25-55mm, up to 150mm height), including traditionally difficult formats.

• Accurate Dosing: A fully servo-driven platform that provides options for peristaltic, flowmeter, or volumetric piston pump, designed for liquids and semi-viscous materials products.

• Proven Across Industries: Dependable technology for pharmaceutical, cosmetic, and food applications that demand speed and precision.

*Speed and performance criteria are subject to testing with actual samples. **BPM = Bottle(s) Per Minute

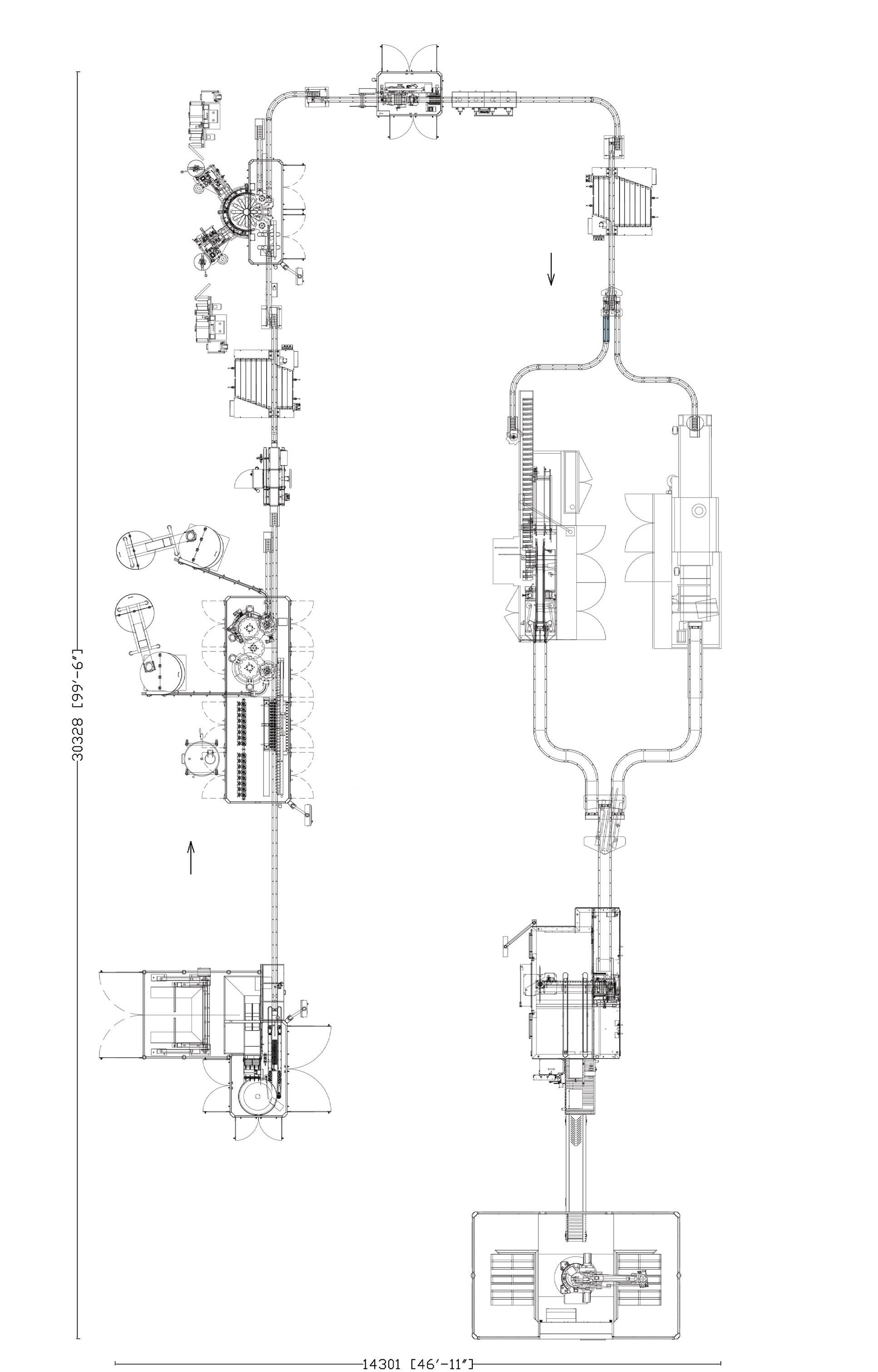

As your one-stop shop for automated packaging machinery, Capmatic provides complete, high-speed packaging lines specifically designed for the careful handling and processing of medical devices. Capmatic’s high-speed BCT (blood collection tube) assembly line utilizes our integration expertise to ensure seamless, damage-free handling of fragile glass tubes at speeds of up to 300* tubes per minute (18,000/hour).

Complete Line Solution Includes:

• Glass Tube Unloading & Puck Loading

• Precision Filling System

• Versatile Capping (Stoppers/Screw Caps for Vacuum/Non-Vacuum Tubes)

• Accurate Labeling System (with Print, Inspection)

• Automated Tray Loading System

Key Line Advantages:

• Comprehensive Inline Quality Control: This system includes various checks, such as detecting broken glass, verifying fill level and weight, checking cap presence and skew, monitoring vacuum level and torque, inspecting OCV and OCR prints, and ensuring the presence, skew, and inspection. Additionally, it features data management and storage, along with production reconciliation, to provide a comprehensive production report. Advanced Vacuum System: Ensures high-quality vacuum rates that are easily adjustable from the system’s HMI, complete with vacuum pressure monitoring and reject capabilities. Capmatic’s positive handling approach alleviates component damages, under/over fills, vacuum losses, and deficient label information and placement.

• Efficient & GMP Compliant: Designed for easy, safe operation, requiring only 2-3 operators. It’s built with high-quality stainless steel contact parts and a frame that meets stringent GMP standards.

*Speed and performance criteria are subject to testing with actual samples.

Address the challenge of loading unstable glass tube bundles with the Road Runner PL. Built on Capmatic’s renowned Road Runner High-Speed rotary system, the PL module is specifically designed to securely transfer tubes from shrink-wrapped bundles into stabilizing pucks at up to 300* BPM** speeds, preparing them for your downstream process needs.

Base Features:

• Secure Puck Loading: Designed to handle delicate glass tubes from bundles into pucks safely.

• High Throughput: Reaches speeds of up to 300* tubes per minute.

• Built-in Inspection: This system includes a vision system that detects damaged tubes, automatically rejecting them and confirming their status presence.

• Easy Input: Features a convenient area for operators to load unwrapped bundles, remove wrapping under laminar flow, for particulate control.

• Reliable Foundation: Employs the established engineering of the Road Runner continuous motion platform.

• Feeds Your Line: Efficiently prepares unstable tubes in pucks for subsequent filling and capping processes.

*Speed and performance criteria are subject to testing with actual samples. **BPM = Bottle(s) Per Minute

Experience high-speed, continuous motion filling without the complexities of rotary systems. The Capmatic FlowStar delivers speeds of up to 400* BPM** in a compact, linear format that is cost-effective, easy to maintain, and best suited for ISO 5 cleanroom processing. Its true strength lies in its ability to handle an exceptionally broad range of products, always with precision and speed.

Base Features:

• Fast & Efficient: Continuous motion design reaches speeds of up to 400* BPM**.

• Handles Difficult Products: Efficiently processes liquids, semi-viscous and viscous products, as well as formulations containing particulates or suspensions.

• Quick-Change Technology: Switch filling methods in under 30 minutes using dedicated carts (Volumetric Piston pump, Peristaltic Pump, Mass Flowmeter) and CIP capabilities.

• Smart Alternative to Rotary: Delivers high performance in a simpler, more streamlined, linear design, reducing maintenance and costs.

Liquid

*Speed and performance criteria are subject to testing with actual samples. **BPM = Bottle(s) Per Minute

For decades, the Road Runner has been a true staple in packaging, serving as the emblematic high-speed, continuous-motion rotary capping system. Trusted across industries, it offers unmatched versatility and proven reliability for virtually any capping application.

Base Features:

• Proven Performance: Decades of reliable performance delivering high-speed, continuous motion capping.

• Unmatched Cap Handling: Effectively manages a wide range of closure types:

◊ Press-on Caps & Dosage Cups

◊ Screw Caps (CT/CR)

◊ Pipettes, Flip Tops

◊ Lotion Dispensers, Pumps & Trigger Sprayers

◊ Delicate and complex cosmetic applications consist of pump crimp caps featuring decorative collars and over-caps.

• Precision Torque Application: Choose magnetic particle clutches or servo motors for precise and repeatable torque control, accurate to 0.5 in-lb.

• Flexible Configurations: With mechanical CAM or fully servo-driven systems, multi-turret options facilitate complex assemblies (cap/over cap, pump/collar, orifice reducer/cap, etc)

• Built to Last: Engineered for demanding, continuous operation in harsh environments.

High-precision Vacuum Capping System

Ensure accurate and compliant labeling at high speeds with the MonoStar Pharma. This continuous motion wrap-around labeler performs exceptionally well with unstable components such as glass tubes, glass or plastic syringes, and ampoules (from/to trays or bundles), achieving speeds of up to 600* BPM** and providing essential features for pharmaceutical production.

Base Features:

• High-Speed & Precise: The continuous motion platform provides wrap-around labeling at speed up to 600 BPM.

• Unstable Component Specialist: Expertly manages glass tubes, syringes, and ampoules while integrating with tray or bundle formats. Adaptable for stable containers via conveyor—see also Capmatic’s PharmaStar.

• Reliability Features: The automatic redundant labeling head eliminates the need for downtime related to label roll changes.

• Quality & Traceability: Includes integrated coding and print inspection (OCV-OCR), as well as a Faulty Label Reconciliation System (FLRS) to ensure label accountability.

*Speed and performance criteria are subject to testing with actual samples. **BPM = Bottle(s) Per Minute

Unlock the ultimate automation value with Capmatic’s RoboFlex. This versatile robotic system intelligently collates products and accurately performs pick-and-place loading. Designed for delicate pharmaceutical items, it is also perfectly suited for food, cosmetic, and industrial products. RoboFlex enhances efficiency and consistency across your packaging line.

Base Features:

• Fully Automated Collation & Packing: Effortlessly assembles and loads products into pucks, cases, trays, or cartons at speeds of up to 400* units per minute, minimizing manual labor.

• Versatile Product Handling: It effectively manages small, unstable, fragile, or aseptic products, as well as robust items. The flexible design accommodates various packaging sizes.

• Gentle & Precise Placement: Custom end-of-arm tooling, whether vacuum or mechanical, ensures product integrity during placement.

• Rapid, Tool-Less Changeovers: Reduce downtime with quick and easy, recipe-driven changeovers. It includes no-tool adjustments for essential components, such as the indexing belt and carton guides.

• Sanitary & Efficient Design: A rugged, sanitary frame with high floor clearance meets industry standards, offering increased uptime and low operating costs.

• Easy Operation & Integration: Simple HMI for operators; integrates easily with most flow-wrappers or other upstream and downstream equipment.

*Speed and performance criteria are subject to testing with actual samples.

Specializing in innovative packaging solutions for inhalers and uni - dose powder & liquid nasal spray.

Building on the proven legacy of Capmatic’s Bambino Monoblock series, the Bambino-S offers a uniquely tailored solution for the automated packaging and assembly of challenging products, such as inhalers of various shapes and sizes. This fully integrated system expertly combines our extensive expertise in handling small, unstable components, precise liquid and powder filling, advanced robotics, and seamless labeling with tamper-evident neck and body banding. Enjoy accurate coding and thorough in-line inspections at every stage. Discover how the compact Bambino-S can improve your production efficiency and quality across numerous applications.

Base Features:

• Delicate Sorting & Feeding: Ensures delicate and precise organization and feeding of diverse components through mechanical and vibratory sorting systems.

• Precise Component Transfer: Achieves precise indexing of components through a combination of linear and rotary servo-driven motion, enhanced by robotic pick-and-place technology for optimal positioning.

• GMP-Compliant Design: Features pharmaceutical-grade construction using only FDAapproved materials, simplifying cleaning and ensuring product purity.

• Comprehensive Quality Assurance: Integrates rigorous inspections at every stage, verifying component presence and integrity, filling accuracy (liquid/powder), torque/pressure, and label quality (coding, presence, skewness).

• Space-Optimized Efficiency: Maximizes production output within a minimal footprint, saving valuable floor space.

Capmatic’s Synergy Alpha, built on 61 years of automated packaging expertise, is now an advanced linear system for nasal spray assembly. It accurately orients and opens hinged containers to receive filled, capped, and labeled products from the Bambino-S, ensuring perfect final presentation and verifying product integrity before precise operation labeling.

Base Features:

• Accurate Hinged Container Feed: Mechanically sorts and supplies hinged containers for consistent processing.

• Synchronized Movement: Servo-driven star wheels and rakes guarantee a smooth and precise movement of containers.

• Consistent Orientation: Precisely aligns hinged containers for proper product insertion and labeling.

• Precise Container Opening: Opens hinged containers to prepare for seamless product insertion.

• Pre-Packaging Quality Check: Vision systems validate the integrity and presence of nasal spray assemblies.

• Gentle Product Placement: Robots precisely place the assembly into opened containers, minimizing damage.

• Secure, Damage-Free Closure: Closes containers securely, protecting the product quality.

• Precise Coding, Labeling & Final Check: Applies precise coding and labeling, followed by a final inspection for compliance.

• Careful Product Removal: Robotic systems carefully remove completed assemblies, preventing damage.

Hinged Cap Handling

The compact, modular BandStar provides essential tamper-evident neck banding and optional shrink-body labeling for automated packaging lines, such as inhaler assembly. It delivers a final, secure cosmetic package, ensuring end-user confidence. Its modular design seamlessly integrates into Capmatic lines, and even as a standalone unit, it has a small footprint with an integrated heat tunnel and enhanced safety features, including an automatic heat-tunnel lift during stops to prevent overheating.

Base Features:

• Robust and Sanitary Construction: Features an anodized aluminum frame fully clad in corrosionresistant 304 stainless steel for durability and easy cleaning.

• Optimized Heat Dissipation: Incorporates a lower stainless steel safety guard designed for efficient heat evacuation, ensuring operational stability.

• Comprehensive Operator Safety: Equipped with safety interlocks that protect personnel during startup and operations.

• Flexible Container Handling: Provides precise container indexing to the banding station via a pneumatic gating system or a servo-driven feed screw, adjustable for component stability and speed requirements.

• Fast and Easy Reel Changes: Includes a fast-loading, self-centering reel holder to minimize downtime.

• Controlled Film Unwinding: Includes a motorized unwinder for consistent and reliable film feeding.

• Rapid and Repeatable Changeovers: Enables quick, tool-free, recipe-based modifications for efficient production transitions.

• Precise Film Feeding: Uses feeding belts powered by two stepper motors for precise and programmable film lengths at high speeds.

• Scalable Production: Available in configurations that support speeds of up to 300* BPM** and accommodate components up to Ø200 mm.

*Speed and performance criteria are subject to testing with actual samples. **BPM = Bottle(s) Per Minute

Precision Powder Filling Elevated: Introducing the Rotary Patriot. Building on Capmatic’s industry-proven Patriot platform, this advanced Monoblock system delivers exceptional accuracy and speed for pharmaceutical and biotech powder filling. While inherently versatile, it adeptly handles liquids, tablets, and capsules, excelling in precise, low-volume powder applications. The Rotary Patriot, an upgrade from the Bambino series, accommodates larger containers and higher throughput.

Core Features:

• Single-index, servo-driven rotary dial or star wheel.

• Servo-driven nozzle bar for programmable bottom-up filling.

• Servo-driven fitting and cap placement with feedback.

• Wrap-around labeling with integrated coding and inspection.

• Integrating Capmatic’s NanoStar for micro-dosing powders.

• Integration of Capmatic’s PowderStar for higher powder volumes.

Additional Options:

• Bottle cleaning using vacuum particulate removal.

• Nitrogen purging to enhance shelf life.

• Automated sorting and feeding of small components.

• Comprehensive inline inspections.

Capmatic’s FlowMatic Combo integrates gravity, pressure, and flow-metering filling technologies into one versatile platform. It transitions seamlessly between methods to accommodate any product and container type. Gravity filling is best for low-viscosity and foamy liquids, while pressure filling works exceptionally well with semi-viscous products at higher speeds.

Base Features:

• 4 to 16 filling stations

• 100 mL to 10 liters fill volume

• Time or volumetric-based filling

• Stainless steel construction

• Drip recuperation & neck centering

• Programmable servo-driven bottom-up filling

• No moving parts, smooth fluid path for easy CIP

• Low maintenance operation

• Suitable for Hazardous Locations

Like any Capmatic automated packaging solution, this system is designed for the pharmaceutical market. Completely covered in stainless steel and featuring no sharp edges or 90-degree angles, it ensures ease of thorough sanitation, which is crucial in this field as DNA, RNA, and corrosion pose significant contamination risk concerns.

Mass-Metering and Over-Flow Filling Solution

Capmatic’s BeltStar utilizes a belt system instead of spindles, offering significantly improved cap control while applying torque and lowering reject rates at speeds of up to 300* BPM**. Take advantage of its versatility and quick changeover capabilities.

Base Features:

• Stainless steel construction.

• Enhanced belt-tightening control compared to standard spindles.

• Programmable electronic torque control via the HMI.

• Automatic recipe driven change-overs.

• Available torque feedback sensor.

BeltStar-R:

Capmatic’s BeltStar Retorquer will deliver precise application torque after manual cap placement or following induction treatment with maximum confidence in your removal torque requirements.

*Speed and performance criteria are subject to testing with actual samples. **BPM = Bottle(s) Per Minute

Our comprehensive line handles over 10 liters of reagent packaging, including Cubitainer box/bag assembly (with insufflator), controlled infeed, mass flow metering filling, servo capping, front and back label application (with print), box closing and sealing, palletizing, and integrated data management. Capmatic solutions are guaranteed to maintain chemical reagents’ accuracy, purity, and stability.

Under the Capmatic Robotika division, the RoboFlex can also be customized for specific applications, such as the Cubitainer infeed system. This solution is part of Capmatic’s reagent packaging line, allowing the automatic feeding of Cubitainer boxes into the filling and packaging line.

Base Features:

• Automated servo-driven infeed side belts.

• Photo eye sensors for the automatic cubitainer indexing.

• Robotic pick-and-place to accurately position the Cubitainer neck in its guides.

• Vision system for precise Cubitainer positioning.

• Vision inspection of box integrity with automatic reject conveyor.

• Quick, tool-free, and recipe-driven changeovers

• Automatic changeover between formats with no extra components required.

• Optional case erector-feeder.

• Optional automatic bag loading and insufflator.

Based on the Coriolis principle, this operational mode will allow for the most accurate fill volumes. Furthermore, when in flow - metering production mode, the system will continuously monitor the product:

• Mass

• Volume

• Density

• Temperature Base Features:

• 4 to 16 filling stations.

• 100 ml to 10 liters.

• Volumetric-based filling.

• Stainless steel construction.

• Drip recuperation & neck centering.

• Programmable servo-driven bottom-up filling profile.

• No moving part with smooth fluid path for easy and thorough CIP.

• Features an unobstructed, open-flow design without moving parts, resulting in a lowmaintenance operation.

• Suitable for hazardous locations.

Mass Flow Meter Filling

Suitable for:

• Liquids

• Oils

• Homogeneous Suspensions and Slurries

All material making product contact are:

• 316L Stainless Steel

• EPDM

• PVC

• Tygon

• Buna

• Viton

• Nylon

Programmable Bottom - up Filling Profile

Introducing the latest evolution in high-volume capping: Capmatic’s Alpha-X System. Building on the proven reliability and operator-friendly design of our acclaimed Alpha-C, the Alpha-X is specifically engineered to accommodate a significantly expanded range of container sizes while retaining the core features you’ve come to appreciate: our efficient CapSort Elevator, precise servo-torque application with real-time feedback, and the remarkable benefit of minimal to no change parts required for different cap and bottle formats. This drastically reduces downtime and operational costs, allowing quicker product changeovers and increased overall efficiency.

Base Features:

• Expanded Container Handling: The Alpha X is designed to accommodate larger containers, ranging from [Ø100mm] to [Ø500mm] in diameter and up to 500mm in height, opening up new possibilities for packaging a wider variety of products.

• Intelligent Torque Control: Our field-proven servo-driven capping chucks deliver precise and consistent torque application, ensuring optimal sealing integrity for even the most sensitive products. The integrated feedback system continuously monitors and adjusts torque in real-time, guaranteeing quality and minimizing the risk of damage.

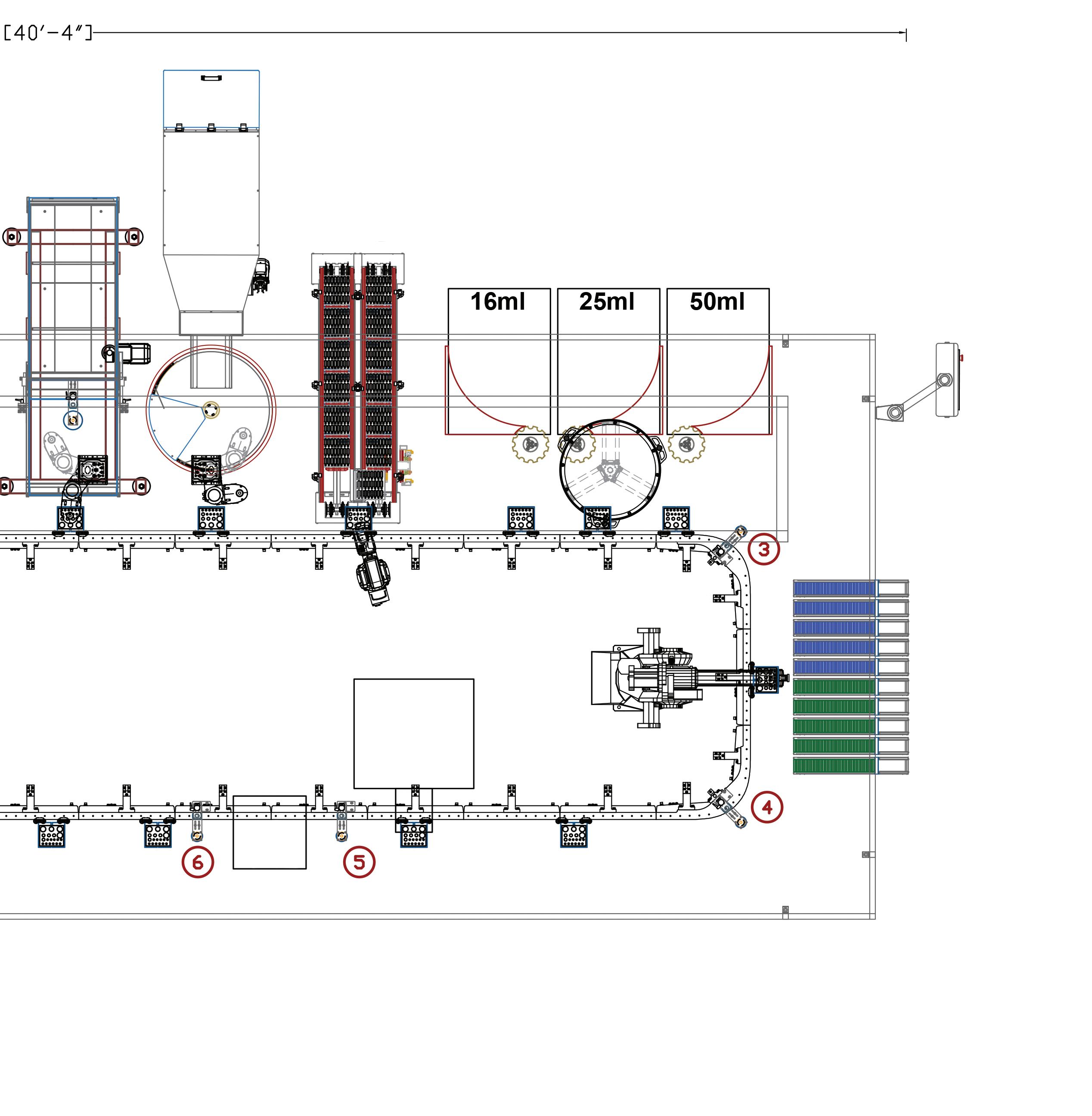

Step into a new era of production flexibility with Capmatic’s Galaxy, a revolutionary automation platform that seamlessly integrates a wide range of processes within a single, intelligent system. Powered by cutting-edge magnetic shuttle transport technology, Galaxy is the ultimate all-in-one solution for your most complex automation needs, covering everything from intricate kit assembly to multi-component packaging.

• Unrivaled Process Integration: Effortlessly combines various operations, including box forming, tray and robotic handling, liquid and powder filling, tablet counting, capping and labeling, advanced vision inspection, and product weighing.

• Ideal for Complex Assemblies: This is ideal for variety packs, assay kits, multi-component box/ tray loading (e.g., bottles, leaflets, swabs), and the gentle handling of delicate or unstable items like ampoules and syringes.

• Intelligent Magnetic Shuttle Transport:

◊ Achieve precise control with individually programmable shuttles for speed, position, and acceleration, effectively eliminating spills.

◊ Benefit from integrated collision avoidance, automatic queuing, and complete shuttle traceability to enhance operational safety and control.

◊ Enable optimized production flow through synchronous or asynchronous movement and variable pitch capabilities to accommodate varying process times

• High Performance & Scalability: Experience a high payload capacity of up to 10 kg per shuttle, modular scalability for future growth, high-speed potential, and low-maintenance operation.

Box forming: Bottles, vials, micro-tubes, micro-plates, leaflets, blisters, syringes, and Ampoules.

Counting

Weighing Station

FOLDED BOX MAGAZINES

OUTFEED & REJECT CONVEYORS

FOLDED CARDBOARD

TRAY MAGAZINES

NEEDLE BLISTER MAGAZINES

VIAL & TUBE FEED CONVEYORS

TRAY FORMING STATION

BOX FORMING STATION

INTELLIGENT RECIPE HMI

SYRINGE FEED ELEVATORS

ODD SHAPE COMPONENT FEEDING

BOX CLOSING STATION

AMPOULE TRAY INFEED & RETURN

SECONDARY HMI

LEAFLET FOLDING MACHINE

MICRO-WELD PLATE & BLISTER PICK & PLACE STATION

MICRO-WELD PLATE MAGAZINES

BLISTER MAGAZINES

1. Box inspection- Presence & Skew

2. Cardboard tray inspection

3. Bottle/ Vial/Syringe inspection & count with Artificial Intelligence camera

4. Microplate and Blisters presence

5. Leaflet presence

6. Box closure confirmation

7. Label inspection - presence & skew

HIGH-SPEED LABELER WITH REDUNDANT HEAD

VACUUM STOPPER INSERTION MACHINE

ROBOFLEX DE-PUCKING / TRAY LOADING MACHINE

INLINE CONTINUOUS MOTION FILLING MACHINE

TUBE FEEDING AND PUCK LOADING MACHINE

WALK-THROUGH OVERHEAD PUCK RETURN CONVEYOR

RTS PHARMA DUAL LABELER SLEEVESTAR BANDER & SHRINK TUNNEL BI-FLOW TABLE

CHECKWEIGHER AND BI-FLOW TABLE

CONQUEST FPC 16/12/12 FILL-PLUG-CAP MONOBLOCK

PRODUCTION FLOW

SORTSTAR BOTTLE UNSCRAMBLER WITH AUTOMATIC PALLET LIFT AND TILT SYSTEM

PRODUCTION FLOW