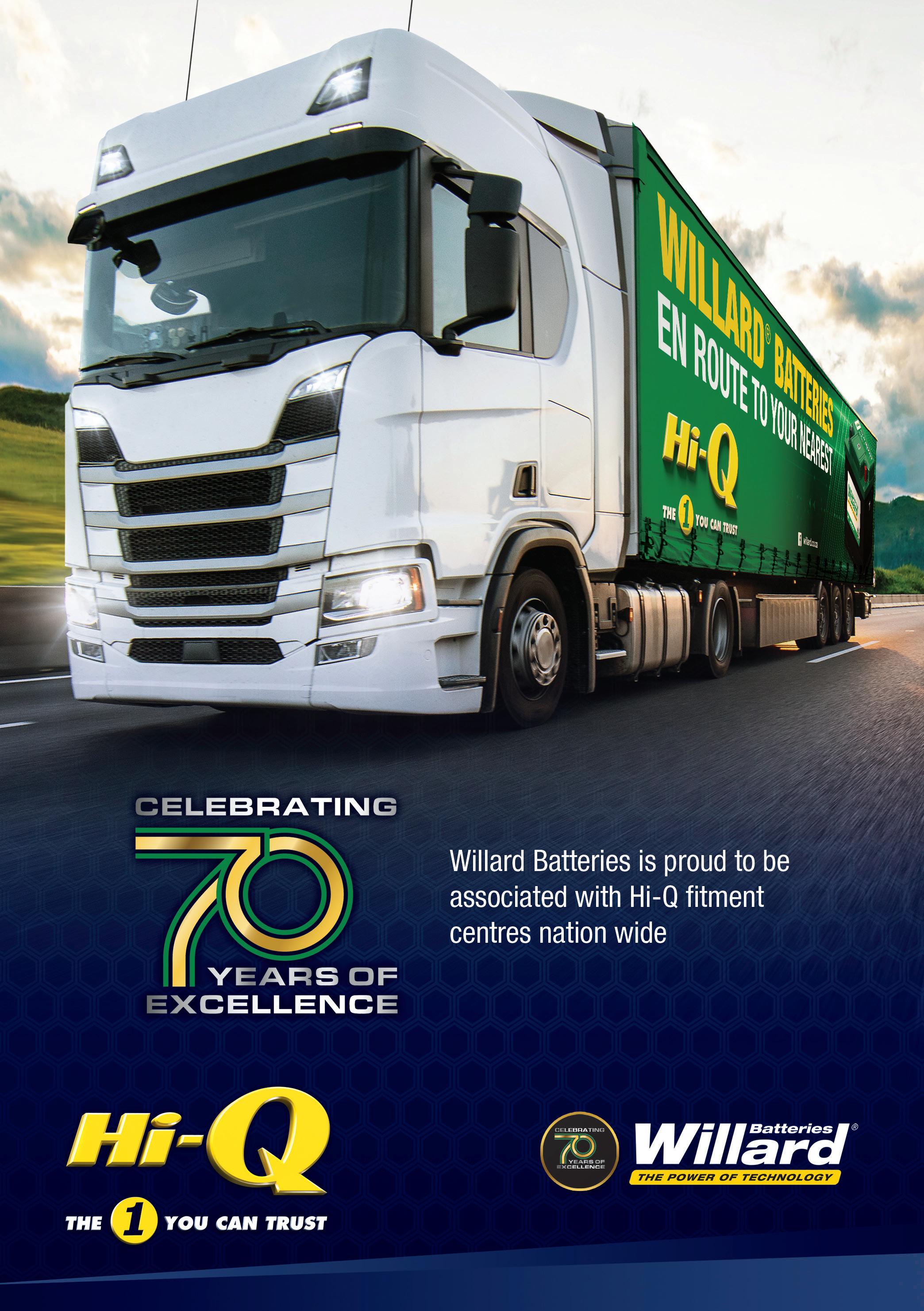

March 2024 african-business-pursuit.net African Business Pursuit Chemical Process Technologies Innovation and Intelligent Design Page 10 HIQ: tyres and Autocare Tyred And Tested Results Page 16

supporting chefs equals great food Page 4 Unilever Food Solutions

Chefs

African Business Pursuit

Published and Distributed by Business Industry Publishing Ltd

For any enquires contact info@business-pursuit.net

Production

Donnie Rust

Editor

Victoria South

Project Manager

Victoria@business-pursuit.net

Charles Brown Business Development Manager charles@business-pursuit.net

James Smith Operations Manager james@business-pursuit.net

Harry Lewis Accounts Manager harry@business-pursuit.net

Design

Felix Baldwin Design Assistant

felix@business-pursuit.net

Harvey Tarlton Graphic Design harveytarlton.co.uk

www.business-pursuit.net

If you would like more information about ways in which Business Industry Publishing can promote your business please call +44 (0)20 32878 795 or email | charles@business-pursuit.net. Business Industry Publishing does not accept responsibility for omissions or errors. The points of view expressed in articles by attributing writers and/or in advertisements included in this magazine do not necessarily represent those of the publisher. Any resemblance to real persons, living or dead is purely coincidental. Whilst every effort is made to ensure the accuracy of the information contained within this magazine, no legal responsibility will be accepted by the publishers for loss arising from use of information published. All rights reserved. No part of this publication may be reproduced or stored in a retrievable system or transmitted in any form or by any means without the prior written consent of the publisher.

© Business Industry Publishing Ltd 2024

March 2024

In this month’s edition, we delve deeper into the innovative strategies driving success in various industries. We examine how Unilever Food Solutions is revolutionizing the culinary landscape with its forwardthinking approach. Additionally, we explore the groundbreaking advancements in Chemical Process Technologies that are shaping the future of manufacturing.

Furthermore, we spotlight HIQ: Tyres and Autocare and how they’re redefining automotive maintenance standards. Our focus also extends to Mopani Copper Mines, where cutting-edge practices are enhancing efficiency and sustainability in the mining sector.

Moreover, we investigate the transformative initiatives undertaken by MTN Benin to redefine telecommunications services in the region. Lastly, we uncover the pivotal role of NATREF in advancing energy solutions and its impact on global sustainability efforts.

As businesses navigate through an ever-evolving landscape, it’s crucial to identify and capitalize on opportunities that align with their core strengths and growth objectives.

Charles Brown Business Development Manager

Business Industry Publishing

editors 2

10

Editor’s Note 04

and Intelligent Design

Chemical Process Technologies Innovation

4 Unilever Food Solutions Chefs supporting chefs equals great food

16 HIQ: tyres and Autocare Tyred And Tested Results

22 Mopani Copper Mines A Rich Zambian Heritage

28 MTN Benin Communicating Into The Future

contents 3

34 NATREF Excitement At The Old Refinery

Unilever Food Solutions

Chefs supporting chefs equals great food

Foylan Rhodes

Unilever Food Solutions

“We are looking at moving all our packaging to recyclable and the enhancements that we are making like taking salt and sugar out. We’re always on the go and have plenty going on.”

Unilever Food Solutions

quickly to meet requirements. She says, “We look specifically at customer relationship management and there are various tools and technologies that we’ve invested in globally that we would never have previously thought of. We’ve invested heavily in creating this really great experience for our customers. With new tools and technologies available, we can really enhance that consumer experience.”

To achieve long-term and sustained success in the industry, forming close relationships with partners is an essential component of long-term growth and achievement. Van Rooyen reveals that during the whole COVID-19 period, they really got to see who was there for the company and who wasn’t. According to her, good partnership is one that you can request more or less of something, and it is listened to. The long-lasting relationships work both ways.

“What we look for is quality and business integrity. Both areas are hugely important but in the case of business integrity, it is very easy to go down the wrong path when they’re desperate for business. We’re very open about sharing what our core values are and what we look for in suppliers and partners too.”

Unilever Food Solutions is continuously taking steps to improve its sustainability drive and reduce its impact on the environment. As such, the organisation has examined the ways it can improve its sustainability and has formed a sustainable living plan that aims at improving the health and wellbeing of over one billion people and reducing its impact on the environment by half, while enhancing the livelihoods of millions.

Between 2016 and 2020, Unilever Food Solutions removed almost 3,000 tonnes of salt, with an average 50 percent salt reduction across its savoury ranges. With salt having always been used to boost flavour, it has increased its herbs, spices, and other ingredients to provide that same great taste.

“We have a lot of sustainability initiatives that are linked to some of our key brands. In South Africa, nutrition is a real problem,” says Van Rooyen, “A lot of people are malnourished and don’t eat enough vegetables. From a food solutions perspective, we’re constantly looking at plastics reduction and are scaling this up. We are looking at moving all our packaging to recyclable and the enhancements that we are making like taking salt and sugar out. We’re always on the go and have plenty going on.”

Unilever Food Solutions 9

Chemical Process Technologies

Innovation and Intelligent Design

Donnie Rust

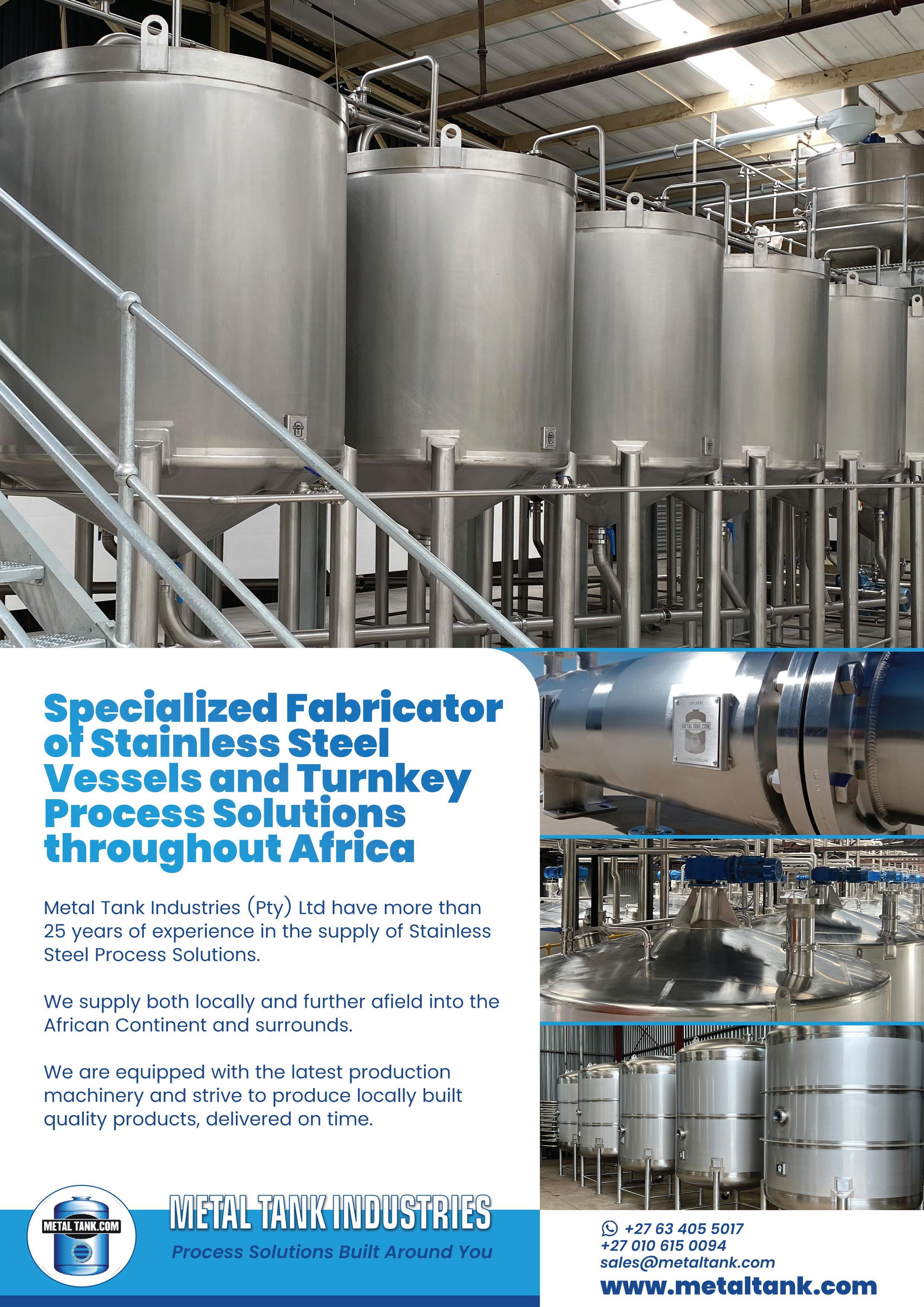

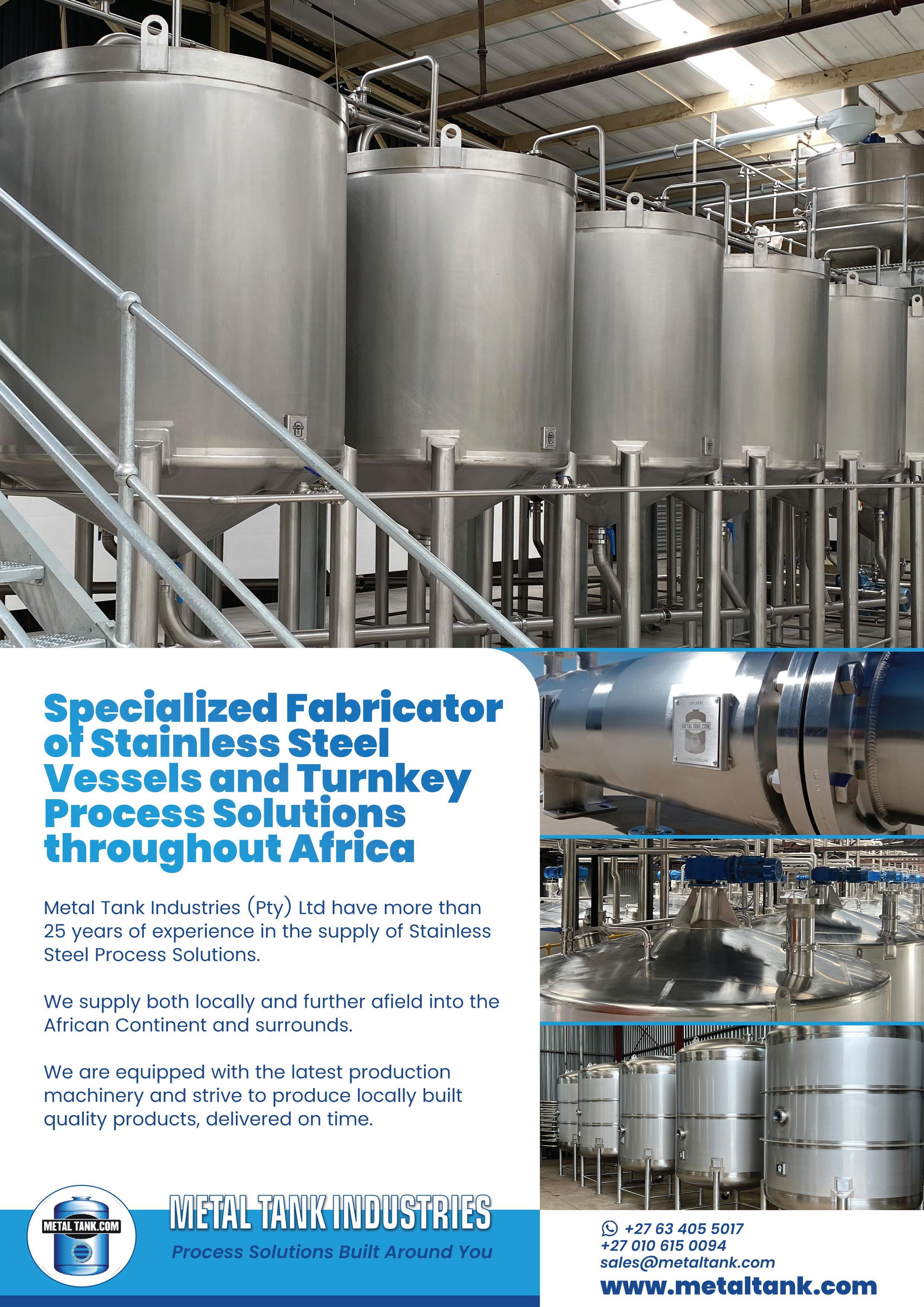

The epitome of South African grit, intelligence and hard work, Chemical Process Technologies (CPT) are a cornerstone of professionalism in an industry where standards matter. Based out of their sprawling 10,000m2 site in Waltloo, Pretoria South Africa, currently exports products to over fifteen countries across five continents and has one of the most enviable cast of expertise and talent in the industry. Despite the trials of the Covid years, Managing Director Hannes Malan explains how a focus on quality and the ability to develop and commercialize technology keeps setting CPT apart from their competitors.

Founded in 2001, Chemical Process Technologies employs 74 permanent employees and is a private chemical synthesis company within the animal health industry who also supply fine chemicals to various other sectors in a global marketplace. The company specializes in the synthesis, creation, of several fine chemicals and formulates numerous end-user products, which are exported to countries in Europe, South America and Africa.

“Chemical Process Technologies is uniquely positioned when it comes to animal health in South African,” says MD Hannes Malan, “Thanks to our combined capacity to synthesize active

pharmaceutical ingredients and commercialise them into formulated products.”

In late 2020, CPT Pharma which is owned by Chemical Process Technologies was granted a license by the South African Health Products Regulatory Authority SAHPRA to manufacture APIs (active pharmaceutical ingredients) for the human medicine, which was a significant step forward for the SA pharmaceutical industry.

Active Growth

According to Hannes, CPT is an innovative chemical synthesis company with an enviable capacity and ability to develop and commercialise competitive organic synthesis routes. This means that CPT has the capacity to create various molecules, he adds, “In developing our own process technology this is a great emphasis place on current and environmentally responsible processes.”

Typical chemical manipulations include oxidation, amidation, alkylation and hetercyclic chemistry, while technology for the commercial manufacturing of water-based nanomaterials is also something the company is involved in.

“We are always in the process of commercialising another API,” Hannes says, “We have almost finished developing the technology

12 Chemical Process Technologies

for a further three which we would like to manufacture locally and then export.”

On the API side there are significant opportunities for growth. Hannes explains that the number of animals in South Africa is staying largely the same and as a result from a final product point of view the market is almost fixed.

“We are still able to improve our market share, nevertheless, by providing our renowned excellent service and also by means of the quality system that we’ve implemented and embedded within the company.”

From a growth perspective there is however not a great deal of expansion left, but Hannes does still see believe in the possibilities and prospects in the provision of active ingredients. He adds that this is a company priority, “Because these are not used only in South Africa but also in a fair number of other counties in the southern hemisphere, which is the area on which we are arguably mostly keenly focussed. To commercialise the technologies that we have developed as quickly as possible so that we can supply increasingly to these countries.”

Such idiosyncratic specialisms are going to prove ever-more crucial to distinguishing CPT from the strong players around it on both distinct arms of the business.

“On the formulation side, it is with local formulators for final product that we are having to compete,” Hannes explains, “Again, the quality systems that we have implemented are important in keeping us ahead. Multinational companies have the same quality system and standards on the animal health products as on the human side, and we have moved a long way down that route ourselves. We are in the process of executing a project to upgrade one of our facilities to be GMP compliant- set to be executed by the third quarter, which will set us apart from any of our competitors in South Africa, most of whom are still adhering to far more lenient local regulations.”

This willingness to invest and continually improve their systems will stand them in excellent stead and the GMP facility will also open further export opportunities which are currently unavailable to them.

Maintaining Competitiveness

Hannes also highlights the flexibility build into CPT’s manufacturing systems as crucial to the success of the company’s formulation side. Although it does come at a price.

“Our business is seasonal,” he says, “And it

is almost impossible to forecast when rain will come and therefore when customers will need our product. This makes things difficult as the lead times on a lot of the raw materials that we import can be anything from six to 12 weeks, and opportunities do no wait around for that sort of timescale.”

They have built and tweaked certain aspects of their business to give the flexibility to ensure that they continually have enough of those required raw materials in place, aided by good relationships with their suppliers assisting them in short lead times for local deliveries. CPT’s willingness to adjust their product plan to align with their customer’s priorities has, in turn, positioned them superbly well in the South African industry.

From the chemical synthesis point of view, there is nobody else doing what CPT are doing in South Africa which is, according to Hannes, another vital differentiator.

“Our competitors are all located in India and China,” he says, “How we set ourselves apart from them is through the technology that we develop. We still have to import most of our raw materials from the same supplier that they are using, therefor our approach, typically, is to look at the molecule that we believe to be of value and then see if there is anything we can do around the technology to allow us to manufacturer the product cost-competitively in South Africa.”

Having the ability to develop and commercialise technology is what they use to remain competitive against those countries. Going through the process of scaling up and commercialising is a painful and challenging route, says Hannes, but he is convinced that it is the only tangible way to maintain independent and competitiveness in the chemical manufacturing industry.

Recently, the company has benefit from a boom rather than a bust, giving the global crisis everyone went through three years ago. Or them it was good on the agricultural side- food supply has of course been especially important and there have been favourable conditions in the industry which has enjoyed a growth of around 24%, which CPT really benefitted from.

On the human side, Hannes said, what was most significant was the boost in interest in local manufacturing and there has been a lot of interest from the South African government and donor organisations that would like to ensure Africa’s independence when it comes to pharmaceutical products.

14 Chemical Process Technologies

Chemical Process Technologies 15

Tyred And Tested Results

Donnie Rust

HIQ: tyres and Autocare

There’s no denying that the tyre business is more digital and connected than ever before. According to HiQ who are the undisputed experts in the UK field, between 60 and 80 percent of tyre-buying consumers conduct pre-sale research online before the pandemic. Today, 10% of all tyres are bought online and many customers walk through the door expecting their tyres to be ready for them.

Digital Movement

One of the benefits of a digital aspect to the sale of car parts and tyres especially is the ability to advise and educate customers about safety while they are on the website. Providing handy guidelines and advice on maintaining tyres that many people would otherwise be unaware of. For millions a car is simply an all-in-one-package that encompasses everything, but a vehicle is a collaboration of carefully calibrated parts working together like an orchestra. It is a travesty that vehicle maintenance is never thought of until something breaks, which is usually when multiple parts end up needing to be replaced due to one part- which could have been repaired or replaced during a routine maintenance check. But it isn’t just the digital landscape that is changing the modern automotive retailing world,

but new entries into the market that require new specifications. Such as the ever more prominent electric vehicle.

What Do HiQ Do?

As is attested on their website, there isn’t a lot that Hi-Q don’t do. They are, for lack of a better term, the Full English of car repairs and services and they pride themselves on offering tip top customer service to everyone who walks through our doors. They don’t sell “part worn” tyres or equipment, choosing only quality new products, so customers cannot buy wrong when they buy from HiQ.

The Future Of Rubber On Road

Electrical vehicles are becoming very prominent on the roads, and drivers have very real questions. For example, do electric vehicles need special tyres? The answer is Yes, and electric car tyres differ from conventional tyres in a few ways. They are designed to withstand more weight, increase grip, reduce noise, and extend driving range. As advanced as an EV is compared to an internal combustion engine, so too are their tyres.

Electric car tyres are designed with a few important factors in mind. EVs have instant

torque and immediate acceleration, their engines make the vehicle much heavier and the low centre of gravity makes for far better manouverability and handling. The tyres have to be able to manage all of this while keeping the car on the road.

Tyred Of Range Anxiety

Something that HiQ is determined to manage is range anxiety. The fear that a vehicle will have insufficient range to reach its destination. It’s a concern for all types of electric vehicles, and that’s why it’s important that electric car tyres are designed to extend the driving range of the vehicle as much as possible.

Extending the driving range can be accomplished by adapting the tyre’s compound or structure and enhancing the aerodynamics of the sidewall. HiQ points out that Goodyear has developed Low Rolling Resistance technologies to reduce energy consumption and extend the driving range.

One of the trademarks of an efficient tyre system is how little noise it makes, and everyone is aware of how quiet electric vehicles are. This is partly due to design but also because tyre manufacturers suddenly became aware of how loud tyres could be when not masked by an internal combustion engine.

18 HIQ: tyres and Autocare

HIQ: tyres and Autocare

Specific Tyres For Specific Vehicles

Tyres are designed specifically for the sorts of vehicles and the sorts of roads, and it is concerning how often this isn’t known by drivers. It is important when selecting tyres for an EV that you choose ones that are appropriate. This helps extend tyre life, reduces energy consumption with low rolling resistance, reduces noise, reduces breaking distance, and increases the durability of tyres to cope with increased weight. HiQ have made it their mission to ensure that drivers are made aware of these factors when they are deciding which tyres to select.

Electric Car Tyre Maintenance

Much like conventional tyres, looking after an electric car tyre is vitally important. It is advised that tyres are checked regularly for the correct pressures against the manufacturer’s recommendations as given in the vehicle Handbook, that dirt is removed from valves and stones from tread and, like all vehicles, that steering alignment is checked in front tyres to keep the vehicle on the road. For all this HiQ is here to assist so you don’t have to.

How Do You Choose?

HiQ are big believers in common sense, and when it comes to selecting which tyres to use, suggest looking first at the original tyres that a vehicle was fitted with. Tyre manufacturers work with vehicle manufacturers very closely to ensure that electric cars have suitable tyres fitted as OE (original equipment).

Beyond this, new tyres can be searched using a vehicle registration number or fitment information on the HiQ homepage. Drivers should remember to look for a tyre exclusively

designed for an electric car; this will ensure the tyre will be able to deal with all the challenges electric vehicles present. HiQ have all premium brands available including Goodyear, Dunlop, Continental, Michelin, and Bridgestone.

Drivers should also think about seasonality when searching for new tyres for their electric car. Gary Thomson from HiQ Tyres & Autocare Warmley (Bristol) says, “Just like for any other vehicle, you need to consider whether you need specialist winter tyres or all season tyres. We’re fitting more and more all season tyres these days, which are designed to perform well in wintry conditions as well as warmer weather in summer. Due to our rather mild climate in the UK, where we can experience all four seasons in one day, all season tyres are a good investment.”

HIQ: tyres and Autocare 21

A Rich Zambian Heritage

Foylan Rhodes

Mopani Copper Mines

Mopani Copper Mines

Mopani Copper Mines Plc is a multifaceted mining investment with operations in Kitwe and Mufulira districts of the Copperbelt Province. The company’s operations encompass the full range of the copper production chain: from extracting the ore underground to concentrating, smelting, refining, and packaging the finished red metal for export.

A Zambian registered entity, Mopani Copper Mines Plc is owned by ZCCM Investment Holdings Plc, a diversified mining investments and operations company with a primary listing on the Lusaka Securities Exchange in Zambia, and secondary listings on the London Stock Exchange in the United Kingdom and the Euronext Access Exchange in Paris, France.

ZCCM assumed ownership of Mopani Copper Mines Plc in 2021 after buying off the majority stake in the mine from Carlisa Investments – a joint venture between Swiss commodity trader Glencore and Canadian-based First Quantum Minerals – which ran Mopani from privatisation in 2000.

In Focus

With a rich history in mining and processing dating back to the 1930s, Mopani’s assets in Kitwe and Mufulira include underground mines, concentrators,

a smelter, and a refinery. Mopani Copper Mines Plc continues to upgrade its infrastructure by investing in new technologies to increase production and improve efficiencies. The new infrastructure includes three deep shafts (Synclinorium, Mindola and Henderson), which were sunk and equipped between 2014 and 2021 to extend the life of the mine by over 25 years, safeguard the existing jobs at both mine sites and ensure Mopani’s continuous contribution to Zambia’s economic development.

Mopani Copper Mines Plc remains committed to supporting the social-economic development of the host communities through its robust Corporate Social Responsibility (CSR) programmes. The company supports the development of sports, local enterprises, education, health, basic infrastructure as well as water and sanitation in the communities of Kitwe and Mufulira.

Operations

Mopani Copper Mines has ensured that it makes the most of what it has and operates in a range of mining approaches, namely shafts, pits, exploration, and processing.

Shafts

Mopani Copper Mines PLC has since 2014 sunk and equipped three shafts to replace the old

infrastructure at both Nkana and Mufulira mine sites, which dates to the 1930s. The three new shafts are Syclinorium and Mindola Deeps Shafts at Nkana Mine in Kitwe and The Henderson Shaft at Mufulira Mine site. Mopani has also built a brand new Concentrator at Nkana mine site, The New Syclinorium Concentrator.

The new infrastructure is expected to extend the life of the mine by over 25 years, improve production efficiencies and safeguard the existing jobs while guaranteeing Mopani’s continued contribution to growing the Zambian economy.

Pit Mining

Mopani Copper Mines PLC owns several open pit mines at Nkana Mine Site in Kitwe, which are no longer active, namely, Area D, Area E, Area J, Area K, Area Nose and Mindola Open Pit. Mindolo open pit, Area D and Area E open pit mines ceased operations in 2012 whilst Area J, Area K and Area Nose ceased operations in 2017 after mining became uneconomical at the pits.

Exploration

Mopani Copper Mines PLC continues to undertake Exploration Drilling at both Nkana and Mufulira Mine Sites. This is expected to help

24

Mopani Copper Mines

increase the resource and reserve base of the Company thereby extending the life of the mine.

Processing

Nkana & Mufulira Concentrator

Mopani Copper Mines PLC operates three Concentrators: two at Nkana Mine Site in Kitwe and one at Mufulira Mine Site. The New Nkana Synclinorium Concentrator in Kitwe was commissioned in March 2022 and is expected to improve recoveries and improve production efficiencies while the Old Nkana Concentrator, which has been in operation since the 1930s, has since been placed under Care and Maintenance. The copper concentrates from the New Nkana Synclinorium Concentrator are trucked to Mufulira and together with those from the Mufulira Concentrator, are fed into the Smelter at Mufulira Mine Site for smelting and processing to produce Copper Anodes.

The Heart Of The Mine

Mopani Copper Mines PLC owns the Mufulira ISA Smelter, where concentrates coming from Mufulira and Nkana Concentrators are blended with Toll concentrates from other sources to produce Copper Anodes containing 99.6 percent copper. The Upgraded Smelter is equipped with two acid plants, which capture up to 95 percent sulphur dioxide and convert it to Sulphuric Acid as part of their commitment towards maintaining a clean atmospheric environment.

Mopani Copper Mines PLC’s Refinery has the capacity to produce 220,000 tonnes of copper cathode per annum. At the Refinery, copper anodes coming from the Smelter are electrorefined to produce cathodes with 99.999 percent Copper and conforming to LME grade ‘A’. Mopani Copper Mines PLC cathodes are among the purest in the world and we bundle them with pride for export.

Settling Issues

With the ZCCM deal being finalised, Mopani Copper Mines PLC has taken the initiative and started clearing the outstanding payments to contractors and suppliers following the inflow of funding.

Many of the contractors, who had demobilised their equipment, have since started re-mobilising after receiving some payments, which have enabled them to also embark on clearing their obligations to their employees.

Speaking when he met the contractors and suppliers in Kitwe, Mopani Chief Executive Officer, Mr. Charles Sakanya and Mr Ravi Sharma, the representative of IRH, stated that the company had set a target to significantly reduce outstanding obligations during the first quarter of 2024.

“I wish to profoundly thank all of you for standing with us as true partners over the past four years to ensure Mopani survived. You demonstrated true partnership and resilience with your ‘never-say-die’ spirit. Now it’s time to

work together and make Mopani successful,” Mr. Sakanya said.

“The remainder of the overdue payments will be settled in instalments over the next few months. The plan is to work hard to meet set targets safely and cost-effectively.”

The Association of Mine Suppliers and Contractors of Zambia president, Mr. Costa Mwaba, commended Mopani for prioritising the payment of outstanding dues to the local vendors, which he said would play a key role in bringing life back to the Copperbelt and the country.

“We take this opportunity to commend you for the job well done under very difficult circumstances. We can see the smiles returning on the faces of our people in Kitwe and Mufulira as well as the whole country as payments continue to flow to the suppliers and contractors. This is very good news for the country, which will have a positive impact on the performance of the economy” said Mr. Mwaba.

Mopani Copper Mines

Mopani Copper Mines

Communicating Into The Future

Daemon Sands

MTN Benin

The last four years have been an enlightening journey for the Chief Executive Officer of MTN Benin, Uche Ofodile, who was appointed to her position in 2020. During her time in the commander’s chair, she has witnessed the growth and transformation of their company in Benin, Africa. During her tenure, MTN Benin has radically improved their services, extended network coverage, strengthened relationships and increased their customers in all verticals, especially in the mobile money sector which has grown to over four million users.

As she relates, MTN Benin occupies a significant role beyond simply that of being a telephone company. It has the potential to offer real change and make a genuine difference to the lives of the people in her country.

“We strive to reduce the digital gap, bring connectivity to remote areas, and give people the tools to build a better future,” she explains, adding, “MTN remains the leader in digital services and the MTN Foundation also does a lot for communities, contributing to women’s empowerment, youth employment and financial inclusion.”

A People Company, Not A Perfect Company

No telecommunications company is perfect and

maintaining connectivity on a reliable platform is a challenge even for the most technologically developed countries. However, whenever a service drops it can have an impact on customer trust and confidence. Uche’s approach in dealing with this is to tackle these things head on.

“We take our responsibilities seriously and continue to work tirelessly to resolve any problems quickly and proactively,” she says, “I understand that incidents of service disconnection affect the trust of our customers, as we are aware of the importance of the mobile money service in the lives of our communities. We continue to do everything in our power to ensure our reliability and security.”

Solving these problems is a long term and ongoing goal which the company takes very seriously and among other things, MTN Benin have increased their investment in technology infrastructure and are working closely with the regulatory authorities to ensure that they meet the highest standards for the security and performance of their mobile telecommunications and mobile money platform.

“We are committed to solving problems as quickly as possible and to regaining the trust of our customers in order to fulfil our promise to offer them all the benefits of a

modern, connected world.”

Open Communication

As a developing nation, Benin, which is situated in West Africa faces the challenge of customer expectations in terms of service and price. Customers will always complain about pricing and Uche believes the only way to address this is to engage with them better to understand their needs and expectations. Affordability is key, and since 2019 most of their package prices have decreased as they’ve been tailored to their customer needs. Concerns about the fast-ending data bundles and airtime can sometimes be resolved by adjusting their customers’ phones correctly but it’s also a simple fact that a faster connection requires more data which costs money to produce.

“Nevertheless, we constantly analyse our offers to ensure that they are fair, and are committed to providing a high-quality service,” Uche explains, “Our aim is to make our customers feel valued.”

Security

The increasing threat of cyber-attacks and data breaches is an ongoing concern for all customers,

30 MTN Benin

A transformative UPGRADE with MTN Benin

The project consisted of MTN Benin core modernization by swapping current Packet Switch & Circuit Switch CORE nodes with new hardware and servers provided from DELL. It also involved their replacement of the existing PCRF system. The main objective was to introduce a scalable virtualization platform with additional functions for customer experience improvement. CIS Benin Team implemented this project which will increase the efficiency and productivity of MTN, and contribute with MTN’s business digitalization journey.

CIS Benin is part of CIS Group, the leading information systems supplier and integrator with a diversified portfolio of ICT products and services, operating in over 30 countries with 50 offices and 1000 employees. This enables us to cater to the expansion of international enterprises such as MTN. Trust built over the years with clients empowers us to have a dynamic local presence in Africa, Europe, and the Near East.

CIS BENIN

LOT 118 ZONE RÉSIDENTIELLE, VON DU PNUD, BENIN

TEL: +229 21 31 75 16

FAX: +229 21 31 75 19

COURIEL: SUPPORT@CISBENIN COM

CIS INTERNATIONAL

TEL: +961 4 410410

COURIEL: MARKETING@CIS.COM.LB

WEBSITE: CIS-SI COM

GROUPE CIS

JAL EL DIB - CIS BLDG

BEIRUT, LEBANON

TEL: +961 4 410410

COURIEL: INFO@CIS COM LB

WEBSITE: WWW GROUPCIS COM

and according to Uche these sit at the top of MTN’s lists of concerns about cybersecurity and data confidentiality. The MTN group benefits from around twenty subsidiaries and they are leveraging this strength to implement a global approach to ensure that customer’s personal information is kept safe and secure.

This approach includes regular risk assessments and vulnerability scans to identify potential weaknesses in their systems, as well as continuous learning and sharing of best practice with their fellow companies.

At the same time, she reveals that staff are trained on an ongoing basis and awareness programs ensure that everyone at MTN is aware of the importance of privacy. Additionally, a series of technical controls and security measures have been put in place to protect personal data against unauthorized access.

These measures include intrusion detection and prevention systems, firewalls, and data encryption to protect their platforms such as Mobile Money and MTN Business.

“Of course, we also work closely with the APDP (the Personal Data Protection Authority) and comply with all data protection regulations,” she says, adding, “MTN is committed to continually improving its security measures so that our customers can have full confidence in entrusting us with their personal information.”

As MTN Benin prepare to launch 5G across the country, it does highlight how important such campaigns are to providing the best possible service to our customers. For Uche, the launch of 5G is a major milestone and they believe it will have a transformative impact on the way people connect and communicate. 5G will enable millions of devices to communicate in real time, paving the way for a new generation of smart technologies. This is set to revolutionize a wide range of sectors, from education and healthcare to transport and entertainment.

Tita By MTN And Other Developments

The project TITA by MTN is one of Uche’s greatest sources of pride, and as a Beninese company, she sees their role is to invest in the country’s success. With this, MTN is committed to empowering young people to create a better future for the Beninese. Benin is a country of youngsters, where over two-thirds of the population is under the age of 25 and Uche believes that it is essential to invest in the technological skills of young graduates.

“The CEOs of tomorrow are being trained right now,” she says, “TITA is a way for us to give back to the community and support the next generation of innovators and leaders. By providing young graduates with the skills, they need to succeed in a digital world, we are helping

to create a more prosperous society. “

Benin’s government has set ambitious goals to increase connectivity and digital infrastructure across the country and MTN is committed to supporting this and have already set up several projects for the development of the digital ecosystem.

For example, they have invested in expanding network coverage across the country, including the provision of the 3G and 4G networks in remote areas. Modernizing the network, upgrading the international link, and building new sites will enable MTN to be more efficient and closer to its customers.

MTN also supports Benin’s development through various initiatives conducted in partnership with the government (digital project LEARN, dispatching of aid funds across the country, etc.), and by providing an extensive mobile services platform that enables customers to access financial services such as insurance and savings (MoMo Sayaa), thereby stimulating financial inclusion and contributing to economic growth.

“Overall, MTN plays a vital role, and we are proud of our efforts to drive innovation and progress in the country, and we remain committed to supporting the government’s goals for a connected and prosperous Benin,”, Uche Ofodile, Chief Executive Officer of MTN Benin, says.

MTN Benin 33

Excitement At The Old Refinery

Donnie Rust

NATREF

36 NATREF

The Natref refinery at Sasolburg was commissioned in 1971 and has been at the cutting edge of refining technology since its inception. As it is situated inland, the refinery’s market for heavy fuel oil was quite limited and as a result, it was designed to get the most out of crude oil and equipped with state-of-the-art technology to achieve this. The refinery makes use of the bottoms up grading refining process, this uses medium gravity crude oil which gives NATREF the capability of producing 70 percent whiter product.

Production

At the refinery, the main products produced are petrol, diesel, jet fuel, bitumen, and fuel oil with a capacity of 108,500 barrels of oil per day. Located in Sasolburg, the Free State, Natref supplies the main South African inland market of Johannesburg and the surrounding areas, however it starts its inland journey 600km (355miles) away at the coast. The crude oil destined for Natref is offloaded in Durban via floating Single Buoy Moor (SBM), which is co-shared with other oil companies and managed independently. In Durban, the crude is stored in 15 crude storage tanks before beginning the long uphill journey to the refinery.

Due to its inland location, near the industrial heartland of South Africa, the refinery is sited in a place where the market for heavy fuel oil is quite limited. Therefore, since it was founded, Natref has needed to squeeze all the value out of their crude, which requires state-of-the-art equipment. By utilising the bottoms upgrading refining process using medium gravity crude oil, the refinery has the capability of producing 70 per cent whiter product than coastal refineries, which must rely on heavy fuel oil.

Having commenced operations over half a century ago, it is no surprise that in that time the refinery has undergone several expansions and upgrades. Mr Dayanand Rajaram, Senior Vice President at Natref, shared some of the more technical details about the refinery’s evolution and current capabilities.

“The refinery was originally designed as a 55,000 bbl/d refinery,” he says, “In 1976, it was expanded to 75,000 bb/d, and then to 86,000 bb/d in 1993 and to 108,000 bb/d in 2002. In 2005, the refinery was upgraded to clean fuels 1 specification. In 2016, the refinery started producing 50ppm diesel.”

He goes on to explain that the refinery configuration has a Solomon complexity factor of 10.9. As mentioned earlier, it has a

significant bottom upgrading unit (residual crude desulphurization – RCD), as well as the capability for processing vacuum residue and atmospheric residue from the crude columns into FCC feed. In addition, the refinery also has several specialised units including a hydrogen reformer unit, a hydrofluoric acid (HF) unit, and a bitumen unit.

There are a number of other recent key developments including several upgrades to infrastructure that have been completed. Such as the human machine interface (HMI), and distributed control system (DCS) upgrades. Health monitoring on key rotating equipment was implemented by upgrading the Bentley system and the company has installed state-of-the-art training simulators on two production units, with a further view to link this with virtual reality to further improve operator training and engagement. Further to these items, solutions that provide online monitoring of critical operating parameters to prevent process safety incidents have also been installed.

“At the moment, the refinery is piloting and rolling out a wireless plant inspection tool that will assist operators and maintenance staff in improving their effectiveness,” Mr Rajaram says, “These are among some of the more

New standards are being set by Velan HF acid valves. Offering unique design features ensuring durability and performance.

Velan’s extensive product portfolio serves HF alkylation and LAB processes. Meeting the demands of Phillips heritage and UOP licensed process units. Providing significant specification variances of individual renown players by supplying API 602 Forged Steel valves, API 600, 623 and 594 Cast valves and Bellows Sealed Cast valves in materials such as carbon steel (WCB and A105), low temperature carbon steel (LCC/LCB and LF2) and Monel® (400 and M35-1).

Velan strive to achieve the highest quality severe service valve products at the lowest total cost of ownership in the market.

VELAN, THE LEADER IN HF ALKYLATION VALVE PERFORMANCE.

EXCLUSIVELY AVAILABLE FROM HEATON VALVES AFRICA

www.heatonvalves.co.za | info@heatonvalves.co.za

GAUTENG HEAD OFFICE: (011) 418-4800

KWA-ZULU NATAL OFFICE: (031) 902-8241 | CAPE OFFICE: (021) 555-2211

NATREF 37

C M Y CM MY CY CMY K

recent changes to improve the data gathering, decision-making and the training of employees.”

New Developments

One company leaves another takes its place.

For decades Natref was owned by TotalEnergies and Sasol, but this changed earlier this year, when British company Prax Group struck a deal with TotalEnergies to buy their stake in the refinery. Although the companies did not reveal the agreed price for the 36.36% stake in the facility it is known that Sasol will retain control of the remaining 63.64 percent.

Prax said this purchase would see it enter the South African market where they envisage Natref serving as a focal point for its expansion into Africa. It also represents the beginning of their move into the

“At the moment, the refinery is piloting and rolling out a wireless plant inspection tool that will assist operators and maintenance staff in improving their effectiveness,”

continent as they plan to make further investments in the asset to establish it as a regional hub.

“The signing of this agreement is the first step towards our entry into Africa which will provide us a solid platform from which to execute our future growth strategy,” said Prax CEO and chairman Sanjeev Kumar Soosaipillai.

“The acquisition marks another significant milestone for the Prax Group and will create unique opportunities across the South African supply chain, meeting the needs of customers and communities for years to come.”

Focus

“The transaction is in line with the Company strategy to focus on its large integrated fuels

38 NATREF

and petrochemicals platforms and to divest its non-core assets,” said Jean-Pierre Sbraire, CFO of Total.

TotalEnergies is a global multi-energy company that produces and markets energies: oil and biofuels, natural gas and green gases, renewables, and electricity. Employing over 100,000 people they are committed to energy that is ever more affordable, more sustainable, more reliable, and accessible to as many people as possible. Active in nearly 130 countries, TotalEnergies puts sustainable development in all its dimensions at the heart of its projects and operations to contribute to the well-being of people. They own a 50.1% stake in TotalEnergies Marketing South Africa.

“The acquisition marks another significant milestone for the Prax Group and will create unique opportunities across the South African supply chain, meeting the needs of customers and communities for years to come.”

The other 49.9% is owned by South African shareholders.

Interesting Future

Natref represents not only a long-term asset that has continued to produce for over fifty years, but is still South Africa’s only inland refinery and processes heavy crude. This provides a number of opportunities for the UK company to take advantage of established infrastructure and employeeskills. Particularly as Prax has interests in the upstream but also in the downstream, which means the future for Natref is going to be an interesting one. Not to be crude, but black gold has never seemed so refined.

NATREF 39

Safe and seamless for Medical and Pharmaceutical deliveries

Our fully compliant, temperature-controlled vehicles provide secure and reliable distribution of medical and pharmaceutical deliveries, including time-sensitive cold chain parcels. With over 40 hubs across South Africa, our state-of-the-art and fully integrated technology and logistics infrastructure solutions makes us the perfect partner for the medical and pharmaceutical industry. Paperless, secure and timeous, our online track and trace system also makes it easy to follow your vital parcel journey from start to finish.

www.ram.co.za From A-to-B, seamlessly. Dispatch from client to RAM from senders’ premises Receiver can track and trace the parcel Receiver can change and/or validate their delivery address Consignment information captured at client Consignment loaded onto a delivery vehicle R Infoslips for analysing billing e-POD available Data is transferred from client to RAM via Web Services Consignment is transported to delivery hub Receiver kept updated 'Good Morning, your order is out for delivery today' Physical delivery to receiver Address is auto validated and cleansed by RAM where necessary Handheld delivery with specific client document requirements B2C data stored according to POPI act B2C B2B Temperature-controlled vehicles High hygiene standards B2B + B2C solutions

27329

Mopani Copper Mines

Mopani Copper Mines

Mopani Copper Mines

Mopani Copper Mines