We discuss which products are built to last when a fire breaks out

Meet Brenton Giliam and Tommy Hopp, owners of FWD Alaska, who contend daily with Alaska’s wild weather

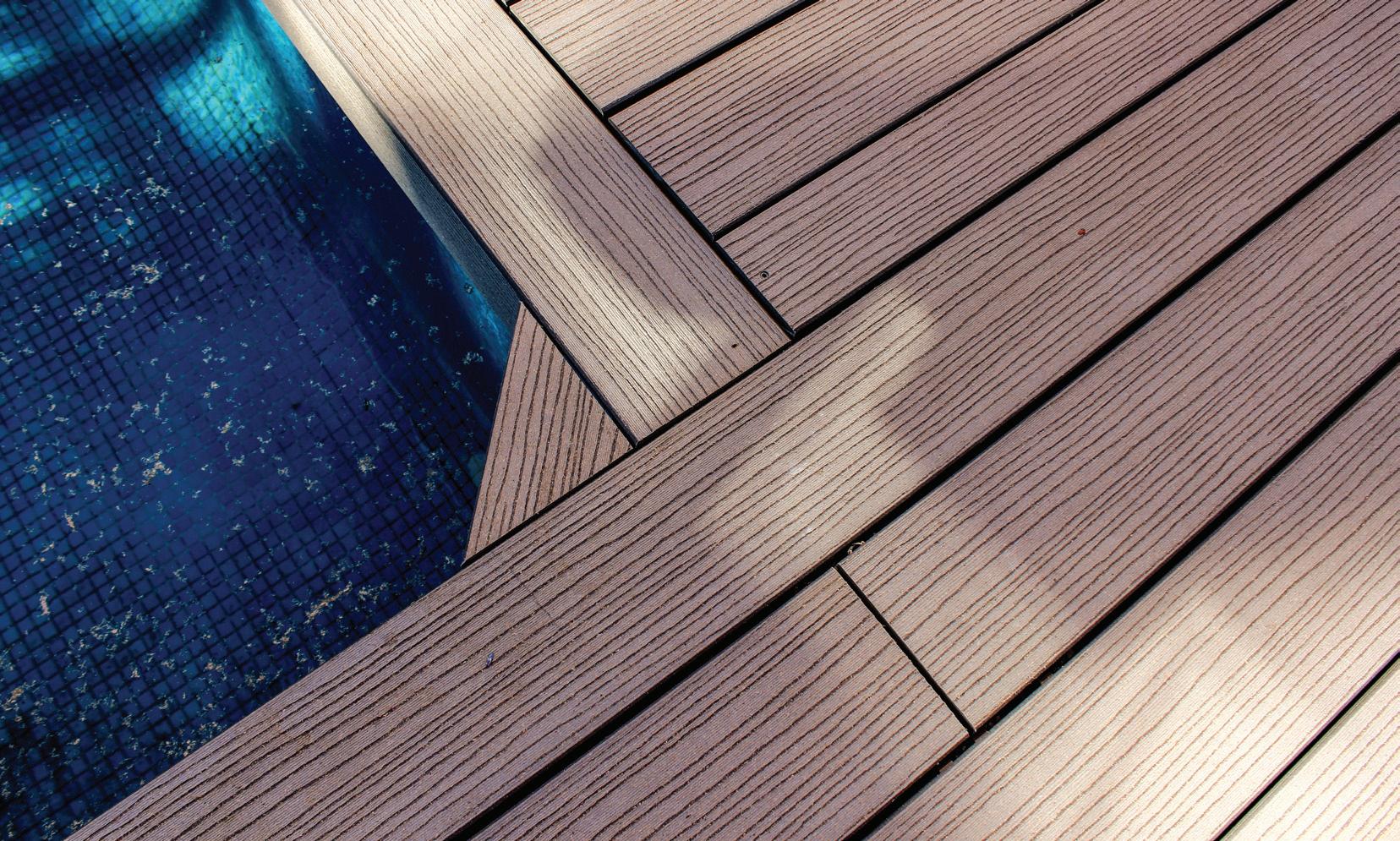

Decking that is built to handle anything Mother Nature throws at it

Steel framers take the industry by storm in this first-of-its-kind builder event

Builders get excited about November’s PSP/Deck Expo in Las Vegas, NV.

ON THE COVER: Early fall is known for its unpredictable weather. Yet, extreme weather is no match for this composite decking in Florida that was specially designed to prevent moisture penetration. (Photo by MoistureShield)

BEAT THE HEAT: As “fire season” impacts the nation, we share ways builders can mitigate the risk when constructing outdoor spaces.

A publication of 526 Media Group, Inc. 151 Kalmus Dr., Ste. E200, Costa Mesa, CA 92626

Phone (714) 486-2735

President/Publisher Patrick Adams padams@526mediagroup.com

Vice President Shelly Smith Adams sadams@526mediagroup.com

Managing Editor Sara Graves sgraves@526mediagroup.com

Editorial Director David Koenig dkoenig@526mediagroup.com

Brendan Casey, Marv Johnson, Bobby Parks

(714) 486-2735

Chuck Casey ccasey@526mediagroup.com

Nick Kosan nkosan@526mediagroup.com

Mitch Tanis mtanis@526mediagroup.com

Alek Olson aolson@526mediagroup.com

Jody Bays jbays@526mediagroup.com

DECK SPECIALIST is published quarterly at 151 Kalmus Dr., Ste. E200, Costa Mesa, CA 92626, (714) 486-2735, www.building-products.com, by 526 Media Group, Inc. (a California Corporation). It is an independently owned publication for U.S.-based builders and contrators that specialize in decking and other outdoor living projects. Copyright®2022 by 526 Media Group, Inc. Cover and entire con tents are fully protected and must not be repro duced in any manner without written permission. All Rights Reserved. Deck Specialist reserves the right to accept or reject any editorial or advertis ing matter, and assumes no liability for materials furnished to it.

Sept./Oct. 2022 • Volume 6 • Number 4

Life is all about pivoting when things don’t go as planned. Some changes are harder than others. And although I am no stranger to change, I have learned a lot in the last year.

I am a mom of two teenagers, one who graduated from high school last summer.

Up until then, I had envisioned that after my son graduated, he’d go straight onto college the following fall. I had even hoped he might have moved out with friends soon afterwards.

Yet, for all our pre-planning, last summer looked nothing like we thought it would.

Instead, by the time my son graduated, he was completely disenchanted with school—thanks to the previous two years of remote learning—and had decided against attending college for the foreseeable future.

And although there was no way we could anticipate how COVID would negatively affect my son, we chose to give him the time he needed to regroup.

Being flexible in the face of change is something I was reminded of as I listened to Ben and Andrew Schoonover, 22-year-old twins who spoke at our second annual Deck Specialist Symposium in early July along with their father Greg Schoonover. In their discussion with our publisher, Patrick Adams, they shared their story of how the pandemic ultimately steered them into deck building.

Ben and Andrew, who followed their father’s footsteps into construction, were still trying to find their place in the industry on the day that changed their business forever.

It was their lunch hour, and they were standing in a client’s kitchen when they read a post on Facebook about four confirmed cases of coronavirus. Not believing things could get

as bad as they eventually did, they laughed off the idea that stores might close, masks would be required, and cruise ships would no longer sail.

“Within a week or two…it went from four to 10 cases to 20,000,” Ben recalls. “We thought we were doomed; we weren’t going to get work anymore.”

After a month or two of chaos, he said, and with the interest in decking having increased due to the pandemic’s isolation, the twins said “‘Alright, let’s steer toward decks’ because we were getting more deck calls, and we really started to realize we loved decks and were passionate about them.”

Today, having pivoted successfully, the twins have more than enough work to fill their calendars for quite some time. Clearly they made the right decision to pivot at the right time.

Similarly, as my son begins his first year at college this fall, having decided to continue his education after all, we too are hoping that this year off will be his well-timed pivot and spell nothing but success for him.

Sara Graves is the managing editor of Deck Specialist. Reach her at sgraves@526mediagroup.com

Avon Plastics and Britton Lumber Co., Fairlee, VT., and Gray, ME., announced the expansion of their partnership to distribute Armadillo com posite deck products and TurboClip hidden deck fasteners throughout New Hampshire, Vermont, Massachusetts, and Maine.

“Avon Plastics and Britton Lumber have already enjoyed a very successful partnership distributing our Grid Axcents line of recycled plastic lattice products for many years,” said Chuck Hayes, national sales and marketing man ager for Avon. “Their superior level of service and attention they give to their customers makes me excited that they are now expanding their offering by adding the Armadillo line of compos ited decking and TurboClip, the fastest installed hidden deck fastener.”

TurboClip now gives builders a hidden deck fastener that can reduce the installation process by as much as 60%.

Brian Moses, sales manager, Britton Lumber, said, “As we continue to expand our outdoor

living product offerings at Britton Lumber, the addition of Armadillo decking felt like a natural fit. Not only does our partnership with Avon Plastics strengthen, but we are also adding a product line that has proven success throughout the country and we are excited to introduce it to the Northern New England market.”

Avon Plastics produces Armadillo Composite Decking, TurboClip Universal Hidden Deck Fasteners, Grid Axcents Decorative Lattice, Quix Interlocking Tile, and Master Mark lawn and gar den products from Paynesville, MN.

Trex Co. has been named by Industry Week magazine as one of the 50 Best U.S. Manufacturers. In its first year of eligibility, the world’s leading manufacturer of wood-alterna tive composite decking and eco-friendly outdoor living products ranked #6 on the annual ranking of top-performing manufacturing companies.

Joining such well-known brands as Apple, Microsoft, Pepsi and Pfizer, Trex earned its high-ranking position on IW’s “50 Best” list following a year of robust demand coupled with expanded capacity that drove strong growth. Net sales of $1.2 billion, revenue growth of 36% and adjusted net income of $243 million helped propel the company not only onto the list for the first time but into the top 10.

Companies ranked on IW’s “50 Best” list are pulled from the Industry Week U.S. 500, an annual listing of the top 500 publicly held U.S. manufacturing companies based on revenue. The “50 Best” formula then examines profit margin, revenue growth and inventory over a three-year period, as well as return on assets and return on equity over a five-year timeframe, with the most recent numbers weighted most heavily.

AVON PLASTICS’ Armadillo composite decking is a favorite of California Custom Decks, St. Louis, MO., a 2022 Deck Specialist of the Year Award winner.

Wolf Home Products is collaborating with the Wolf Conservation Center (WCC) of New York to enhance their facility and popular Wild Nocturnal Adventure experience.

The WCC teaches thousands of people each year about the importance of wolves through onsite educational programs and helps to give critically endangered wolves a second chance by housing and breeding wolves for eventual release into the wild.

As part of this collaboration, Wolf Home Products will donate products that suit WCC’s state-of-the-art 4,700 sq. ft. education center and 12 new camping pods. Products to be donated include:

•Wolf Perspective Decking for the camping pods

•Wolf siding products for the education center and camping pods

•Wolf Classic cabinets for the education center kitchenette

12 CAMPING PODS, which will replace tents used for overnight stays, are designed for the “Sleeping with the Wolves” experience, which allows campers to sleep safely overnight with the 30+ wolves that call WCC home.

“We are eager to break ground and support the Wolf Conservation Center in educating individuals about wolves, their relationship to the environment, and the human role in protecting their future, said Craig Danielson, president and CEO of Wolf Home Products.”

WCC chose Wolf Home Products due to its history of providing products that stand the test of time, especially against harsh weather.

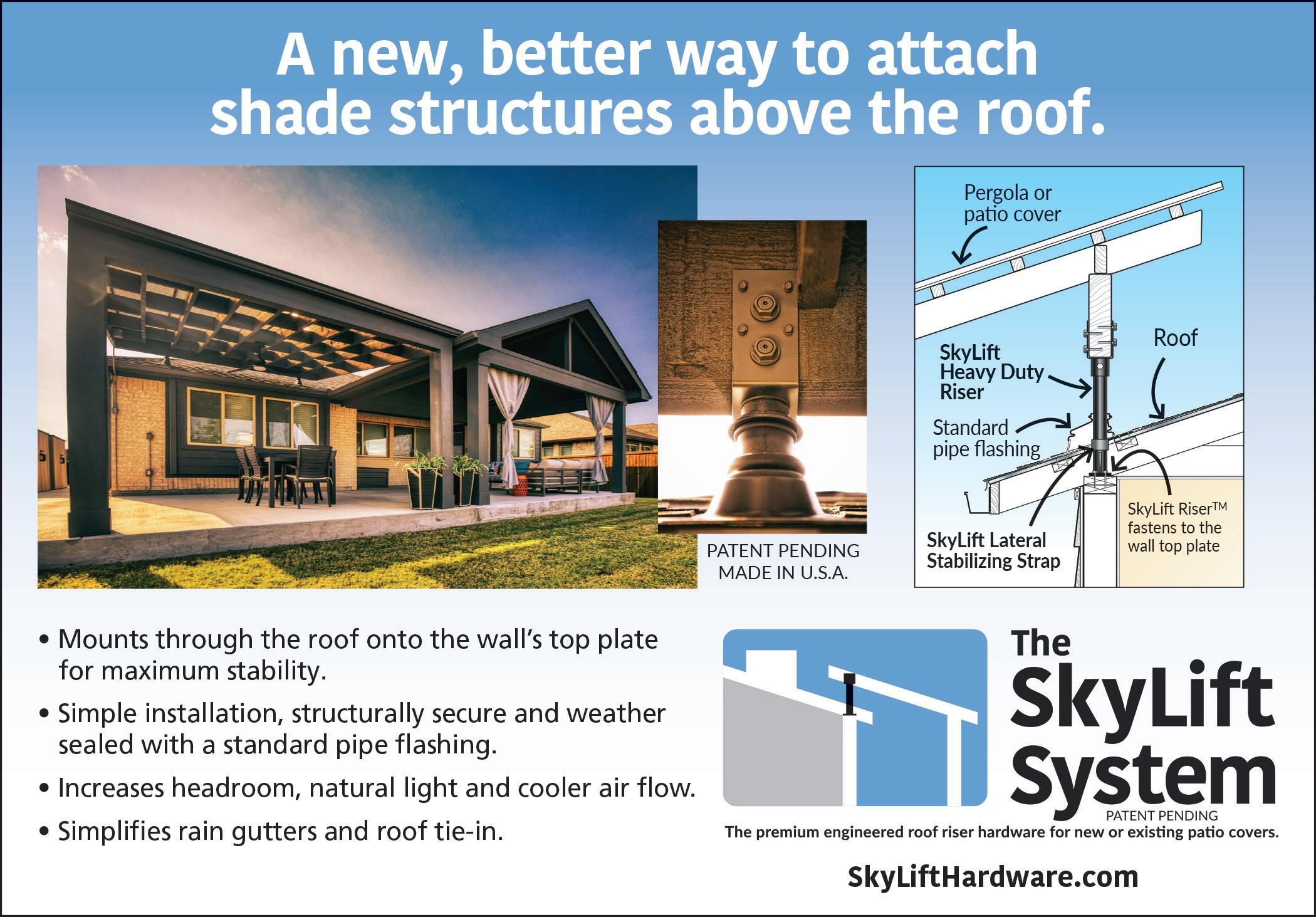

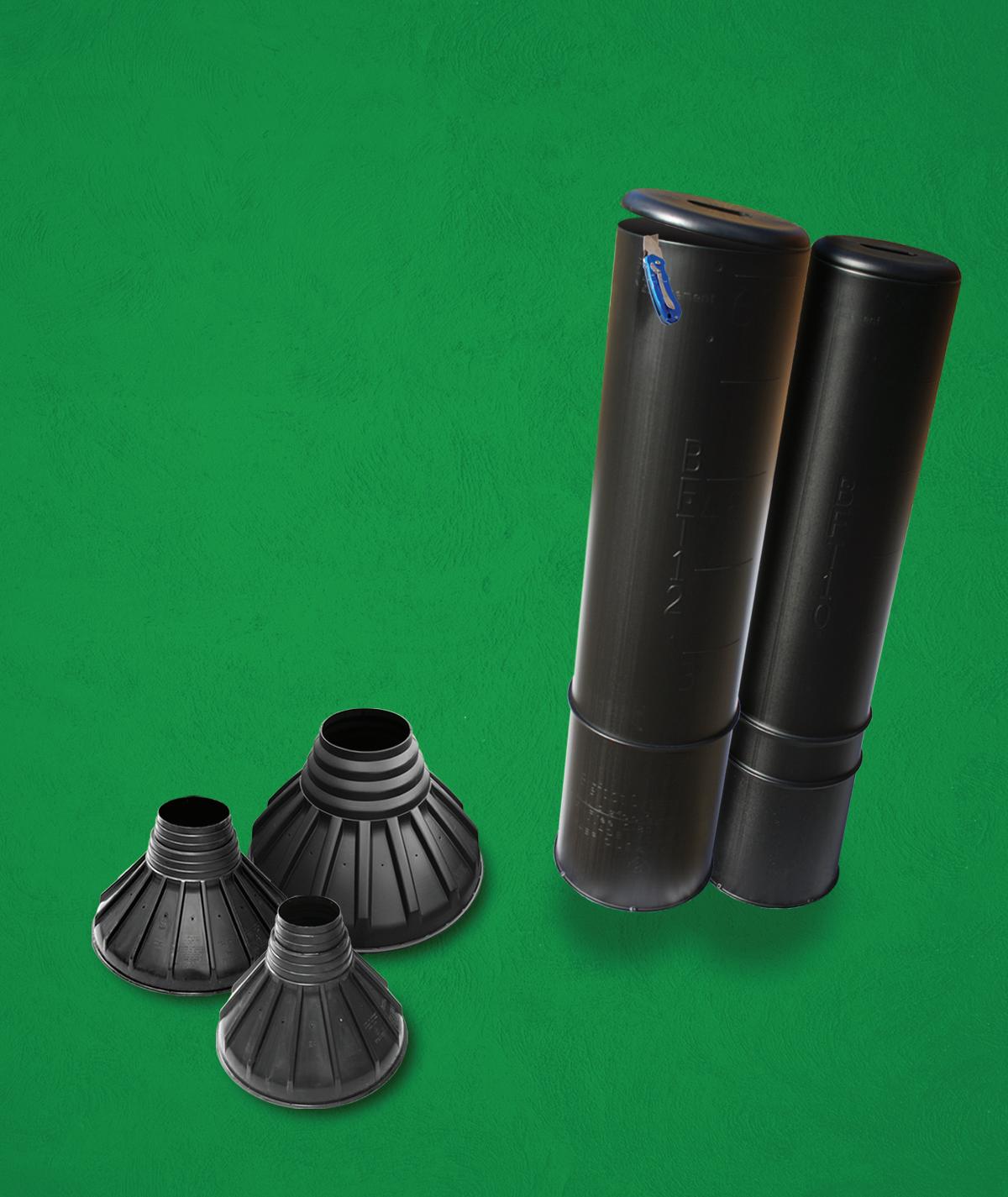

Patio Roof Risers are an excelent choice for any builder that wants to make building elegant covers simple.

Engineered for success, Patio Roof Risers are backed by comprehensive engineering documents and install entirely outisde the building envelope of the house, greatly reducing liability.

Waterproof seal. No leaks, guaranteed.

To learn more, visit patioroofriser.com

As fall gets underway so does “fire season” across certain regions in the country.

We take a look at the impact that wildfires and home fires have on customers, and how builders can help mitigate the risks when constructing outdoor living spaces.

Fire is one of the primary causes of property loss among homeowners.

In fact, most home fires and fire casualties re sulted from one of five causes: cooking, heating equipment, electrical distribution and lighting equipment, intentional fire setting, and smoking materials, according to the National Fire Pro tection Association (NFPA)’s Home Structure

Fires Oct. 2021 study. Moreover, cooking was the leading cause of home fires and home fire injuries over the five-year period of 2015-2019.

Moreover, certain regions, such as California, are seasonally more prone to forest fires caused by either lightning strikes or electrical sparks in the fall.

Builders working in these areas are therefore required to adhere to stringent building codes.

Decking is a particular concern because it is

often the first line of defense against an advanc ing forest fire.

According to Michele Steinberg, NFPA’s Wildfire Division director, once there is a wildfire in a region, many homes can be ignited simultaneously from the embers, surface flames and radiant heat that the fire generates.

“What we have seen over and over again is that a home exterior that is ignition-resistant and doesn’t provide either a place for embers to accumulate, nor entry for embers to get into the structure, along with at least 5 feet of space around the home perimeter and attachments (including decks) that has nothing in it that can burn (no plants, no mulch, no woodpiles) leads to a better outcome,” she said.

She added that if neighboring properties are also ignition-resistant, the potential of home loss is reduced because “if those nearby homes/decks/ fences don’t ignite, they won’t burn and throw radiant heat at their neighbors for hours.”

When it comes to the combustibility of deck ing, Steinberg added, many decks are built with susceptible deck boards that ignite due to narrow

board spacing that traps debris and embers, al lowing them to smolder and eventually ignite the deck material and then the adjacent structure.

Any ignitable material stored or allowed to ac cumulate under decks is a wildfire exposure, she added. Decks that overhang steep slopes are at special risk due to how wildfires move up slopes, preheating any fuel (vegetation or structures) along the way.

Typical vulnerabilities to decks made of com bustible material include:

•Embers between boards spread fire–the tighter the gap, the more likely fire will be to spread from the ignition point.

•Embers between boards and on top of com bustible joists spread fire very fast, both on the surface and down into the joist under the deck.

•The intersection of deck and house is vulner able to ember massing (creating fire exposure).

•Under a deck made of combustible boards and joists, flame impingement from material/vegeta tion on the slope heats up and ignites joists.

•Embers burning on top of joists (via gaps in deck boards) take out joists, spreading fire quickly to the house.

In lieu of the potential for property loss, build ers and their customers are constantly looking for more fire-friendly solutions that are attrac

tive yet provide much needed prevention.

A.J. Jesiolowski, director of framing & per gola for Fortress Building Products, agrees: “In hot and dry parts of the country, concern about another devastating wildfire season is motivat ing many homeowners to reconsider traditional building products to reduce the vulnerability of their homes.”

The NFPA offers these recommendations for new decking in fire-prone areas:

•Use non-combustible solid surface materials and metal joists–which offer the best protection, but at a higher price.

•Use code-compliant deck boards (e.g., plastic composite).

•If using deck boards instead of solid surface, design gap to be 1/4” rather than 1/8”.

•If using combustible joists, increase joist spacing from 16” to 24”.

•If using combustible joists, apply a foil-faced self-adhering adhesive flashing tape on top of each joist.

•When planning a deck that overhangs a steep slope, determine with local authorities if vegeta tion on the slope/under the deck can be adequate ly cleared away to prevent fuel build-up.

Fires burn differently based on what fuels them. Therefore, building products are rated by their fire performance, including their flame spread index and heat release rate.

In terms of the flame spread rating (rated A-D or K), each product’s classification is derived by testing the material against a gas flame in a hori zontal tunnel to time how quickly fire spreads on it. The heat release rate testing determines how much energy is released when the materials is burning.

A building product’s fire classification char acterizes each material by how well it performs compared to similar products. For instance, when it comes to decking products, framing is of particular importance to preventing a ground fire from spreading quickly.

Some of the deck framing and boards that help mitigate fire risk include steel deck framing, composite, redwood, hardwoods, and chemically treated wood.

Steel is one popular choice for deck framing in fire-prone areas because it is considered Class A, meaning it is highly resistant to catching on fire, and flames do not spread quickly on it. Fortress Building Products’ Evolution is one such product that has a Class A fire rating through Intertek.

Jesiolowski said that steel deck framing sys

GORGEOUS REDWOOD decking in Harrison Lake, Canada, was treated with Chemco’s Thermex exterior fire retardant to achieve a Class A rating after treatment to meet local WUI building codes. (Photo by Attilio Fiumarella).tems are a noncombustible option for building a deck that can support outdoor kitchens, pergolas and other popular outdoor living amenities.

Composite decking has proven to be another popular choice for homeowners looking to mit igate their fire risk, especially in regions that experience brush and forest fires yearly.

California, for instance, has created a specific set of building codes called Wildland Urban In terface Codes (WUI) that are designed to ensure structures are built with building materials to minimize damage.

In addition, California’s Department of For estry and Fire Protection (CAL FIRE) has a pro gram called the Office of the State Fire Marshall (OSFM) that protects life and property through the development and application of fire preven tion, training, education, and enforcement.

It’s important to note that OSFM has a PDF of the WUI zone-listed products posted on its website at osfm.fire.ca.gov listing each product’s flame spread class rating.

And for composite decking to meet the code acceptance criteria for alternative decking under ICC-ES AC 174, it must have a Class C flame spread rating using ASTM E84 fire testing.

Certain wood decking meets the necessary criteria to be installed in fire-prone areas. Cedar and birch are two that are naturally high-heat resistant.

Similarly, western red cedar meets the flame spread and fire-retardant ratings necessary for it to be used in California’s WUI areas. Specifi cally, it received a Class B rating and was found to be self-extinguishing, according to scientific testing conducted in April of 2014. It also passed ember penetration tests.

Builders turn to redwood because it has been approved by the OSFM for WUI-code-approved use for more than a decade.

In fact, since 2008, new decks built in Califor nia’s WUI areas have been governed by Califor nia Building Code Chapter 7A, titled: “Materials and Construction Methods for Exterior Wildfire Exposure.”

For this approval, redwood decking has demon strated that it meets the performance require ments of SFM Standard 12-7A-4A while addi tionally having a Class B flame spread index in accordance with ASTM E84.

Hardwoods are another favorite among home owners for their beauty and durability. Ipé is generally rated at a Class B or lower, but remains a popular choice.

If additional protection is needed, builders can opt for fire retardant wood decking instead, which is considered environmentally safe.

While California 7-A allows for untreated decking materials that have passed the Chapter 12 7-A decking tests to be used, some counties not only in California, but Colorado, Arizona, and Oregon, have adopted the decking and siding standards of the IWUIC, which requires any exterior wood products be Class A “Ignition Re sistant,” said Bill Hendricks, representative for Chemco and Thermex FR Treated Products. The IWUIC has a more restrictive standard than CA 7-CA-7A.

Hendricks recommends stainless steel fasten ers, and end cutting for length, but no ripping of the product. No additional treatment is neces sary on the end cuts. The material can be stained using an oil-based stain for continued beauty of the treated wood deck without interfering with the fire treatment, he added.

“As far as the future, the future is now!” Hen dricks said. “(The) industry will always meet de mands, whether being codes or consumers!” DS

INDOOR AND OUTDOOR COOKING is a leading cause of home fires and residential injuries. Installing code-compliant decking underneath an outdoor kitchen decreases the risk.Visit RailFX.net to find a dealer near you.

With RailFX ®, it’s easier to give your customers the custom look they desire. With online specifications, made-to-order systems, intuitive installation, and a representative on standby should you need assistance, RailFX is with you every step of the way.

When Ashley Campbell of Decked Out Construction and Outdoor Living, Gilmer, TX., posted on Facebook at 2 a.m. saying that he wanted to pit Fortress Evolutions against newly launched New Castle Steel in a side-by-side steel framing build at his new store, he unintentially ignited a spark of enthusiasm in the industry.

Although he said it was admittedly a joke at first, the industry caught wind of it and as Scott “The Godfather of Steel” Kelly put it: It picked “up momentum faster than an east Texas tornado.”

Within hours, Campbell had landed the commitments of both Fortress and New Castle Steel to attend. The catch was that both compa nies said they would participate only if it was a collaborative event, not a competitive one.

Set to happen in just a few short weeks at Campbell’s Extreme Backyard & Beyond show room in Mount Pleasant, TX., builders and man ufacturers from across the country and Canada heard about the event and responded with great support.

UFP, Deckorators, ProWood, CAMO Fasten ers, Simpson Strong-Tie and NADRA all agreed to attend, as well as industry leaders, including

Shane Chapman and Wade Laurent from “The Ultimate Deck Podcast,” Kelly, and Wood Bully’s Gordon South.

With it suddenly taking off, Campbell enlisted the help of Chris Breen, Legacy Decks, to launch the first Steel Sharpens Steel on June 27-29.

It turned out to be bigger than Campbell first imagined. “We thought there would be at most 30-40 people,” Campbell said. “It ended up closer to 100.”

“Remarkably, so many top builders, such as Jason Varney, Blake Carter, Mike Scott, Mike Mitchell, Justin Wiley, Christopher French, and Scott Kelly, showed up to support this newer part of the decking industry,” said Jason Alloway, New Castle Steel’s owner.

And for steel manufacturers to “share their secrets and inside knowledge” with the rest of the industry really impressed Campbell. “To have two (steel) manufacturers working side by side together that normally compete against one another—that never happens!” Campbell exclaimed.

He added that it was an all hands-on-deck event, and that no one was standing around. “Literally 100 people were working together.

COLLABORATIVE Steel Sharpens Steel brought manufacturers and builders together to showcase steel framing in a first-of-its-kind demonstration. (Photos by Fortress Building Products)

Kelly, who owns Precision Construction in Golden, CO., agreed, adding that he was impressed to watch Fortress discuss openly and candidly the strengths of New Castle Steel, the marketing and railing teams from Fortress help ing in the installation and the Deckorators certi fied installers installing Fortress Apex Decking.

Other highlights, Kelly said, included watch ing contractors showing decking reps how the CAMO EdgeX metal clips and the Clip Drive in stallation tool work, and David Settlemyer of LS Underground heat bending an Apex decking radius.

Campbell attributes much of Steel Sharpens Steel’s success to people wanting to see steel being built in person.

“You can say it’s easier, but to see it done is another thing,” he said, adding that there has been a ton of outpouring of people new to steel framing who watched it live on Facebook and now are interested in using it.

“I’ve had calls about four frames from builders who never touched steel in their lives,” he said. “One builder, who has been in the industry for 15 years, wasn’t convinced about steel until he watched it.”

Builders, including South and Kelly, were on hand to share their steel framing expertise.

“We had lots of great feedback,” South added. “I’ve always had viewers take interest in what kind of steel framing I use, and I think this has really helped spread that awareness. We even had some Wood Bully followers from Texas show up to take part in the event.”

Kelly made the switch to steel on a project where he had to do a large span to protect the view of a client that “was basically impossible to do with wood.”

“On a project right after that, we fought and fought with wood framing to try and get it to be straight and flat,” he added. “So, after that, there was no going back. I decided that steel was far too superior of a product, and I didn’t want to offer anything except that to my clients from that point on.”

In addition, he said, steel enables him to dic tate his price point because he is not competing against nearly as many people. “I feel like my job is to represent the best interest of my client. Steel gives me that peace of mind that I’m giving someone the best possible product that I can.”

For those builders who are interested in trying steel after watching the build online, Kelly suggests giving it a shot.

“The biggest misconceptions about steel are that you need to have special tools, that you need to have special knowledge, and that it’s harder to handle than wood,” he added. “But once you try it, you will find out that in a lot of ways it’s easier than wood. There are less tools. You don’t have to play in the lumber. You don’t have to grade it. You don’t have to tape it. You don’t

CAREFULLY MEASURING the steel framing, Gordon South of Wood Bully (left), and Chris Breen, Legacy Decks (right), discuss the Fortress build at Steel Sharpens Steel. REPRESENTATIVES from Fortress’ marketing and railing teams were on hand to assist with the steel installation at Steel Sharpens Steel in June.have to paint the end cuts. You just take your delivery and you start building with it.”

Campbell, who has experience using both Fortress and New Castle steel framing, agrees: “The fact is once you put (steel) up, you’re done. There’s no planing or taping. Once you install it, you’re ready to deck it. It cuts labor time. There’s no work once you put it together.”

“Both have advantages,” Campbell added. “Fortress is a lot easier to put together. It is a cookie-cutter system. There are no cuts. Just bolt it together. Jason’s (New Castle Steel, for merly Trex Elevations) requires more technical expertise. It’s like putting together Legos compared to an Erector set.”

Alloway, who has been championing steel for over 15 years, said the event allowed him to show the industry how easy it is to put New Castle’s steel framing together: “It’s quick and strong, and now everyone knows it.”

With interest in steel growing, there are changes and improvements still being made.

For instance, Alloway is currently working on patenting a thicker-gauge steel post bracket “that is really heavy and beefy,” Campbell said.

Kelly agreed, adding that Alloway had already made significant changes and improvements in cluding a new 2”-wide, 14-gauge joist, and improved post and post-to-beam connections.

In addition, Alloway said he opened a new

manufacturing facility and warehouse, is bring ing on additional employees, and is continuing to evaluate and add distribution channels for more product availability.

Kelly had nothing but positive things to say about the event: “For three days some of the biggest names and most talented builders in the industry worked together to bring three display decks to life. Every conversation I heard and participated in centered on comradery, and ways to improve the industry, collaboration at its finest. Steel Sharpens Steel was a success not only for bringing exposure to steel framing and its benefits, but, arguably more importantly, for showcasing the community that is the deck building industry.

“NADRA has a saying—‘collaboration, not competition’—and Steel Sharpens Steel was the perfect embodiment of this mantra,” Kelly said.

And although the event may have started off as a joke, it had quite a different punchline than Campbell expected: “(This event) has awoken the industry again,” he said.

And building on this first success, Campbell is currently planning a second two-day industry get-together at the end of October at his Mount Pleasant store. The Maximum Bend Event will be a collaborative project with LS Underground in which they will be bending decking into the shapes of Texas and Colorado. DS

EVERYONE PITCHED IN to assemble the steel framing at Steel Sharpens Steel, which drew close to 100 people.

Service Area: Anchorage, AK.

Specialty: Deckorators

Owners: Brenton Giliam & Tommy Hopp

Year Founded: 2019

Website: fwdalaska.com

Instagram: @fwd.construction

Facebook: FWD Construction

build them up through our processes.

We put a heavy emphasis on training our team our way. Our guys go through an intense training course at the beginning of each season to ensure that our best practices and processes are standard throughout the company. We also provide weekly training and study guides for our team to help sharpen their skills throughout the year.

High school friends Brenton Giliam and Tommy Hopp had discussed starting a deck building company. Out of high school, they went their separate ways, with Brenton pursuing a construction career. Years later, they revisited the idea of starting a business together. Initially, their projects were simple. Today, they build larger, more elaborate projects with Deckorators decking.

Q. Can you tell us about your team?

A. We are a young company made up of pretty young guys. We are in our twenties and so is almost everyone on our team. Some look at that negatively and would try to hide it, but we believe it’s a really big positive. It brings an energy and passion that’s fresh to an industry that can often be old and stagnate. We don’t require previous construction experience because we almost prefer someone to come in with zero assumptions or preconceived ways of building or doing business. We then get the opportunity to

What’s unique about our team is not the age or previous experience when we bring someone on, but their character and passion. We know that ultimately our employees are the company. They are the product, and they are the culture. The experience that they have working at FWD, and in their personal life, is the experience that our clients will ultimately have. So our team is a

Brenton Giliam and Tommy Hopp are two young, creative and passionate deck builders who strive to move their company forward.

Tommy Hopp

Brenton Giliam

DECKORATORS SIERRA DECKING creates a sharp contrast to the Toja black pergola above it.

Brenton Giliam and Tommy Hopp are two young, creative and passionate deck builders who strive to move their company forward.

Tommy Hopp

Brenton Giliam

DECKORATORS SIERRA DECKING creates a sharp contrast to the Toja black pergola above it.

creative and passionate bunch who looks to move forward in all that we do.

Q. What prompted you to become a Certified Pro Elite company for Deckorators, and why do you prefer using that product?

A. We’ve used all the main brands of decking and we’ve really come to like Deckorators. It’s been a long process of finding what products to provide and recommend. As the experts, clients put a lot of trust in our opinions and we don’t take that lightly. We can greatly influence the product that someone decides to build with and so we look to brands that we can trust.

What matters to us is does it last, and does it look good. Deckorators warranties and technology speaks for itself, but we really find confidence in the aesthetic of the product.

We get overwhelmingly good feedback on the final appearance and look of the decking.

I would also say they are wonderful to work with and they really take care of their contractors, which helps build more trust.

Q. What project are you most proud of?

A. We’re most proud of the Eagle River, AK., project. At the time it was a challenging build and it turned out to be such a great space. We built it over an unusable slope in the backyard of

a home. Our footing installers couldn’t get down the slope with their tractor, so we actually built the deck off temporary piers first. Our footing installer then drove their tractors on the finished deck surface and installed the helical piers through the deck, down 20 ft. below. It was cool to see how it expanded their yard, giving them usable space somewhere that was useless otherwise.

Q. As an Alaskan builder, how does weather and shipment costs affect your business?

A. People call it the Wild West of building. It takes longer to ship things here than anywhere in the U.S., and our builds have to withstand extreme conditions. The shipment delays take a lot of planning and preparation. We have to be organized with our ordering and plan jobs months in advance.

The weather in Anchorage is mild compared to central or northern Alaska, but relative to the rest of the U.S., it is still pretty extreme. The biggest two challenges are the shortened season, and the frost heaving.

The frost depth in anchorage is 42". It’s not uncommon to see seasonal frost heaving of 6-12 inches. There’s a couple things we do to combat this. We keep all framing material 6-8 inches above the ground. We also don’t use concrete

COMPOSITE DECKING with a cedar pergola and cedar chalet-style roof finish off this cantilevered deck in Eagle River, AK. (Photos by Ryan Black, Blax Photo)footings. Instead we build on helical piers as a foundation.

Q. What unique considerations must you make when planning and designing your decks?

A. The climate and ground considerations influence our design. Paver patios and concrete patios are less common in Anchorage. It is difficult to ensure a solid and long-lasting patio due to the frost depth. Often the heaving destroys pavers and cracks concrete. We take this into consideration when designing and try to maximize the functional space of the deck. Less ground level yard space for living requires more deck square footage.

Q. What role does social media have on your company’s growth?

A. I’d say the most valuable role it has played has been education and collaboration. We’ve been able to connect with and learn from the best deck builders in the world. Seeing other professionals’ methods, products and processes has pushed us to innovate and improve. It has also given us a place to showcase not only our work, but our company culture and the personality and passion of our company.

Q. How would you describe your approach to serving customers?

A. We want them to have zero questions. We hope our process is so clear that there’s no confusion at any stage—whether it’s the 3D rendering we provide to clearly communicate the visual prior to signing a contract or the location of the dumpster on their property. Their experience is as important as the deck, and takes just as much intentionality.

Q. What is unique about your company that sets you apart?

A. We chose the name FWD or “Forward” to represent our mindset. We want to move forward in everything. We hope to move the industry forward with more efficient processes and better customer experiences. We are creating a unique work environment and company culture. Not one of the stereotypical construction companies, but one where everyone’s voice is heard and the experience of our people is the priority. We push our employees to grow personally as well as challenge any process of our company. If someone has a better idea of how things should be done, we listen. The attitude and mindset we try to embody is summed up in our company’s mantra, which is “Big Deck Energy.” DS

TOJA PERGOLA provides shade and a 3D aspect to the sitting area that is made complete with deck furniture purchased by the homeowner. ANCHORAGE HILLSIDE project near Alaska’s Chugach Mountains features Deckorators Khaya decking with a stained cedar rail and black steel cable.

Introducing YellaWood Protector® Semi-Transparent Stain and Clear Water Repellent.

It takes a whole lot to earn the right to wear the Yella Tag. Backed by fifty years of proven knowledge and quality, YellaWood Protector® products are specifically formulated by the makers of YellaWood® brand pressure treated pine. YellaWood Protector® products provide long-lasting, rich color and the superior protection savvy homeowners demand. All with a limited warranty against chipping, peeling, water damage, mold, mildew and color fade. Since there are no long drying times or even in-store mixing or tinting required, you’ll love how easy it is to use. Find your local dealer at yellawood.com/protector and finish like a pro.

yellawood.com/protector

YellaWood® brand pressure treated products are treated with preservatives (the “Preservatives”) and preservative methods, and technologies of unrelated third parties. For details regarding the Preservatives, methods, and technologies used by Great Southern Wood Preserving, Incorporated, see www.yellawood.com/preservative or write us at P.O. Box 610, Abbeville, AL 36310. Ask dealer for warranty details. For warranty or for important handling and other information concerning our products including the appropriate Safety Data Sheet (SDS), please visit us at www.yellawood. com/warranties or write us at P.O. Box 610, Abbeville, AL 36310. YellaWood and the yellow tag are federally registered trademarks of Great Southern Wood Preserving, Incorporated. All other marks are trademarks of their respective owners and are used with their permission.

YellaWood® brand pressure treated products are treated with preservatives (the “Preservatives”) and preservative methods, and technologies of unrelated third parties. For details regarding the Preservatives, methods, and technologies used by Great Southern Wood Preserving, Incorporated, see www.yellawood.com/preservative or write us at P.O. Box 610, Abbeville, AL 36310. Ask dealer for warranty details. For warranty or for important handling and other information concerning our products including the appropriate Safety Data Sheet (SDS), please visit us at www.yellawood. com/warranties or write us at P.O. Box 610, Abbeville, AL 36310. YellaWood and the yellow tag are federally registered trademarks of Great Southern Wood Preserving, Incorporated. All other marks are trademarks of their respective owners and are used with their permission.

When it came time to update an old deck that had clunky railings blocking the beautiful views of Ontario, Canada’s Georgian Bay, Simcoe Decks had to remain clear-headed to find creative solutions to bring beauty back to the deck.

“With gorgeous views of the Georgian Bay, it was important that there was as little obstruction as possible to allow for a full view of the water from both the deck and the interior of the home,” said Michael Scott, owner of Simcoe Decks, Barrie, Ontario.

“We realized that we had the opportunity to create a truly one-of-a-kind solution that hadn’t been done before. Since nothing like this had been done, we didn’t have an install guide on how it would all come together,” Scott said. “We

originally planned on a spigot frameless glass system, but through talks with the clients, we came up with the idea of doing just straight glass panels with the mounting hardware concealed directly inside the deck framing to give the illusion that the glass ‘floats out of the deck.’”

And with time delays on custom glass averaging about four to six weeks, they didn’t have “the luxury or flexibility of changing ideas on the fly.”

A single piece of glass was ordered to test out how the project would come together.

Unfortunately, the original piece was delivered with incorrect placement for mounting hardware and the team was unable to try it on the project beforehand.

“With almost $50,000 in glass alone on this

SIMCOE DECKS’ project took second place in the railing category of the NADRA 2021 National+ Deck Competition. The glass hardware is concealed inside the deck framing. (Photos by Nat Caron, Nat Caron photography)project, it was extremely nerve racking knowing we would have to just bite the bullet and order the glass without being able to test our theory to make sure the glass would work on the project,” Scott said.

“We designed a couple of temporary mock ups, and in the end had to cross our fingers as we paid for all the custom glass to be manufactured. We unfortunately had a few pieces show up with wrong locations for mounting hardware, but instead of waiting for new glass panels, we improvised on site to make them work,” he said.

Another major issue that Scott and his team faced was the front entrance to the home was inaccessible due to old, dilapitated stone steps that posed a safety hazard to the homeowners.

“The homeowners were having to use a side entrance that was not the most practical so giving them back the front entrance was huge on the priority list,” he said.

In addition to the dangerous stone steps, the main entrance was “a mess with public and private utilities exiting the house right at the front entrance,” Scott added.

“Since the majority of projects are built in the backyard, we rarely have to deal with utility lines,” he said. “With this project, we had hydro, cable, Internet, irrigation, power to the garage, as well as sewer to the streets. We had to hand dig all the holes to expose the utilities before we were able to install our helices.”

The final 800-sq. ft. project with three decks came in at over $150,000 and took six weeks to complete. The project was built using Fortress Evolutions steel framing built on helical piles, with Deckorators Voyage decking in multiple widths, custommanufactured Starfire glass panels, and in-lite lighting.

“In the end we fought through the challenges and it turned out absolutely flawlessly,” Scott said. “As neighbors drove by, they constantly slowed down to check out the project. We had many stop and offer their praise on how well the project came together.”

“The project was one of our favorites as we were able to completely transform the exterior of this home and give the clients a usable outdoor space, which they are able to enjoy with family and friends,” he added. “Teaming up with our landscape partners, we were able to offer a complete turnkey service for this project.” DS

THREE DECKS, built with Deckorators Voyage decking in multiple widths, allow the homeowners to appreciate their view of the Georgian Bay. ACCESS TO THE HOME was made possible so the homeowners could enter from both the front and the side entrance without risk of injury.Last year, our nation experienced some of its worst weather on record. In fact, nearly one in three Americans live in a county that was hit by a weather disaster in a three-month window last year, according to The Washington Post’s analysis of federal disaster declarations.

Not surprising, this year is equally set up to hit some records, as seen by this year’s storms and summer heat, namely winter storm Landon that brought heavy snow and ice to more than a dozen states stretching from Texas to Maine, catastrophic flooding that devastated parts of Kentucky and triple-digit temperatures that broke records in the Northeast.

Clearly, building a deck to withstand Mother Nature’s hardest blows, whether it be relent less rain, ice, snow, hurricane winds, scorching heat—or a combination of these—takes a lot of forethought and planning.

For many builders, it’s during those cold winter months that they contend with Mother Nature the most, namely the frost heave that oc curs when there’s cyclical freezing and thawing of water in soil or rock. Consequently, choosing the sturdiest foundation for a particular region,

depending on its temperature fluctuations, is crucial for building a deck with staying power.

Phil Andrews, Andrews Decking & Carpentry, Ontario, Canada, opts for helical piles whenever possible to deal with his area’s significant frost heave. And when he cannot use helicals (in those areas where the impenetrable Canadian Shield is only 2 ft. underground), he will “epoxy rebars down and form our concrete piers on that with some sort of adjustable saddle.”

Similarly, Lawrence Winterburn, founder of GardenStructure.com near Barrie, Ontario, Canada, also uses a few different types of helicals in his builds since the Canadian Shield is often near the surface of where he is digging.

“We build in flood zones to 19 ft. base flood elevation, (BFE), 120 mph wind zones, and have 100-degree seasonal temperature swings,” said Kevin Choquette, owner/operator of Ravin Builders, Wood River Junction, R.I.

Therefore, he uses Mascore helical piles in his builds, along with Deckorators composite decking, Mitsubishi G-Tape, CAMO Fasteners and “truckloads of Simpson structural bolts,

STANDING UP TO rain, snow or hail, composite deck boards are engineered for all types of weather that might be experienced throughout the year. (Photo by MoistureShield)

ties, straps and fasteners.”

In and around Monee, IL., where Mike Mitchell, owner of Mitchell Construction, builds, extreme temperature swings are not uncommon. To combat them, Mitchell uses helical piers for the foundation to prevent frost upheave and to provide uplift support. In addition, he uses flashing tape on top of all treated wood to help assist in preserving the wood. “We have big temperature swings, so we don’t miter our fascia and stay away from butt seams in the field of decking to control expansion and contraction issues,” Mitchell added.

For other regions, such as in the South, that experience seasonal high wind events, such as hurricanes or tornadoes, helical foundations are used to keep deck foundations from failing.

“The fluctuating high winds can proved to be challenging on a structure’s point and later al loads,” said Paul Birdsong, Florida regional manager for Cantsink, a Georgia-based helical pile manufacturer. “In a hurricane or a tornado, with the wind blowing under an elevated deck at 120 mph, the deck can now become a sail if not properly designed. This can also rip the piles out of the ground and cause failure of the structure.”

He added that if designed properly, the deck ing support columns would most likely fail long before the bolt connections break that secure the deck to the top mounting bracket to the helical pile.

And once the foundation is in place, picking the best framing material for a particular region is an equally critical consideration when producing a deck that can withstand harsh

weather conditions.

For many builders, steel is the way to go. “As natural disasters become increasingly common place across parts of the country, it’s never been more important that deck specialists consider the type of deck framing material that can deliver strength, resiliency and longevity to the outdoor equation,” said Rob Holthaus, sr. product mgr., framing, Fortress Building Products, which pro duces Evolution steel deck framing.

“As deck specialists know, strength is only half of the question when it comes to constructing a deck that can withstand storms and high winds. A very durable material, those that frame with steel, can ensure the long-term structural integ rity of their deck build,” Holthaus added, saying that steel is resistant to most tangible threats that can wreak havoc on wood frame decks, such as “deterioration after long-term exposure to moisture, splitting under hurricane-force winds and warping as a result of extreme changes in temperature.”

In addition, steel can provide peace of mind to customers that be apprehensive about investing in their outdoor living space because of where they live, Holthaus said. “With a yield strength approximately 10 times greater than wood,” he said, steel profiles can support amenities, such as full outdoor kitchens and pergolas. “There is no reason to fear the added weight of these ameni ties will result in premature failure.”

Kevin Choquette, owner/operator of Ravin Builders, Wood River Junction, R.I., agrees, adding that he likes to use steel framing when the project warrants it. “Unfortunately for us, most

INTENSE STORMS have become a yearly occurrence in some parts of the country. Knowing how to construct a deck and which products will work with your region to withstand high winds and intense heat fluctations is key to building a lasting deck.DECKS AND DOCKS are subjected to intense conditions each year. Choosing the best materials for a region’s seasonal weather patterns is paramount to the lifespan of those decks or docks.

of our high-value projects are coastal so steel isn’t the best fit” due to the warranty limitations on steel when used near salt water. He added that he runs into similar complications when using aluminum railing.

Conversely, other builders prefer composites and other types of decking for their projects. For example, Dale Dossett of Mr. Fence, Evansville, IN., prefers to use composite in his projects, and he builds to “at least minimum code. We overbuild everything, and for decking we only use composite and have not had any issues,” he said.

However, in Winterburn’s projects, he said he prefers to use PVC over composites because com posites swell due to his area’s freeze/thaw cycles.

Andrews meanwhile opts for pressure treated wood for framing where he builds. And to com bat weather-related decay, he tapes all joists and beams to help prevent rot from standing water and snow, which he sees for one third or more of the year. He has also moved to using ledger pucks to help increase the life span of the ledger to house connection.

And as for decking material, Andrews recently made the switch to primarily using Deckorators mineral-based composite decking due to its “in sane traction and the fact that it is entire water

contact ready.”

“Being that we have summers of +40 degree Celsius and winters -40 degree Celsius here sometimes,” Andrews said, “the very low thermal movement is also nice, and likely helps in the lifespan of the screws and fasteners too.”

“But with all things deck and water related,” Andrews added, the types of blocking used for railings and picture frames are all affected by factors, such as decking material type, compass direction and average wind directions to carry rain or snow, if there a roof over to protect it, etc. He advises to always end grain seal every single cut no matter where it is for.

Storm surge is another major consideration for decks and docks built in hurricane-prone regions. Docks are particularly vulnerable as they are subject to submersion.

“Rising and falling water levels can be challenging for dock builders, because it leaves dock areas that have been under water exposed,” said Brandon Martin, owner of Martin’s Custom Tidesides of Sodus Point, N.Y., who uses MoistureShield composite boards in a vertical application as side skirting to accommodate changing water levels.

Another company that has addressed dock vulnerability is Fibergrate, which has produced

unless

is specially designed to allow proper light transmittance below the dock surface so that seagrass and other shallow marine habitats are protected

Mother Nature may have her arsenal of weather-related weapons at ready, but our builders are

Strength and selection go together with Outdoor Accents ® decorative hardware from Simpson Strong-Tie. We’re always expanding our Mission Collection ® and Avant Collection™ lines with new products and accessories, making it easy to enhance outdoor structures and living spaces. Both lines feature an innovative hex-head washer and fastener combo for the look of a bolted connection that installs as easily as driving a screw. Plus, our code-listed connectors and fasteners are rigorously tested for performance. So whether you’re building a planter box or a pavilion, it will be strong, safe and beautiful for years to come.

To see our complete lines of Outdoor Accents decorative hardware and download free project plans, visit go.strongtie.com/outdooraccents or call (800) 999-5099.

When it comes to creating an allseason outdoor oasis that creates a transitional extension between the inside and outside of your home, nothing says outdoor living more than an outdoor kitchen. With stylish designs that seamlessly coordinate with any aesthetic and an abundance of options to choose from, it’s not surprising these amenities remain a hot commodity all year long.

“Outdoor living is no longer restricted to spring and summer, nor reserved for certain parts of the country,” said Leslie Adkins, VP of marketing for Trex Co., which offers a line of outdoor kitchens manufactured by Danver. “Thanks to new high-performance materials and innovative design approaches, people everywhere are transforming their outdoor spaces into multi-seasonal extensions of their homes.”

A key to making these spaces functional year-round is having options that are flexible

NATURE-INSPIRED GREENS are a popular choice for homeowners who want to create a functional, yet luxurious outdoor living space. EYE-CATCHING COLORS in the Trex Outdoor Kitchen collection transform any outdoor living space and make it an inviting place to entertain guests or enjoy a family meal. (Photos by Trex and Danver)enough so they can work in a variety of outdoor living spaces.

For example, installing cabinetry as a separate sideboard or bar can help merge the kitchen with low seating or dining elements, according to Mitch Slater, president and owner of Danver. Likewise, installing an outdoor kitchen immediately next to the pool, with the potential for swim-up eating and dining, can help integrate outdoor entertaining features.

A clever, outdoor kitchen solution is Danver’s Post and Panel System (PPS). The PPS is a first-of-its-kind outdoor kitchen solution that was designed for multi-family properties. It is an extension of outdoor cabinetry designed for shared common spaces, rooftop destinations, or anywhere counter space is needed but storage is not. Constructed of stainless steel and powder coated for a modern aesthetic with exceptional durability, the PPS integrates the look of Danver’s existing cabinetry while eliminating unnecessary storage areas and weight. Engineered to provide strong countertop support, the simple, inline design makes design flexibility a priority by accommodating a wide range of lengths. It also features removable panels that can easily be switched out.

In addition, Danver recently released its Cosmopolitan Table Collection that is designed to blend seamlessly with Danver’s other outdoor kitchen products so homeowners can build their kitchen space over time. The collection is the brand’s first table offering and its latest collaboration with celebrated architect, designer, and creative director Daniel Germani.

The collection includes three new tables: the Cosmopolitan Prep Table, Cosmopolitan Dining Table, and Cosmopolitan Cooking Table. The Cooking Table introduces innovative Invisacook induction technology, that works both in a smaller outdoor space where an open flame is not permitted, or as a warming table in a larger-scale outdoor kitchen. The tables are constructed of durable, powder-coated, stainless steel.

Design has become a top priority for customers. According to Slater, a growing number of homeowners are prioritizing their outdoor kitchens and planning for them just as they would any interior room, including dedicating larger footprints and budgets to these living spaces.

“Outdoor kitchens have come a long way over the past two decades,” he said. “What began as a grill and food prep station against the house has evolved into a robust outdoor entertaining space that can flow seamlessly with any indoor

aesthetic. Creating an outdoor space that maintains the interior aesthetic is one of the easiest ways to help outdoor design feel cohesive and intentional.”

Nature-inspired greens and blues remain a favorite among homeowners. “As bigger and brighter colors make their way into the home, our powder-coated hues span a large range of colors–like fiery Chili, sophisticated dark green Chromica Feroe, and crisp Sea Spray–and provide homeowners with a selection to fit any aesthetic,” Slater said. “These new colors reflect the forecast for bold colors finding a more prominent home in outdoor design–especially since many homeowners are more willing to take risks for their outdoor living spaces in particular.”

As the color choices have evolved, so too have the cabinet configurations. For example, the Danver and Trex kitchens feature stainless steel cabinets that are available in a wide range of configurations, in 3” increments, for nearly unlimited design possibilities. All cabinetry is made-to-order in either 304 or 316L grade stainless steel.

It’s a small wonder with so many options and colors available in outdoor kitchens, homeowners will want to eat anywhere but outdoors if everything they need to keep the food hot and the company fed is outdoors in a stylishly designed outdoor living space. DS

EXPANSIVE AND FUNCTIONAL kitchens, such as this one from Danver, are built to withstand the elements so homeowners can enjoy year-round outdoor dining.

EXPANSIVE AND FUNCTIONAL kitchens, such as this one from Danver, are built to withstand the elements so homeowners can enjoy year-round outdoor dining.

It’s not breaking news to say that Amer icans have been spending more time at home for the last couple of years. It’s also true that what homeowners expect from their homes has changed significantly during this time. Because of this shift, home renovation projects are more popular than ever before. Outdoor decks and living areas, in particular, have become increas ingly important. Just as homeowners report wanting more from the interiors of their homes, they expect more from their exteriors too.

Building professionals are responding to this growing interest in outdoor living spaces. According to a recent survey by the New Home Trends Institute, 58% of residential building professionals stated that creating a connection to the outdoors will be a major theme of their designs in the next three years.

Drawing parallels between indoor and outdoor spaces makes sense. Homeowners are beginning

to pay more attention to the appeal of a seamless aesthetic while building professionals are em bracing the challenge of showing what is possible in today’s deck and outdoor living space con struction.

For deck professionals, showing homeowners how to tie together a home’s interior and exte rior can pay off in a significant way. Thoughtful finish selections and design details make clients happy, which can lead to more referrals, improve the bottom line, and increase margins.

Assessing a home’s interior design elements prior to planning an outdoor space can be a great source of ideas for connecting the inside with the outside. Whether building a new deck or re modeling an existing one, here are five elements worth considering to achieve a cohesive look that elevates both the interior and exterior of a home.

LINEAR LED LIGHTING, such as Feeney's 24V Wet Location Strip Light, provides high output lighting for indoor and outdoor applications. (Photos by Feeney)Decking. Connect interior and exterior spac es by choosing a deck material similar to the flooring in a home. Many homes have a living space that opens directly onto a patio or deck. Installing decking in the same, or similar shade as interior flooring can help the two spaces flow together and feel like a single, unified living area. Think beyond wood too. Available options include concrete, fiberglass, plastic, PVC, aluminum, rubber and composite decking materials in a range of shades.

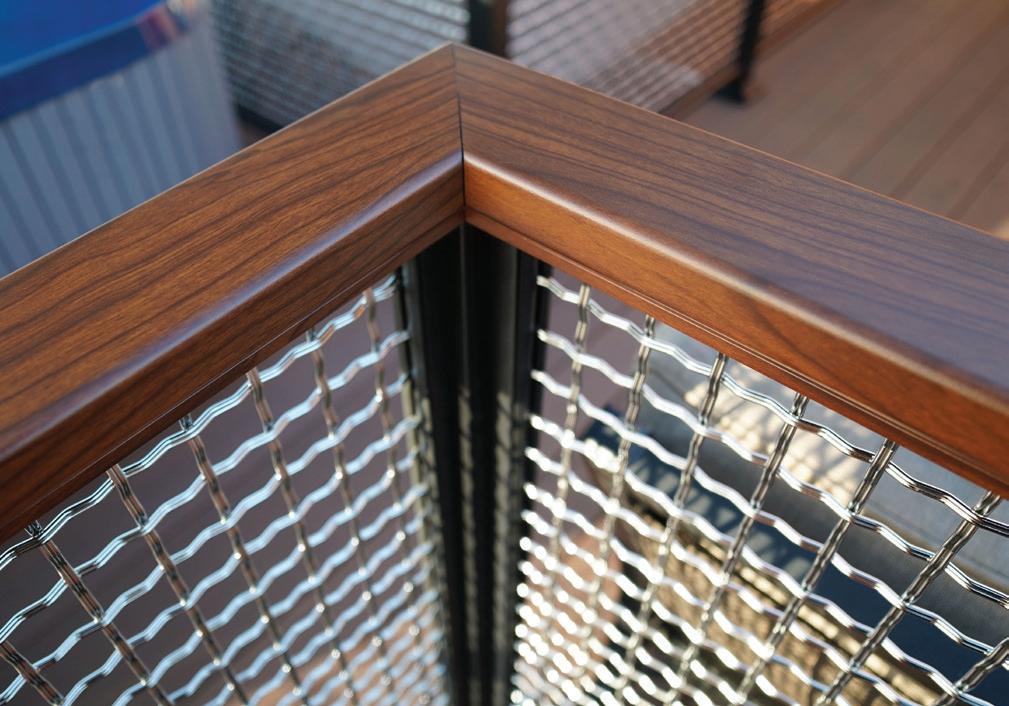

Deck Railings. Consider choosing a deck rail ing that showcases hardware or accessories found in the home. For example, a railing in oil-rubbed bronze could be selected to harmonize with kitchen fixtures, or door and cabinetry hardware. Or mirror interior wood elements by installing a natural wood cap rail or powder-coated aluminum railing system with a wood grain finish top rail, which provides the organic look of wood without the maintenance requirements.

Powder-coated deck railing comes in a variety of colors, making it easy to coordinate railings with exterior elements such as siding and trim along with interior finishes for a more coordinat ed appearance that makes spaces feel more inten tional.

While both traditional picket infill and cable infill remain popular, newer railing infills contin ue to expand the design possibilities for outdoor spaces. For example, stainless steel wire mesh infill and laser-cut aluminum panels in geometric and nature-inspired patterns, along with custom designs, provide an unexpected way to tie togeth er interior and exterior spaces while making a statement.

Lighting. Select outdoor lighting fixtures that coordinate with fixtures inside the home to create a smoother transition from inside to outside. Use the same bulb types and light temperatures in both areas for a seamless feel. Installing dim mers and setting a similar brightness level also contributes to the illusion of a continuous space. Light should come from more than one source for even lighting, so explore using downlights and under-rail or post accent lighting, which not only helps to ensure safety, but brings an additional design element to deck areas. Look for wet-rated lighting for additional protection from moisture.

Awnings. Another way to create a harmonious look is to install exterior awnings that comple ment elements such as siding and trim, or that carry a color scheme through from a visible in terior space. These outdoor architectural accent pieces can be installed over doors and windows, providing protection from the weather, along with an easy way to coordinate finishes between the exterior and interior of the home.

Stationary-type awnings, such as powder-coat ed aluminum awnings with polycarbonate panels, offer durability and impact resistance along with the ability to choose an array of color options that coordinate harmoniously with railings and other exterior elements.

Trellises. Adding a trellis, or series of trel lises, to a deck area can mirror botanical design elements used inside the home while creating a connection to the outdoors. Echo the theme of a prominent piece of art or an upholstery pattern by placing live plants on strategically-placed trel lises. A number of trellis options are available, including marine-grade stainless steel versions, which resist the weather while providing a sleek, understated backdrop for plants and vines.

Especially when it comes to decks, railings, and awnings, look for product lines that provide visual aids, such as—color swatches, chip sets, and online visualizers which make it easier for homeowners to envision how products will look in their home once installed.

Today’s homeowners desire outdoor living spaces that are not only beautiful and low-main tenance, but function as an extension of their homes. Fortunately, options continue to grow as manufacturers introduce innovative outdoor products focused on creating indoor and outdoor environments that look as if they were designed as a single space.

By presenting a broad range of trend-forward design options to homeowners, deck professionals can set themselves apart and be seen as partners who can help to transform indoor-outdoor living spaces from ordinary to spectacular. DS

– Kym Nosbisch is the director of retail & product marketing for Feeney Inc.

COLOREASY powder coating program for Feeney's DesignRail Aluminum Railing System features 18 colors including bright white, Blue Steel and walnut (shown).ANTICIPATION OVER Deck Expo, which is held in conjunction with the Pool/Spa/Patio Expo in November, is heating up as builders and vendors are excited about attending the education sessions and seeing the latest new products.

Deck Expo once again promises to deliver an exciting array of decking, railing and outdoor living show products that every builder needs to see in person.

Held in conjunction with the International Pool/Spa/Patio Expo at the Las Vegas Conven tion Center, Las Vegas, NV., from November 12-17, Deck Expo not only provides the opportu nity for builders to meet exibitors and industry experts face to face, but it enables them to catch up with one another.

And as the event gets closer, the buzz online is gaining momentum as builders are talking with each other about meeting up at the show.

For instance, nationally known contractor Bobby Parks said to fellow builders on Facebook’s Elite Deck Building Professionals group: “For most of us, this gathering is so much more than just seeing products—it’s a family reunion with some of the best people that exist.”

He added that the personal engagement and connections made at the show between vendors and builders are what solidifies relationships and loyalty.

“Attending Deck Expo provides benefits that only occur with personal exposure and is one of the few events that provides focus on our indus try,” he added.

Chris Breen, owner of Legacy Decks and

Legacy Decks Academy, Greenville, S.C., said that at the show he will be sharing some of the things his company has been working on. He is particularly excited about the North American Deck & Railing Association (NADRA) education session that he and his wife, Amy, will be head ing up at the show. Titled “Start with the End in Mind: Secrets to Build Predictable Profitable Growth,” the Breens will explain how builders can reverse-engineer their results by starting with the end in mind. The session will take place on Monday, November 14, from 1-4 pm in the LVCC West Hall. Attendees will leave with a 90day action plan guide.

April Edwards, founder of Deck Builder Marketers, Carlsbad, CA., commented: “Looking forward to seeing my deck builder clients in per son and the rest of this amazing community. And hearing Chris Breen speak will be fire!”

Parks added that interacting with NADRA members at their booth and other meetups strengthens existing contractor relationships and creates new ones. He said it is one of the best networking and information sharing platforms out there. “In my opinion it is an investment well worth making and one that provides returns.”

Mike Mitchell, Mitchell Construction, Monee, IL., is also excited for the NADRA education. He said he is looking forward to spending time

WHERE: Las Vegas Convention Center, Las Vegas, NV.

• Outdoor Kitchen Design; Railing Requirements for Multifamily and other R2 dwellings: 7:30 - 8:45 am

• Keynote: 9 - 10:20 am

• Visit with Vendors: 10:30 - 5 pm

• Welcome Party: 5 - 7 pm

• Strategies to Keep Your Customers on Your Doorstep; Post-COVID Business Awareness: 8:45 - 9:45 am

• Visit with Vendors: 10:30 am - 5 pm

• BBQ Bash: 5 - 6:30 pm

• Pool Nation Awards: 6 - 9:30 pm

• Building Your Lean Projects for Profitable Results: 7:30 - 9 am

• How to Create Beautiful and Comfortable Outdoor Rooms: 9:15 - 10:30 am

REGISTER: www.poolspapatio.com

catching up with his industry friends, talking shop and learning from the best in the business.

Mitchell added that he looks forward to learn ing from and helping to guide the new guys “to be the best they can be,” as well as checking out the new products at the show “to make sure I can offer my customers all the best options.”

Parks agrees, adding that “nothing beats see ing products displayed and explained first hand,” especially in a combined show that provides the opportunity for builders to see new crossover products. “You never know what the missing piece or product option is until you see it.” DS

Few outdoor living spaces are complete without the perfect deck railing, and the range of materials and styles available ensures there’s a look for every need. But with so many options, how can your customers choose the ideal deck railing for their project?

The easiest way to narrow down deck railing selections is to answer a simple series of ques tions that cover the railing’s required function ality, a buyer’s desired tastes, local codes, and other factors. Once that process is complete, the possibilities are much more approachable.

The first step is to consider which railing will best fit the project’s parameters. Focus on these questions:

1. What is the required height in your area?

The code will call for 36" or 42".

2. Does the deck have a lot of angles?

If there are level runs with angles, certain styles of railing will be more user friendly. Alu minum railings, for example, are the easiest to

install on level angles. Composite or cellular PVC railings also can be used, but may require a larg er post sleeve at the angle. The degree of angles is much more limited with vinyl railings.

3. What are the surroundings like?

Is there a view or openness they want to maintain? This will eliminate certain bulkier rail styles while moving lower-profile options to the top of the list. This can also inform the style of infill they want to use for the project.

4. What is the project’s budget?

Deck railing materials and styles vary in price. From a materials standpoint, in general vinyl tends to be the most affordable, then steel, then composite and cellular PVC, and then aluminum.

In terms of infill styles, square balusters tend to be more budget friendly and then round bal usters. Glass panels and cable railing are on the more expensive end of the spectrum. But you also can mix and match to meet both budget and style needs; for example, choose white vinyl top rails with black aluminum balusters for a custom look.

(Continued on page 42)

ROBUST RAILINGS, such as these Envision V215 vinyl, make a bold statement against the Envision Ridge Premium decking in Black Walnut shown here. The V215 is modified to include a drink rail, making it ideal for entertaining.

Or if cable rail is desired but out of the price range, horizontal balusters offer a similar look at a lower cost, while also requiring less mainte nance than cable rail.

5. Where is the project located?

Coastal areas need railing materials that can withstand the salty moist air, so vinyl, compos ite, and aluminum are a better option than steel.

Of course, aesthetics play a critical role in deck railing choices. From a taste or trends perspec tive, consider these questions:

6. Will the deck be used into the evening and therefore need lighting?

This is an important question because a twopiece top rail will provide the most labor-friendly application of LED wiring. A two-piece design also makes it easier to access the lighting in the future should it need to be repaired.

7. Will the deck be used for frequent enter taining?

If so, a drink rail may be a great fit, as it pro vides a flat surface for placing drinks and small plates.

8. What is the style of the home?

Though there are no official rules, certain types of railings pair better with particular home styles. For example, an ultra-modern house will likely look best with sleeker, slimmer top rails

and balusters or with cable rail infill. A curvy, more ornate top rail or more robust baluster is well suited to a traditional house style.

9. Is the desired look bold or blended?

In the early days of composite decking, proj ects often matched the deck with the railing, choosing composite railing in the same or similar color as the deck boards. Today, it’s trendy for railings to provide a pop of color and to choose deck railing material based on preference, rath er than only to match the composite decking. The choice the customer makes comes down to personal preference, and there are few right or wrong answers. This is where on online deck visualizer tool comes in handy—you and your customers can experiment with decking and railing colors and styles to see what appeals and looks best.

If your customers are still having trouble choosing a railing, it rarely fails to look for ex amples. Look to your manufacturer partners for tools and inspiration, including deck visualiza tion software, case studies, and idea galleries. DS

Chase Moritz is director of marketing & communications for composite decking/railing manufacturer Envision Outdoor Living Products (envisionoutdoorliving.com.)

CONTRASTING deck railing provides the much-needed pop on this relaxing deck. Shown is Envision Distinction composite decking in Spiced Teak with an A210 three-rail aluminum railing with vertical balusters.

CONTRASTING deck railing provides the much-needed pop on this relaxing deck. Shown is Envision Distinction composite decking in Spiced Teak with an A210 three-rail aluminum railing with vertical balusters.

Nichigo G-Tape™ 3040BK is a selfadhering flashing tape that is suitable for installation of exterior wall fenestration products. Including, but not limited to, decks, windows and doors. 3040BK maintains its performance even after prolonged exposure to sunlight and rain. 3040BK adhesive self-heals around steel and galvanized aluminum fasteners, protecting from rust and wood rot.

UNIQUE projects, such as this stylish Middletown, N.J., deck built by Decks by Kiefer LLC, which won third place in NADRA’s National+ Deck 2021 Competition, is an example of the high quality of work necessary to successfully scale a business. (Photo by Decks by Kiefer)

As a deck builder or outdoor living contractor, how “big” do you need to be in order to be profitable and successful? Can you meet your financial goals doing $500,000 a year or is $1 million the mark you should be shooting for? Do you possess the experience, skills, and drive to grow to be a multimillion-dollar business? Or, can you maintain your company at a smaller level and still be profitable enough to create financial stability?

The simple answer is you need to be big enough to achieve your personal goals. It’s less about size and more about having a realistic plan, predict able profitability, balance of sales and produc tion, and a manageable process of operations. It should be about being one of the best in your mar ket. It has everything to do with the quality of the projects you design and the process in which you deliver them. And it’s about having balance in your life and feeling proud of what you do.

The majority of deck builders are smallervolume contractors with many operating only one crew. Fewer operate in the multimillion dollar range. All sizes and models include challenges, benefits, and risk. So, there are no right or wrong answers as there are ways to be successful or fail with either. From a financial standpoint it’s not

about how much you gross, but more about how much you net. There are smaller companies that work off higher margins and multimillion-dollar operations that work off lower to average margins. Some of the better larger companies do both volume and strong margins.

Self assess. To determine if you even want to grow larger, ask yourself these questions: Do you have the organizational and business skills to scale your business to a higher level? Do you have or are you willing to implement systems that assist with this? Do you have the motivation, discipline, desire, confidence, and commitment to undertake all involved? Are the market demo graphics in place and is the labor force available?

Other factors to consider include your personal makeup and limitations: your self confidence, drive, leadership abilities, technical skills, sales ability, people skills, and competitive mindset.

Growth at a certain point requires you to remove yourself from the field to work and manage a business. You will need to insert people into positions and delegate duties as you scale upward. This increases the fixed overhead cost.

All things being equal, a smaller company won’t provide the same profits as a larger one. At the same time, depending on how organized

a company is, the headaches and risk grow with size. The mission is to maximize profit. It boils down to running an efficient business, and track ing and maintaining targeted profit margins through job costing.

Whatever size you target, you need an annual business plan that you create, monitor, and track versus just moving forward from day to day and crunching the numbers at the end of the year with hopes you show a profit. Size is determined by your sales and production capacity with the gross sales and margin formulas includ ed. Technically, the higher the net margin, the lower your sales could be. At the end of the day, it come’s down to hitting sales numbers and net margins that provide you financial security. The buildout capacity has to be in balance with the sales each year to fully gain the profitability benefits. Creating efficiencies and a strong reputation that allows you to increase actual profit margins makes it easier to flourish as a small building contractor.

I believe you’re going to be better off with a goal to grow your crew to a size that doesn’t require you to contribute physically full time each day. This opens up a path to be able to be a

contractor longer as you age. Considering the hiring challenges today, most deck builders may be better off developing and refining a smaller- to medium-size company. This model will be easier to staff and maintain the quality and service standards that you want to be known for. What you may lack in production can be made up in margin if approached properly.

Once you’ve achieved this level with efficient systems in place that are scalable, you always have the choice to take it to another level. And keeping overhead low likely positions you better to handle downturns when, and if, they occur.

So, how big does your company need to be? That’s entirely up to you. But base it on it being the size and type of company that you can be proud of. Don’t overreach. Self assess and you’ll know.

Bobby Parks is a national ly known contractor who has delivered over $40 million of outdoor living projects. He is founder and former owner of Peachtree Decks & Porches LLC and current president of BP Consulting & Design LLC.

In our last edition, we discussed “Who do you work for?” and received such an outpouring of love across the deck building community that I was moved to follow it up with a companion article about the brotherhood in great deck building.

I watched as the article was being shared on just about every form of social media, I was actually overwhelmed by how many lives and hearts were touched in such a positive manner. A bunch of hardcore, he-man deck builders getting sentimental over their families. It really puts the human perspective into our livelihoods.

And anyone who has been in this industry for any length of time knows how fraught it was with backstabbing, secrecy, misinformation, or even deceiving practices from our suppliers, but like the phoenix, a brotherhood has risen from those ashes. It has developed to a point where you can go anywhere in this country and find a friend who is willing to help, advise, and provide guidance and leadership. It’s about how the older generation is willing to provide the necessary influence to the next group while also being open minded enough to learn cutting edge ideas and techniques from the younger guys.

Over the past couple years, I have been conversing with contractors from all over the U.S and Canada about previous articles. One

resounding concept that always pops back up is this brotherhood of deck builders. Whether it was at “the builder Olympics,” sitting by the pool, at the banquet tables during the NADRA Awards presentation or at Deck Expo, brotherhood kept popping into the conversation.