We

Top deck builders share what their clients are asking for The

The latest

correct tools are changing how builders build their decks

Chuck

John

We

Top deck builders share what their clients are asking for The

The latest

correct tools are changing how builders build their decks

Chuck

John

During the pandemic, I resolved to only travel within the U.S. borders when we were once again able to freely move around the country. That was until my best friend’s husband passed away and I became her new travel partner. Most recently, we spent a week in the Dominican Republic.

Initially, when she asked me to join her on this Caribbean island, I wondered if it would be safe. I knew very little about the island except it shared a border with notoriously crime-ridden Haiti. This would be the first third-world country I would travel to since acquiring my passport.

It wasn’t until a few weeks later when another close friend of mine showed me her personal photos from the DR that I began to seriously consider going. My friend’s glowing recommendation of the country spoke volumes and gave me the assurance I needed.

Personal recommendations, such as my friend’s, are invaluable. Just ask any of the builders whose work was recently recognized at NADRA’s 2023 National+Deck Awards (see page 26).

In fact, in their own words, here’s what some of our Deck Specialist columnists had to say about their experience at this year’s NADRA awards.

“I am an artist with a vision to create amazing outdoor space,” says Andy Henley, whose company

Hen-House Decks received two NADRA awards. “Using the NADRA awards as a reference in my sales pitch, my customers have full confidence in my vision when I am designing their deck.”

Bobby Parks, who helped moderate, adds, “To win an award in the NADRA National+ Deck Competition adds immediate credibility to your personal and business resumés and provides respect and admiration from your peers in the industry.”

Brendan Casey agrees, “Clients tell everyone, especially on social media, that they won a national award and always promote the excellence of the company that built it.”

“After winning our first NADRA national award, our local paper ran an article on us in the annual Home Show insert,” Casey adds. “For two days, we had a line (at another show) that never became less than 30 minutes long. Our booth was standing room only and prospective clients drove from over 1-1/2 hours away to meet with us. We couldn’t pay for that level of marketing.”

It’s for this reason that we fill the pages of each issue with photos of the amazing work of builders in our industry. It’s why we are highlighting the work of Deck Nerds, and Ace of Decks LLC on pages 20 and 28 in this issue alone. We know that if your potential customers hear about your work, and see the amazing pictures of the projects you share with us on a regular basis, your work will sell itself. A picture is, after all, worth a thousand words.

New Castle Steel, Inc. has formed a strategic dealer partnership with AdvantageLumber.com to make New Castle Steel deck framing products more readily available online and nationwide via Advantage Lumber’s website and four U.S. warehouses. Advantage Lumber will ship New Castle Steel orders directly to customers’ homes or job sites.

“Our company values and service expectations are closely aligned, and they are staffed with a team of knowledgeable experts ready to assist with New Castle Steel framing questions and orders,” said Jason Alloway, founder and president of New Castle Steel, Inc. “The addition of online ordering capabilities will allow us to reach and serve more customers nationwide and grow awareness for steel framing as a superior alternative to wood frames.”

AdvantageLumber.com will begin onboarding the new product line with shipments available in early second quarter 2024.

Simpson Strong-Tie will invest $110 million to expand its operations in Gallatin, Tn., by adding a new facility that allows the company to meet growing product demand and relocate a portion of its fastener manufacturing operations.

“This expansion more than doubles our current production capacity and footprint, enabling us to meet increased product demand and keep fastener manufacturing close to our North America customers,” said Mike Olosky, president and CEO. “The new site will also improve efficiency, help ensure we continue to provide exceptional customer service, and open up career opportunities for employees and job applicants alike.”

Upon completion of the new facility, Simpson Strong-Tie will employ nearly 250 people across Tennessee.

YellaWood producer Great Southern Wood Preserving purchased 150 acres in Tyler, TX., to build a new lumber treating plant. The facility will be built on 50 acres within the new 412-acre Tyler Interstate Commerce Park. Great Southern’s remaining 100 acres will be used for “future development.”

The newest Lumber Plus franchise location in Sagamore Beach, just minutes from Boston, MA., strategically caters to the entire Northeast region, providing convenient access to customers in Massachusetts, New Hampshire, Vermont, and Maine.

“We are excited to bring Lumber Plus to Boston,” said Guto Fugiwara, president of Lumber Plus. “Our mission has always been to provide the best quality lumber and building solutions to our customers, and this new location allows us to do just that in the heart of the Northeast.”

“Joining Lumber Plus has been a gamechanger for me in the building industry,” said Cezar Lanca, Lumber Plus Boston franchisee. “From a steady supply of topquality wood products to a dedicated marketing team sending me leads, it’s clear that they’re invested in my success.”

For more information about Lumber Plus franchising, visit LumberPlus.com.

ALTHOUGH THE MAJORITY OF DECKS are still built on pressure-treated wood frames, builders now have an array of choices. New deck framing materials including steel, aluminum, engineered wood and composite, have recently been introduced, attempting to tempt builders with higher-end products.

Steel Treated Wood

Steel Treated Wood

“

Many are gravitating toward wood-alternative building materials that check multiple boxes: high performance, stylish, low maintenance and sustainable.— JEFF SCHULZ, FORTRESS BUILDING PRODUCTS

“

Steel emerged in the last decade as the first real alternative to pressure treated wood for deck framing. “Over the last few years of high-renovation activity, we’ve seen a major shift in homeowner priorities and purchasing decisions,” said Jeff Schulz, senior VP of sales and marketing, Fortress Building Products. “Many are gravitating toward wood-alternative building materials that check multiple boxes: high performance, stylish, low maintenance and sustainable.”

Schulz says steel is strong enough to support the added weight of today’s most in-demand outdoor amenities (such as outdoor kitchens or steel pergolas).

“That’s why so many builders have already made the switch from lumber to steel for underdecking construction,” he adds. “Builders who frame a deck with steel can create a lasting outdoor space that exceeds their customers’ expectations. Steel deck framing systems, like Evolution from Fortress Building Products, leverage steel to support today’s ever-evolving deck functions and enormous loads.”

Introduced in response to feedback from pros who already use the system, Evolution, which has a Class A fire rating, now features 5.5” x 5.5” posts that are 20’ tall. With steel posts that extend 20’ into the air, builders can give homeowners more usable space between the first, second and even third levels of a deck structure. A powder-coated finish provides improved corrosion resistance and UV protection.

In addition, steel is resistant to long-term exposure to moisture, splitting and warping as a result of extreme changes in temperature, he explains. In application, steel frame profiles will remain straight and true over time. This makes for an enduring, dimensionally stable underdecking solution that keeps surface boards flat and smooth underfoot.

TimberTech is known for its composite decking and composite and aluminum railings. It believes the future of deck framing is in aluminum. In fact, it introduced its new Aluminum Framing product last November. Ideal for decking projects in fire-prone areas, the framing product is compatible with all TimberTech decking and railing systems, and provides a solution with engineered components designed to work together. It will not split, rot or decay, and comes with a 25-year limited product warranty.

TimberTech’s senior VP, product management, Patrick Barnds, adds there are a few steel-based systems on the market that have some of the advantages of using metal to replace wood. They are straight and more consistent than wood, and if installed carefully and inspected and maintained over time, they can last for 15-25 years or more.

While steel may be cheaper, Barnds claims that it is susceptible to rust, even with routine maintenance, and is generally not recommended for use in coastal regions or other challenging environments. It also requires cut ends to be

prepped and painted on the jobsite, is harder to work with, takes longer to install, requires special tools.

Barnds stresses that aluminum doesn’t have any of those steel-based issues. The ease and speed of installation, strength and quality of the finished product, extended durability (even in coastal environments), lack of rust, sustainability (it’s made from up to 50% recycled material and is recyclable at end of life) and other benefits make it a logical choice of material for this application.

He illustrates that cutting aluminum is much easier than cutting steel, because it doesn’t produce any sparks, is non-combustible—which is why it’s a great building material for use in WUI regions or fire-prone areas. In addition, it is much lighter than steel–a single 12-ft. joist weighs less than 30 lbs.—making it easier to move.

Barnds shares his company hears complaints from decking contractors about the inconsistency of wood framing when it arrives on the jobsite. “Contractors don’t want to spend half the day shimming, planing, blocking and otherwise having to fix the boards of a wood subframe to get a flat, level, stable and consistent deck surface. Then, after installation, a wood subframe has the potential move and change with the seasons and over time, which could result in a contractor callback.”

And although the upfront cost of aluminum is more expensive than a deck substructure made from traditional dimensional pressure-treated lumber, Barnds says it’s a different story in the long run. “Once you figure the cost of repairing and replacing a wood substructure every 15 years or so in many climates, there is less of a cost difference over the lifetime of the deck with an aluminum substructure, if any at all.”

From both a lineal foot basis and from a system perspective—when constructing the entire deck substructure—PWT Treated LVL costs less than steel and aluminum, says Duane Smith, VP of marketing and business development at PWT. It is more expensive than pressure-treated lumber on a product vs. product basis, but when you think of the substructure holistically and factor in the labor savings, it’s not much more to use PWT Treated LVL–and it won’t crown, twist or warp.

Contractors who frame with PWT Treated LVL can eliminate a mid-beam line, columns and footings and end up saving on labor because they don’t have to crown every joist to make sure it’s perfectly flat. Smith adds that being a wood product with the benefits of metal, PWT Treated LVL provides the best of both, and it doesn’t cost a lot more than pressure-treated lumber. “Think about the deck’s substructure holistically, and don’t limit your thinking to just the front beam. PWT Treated LVL can be used to eliminate sight lines in that capacity, but it can also be used for deck joists, ledger boards, blocking, stair stringers and every other

aspect of the substructure. The benefit of applying it this way is labor savings: teams don’t have to hand-crown every piece, but they still get a perfectly flat deck surface,” Smith says.

An entirely new material—a structural wood-free composite— is being rolled out. Owens Corning’s OC Lumber is specifically designed for deck and dock framing applications and is reinforced with Advantex Fiberglass, a proprietary corrosion-resistant technology that adds strength and durability, while resisting mold, mildew and pests. The product cuts and installs like wood, yet remains flat and uniform.

The product is an extension of Owens Corning’s 2022 acquisition of WearDeck. As executive VP and CFO Kenneth S. Parks noted, “With opportunities to displace traditional materials and expand our product lines across residential and commercial structures, we didn’t just acquire a decking company. We gained a new technology and capability to enter new markets and build a much bigger business. OC structural lumber is a great addition to our family of marketleading products and solutions and a great example of how investments in product innovation are helping our customers win and grow in the market while creating new growth avenues for our company through material conversion opportunities.” DS

DESIGNING OUTDOOR LIVING SPACES has become more complex and intricate in recent years. To please customers, contractors must go beyond aesthetics and create intentional custom designs that acknowledge an organic connection to nature while honoring the style of the home and meeting the needs of the homeowner. Functionality now plays an essential role in how design elements are brought to life, but also, it’s important to consider the psychological influence that a space has on a homeowner and how that experience can be elevated.

The power of texture in creating a sensory experience is significant as it pertains to not only aesthetics, but functionality. The textures chosen can add a dimensional aspect or an element of sophistication that levels up a small space or shines in a large-format project.

With the technology available today, hardscapes are no longer limited to a few neutral tones and flat textures. You can find dimension in the tone and texture of concrete, porcelain and permeable pavers whether it be sculpted, cobbled, dimpled, smoothed, distressed or more.

Hardscape manufacturers are capitalizing on the trend of textured

pavers, creating interesting patterns in the material that complement any design style. Pavers with a texture like organic rock or stone pair well with both modern and rustic design styles.

Creating a quality, functional design highlights your teams’ skills and helps deliver impressive results. One way to create a truly unique space that reflects the client’s personality is creatively using a mix of different materials. For more contrast, pair organic hardscapes with other materials like metal, glass, wood and composite decking. This helps spaces feel less flat and linear.

Other accents and accessories like water features, fire pits or even decorative gravel can add more texture to a space that is traditionally ordinary. Mixing these elements adds a new layer of functionality to a backyard, creating multi-use spaces the homeowners can use to relax, entertain, work and more.

In addition to incorporating these textures and mixing materials, natural elements such as plant life and gardening are a great way to influence an area to be more welcoming and brighter. Biophilic design is a growingly popular concept that emphasizes the importance of using elements in a design that connect homeowners to the nature around them. The style lends itself to a more organic look and feel, usually leaning away from defined breaks and relying more on rougher, irregular edges and natural materials. By creating an illusion of pavers entangling with a lawn or creating a steppingstone effect, homeowners feel more drawn the nature around them and in turn benefit from positive psychological effects.

Papyrus is a perfect example of introducing texture and biophilic elements into your design. Reminiscent of handmade textiles or dried earth, Papyrus looks natural and seamlessly blends into a space, simplifying

the design process. Whether it is for a welcoming patio or a pathway to the garden, Papyrus infuses the hardscapes with the surrounding landscaping.

Modularity Increases Functionality

Modular, linear design is a trending style among today’s homeowners, but also has benefits for contractors and crews. Modular design uses individual parts to create a holistic plan more efficiently. With this easier and faster installation method, outdoor product manufacturers and contractors can optimize their workflow and free time for additional projects and more creative designing time.

It’s no secret that the growth of the outdoor living industry and the increasing expectations of homeowners now enables designs to become more complex and customized. Introducing modular, geometric standard patterns comprised of clean lines and simple formats creates an uncluttered aesthetic, while allowing the homeowner to include various features in their spaces efficiently.

To maximize space and build fully functional backyards, it’s essential to be intentional with each element. Can an outdoor dining table double as an office space, or can a wall double as seating? Offering design services that take these questions into consideration and can provide simple solutions is key to success in the future of the outdoor living industry .

Belgard Artforms is a great example. Artforms is a large-format modular panel system that can create various shapes and elements. Contractors can use Artforms to build seating, grill areas, fire features, and

more. It is versatile and can help establish a cohesive aesthetic in a bigger way.

Another example of recent innovation in modular design for outdoor living—pavers, which work off common nominal sizes, allowing contractors to play more with shape, size and texture within the design. The modular fashion makes integration easier, as less installation time is required.

When contractors master the art of harmonizing both texture and modularity in their designs, you find more cohesive and inviting outdoor spaces. Biophilic elements like texture and color, as well as functional benefits like modularity and multi-use spaces, will remain drivers in homeowner decisionmaking, so those that implement new technologies and stay ahead of emerging trends will continue to be successful. DS

Joe Raboine, Vice President of Design, Oldcastle APG

Joe Raboine, Vice President of Design, Oldcastle APG

In his current role at Belgard, Joe oversees the Belgard Residential Program. He collaborates with both sales and marketing to ensure that Belgard’s contractors and dealers are receiving best-inclass service, products and experiences. Joe started his career as a contractor more than 25 years ago.

WHEN LOU LATTANZIO of The Deck Nerds, a company that has built all but one of its projects in the Ocean Isle Beach, N.C., area, received a referral call from a customer, he learned two things about the proposed project: his customer wanted to maximize the amount of square footage on their deck redo project, and they didn’t want a run-of-the-mill square deck. This may sound like a straight-forward type of project until you consider that in the Ocean Isle Beach area, there’s a limit to how far the base of the steps can be away from the dock.

In fact, Ocean Isle Beach is an area where homeowners feature grand sets of stairs leading down to the water. This customer, however, wanted to remove the grand set of stairs previously installed by another builder because they were obstructing his view. And instead of replacing them where they were situated, he asked Lattanzio to reconfigure the deck to keep as much square footage as possible from one end of his house to the other.

The problem was the Coastal Area Management Act (CAMA), which was passed in 1974 and is designed to regulate development along the North Carolina coastline to protect areas of environmental concern. As a result, homeowners building within

the CAMA-regulated area were only allowed to add 200 square feet of deck to their homes with a 6 ft. right of way from the base of the steps to the dock. To stay within these parameters, yet give the homeowner as much square footage of deck as possible, Deck Nerds had to cut corners.

Originally, the square footage Deck Nerds was working with was 380 sq. ft. To trim the necessary 180 sq. ft. from

their total deck, they subtracted 6 ft. of decking from the stairs to the dock by curving the decking, and they cut the decking back to the house near the stairs, saving an

kitchen. The Zip-Up system was used purposely because it is designed to withstand hurricane winds up to 130 mph when installed correctly.

When it came to the stairs leading down the walkway to the dock, Lattanzio said he knew he needed something more, but didn’t know what. That’s when he sought the help of Deck Specialist columnist and co-owner of Casey Fence & Deck, Brendan Casey. To make the walkway appear more substantial, Lattanzio mimicked the adjacent steps and created the appearance of four steps instead of two.

Lattanzio adds that it has been the help of Casey and other builders including Deck Specialist TNT columnists Andy Henley and Mike Mitchell and David Settlemyer,

HOMEOWNERS ARE prioritizing a balance of form and function to create flexible-use spaces that enhance their enjoyment of the outdoor experience, according to leading builders consulted for Deckorators’ annual Outdoor Living Report.

The 2024 report focuses on what homeowners have been requesting most for their outdoor spaces, including functional design, regional color trends, and more.

Among the top trends cited:

Functional Design: Homeowners are looking to utilize their outdoor spaces for multiple purposes, and in all kinds of weather, from season to season. Flexible-use zones throughout the deck are becoming a design standard, revealing a trend toward maximizing utility and prioritizing spatial flow.

Cocktail Rails: Signifying a shift away from the structured dining table, the recent spike in bar rail additions frees up space on the deck and creates additional opportunities for socializing.

Monochrome Moment: Homeowners’ preferences

for deck colors are becoming minimalistic, opening up more opportunities for pops of color and texture elsewhere that can be easily updated with changing trends.

Catherine Lippincott of Premier Outdoor Living, Palmyra, N.J., noted the recent shift toward monochromatic decking palettes: “We find that a lot of clients want to bring the project to life with more textures, mixed materials, and greenery instead of really bold color choices. A lot of people are moving more towards neutrals for something that’s muted and not super loud.”

Premier’s Sean Collinsgru said the colors their customers are asking for are trending toward neutrals that can work with the exterior of the house. “People just want something that’s natural and neutral, not in your face. They want more textures to bring the project to life, rather than the colors,” he added.

Privacy Walls & Shade Structures: These features make the outdoor experience more comfortable, offering seclusion from neighbors and protection from the elements. Privacy walls commonly serve

for outdoor kitchens with lots of prep areas and extended counter spaces. Rather than guests huddling up around the interior kitchen or the hosts holed up with meal prep indoors, outdoor kitchens create a collaborative environment so everyone can participate in the party as it’s happening.

Photos by Premier Outdoor Living

“My customers really tend to gravitate towards browns — a lot of Khaya, with Dark Slate. We don’t do too many grays.”

– JONATHAN MOELLER, COLORADO CUSTOM COVERS & DECKS“90% of our jobs are Costa. We find that it’s a great color to pair with nearly any house. If you pair it with a brown, it pulls out more of the brown tones in the color… whereas if you pair it with black or gray, it’ll pull some of the grays out of that color. It’s really versatile.”

– CATHERINE LIPPINCOTT, PREMIER OUTDOOR LIVINGMIDWEST

“We don’t see many red tones being used in our outdoor living projects, like you might see in more mountainous areas. Lighter colors are very common here — we use a lot of Tundra and Khaya. We do still get requests for gray in our market; I’d say it’s about 50-50 between browns and grays here. People either go with the combination of Sierra and Slate or they’ll go with Costa and Khaya.”

– JOE HAGEN, ALL DECKED OUT“We used to do a lot of grays; that was the popular mix for a while. This year, we’re doing a lot more brown. Costa is extremely popular. We still do a lot of projects with a different colored accent board, but a lot of customers are wanting the same color accent board as their field board, for more of a minimalistic look.”

– LEIF WIRTANEN, CASCADE FENCE & DECKdual purpose, incorporating entertainment centers and greenery.

Outdoor Kitchens: Homeowners are treating the outdoor kitchen as a place for both cooking and camaraderie, showing increased interest in upgrades such as extended counter space and built-in appliances.

Heaters & Fire Features: Homeowners are challenging the seasonality of their outdoor spaces with heated elements, whether it be the sleek, discreet warmth of outdoor heaters or the eye-catching ambience of a central fireplace.

Collinsgru said fire features are a huge request from almost all of Premier Outdoor Living’s clients, and 90% of those are gas so the customers can come out and turn it on, enjoy the fire, and when they’re done, simply turn it off and walk inside with no mess or no smell.

Joe Hagen, All Decked Out, Cincinnati, Oh., said, “Electric heaters are very popular in our area. We recommend adding heaters to nearly any roof structure, because you’re able to enjoy the space an extra three months out of the year. I think it’s worth it on every project.”

Dock Upgrades: Waterfront spaces are evolving to include upgraded elements that encourage gathering and connection.

Designer/Homeowner Collaboration: Overall, homeowners are showing more interest in being involved in the outdoor design process, from start to finish.

“Nearly everyone who contacts us recently has been requesting an outdoor kitchen in some capacity,” Collinsgru said. “And people are putting a lot more thought into those kitchen areas. On some projects, it feels like we’re designing an interior kitchen for our clients, because they really dial into every appliance, every little detail.” DS

BY DAVID KOENIG

BY DAVID KOENIG

CONVINCING A DECK BUILDER to use a different type of tool can be like trying to get a Coke drinker to switch to Pepsi.

Consequently, manufacturers of standup screwdriving systems have faced an uphill battle... one that seems to finally have turned the corner. There are now about a half-dozen different standing systems available, and builders are singing their praises.

The tools not only save wear and tear on the user (“we’re a heavily crouching industry”), they ensure pinpoint placement—thanks to alignment tips— while speeding up installation.

1] HIDfast: Rather than an attachment, HIDfast is a selfcontained tool that air-drives collated hidden fasteners into wood, composite and PVC decking. The tool appears to have caught on best with certain brands of decking, including AZEK and Wolf.

2] DuraLife InstaDeck Outdoor Flooring System: With Barrette Outdoor Living’s system, the reduction in kneeling comes not from a hand tool, but from a clever track that deck boards snap into. Builders lay down the interlocking tile foundation, then attach Step-Clip hidden fasteners. They then lay composite deck boards on top of the track and step on them, locking them securely in place. Tommy Holstein II, Solid Ground, Wentzville, MO., uses DuraLife decking with the Step Clip system for the majority of his company’s decks, opting for the CAMO system if a client chooses a brand other than DuraLife.

3] FastenMaster PAMFast AutoFeed System: FastenMaster PAMFast’s system also attaches to a drill, and can be used for a range of applications, such as decking, railing, subfloors, underlayment, roof tiles, and even steel framing. It’s a two-in-one interchangeable length device, so for example it can be used long for decking and short for drywall.

Mark King, Infinite Decks, Lakeville, MN., says, “We use the FastenMaster PAMFast gun to install Cortex screws for an entire deck, and it’s great! Saves hours of kneeling.”

4] CAMO Drive and ClipDRIVE: The tools that seem to be getting the most buzz among builders are the CAMO systems.

The CAMO Drive attaches to a drill to drive collated screws into wood, composite and PVC decking and universal deck clips between boards. CAMO ClipDRIVE is exclusively for use with universal deck clips on grooved decking.

“CAMO Drive has substantially changed our company’s output,” offered George Justynski, Jerzy Decks, Steger, IL. “I finally started to realize how all the bigtimers were making insane times on their installs. Best investment I’ve ever made, hands down.”

“CAMO Drive has revolutionized the industry,” agrees Kevin Choquette, Ravin Builders, Wood River Junction, R.I. “It’s such a good tool.”

“It’s one of the best tools I own,” adds Levi Tippetts, TC Custom Decks, Saratoga Springs, UT. “It saves time, money and my back.”

5] Hilti SDT 30 Stand Up Decking Tool: Hilti’s twinhandled device is designed to drill collated decking screws into metal decking applications.

6] Simpson Strong-Tie Quik Drive: One of the first stand-up driving systems, the Quik Drive auto-feed screw system from Simpson Strong-Tie is used not just on decking, but on a full range of fastening applications, including drywall, roofing and sheathing.

When they’re driving outfaced screws instead of hidden fasteners, Tippetts and Christopher French, French’s Custom Outdoor Concepts, Live Oak, TX., forgo their CAMO systems for the Quik Drive.

Simpson Strong-Tie recently introduced a heartier stand-up system, Timber Drive, for heavier duty jobs. DS

THE NORTH AMERICAN DECK AND RAILING ASSOCIATION (NADRA) honored its 2023 National+ Deck Competition award winners at its annual meeting on Jan. 4 in Clearwater Beach, FL.

Deck Specialist columnist Bobby Parks, who helped moderate the awards night and received his own award for being a 15year member of NADRA, said to those in attendance, “You set the standards and—the ideas you provide—you’re really the leaders in this industry in a bigger way than you probably realize.”

Vincent Carrubba, president of NADRA, says of the event, “The NADRA National+ Deck Awards & Summit is where the finest outdoor lifestyle projects produced during the past year compete for awards. Projects often include beautiful decks, hardscape, pools, hot tubs, screened-in porches, outdoor kitchens, fire pits, waterfalls, lighting and landscaping—these projects truly create a spectacular backyard oasis that transform the lives of homeowners’ families.”

Parks and the other Deck Specialist columnists in attendance couldn’t agree more, adding that being a part of NADRA and winning its awards are an important part of their brand marketing.

“To list on your website that you’re a NADRA award winner or to have plaques hanging in your office when a potential customer walks in, adds a solid layer of credibility that only a small percentage can claim,” Parks adds.

Andy Henley, whose company, Hen-House Decks, won two awards, agrees, “For me, the NADRA awards are an important part of my brand that I’m trying to create. For example, I have branded myself to my clientele, as I am more than just a deck builder. I am an artist with a vision to create amazing outdoor space. My customers have full confidence in my vision when I am designing their deck.”

Brendan Casey, whose company, Casey Fence & Deck LLC, won three awards this year, adds that joining NADRA has been a major boost to his business. “NADRA is the equivalent of a lighthouse guiding a ship on a foggy night. It helps give your business direction.”

Casey says that winning his first NADRA award in 2018 enabled his company to double its business the following year, it validated the company as a premier builder in the community. And although he says he

Commercial Outdoor Living Project

1st: Q-Ice Builders, 2nd: Chicago Roof Deck and Garden, 3rd: Ridgeline Decks Co.

Best Product Display

1st: Fraser Decks and Patio Covers, 2nd: Deck and Basement Co., 3rd: Deckscapes of Virginia

Refurbished Deck/Refinished Decks

1st: Ravin Builders, 2nd: Fraser Decks and Patio Covers, 3rd: LS Underground

Closed Porch

1st: CrossTek Construction, 2nd: Decksouth, 3rd: Holloway Co.

Open Porch

1st: LS Underground, 2nd: Decksouth, 3rd: Decks by Kiefer LLC

Hardscape

1st: Holloway Co., 2nd: Deckscapes of Virginia, 3rd: California Deck Pros

Pool Deck

1st: Stone Ridge Decking, 2nd: Decks Unlimited, 3rd: Deckscapes of Virginia

Dock

1st: Q-Ice Builders, 2nd and 3rd: Dock & Deck

Inlay on a Deck

1st: LS Underground, 2nd: Homes & More by Hand LLC, 3rd: Hen-House Decks

Illumination

1st: Northern Outdoor Living, 2nd: Baxter Construction, 3rd: LS Underground

Unique Feature

has never built a project to win an award, the 16 awards his company has won in total has developed an elite level mindset in his crew. “It’s an addictive sensation that drives them to strive for greatness on every project.”

Mike Mitchell, who shares the Deck Specialist TNT column with Andy Henley (see page 44), says he enjoyed this year’s roundtable discussions because they provided an opportunity for him to make connections with people he had not previously met. “It allowed for multiple different views and opinions on several topics from other builders, suppliers, and manufacturers. It was also a great to get feedback on your opinions and bounce your ideas off of other like-minded people from our industry.”

The overall 2023 NADRA winners honored that night were: 1st: Stone Ridge Decking; 2nd: LS Underground; and 3rd: Deck Remodelers.com. DS

Tie for 1st: Mayor Construction Inc. and LS Underground, 2nd: California Deck Pros, 3rd: The Deck Nerds

Railings on a Deck

1st: Baxter Construction, 2nd: Ravin Builders, 3rd: Fraser Decks and Patio Covers

Wood Deck Under $25k

1st: Casey Fence & Deck LLC, 2nd: Hen-House Decks,

3rd: Fraser Decks & Patio Covers

Wood Deck $26K-$50k

1st: Decks By Kiefer LLC, 2nd: Casey Fence & Deck LLC,

3rd: Green Shield Deck Builders

Wood Deck Over $50k

1st: Fraser Decks & Patio Covers, 2nd: Decks By Kiefer LLC, 3rd: SG Construction

Alternative Deck Under $35k

1st: The Deck Nerds, 2nd: My Deck LLC, 3rd: Casey Fence & Deck LLC

Alternative Deck $36k-$70k

1st: Deck Phenom, 2nd and 3rd: My Deck LLC

Alternative Deck $71k-$150k

1st: LS Underground, 2nd: Ridgeline Decks Co.,

3rd: Decks Unlimited

Alternative Deck $151k-$250k

1st: Deckscapes of Virginia, 2nd: Deck Remodelers.com,

3rd: Colorado Custom Covers and Decks

Alternative Deck Over $250k

1st: Stone Ridge Decking, 2nd: Deck Remodelers.com,

3rd: My Deck LLC

Limitless Creation $35k-$70k

1st: Northern Outdoor Living, 2nd Tie: Northern Outdoor Living and Coppens Custom Solutions, 3rd: Ravin Builders

Limitless Creation $71k-$150k

1st: Ridgeline Decks Co., 2nd: Decks Unlimited, 3rd Tie: Ridgeline Decks Co. and All Decked Out 513, LLC

Limitless Creation $151k-$250k

1st: LS Underground, 2nd: Master Home Remodelers, Inc., 3rd: Baxter Construction

Limitless Creation Over $250k

1st: Dock & Deck, 2nd: Holloway Co., 3rd: Chicago Roof

Deck and Garden

Q. How did the idea of starting the company come up?

A. After attending the University of St. Francis for a business degree, I made a deliberate choice to specialize in decks. Equipped with both the necessary tools and experience to construct high-quality, lowmaintenance decks, it felt like a natural progression for me to dive headfirst into this venture.

Q. What are your individual strengths and weaknesses as a company?

A. I think our biggest strength is our strong vision that is clear and in sync among our team.

Q. Share a time when you had to deal with a very difficult client or supplier. How did you deal with the situation? What would you do, if anything, differently the next time? What did you learn from the experience?

A. I have had experiences where we have gone above and beyond to make a project complete at the expense of investing part of my profits from the project to make a customer happy.

What I learned from these experiences was to cut your losses soon. Sometimes it’s time, sometimes it’s money, but the quicker you can resolve the problem, the better off you will be.

Q. Provide an example of when you’ve had to go above and beyond to get a project done on schedule. What steps did you have to take to finish the project on time? What was the final outcome?

A. The closest we got to a tight deadline like this was for a client who wanted to have the deck ready for

GEOGRAPHICAL AREA: We service the Chicagoland Suburbs. We are based out of Bolingbrook, IL.

COMPANY’S SPECIALTY: Complete, low-maintenance, outdoor living spaces.

YEAR FOUNDED: 2019

COMPANY CHANNELS:

Website: aceofdecksllc.com

IG: @aceofdecks_llc

FB: @AODspecialists

YT: Ace of Decks LLC

TikTok: @aceofdecksllc

a family wedding party. As the project progressed, we got slammed with May showers and could not complete the deck. Eventually they decided to not have the party due to the weather.

Q. Tell me about your decking projects.

A. It’s about creating a space that is truly magical once we step away from the house. We tailor our approach to ensure that no two projects are alike, resulting in spaces that are distinctive and reflective of our clients’ individuality.

Q. What are some challenges faced by your business and how do you overcome them?

A. It’s crucial to recognize that both the highs and lows in business are temporary. It’s about riding the waves, embracing the challenges, and acknowledging that perseverance is key to enduring the everchanging landscape of entrepreneurship. DS

Plan, quote and build outdoor structures faster and easier.

Grow your construction business with free Outdoor Living software from Simpson Strong-Tie. Our design apps include Deck Planner Software™, Pergola Planner Software™ and Fence Planner Software™. The in-app tutorials make it easy to select materials, dimensions, colors and hardware. Add patios, sheds, landscaping or other features, then show customers their entire yard in a realistic 2D or 3D view. Once your design is complete, you can print a full materials list, provide a quote, review permit submittal pages, and select a local dealer with available supplies in your area.

Download free design software at go.strongtie.com/outdoorliving Or call (800 ) 999-5099 to learn more.

IN WILDLAND-URBAN INTERFACE (WUI) LANDSCAPES

BY CHARLIE JOURDAIN

REDWOOD IS AN ICONIC WOOD SPECIES used for exterior residential decking throughout California and much of the western U.S. Redwood lumber is highly valued for its natural decay and termite resistance; however, like all exterior wood applications, specific installation techniques can help mitigate the risk of wildfire exposure for wood decks situated in WildlandUrban Interface (WUI) areas. By following this guidance, consumers can help build wildfire resilience into their homes and outdoor structures.

Redwood

Redwood has long been known as a species that will perform well under fire conditions. This is due to its Class B Flamespread rating (ASTM E-84) and its acceptance under Chapter 7A of the California Building

Code (Materials and Construction Methods for Exterior Wildfire Exposure). Furthermore, a listing for redwood (No. 8110-2041:0002, Decking for Wildland Urban Interface) can be found under the California Office of the State Fire Marshal Building Material Listing Service. Consumers should feel confident that their choice of redwood decking is appropriate under these conditions. Numerous other factors should be considered to improve the survivability of residences throughout the fire prone western U.S.

• Home and building loss during wildfires occur due to some part of the building igniting from one or more of the three basic wildfire exposures: 1) embers, 2) radiant heat, and 3) direct flame contact.

• Wildland fires spread by a combination of a moving flame front and the wind distribution of burning embers, which are light enough to be blown through the air and can result in the rapid spread of wildfire.

• You can significantly improve your home’s chances of surviving a future wildfire through material choices, design and installation options, and regular maintenance.

Defensible space is the buffer between your structure and the surrounding area and is particularly important in WUI areas. Key considerations and defensible space zones are as follows:

igniting materials that can spread fire to the structure.

Zone 1 (5-30’): Eliminate the connectivity between islands of vegetation by increasing the spacing between trees, removing lower branches of trees and shrubs, and creating areas of irrigated and mowed grass or hardscape between lush vegetation islands. Plants should be properly irrigated and maintained to remove dead/dry material. These actions reduce potential fuels for fire.

Zone 2 (30-100’+): Reduce the density of the trees, shrubs, plants, and grasses to slow fire spread and reduce flame heights. Keep shrubs and trees wellspaced and pruned to eliminate fuel ladders, where fire can climb from the ground to the tops of the vegetation. 100 feet of defensible space is required

CONTINUED FROM PAGE 33

The following deck construction details have been shown to reduce the potential for ignition from embers and improve the survivability of a deck exposed to wildfire conditions.

• Space joists 24 inches on center. This creates fewer joists for embers to accumulate on.

• Application of a metal-faced, bitumen backed flashing tape to the top edge of the joists. This type of flashing tape is available at homecenters and hardware stores and is available in 4 and 6” widths. It should be wide enough to fold over the faces of the joists by 1 to 2 inches. The intent of this flashing is to minimize the damage and flame spread from ignition of the deck joists by accumulated embers. If the appearance of the metal-faced flashing is objectionable between the deck boards it can be spray painted flat black prior to decking installation.

• Incorporation of a 1/4” deck board gap spacing. The recommended gap for redwood decking is 3/16” at installation, as the spacing will typically increase to 1/4” or greater during the hot dry seasons when wildfire threat is the greatest. This size gap will allow embers to easily pass through to the boards to noncombustible space below the deck where they will typically self-extinguish (assuming that combustibles have been eliminated below the deck).

• Install metal flashing or grates along the deck edge where it joins the vertical wall of the structure. Metal flashing at this junction can minimize the chance that accumulated embers can ignite combustible siding and underlying sheathing. Use of these grates will allow embers to fall below the deck and extinguish and as long underdeck conditions do not include combustible items (e.g., grass, stored materials, mulch, etc.) Alternatively, if the siding on the building where the deck joins the wall uses a noncombustible material, and the sheathing is not exposed, this may eliminate the need for flashing or grate installation.

• Regularly clear the gap between deck boards so that these gaps do not become clogged with dirt, leaves, pine needles, or other debris that may ignite if encountered by embers. DS

Charlie Jourdain is manager, business development for the Mendocino Companies, Santa Rosa, CA., including Humboldt Sawmill, Mendocino Redwood Co., Mendocino Forest Products, and Allweather Wood. For more information, visit www.mendoco.com.

WE SEE HIGHER-END, award-winning projects in every issue of this magazine and every day on social media. As amazing and inspiring as these projects are, they account for a small percentage of the overall job count delivered across North America each year.

This means that the majority of builders in the industry are delivering something else. This includes a wide range of options from simple to complex wood and composite decks of all sizes and categories. These builders design, build, and sell what the masses can afford and demand.

Regardless of where you operate, embrace it and make the most out of it. Take pride in what you do and strive to be the best in the “category.”

Almost all homes require a patio or deck, but not all market demographics support the higher-end projects. Budgets are often based on percentages of the home value and in many areas that doesn’t allow the dollars needed to deliver anything beyond average.

Figures vary but it’s estimated that the current

demand for wood decks in the U.S. is around $7.8 billion with alternatives at $3.5 billion (globally the numbers are much higher). Considering the lesser cost of pressure treated wood decks, lower- to mid-cost projects will account for a much higher build count.

Ten to 20% of lower cost home values don’t add up to allow for a higher cost investment. Many customers don’t have the budget or desire to invest in a higher-cost option, and just want simple function.

Product manufacturers aside, customers, contractors, and building supply stores influence selection—customers because of budget and option awareness, contractors because of customer budgets, market demographics, preference, and sometimes skill and confidence levels in sales and experience. Lumberyard approaches vary, with some promoting alternatives while others are order-takers for wood or whatever the customers think they want.

Different regions of the country also factor in. Mid

Atlantic and New England markets will have higher percentages of alternatives than Southeastern or much of the Midwestern regions. Canada and the Western regions of the U.S. may have a higher mix of alternatives and higher wood quality offerings. Pressure treated still dominates much of the country especially the Southeast.

Even the most talented and inspired builder may choose to keep it simple with deliveries if that’s what their market dictates. It simply requires an assessment and evaluation of your market and yourself, and then adapting your approaches accordingly.

In some cases, experience determines where you operate. Some builders are newer to the business and have not yet progressed from an experience standpoint to where they will ultimately end up, which temporarily limits them. For those that are in good markets but are held back because they currently don’t have the skill, motivation, ambition, or creativity to operate in a highend arena, hopefully progression will occur.

Most award winners I know don’t base their business on trying to win awards. They strive to make the most out of every design opportunity regardless of size. If they happen to hit on one that they believe will compete, they enter it. They plan for deliveries that they can be

profitable with, which includes plenty of average, breadand-butter decks. Awards provide opportunities to leverage off of, but don’t necessarily pay the bills. A solid business model does.

Deck builders can be creative and profitable in all categories. Each requires a balance with sales, overhead, and production. Whether it’s wood decks, simple composites, or highly designed monster decks, there’s a place and business model that works for all involved.

You may or may not provide the same inspiration or win the awards that some of the higher-end builders do, but you can be profitable and have a solid business. When it comes down to it, what would you rather have the most of, awards on the wall or money in the bank? It’s better to have a good business model with lower end than a bad one with higher end.

At the end of the day, the right choice is where you’re comfortable and what your market allows. What’s important is that you make the most out of it by adopting a sound building philosophy along with business and operational efficiencies that work.

One of the challenges with simple decks is that the easier something is to do, the more builders that can do it. Simple makes it more challenging to separate yourself

CONTINUED ON PAGE 38

from others, partly because there are more others. It really can be a race to the bottom from a pricing perspective for some builders.

Challenges with larger, higher-end jobs are knowing what it takes to deliver, what to charge to be profitable, and how to present and sell the value. Selling at the right price and being efficiently productive are keys at any level.

As you move towards the higher-end deliveries, the competition count may drop off. To progress beyond average, you’ll need a healthy supply of inspiration, motivation, ambition, organization and inner drive. Otherwise, no matter how talented you are or how good your market demographics are, you’re not likely to achieve the rewards possible.

At any level be sure you’re using the best possible materials combined with the best installation techniques. Be realistic when setting short- and long-term performance and maintenance expectations to your customer. Build and protect your reputation by being honest with what you offer.

If you’ve read my previous columns, you’ll know I’m

ABOVE: Small to midsize jobs account for the majority of deliveries. LEFT: It takes creativity to elevate small to mid-size decks.

a believer in alternative framing, decking, and railing products. I’m also skeptical about today’s pressure treated wood performance. But I also realize that wood decks will continue to dominate market share for the foreseeable future simply because of market demographics and the price point.

So, although I believe this industry is better off as more alternatives are used, this piece is intended to encourage builders regardless of where you play and to be proud of what you do.

It’s a push to be the best you can be to the extent your skills and market demographics allow. It’s intended to encourage you to max out the meter needle when it comes to professionalism, creativity, and to make the most of every design opportunity, regardless of size.

It’s a suggestion to focus on a smooth delivery and be the best possible in your category. It’s to remind you to create the layers of credibility by being organized with photos, reviews, and your presentation to a customer.

But if your passion drives you towards higher-end and you’re being held back because you live in a market that limits your potential, maybe you should move. DS

Bobby Parks is a wellknown contractor who has delivered more than $40 million in outdoor living projects. He is the former owner of Peachtree Decks & Porches.

IN MY LAST THREE articles, I discussed how clients and/or society in general tends to look down their noses on deck builders and blue collar workers (“I’ll be a Dirty Word,” July/Aug. ’23), divisiveness created in the industry, manufacturers and distributors creating tribes and choosing up sides (“Be the Solution,” Sept./ Oct. ’23), or how we don’t have a right to the same success as the white collar community (“It Must Be Nice,” Nov./Dec. ’23).

Now it’s time to change gears and take a moment to be thankful to the clients who admire and respect how we are able to turn the blank canvas of their yards and a truckload of materials into their own personal oasis.

This is not about the negative, demeaning clients that reduce our efforts to its least common denominator of it just being a “box with boards on it,” or “something my buddies and I could do over the weekend.” We’ve spent enough time on that mindset.

It’s time now to focus on the prospective clientele that didn’t just randomly pull our name out of a generic search along with 10 other companies, but the one that did their due diligence, sought us out and researched our companies. They want to make a value-based decision on their higher-end, outdoor living investment. These clients dive deeper into our backgrounds, scouring our webs and social accounts, seeking out a company that

doesn’t have just one nice project, but a track record and history of delivering timeless beauty on a daily basis with 25, 50, 100 or more awe-inspiring projects under their belt, especially if that company has won any local or national awards. (I can’t emphasize enough how valuable this is when it comes to building client confidence.) The discerning client loves to see you are the specialist the other builders in your area look up to. Remember: people love to be associated with a winner.

Keep in mind, all the marketing dollars, time, effort and creativity you invest isn’t really to impress other builders who follow your social accounts; it should be 100% targeted towards this consumer that has a greater appreciation for the true Deck Specialist. It is their confidence you are truly seeking. Again, this consumer affords us those “Must Be Nice” moments.

My real point here is to show some respectful appreciation to the client who chooses our company; the one who puts their faith in us to take an investment commensurate with the cost of a luxury vehicle and create a beautiful, functional, and above all, a safe outdoor living environment for their family.

With that comes a great responsibility that the neighborhood “Bob in his Beater” can’t or doesn’t fathom. There are those among us who view this customer as a cash register waiting to pay off. I actually prefer the

... take a moment to be thankful to the clients who admire and respect how we are able to turn the blank canvas of their yards and a truckload of materials into their own personal oasis.

term clients, since they are someone we are building a relationship with. To me, there is a major difference.

I applaud these insightful homeowners for granting us the opportunity to release our creative juices and come up with some of the most awe-inspiring projects. Sometimes I’m not sure if it is a tapestry or a deck, but the men and women of this industry are achieving unimaginable success while delivering mind-boggling projects. Someone is footing the bill for these and it’s the client who truly respects our vision and talents.

A few years ago, we had a repeat client who wanted to create something unique with her deck. She said she trusted our creativity, gave us a budget and free rein on the design. We listened to her desires while paying attention to the stylings in her home as she intimated how they wanted to be able to privately enjoy their hot tub while stargazing, and a desire for more lighting than what was on the original rectangular starter deck.

We built her a large, curved deck with lights on every post, added an illuminated, 8x8-ft. star within a star and

privacy for the spa area. The project ended up winning us multiple NADRA national awards. It also led to a significant amount of additional projects in the same neighborhood and several more National+ awards. Yes, we really appreciated the relationship we developed with this client and all the others she has put us in contact with. Clients like this inspire you to make the extra effort.

Recently, I had the opportunity to interview a couple of industry friends to gain their perspectives on similar client interactions. Since one of them is in Walnut Hollow, W.V., and the other is located “across the pond” in Wales, it was really comforting to realize the similarities in their experiences.

First, I spoke with Mannie and Kathryn Fisher of West Virginia’s Walnut Hollow Construction, this is what they had to say:

“When clients express their appreciation for our workmanship on a daily basis, it makes it worth getting up in the morning and putting in the effort. This client was no exception, he gave us free rein to design the

railing how we saw fit. While we are ultimately in business to make money for our families and ourselves, it becomes more than about the money... Our mission is to provide an unforgettable experience for the client by designing and creating an amazing dream of an outdoor living space.”

Mannie, with that approach and beautiful projects like this, I’m pretty sure you will never run out of quality-minded clients. To see more of the amazing projects created by Walnut Hollow you can follow them on their different accounts (whcdecks.com, FB: walnuthollowconstruction, or @whcdecks).

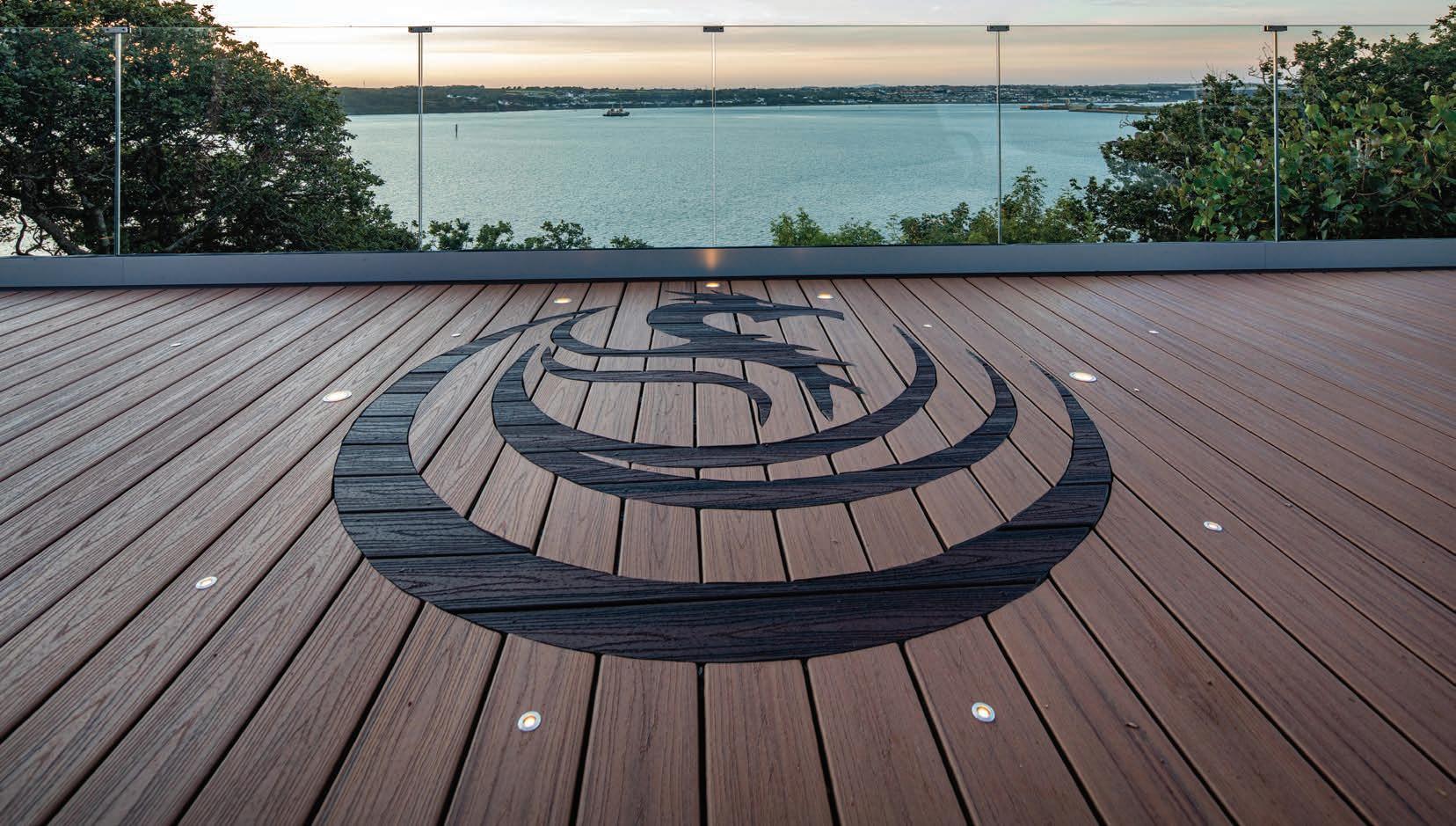

I also spoke with another amazing gentleman many of you may recognize. A man who never met a board he didn’t want to bend or a deck that didn’t call for an inlay— Simon Thomas of Simon Thomas Deck and Design in Wales. Simon’s clients give him free rein with his artistry, designs, and inlays. He had the following to say:

“At first I wanted to build what we call ‘custom decks’ to make my labor more valuable. I was lucky enough for people to take interest in my work. I was asked to put my logo (a Welsh Dragon) into a big build up on a cliff. For a client to request that on such an expensive deck was a feeling I just can’t put into words, I felt like I had made it to the top. I educated myself on marketing and using the Internet, targeting the more affluent clientele, and ensuring people saw my work. Once they find me, they see I’m everywhere and they can view my portfolio of projects. At this point in my career, I can accurately price my designs and the simple inlays. The more intricate ones that I need to build in my shop come with an additional agreed-upon fee that can go into the thousands. This has

made my labor far more valuable, but there has to be something else driving you to make the effort. For me, I build with my heart.”

Well put Simon, I have the greatest respect for your creations.

If you would like to view more of Simon’s work please visit him at simonthomasdeckanddesign.co.uk or on Facebook @Simonthomascarpentry.

I agree 100% with both Mannie and Simon, you want to see past the dollars to put your heart, soul, and passion into the projects you create. The clients that share in those visions are the ones you want to work with. They make your jobs more enjoyable and have a greater appreciation for your efforts. So, let’s get beyond the ones that look down, and focus on the ones that look across or up to us and admire our uniqueness, because Deck Specialists are some of the most unique individuals in the outdoor living industry. DS

Brendan Casey with Casey Fence and Deck is a 16-time national award winning Deck Specialist with over 40 years of professional experience. He and his wife, Dianna, started their business 25 years ago and immediately gained a reputation for high quality and a unique approach when it comes to delivering exception al value for your outdoor living investment.

IN THE WORLD of deck building, there’s been a lot of talk about Joist Runners–a cool new ergonomical scaffolding system that helps builders with putting in joists, blocking, and joist tape.

On October 20th, 2019, Ron Latterell of Dayton, MN., in response to employee discomfort working on their knees, embarked on creating ergonomic scaffolding. The first attempt fell short of ANSI standards, and while the second, designed by an engineer, met criteria, it was expensive and slow for mass production.

Enter Gen 3 Joist Runner, a streamlined version by the same engineer, prioritizing manufacturing ease, efficient shipping, and ANSI compliance–a successful evolution towards a commercially viable and workerfriendly solution. They are 100% made in the USA with 319 aluminums. Manufactured by H&H Casting in York, PA. (Fourth-generation casting company), the runners are super solid but lightweight.

Andy/Mike: First of all, they were easy to purchase online (direct), and they shipped quickly. Each runner came in a compact box and separated into two pieces. To assemble them, it only took two bolts that connect the arm to the body, and they were ready to go. The runners were pre-set for 2x10 joists, but with a few bolts, you can adjust them to fit on 2x12 joists. Each runner came with some suspension clips and cams.

Gen3 Price: $499.00 Includes 1 Joist Runner, 10 joist clips, 2 cams deckscaffoldingsystems.com

USE PROMO CODE: TNT10 for 10% off (exclusive offer for Deck Specialist readers)

Mike: One of the standout features is the ingenious design. The runners securely hook onto the deck joists, creating a reliable foundation. The arms extended below the joists, forming a plank holder approximately 2 ft. below the deck. This design placed me at an optimal height, providing comfort and ease during various tasks. Once the plank is in place, it created a convenient and safe working platform for myself and my team, eliminating the need for precarious balancing acts or working off ladders.

Mike: A notable practice we utilized was attaching the suspension clips to all joists on the ground beforehand. Then we propped up a board for them to hang on like a ledger so we could organize and grade them before installation. After they were all in order, with the clips on, we would simply set them in place hanging on the clips. Since they were held in at the right height, we had a free hand to get the joist on the mark and install it much easier. This really helped to maintain a nice, flat deck frame.

The scaffolding system addressed decking tightness with the inclusion of cams. These cams grab the joists and then have a spot to set clamps parallel to the joists, allowing us to push the decking tight. When we used everything together working on the deck as if it were ground level, it not only made installation quicker and safer, but also contributed to the precision and uniformity of the deck.

Mike: One thing that really stood out to us was during the installation of RainEscapes. RainEscapes is an underdeck drainage system that diverts rainwater, creating a dry space underneath the deck. There are troughs and downspouts that get stapled to the joists and tape that goes over the seams. This scaffold system allowed us to install almost all of the RainEscapes system at an ideal working height. This was by far the easiest way to get the troughs, downspouts, and tape down. It was more comfortable, much quicker, and more accurate. After removing the scaffold, we only had a few joist bays to address and then started decking.

Andy: I was just getting ready to start a 12’-high re-deck when I received my Joist Runners. I knew immediately that this product was going to be a game-changer when we started adding blocking and joist taping. What I didn’t realize was that it was so helpful when removing the existing deck boards! Due to the height of this project, we brought out several ladders and planks. That was a waste of space and time! All we needed to bring was the Joist Runners with a few planks and leave the bulk of our ladders at the shop. After removing some of the existing wood deck from above, we set the scaffolding on the exposed floor joist and worked to remove the rest of the deck with ease.

Andy: After my existing wood decking was removed, we were ready to start the build process. This project had a triple border and center inlay. This required tons of blocking. Normally we would have done this from the joist or worked off of ladders. This time we set up the runners and added a plank in-between to work off. Wow!

This sped the process up by allowing us to install the blocking close to waist level and felt safe.

Andy: On new construction, we will joist tape our lumber before installing from the ground. However, on our redeck project, we didn’t have that luxury. The safety and efficiency this product gave us were awesome. My guys

LET’S TALK about an oldie but a goody. The router. Yes it’s been around a long time. It’s always been used for various wood projects, but this day in age we’re finding all kinds of uses for the router. It has become a staple in building decks.

Briezy Home Solutions in Lincolnton, N.C., uses the cordless DeWalt router on nearly every deck they build—from routing end grain edges of wood decking for a clean finish to routing the composite fascia boards for stair stringers while attached to the stringers! The cordless router is a workhorse that makes the finer finishing pieces quick and easy work.

If you want to learn more ways Briezy Home Solutions use the router for decking , give them a shout on Facebook and Instagram @briezyhomesolutions.

Alex Larson, Thayer Lynn Carpentry, N. Illinois Instagram: @a.l._carpentry

not only installed the tape in a timely manner, but they were able to perform this task with the highest quality. It’s funny; this product sped the process up, but also allowed the crew to slow down and focus on craftsmanship. They said it felt like they were working on a low-level deck.

In conclusion, we think the Joist Runner scaffolding system stands out as a comprehensive and thoughtfully designed solution. From the strategic placement of joist runner’s attachment point and working height of the plank holders to the efficiency brought by suspension clips and the precision achieved with cams, this system redefines the standards of safety and productivity in the deck building industry. If you’re a deck enthusiast, investing in a scaffolding system is a step towards elevating your construction experience.

Stay tuned for our next dynamite review! DS

Pros:

Safety, Efficiency, and Accuracy, MADE IN THE USA.

Cons:

As tested, doesn’t work with some alternative framing. (Would be nice if it had a built-in retainer to clamp the plank in place.)

TNT Review score: 9.9/10

Andy Henley is the owner of Hen-House Decks, Uniontown, OH. Mike Mitchell is the owner of Mitchell Construction in the Chicagoland market. Andy and Mike can be reached in the DeckingTNT Facebook group.

IT’S HIGH TIME we had a frank conversation about your company’s growth and the role of marketing in 2024. You’ve established your presence, built a team, and conquered challenges. But there’s a crucial piece you might be neglecting—it’s not just craftsmanship anymore; it’s about making those bold moves you’ve been avoiding to build the business you deserve. This isn’t just about getting your hands dirty; it’s about strategizing, planning, and scaling up.

Are you comfortable where you are? Do you have any uncertainty as to what the future holds for your business?

I know you love your craft and building amazing outdoor living spaces that stand out. When you stamp that project with your signature style, it is extremely rewarding. However, what does the future of you and your business look like?

Do you want to be 70 and still working hard every day? Do you want to retire? Sell your business? Build a legacy? How will you set yourself up for continued success and your future?

Gone are the days when quality work alone kept you ahead. The decking industry is changing, and to stay on top, you need to adapt. This means rethinking your approach to business, exploring new marketing avenues, and understanding the modern consumer.

Your experience and reputation are invaluable, but without a strong marketing plan, they might not get the spotlight they deserve.

Before stepping into 2024, first things first: what’s your bigger vision for your business? And I don’t mean the next project, but the long haul.

To be frank, what’s your Big Ass Hairy Goal (BAHG)? Maybe it’s doubling your revenue, expanding your team,

or revolutionizing deck design in your community.

Whatever that goal is, it needs to be clear, actionable, and something that gets you fired up every morning. Without this vision, you’re just drifting from one daily task to another instead of navigating toward your grander goals.

This year, take steps to change the narrative for your life and business. No more sitting on the sidelines, watching opportunities pass by. It’s time to get in the game—and play to win. Set your goals, roll out your strategies, and dive into the nitty-gritty of growing your business.

It’s time to take marketing seriously. If you’ve been hesitant to invest in marketing, now is the time to start. Explore digital marketing, social media, SEO, and other tools that can take your brand to the next level. Think of marketing as an extension of your craftsmanship—it’s another way to showcase your expertise and commitment to quality. Besides, it’s the first impression people have with your business.

And don’t let the word “invest” scare you. If cash is low, I want to encourage you to think creatively and set aside some time to figure out ways to grow your brand on a grassroots level. Everyone has to start somewhere. Taking that step can sometimes be the hardest part!

Spread too thin already? How much is your time worth? Figure out your hourly rate. If there are tasks

that you can delegate to someone else for less than that, do it! If you want to grow your business by 10% or more, you are going to need something in place to make it happen.

Working with a marketing professional that ensures your brand stands out and gets in front of the right people–whether they are at the beginning of their journey or ready to take action to upgrade their outdoor living space—can short cut your trials and errors with the aim of delivering lasting results.

So, what are your next steps?

1. Identify the leaks: Now, let’s get real about where you’re losing time and money. Are you still the oneman show answering every call and pounding every nail? That’s not sustainable. You need to delegate, and yes, it’s scary. But guess what? It’s also necessary. Identify the parts of your business that are sucking your time and energy—these are your leaks. Plug them up by delegating tasks, automating systems, or maybe even turning down projects that don’t align with your goals.

2. Be a business leader: Leadership is where the real growth happens. Stepping back from the day-to-day tasks doesn’t mean losing control; it means gaining perspective. It’s about guiding your team, setting the course, and watching your business flourish from a

Whatever that goal is, it needs to be clear, actionable, and something that gets you fired up every morning.

new vantage point. Sure, it’s comfortable on the deck with a tool in hand, but your business needs you at the helm, making the calls that propel you forward.

3. Delegate: It’s not always smooth, but it’s necessary: Delegating is not about expecting others to be your clone. It’s about empowering your team, trusting their abilities, and accepting that 80% of your perfect is still pretty darn good. It’s a learning curve for you and them. There will be hiccups, but that’s part of growth. Let others shine in their roles while you focus on the big picture.

4. Invest in marketing, invest in your future: Investing in marketing is investing in the future of your business. It’s not just about attracting new clients; it’s about setting your business up for long-term success.

The Big Leap in 2024

It’s your time to shine. Don’t let this be just another year, make it your year. Let this be the year you take control, make strategic moves, and surpass your own expectations. Embrace the challenges and push forward.

You’re more than just a deck builder; you’re building a future. Start this year with a clear plan and the courage to step out of your comfort zone. There’s support all around —in your team, in your peers, and in the deck building community.

Dive into free resources like the We Love Deck Builders podcast, NADRA’s Connect platform and the Deck Builder Marketing Mastermind Facebook group. Engage in communities, learn, adapt, and grow. 2024 is your year.

Go get ’em, tiger! DS

April Edwards is a digital marketing strategist and Founder of Deck Builder Marketers, Oceanside, CA. You can message her on Instagram @deckbuildermarketers or learn more by visiting deckbuildermarketers.com.

TimberTech’s new Aluminum Framing offers homeowners a solid deck substructure that will not split, rot or decay, meaning a long life and 25-year limited product warranty. Builders are provided a full solution with engineered components designed to work together and install easily.

Compatible with all TimberTech decking and railing systems, the new framing is made in part from recycled aluminum and can be reused or recycled at end of life. And, because it’s made of aluminum, it’s a better choice for fire-prone regions than wood framing.

[timbertech.com]

Aurora DIY Plug & Play Smart LED Kits are designed to incorporate permanent custom lighting into any home or outdoor living space. Powered by Neuterra’s Smart Lighting Technology, the kits make it easy to create custom colors and lightshows for everyday or special occasions.

Each kit contains 60 ft. of colored LEDs, easy-toinstall aluminum channel, cables, controller with app and outdoor-approved power adapter.

[neuterralighting.com]

Milwaukee Tool has released the M18 Fuel 1/2” High Torque Impact Wrench with Friction Ring that is up to 2” shorter in length so builders can access tight spaces.

The M18 Fuel 1/2” High Torque Impact Wrench is 7.6” long and features a Powerstate brushless motor that delivers up to 1,200 ftlbs of fastening torque and 1,600 ft-lbs of nut-busting torque with a M18 Redlithium Forge battery.

Other features include a four-mode Drive Control that provides greater control over output speed and power, an auto shut-off control that prevents overtightening and applies no more than 50 ft-lbs of torque, and a friction ring (hog ring) that ensures quick and easy socket changes.

[milwaukeetool.com]

Composite Fascia Board Fastener

Cutting Wings create an over-sized hole to allow for expansion and contraction

Type-17 Point for quick start

Oversized Flat Top Head provides increased bearing surface and maximum hole coverage

Colors Available

Two different hidden deck systems to better meet

New improved thread design drills easier with LESS MUSHROOMING in composite lumber.

T-20 Star Drive eliminates driver bit camout (driver bit included)

Trim Undercut Head traps loose material while countersinking

Top Threads push composite material back into the deck (no mushrooming)

Deep Tri-Thread Design for superior holding value

Colors Available •Gray •Tan •Redwood

Type-17 Point for quick start

Designed to fit any board in any deck pattern, National Nail’s new CAMO Wedge and WedgeMetal clips reportedly deliver a faster, easier, better installation.

Clips are pre-assembled for onepass fastening and stay in the groove until you’re ready to fasten for one-handed installation. They are also reportedly the strongest clips on the market in reducing lateral movement and uplift holding power.

Wedge clips are versatile, for use on grooved composite, PVC and hardwood deck boards. They boast a 316 Stainless Steel Marine Grade screw and gusset, offering the best corrosion resistance for coastal applications or projects in highly corrosive environments.

WedgeMetal clips feature a 410 Stainless Steel drill point screw for use on 14-18GA metal joists. [camofasteners.com]

DeckWrap PowerBond® is the quick and easy way to extend the life of deck support systems and posts. Our patented PowerBond® adhesive aggressively adheres to all wood types, even in temperatures as low as 25°F. Self-adhering and self-sealing for protection you can trust, roll after roll.

SaberDrive Platinum

Construction Lags from Midwest Fastener Corp. offers exceptional quality and outstanding results. Equipped with a star drive, serrated threads, an XL1500 coating and ICC certification to meet code, this an ideal fastener for builders who are looking for consistent results. [mwf.net]

MOSO Bamboo Thermo is a solid, thermo-density engineered lumber made from compressed bamboo strips. A special thermal modification process at 392° F and high pressure provides the decking with impressive hardness and stability that are similar to outdoor-rated exotic hardwoods.

The decking is available in 1x6 and 1x4 grooved planks designed to accept MOSO’s asymmetric fastener. The Thermo decking program also includes an exclusive 8”wide perimeter board and 4”, 6”, 8”, and 12”-wide, squarestock for trim, fascia, and drink-rails.

[moso-outdoor.com

Simpson Strong-Tie has extended its line of StrongDrive TF Wood-to-Steel screws with options for increased corrosion resistance, particularly in trailer-floor applications.

Designed for performance and productivity in high-paced environments, the screws eliminate the need to predrill and install 26% faster than traditional predrill and handdrive methods. The load-rated structural fasteners are engineered to bore through wood and into steel up to 15/32” thick.

They feature a flat head with nibs for easy countersinking and pull through resistance, along with a #5 drill point with wings to bore through the wood member before engaging with the steel. A six-lobe recess provides for secure driving, and self-tapping threads securely fasten into the steel member.

[go.strongtie.com/proshd]

•

•

A mortarless stone veneer by NCP Industries has the capacity to capture C02 from the air, making it an environmentally friendly solution that actively works to neutralize the carbon footprint.

The Adorn Stone profile, designed in partnership with builder Premier Outdoor Living, presents a new era in eco-conscious design and sustainable building. The first product in the company’s EcoLuxe line, one pallet (96 sq. ft.) of Adorn Stone captures the same C02 as five mature trees (up to 1.5 lbs. of C02 captured per panel.

The product is launching with additional colors, profiles and products in 2024.

[ncpindustries.com]