1 minute read

Good Planning Increases Plant Efficiercy, Pole Construction Cuts Costs

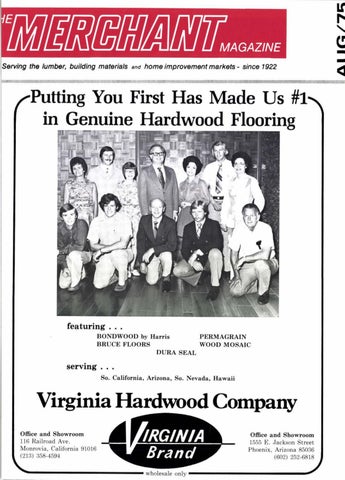

Increased plant efliciencies of 30% to 50% were realized by our close cooperation with our client, Commercial Lumber Company, Inc. of City of Industry, Ca. Here, Vice-president Raymond Gutierrez ol Commercial Lumber confers with Leon Durham of Treated pole Builders, Inc.

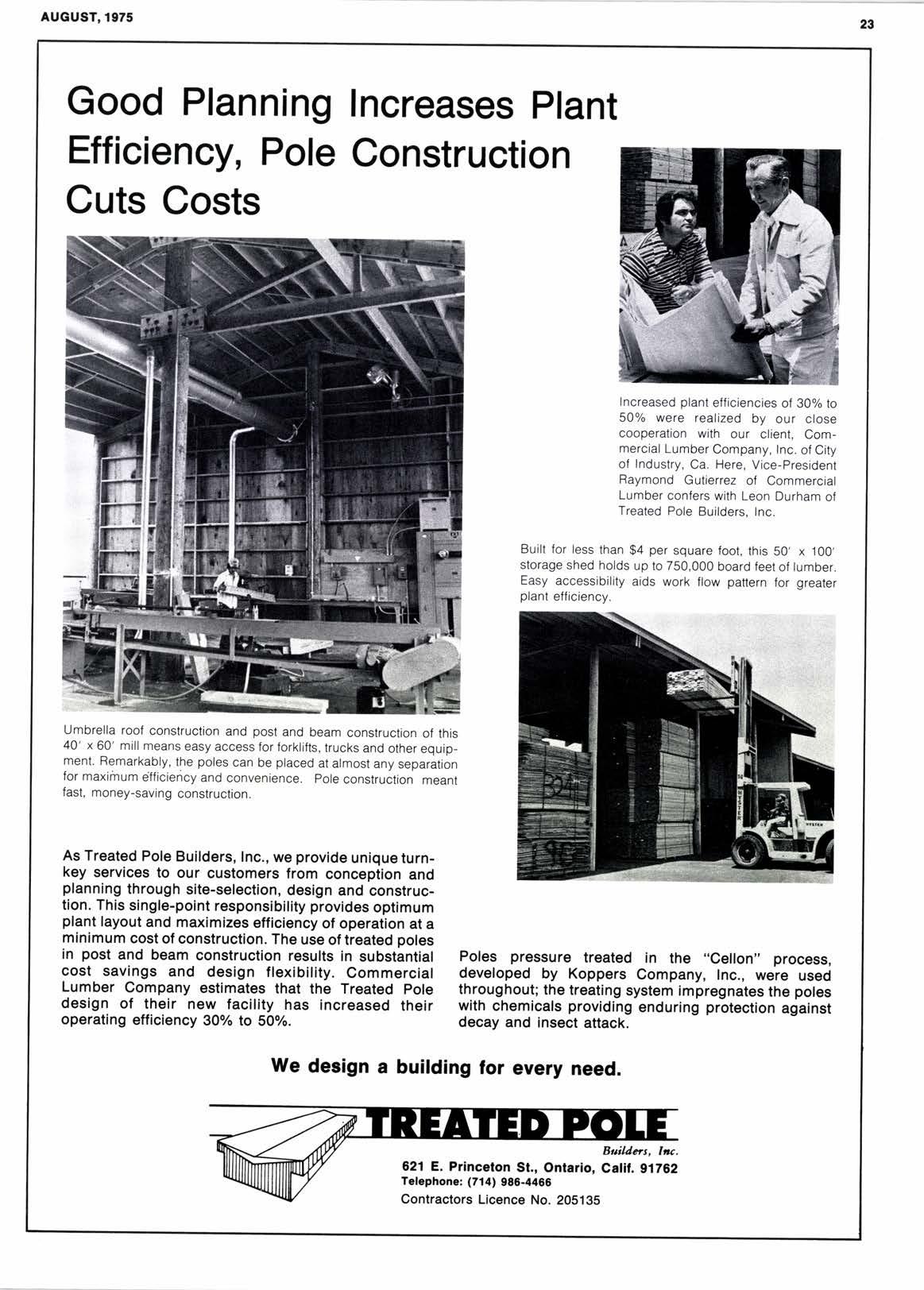

Built for less than $4 per square foot, this S0, x .100, storage shed holds up to 750,000 board feet of lumber. Easy accessibility aids work flow pattern for greater plant efficiency.

Umbrella roof construction and post and beam construction of this 40' x 60' mill means easy access for forklifts, trucks and other equip_ ment. Remarkably, the poles can be placed at almost any separalon for maximum efficiency and convenience. pole construction meant fast, money-saving construction.

As Treated Pole Builders, Inc., we provide unique turnkey services to our customers from conception and planning through site-selection, design and construction. This single-point responsibility provides optimum plant layout and maximizes efficiency ot operation at a minimum cost of construction. The use of treated poles in post and beam construction results in substantial cost savings and design flexibility. Commercial Lumber Company estimates that the Treated pole design of their new facility has increased their operating efficiency 30% to 50%.

Poles pressure treated in the ,,Cellon" proc€ss, developed by Koppers Company, Inc., were used throughout; the treating system impregnates the poles with chemicals providing enduring protection agalnst decay and insect attack.

We design a building tor every need.

Btildas, Isc.

621 E. Princeton Sl., Onlario, Calll. 91762

Telophone: (71t|) 986-4466

Contractors Licsnce No. 205135