1 minute read

Treated pole construction is k"y to quick building

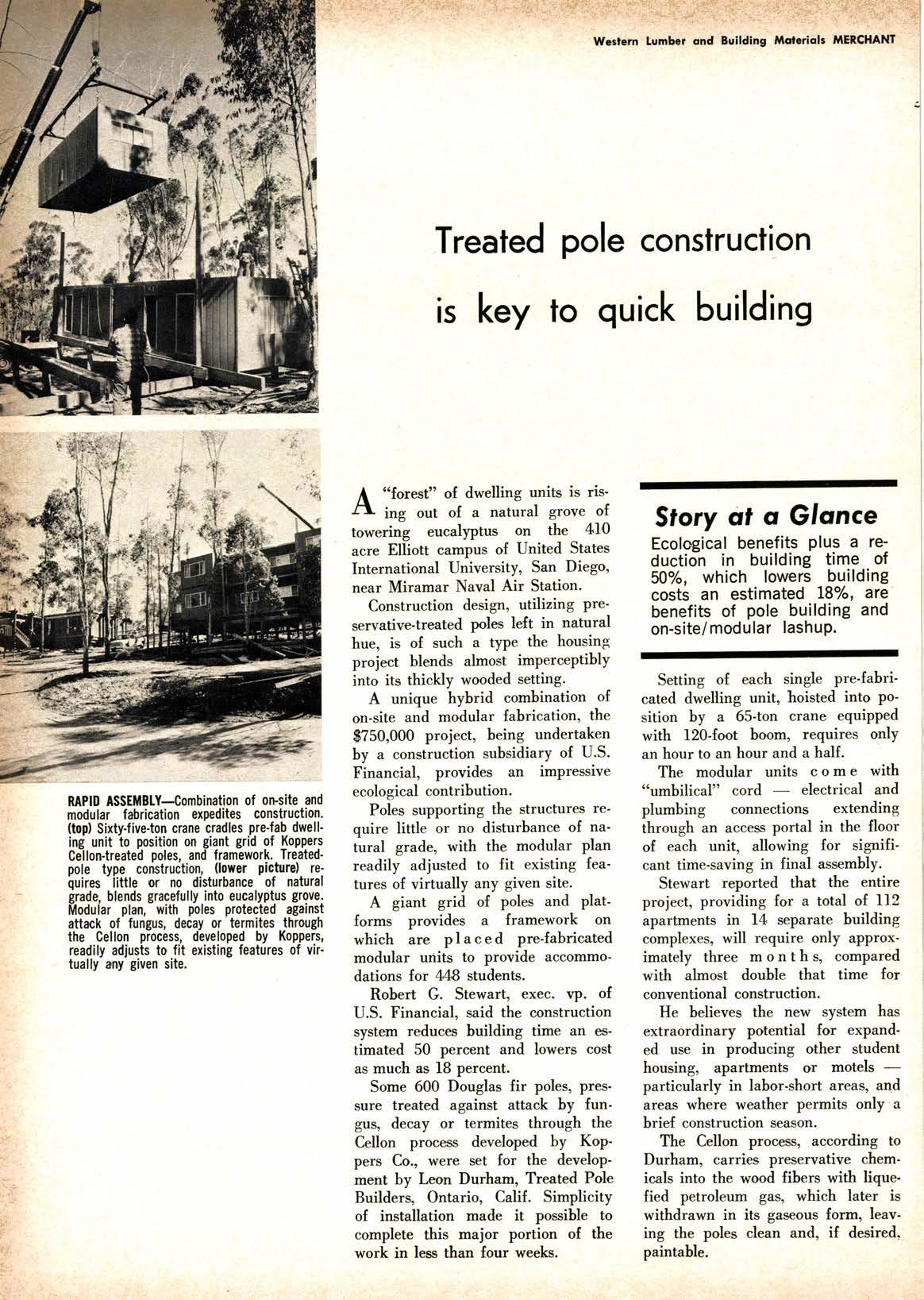

A "forest" of dwelling units is risfI itt* out of a natural grove of towering eucalyptus on the 4I0 acre Elliott campus of United States International University, San Diego, near Miramar Naval Air Station.

Construction design, utilizing preservative-treated poles left in natural hue, is of such a tyPe the housing project blends almost imperceptibly into its thickly wooded setting.

A unique hybrid combination of on-site and modular fabrication, the $750,000 project, being undertaken by a construction subsidiary of U.S. Financial, provides an imPressive ecological contribution.

Poles supporting the structures require little or no disturbance of na' tural grade, with the modular Plan readily adjusted to fit existing fea' tures of virtually any given site.

A giant grid of poles and platforms provides a framework on which are placed pre-fabricated modular uriits to provide accommodations for 448 students.

Robert G. Stewart, exec. vp. of U.S. Financial. said the construction system reduces building time an estimated 50 percent and lowers cost as much as 18 percent.

Some 600 Douglas fir poles, pressure treated against attack by fungus, decay or termites through the Cellon process developed by Kop' pers Co., were set for the development by Leon Durham, Treated Pole Builders, Ontario, Calif. Simplicity of installation made it possible to complete this major portion of the work in less than four weeks.

Story ol o Glonce

Ecological benefits Plus a reductio--n in buildinei time of 50o/o, which lowers building costs an estimated L8/", are benefits of pole building and on-site/modular lashuP.

Setting of each single Pre-fabri' cated dwelling unit, hoisted into position by a 65-ton crane equipPed with 120-foot boom, requires onlY an hour to an hour and a half.

The modular units come with "umbilical" cordelectrical and plumbing connections extending through an access portal in the floor of each unit, allowing for signifi cant time-saving in final assembly.

Stewart reported that the entire project, providing for a total of ll2 apartrnents in 14 separate building complexes, will require only approximately three months, compared with almost double that time for conventional construction.

He believes the new system has extraordinary potential for expanded use in producing other student housing, apartments or motelsparticularly in labor-short areas, and areas where weather permits only a brief construction season.

The Cellon process, according to Durham, carries preservative chemicals into the wood fibers with liquefied petroleum gas, which later is withdrawn in its gaseous form, leaving the poles clean and, if desired. paintable.