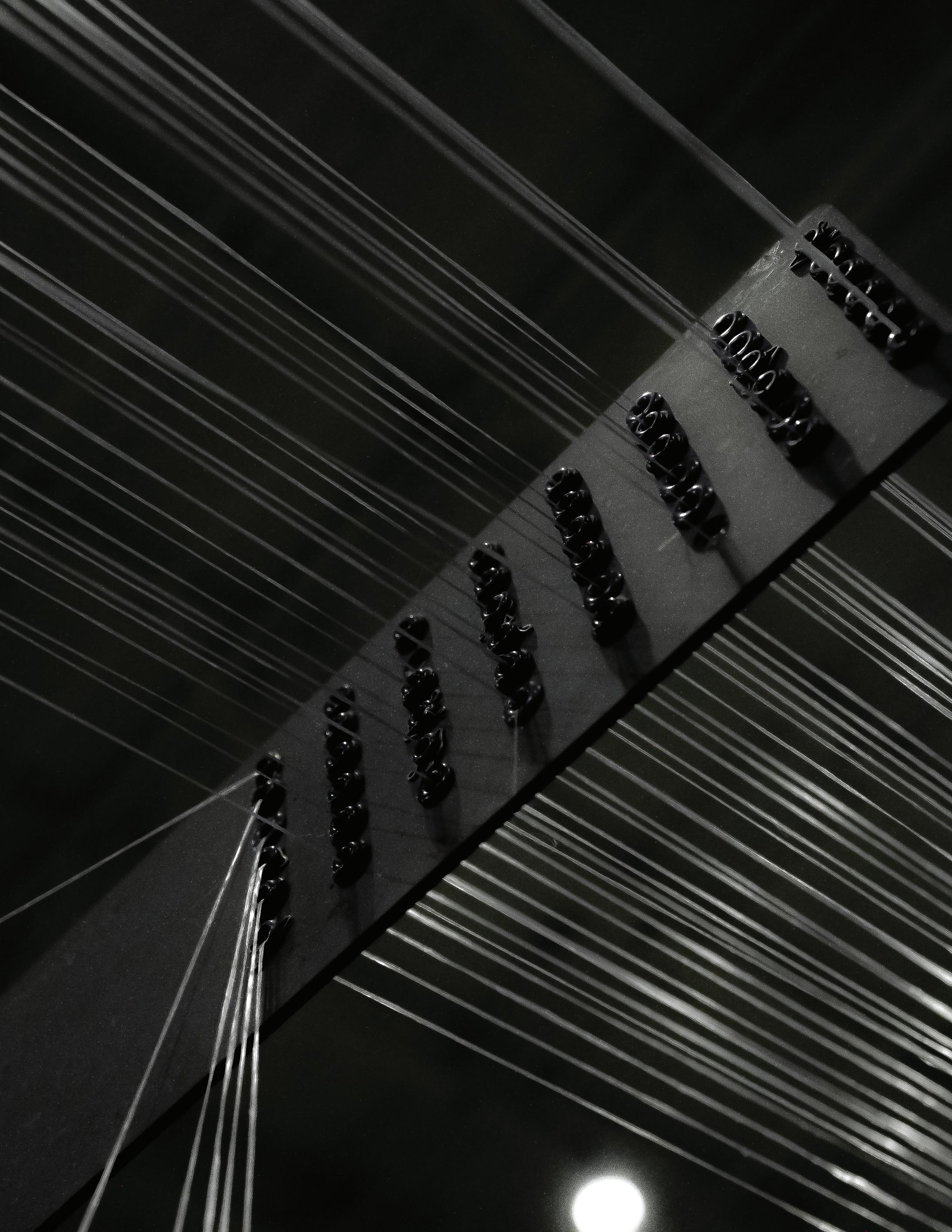

It’s the foundation of the strongest conveyor belt you’ve ever used.

At Fenner Dunlop, our domestic manufacturing model ensures that everything from weaving and treating the fabric and finishing the final belt is done close to our customers.

Fenner Dunlop’s Weaving and Treating Facility in Lavonia, Georgia, USA

Tough Belts For Tough Applications For industrial and mining conveyor belt sales, call: 1-(800)-661-2358. www.fennerdunlopamericas.com

CHAIRMAN'S LETTER

Forecasting the unpredictable: Why people, not models, drive our economy

PRESIDENT & CEO MESSAGE

The economy in crosscurrents

FEATURE STORY

Building California’s Future: UNACEM North America and Tehachapi Cement’s Commitment

ADVOCACY

CalCIMA goes to Washington D.C. for Hill Day

ECONOMY

County of San Bernardino showcases the value of mining at 2025 State of the County Address

TRANSPORTATION

The future of transportation funding in California

LEGISLATIVE

Building with Resilience: Legislative update and looking ahead

PROJECT HIGHLIGHT

CalPortland delivers the concrete backbone for LA County Museum of Art David Geffen Galleries

LEGISLATIVE

Federal mineral funding in 2025: Streamlined processes signal major critical mineral infrastructure investment wave

TECHNOLOGY

Leadership in the age of A.I.

NATIONAL ASSOCIATION NEWS

CalCIMA

455 Capitol Mall, Suite 210 Sacramento, CA 95814 (916) 554-1000 www.calcima.org www.distancematters.org

Publisher

Desirea Haggard, P.E., VP of Sustainability and Environmental, UNACEM North America

Fatima Castro Hidalgo, Strategic Communication, Reputation, Digital Marketing, Grupo

Matt Hinck, VP, State Government Affairs, CalPortland

Charley Rea, Vice President of Policy & Communications, CalCIMA

Cameron Richardson, Director of Technical Affairs, CalCIMA

Kerry Shapiro, Partner, JMBM LLP

Julia Sobrevilla, Director of Corporate Affairs and Sustainability,

Erik Turner, Director of Legislative Affairs, CalCIMA

Martin Willoughby, CEO, Command Alkon

The Conveyor is published quarterly each year by Construction Marketing Services, LLC

All rights reserved. Reproduction in whole or in part without permission is prohibited.

In my years navigating the construction industry, I’ve noticed meteorologists consistently outperform economists at their predictive craft. This isn't for lack of rigor—economics majors wrestle with calculus, linear algebra, game theory, and econometrics that would challenge any aspiring oracle.

Yet despite this mathematical arsenal, economic predictions remain about as reliable as forecasting afternoon weather on a Rocky Mountain ridgeline. The comparison is instructive: Mountain weather contends with elevation changes, the Continental Divide's topography, and competing Pacific and Gulf moisture streams. But at least atmospheric physics follows consistent laws. The economy? It pivots on the whims of human psychology and collective decision-making—forces that make mountain weather patterns look predictable by comparison.

Need evidence? Cast your mind back to 2005, when economists declared a California housing bubble “geographically impossible.” That pronouncement spoiled faster than milk in a Central Valley heat wave. Throughout my career, the profession's crystal ball has consistently clouded before tech booms, tech busts, housing crashes, bond defaults, and pandemic-driven inflation spikes.

This issue of The Conveyor examines economic trends, and while I’ve learned to regard econometric models with the same skepticism I reserve for fortune cookies, these projections serve a purpose: They force us to consider change and prepare for multiple scenarios. My economics training taught me one reliable principle—brace for the unpredictable surges and retreats of human behavior that drive market cycles.

One forecast I'll stake my reputation on: People remain the economy’s foundation. They produce, consume, innovate, and their employment levels signal economic health more reliably than any algorithm. Our industry benefits from exceptional people who generate economic value daily. This issue is full of many examples.

This fall, as the Concrete Industry Management program at CSU Chico marks two decades of preparing young professionals for our sector, I'm encouraged by the renewed commitments from individuals, companies and associations to sustain this pipeline. We may lack crystal balls for divining economic futures, but investing in emerging talent—like CIM's graduates—will prove essential regardless of which economic road we travel. n

Dana Davis President - Teichert Materials CalCIMA Chairman

As our Chair noted in this issue, one of the few certainties about the economy is its unpredictability. Forecasts can miss the mark, but what remains constant is the need for people— and for the essential minerals and materials they rely on. For CalCIMA members, that reality has been especially clear this year, as our markets have faced both opportunity and challenge.

On the construction side, the picture is more sobering. Single family housing starts are down, weighed down by regulatory barriers, affordability pressures, and an uncertain investment climate. We are hopeful that CEQA reforms passed by the legislature may spur housing starts in the coming year. Fortunately multi-family is up. Public works should be a steady foundation for the economy but it is a constant battle to keep state and federal transportation dollars invested in traditional repairing and building the miles of infrastructure Californians desperately need. At the federal level, ongoing budget fights and the threat of shutdowns add to the instability.

Sacramento labeled 2025 the “year of affordability,” yet nearly every significant bill increased costs for businesses and families. CalCIMA fought back—and delivered results. A key success was to create stable funding for rail, transit, and other alternative transportation through the re-worked Cap-and-Trade/Capand-Invest program; thus, potentially, alleviating pressure to fund those modes through more traditional transportation funding sources. We also continue to support Assemblywoman Lori Wilson’s leadership in advancing a serious dialogue about the long-term sustainability of California’s transportation funding model. Without

durable solutions, the state’s infrastructure backbone remains at risk.

Demand for essential and industrial minerals continues to grow, driven by high-tech manufacturing, renewable energy, and advanced storage systems. From aggregates and cement to rare earths and precious metals, these materials are critical to batteries, semiconductors, and clean energy technologies. This demand is fueling investment and new opportunities—particularly in Southern California mining operations—and underscores that our industry is not just part of California’s past, but indispensable to its future economy.

The Federal Reserve’s recent interest rate cuts are no panacea, but they are already encouraging new investment. Confidence is just as important as capital, and both will be needed to stabilize housing, sustain public works, and unlock the potential of new mineral markets.

As CalCIMA’s chair highlights in his column, people remain the foundation of our economy. For our industry, that means both the workforce that drives daily operations and the communities that rely on us. California cannot build homes, schools, roads, or clean energy infrastructure without the minerals and materials our members provide.

Amid chaos and conflict, regardless of economic fluctuations, our industry remains essential. CalCIMA will keep pressing for stable policies, fair funding, and recognition of the critical role you play. Together—with resilience and optimism—we will keep California moving forward. n

Sincerely,

Robert Dugan President/CEO CalCIMA

By Desirea Haggard, P.E., Vice President of Sustainability and Environmental, Fatima Castro Hidalgo, Strategic Communication, Reputation, Digital Marketing and Julia Sobrevilla, Director of Corporate Affairs and Sustainability

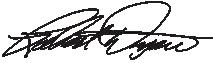

Left: One of UNACEM North

Above: Safety is a core value of

defined

California has long been one of the most important markets for cement and mineral production in the country. Meeting demand for public infrastructure, housing, and private development projects requires strong industry players willing to invest for the long term. Into this scenario comes Grupo UNACEM, a centuryold Peruvian industrial leader, making a bold commitment to the U.S. through its subsidiary, UNACEM North America. With integrated operations in Arizona and California, the company is expanding its cement capacity and expanding its footprint in the Southwest.

Grupo UNACEM is a multinational industrial group with operations in Peru, Ecuador, Chile, Colombia, and the United States. More than a century ago, it set out on a path driven by the effort and vision of people who understood, from the

very beginning, that cement was more than just a material for building structures — it would become one of the driving forces of development, shaping the future. Since then, the group has become a regional leader, with a diversified portfolio in cement, concrete, energy, and related services. Today, Grupo UNACEM has an annual production capacity of 12.5 million tons of cement, 5.5 million m³ of concrete, 652 MW energy and 9.7 million tons of aggregates.

In 2023, Grupo UNACEM proudly announced the integration of Tehachapi Cement, LLC into its portfolio, marking a transformative milestone for one of California’s most historic industrial facilities. This move underscores how international players are investing in California’s long-term growth.

The U.S. market is not new for Grupo UNACEM. Back in 2011, the company inaugurated Drake Cement

LLC, located in Yavapai County in Central Arizona. The plant started with a production capacity of approximately 600,000 short tons of clinker and 624,000 short tons of cement per year, representing the group’s first major U.S. investment. Today, Drake Cement has a capacity of 1 million short tons of cement per year and continues to expand the company’s presence.

In April 2024, Grupo UNACEM consolidated operations in the U.S. as UNACEM North America, and through the integration of its Drake Cement and Tehachapi Cement plants, the company is strengthening its management presence in the Southwest. This transformation enables operations under a unified identity while reaffirming its purpose: “Together we grow to build a sustainable world.”

“Today, we are building an integrated, multi-state operation rooted in a unified culture and positioned for sustainable growth,” said Rafael Villalona, CEO of UNACEM North America. “As we expand our footprint, we look forward to serving a broader market across Arizona, California, and Nevada.”

The Tehachapi cement plant acquisition significantly expanded Grupo UNACEM’s production footprint in Southern California, nearly doubling its capacity and reinforcing its strategic commitment to sustainable growth in key markets. Originally constructed in 1908 to support the Los Angeles aqueduct project, the Tehachapi cement plant has long stood as a cornerstone of the region’s infrastructure, supplying high-quality Type II/V Portland cement to projects across the Southwest. With its deep roots in the Tehachapi Valley—an area known for its beauty, seasonal climate, and rich Native American heritage—the plant now enters a new era of innovation, sustainability, and expanded market reach under the new leadership.

The facility is expected to produce approximately 1.1 million tons of cement annually, supporting critical infrastructure projects throughout California and neighboring states. This output will be bolstered by a suite of upgrades, including advanced data analytics, automation, and digital tools designed to optimize production workflows, reduce waste, and enhance operational efficiency.

Grupo UNACEM’s vision for UNACEM North America and Tehachapi Cement is anchored in three core pillars: Sustainability, safety, and community. The company has pledged to achieve carbon neutrality across all its operations by 2050, and the Tehachapi facility will play a key role in that journey. Investments in energy-efficient technologies, alternative fuels -such as pistachio shells used as biomass to replace 7% of fossil fuels- and emissions reduction strategies are already underway, positioning the plant as a model for environmentally responsible manufacturing.

Safety remains a top priority. Enhanced protocols and training programs are being implemented to protect employees, contractors, and visitors through the Life First program, Grupo UNACEM’s corporate safety program.

Grupo UNACEM fosters a culture of respect, accountability, and continuous improvement, empowering every team member to contribute to a safe and productive work environment. Equally important is the plant’s relationship with the local community. Tehachapi Cement has long been a source of employment and economic stability in Kern County, and Grupo UNACEM is committed to strengthening those ties through expanded outreach initiatives, educational partnerships, and support for local infrastructure projects that benefit residents and businesses alike.

The integration of Tehachapi Cement into Grupo UNACEM is a strategic investment in cultural stewardship, environmental leadership, and forward-thinking innovation. As the plant enters its next century of operation, it does so with a renewed sense of purpose: Honoring its roots while embracing the possibilities of tomorrow. With a legacy built on resilience and a future shaped by global expertise, Tehachapi Cement is poised to remain a vital force in the region’s industrial and environmental landscape for generations to come. n

At G3 Equipment AC Specialists, we provide expert AC repair services for commercial fleets. Our skilled technicians ensure your systems operate safely and efficiently— keeping your vehicles running smoothly and your drivers safe and comfortable.

RED DOT Roof Top

Air Central

Mobile AC Hoses

By Cameron Richardson, Director of Technical Affairs, CalCIMA

Nearly 350 people with a passion for the construction materials industry made their way to Washington, D.C. to advocate on behalf of themselves and their companies this past September for Hill Day.

Coordinated by the National Stone Sand and Gravel (NSSGA), National Asphalt Pavement Association (NAPA), and the National Ready Mix Concrete Association (NRMCA), the three associations prepared members with the how-to and the know-how of what the issues are and how to best convey our collective concerns and desires to lawmakers. Members met with lawmakers from both the U.S. House of Representatives and the U.S. Senate.

The California contingent was scheduled to have 24 meetings with lawmakers from districts throughout the state. As a full group, we were able to meet with the offices of both U.S. Senators Adam Schiff and Alex Padilla before we broke into regional groups. The goal was to have company representatives meet with congressional offices in whose districts they have operations. These were key messages:

• Supporting and adopting a comprehensive transportation reauthorization bill prior to expiration of the current authorization in September 2026; indexing revenue appropriately to let transportation projects plan

for the future of California; and retaining the 80:20 ratio for revenue investment between highway and transit.

• Supporting comprehensive permitting reform for transportation projects, by supporting the SPEED Act. It will provide more firm guidelines on the National Environmental Policy Act, Endangered Species Act, and Clean Water Act and reduce the potential for litigation that delays transportation projects.

• Supporting workforce development funding, including allowing Pell Grants to be used for trade schools and skilled workforce

readiness programs, and immigration reform to provide more employment-based visas.

• Maintaining materials neutrality. In other words, let the engineers and experts decide what materials are best for each project based on performance backed research, which allows for innovation and cost effectiveness.

CalCIMA companies in attendance included Granite Construction, Teichert Materials, Vulcan Materials Company, Holliday Rock Co. Inc., and George Reed / Reed Family Companies. Each company divided personnel into three groups to

represent Northern, Central, and Southern California.

As my first time attending this event, I was thoroughly impressed by the united front and collaboration demonstrated by the three associations. Seeing leaders from aggregates, asphalt, and concrete come together with one voice highlighted the strength of the construction materials industry when it speaks collectively. What struck me most was how the surface infrastructure sector remains one of the few issues that still can generate genuine bipartisan support within the Federal Government.

Regardless of political affiliation, there is a shared understanding that maintaining and improving

our nation’s infrastructure is not just a matter of politics, it is fundamental to safety, commerce, and economic competitiveness. Roads, bridges, ports, are the foundation of how people travel to work, how goods reach markets, and how services are delivered to communities across the nation.

Investing in infrastructure is, at its core, about ensuring reliability, efficiency, and opportunity for future generations. It is encouraging to see that, despite the political divides that often dominate headlines, there is still broad agreement that keeping America’s transportation network strong is a responsibility we all share.

Robert Dugan, President and CEO of the California Construction and Industrial Materials Association (CalCIMA) was a featured speaker at San Bernardino County’s 2025 State of the County Address to highlight economic contributions from the County's mining sector and mining’s integral role in building California’s future. Dugan was joined by Supervisor Dawn Rowe, who conducted a live on-stage interview highlighting the importance of mining to local

communities, infrastructure, and economic development.

In his remarks, Dugan emphasized that the CalCIMA member companies provide the essential materials and minerals that literally build California, from roads, bridges, and schools to homes, from renewable energy infrastructure to consumer and national security equipment.

“Our communities, economy, and environment depend on us,” Dugan said. He closed his remarks with a powerful statement that resonated with the audience: “If it’s

built, County of San Bernardino is in it.”

This message captured the enduring truth that mineral resources are woven into every aspect of daily life from concrete sidewalks to wind turbine foundations and that responsible producers play a vital role in balancing growth, sustainability, and local prosperity.

A county rich in mineral heritage Mining has long been part of the County of San Bernardino identity and prosperity. The county is widely

recognized as the most mineral-rich county in California, with resources ranging from aggregates, limestone, and rare earth elements to cement, clay, and decorative stone.

These materials have shaped the communities and quality of life of Southern California and continue to provide the foundation for economic growth across the state. From the limestone quarries near Lucerne Valley to the aggregate, asphalt, and concrete plants in the Inland Empire, and the critical mineral mines deep in the desert, County of San Bernardino’s mineral producers are cornerstones of modern infrastructure and community development.

The county’s leadership has consistently demonstrated an understanding of this value. During the State of the County address, Supervisor Paul Cook debuted a powerful video highlighting the mining industry’s contributions to

the region. The short film ‘Mining: Building the Future’ celebrated the people who extract, process, and deliver the materials that sustain California’s progress. The video underscored not only the importance of mining operations but also the industry’s commitment to safety, stewardship, and community partnership.

Dugan’s participation in the State of the County event reinforced the strong collaboration between local government and industry. Under the leadership of Supervisors Paul Cook and Dawn Rowe, County of San Bernardino continues to acknowledge mining’s central role in supporting jobs, infrastructure, and sustainability goals.

Mining and construction materials producers contribute

thousands of high-quality jobs, sustain billions in regional economic output, and support the development of renewable energy, housing, and transportation projects that benefit the broader Southern California region.

As Dugan noted, every road paved, school built, and hospital expanded in County of San Bernardino bears the imprint of its local mineral producers.

Through partnerships like these, the County of San Bernardino continues to honor its heritage while building the foundation for a resilient, sustainable, and prosperous future. n Scan

• NRMCC leads in sustainability by fully adopting Type 1L cement and introducing our Type 1T cement (LC3) the first in the Western U.S. with nearly 40% lower GWP than the OPC national average.

• Utilizing Type 1L (HS) low carbon cement to reduce embodied carbon and CO2 emissions.

• Providing innovative, high performance mix designs with third party verified Environmental Product Declarations (EPDs) available with every mix.

• Incorporating a large fleet of bulk material haulers (aggregate and cement) and concrete mixers that run on renewable natural gas RNG, reducing GHG emissions.

• Technically advanced, high production facilities providing superior quality and service throughout Los Angeles, Orange and Ventura Counties.

nrmcc.com

By Erik Turner, Director of Legislative Affairs, CalCIMA

This past October, Assemblymember Lori D. Wilson (D-Suisun City), Chair of the Assembly Transportation Committee, brought together regional leaders, transportation officials, and state analysts at the Solano County Transportation Authority to discuss the future of transportation funding in California. CalCIMA attended the discussion, applauding Wilson’s leadership on this critical issue and highlighting the importance of establishing a reliable, long-term infrastructure investment for the state’s transportation infrastructure that connects communities and drives our economy.

The town hall was the second in a statewide series of regional town halls Wilson is hosting, designed to gather input and educate communities on sustainable and equitable solutions for funding California’s roads, bridges, and transit systems. The discussion centered on a growing fiscal challenge: According to the California Transportation Commission (CTC), the state will lose a projected $31 billion in transportation funding over the next decade because more fuel efficient and zero-emission vehicles do not pay their fair share of fuel related taxes.

“Transportation is essential for public safety and economic opportunity for millions of Californians,” Assemblymember Wilson said. “I am very grateful to my neighbors here in Solano County who shared their thoughts and priorities. As always, I look forward to sharing the unique perspectives of the communities in my district with my colleagues in Sacramento.”

“Drivers of fuel-efficient vehicles, hybrids, and EVs pay little or nothing toward road maintenance, even though they use the same infrastructure,” said Kiana Valentine, executive director of Transportation California. “We are grateful for Assemblymember Wilson’s leadership on this difficult issue so that we can find modern funding solutions that are fair, balanced, and equitable and keep Californians moving for generations to come."

California’s transportation system is funded primarily through federal and state excise taxes on gasoline and diesel, commercial vehicle weight fees, and vehicle registration surcharges. Nearly three-quarters of this revenue depends on fuel sales. While that structure has sustained the system for decades, the rise of electric vehicles and higher fuel efficiency have steadily eroded revenues.

Currently, drivers pay a base state excise tax of 61.2 cents per gallon on gasoline and 46.6 cents on diesel, in addition to federal taxes. But as motorists buy less fuel, revenues decline—even as maintenance and construction costs rise.

Enacted in 2017, Senate Bill 1 (the Road Repair and Accountability Act) remains a cornerstone of California’s transportation funding framework, generating about $5.2 billion per year for maintenance and improvement projects. Since 2020, nearly $365 million in SB 1 funds have been invested in Solano County alone, supporting key projects such as the I-80

Express Lanes, Westbound I-80 Truck Scales, and SR-37 corridor improvements. These investments demonstrate how SB 1 has delivered real benefits for mobility, freight movement, and economic resilience.

Yet SB 1’s structure is also tied to fuel consumption, and revenues are projected to decline. Without a new approach, future projects— such as the $196 million SR-113 corridor improvements in Dixon— may face funding uncertainty.

At the town hall, the Legislative Analyst’s Office (LAO) outlined several policy options to address the long-term funding gap. Each approach carries trade-offs:

• Increase existing fuel taxes or vehicle fees, which is simple to administer but increasingly unsustainable.

• Shift transportation costs to other fund sources, such as the General Fund, which risks crowding out other priorities.

• Reduce or reprioritize spending, which would defer needed maintenance and increase future costs.

• Introduce new user-based charges, including per-mile road charges or taxes on alternative fuels such as electricity and hydrogen.

The “user-pays” principle— linking costs to road usage—was widely discussed as the most equitable and durable option, though implementation challenges remain significant.

By Erik Turner, Director of Legislative Affairs, CalCIMA

California stands at a defining moment for how it builds, rebuilds, and plans for the future. The wildfires of recent years—and the devastation of 2025 in Southern California— underscore the need for stronger, safer, and smarter construction. Against this backdrop, CalCIMA formed a coalition and launched the Building with Resilience initiative, promoting fire-resistant and non-combustible materials as central to the state’s climate adaptation strategy.

CalCIMA co-sponsored Senate Resolution (SR) 61, authored by Senator Sasha Renée Pérez and co-authored by Senator Ben Allen – both representatives in the state senate for the areas affected by the LA wildfires – with the California Nevada Cement Association (CNCA). SR 61 calls for the adoption of resilient construction practices, including the use of noncombustible materials, and urges relevant agencies to evaluate opportunities to strengthen resiliency, support innovation, and reflect best practices in fire- and climate-adaptive construction.

Broader wildfire legislation this year—such as AB 1 (Connolly) and SB 616 (Rubio)—signals growing state commitment to community hardening, insurance reform, and the integration of wildfire mitigation into planning and building practices. Together, these bills reflect a policy shift toward prevention through design, rewarding construction choices that reduce risk before disaster strikes.

CalCIMA recently joined legislators, staff, and fire safety officials for a live burn demonstration hosted by CAL FIRE’s Office of the State Fire Marshal and the Insurance Institute for Business & Home Safety (IBHS) in Sacramento. The demonstration featured two structures: One built with traditional combustible materials and another built to Wildfire Prepared Home standards using ignition-resistant components. As flames spread rapidly through vegetation, wood fencing, and furniture surrounding the untreated structure, the hardened structure—with Zone 0 defensible space and noncombustible materials—remained intact. This powerful visual confirmed what data already show: construction choices determine survival.

The California Board of Forestry and Fire Protection is finalizing new Zone 0 defensible space rules pursuant to Public Resources Code 4291. The draft regulations, released in August 2025, define how property owners must manage vegetation and materials within five feet of structures.

Recent rulemaking documents (September 2025) outline inspection protocols, compliance timelines, and guidance for both homeowners and local governments. The rules are designed to:

• Eliminate combustible materials adjacent to structures

• Promote ignition-resistant construction

• Improve inspection consistency across high fire hazard zones; Complement home hardening requirements in Chapter 7A of the California Building Code.

CalCIMA supports these measures as a necessary framework for integrating materialsbased mitigation into California’s broader wildfire resilience strategy. Concrete, aggregates, and masonry not only resist ignition but also create defensible space features— driveways, patios, retaining walls, and foundations—that slow or stop advancing flames.

At CalCIMA’s 2025 Education Conference, this effort will be further highlighted during a building with resilience panel. The panel will convene experts in engineering, policy, insurance, and construction to discuss practical steps for building safer communities. Panelists will

California’s trajectory is clear: We must build better and smarter, not just build more and not just rebuild the same as before.

Through SB 61, CalCIMA is helping write resilience into statewide policy. With AB 1 and SB 616, the Legislature is signaling that mitigation, material standards, and insurance policy must evolve together. We cannot continue rebuilding the same way and expect a different outcome.

explore fire-resistant construction techniques, home hardening, and Zone 0 defensible space—the 0–5 foot zone around a structure where flammable materials must be eliminated. Discussion will also address how regulatory agencies, insurers, and local governments can collaborate to scale these practices statewide.

Through advocacy, education, and partnership, CalCIMA is ensuring that California not only recovers from disasters but rebuilds in ways that reduce future risk. Building with Resilience is more than an initiative—it is a long-term commitment to a safer, stronger California. n

By Erik Turner, Director of Legislative Affairs, CalCIMA and Matt Hinck, VP, State Government Affairs, CalPortland

The Los Angeles County Museum of Art (LACMA) is in the midst of a major transformation with the construction of the David Geffen Galleries. CalCIMA member company CalPortland, through its subsidiary Catalina Pacific, was central to the material delivery and execution of LACMA’s new David Geffen Galleries. The company supplied more than 87,000 cubic yards of concrete, from the building’s deep foundation systems to its dramatic 80-foot cantilevers. This included 1,717 cubic yards of custom decorative topping slabs for the interiors and 5,740 cubic yards of decorative hardscape surrounding the structure. CalPortland’s work provided the material backbone that enabled the ambitious design to span Wilshire Boulevard and rise as one of the most complex cultural projects in the United States.

The museum’s transformation represents an unprecedented architectural and engineering achievement. Substantially completed in late 2024, the $700-million project is now in the art installation phase, with phased public access beginning in summer 2025 and an official opening set for April 2026. When open, the David Geffen Galleries will encompass approximately 350,000 square feet, including 110,000 square feet of gallery space, making LACMA the largest museum in the Western United States and home to more than 150,000 works spanning 6,000 years of history.

"It is an honor to be part of this historic project. For generations, CalPortland employees can be proud of the part they took in building this iconic museum that will be visited by millions," said Eric DeCrescenzo, Sales Manager at CalPortland

The structural system reflects the scale of CalPortland’s contribution. The project required 1,500 vibro-piers, 1,500 piles driven 120 feet deep, and 450 helical piles, along with 15,000 tons of reinforcing steel and 360 miles of post-tension cable. To address seismic safety, 56 base isolators—16 weighing 7,500 pounds and 40 weighing 50,000 pounds—allow the building to move up to five feet in any direction during a major earthquake. The exterior envelope incorporates 243 glass panels on the exhibition level and 73 at ground level.

The project also targets LEED Gold certification, underscoring CalPortland’s role not only in structural performance but also in sustainability. The company supplied mixes with 15–30 percent cement replacement using fly ash and incorporated high quality aggregates to lower cement demand. These measures significantly reduced embodied carbon while maintaining design strength. Additionally, Catalina Pacific operates a renewable natural gas–powered truck fleet, cutting greenhouse gas emissions

by over 70 percent and nitrogen oxides by more than 90 percent compared to diesel.

Designed by renowned Swiss architect Peter Zumthor, the David Geffen Galleries replaces four aging structures with a single fluid form, characterized by its concrete and glass façade and its elevated span across Wilshire Boulevard. Interior images highlight how light

Left: Interior view showcasing LACMA’s curved concrete structure and expansive glazing crafted with CalPortland materials.

Right: Aerial view of LACMA’s new David Geffen Galleries, built with 87,000 cubic yards of CalPortland concrete spanning Wilshire Boulevard.

floods the expansive gallery floor, where sculpture, ceramics, and large-format works will benefit from natural illumination. Sensitive artworks will be shown in interior chapels designed with controlled light conditions.

When the David Geffen Galleries open in April 2026, they will feature new theaters, classrooms, dining, and retail

spaces alongside 110,000 square feet of gallery space. Just as importantly, the project will stand as a testament to how CalCIMA members like CalPortland deliver both the scale and the sustainability demanded by California’s most iconic cultural institutions. n

The federal government has restructured its approach to critical mineral funding in 2025, moving from a fragmented, agency-by-agency system to an integrated framework that promises to accelerate approvals and reduce administrative barriers. With nearly $2 billion available across multiple agencies, this transformation reflects a strategic recognition that domestic mineral security requires coordinated federal action rather than competing bureaucratic silos.

The Department of Energy leads this effort with nearly $1 billion in proposed funding opportunities, including a flagship Battery Materials Processing program offering up to $500 million for critical mineral processing facilities. The Department of Defense continues strategic investments through Defense Production Act awards, including recent commitments of $24.8 million to Perpetua Resources for antimony development and $150 million in loans to MP Materials for rare earth processing capabilities.

The cornerstone of this new approach is the June presidential memorandum mandating federal agencies to share information regarding funding applications and eliminate duplicative processes. The memorandum specifically addresses the burden placed on applicants who previously faced requirements to complete multiple, complex, and substantially similar applications while agencies redundantly conducted substantially the same diligence.

The most significant procedural change is the development of a common application system that allows simultaneous submissions to multiple federal programs. This represents a shift from the traditional approach where applicants navigated separate funding applications for each agency, often requiring different formats, timelines, and documentation standards.

This federal policy shift extends beyond funding applications to fundamental changes in how federal agencies evaluate projects. This shift mirrors the federal approach to permitting through FAST-41, which streamlines environmental reviews for major infrastructure and mining projects through federal interagency coordination. The mineral funding framework applies similar coordination principles to financial evaluation, creating unified federal decision-making processes. Central to this coordination is the National Energy Dominance Council, which serves as the information clearinghouse for all federal energy and critical mineral funding.

The Trump administration’s broader mineral security strategy also encompasses export financing through the Export-Import Bank (EXIM), the federal government’s official export credit agency. EXIM has aligned its programs with domestic mineral priorities through its Supply Chain Resiliency Initiative, which specifically targets

critical minerals projects that reduce foreign dependence while requiring signed long-term off-take contracts with U.S. companies. In addition, the National Security Council will connect private investors with viable mineral production projects aligning private capitol with national security priorities through the National Security Capitol Forum.

The transformation from fragmented agency programs to coordinated federal strategy represents more than administrative efficiency—it signals a federal shift toward treating domestic mineral development as a strategic national priority requiring comprehensive federal coordination and support.

While current federal funding priorities focus primarily on critical minerals, the scale of investment signals massive infrastructure development across the mineral supply chain.

By Martin Willoughby, CEO, Command Alkon

Artificial intelligence is no longer an abstract idea— it’s becoming part of the everyday fabric of our industry. From the quarry to the batch plant to the dispatch office, AI has the potential to streamline operations, improve safety, and enhance service. But here’s the truth: Technology alone doesn’t change anything. People do.

That means the most important work for leaders today is not just adopting AI but equipping our people to succeed with it.

From Buzzword to Real-World Value

Leadership in the heavy building materials industry has always been about solving tough, practical problems: getting materials where they need to be, keeping crews safe, and meeting customer demands. AI is simply another tool in that tradition.

The real opportunity lies in applying it to the basics:

• Safety & Compliance: Surfacing patterns in reports to prevent incidents before they happen.

• Operations: Optimizing dispatch routes, reducing downtime with predictive maintenance, and spotting quality issues early.

• Customer service: Quickly summarizing project histories and specifications so we can respond more accurately and faster.

Each of these use cases ties directly to the key performance indicators (KPI) we already track—

tons per hour, on-time delivery, cost per yard, fuel efficiency. The lesson for leaders is simple: don’t chase shiny technology. Focus on where AI can remove friction for your people and deliver measurable results.

Leadership as the Differentiator

What separates successful organizations from the rest won’t be the software they buy—it will be the leadership practices around it.

AI brings new risks: Bias, errors, and data security challenges. Frameworks like the National Institute of Standards & Technology (NIST) AI Risk Management Framework remind us to treat AI with the same seriousness we bring to safety-critical systems: Establish clear roles, document how data is used, validate results, and monitor outcomes.

But leadership goes deeper than risk management. It’s about creating the right culture. Just as highperforming crews speak up about near misses, leaders must foster environments where people feel safe questioning AI outputs. When teams feel empowered to raise a hand, ask a question, or challenge a

result, trust is built—and trust is the foundation of adoption.

Equipping People for the Journey

AI won’t replace skilled people; it will reward them. The job of leaders is to help their teams build confidence and competence to use these new tools well. Here’s how:

1. Train for tasks, not titles. Dispatchers should learn how to shape AI inputs for complex delivery routes. Operators should know how to interpret model confidence levels. Sales teams should verify AI-generated estimates against customer specs.

2. Write clear “rules of the road.” Define what data is appropriate, when human oversight is required, and how sensitive information should be protected. Put it in plain language, not tech jargon.

3. Celebrate progress. Recognize employees who experiment responsibly with AI. Even small wins such as —time saved on paperwork, fewer errors, and quicker responses—should be highlighted.

When people see that AI makes their jobs safer and easier, adoption follows naturally.

Leading with Clarity and Cadence

Introducing AI is no different than any other change effort: Success depends on steady progress, not big one-time pushes. Leaders can build momentum by:

• Forming a cross-functional team that includes operations, IT, safety, and HR.

• Running short pilots (6–8 weeks) with clear goals and lessons learned.

• Sharing results openly—what worked: What didn’t, and what’s next.

Above all, communicate constantly. People want to know

why changes are happening, how they’ll be supported, and what success looks like.

CalCIMA members literally build California’s foundation. In a state that values safety, sustainability, and efficiency, AI is becoming an expectation, not an experiment. But the heart of this transition is not the technology itself, it’s the leadership around it.

As leaders, our job is to keep people at the center: To equip them with skills, to create cultures of trust, and to guide them with clarity through change. If we do this well, AI won’t feel like a disruption. It will feel like an enabler—helping us build safer workplaces, stronger businesses, and better communities.

That is leadership in the age of AI. n

Industry Update

EMA hosted its Fall Conference in September, where members heard from high level officials from the Trump Administration, including EPA Administrator Lee Zeldin and Deputy Secretary of the Interior Kate MacGregor. Permitting reform and tariffs continue to be issues for members, and several members of Congress said there is an appetite to work on permitting reform this fall. EMA continues to advocate on this issue to bring about changes that would secure domestic minerals supplies.

The Food and Drug Administration (FDA) is making waves that could impact large swaths of the minerals industry. EMA is responding to an FDA and USDA comment request on “a collective definition of ultra-processed foods,” in which EMA urges the agencies to strongly consider the essential role of minerals in food fortification, preservation, and public health. FDA is also looking at the “Generally Recognized As Safe” (GRAS) definition, which also could impact several mineral sectors. If you have any questions about these issues, please email EMA at info@essentialminerals.org

Airfield Paving Resources

Several new resources are available from the Airport Asphalt Pavement Technology Program (AAPTP) to help with airfield paving projects, offering technical information and best practices for

creating safe and durable asphalt surfaces. They cover topics from general construction to specific engineering challenges. Find them at AAPTP.us

A key resource is the all-new Asphalt Paving Handbook, a comprehensive guide with a special emphasis on airfield projects. A report on Balanced Mix Design: Rutting Performance Tests provides new protocols and thresholds for testing airfield asphalt mixes to improve pavement reliability and safety. A three-volume report on Improving Performance of Longitudinal Joints in Airfield Asphalt Pavements offers a literature review, field inspections, and a manual of best practices for joint construction and maintenance. Additionally, a report on Guidance for Selection of Proper Asphalt Binder Grade provides recommendations for choosing the right asphalt binder for specific airfield applications, supported by a free web-based tool.

Industry Priorities for Surface Transportation Reauthorization

On Sept. 18, association members from NSSGA, NAPA and NRMCA met with lawmakers during the annual Joint Hill Day in Washington, D.C. The Hill Day came at an important time for the aggregates industry, as the next surface transportation legislation must be considered before September 2026.

As conversations around the next transportation bill heat up, NSSGA is advocating for Congress to address several key issues.

These issues include:

• Ensuring long-term solvency for the Highway Trust Fund through sustainable revenue sources

• Maintaining support for dedicated highway investment to alleviate congestion and improve access

• Continuing the construction materials exemption from federal Buy America requirements

• Improving work zone safety by providing the FHWA and State DOTs with more resources and tools

• Harmonizing state and federal truck weights for perishable products to reduce fuel consumption

Policymakers must consider industry feedback while drafting the next surface transportation legislation. NSSGA will continue working with Congress on these important issues to support the aggregates industry and strengthen the national economy. To learn more, visit nssga.org

The ready mixed concrete industry has felt the impact of economic headwinds, with national production volumes down compared to last year. With this in mind and as part of our customary process, NRMCA has been developing a revised

strategic plan, both for the association and the promotion department, to ensure our resources are aligned with the market and to continue to position concrete as a sound economic choice in a competitive economy.

In October, NRMCA will host ConcreteWorks and our Board of Directors meeting, bringing together members to discuss priorities that strengthen both the industry and association. The popular National Mixer Driver Championship will again spotlight the professionalism and skill of our workforce, reinforcing the essential role delivery professionals play in the supply chain.

Additionally, NRMCA, in partnership with the American Cement Association and the American Society of Concrete Contractors, is delivering blended cement workshops nationwide, helping producers and contractors adapt to new materials and remain competitive in today’s economic climate. The next workshop in the western U.S. will be at the PPA Event Center in Denver, CO on November 12, 2025. Register at cement.org n

Sandvik we have combined years of industry expertise and the latest advances in technology to develop pioneering mobile crushing and screening solutions for you. Utilizing Sandvik’s renowned, proven technology and smart process solutions, such as My Fleet remote monitoring, our equipment is designed to increase operational efficiency, optimize productivity and maximize uptime.

vcesvolvo.com

The mobile MOBIREX impact crushers are used in soft to medium-hard natural stone and in recycling. The performance of the plants is impressive – not just in terms of pure volume reduction. The focus today is on cost and environmental awareness, availability, versatility and, above all, the quality of the end-product to be achieved. The MOBIREX plants crush stone so e ciently that the grain shape, grain size distribution and cleanness comply with the strict standards for concrete and asphalt aggregates.