1 & 2 hour rated wall systems for commercial and multi-family construction.

Tested in accordance with ASTM E119. ASTM E119 testing evaluates the duration for which assemblies can either contain a fire, retain structural integrity, or both.*

Surface applied fire retardants like paints, stains, penetrants, and intumescent coatings ARE NOT building code compliant in applications where Fire Retardant Treated Wood is required. FlamePRO Fire Retardant Treated Wood is pressure impregnated, fully code compliant Fire Retardant Treated Wood. It is appropriate for use in all applications where Fire Retardant Treated Wood is required.

*For details refer to ESR Report 4244. Visit kopperspc.com for additional information.

INQUIRE ABOUT OUR PRESSURE TREATED LUMBER

We use Koppers Performance Chemicals to provide the most environmentally friendly, and effective pressure treated lumber available for a multitude of applications.

2,600 dedicated employees, and one of the most extensive product offerings of value-added treated lumber, we can deliver in ways few others can. PRESSURE

Our most popular treatments are NatureWood ® for Copper Azole (CA) treatment, Advance Guard ® for borate and FlamePRO ® for fire retardant.

PRESIDENT/PUBLISHER

Patrick Adams padams@526mediagroup.com

VICE PRESIDENT

Shelly Smith Adams sadams@526mediagroup.com

PUBLISHER EMERITUS

Alan Oakes

MANAGING EDITOR

David Koenig dkoenig@526mediagroup.com

SENIOR EDITOR

Sara Graves • sgraves@526mediagroup.com

COLUMNISTS

James Olsen, Claudia St. John, Dave Kahle

CONTRIBUTORS

Dave Bueche, Nicole Butler, Timm Locke, Paige McAllister, Brittany Poe, Belinda Remley

ADVERTISING SALES

(714) 486-2735

Chuck Casey • ccasey@526mediagroup.com

John Haugh • jhaugh@526mediagroup.com

Nick Kosan • nkosan@526mediagroup.com

DIGITAL SUPPORT

Katherine Williams kwilliams@526mediagroup.com

CIRCULATION/SUPPORT info@526mediagroup.com

151 Kalmus Dr., Ste. J3, Costa Mesa, CA 92626 Phone (714) 486-2735

CHANGE OF ADDRESS Send address label from recent issue, new address, and 9-digit zip to address below. POSTMASTER Send address changes to The Merchant Magazine, 151 Kalmus Dr., Ste. J3, Costa Mesa, CA 92626. The Merchant Magazine (ISSN 7399723) (USPS 796-560) is published monthly at 151 Kalmus Dr., Ste. J3, Costa Mesa, CA 92626 by 526 Media Group, Inc. Periodicals Postage paid at Newport Beach, CA, and additional post offices. It is an independently-owned publication for the retail, wholesale and distribution levels of the lumber and building products markets in 13 western states. Copyright®2025 by 526 Media Group, Inc. Cover and entire contents are fully protected and must not be reproduced in any manner without written permission. All Rights Reserved. We reserve the right to accept or reject any editorial or advertising matter, and assumes no liability for materials furnished to it. Opinions expressed are those of the authors or persons quoted and not necessarily those of 526 Media Group, Inc. Articles are intended for informational purposes only and should not be construed as legal, financial or business management advice.

Volume 104 • Number 4

Rosboro began producing glulam in 1964 and has been leading the way ever since. Innovators of the X-Beam® stock glulam, the industry’s original full-framing-width architectural beam, we have grown with our customers to become the most sought-after glulam partner in North America. Glulam is what we do.

Our personalized customer service and in-house engineering expertise ensures your glulam program runs smoothly, allowing your sales teams to spend their time serving customers instead of chasing vendors. And we continue to invest in our business, which means we are also investing in your growth.

Rosboro was with you then, we are here for you now, and we will remain by your side long into the future no matter how your needs change.

For anything glulam, you can count on us.

Western Wood Preservers Institute provides everything you need to know to sell more preserved wood, including the state of the industry, marketing tips, FRTW, new markets, the vital importance of product knowledge, and much more

Marking

------------ BY PATRICK ADAMS

MY SON IS NOW 8 years old and, so far, he’s a “Momma’s boy.” From everyone I talk to, this is normal— first daughter is a tomboy, Daddy’s girl, and the youngest boy ends up the opposite. This has never really bothered me because if my kids know we both love them and that, in their many phases, they have at least one of us they can talk to, I chalk it up as a win.

A few years back, I bought some Nerf Gun sets in hopes of reliving a safer version of the BB gun wars I had in the front yard with neighborhood kids. Well, at the time, my son just kind of looked at them and moved on to something else. Recently, however, he’s getting a bit rowdier and the guns came out! He didn’t even get his request to me out of his mouth before we were in the back yard, locked and loaded.

As the “war” unfolded, kind of a tactical game of tag, I found the countless hours of training coming back like riding a bike. Stalking, ambushing, firing from cover. He was outmatched. During one engagement, I rolled from cover, unloaded one magazine hitting him several times, reloaded magazines, and continued firing on the move, striking him several more times, somehow without taking a single hit. It was pure domination of an 8-year-old.

I waited to see his reaction. Would he quit? Get angry? Cry from the countless hits and frustration? To my surprise, he walked up and said, “Daddy, how did you do that?” I was proud, and immediately overwhelmed as my mind attempted to unpack “how” that was the byproduct of so many hours of training that it seemed impossible to break down.

But it reminded me of how important “how” is. To me, “what” is done matters very little if “how” it is done is careless. The same message, action or event can have a very different impact depending on how it is executed. I believe this is a universal truth that carries through every

portion of our life from personal, to business, and even our legacy after we’re gone.

As leaders, this is even more important and, I will argue, is the most important element that defines good leadership. I believe in the philosophy of “leading from the front.” I inform my team of what we’re doing, why we’re doing it, who does what, and then, I am the first through the door. I don’t ask people to do what I’m not willing to do, and I make sure that how we do what we do is in line with our goals and values—both short term and long term.

Often I find I don’t necessarily disagree with a leader’s goals, but rather how they pursue them that causes disappointment. Kind of analogous to winning the battle, but losing the war. Maybe this is experience, or wisdom, or perhaps just empathy, but I do believe it is the foundation of good leadership.

I knelt down to my son and asked if he wanted me to teach him how to do that. He quickly shook his head up and down and said, “Yes!” We then spent a few minutes walking through the fundamentals of shooting on the move and tactical reloads, but especially how the fundamentals would allow him to learn a lot more. I wondered if any of this set in, but noticed about 15 minutes after walking inside, he was out there practicing over and over what I had walked him through.

Whether it is our relationships at home, our team at work, or our own community, I hope you spend time considering how you do “that.” In our hectic days, it’s easy to forget and instead just focus on the “what.”

As always, I am grateful to serve you and this great industry! I hope that how you are doing what you’re doing is leading to another great year!

PATRICK S. ADAMS, Publisher/President padams@526mediagroup.com

Like the foods we buy, when it comes to decking, we want natural and real. Redwood is always available in abundance of options. So stock the shelves! Unlike mass-produced and inferior products, Redwood is strong, reliable and possesses many qualities not found in artificial products. They maintain temperatures that are comfortable in all climates.

Redwood Empire stocks several grades and sizing options of Redwood.

CHALLENGED OVER the past year by slower new construction, repair/remodeling, and industrial markets, wood preserving companies have pursued a variety of strategies to improve on prior performance.

Some treaters tightened their belts, while others implemented new processes. Great Southern just started up a new facility. UFP/ProWood is rebranding. And others—including Doman, Culpeper and United Treating & Distribution—added significant annual revenue and capacity through acquisition (although the pace of

consolidation has certainly slowed compared to recent years).

As Doman chairman Amar S. Doman explained, “We successfully navigated through 2024 by maintaining our focus on operational excellence through inventory and overall cost management, all while strengthening our financial position and executing significant and strategic growth opportunities.”

Each company has its own methods for best serving the $6 billiona-year treated wood industry. MM

The following 11 companies are those that operate at least three treating plants in the U.S. They are ordered by number of facilities, not by production volumes.

Stella-Jones saw sales rise 5% last year to $3.469 billion. Infrastructure sales (utility poles, railway ties, and industrial products, which make up 79% of Stella-Jonesʼ sales) were up 6%, while residential lumber sales slipped about 5%. Stella-Jones operates 45 treating facilities (29 of them in the U.S.) and 12 pole-peeling plants. Treatments are CCA, creosote, CuNap, borates, MCA, CA and ACQ.

Doman Building Materials, Vancouver, B.C., last fall purchased South Carolina-based C.M. Tucker Lumber, including its three treating plants. Doman now has 37 treating plants in North America. Treatments include MicroPro XPS, Advance Guard borates, FlamePRO FRTW,

UFP Industries operates 220+ affiliated operations in nine countries, including 22 treating plants from Colorado eastward, primarily along the East Coast, Midwest and Texas. Treatments include ProWood brand MCA, CA-C, borates and ProWoodFR FRTW. UFP also owns Sunbelt Forest Products, Bartow, Fl., which operates 11 plants in the Southeast and mid-Atlantic regions, utilizing Ecolife, TimberSaver borates, Preserve CA, Preserve Plus CA with water repellent, Wolman E MCA with BARamine technology. Last year, ProWood sales slipped 5%.

Culpeper Wood Preservers, Culpeper, Va., has grown to 22 facilities that extend from the Southeast to the Northeast through the Midwest, with its September 2024 acquisition of Fortress Wood Products’ three plants in North Carolina and its August 2024 purchase of Life Long Treated Wood, Hebron, Md. Treatments include MicroPro MCA, Advance Guard borates, CCA, FlamePro interior FRTW, and CA-C.

Great Southern Wood Preserving, Abbeville, Al., is among the nation’s highest volume treaters from its 16 facilities throughout the South, Midwest and Eastern Seaboard. Number 16 began production earlier this year in Tyler, Tx. Its YellaWood brand family of products includes YellaWood Select and SuperSelect KDAT products, YellaWood Columns, MasterDeck decking, and Rainwood with water repellent, plus fencing, railing, specialty products, fasteners, joist tape, stains and sealants. Treatments are MCA, borates, FRTW, CCA and CA-C.

Koppers Utility & Industrial Products a division of Koppers Holdings, operates 16 industrial plants, mostly in the Southeast—nine specializing in crossties, seven in utility poles. Koppers continues working toward opening a wood treating, peeling and drying operation on 70 acres in Glendale, Or., it acquired in 2023 Treatments include CCA, penta, CuNap and creosote.

Hoover Treated Wood Products, Thomson, Ga., late last year extended its long-established relationship with distributor Boise Cascade, adding Hooverʼs FRTW brands at all Boise branches in the Southeast. The Hoover name is synonymous with fire retardant treating wood, in addition to operating 10 of its own treating plants, from coast to coast, offering Pyro-Guard interior FRTW, Exterior Fire-X exterior FRTW, CCA, permethrin/IPBC-based Clear-Guard, Cop-Guard CuNap, Micro-Guard MCA, and DuraGuard ACQ.

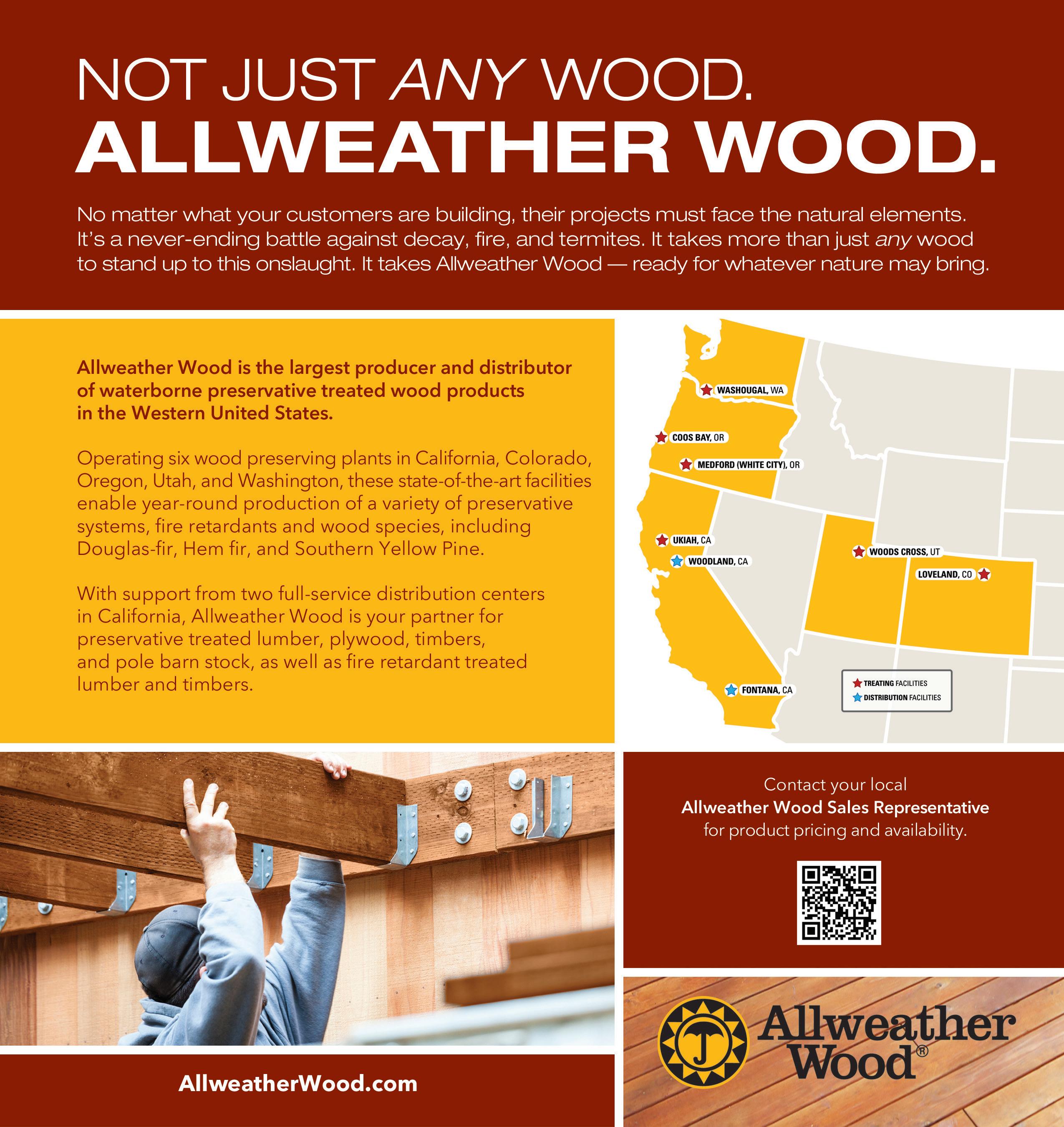

Allweather Wood is the largest waterborne preservative-treated lumber manufacturer and distributor in the western U.S., with six treating plants in California, Colorado, Oregon, Washington and Utah. Treatments include borates, CA-C, CCA, MCA and interior FRTW.

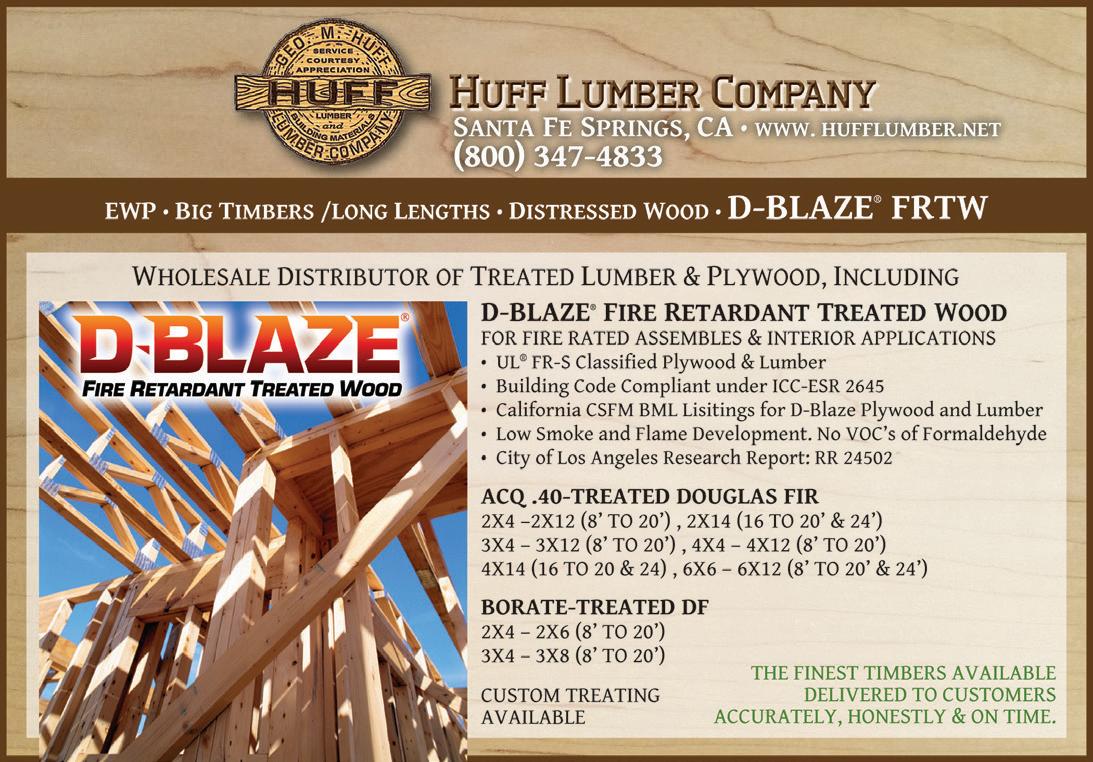

Bestway, Cortland, N.Y., has four treating plants (in New York, Pennsylvania and North Carolina) that offer Wolmanized Outdoor Wood, Wolmanized Heavy Duty CCA, and D-Blaze interior FRTW.

Biewer Lumber’s three treating plants (Lansing, Mi.; Seneca, Il.; and Prentice, Wi.) have a combined annual capacity of 350 million bd. ft. of CA-C, MCA and FlamePro FRTW.

Conrad Forest Products treats in North Bend and Rainier, Or., and Arbuckle, Ca., using Wolmanized Heavy Duty CCA, Chemonite ACZA, Wolmanized Outdoor Wood CA-C, Sillbor/ FrameGuard borates, interior and exterior FRTW, and QNap.

As the top supplier of FRTW for commercial and multifamily markets, our cutting-edge Fairfield, TX, facility delivers unmatched quality and performance. With our focus on innovation and reliability, we’re driving the future of building construction- helping you meet demand and grow your business.

BY BELINDA REMLEY

WHEN DID chemical become a four-letter word?

Some time, in the not-too-distant past, the world became afraid of chemicals—focusing only on the possible harm. We forgot that chemicals are all around us, doing good and keeping us clean and protected.

“Chemicals are in your toothpaste, your shampoo, and the cleaning wipes you use to disinfect your kitchen counter,” says Jay Hilsenbeck, global product director and North American marketing director for Arxada. “Chemicals are used in the manufacture of an uncountable number of materials, keeping our world clean and our bodies healthy.”

Chemicals enhance our lives every day and, for the most part, we don’t even realize it’s happening. But how do those chemicals become useful ingredients in our everyday products? For a closer look, let’s examine the wood treating industry. For thousands of years, humans have been using chemicals to enhance the performance of wood.

“In more modern times, chemicals have been extending the service life of wood to create an inexpensive, readily available, easy to install, and inherently renewable building material,” Hilsenbeck says. “Preservatives have been formulated to take nature’s sustainable building block and make it better. Yet, those preservatives do not detract from the appealing qualities of wood, such as availability, flexibility, and beauty.”

More than 100 years ago, Dr. Karl Wolman discovered a method by which wood could be infused with chemicals to lengthen its life. Dr. Wolman discovered certain chemicals react well during a pressure process in which the chemicals are forced into the wood to make it resistant to attack by termites and decay fungi.

Chemical formulations used within the wood industry— as with other industries—were developed based upon needs at the time of innovation. For example, pentachlorophenol (no longer used the wood treating industry) had been used by the Navy to treat rope in World War II. Before this it had even been used in North America to defoliate of crops before harvesting. When the war ended and there was surplus chemical, its use turned to wood preservation.

Preservatives are developed in response to market need, so when the world recognized importance of more healthful and environmentally conscious products, re-

search and innovation focused on the formulation of biocides used in paints and coatings as well as products designed for hygiene, crop protection and other needs.

“It was in the 1970s, with the establishment of the EPA, that people started to say we should really be paying more attention to what we’re handling, what we’re putting into wood, and what’s going into the environment,” explains Dr. Stephen Uphill, technical lead for Arxada’s Wood Group Research and Development team - Americas and Industrial. “And at that point the industry as a whole started to move away from more toxic chemicals.” More modern biocide chemical formulations to protect wood were developed.

Thus begins the product development process of new chemical formulations for the wood industry. Questions are asked, Uphill explains. “Which biocides, fungicides, insecticides, do we need to use together to protect wood in specific situations? Do they only work for crop protection, or will they work to protect wood as well? Will they meet EPA regulatory requirements for wood preservatives?”

“To answer these questions affirmatively, the research and development team performs screening tests,” Uphill says. “The team develops formulations and tests them to see if they work to protect wood. They discuss the risk phrases and health risks and anything else that might send a red flag and possibly prevent EPA registration. We want to constantly ensure we’re using enough of the correct active ingredients to protect from deterioration, without over treating.”

Treated wood becomes part of its environment where it’s going to last for a long time, fighting different decay organisms that might occur over its decades-long service life. While in crop protection, developers are trying to defend against specific organisms for a short time during growth/harvesting, wood preservatives need to provide long-term protection against a wide range of decay organisms that occur in nature in different locations around the world. “We are putting wood out in the environment for decades, and we want it be protected,” Uphill says.

How did researchers develop copper azole, the most prominent formulation used in residential applications today? They followed the science. Copper, prominent in many wood protection formulations, is a well-recognized chemical and used in many industries, including protecting hospitals from organisms such as bacteria and viruses. Researchers discovered that azoles, such as propiconazole and tebuconazole, work on their own to protect against decay fungi. Combining copper with azoles results in a formulation in which these chemicals enhance one another’s effectiveness in fighting the natural enemies of wood, allowing them to be used at much lower levels than if used individually.

This sort of product development process does not happen quickly. “A lot of formulation work has to be completed in order to make a stable system that can be sold as a concentrate, for transport all around the world, that is stable at different temperatures, can be diluted in different waters, can penetrate deep into the timber, and doesn’t wash out when it rains,” explains Uphill.

It takes months or even years in some cases to get the correct formulation. Testing continues with treating and retreating the wood to arrive at the final formulation. Then

CHEMICAL MANUFACTURERS take great care, employing important safety measures, when delivering products to treaters.

formal efficacy testing that could take years begins.

Finally, the government approval process starts and the Regulatory group takes over. “Developers must consider the regulations and all of the technical registration work in order to support the process to gain EPA approval,” Uphill says. “There is always more work to be done surrounding environmental emissions, leaching aspects, and other things. Products also must go through code approvals as well as meet AWPA standards and/or ICC approval.”

Teri Muchow, senior manager of regulatory affairs for Arxada, explains that the research team hands over their findings and the product registration process begins. “When formulation of new product is set,” she says, “testing needed to support the registration, such as product chemistry and acute toxicity, begins. Results from this testing are used to draft hazards statements proposed for use on the product label.”

When Regulatory is ready, they give the registration package to regulators at the U.S. EPA. The package includes the formulation, supporting data, description of use and proposed label language. Upon completion of its review the EPA renders a decision regarding product approval. If successful, then the process for state registration begins. It is necessary for each state where the product will be used to also grant approval. The entire process takes anywhere from one to two years.

“Once the EPA approval is received, the team creates a Safety Data Sheet and a graphic label for the new product and sales and marketing can start promoting and selling it,” Muchow says.

Even though a product passes initial registration and

can be sold, its active ingredients go through EPA registration review every 15 years.

“So, my rule of thumb for new product approval in North America is five to seven years from conception to having a registered product. For Europe, it’s eight to 10,” Uphill says.

This cautious, meticulous approach to innovation is typical throughout the entire wood preservatives market, whether it be specialties (sawmills, engineered wood, etc.), residential (backyard projects), or industrial (utility, marine, agriculture, railroad) applications.

“What we should realize,” Uphill adds, “is that we as an industry do not believe in the overuse of chemicals. We do have to acknowledge that chemicals have their place in our world. When you’re using the right chemicals responsibly, they make our world better. And it’s our role within the wood industry to ensure we’re innovating with chemicals that complement our environment and our lives. We use chemicals to make the world’s only truly sustainable building material even better, by extending the service life

of wood, locking away carbon, and allowing more trees to grow. Preserved wood supports leisure and infrastructure, for decade after decade.”

When properly studied and scientifically applied and used, chemicals enhance our lives often in unseen ways.

“Today, the world is leading us toward sustainable products that are safe and effective. That is why treated wood will always be the product of choice when it comes to residential outdoor projects and protecting our infrastructure, marine and agricultural applications,” says Hilsenbeck.

So, the next time you wash your hair, grab a wipe to clean your counter, relax on your deck or countless other things we routinely do every day, thank the researchers who spent countless hours developing that chemically-enhanced product that makes your life better. MM

– Belinda Remley has been promoting the wood industry for more than 30 years. She is a marketing communications professional with Arxada, a leader in wood preservation and the preservative manufacturer behind Wolmanized Outdoor Wood (www.wolmanizedwood.com).

By Timm Locke, WWPI

I recently went to the local big box home center to pick up a treated 2x4 for a fence repair. Some signage on the lumber racks helped me find what I needed, which I appreciated. Because I do what I do for a living, I knew I needed the right type of fasteners and some topical preservative to treat any end cuts. I knew I had those at home, so I bought my 2x4, went home, and crossed another project of my “honey do” list.

What if I didn’t work for WWPI? Would I have known I needed certain fasteners and the can of top-

for you. Merchandising

ical preservative? Would I have remembered to pick them up while I was at the store? I’ll say, “Maybe.” My wife would say, ”Probably not.” If she’s right, I’d have had to make another trip. But this time I’d go around the corner to the neighborhood hardware store.

The home center I visited is missing a bet. Many consumers don’t know preserved wood requires them to use certain fasteners and to field treat end cuts. Those who do know might be as absent minded as me. Either way, if the home center had reminded me they might have sold me not just the 2x4, but also a box of hot dipped galvanized screws and a can of topical preservative for field treating, making my $10 purchase more like $20-$25.

Merchandising is not a new concept for retailers. Many building supply dealers do it well in areas throughout their stores. Are there areas you’re missing? For the home center I visited the answer to that is “yes, the treated wood racks.”

When a customer is looking for treated wood, it’s a sure bet they have a project in mind. Whether they know it or not, they need proper fasteners and they’ll need to treat end cuts. A simple “Got the right type fasteners?” sign posted where it attracts that customer’s attention might do the trick. The customer will be glad for the reminder and your sales will increase. A portable display stocked with end treatment solution, a variety of fasteners and product use information from WWPI probably would work even better.

Doing nothing? Well, that’s a good way to boost sales for the neighborhood hardware store.

When it comes to Class A, ignition resistant, appearance grade, exterior FRTW nobody does it better than The Watkins Group.

International WUI Code Compliant

ASTM E84 Extended 30 Minutes

ASTM D2898 Accelerated Weathering

ASTM E108 Class A Roof Assembly

Listed: OSFM / CAL FIRE (7A WUI)

Listed: Cool Roof Rating Council

Meets Title 24 of CA Energy Code

AGRICULTURAL market is often overlooked by preserved wood seller, but in many areas it could be ripe for cultivation.

BY TIMM LOCKE

AGRICULTURE is a sometimes overlooked market for preserved wood. Lumber dealers servicing areas with heavy agricultural influence can potentially expand sales by focusing more attention on the needs of agricultural producers.

California and the Pacific Northwest (Oregon, Washington and Idaho), for instance, could be particularly ripe markets for agricultural use of preserved wood posts. These states dominate U.S. production of grapes and hops, both of which require plants to be elevated and supported by trellises in order to grow well. Those trellises are an ideal application for preserved wood posts.

California is by far the top grape producer in the U.S., delivering some 6.5 million tons of grapes, about 90% of the country’s total harvest in 2022. Washington, the country’s second biggest producer, delivered approximately 1.5 million tons and Oregon, ranked eighth, came in at about 800,000 tons.

The Pacific Northwest (PNW) accounts for virtually all of U.S. hops production. In 2023, total U.S. hops production was over 104 million lbs. Of that total, Washington growers accounted for 76.6 million lbs. Idaho produced 16.9 million lbs., and Oregon produced 10.6 million lbs.

Like all commodities, hops production varies year over year as it responds to the ebbs and flows of demand, but the trend, fueled mostly by the growing craft beer sector, has been generally up.

Combined, there are well over a million acres in the four states being utilized for grape and hops production. That’s potentially a lot of preserved wood posts.

While price is the main driver for those selling to the very large brewers and vintners like Miller, AnheuserBusch, Mondavi and Gallo, markets also include hundreds of craft brewers and small family vineyards who are equally interested in concepts like sustainability. To serve those smaller customers, grape and hops pro-

ducers sometimes seek to be Certified Organic, which can make it difficult to compete for the high-volume price-driven customers.

For those growers seeking to balance sustainability with lower cost, preserved wood offers what might be the best of both worlds:

Researchers at Oregon State University have been studying if preservation migration from preserved wood trellises used in vineyards might contaminate the soil and/or fruit. To get their answer, researchers analyzed soil, foliage and fruit samples for evidence of increased copper levels. Results showed nearly indetectable copper level increases in soil samples taken immediately adjacent to the treated posts, but no measurable differences in samples taken further from the posts, nor the fruit and foliage samples from the vines.

When treated wood posts are more cost-effective than the metal posts used by producers to comply Organic certification, this means growers can achieve near Certified Organic production at a lower cost, potentially satisfying both ends of the hops and grape markets.

Of course, agricultural market opportunities for preserved wood go far beyond posts for trellises. Pole barns and fencing represent much larger potential markets which may be there for the taking. As always, the key to gaining a foothold is to learn what the market needs and offer the preserved wood products that fit those needs.

A number of WWPI members specialize in agricultural products. Learn more at preservedwood.org/uses/ agriculture. MM

– With more than 30 years of experience in the wood products industry, Timm Locke is marketing director Western Wood Preservers Institute (www.wwpinstitute.org).

Hi-bor® brand treated wood is a borate treated wood product designed for interior house framing in Hawaii. Hi-bor treated wood resists attack by Formosan and subterranean termites and numerous household insects and pests, as well as fungal decay. Hi-bor borate treated wood is also backed by a 20 year limited warranty*.

FirePro® brand re retardant treated wood is treated with a patented formulation that contains no phosphates and has been shown to exhibit exceptional re performance properties without compromising other critical engineering properties such as strength, durability, corrosivity, and hygroscopicity. FirePro treated wood is also backed by a 50 year limited warranty*.

Advance Guard® borate pressure treated lumber is recommended for sill plate, furring strips, joists, studs, roof trusses, blocking, rafters, beams, and other framing applications. Advance Guard is also recommended for fascia, trim, wall sheathing, roof sheathing, and sub- oors. Advance Guard borate pressure treated lumber is also backed by a lifetime limited warranty*.

------------

BY DAVE BUECHE, PhD

BEFORE REBUILDING from January’s L.A.-area wildfires begins in earnest, you can bet plenty of attention will be focused on fire-resistant building products and construction methods. No doubt some will use the opportunity to turn up the volume on marketing pitches touting the fire-retardant properties of products which are questionable at best.

Even before the fires, there was no shortage of ambiguous misleading claims intended to have you thinking fire-retardant paints and other surface-applied coatings applied to untreated lumber and plywood can be used in place of fire-retardant-treated wood (FRTW) in construction applications where building codes call for combustion-resistant materials.

Nothing could be further from the truth. Using these coatings on untreated wood in place of FRTW is not just a violation of building codes, it’s also a dangerous threat to public safety. Selling them for use where FRTW is required could result in legal problems and financial liability lumber dealers probably don’t want.

Rigorous standardized testing protocols have been established to ensure code-approved products such as fire-retardant-treated wood meet the requirements needed to earn a Class A fire rating. These test methods were established by consensus and are referenced in building codes developed (also by consensus) by the International Code Council (ICC) and the National Fire Protection Association (NFPA). Those codes, including both International Building Code (IBC) and the International Residential Code (IRC), are in force nationwide.

Products that are untested, tested using methods other than those specified in the codes, or that fail to

achieve the results required for a Class A fire rating should never be sold or used in lieu of code-compliant, pressure-impregnated, fire-retardant-treated wood. They do not meet the code standards called out in the IBC Section 2303.2, the section which relates to fire-retardant wood products used in structural applications.

You might hear claims from promoters of these coating products that they are “code compliant.” Often, they are but that compliance is limited to sections of the codes governing interior non-structural applications, not the structural applications governed by Section 2303.2. It pays to be wary when descriptions like “code-compliant” get tossed around without reference to specific code sections.

It’s no surprise when building materials dealers and their customers are tempted to consider these lower-cost alternatives marketed as “FRTW-equivalent.” Who wouldn’t be? When that temptation presents itself, you are best served knowing and understanding the actual code language.

The building and fire codes in force in the U.S. explicitly exclude use wood products painted with “fire-retardant” coatings as substitutes for pressure-impregnated, fire-retardant-treated wood in structural applications. Several modifications have been made to language in the IBC over the past 20 years to clarify what is meant by “fire-retardant-treated wood” as it relates to Section 2303.2.

The 2024 IBC states:

2303.2 Fire-retardant-treated wood. Fire-retardant-treated wood is any wood product that, when

(Continued on page 20)

impregnated with chemicals by a pressure process or other means during manufacture, shall have, when tested in accordance with ASTM E84 or UL 723, a listed flame spread index of 25 or less. The ASTM E84 or UL 723 test shall be continued for an additional 20-minute period and the flame front shall not progress more than 10-1/2 feet (3200 mm) beyond the centerline of the burners at any time during the test.

(NOTE: Code excerpts and references in this article all refer to language in the 2024 edition of the IBC)

Read section 2303.2 carefully. It describes the required production process, “…impregnated with chemicals by a pressure process or other means during manufacture.” It also specifies the test methods that must be used and the results that must be achieved to prove products comply with this section of the code.

Subsections 2303.2.2, 2303.2.3, and 2303.2.4 further clarify the phrase “when impregnated with chemicals by a pressure process or other means during manufacturer”:

2303.2.2 Pressure process. For wood products impregnated with chemicals by a pressure process, the process shall be performed in closed vessels under pressure not less than 50 lbs. per square inch gauge (psig) (345kPa).

2303.2.3 Other means during manufacture. For wood products produced by other means during manufacture, the treatment shall be an integral part of the manufacturing process of the wood product. The treatment shall provide permanent protection to all surfaces of the wood product. The use of paints, coating, stains or other surface treatments are not an approved method of protection as required in this section.” (emphasis added)

2303.2.4 Fire testing of wood structural panels. Wood structural panels shall be tested with a ripped or cut longitudinal gap of 1/8-inch.

This 1/8-inch gap requirement mimics field conditions, where visible gaps often are visible between installed panels. It also exposes bare wood during testing if the product is not thoroughly impregnated by the fire-retardant.

Critical takeaways are that fire-retardant-treated wood products must be “impregnated with chemicals,” that “…use of paints, coating, stains or other surface treatments are not an approved method of protection…” by the codes, and that the products must achieve a flame spread index of 25 or less when tested using specified test methods.

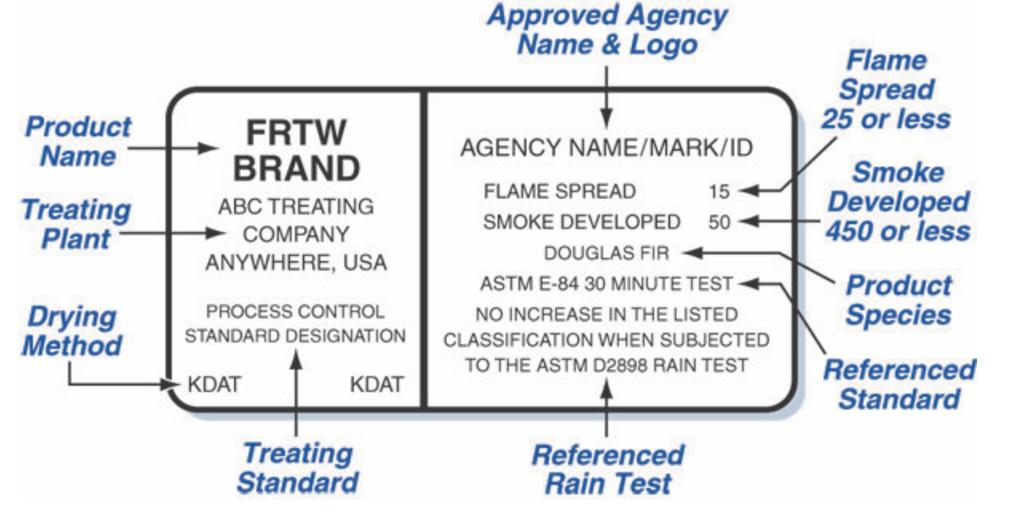

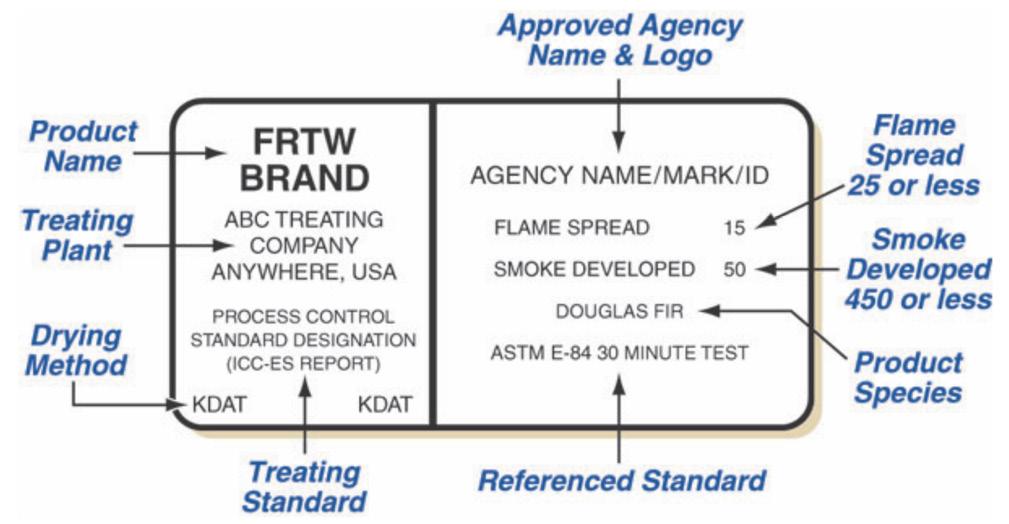

To make it easy for contractors, inspectors and others to identify FRTW, the codes require each piece to be marked with a label that includes, among other things, the identification mark of an approved certification agency, the name of the treater, the treatment used, the wood species, and the flame spread- and smoke-developed indexes achieved during testing. If the FRTW is intended for exterior use, the label must also reference the ASTM D2898 Rain Test.

When building inspectors encounter situations where wood required to be FRTW is not properly labeled, they can require it be removed and replaced. That can be expensive and it always causes delays, so if it happens the contractor, your customer, is probably going to look for someone to blame and you likely will have a dispute on your hands. If the inspector doesn’t catch it and the building later catches fire… well, you probably don’t want to think about that. MM – Dave Bueche, PhD, is director of Fire & Life Safety Codes at Hoover Treated Wood Products. He has over 30 years experience and is a leading expert in building code development and combustion-resistant building products.

Continuing to bring the finest mahogany decking

Genuine Fijian Mahogany is a naturally beautiful and durable wood. Mahogany ages gracefully to a rich gray and easily accepts stains for a custom look. Its exceptional stability makes it ideal for the Pacific Northwest’s wet climate, with kiln-drying ensuring minimal moisture and resistance to splitting. As a fully renewable resource, this True Genuine Mahogany has been sustainably grown on the Fijian Islands since World War II, continuing a legacy of responsible forestry.

Conrad’s partnership with Sequoia merges decades of excellence with cutting-edge innovation bringing you the best redwood fencing available! Customers can count on a steady supply of high-quality redwood fencing from Sequoia Forest Product’s state-of-the-art mill. With a direct connection to the timberlands, Sequoia ensures a consistent supply chain. Sequoia’s partnership with CFP ensures unmatched quality, durability, and beauty in every redwood fence!

------------ BY NICOLE BUTLER

THINK HOW often you use standards. There are standard countertop heights, standard sizes for lumber and plywood, standard systems to describe nails and screws, standard opening sizes for doors, refrigerators, ranges… You probably refer to standards dozens of times every day without even thinking about it. No doubt you take standards for granted; we all do.

Standards ensure product consistency across every aspect of our lives— from plugging in a lamp without worrying if the plug will fit, to expressing blood pressure measurements from any device type in universal terms your doctors can read and interpret, to making sure no matter who your wireless carrier is, your phone will skitter across the table in a panicked vibration when an Emergency Alert is issued.

The American Wood Protection Association (AWPA) is an ANSI-accredited standards developer comprising the

largest collection of wood protection experts in North America. These experts evaluate wood preservatives and treatment processes for the purpose of establishing the standards published in the AWPA Book of Standards.

But why should you care? In short, AWPA Standards help provide the guidance customers need to choose the right preserved wood products for their projects and they help protect you, the seller, from negative consequences if they don’t.

Standards provide for the consistency across products that is essential to ensuring those products will perform as they should when used as intended. The labeling found on preserved wood products affirms the standards to which those products adhere and it helps identify the correct products for the applications the user has in mind, offering assurance that those products will perform in the way

that is promised.

AWPA Standard U1 is the primary tool for specifying preservative treated wood. AWPA’s Technical Committees undertake intensive reviews of wood preservatives and define the levels at which preservatives should be used for individual use categories. To help consumers select the treated wood most appropriate for their project, another standard requires preserved wood sold through distributors, home centers and lumberyards to be labeled with an end tag that carries certain required information such as the use category and whether the product is suitable for ground contact. Use categories cover virtually every treated wood application you can imagine—interior dry conditions, exterior above ground, exterior ground contact, marine use, and anything in between. There even are use categories to identify interior and exterior fire protection (see table at right).

End tags provide a great deal of information; interpreting that information requires understanding the AWPA. For example, an end tag might say “AWPA U1, UC3B.” Without a solid grasp of the Use Category System, you might not know that means the wood is intended for use in exterior, above ground situations (uncoated or in a poor run-off area). To help with this, AWPA has published an infographic that identifies the appropriate use categories for most common residential projects calling for preserved wood.

AWPA also offers a portion of the AWPA U1 standard for free download and reference at AWPA.com. Floor personnel at lumberyards and home centers will find these tools are handy when helping customers find the products they need (see image upper left). A downloadable pdf of the infographic can be found at preservedwood.org.

Use Category Brief Description

UC1 Interior Dry

UC2 Interior Damp

UC3A Exterior Above Ground, Coated with Rapid Water Runoff

UC3B Exterior Above Ground, Uncoated or Poor Water Runoff

UC4A Ground Contact, General Use

UC4B Ground Contact, Heavy Duty

UC4C Ground Contact, Extreme Duty

UC5A Marine Use, Northern Waters (Salt or Brackish Water)

UC5B Marine Use, Central Waters (Salt or Brackish Water)

UC5C Marine Use, Southern Waters (Salt or Brackish Water)

UCFA Interior Above Ground Fire Protection

UCFB Exterior Above Ground Fire Protection

Applying the Standards

Let’s look at how all this can be put to use in real-world situations. I’ll start with a story close to home: Not long ago, my daughter came home with lumber she had bought to build shelving for her dorm room. The end tag looked like the photo at upper right.

As you can see from the use category table, the lumber

she bought was preservative treated and suitable for use outdoors in a ground contact situation. As an uninformed consumer she purchased wood treated to a much higher level than she needed. No real problem there, other than she likely paid a lot more than necessary, as untreated lumber would have been just fine for building her shelves.

Now imagine your neighbor plans to build a deck. When shopping for structural posts to support the deck, they bring home lumber treated to Use Category UC2—wood intended for interior use in damp areas such as basements. It probably won’t last long inserted 2 ft. deep in the ground. When the wood begins to decay much sooner than expected, it creates a risk of the deck collapsing and someone being injured. At the very least, it’s likely to trigger a complaint from a miffed customer. Most often, that call will be to you, the seller. Treaters also get these calls sometimes. I’ve even had a few come to the AWPA office.

I think we all agree it’s much better if customers are well-informed up front so they buy the right product in the first place. That’s where you come in. If you understand the system and have the resources on hand to help consumers learn what they need to know, everyone goes home happier. MM

– Nicole Butler is executive director of the American Wood Protection Association (www.awpa.com)..

BY BELINDA REMLEY

TREATED WOOD that arrives to dealer/retailer locations can be trusted to last. But you don’t have to take our word for it. You can believe the science behind preservative treated wood.

The wood industry, as a whole, takes great care in ensuring that quality treated products are stocked on the shelves of every retailer/dealer and at every building site. Regardless of whether the wood is treated to protect against termites and fungal decay, flame spread and smoke development, or mold and moisture, quality checks are in place to make sure the wood will perform as expected.

Testing of both the preservatives and the treated wood are performed within the treating facility by plant personnel. Additionally, the treaters

regularly send their samples to their preservative manufacturer and a third-party lab for testing. Finally, third-party agencies also visit plants to perform independent testing and inspections.

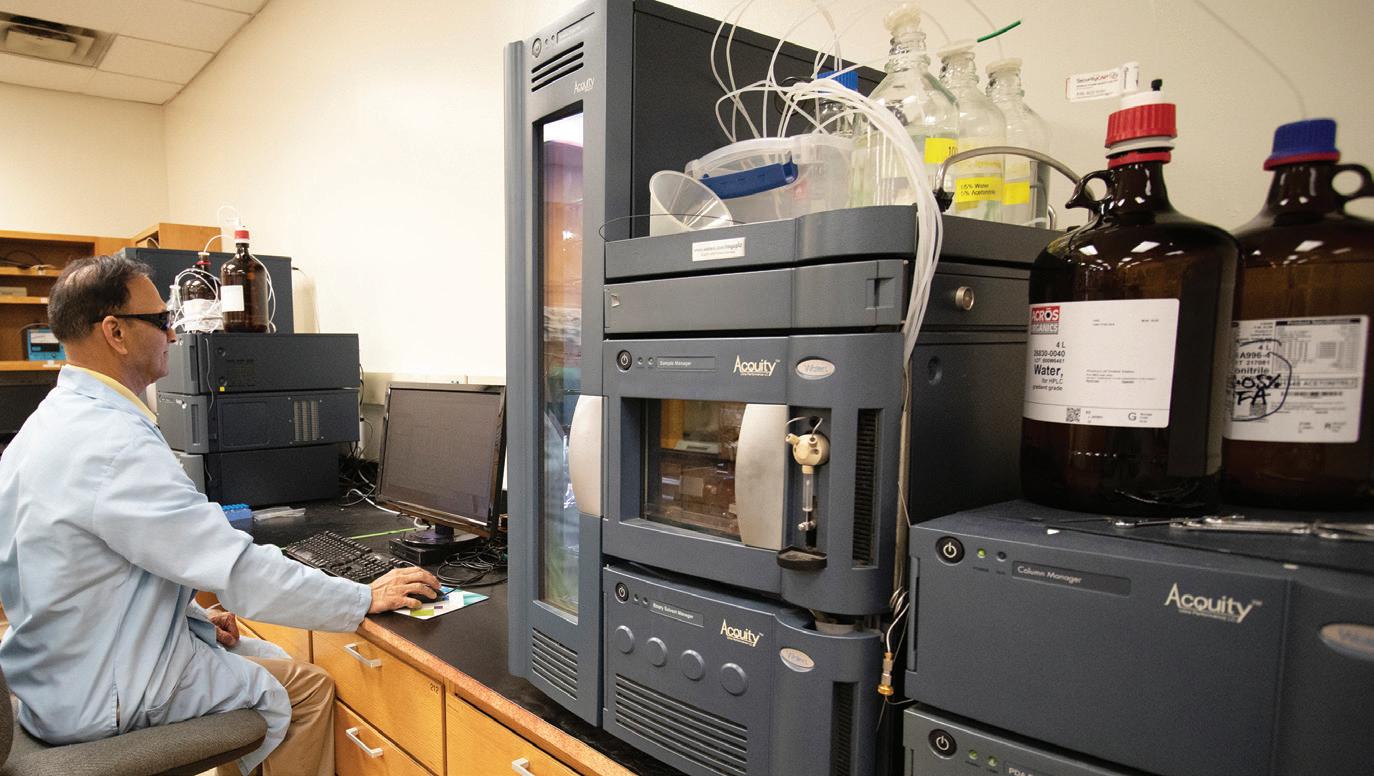

According to Steven Jang, Arxada’s senior technical services manager for the Wood Group, Arxada’ Conley, Ga., lab tests about 1,500 samples per month. “We provide the necessary Quality Control (QC) checks on the samples we receive to ensure the delivery of accurate and reliable data that can accurately describe the characteristics and concentrations of wood preservatives in the product, treating solution, and treated wood,” he says.

Arxada, like the other manufacturers, provides testing results to treaters, giving them the science to know

that what they are treating meets specifications set out by the industry.

“We want to help our customers by ensuring the accuracy and reliability of data produced by wood customers in their QC labs,” says Jang. “It’s like a back-up for the treaters.”

This not only helps the treaters in case they need to make adjustments within their plant but also maintains the customers’ status as a part of the product warranty program.

“We can also provide analytical testing that cannot be handled in the wood customers’ QC labs,” Jang adds. “Our QC lab equipment includes X-ray fluorescence (XRF) analyzer for metal-based wood preservatives, inductively coupled plasma spectroscopy (ICP) for metal-based preservatives and metal screening, high/ultra performance liquid chromatography (HPLC, UPLC) and gas chromatography for organic wood preservatives, and titrators for inorganic preservatives.”

Treaters obtain samples from their concentration tanks as well as the treating solution tanks and cores from their treated wood. Some samples are tested on site by the treaters. Some are sent to the preservative manufacturer QC lab for testing. “Using the sophisticated equipment located in our lab,” Steven explains, “our team of expert scientists test samples of the concentrates, treating solutions and treated wood.”

In addition to that testing, treaters partner with third-party inspection agencies, who visit the treating facilities to ensure that the wood is treated properly. According to David

Jones, PhD, director of treated wood & laboratories with Timber Products Inspection, “In order to comply with the building codes, an accredited, independent third-party agency is required to inspect a facility producing preservative treated wood. The wood also must carry a quality mark with the third-party’s logo, the accreditation agency (ALSC, ICC-ES) and the proper information as outlined by AWPA or ICC-ES.”

The inspection agencies visit participating smaller treating plants about once per month and larger plants approximately every two to three weeks when inspectors go over any changes that have been produced by the plant and then review the QC records of all charges since the previous inspection.

According to Kim Merritt, director of the Treated Wood Division at the Southern Pine Inspection Bureau, “the third-party inspection process includes reviewing in-plant quality control records, random sampling, visual inspections, preservative retention testing, performance evaluations, and documentation of results. It also involves corrective actions for non-compliance and continuous monitoring to maintain consistent product quality and adherence to industry standards. Treated materials that pass this rigorous inspection process are marked with an ink stamp or plastic end tag, which displays treatment details, the standard reference, and the accredited agency’s quality logo.”

The inspection agencies take their guidance from the AWPA Book of Standards, the American Lumber Standards Committee Treated Wood Enforcement Regulations, and the ICC-ES code reports. “We work hard to build a relationship with our treater partners that help them stay in compliance and understand the overall treating standards,” Jones says.

Merritt, former president of the American Wood Protection Association, says, “through our Treated Wood Quality Audit Program, we help treated wood producers meet industry standards. We collaborate closely with our subscribers, providing accurate inspection data to improve product quality, ensure compliance with Building Code requirements, extend service life, and support sustainability in the industry.”

Agency inspectors analyze treated wood cores taken from lumber or timbers to determine whether the preserved wood meets the penetration standards outlined in the AWPA Book of Standards, and assay samples are sent back to the agency lab for analysis. After the samples are obtained and tested, the inspector also checks equipment to ensure that it is providing reliable results. Gauges and instruments are checked for the appropriate calibrations, and overall functionality of the facility is observed.

“All of the checks are to assure that the preservative treated wood leaving a treating facility meets the requirements outlined in the AWPA Book of Standards or the corresponding ICCES Code Report,” Jones says. “This gives both the producer, the seller,

and the buyer piece of mind that the products they receive will perform as intended when used properly.”

All of this testing is performed regularly with an eye on accuracy and maintaining the high standards to which the entire industry holds itself. The end goal is making sure that treated wood is delivered and sold with the knowledge that it will last and that customers who purchase the wood will build with confidence in the product and their project. MM

– Belinda Remley has been promoting the wood industry for more than 30 years. She is a marketing communications professional with Arxada, a leader in wood preservation and the preservative manufacturer behind Wolmanized Outdoor Wood (www.wolmanizedwood.com).

BY BRITTANY POE

SUSTAINABILITY, alongside quality and affordability, continues to grow as a factor in consumers’ purchase decisions, giving lumber retailers the opportunity to guide customers toward options that provide the performance they need while reducing overall environmental impacts. Appealing to customers’ sustainability values will go a long way toward earning their repeat business.

Wood is inherently the greenest building material available for consumers’ home projects. It is the only commonly-used building material that is renewable, with added benefits such as atmospheric carbon sequestration, a low carbon footprint, and its contributions to greater biodiversity and improved air and water quality.

While preserved wood offers all those inherent benefits, customers may also have questions about the preservatives used to treat the wood. They’ll be interested in the extended service life preserved wood offers, certainly. They might wonder if preserved wood products are safe to use and how scraps should be disposed of.

Having a working knowledge of the preservatives used to treat wood will help you provide answers regarding the products you sell. Every customer who walks through your door wants that expertise, but they don’t necessarily expect to find it. When they encounter it, they’ll be more likely to make you the go-to for all their future needs.

A good starting point for gaining an understanding of the preservatives in treated wood is the WWPI PreserveTech publication Options for Preserved Wood Products

Any concerns consumers may have about treated wood likely stem from the 1990s, when chromated copper arsenate (CCA) was the most common preservative used to treat the lumber and plywood found at local lumberyards. CCA is economical and highly effective, with numerous in-service examples dating back to the 1930s to prove it. In 2002 the EPA was concerned about CCA’s arsenic component. So in 2004, the preserved wood industry voluntarily agreed to stop using CCA in products intended for residential use. Thanks to the Internet, remnants of that debate have gained immortality in the mind of the public and customers might associate today’s preserved wood with the CCA-treated wood of yesteryear.

Many alternative formulations have been introduced over the past two decades. Today copper azole (CA) is used to treat most residential preserved wood products. Copper azole has proven to be an effective wood preservative and

both of its active ingredients, azoles and copper, are found in scores of other consumer products including sanitizers and topical medications. Scientific research is proving that in normal use, such as for decks or raised beds for gardens, there is no reason for concern that the components in CA might migrate from the wood and contaminate the soil or plants growing nearby.

Many people believe the best performing wood protection combines extended decay resistance with the maximized dimensional stability (reduced splitting and warping) offered by oil-borne preservatives. One such formulation, copper naphthenate (CuN), is most often used to treat essential infrastructure such as bridges, rail ties, and utility poles due to its longevity and durability in the field. But CuN also is sold at retail. It’s the active ingredient in end-treating solutions such as Copper-Green, Rust-Oleum CopperCoat, or Nisus QNAP2, one or more of which you probably have in stock. Your preserved wood customers all should be made aware of those products, as it is essential they treat end cuts and drilled holes made in treated wood.

While not as prevalent as copper azole, CuN is used by some producers to treat preserved wood for residential use. It is a strong contender for outdoor projects in settings where the wood will be in near-constant exposure to brackish or fresh water such as dock pilings and decking, pedestrian bridges over creeks or streams and boat ramps. MM

– Brittany Poe is a communications specialist at Nisus Corp., a chemical manufacturer based in Rockford, Tn. (nisuscorp.com).

Located in Sumner, Washington, Western Wood Preserving Co. has been a manufacturer of pressure treated wood products, supplying residential, commercial and industrial markets of the Paci c Northwest since 1971. In addition, our strategic location near the ports of Tacoma and Seattle, provides easy access to the Alaskan, Hawaiian and Paci c Rim markets.

Our facility includes 12 acres of treatment, drying and storage areas, and produces top quality treated wood products for residential and commercial consumers in the wholesale market.

I WAS FORTUNATE to work for great sales companies as a salesperson. I was surprised when I began consulting with companies because I thought all companies would understand the importance of having a strong sales team and culture. Many do not. Many see and treat the sales team as a necessary evil. They see it as a war to get the most from the sales team and pay them as little as possible. I consulted with a firm that always complained about the quality of their team. I told them, “You treat your sales team badly, you talk down to them. Of course your team is weak because good salespeople won’t take poor treatment. They’ll leave for a company that will treat them with respect.”

My brother was senior VP of sales & marketing for DirecTV. Before he took over the job, the sales team was “the butt of all jokes” inside the company. He changed that, and sales and profits skyrocketed.

Companies that have strong sales teams and great sales cultures do many of the following:

It takes a certain kind of person to be successful in sales. Intelligence, creativity, ego drive and relatability are the key attributes that make up a great salesperson. There are several tests available that help companies ascertain whether a particular candidate has these attributes. Turnover is costly so these test are worth the money it takes to administer them to potential hires.

1. Hogan psychometric assessment - predicts job performance by assessing normal personality, derailment characteristics, core values and cognitive reasoning ability.

------------ BY JAMES OLSEN

2. Core values assessmentmeasures fundamental beliefs and principles that guide a potential hire’s actions and decision-making, revealing areas of alignment and potential for growth or change.

3. EQI assessment - measure emotional intelligence.

4. Wonderlic assessment - The test assesses verbal reasoning, problem-solving, general knowledge, and mathematical aptitude.

Over time, companies build a baseline of attributes that the successful salespeople in their organization possess and measure those against the test scores of potential hires.

The turnover rate in sales is about 35%. This is about three times higher than the rate in other job areas. Companies that want to grow a strong sales team budget for this. Of course they’d like all hires to make it, but are realistic. One client, who took 15 years to build from two to a team of 25 killer salespeople, says, “My only protection is to hire more salespeople.” His turnover rate hovers around 40%.

They take their time in the interview process, test (see above) potential salespeople to make the right decision.

Successful companies have clear/ fair compensation packages. I closed a consulting job with a large distribution company. The first day the owner started explaining their compensation package to me. I’d been in sales for 20 years at the time. I could not understand it. He said, “Well, you need to learn it.” I said, “No, if you can’t explain your package in less than two sentences, then it is

demotivating to the sales team.”

I worked with them for two years. I asked general managers at five different branches and multiple salespeople, and none of them understood or could explain it to me. A seasoned and successful salesperson at the company told me, “James, it’s confusing and I think they want it that way.” I quoted that to the owner, and he said, “Oh that probably comes from ----; he’s always complaining.” I said, “No. It’s coming from one of your superstars, ----.”

Sales contests work. Salespeople enjoy competition and prizes! Successful sales companies celebrate their sales teams. They motivate them by offering trips or free dinners or cash for salespeople who hit their goals. They give awards to the highest performers in several categories, i.e., the highest sales margin, highest number of sales, highest number of new customers, etc.

Successful sales companies offer sales training. Sales training decreases turnover, helps salespeople become profitable more quickly and strengthens sales cultures.

Building a strong sales team takes sustained work, but is doable. MM

JAMES OLSEN

Olsen is principal of Reality Sales Training, Portland, Or., and creator of SellingLumber.com. Call him at (503) 5443572 or email james@realitysalestraining.com.

Introducing the Simpson Strong-Tie ® EasyFrame automated marking system. A combination saw and printer, EasyFrame cuts detailed wall panel framing members that are pre-marked for fast, accurate assembly. Designed for efficiency, EasyFrame prints framing plans directly onto lumber, including locations of boards, connectors, wiring and more. It can be paired with a manual or automated saw, and features a blade enclosure for safety. Powerful software also lets you ensure precision and optimize material use. EasyFrame is supported by our installation and onboarding services, training and technical expertise. It’s a smart way to equip customers for wall panel jobs while setting your business apart. Add EasyFrame to your lumber sales area. To learn more, visit easyframesaw.com or call (800) 999-5099.

------------

BY PAIGE McALLISTER

PRESIDENT TRUMP’S administration has made or proposed significant changes that will impact how companies do business and manage their workforce. Among the most drastic actions we have seen is immigration, which is unsurprising given its focus of attention during the campaign and from his supporters.

President Trump has stated he intends to deport up to 20 million people, while experts estimate there are only 11 million undocumented people in the U.S. currently. Since only two million non-citizens have criminal histories and/ or previously issued final orders of removal, the other 18 million immigrants impacted will likely be those currently protected under Deferred Action for Childhood Arrivals (DACA or “Dreamers”), Temporary Protected Status (TPS), Deferred Enforced Departure (DED), and other humanitarian parole programs.

Department of Homeland Security (DHS) Secretary Noem began rescinding previously extended TPS—and therefore their Employment Authorization Documents (EAD)—for citizens of certain countries with more expected in the future. Her actions have already changed the TPS expiration for Haitian citizens to Aug. 3, 2025, and for Venezuelan citizens to April 7, 2025, or Sept. 5, 2025, depending on which extension they were under. This means that, unless they have been able to gain a protected immigration status outside of the TPS, more than one million people will no longer be able to legally live and work in the U.S. within the next six months. Additionally, the DEDs (and their EADs) for people from Hong Kong and Palestine will expire this year, and those for Lebanon and Liberia will expire in 2026.

DHS has also announced that it will expand its use of the expedited removal process. The expedited removal process allows the U.S. to quickly deport a person they believe to be an undocumented non-citizen without further processing, including seeing a judge, unless they pass a screening interview justifying their fear of returning to their country. This expedited removal process has been standardly used on undocumented people found within 14 days of their arrival in the U.S. and 100 miles of the border. However, DHS has announced that it will begin using the expedited removal process for any undocumented person who cannot prove they have been in the U.S. continuously for the past two years, regardless of where in the U.S. they are.

ICE agents, working with law enforcement agents from other federal, state, and local agencies, have begun conducting raids to find, detain and deport undocumented immigrants. While the initial focus was to be only those convicted of criminal activity, others with non-violent or even no criminal history other than having no current authorization to reside or work in the U.S. are also being detained as part of these sweeps.

Additionally, agents from ICE and Homeland Security Investigations (HSI) have also been tasked with increasing their I-9 audits to locate those workers who are not eligible to work in the U.S. and employers allowing them to work. It is expected that the Trump administration will aim to conduct 15,000 I-9 audits per year, as was the intention of his prior administration before COVID-19. As a result of these audits, employers could face fines ranging from $281 to $2,789 per violation for paperwork errors alone for

properly documented employees and ranging from $698 to $27,894 per violation for employing and/or retaining workers who are not authorized to work in the U.S.

Review I-9 Forms and Processes. Under the Immigration Reform and Control Act of 1986 (IRCA), all employers must verify the work authorization of every employee hired since November 6, 1968, and retain proof of this authorization by completing a “Form I-9: Employment Eligibility Verification.” Form I-9 demonstrates your goodfaith effort to comply with IRCA but has some very specific requirements to be correct.

Any and all mistakes and/or omissions could result in fines, each one contributing to a possible hefty total penalty. To reduce your exposure in case you are one of the 60,000 companies targeted for a Form I-9 audit in the next four years, we recommend reviewing your process for completing I-9s for new hires, training those who will be completing them, reviewing your recordkeeping practices, and doing an internal audit of your I-9s.

ICE agents could visit a company for several reasons. They could be serving a Notice of Inspection (NOI) to audit the I-9 Forms, investigating a specific person or a group of employees (usually under an administrative warrant), or conducting an immediate enforcement action under a judicial warrant (“raid”). While these actions have different characteristics in terms of severity, timing, and comprehensiveness, a company’s action plan can minimize impacts while ensuring compliance in each case. It is critical

Q . We received an anonymous complaint about one of our employees. It was a vague "inappropriate conduct" complaint left on our general voicemail. We have no way of following up with the person or anything specific to pursue through an investigation. What do we do?

A. While you should take every complaint seriously, you probably need more information to investigate.

If there is no way to contact the person who made the complaint (i.e., caller ID), you can do whatever you can with the information they provided. You can also determine how much credibility you want to place in the complaint of someone who won't give you their name or specific details.

If the allegations can be explored through a resource such as security footage or account reconciliation, try that. You can also inform the named employee of the complaint and see what they say— maybe they know who the person is or the underlying reason for the complaint. Do not feel like you need to discipline the employee if there is not enough evidence of wrongdoing.

As with any investigation, exhaust whatever means you have to try to find out what actually happened. Document everything—noting your actions and the challenges you faced during the investigation. Then, if appropriate, you can reopen the case if you get more information in the future.

that you engage legal counsel familiar with immigration law not only to review your plan of action, but also to call as soon as agents arrive to counsel you through their search, investigation and audit.

Review and update your plan of action, designated point people, and procedures regularly to ensure your organization is always ready for a visit from ICE or other law enforcement.

The Workplace Advisors can help you and your HR team review your Form I-9s and your procedures for their completion and recordkeeping to reduce your exposure in case you are one of the 60,000 companies targeted for a Form I-9 audit in the next four years. We can also help train the employees responsible for completing the forms. Additionally, through our compliance-focused HR Support Plan, we can create or update your employee handbook, notify you of regular updates, and offer one-on-one guidance on specific management or compliance situations. MM

Paige McAllister, SPHR, SHRM-SCP, is vice president for compliance with The Workplace Advisors, Inc. Reach her at (877) 660-6400 or paige@theworkplaceadvisors.com.

------------ BY MEGAN COSGROVE

RECRUITERS are special people, as uniquely skilled in their craft as their clients are in theirs. You’ll know you’re hiring the best if your potential recruiting firm partner shows these traits.

1. Start With a Focus on Culture

A company’s culture trumps its strategy, and maintaining a successful culture depends on who is hired to continue it. A great recruiter strives to learn the client company’s three key core values and how are they routinely actioned and celebrated. Then that recruiter strives to attract the people who advance that culture while—even more importantly—spotting and rejecting those who don’t.

2. Understand Your Business and Your Competitors

Recruiting goes beyond filling open positions—it’s about finding the right fit for your company’s challenges, and strategic goals. A great recruiting firm will take the time to understand: Who are your customers? Who are your competitors? Given the competitive options, why are your customers choosing you? What is your competitive advantage today and what do you want it to be tomorrow?

3. Excel at Marketing and Selling All Aspects of Your Business

The LBM industry has lots of great companies run by Grade A leaders that aren’t very well known because the firms are privately held, and the leaders are often overly modest. Grade A talent wants to work for such leaders, but it often takes a great recruiter to make such talent aware of the opportunity. The recruiter must be able to create a positive story about your market, be it small or large, warm or cold. Spousal income opportunities and education offerings for those with children also are a must in a proper presentation introducing talent to new area.

The quality of the talent pool directly impacts the caliber of candidates delivered to the dealer. Expect good recruiters to start most projects with a research pool of 300 to 400 candidates. After thorough filtering, interviews and multiple rounds of vetting, the recruiter will narrow the list to just five to seven top-tier candidates. This power of comparison process minimizes risks and ensures that only the best fit your needs.

It’s not uncommon for companies to seek the “perfect” candidate who ticks every box. However, market compensation realities often don’t align with these expectations. A good recruiting firm will help manage those trade-offs and help focus compensation dollars on what matters most to the candidate.

Effective communication is the foundation of any successful partnership. A great recruiting partner should keep you updated weekly throughout the search process. Full transparency, providing Friday updates that include:

• The number of candidates contacted

• Candidate turn-downs

• Progress on double vetting

• Final candidates being presented

• Compensation market data

This level of transparency ensures you have the facts and data to make informed decisions at every step of the process.

7.

A great recruiter doesn’t regard filling the role as a win. Rather, it defines victory by how the new hire lifts the company economically and enhances its culture. Such an attitude regards recruiting as a long-term partnership based on the performance of the hired professional one to three years past the hire date. A recruiter’s 12-month satisfaction fee can ensure that you’re making a sound investment in your future leadership. MM

MEGAN COSGROVE

Buse Timber & Sales, Everett, Wa., which ceased operations last year, is resuming manufacturing high-quality lumber products under the name Buse Mill Co.

Buse selected Elk Creek Forest Products, McMinnville, Or., as its exclusive sales agent, responsible for all sales, marketing and distribution.

“We are thrilled to partner with Buse as they restart production,” said Brett Slaughter, president of Elk Creek. “This collaboration strengthens our ability to provide our customers with an even more

consistent and reliable supply of top-quality lumber while also supporting the local economy and job creation in the region.”

Located in Everett since 1946, Buse has long been known for its commitment to producing premium lumber. With this reopening, the mill is set to resume producing the same high-quality lumber products like FOHC timbers, transmission crossarms, industrial clears, and structural lumber that Buse has traditionally delivered.

In June, Hardwoods will open its newest and largest distribution center in Stockton, Ca.

The warehouse will replace existing facilities in Livermore, Modesto and Rancho Cordova, Ca. When the move is complete, Hardwoods will operate six facilities in the region.

The new 150,000-sq. ft. facility features 27-foot-high clear span ceilings, 16 docks and five all-weather

loading doors. The 9-acre site provides considerable room for future expansion. Its prime location and the installation of advanced automated systems will significantly improve operational efficiency.

“This new distribution center represents a substantial investment, confirming our commitment to the Northern California market, and strengthening our strategic service

The Trump Administration mandated additional 25% tariffs on lumber imported from Canada and Mexico that, as of presstime, were set to go into effect April 2.

Foxworth-Galbraith Lumber reopened its Ruidoso, N.M., location with a weeklong sale in early March. The branch closed last summer due to flooding.

Ace Hardware opened a 7,500-sq. ft. small-format store in Montebello, Ca.

Home Depot opened a new location April 3 in Surprise, Az., with another coming this spring in Moscow, Id.

Beacon has acquired DM Figley Co., Inc., Menlo Park, Ca., a wholesale distributor of sealants, waterproofing and concrete repair materials, with additional locations in Anaheim, Oakland, Sacramento and San Diego, Ca.

Wausau Supply is now carrying Deckorators products, including decking, railings and privacy screens, at its 22 locations, including in key markets in Washington, Idaho, Colorado and Utah.

Do it Best is expanding Milwaukee and Diablo power tools and accessories to its True Value distribution centers.

James Hardie agreed to acquire The AZEK Co. in a $8.75 billion deal.

footprint across the West,” said Nick Smith, regional vice president of Hardwoods West.

The facility will boast a bright, modern work environment for Hardwoods employees, a comprehensive showroom showcasing the company’s extensive product line, a well-stocked sample room featuring a complete selection of the company’s high-quality products, and a dedicated and efficient Will Call area that will ensure quick and easy order pick-up for local customers.

Business operations will continue uninterrupted during the relocation.

From its headquarters in Langley, B.C., Hardwoods, a division of ADENTRA, operates 32 regional customer service centers throughout the United States and Canada.

At Orgill, we work for you—never the other way around. As our customer, you’ll gain access to innovative retail solutions, flexible programs, and a vast selection of products—all tailored to fit your business. We can help you select what might work best for you, but the choice is always yours. There are no strict mandates or risky investments. With Orgill, you’re free to invest in what matters most: YOUR business.

To find out about how Orgill is a different kind of partner, visit Orgill.com/opportunity

Mandy Arnold General Manager of Morrison’s Hardware & Building Supply Nashville, Georgia

Facing stagnant sales and an outdated layout, Morrison’s Hardware & Building Supply partnered with Orgill to do a customized reset, enhance their assortments and refresh the store’s branding. The result? More customers, better selection, and a fresh new look driving growth.

Get an inside look.

Full-service lumber producer and distributor Elk Creek Forest Products, McMinnville, Or., has signed a letter of intent to acquire All-Coast Forest Products, Cloverdale, Ca.-based independent wholesale manufacturer and distributor of quality lumber products and building materials since 1975. The deal was expected to close by March 31, 2025.

Brett Slaughter, president of Elk Creek, said, “All-Coast Forest Products is a company that we have always admired, and we are deeply

honored to be carrying on their long-standing legacy and tradition.”

Being a family-owned business since 1978 and located in Cloverdale since 1988, All-Coast shares values that resonate with Elk Creek Forest Products, creating a strong foundation for integrity, commitment to service, partnership and innovation. Slaughter continued, “We are grateful for the opportunity to join the Elk Creek and All-Coast families together, carrying on a joined legacy for both companies.”

After 75 years in the same location— providing quality lumber, building materials, and expert advice to Cheyenne contractors and do-it-yourselfers, it was time to grow, and for the old site to go. Learn how CT-Darnell and Sunbelt Rack helped employee-owned Mead Lumber design and build a brand-new yard with more covered space, more SKUs, and maximized efficiency for an onsite experience that proves there’s no place like (a new) home.

The transition will be managed with a focus on continuity, ensuring a seamless experience for employees, customers and suppliers for both companies. Elk Creek is committed to preserving the legacy of quality lumber products and customer service that has defined All Coast’s success.

Westlake Ace Hardware has signed an agreement to open a new store in the Sacramento, Ca., area.

Ace Hardware of Land Park will be located in a former Raley’s grocery store and will feature roughly 19,000 sq. ft. of retail space. Renovations are expected to begin in the latter half of 2025, and a soft opening is tentatively planned for early 2026.

Westlake Ace owns and operates 10 other locations in Northern California. Ace Hardware of San Leandro is expected to open this summer, becoming Westlake Ace’s 24th location in the state.

In total, Westlake Ace operates more than 170 stores in 13 states. It is a wholly owned subsidiary of Ace Retail Holdings, which owns more than 250 Ace Hardware stores nationwide under six different brands.

Woodgrain, Fruitland, Id., has closed on the asset purchase of Kelleher Corp., San Rafael, Ca. The acquisition includes distribution locations in Sacramento, Ontario, Carneros and Blackpoint, Ca., along with Honolulu, Hi.; a manufacturing location in Bear Valley, Or.; and an office in San Rafael.

Kelleher Corp. specializes in the distribution of moulding, lumber and doors, serving customers in California, Nevada and Hawaii. The acquisition of Kelleher positions Woodgrain for significant growth in these key markets and is expected to bring enhanced service offerings, increased product availability, and a continued commitment to quality.