2 minute read

Carcful handling and storage prctects rcdwood prcfits

EDV/OOD is a quality building material for highly-visible applications like siding, interior paneling and landscape architecture. When customers buy redwood, they buy it for its appearance. You can expect customer satisfaction because redwood lives up to its promises.

Naturally. customers expect to receive redwood lumber in good condition. The best way for your store to earn a reputation for quality is to educate employees about storing and handling redwood. This way the profits don't have to pay for damaged stock. Common sense rules about storage and handling can keep profits up and customers satisfied with the quality of their redwood purchases.

Redwood should be stored in a dry location under cover. This is important for the certified kiln dried architectural grades, but it also holds true for unsea- soned or air-seasoned garden grades. Keeping redwood under cover protects it from sun as well as rain and other weather. Redwood shrinks less than other woods. but proper stora-ge helps prevent shrinking. splinin-e and warping.

Lumber should not be stored near excessive heat sources such as boilers. It

Story at a Glance

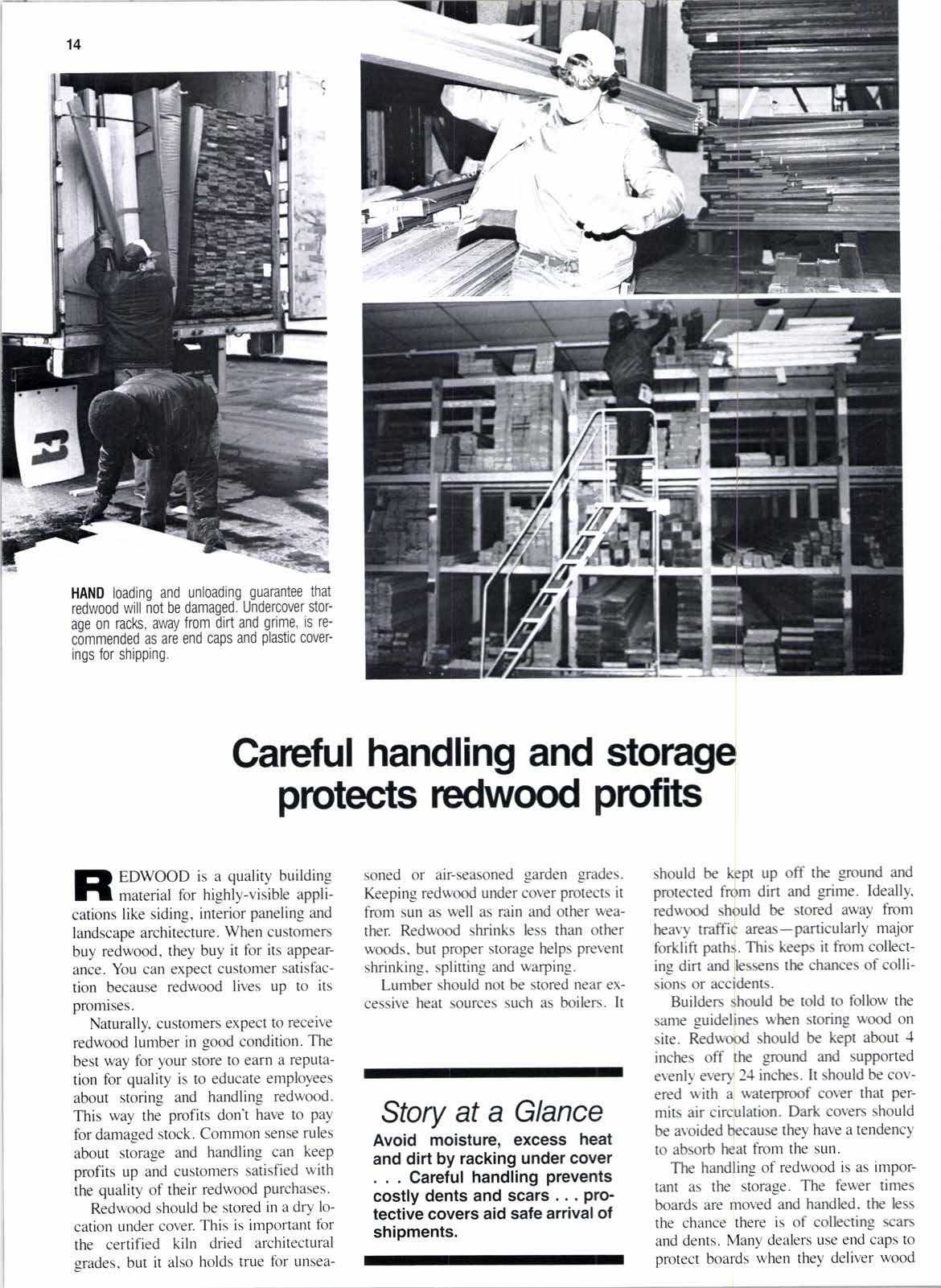

Avoid moasture, excess heat and dart by racking under cover . . . Careful handling prevents costly dents and scars Plotective covers aid safe arrivalof shipments.

should be kept up off the ground and protected from dirt and grime. Ideally. redwood should be stored away from heavy traffic areas-particularly major forklift paths. This keeps it from collecr ing dirt and hssens the chances of collisions or accidents.

Builders should be told to follow the same -euidelines when storing wood on site. Redwood should be kept about 4 inches off the ground and supported erenly every 24 inches. lt should be covered with a waterproof cover that permits air circulation. Dark covers should be aroided because they have a tendency to absorb heat from the sun.

The handling of redwood is as important as the storage. The fewer times boards are moved and handled. the less the chance there is of collecting scars and dents. Many dealers use end caps to Drotect boards when they deliver wood to a construction site. But the main ingredient for proper handling ofredwood is care and an appreciation for its value.

Marc Canizzaro of Rafael Lumber. San Rafael, Ca., commented, "When someone buys lumber from us, it is going to be used as a finish product. We assume they are going to use a clear finish on it and we treat it like that. Our yard people average about l0 to 12 years of experience so they know what is expected."

When redwood lumber arrives there, it is offloaded by hand and placed on racks. When it is shipped out it is usually covered with plastic. "Basically, the care comes from a feeling that we are dealing with quality materials." Obviously, it is a feeling that is instilled in employees and comes from the top.

Redwood is not fragile. It is among the most durable woods on earth. It shrinks less than other woods when exposed to sun and moisture and resists erosion from weather better. Architects, builders and homeowners have all come to expect these qualities from redwood. They also expect it to do the job beautifully. Properly cared for and properly applied, it can have a higher customer satisfaction rating than any other wood available.