3 minute read

cr:o SCTV1CC

Computer Estimator

"Mr. Estimate", a low cost microcomputer program to provide estimates of one and two family dwellings in minutes rather than hours, is now available through The National Lumber and Building Material Dealers Association.

In announcing it, Philip Lyon, The T. M. Deal Lumber Co., stated that fast, efficient, accurate pricing of a builder's bill of materials is absolutely essential. As chairman of ' NLBMDA's dealer service committee, he praised the system because it produces a quick estimate, while at the same time reflecting variations in price.

A complete system, it is flexibile in providing for a multitude of changes to fit the specifications of home plans. It allows for different size lumber and spacing for walls, floor joists, or manufactured floor trusses. Structural design variations also apply to ceiling and roof construction of any pitch, hip or gable end configuration.

Two estimate printouts are available. One is a breakdown on quantity, description, footage retail price units and a page total. The second is a quantity and description with a page total.

Thot's How lt Goes!

The Merchonl Magozine iog, itters to h in kiln with cedar and pine ,Let us show you play work. how to Call

Oun big Woodland, Ca., plant has the equipment to do the job fon you. Oun nemanufacturing machinery includes a planer, moulden, straight line rip, a gang nip, a single and a double nesaw and P.E.T.

We're neady to help, just call Portland, Or. [so3] 684€440

Bard Brown

Jim Hcbcrlcin

Woodland, Ca. [916] 666-1991

Dick Chcrmak Frank Haay Duan Chartcr Mltth.w Thomes Ed Gaglc Frcd Duchi

Weed, Ca. [916] 938-2771

Bill Duchi Jor Hattrup

We're proud to be members of the Western Wood Products Association Grading Service.

Marketing Misses Mark

Marketing efforts of building materials manufacturers for the professional remodeling trade could stand improvement, a survey of residential contractors has found.

Contractors responding to a poll conducted by Frost & Sullivan, Inc. rated the effectiveness of manufacturers' marketing programs as fair at best. On a scale of one to l0 (10 the highest score), demonstration kits rated 4.8; product samples 4.9, and effectiveness of sales tools 5.3. The only marketing category to fall within the top five of 16 categories surveyed was consumer advertising, with a 6.0 rating. Pricing (5.2) and supply of replacement parts (5.4) rounded out the bottom five.

"Manufacturers have not been marketing oriented in dealing with remodelers," Frost & Sullivan observes in its 360-page report, Contractor Remodeling Market. "The results indicate a strong need for more marketing emphasis in working with remodelers. They apparently need more tools to sell the job."

Manufacturers failed to achieve a good to excellent rating (8-10) in any of the categories studied. Ease of installation rated best at 6.7, followed by depth of line at6.3, handling customer orders and product application time at 6.2 each.

The survey indicated that most residential remodelers are small businesses. A full 57v/o of the 286 firms polled do under $200,000 a year in sales and only 7s/o generate more than $l million. Only 490 of the firms had more than 20 people on their construction payroll. Some 5390 had one to three construction personnel on staff, while 7990 had six or less.

Frost & Sullivan estimates that remodeling contractors spent over $10.8 billion on building materials and supplies in 1979. With purchases of $1.57 billion, lumber and plywood accounted for the largest single share of the market (14.5s/o), followed by plumbing at $813.3 million (7 .5u/o), siding at $661.5 million (6.190) and kitchen cabinets at $628.9 million (5.890).

The $10.8 billion represents more than 250/o of the $42.2 billion spent on residential alterations and repairs in 1979. Of that figure, $27.3 billion stemmed from improvements, which have been growing at a faster rate than repairs.

The outlook for residential remodeling is encouraging, the study says. Approximately 28 million homes in the U.S. are over 20 years old.

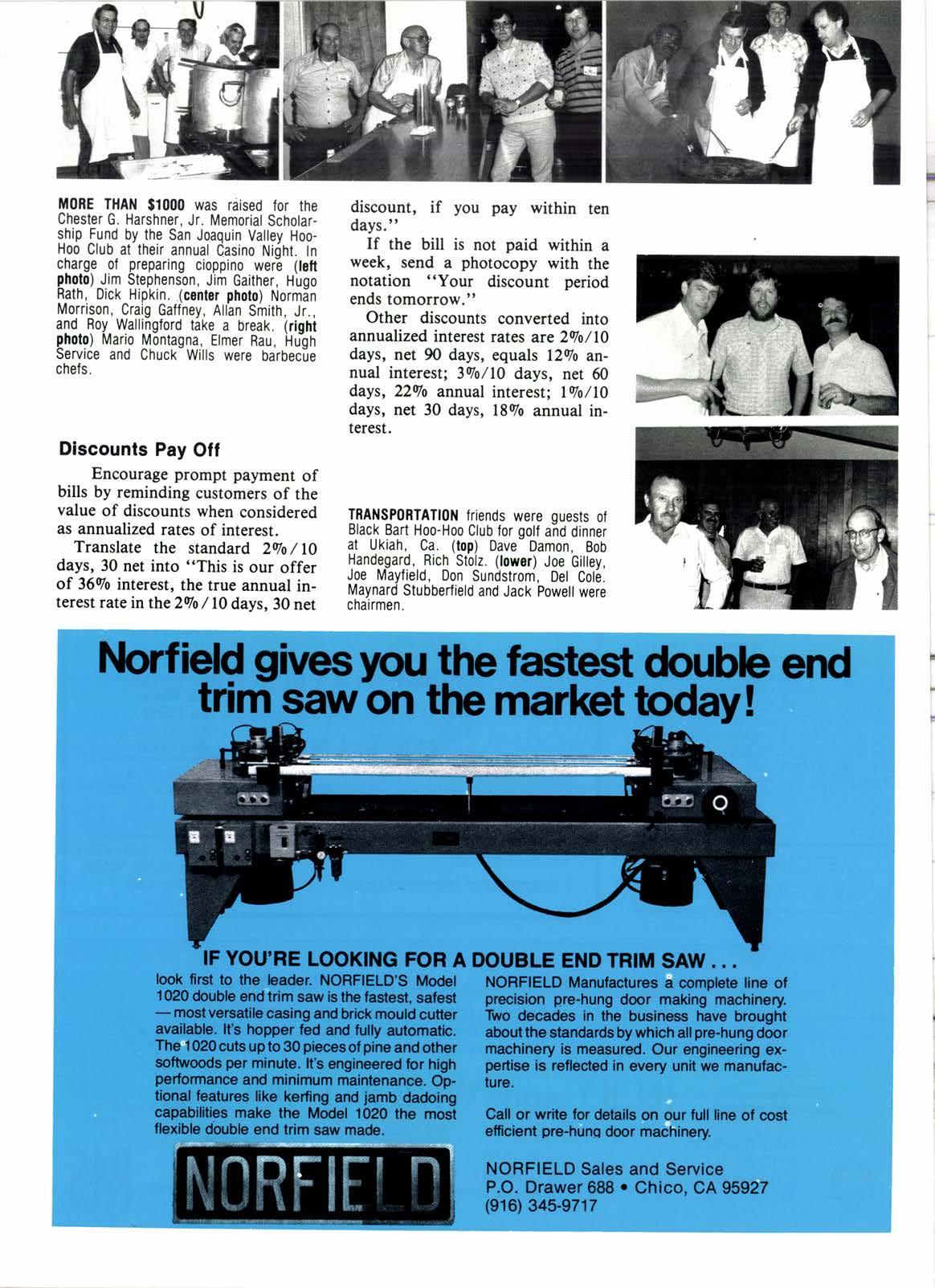

SANDER SURFACING ol Douglas fir and hemlock clears has replaced knife surfacing at Weyerhaeuser Company's major Longview, Wa. and Springfield, 0r. mills. Closeup of sander surfacing machine shows upper and lower sander belts (center of pic- ture and through windows). The four 48" wide sandpaper belts, two top and two bottom, do the surfacing. The clear lumber is fed through in 48" wide batches ol a single width. The two mills are the sole processors of the company's Coast clears.