We look at brushes differently.

We look at brushes differently.

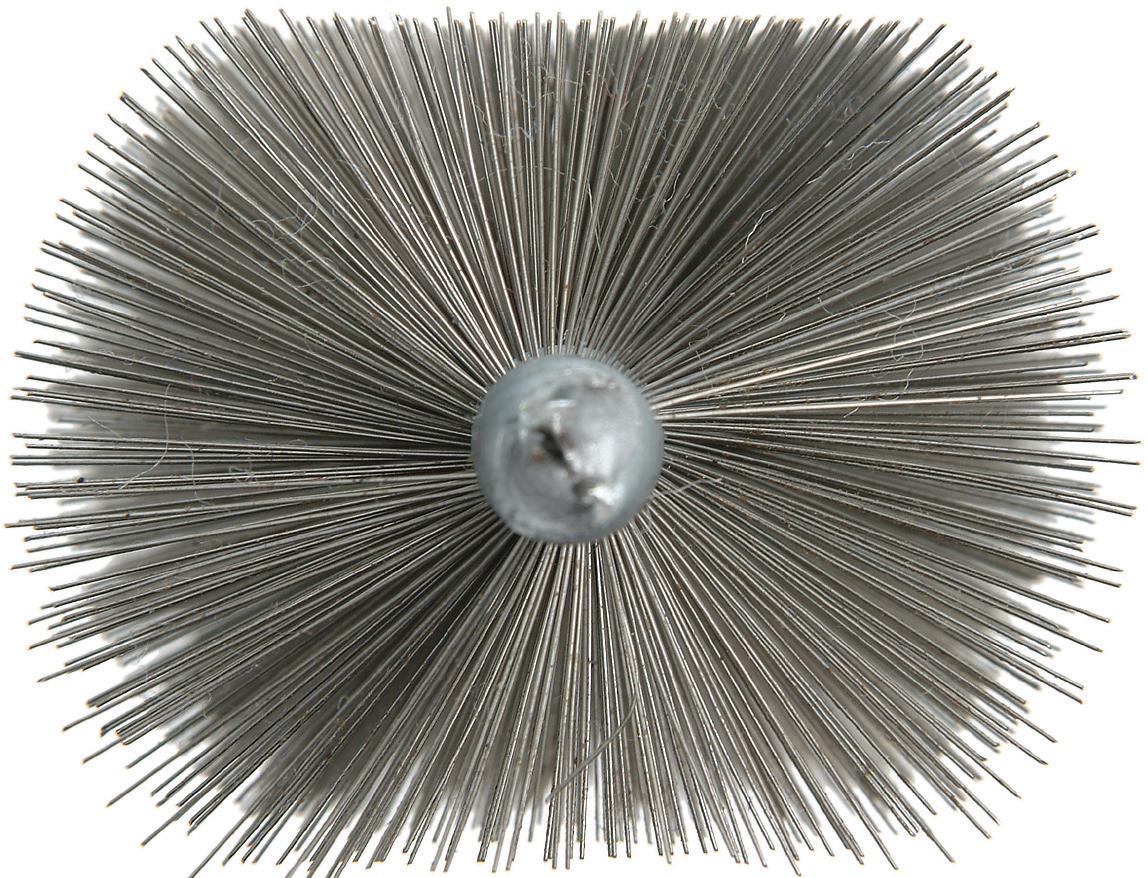

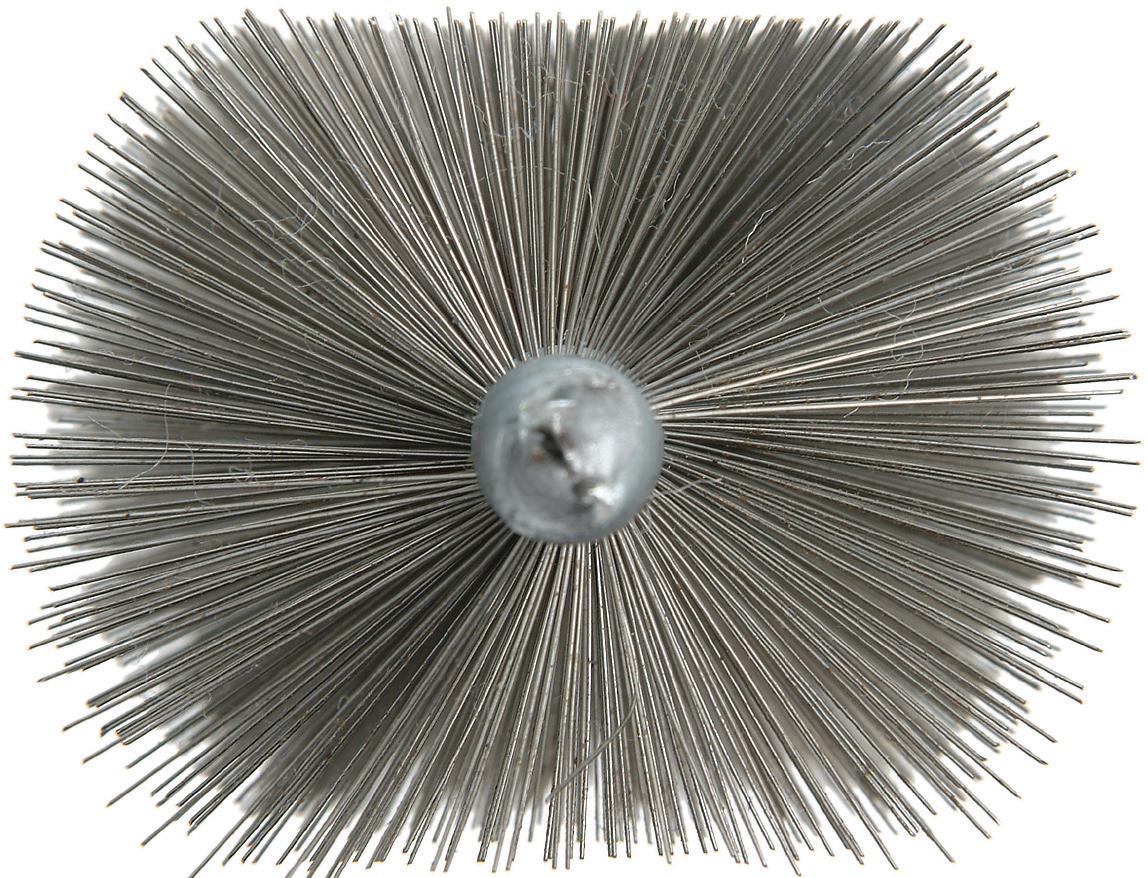

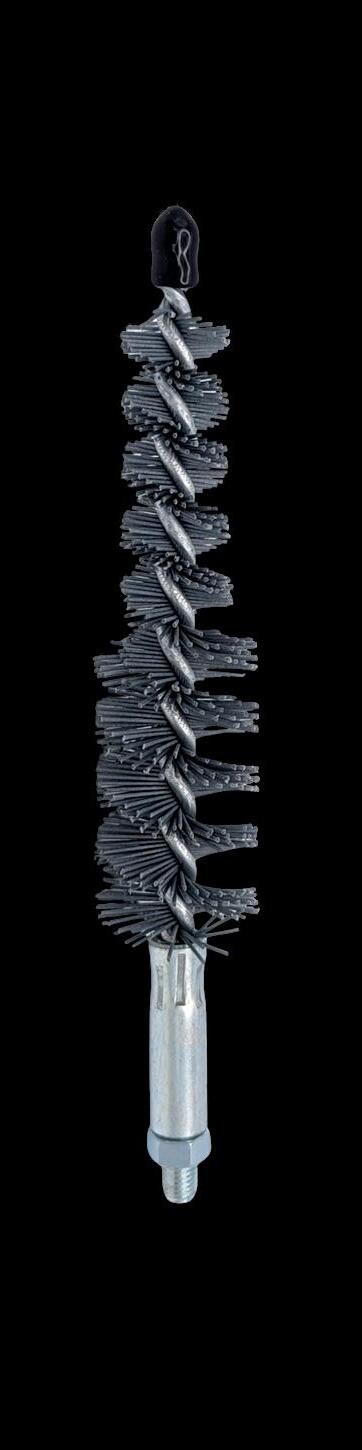

We’re the largest manufacturer of the world’s smallest brushes. Mill-Rose miniature brushes are available in a variety of styles and configurations as small as 0.014” in diameter to deburr, clean and ream very small holes and cavities.

We look at brushes differently, analyzing them from every perspective to insure optimum performance. From miniature brushes as small as 0.014” in diameter to large, wire wheel brushes that perform long after other brushes fail. Mill-Rose has set the standard for quality, performance, and innovation in brush technology for the past 100 years.

We also make large brushes and custom-designed brushes. Mill-Rose has set the standard for quality, performance, and innovation in brush technology for the past 100+ years. Choose from thousands of standard and not so standard sizes and shapes. Call or visit MillRose.com.

We’re the largest U.S. manufacturer of twisted-wire brushes. Mill-Rose designs, engineers and manufactures standard and custom brushes in any quantity. Choose from thousands of standard and not-so-standard sizes and shapes. Call or visit MillRose.com.

Happy Holidays from the team at Brushware! This massive combo edition features the Machinery Showcase and the Supplier/Manufacturer Spotlight to serve as one of the industry’s most valuable resources. The edition highlights the remarkable companies that keep our industry moving forward with state-of-the-art machinery, in addition to a wide range of suppliers across the globe that provide the raw materials and components that drive brush industry manufacturing.

But that’s just the headliner — this issue also includes comprehensive coverage of the 65th FEIBP Congress, held in October in Ischia, Italy, with reporting by Alice Castle from Brush Expert. Her feature captures the atmosphere of collaboration and innovation that defines this annual European gathering, along with insights from member companies and the association’s leadership.

Rounding out the issue, we are also pleased to present an in-depth profile of Jaroslav Markvart from Wöhler Bohemia based in the Czech Republic and the Annual Economic Forecast from Phillip M. Perry as he offers an analytical look at global manufacturing trends, inflation pressures and what brush manufacturers can expect heading into 2026.

I am amazed that we are now finishing our seventh year with Brushware. It's been quite an adventure and I continue to be inspired by the tremendous support and kind words we receive from readers and contacts across the industry. It’s a privilege to serve as the publisher of a legacy magazine founded in 1898, and we take great pride in being a trusted resource and touchstone for this global community.

One small but meaningful way you can help sustain Brushware’s legacy is by letting suppliers know when our publication has played a role in your business decisions, whether the magazine or website has helped you discover a new brand or just reinforced your choice to reach out. Those mentions go a long way in showing that our platform continues to help build valuable connections.

Looking ahead, our January/February issue will mark the return of the Second Annual Photo Issue, and we’re once again inviting readers to share their creativity. If you have an interesting product photo or industry-related image that deserves the spotlight, please send it to news.brushware@goodwinworldmedia.com. It’s a great way to showcase your company’s work — and earn a well-deserved shoutout in the new year.

Dylan Goodwin | Publisher

dylan.goodwin@goodwinworldmedia.com

Brushware is a bi-monthly publication edited for key personnel in the brush, roller, broom, mop and applicator industry. Published continuously through the years, the one publication that is provides a voice and community for the brush and allied industries: 1898-1923, called Brooms, Brushes & Handles; 19241947, called Brooms, Brushes & Mops, 1948-today, called Brushware

PUBLICATION OFFICE

Brushware Magazine

Goodwin World Media LLC P.O. Box 7093 Overland Park, KS 66207 Tel: 913-636-7231

GENERAL MANAGER

Susan Goodwin info.brushware@goodwinworldmedia.com

PUBLISHER

Dylan Goodwin dylan.goodwin@goodwinworldmedia.com

CHIEF OF STAFF

Lisa Ray news.brushware@goodwinworldmedia.com

MAGAZINE EDITOR

Gwyneth Bowen

WEB EDITOR

Linda Blachly

CORRESPONDENTS

Bob Lawrence

Phillip M. Perry

Katharina Goldbeck-Hörz

Mark E. Battersby

Lisa Anderson

Marion Keller

Brushware Magazine (ISSN 00072710) is published bi-monthly by Goodwin World Media LLC, P.O. Box 7093, Overland Park, KS 66207 USA. Printed in the USA. Subscription: $95/year for US, Canada and Mexico. All other countries $210/year.

POSTMASTER – Send address changes to Brushware Magazine, P.O. Box 7093, Overland Park, KS 66207. Copyright 2025. All rights reserved. Materials in this publication may not be reproduced in any form without permission. Requests for permission should be addressed to: Brushware Magazine, P.O. Box 7093, Overland Park, KS 66207.

7901

785

Nexstep Commercial Products (Exclusive Licensee of O-Cedar) has announced that Everest Reps, of Austin, TX, will now be representing the company in the Texas, Arkansas, Oklahoma, and Louisiana markets. Everest Reps has merged with Swatzell Sales Company, who previously represented Nexstep Commercial Products in the territory.

“Everest Reps is a sales agency committed to delivering exceptional products and services in the jan/san markets with a focus on driving sales growth while building long-term relationships with customers,” according to the statement from Nexstep. “They have a dedicated team of experienced manufacturers’ representatives who manage sales territories and support both manufacturers and distributors. They achieve this through hands-on sales management, detailed communication and a commitment to excellent service.”

Regarding the transition, Everest Reps President James Ammons said, “We are honored to partner with Nexstep Commercial Products and represent the O-Cedar brand in these markets. Together, we look forward to driving growth and strengthening support for our distributor partners and customers.”

Marcegaglia Oskar, a company specializing in the production of metal broom handles, has launched a structured process aimed at obtaining SA8000 certification, one of the world’s most recognized standards in the field of corporate social responsibility. In a press release, the company pointed out that this commitment is in line with the broader vision of the Marcegaglia Group.

According to Marcegaglia Oskar, the initiative builds upon a strong platform of quality and sustainability. “The company already holds ISO 9001, ISO 45001, ISO 50001 and ISO 14001 certifications, which testify to our long-standing dedication to operational excellence, workplace safety, energy efficiency and environmental stewardship,” Marcegaglia Oskar said in a statement, adding this commitment is “anchored in policies and practices that serve as the cultural and operational backbone of this journey,” including:

• SA8000 Social Responsibility Policy — defining clear principles for worker protection, while promoting diversity, equity, and inclusion, as well as systems for whistleblowing and monitoring.

• Responsible Procurement Policy — extending ethical standards throughout the supply chain by requiring suppliers to uphold human rights, fight corruption, protect the environment and guarantee safe working conditions.

The company said these are not just aspirations, but a practical framework that guides its everyday operations. “Moving forward, our work on SA8000 involves a range of ongoing initiatives,” including:

• Supplier mapping and involvement — helping partners align with ethical, environmental and social values to create a transparent and resilient supply chain.

• Process improvements — enhancing compliance, strengthening reporting channels and preventing risks across operations.

• Training and awareness — delivering educational programs to employees and collaborators to nurture a culture grounded in human rights, safety and shared responsibility.

• Environmental and energy stewardship — taking action to cut emissions, manage resources responsibly, and pursue continuous improvement in environmental performance.

“For us,” the company added, “SA8000 is not a mere certification exercise but a valuecreating step that strengthens trust with customers, employees and stakeholders. It reflects our determination to embed social responsibility into our business model and to view it not as a constraint, but as a growth opportunity towards a more sustainable, competitive and inclusive future.”

Learn more about Marcegaglia Oskar at www.oskaritalia.it.

Professional Strength Blue Monster® SLASH Cleans and Degreases in a convenient spray format

Blue Monster SLASH, a heavy-duty cleaner and degreaser that works on a wide range of surfaces, is now available from Clean-Fit Products, a division of The MillRose Company.

Blue Monster SLASH’s citrus-based formula loosens and dissolves dirt and grease with minimum effort. Applications include cleaning and degreasing black iron pipe, appliances, countertops, hydraulics, automotive parts and industrial jobs. Simply spray smooth and irregular surfaces with SLASH and wipe clean.

“Save the elbow grease for other jobs. SLASH delivers the power of Blue Monster Citrus Scrubbing towels in a convenient spray format,” said John Kirkland, National Sales Manager for Clean-Fit Products. SLASH utilizes the same cleaning formula used in Blue Monster Citrus scrubbing towels. The spray action allows for cleaning/degreasing in hard-to-reach areas.

SLASH is a safe, effective cleaning solution free of harsh solvents and chemicals. It is environmentally friendly (VOC compliant), water soluble, and meets Southern California air quality management district regulations on volatile organic compounds (VOC) – privacy.ca.gov.

SLASH complements other Blue Monster cleaning products, including Blue Monster citrus towels and Blue Monster Wipes industrial dry towels. Blue Monster® SLASH is available in a 26-ounce spray bottle and sold at leading PHC supply houses. Blue Monster Products are offered exclusively by Clean-Fit Products, a division of The Mill-Rose Company. Mill-Rose is the world’s leading supplier of PTFE thread sealants and the largest manufacturer of twisted-in-wire brushes in the U.S.A.

Learn more about Clean-Fit Products at www.cleanfit.com

November 11-13, 2025

ISSA Show North America | Las Vegas, Nevada www.issashow.com

November 12-13, 2025

PARTS FINISHING | Karlsruhe, Germany www.parts-finishing.de

November 18-19, 2025

National Painting/Decorating Show | Coventry, UK www.paintshow.co.uk

December 9-11, 2025

CIBRUSH | Shanghai, China www.cibrush.com

December 11-13, 2025

International Hardware Fair India

Pragati Maidan, New Delhi www.hardwarefair-india.com

February 6-9, 2026

Creativeworld | Frankfurt, Germany www.creativeworld.messefrankfurt.com

March 8-10, 2026

IBS New York | New York, New York www.ibsnewyork.com

March 10-12, 2026

The Inspired Home Show | Chicago, Illinois www.theinspiredhomeshow.com

March 24-27, 2026

ABMA Annual Convention | Rio Grande, Puerto Rico www.abma.org/convention/

March 26-29, 2026

Cosmoprof Worldwide Bologna | Bologna, Italy www.cosmoprof.com

April 14-17, 2026

Interclean Amsterdam | Amsterdam, The Netherlands www.intercleanshow.com/amsterdam

April 20-22, 2026

ISA26 | Cleveland, Ohio www.isapartners.org

May 17-19, 2026

Creativation by NAMTA 2026 www.namta.org/creativation-by-namta

September 14-19, 2026

IMTS | Chicago, Illinois www.imts.com

October 12-16, 2026

Fakuma | Friedrichshafen, Germany www.fakuma-messe.de

May 5-6, 2027

International Hardware Fair Italy | Milan, Bergamo www.hardwarefair-italy.com

May 16-18, 2028

World Brush Expo | Ghent, Belgium www.worldbrushexpo.com

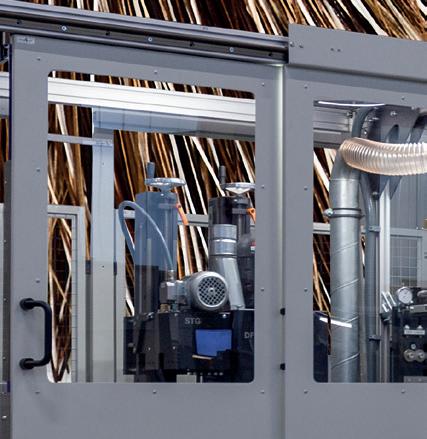

ZAHORANSKY will showcase its latest innovations at CIBRUSH 2025, taking place December 9–11, 2025, at the Shanghai New International Exhibition Center (SNIEC). With more than 700 patents and operations across seven countries, ZAHORANSKY continues to set the standard in brush machinery for broom, PersonalCare and HealthCare production. The company will present several of its latest solutions, including:

Z.AERO — A fully automatic 3D tufting line for finished toothbrushes, offering up to 3,000 brushes/hour and multicolor filament capability.

Z.SAILFIN + Z.IDP — Compact, fully automatic systems for producing interdental and mascara brushes with 24-hour operation and camera inspection.

Z.ORCA — An all-in-one anchor toothbrush machine featuring tufting, trimming and finishing with up to 3,600 brushes/hour and rapid changeover design.

Z.TIGER MT — A 5-axis household and technical brush machine with robotic handle feeding, optional filament automation and a 30-second quick-change tool system.

ZAHORANSKY’s display will demonstrate its continued commitment to automation, precision and efficiency for the global brush manufacturing industry.

The 2025 Assospazzole Members’ Meeting and 35th Industry Gathering took place on September 27 in Castelfranco Emilia, hosted by Borghi SpA, one of Italy’s leading brush machinery manufacturers. The association expressed its gratitude to Borghi for its hospitality and excellent organization, as well as to Wöhler for its ongoing support as event sponsor.

The formal shareholders’ session included the presentation of the association’s annual activity report and the approval of the financial budget. Following the official proceedings, the open industry meeting welcomed both member and non-member companies from across the brush sector. During the technical segment, Dr. Laura De Carli of ZPC Milan delivered an insightful presentation on upcoming European sustainability initiatives and the implications for manufacturers. Her overview provided valuable context for how the industry can prepare for new environmental standards and compliance measures.

Assospazzole President Paolo Spinelli followed with a discussion on staff training and professional development, encouraging feedback from attendees. The session sparked strong engagement, with participants showing enthusiasm for potential training programs and collaborative initiatives aimed at upskilling the workforce.

Additional discussions covered key topics impacting the brush manufacturing industry, including product labeling regulations, market volatility, and generational transitions within family-run businesses. The day concluded with a guided tour of Borghi SpA’s production facilities, followed by a convivial lunch at a local restaurant. Attendees then visited the Righini private car collection, a renowned showcase of historic automobiles, rounding out the event on a cultural note.

For information about Assospazzole, visit www.assospazzole.it.

Ebnat AG, a leading European manufacturer of household brushes and cleaning products, has announced a comprehensive rebrand featuring a modernized logo, visual identity, and digital presence. The initiative reflects the Swiss company's commitment to balancing its century-long heritage with forward-looking innovation.

The rebrand aligns Ebnat's external appearance with its core values of reliability, holistic thinking and sustainability. "Our values have grown over the years—now they are reflected in our appearance," the company stated. "Modern, clear and forward-looking—without forgetting our roots."

Key elements of the rebrand include an updated vision ("Inspire sustainably!"), refined mission statement emphasizing customized, quality-focused solutions and a refreshed digital presence. The company maintains that quality standards, team structure and customer service remain unchanged.

The transition will be gradual, with the new identity appearing progressively on communications, packaging, and invoices. Article numbers remain consistent, and a new online product catalogue is forthcoming. Ebnat invites customers to join the company on this evolutionary path.

Extraordinary brushes start with innovative filaments by Celanese. Explore the unparalleled quality, versatility, and innovation that defines Celanese Filaments. We have been developing and refining our extensive line of monofilaments for over 80 years.

Paintbrushes: Tynex® and Chinex® brand tapered nylon monofilaments, Orel® brand tapered polyester monofilaments, and Kulex® brand level polyester monofilaments

Industrial/Abrasive Brushes: Tynex® A, Tynex® AD and Herox® A brand nylon monofilaments containing abrasive grits

Toothbrushes: Celanese Tynex®, Tynex® RS, Tynex® Eco, Herox® brand nylon monofilaments, Kulex®, and Kulex® RS brand polyester monofilaments

Cosmetic Brushes: Tynex® and Natrafil™ brand fine filaments

Contact Celanese Filaments to create your Extraordinary Brush! 1-304-409-9584 | celanese.com/products/filaments

Three industry veterans were elected to the International Housewares Association’s (IHA) Board of Directors at IHA’s fall Board meeting. In addition, three continuing Board members were appointed to officer positions for the 2025-2026 fiscal year. New Board members are Mark Adkison, president, Kuhn Rikon Corporation; Cze-Chao (Sue) Tam, CEO, TRINITY International Industries and David Zrike, president, R Squared/Zrike Brands.

The current directors appointed to officer positions (one-year terms) are Chairman – Mike Otterman, President & CEO, Lodge Cast Iron; Vice Chairman/ Chairman Elect – Tom McMahon, President, Jura Inc. and Treasurer – Sal Gabbay, CEO, Gibson Homewares.

The American Brush Manufacturers Association (ABMA) is pleased to announce that submissions are now open for the prestigious William A. Cordes Innovation Excellence Award. The Cordes Award is a unique opportunity for visionary creators and forward-thinkers to showcase their groundbreaking products. From advancements in technology and design to breakthroughs in sustainability and user experience, the award highlights innovations that push boundaries and redefine industry standards. It is not only about honoring great ideas, but also about inspiring the entire industry to aim higher and think bigger.

The ABMA strongly encourages companies and individuals across all segments of the industry to take part in this celebration of innovation. The deadline for submissions is November 30, 2025. Don’t miss this opportunity to shine a spotlight on your exceptional work and be recognized among the leaders of innovation in our industry.

For more details on eligibility and entry guidelines, please visit www.abma.org/about/innovation-excellence-award/.

> 45% increase in productivity

> High level automation

> Maximum flexibility

> Super fast product change over

> High tufting speed – up to 1200/min

> Low TCO

> Easy accessibility

Weiler Abrasives, a global leader in surface conditioning solutions, announced the appointment of Dr. Ingo Kuhl as Vice President of Technology and Product Development. In this role, Kuhl will lead Weiler’s global efforts to design and deliver the next generation of valueadded products that help customers improve productivity, safety and performance across essential industries.

“We are thrilled to welcome Ingo to the Weiler team,” said AJ Roshan, President and CEO of Weiler Abrasives. “He brings a unique blend of technical depth, customer awareness and strategic vision that aligns perfectly with our mission. As we look to the future, we see increasing demand for solutions tailored to the specific challenges of our customers.

Ingo’s leadership will be instrumental as we continue to expand our investment in product development and customer support worldwide.”

In a statement, Weiler Abrasives said the company “continues to advance its mission of creating distinctive value through collaboration and innovation. Guided by its strategic plan, the company is expanding its product portfolio and developing solutions that address the most demanding applications in critical industries — from metal fabrication to engineered surface management.”

Kuhl brings over 20 years of global experience in the abrasives and materials industry. Most recently, he served as Managing Director at Krebs & Riedel, where he oversaw R&D, production, quality and international expansion initiatives in China and India. Previously, he led research groups at RWTH Aachen University and held senior technical and production roles at Rüggeberg and Alfons Schmeier. Kuhl holds a Doctorate in Metallurgy and Materials Engineering from RWTH Aachen University and has led numerous research collaborations with academic and industrial partners.

With Kuhl’s appointment, Weiler said it “strengthens its commitment to innovation and reinforces its position as a trusted partner for surface conditioning excellence worldwide.”

By Lisa Anderson

During volatile times of heightened uncertainty, companies typically batten down the hatches to save money and avoid rocking the boat. As the business outlook pivots to the positive within the next several months, demand will be stimulated, providing huge opportunities for those companies prepared to scale rapidly and serve customer needs. To take advantage of the opportunities to come, artificial intelligence and advanced technologies are required to scale up rapidly, maximize EBITDA and ensure customer success.

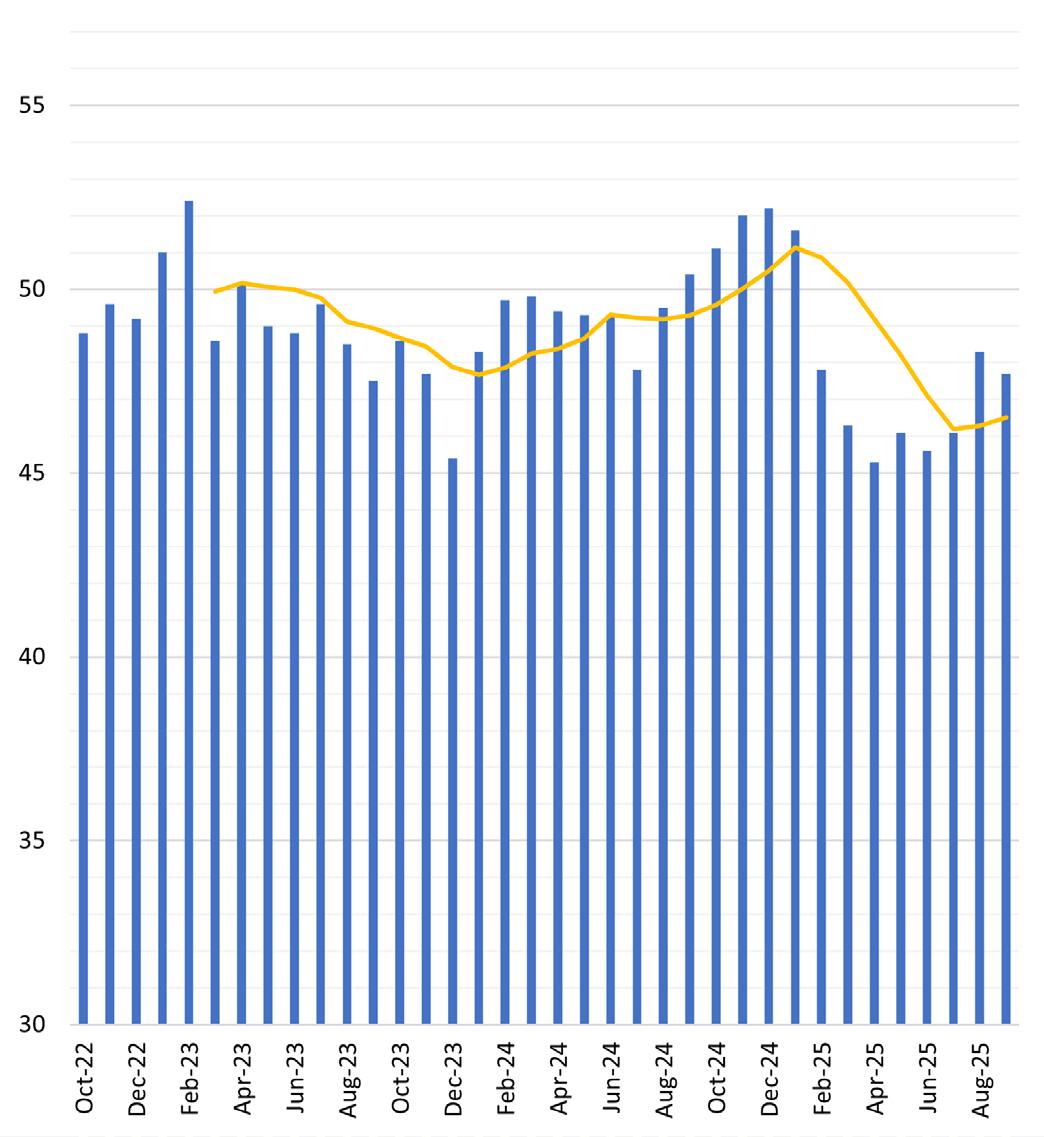

US manufacturing has officially been in a recession for about 18 months — briefly going into expansion in January and February earlier this year, but quickly returning to contraction. It started with heightened inflation and a steep rise in interest rates that dampened demand, which then saw a decline in backlogs for companies across most industries. Three key factors are in play as firms look to a path forward.

First, US firms need tax rates that remain competitive across the globe. When the tax law passed, it secured competitive tax rates and offered several advantages to manufacturers to encourage investments. Second, tariffs caused business instability when announced based on inflation concerns. However, as fears didn’t materialize and valueadded trade deals resulted, business stabilized. Third, companies must have access to capital. With high interest rates, access to affordable capital is limited, further dampening demand. Interest rates are expected to decline in the next few months, putting the third leg of the stool in place, thereby creating a positive business outlook. When combined with substantial investments in manufacturing coming down the pike, manufacturers will go from bust to boom.

Companies that are prepared for success will be ready to take advantage of the opportunities as the three legs of the stool come into place. If you wait for certainty or your sales funnel to fill before moving, you will be left in the dust. As Newton’s law states, an object at rest stays at rest, whereas an object in motion stays in motion. Thus, smart companies will be upskilling their people, upgrading their processes and rolling out AI and advanced technologies to not only prepare for success but also to increase their productivity, financial performance and value to their customers in the interim.

Start by rolling out the appropriate AI and advanced technologies that will support customer needs and help your company successfully deliver customer orders on time and efficiently. A modern ERP system is a must to support the basics and automate manual tasks. Beyond that, review what will best support your business. AI has been incorporated into most Customer Relationship Management (CRM) and sales forecasting systems to help increase your revenue, expand your customer base, and create predictable revenue. Advanced planning systems (APS) utilize AI to model constraints, optimize production plans and automatically incorporate real-time visibility. When combining SIOP (Sales Inventory Operations Planning)

processes and supply chain visibility capabilities with APS systems, companies benefit with predictive ETAs (estimated time of arrival), insight into potential disruptions coming down the pike, and their AI-powered systems will automatically re-route and optimize customer performance while minimizing costs.

From a manufacturing process perspective, companies can get in front of machine breakdowns with predictive maintenance programs. AI-powered robotics systems can help companies scale rapidly with around-the-clock production without additional employees. However, these systems do not just start up and work on the first try. Companies must test, pilot, roll out, tweak and optimize systems so that they are ready to perform. In addition, companies can install automation and autonomous systems to scale up without adding resources. Simple camera systems can catch quality defects upfront, thereby minimizing waste and increasing output. MES (manufacturing execution systems) can optimize runtime and enhance your ability to scale

An industrial products manufacturer was under pressure to meet volume commitments to meet revenue goals, but they struggled to find talent and the training curve required 6-9 months to achieve the appropriate skills to contribute meaningfully. Thus, they installed automation systems and robotics to allow their bottleneck operation to run around-the-clock without a third shift crew. These AI-enabled systems allowed them to scale production and meet their revenue objectives. In addition, their margins increased as production increased without a commensurate increase in cost.

As business growth is on the horizon, forward-thinking executives are embracing AI and advanced technologies to get ready to scale and support customer growth. There are several AI-powered options to automate, digitize and rapidly scale operations. Select a value-added priority and embrace the journey to utilize advanced technologies to support and ensure manufacturing success.

Lisa Anderson is the founder and president of LMA Consulting Group, Inc., a consulting firm that specializes in manufacturing strategy and end-to-end supply chain transformation that maximizes the customer experience and enables profitable, scalable, dramatic business growth. She recently released “SIOP (Sales Inventory Operations Planning): Creating Predictable Revenue and EBITDA Growth,” an e-book on how to better navigate supply chain chaos and ensure profitable, scalable business growth. A complimentary download can be found at www.lma-consultinggroup.com/siop-book/

CIBRUSH 2025 | SHANGHAI, CHINA

DECEMBER 9-11, 2025

Returning to Shanghai in December, CIBRUSH 2025 expands its reach with new product zones and a virtual expo designed to link the world’s brush manufacturers across every segment of the industry.

DATES: December 9-11, 2025

VISITORS: 2500

EXHIBITORS: 120

EXPO AREA

12000 m2

VENUE

SNIEC China, No. 2345, Longyang Road, Pudong New Area, Shanghai, China

EXPO HOURS: December 9-10, 2025 | 09:00-18:00 December 11, 2025 | 09:00-16:00

WEBSITE: www.cibrush.com/en/

CIBRUSH was founded in 2015. It is organized every two years by Beijing HJT International Exhibition Co., Ltd. CIBBRUSH is an international and professional exhibition for brush industry and one of the largest brush industry exhibitions in the world. Over the years, CIBRUSH has focused on brush making technology and served the upstream and downstream sectors of the brush industry, enjoying a strong brand reputation worldwide.

CIBRUSH 2025 coincides with the 10th anniversary of the brand’s establishment and will return to Shanghai on December 9-11, 2025 with the theme “Welcome Global Brush Makers.” This time, the exhibition will extend a new “Semi-Finished and Finished Products Area” aiming to create a platform that covers the entire industrial chain of brush industry. A “Virtual Expo” platform focusing on online supply and demand matching of international trade will also be launched, along with continued digital marketing promotion in overseas markets, to deepen the connection between China’s brush industry and the global market.

Visitors to CIBRUSH 2025 can expect a comprehensive display of machinery and materials covering every facet of brush production. Exhibitors will showcase fully automatic brush-making lines, tufting and trimming systems, paint brush and roller processing equipment and integrated automation solutions designed to enhance productivity. Supporting technologies such as packaging, cutting, handle processing, filament extrusion and injection molding will also be featured, providing attendees with a full view of the industry’s supply chain. The exhibition will also spotlight advancements in polymer, natural and metal filaments, alongside a growing presence of OEM and ODM manufacturers offering private-label production capabilities.

To mark its 10th anniversary, CIBRUSH is expanding its scope with a new Semi-Finished and Finished Products Area, designed to connect producers more directly with end-use manufacturers and brand owners. In addition, a Virtual Expo platform will enhance global engagement through real-time digital matchmaking, allowing buyers and suppliers to connect before, during and after the show.

Exhibition Highlights

CIBRUSH 2025 emphasizes connection and innovation under the themes “Create Opportunity Face to Face,” “Link to the Global Brush Making Industry,” and “Brush Making is Getting Smarter.” The show continues to attract professionals across the full spectrum of the industry, from toothbrush and cosmetic brush manufacturers to industrial and paint tool producers.

Visitor Information

Admission to CIBRUSH 2025 is free, and international guests will have access to a VIP rest area along with complimentary digital editions of the conference catalogue.

CIBRUSH 2025 | SHANGHAI, CHINA

DECEMBER 9-11, 2025

COMPANY (YEARS AS EXHIBITOR)

BOOTH #

ALLJOY TAICANG INDUSTRY CO., LTD. (2016/2018/2023/2025) F02

ANHUI HUIDATONG NEW MATERIAL TECHNOLOGY CO., LTD. (2018/2023/2025) F07

ANPING COUNTY HONGXING BRUSH CO., LTD. (2018/2023/2025) C13

ANPING COUNTY SHUANGMA MANE TAIL PRODUCTS CO., LTD. (2016/2018/2023/2025) B15

A-ONE PAINTING TOOLS (NEW) D41

APEX FILAMENTS PVTLTD (2018/2023/2025) D38

BAODING YINGTESHENG BRISTLE AND BRUSH MAKING CO., LTD. (2016/2023/2025) B01

BBC CO., LTD. (2018/2023/2025) D30

BORGHI (2016/2018/2023/2025) ......................................... E33 www.borghi.com

CALA BRUSH SUPPLY (2016/2018/2025)

CHANGSHA YONCOL TRADING CO., LTD. (2023/2025) B05

CHANGZHOU AOTENG ELECTRONIC TECHNOLOGY CO., LTD (NEW) G08

CHANGZHOU KUANGYUE MACHINERY CO., LTD. (2018/2023/2025) D19

CHANGZHOU XIANGYANG TOOLS CO., LTD. (2018/2023/2025) B02

CHARMINAR POLYMERS (NEW) C32

CIXI JIEDA NANOMETER TECHNOLOGY CO., LTD. (2016/2018/2023/2025) E25

CIXI JINGCHENG MOLD CO., LTD. (2016/2018/2023/2025) E28

CRAFTLON FILAMENTS LLP (NEW) D40

DONGGUAN DATANG PLASTIC & RUBBER CO., LTD. (2016/2018/2023/2025) F32

DONGGUAN GUOSHENG AUTOMATION TECHNOLOGY CO., LTD. (2018/2023/2025) F28

DONGGUAN NEW SUPER MICRO INTELLIGENT TECHNOLOGY CO., LTD (NEW) E37

DONGGUAN SANMA PRECISION BRUSH CO., LTD (2023/2025) D29

DONGGUAN XINSHENG HARDWARE MACHINERY CO., LTD. (2016/2018/2023/2025) D13

DONGGUAN YALAN PACKAGING MATERIAL PRODUCTS CO., LTD. (2023/2025) G09

FEM METAL PRODUCTS (KUNSHAN) CO., LTD (NEW) B12

COMPANY (YEARS AS EXHIBITOR)

BOOTH #

FOSHAN CHAOSHENG AUTOMATION EQUIPMENT CO., LTD. (2016/2018/2023/2025) E03

FOSHAN HUITAI PLASTIC PRODUCTS CO., LTD (NEW) H09

FUJIAN SHUANGYAN XINGYE TRANSMISSION TECHNOLOGY CO., LTD. (2023/2025) B17

GAOZHOU GUANYU NEW MATERIAL WEAVING CO., LTD. (2016/2018/2023/2025) C01

GUANGDONG CHUANGYAN SCIENCE AND TECHNOLOGY CO., LTD. (2016/2018/2023/2025) D12

GUANGDONG MEIBANG DAILY CHEMICAL CO., LTD (NEW) E50

GUANGLING ZHIGAO ELECTRIC PACKAGING MACHINERY FACTORY (2018/2025) A06

GUANGZHOU NANFANG PLASTIC CO., LTD. (2018/2023/2025) G01

GUANGZHOU NANSHA MINGWANG SYNTHETIC FIBER FACTORY (2016/2018/2023/2025) D25

GUANGZHOU TAIBO AUTOMATIC EQUIPMENT CO., LTD. (2016/2018/2023/2025) C01

GUANGZHOU YUANHUI BRUSH-MAKING CO., LTD. (2018/2023/2025) B09

HENAN HUAZE NEW MATERIAL TECHNOLOGY CO., LTD (NEW) C19

HESHAN SENHE PLUSH CO., LTD (NEW) C23

HUAI’AN WEIYE BRUSH CO., LTD (NEW) C02

JIANGSU JINHE HIGH TECH CO., LTD (NEW) B19

JIANGSU TAIBO STEEL WIRE PRODUCTS CO., LTD. (2023/2025) C21

JIANGSU YIMEISI NEW MATERIALS CO., LTD (NEW) C03

JINGXIANG BRISTLE INDUSTRIAL CO., LTD. (2016/2018/2023/2025) F13

JUSOU NYLON TECHNOLOGY CO., LTD. (2016/2018/2023/2025) E18

KUNSHAN QIANLI PACKAGING MATERIALS CO., LTD (NEW) H03

LINYI XINDA HARDWARE TOOLS CO., LTD. (NEW) H12

LONGHAI SENMAO PLASTIC CO., LTD. (2016/2018/2023/2025) G06

LUYI COUNTY HEZHISHENG BEAUTY TECHNOLOGY CO., LTD (2016/2018/2023/2025) A08

MARCO KRACHT COMPANY (NEW) H01

MIANYANG NENGHE BRISTLES PROCESSING PLANT (NEW) B18

NANYUE HUANLEI FILAMENT INDUSTRY CO., LTD. (2018/2023/2025) B08

NINGBO HAOYU AUTOMATION EQUIPMENT CO., LTD. (2023/2025) D36

COMPANY (YEARS AS EXHIBITOR)

BOOTH #

NINGBO JINGLUN NEW MATERIALS CO., LTD (2018/2025) D32

NINGBO KEYING NEW MATERIALS TECHNOLOGY CO., LTD. (2023/2025) F12

NINGBO YINZHOU WENGUJIE MACHINERY FACTORY (2016/2018/2023/2025) D20

QINGDAO BYRICHER AUTOMATION TECHNOLOGY CO., LTD. (2018/2023/2025) A03

QINGDAO JIAYIJIE COMMODITY CO., LTD. (2018/2023/2025) G11

QINGDAO JINFUXIN PLASTIC MACHINERY CO., LTD (NEW) C09

SHANDONG CHAOYA BRUSHING WIRE CO., LTD. (2018/2023/2025) A01

SHANDONG HENGTAI TEXTILE CO., LTD (2016/2018/2025) D22

SHANGHAI WENDU TRADING CO., LTD. (2016/2018/2025) B17

SHENZHEN DONGGANG NEW MATERIAL TECHNOLOGY CO., LTD. (2018/2023/2025) E30

SHENZHEN FIRMFAITH SCIENCE TECHNOLOGY CO., LTD. (2018/2023/2025) E35

SHENZHEN HONGDAWEI PLASTIC CO., LTD. (2023/2025) C25

SHENZHEN KANGDE TECHNOLOGY CO., LTD. (NEW) C20

SHENZHEN KANGPUTE CNC EQUIPMENT CO., LTD. (2016/2018/2023/2025) E39

SHENZHEN

(2018/2023/2025) F33 http://en.tidesz.com/

SHENZHEN XINBU INTELLIGENT EQUIPMENT CO., LTD (NEW) G17

SHENZHEN YONGHONGDA TECHNOLOGY CO., LTD. (2023/2025) E34

SICHUAN CHUANHU BRISTLE CO., LTD. (2016/2018/2023/2025) B06

SUZHOU SHENGGUANG PLASTICS TECHNOLOGY CO., LTD. (2018/2023/2025) G15

TAIZHOU DAIFEILE FILAMENT CO., LTD. (NEW) G08

TAIZHOU VASTSKY INTELLIGENT EQUIPMENT CO., LTD. (2018/2023/2025) F07

TIANCHANG SANHE RAYON CO., LTD. (2018/2023/2025) F18

TIANJIN FEIYI WOOL PRODUCTS CO., LTD. (2023/2025) G07

TONGCHENG BAIMA FLANNELETTE CO., LTD. (2018/2023/2025) D31

TONGCHENG SHENGFENG MACHINERY FACTORY (NEW) G12

TONGCHENG ZHONGMAO PLASTIC INDUSTRY CO., LTD. (2018/2023/2025) B03

TONGXIANG HONGYE AUTOMATION EQUIPMENT CO., LTD (2018/2025) F33

WENZHOU ANCHUANG MACHINERY TECHNOLOGY CO., LTD. (2018/2023/2025) F01

WENZHOU DANAN ELECTRIC CO., LTD. (2018/2023/2025) G01

WÖHLER BRUSH TECH GMBH (2023/2025) ...........................C14

WUJIANG J&D I/E CO., LTD. (2018/2023/2025) G07

WUXI XINGDA NYLON CO., LTD. (2018/2023/2025) D18

XINGTAI FUYI BRUSH MANUFACTURING CO., LTD. (2018/2023/2025) H10

YANGZHOU BAOTIAN MOULD CO., LTD. (2018/2023/2025) C15

YANGZHOU CHENHONG BRUSH INDUSTRY EQUIPMENT CO., LTD (2016/2018/2023/2025) E01

YANGZHOU HAIXING CNC BRUSH MACHINE CO., LTD.. (2016/2018/2023/2025) D01

YANGZHOU HANDE AUTOMATION CONTROL EQUIPMENT CO., LTD. (2023/2025) C07

YANGZHOU JIAMEI BRUSH MACHINERY CO., LTD (NEW) E15

YANGZHOU JINGDU BRUSH CO., LTD. (2016/2018/2023/2025) G18

YANGZHOU JUNDONG AUTOMATIC PACKAGING MACHINERY CO., LTD (NEW) E02

YANGZHOU JUNRONG PRECISION MACHINERY CO., LTD (NEW) E19

YANGZHOU KAIYUE BRUSHING MACHINERY CO., LTD (2016/2018/2025) E12

YANGZHOU MEIYOU PLASTIC MOLD CO., LTD. (2016/2018/2023/2025) E02

YANGZHOU MINGTU BRUSHING EQUIPMENT CO., LTD (2018/2025) D28

YANGZHOU MINGXING BRUSH MACHINE CO., LTD. (2023/2025) G09

YANGZHOU PUSLUO AUTOMATION TECHNOLOGY CO., LTD (2018/2025) F09

YANGZHOU RONGCHUANG BRUSH CO., LTD (NEW) B07

YANGZHOU SHENGLONG PLASTIC PRODUCTS FACTORY (NEW) B11

YANGZHOU TONGTU PRECISION BRUSH MAKING EQUIPMENT CO., LTD. (2018/2023/2025) D18

YANGZHOU YANRUN MACHINERY AUTOMATION EQUIPMENT CO., LTD (NEW) H07

YANGZHOU YIMEISI BRUSH WIRE CO., LTD (2018/2025) B16

YIXING HUAXING BRUSH CO., LTD (NEW) C12

ZAHORANSKY AG (NEW) D43

ZHANGZHOU HENGYU AUTOMATION TECHNOLOGY CO., LTD. (2016/2018/2023/2025) G05

Information from October 16, 2025. Booth #s are subject to change.

Now leading Wöhler Bohemia and HTFilament, Jaroslav Markvart continues the family tradition of excellence with a focus on automation, efficiency and developing the next generation of engineers.

What year did you start in the industry and how did you get started?

COMPANY: Wöhler Bohemia s.r.o.

LOCATION: Pelhřimov, Czech Republic

TITLE: CEO

My professional journey with Wöhler Bohemia can be traced back to my childhood. The company was founded in Pelhřimov in 1994 by my father together with Mr. Wöhler, so it naturally became a part of my life. Business challenges and opportunities were often discussed at home, so I was familiar with the industry from an early age.

I gained my first professional experience directly in the workshop, where I worked parttime during my studies. This hands-on work gave me valuable insight into the practical side of production and allowed me to get to know our products “from the ground up.” Later, while studying at university, I began helping in the design department, where I spent about five years contributing to the development of new products.

After that, I took a break from the family business to pursue a new challenge. I joined another company in the field of heating systems controlled by alternative energy sources. It was an invaluable experience that gave me the opportunity to see how processes function in a different environment. Thirteen years later, I returned to Wöhler Bohemia. For the last five years, I had the honor of working side by side with my father, learning from his experience.

Two years ago, my father retired, and I took over the leadership of both our companies — Wöhler Bohemia and HTFilament. I am proud to continue what my father and Mr. Wöhler started and to carry forward our family tradition.

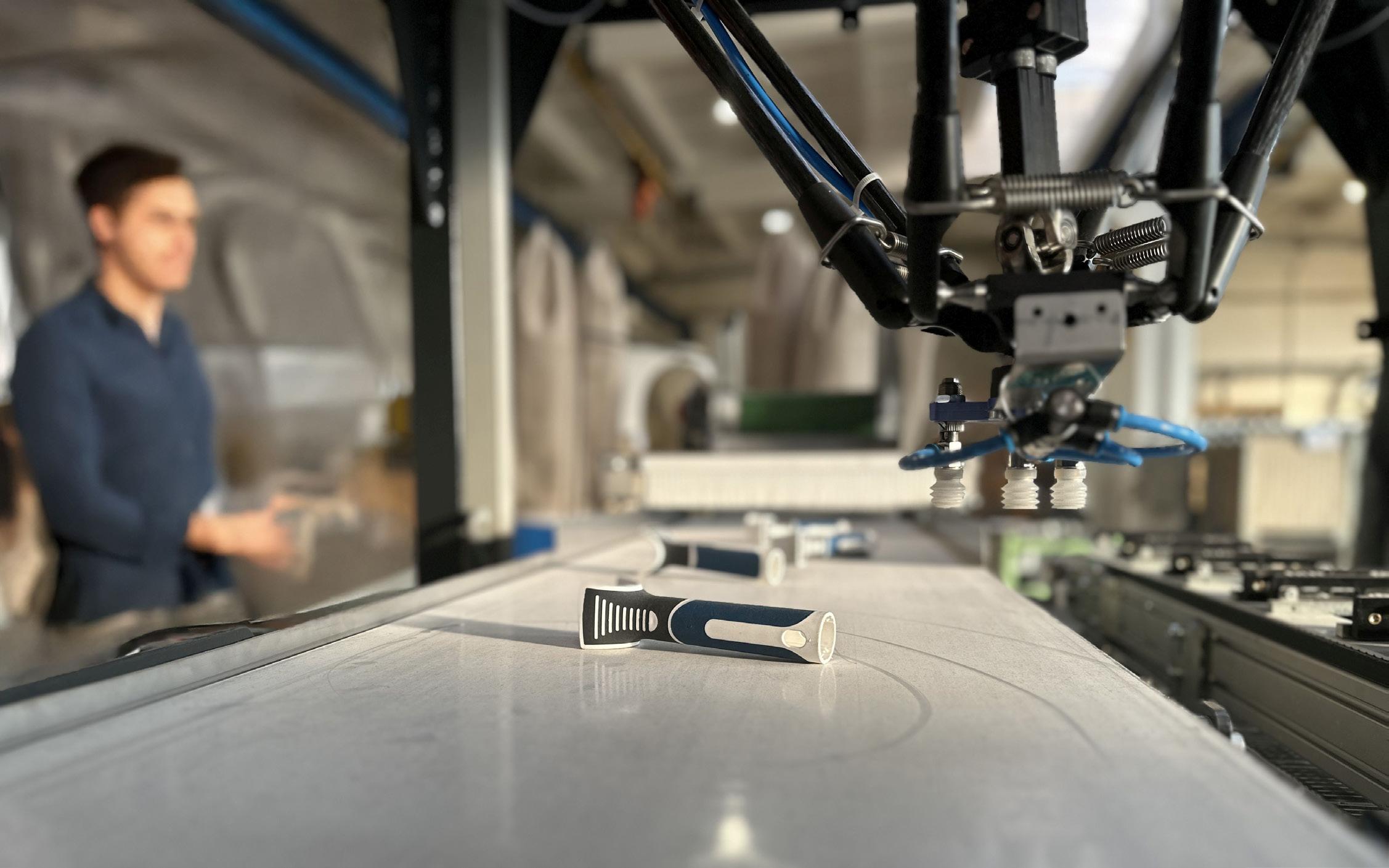

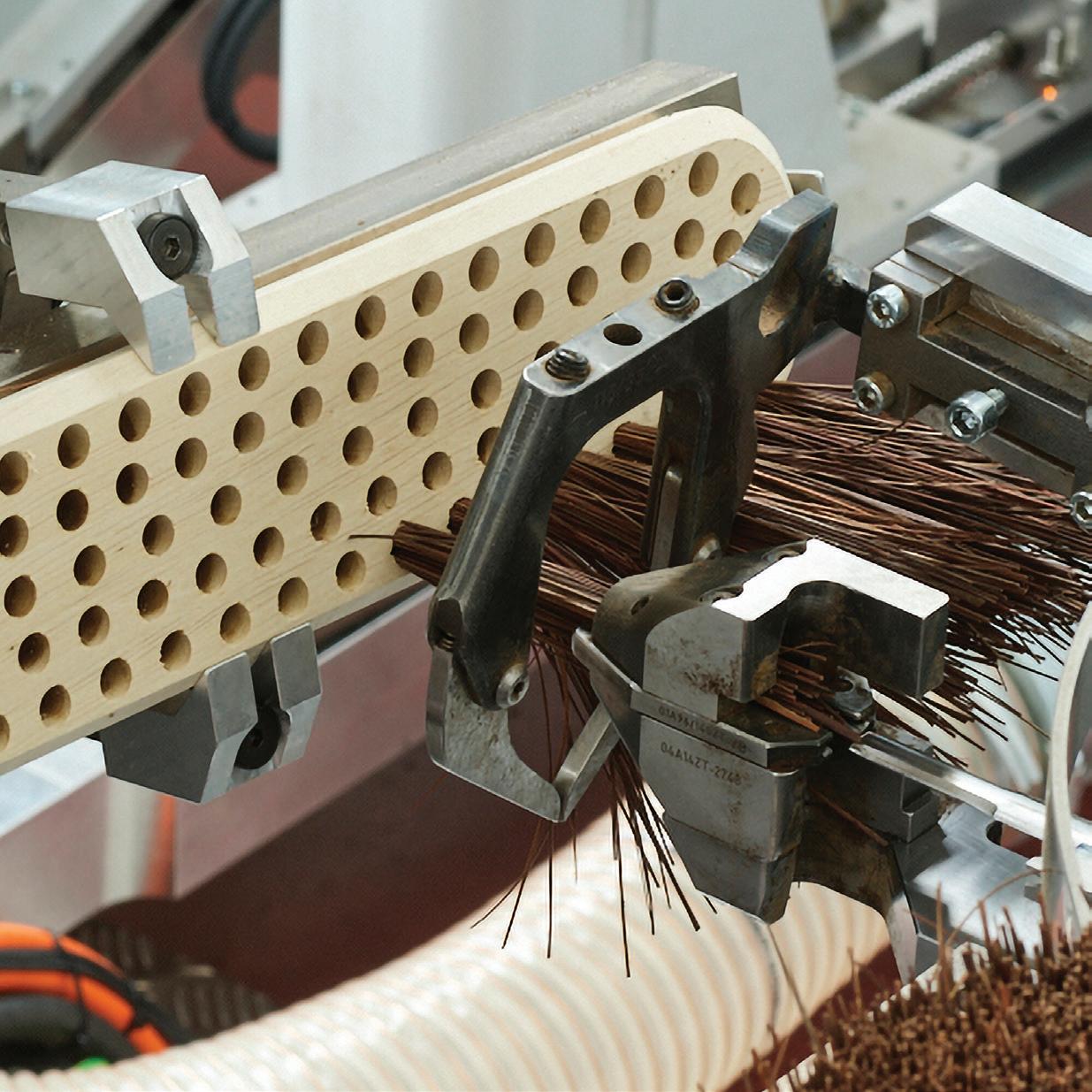

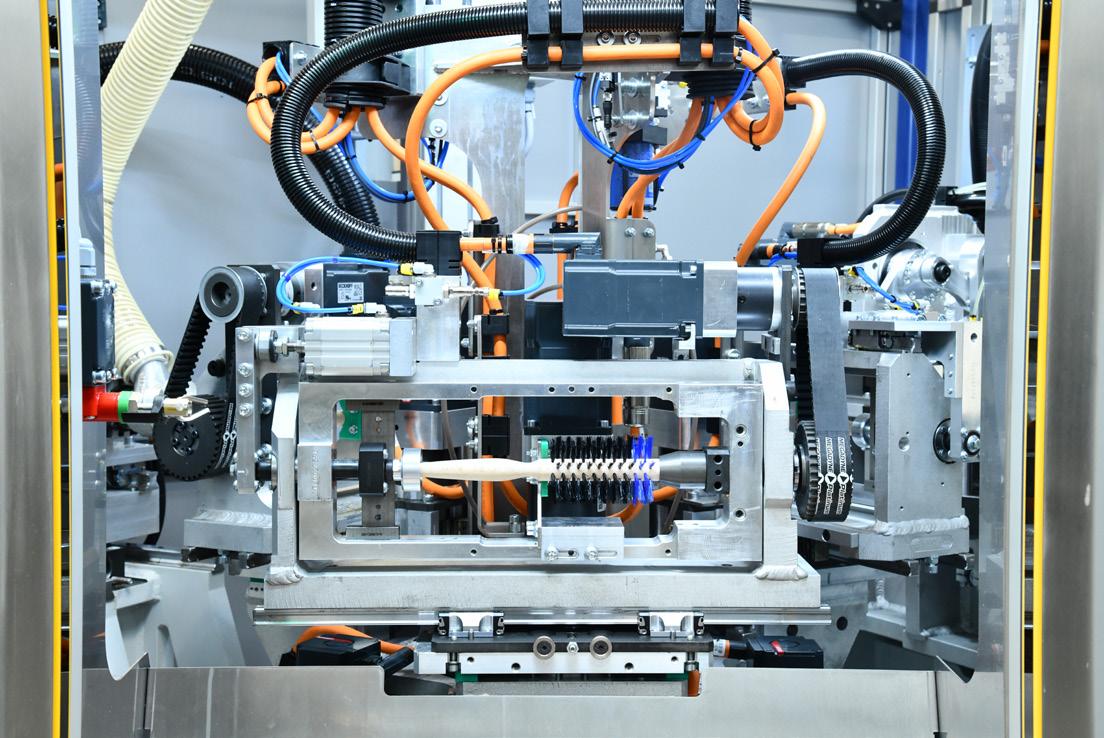

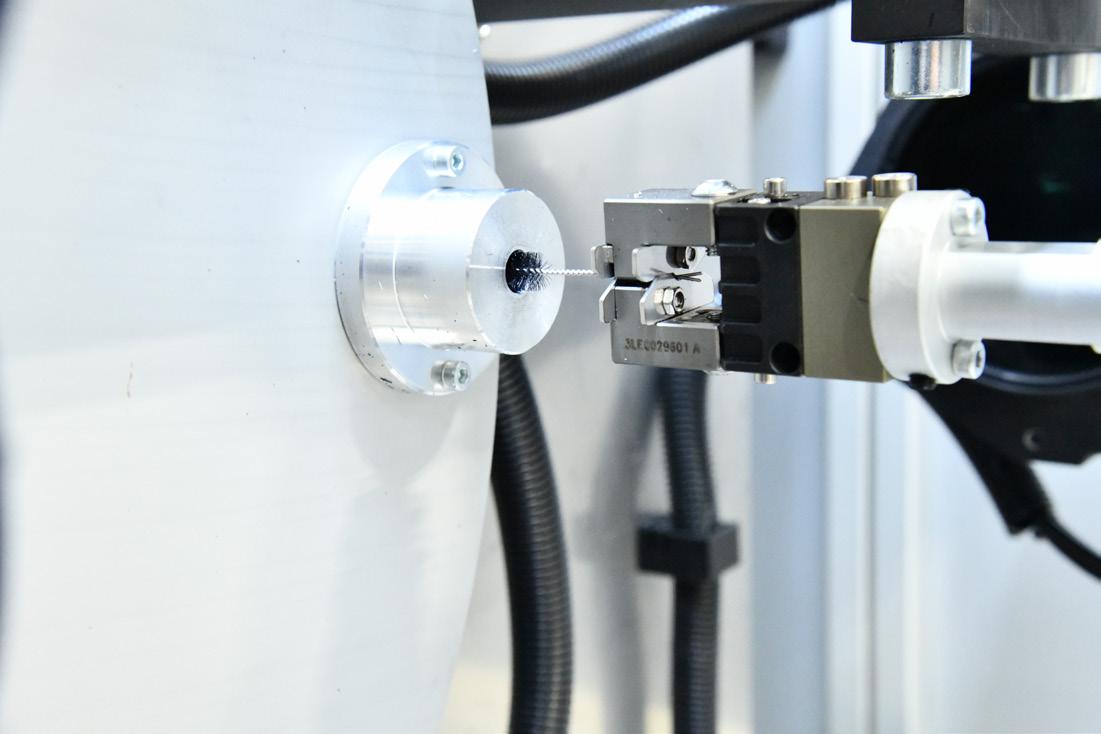

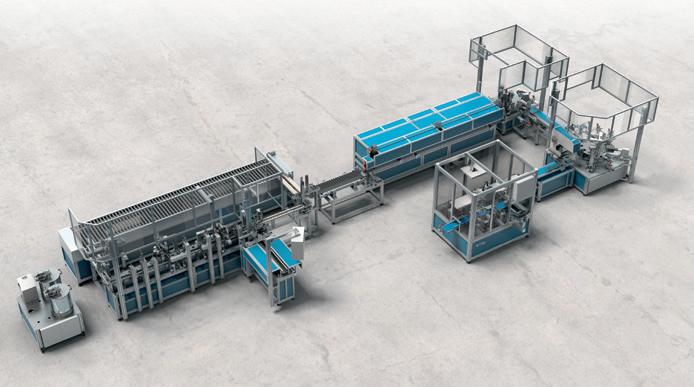

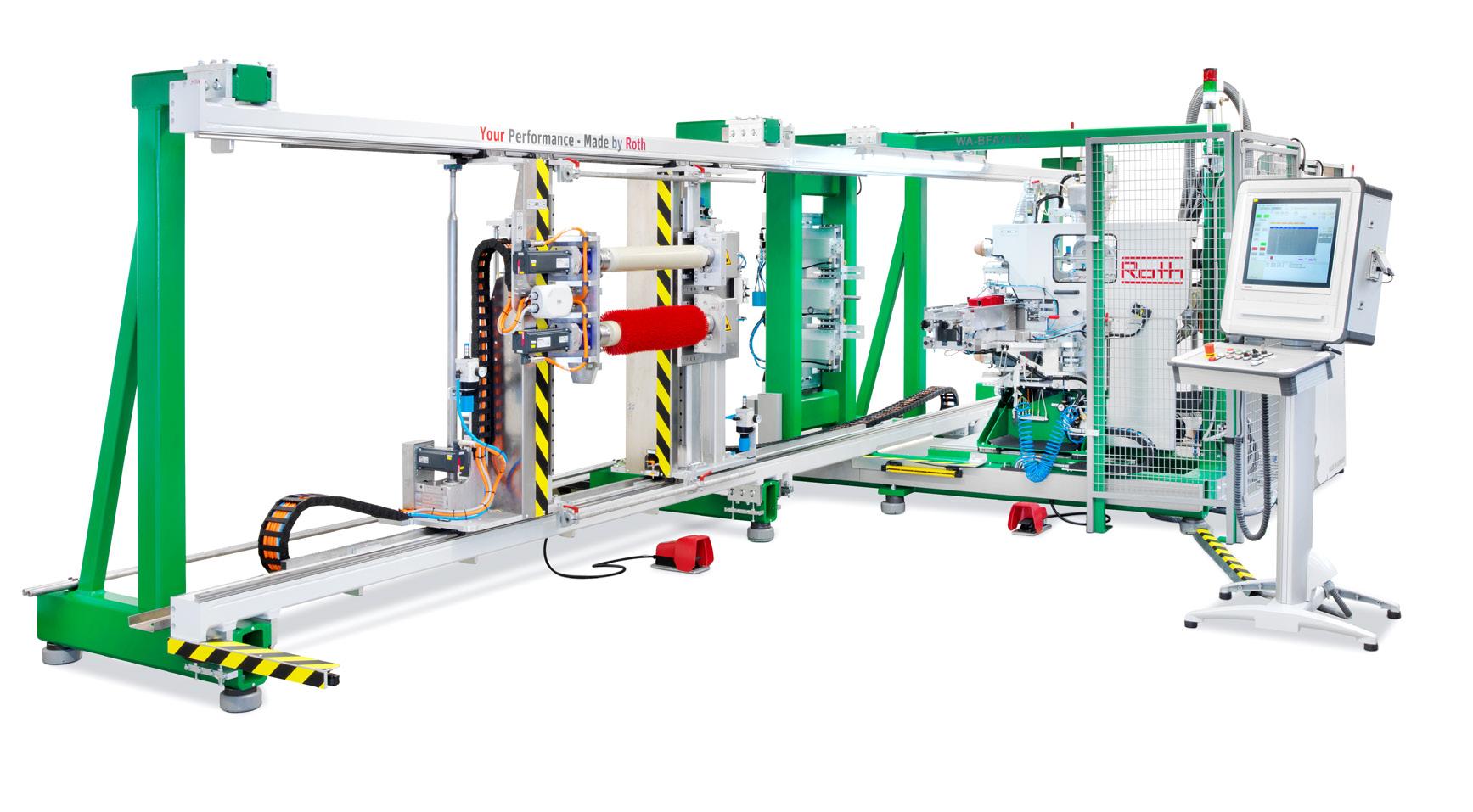

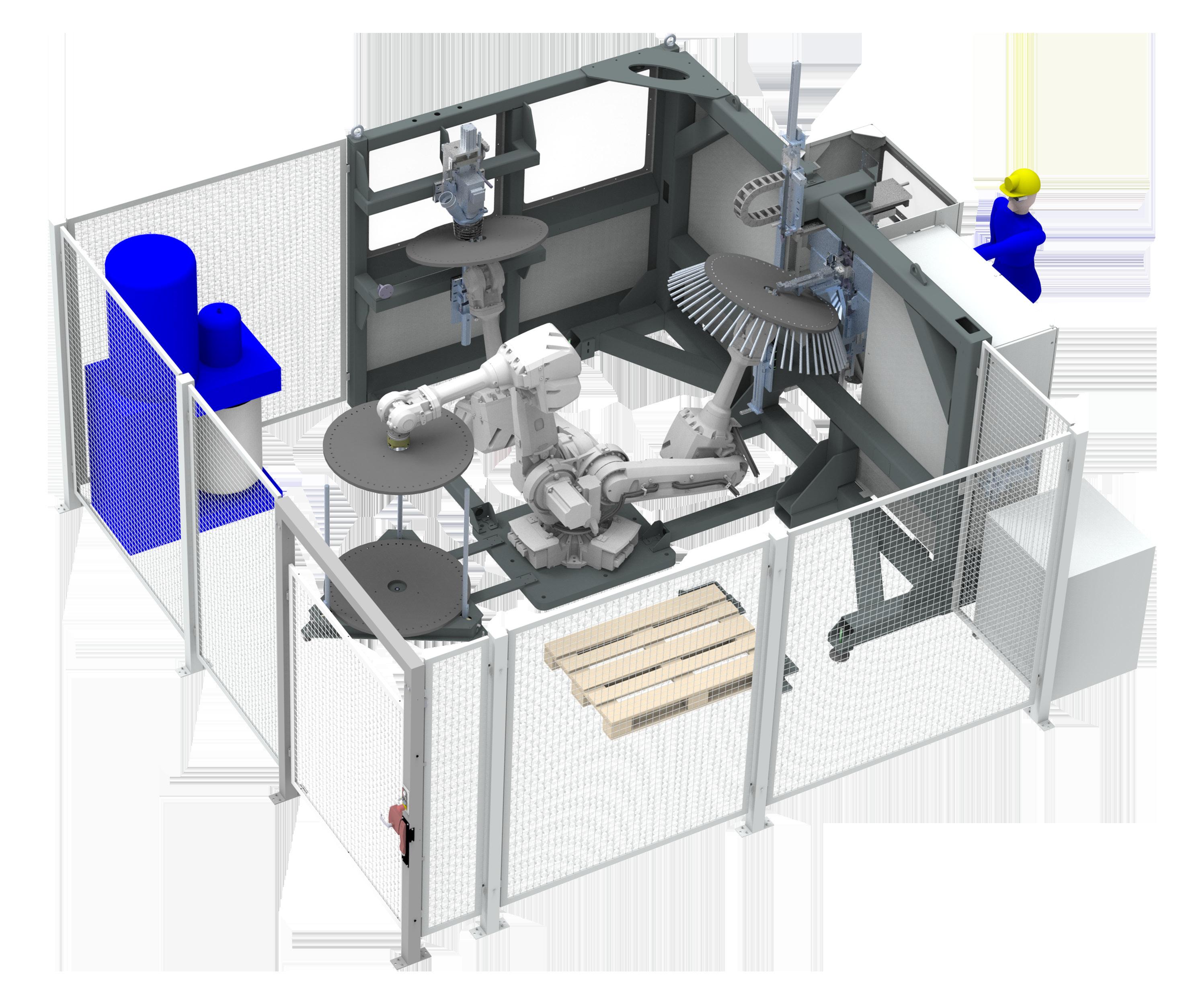

When I think about our greatest accomplishment, I view it through the lens of the company’s entire portfolio. Today, Wöhler Bohemia operates in four distinct production and business areas: the manufacture of technical and craft brushes, our own metalworking, the sale of measuring instruments and the production of fully automated lines for brush and roller manufacturing.

The last of these — automated production lines — is probably the most prestigious but also the most challenging part of our business. I’m extremely proud that in recent years we have not only entered this highly specialized segment but also managed to succeed in it.

However, the greatest achievement for me is not the machines themselves, but the people behind them. I am proud that we have managed to stabilize and build a team of true professionals who make these complex machines possible. Our colleagues in R&D, design, programming and electrical engineering, as well as our production managers, are the reason we can push boundaries and remain competitive. It’s a team effort — and that is our biggest success.

What is you favorite part of working in the brushware industry?

To be honest, my favorite part of this job is the moment we commission and hand over a machine to a customer. That moment closes a long and demanding process that begins with initial discussions with the client, continues through design and engineering, and culminates in production. These steps are often stressful and challenging, but seeing our work come to life and help a customer in their operations is the most rewarding feeling for me.

What are the key challenges you are facing right now at Wöhler Bohemia and how are you solving those challenges?

Every new order is a challenge for us, because every customer requires a machine customized to their specific needs. We have never produced two identical machines. Although this is our greatest advantage, it also has a significant disadvantage. Each machine is essentially unique, which has a direct impact on price — our machines can be more expensive than those of our competitors, who focus on mass production.

Our strategic goal and greatest challenge is therefore production efficiency. We are working to streamline processes while maintaining the flexibility needed to manufacture unique machines. It is a constant and demanding task, but we believe that striking this balance is the key to our future success.

Are there any new products or initiatives for Wöhler Bohemia that you would like to share?

Yes, we are currently working on several exciting projects in close cooperation with our customers. A few highlights:

Finishing machine for long rollers: This machine can cut rollers up to 750 mm in length, clean them with a brush, and bevel the edges.

Ferrule manufacturing machine: Another significant development is a machine that produces metal ferrules for larger brushes (1/2” to 4”).

High-speed roller cutting machine with robot: This fully automated line uses two cutting units to keep up with the upstream roller winding (thermo-fusion) process. A robot is placed between the two machines to ensure full automation without the need for human intervention.

Recruiting skilled workers overall and also young workers has been stated as a concern in the industry. How do you think that is best addressed?

Recruiting skilled workers is indeed a major challenge in our industry, and I believe it’s not just an issue in our country. We actively address this in several ways. A key step is our cooperation with universities, where we participate in the development of new technologies. This allows us to show students during their studies that engineering is not just a traditional field, but also a field full of innovation and modern solutions. We believe that this approach helps build long-term partnerships with future experts and generates their interest in our work.

We are also involved in our local community in Pelhřimov and support young people. For example, we provide financial support to the local floorball club to show that we really care about the next generation. For us, this is an important part of our social responsibility.

What do you like to do outside of work?

With my busy work schedule, I don’t have much free time. The time I do have, I dedicate to my family. I have two young sons, and we spend a lot of time doing sports together. They play floorball and soccer, and I often join them — sharing tips and advice from my younger days when sports were my life. Outside of sports, we enjoy spending time outdoors at our family’s cottage.

What is one thing about you that people might find surprising?

People might be surprised that although I work with automated and precision machines every day, in my free time, I enjoy spending time on DIY projects and repairs at our cottage. This work has taught me that planning and systematic procedures are essential for achieving good results. As in engineering, if you want everything to work perfectly, every detail matters.

What have you learned in life or in the industry?

One of the most important lessons I have learned is that every barrier is an opportunity for growth. I have faced many challenges throughout my career, but I have always found that perseverance leads to creative solutions. This experience has taught me that determination and persistence always pay off.

CEO/President: Ing. Jaroslav Markvart, Ing. Jiří Vondrák

Headquarters Location: Pelhřimov, Czech Republic

Founded: 1994

Ownership Structure: Holding Company Member/LLC

Number of Employees: 57

Manufacturing Plants: One

Total Facility Square Footage: 4000 m2

Primary Product Categories: Machinery / Tools / Brushes

Key Industries Served: Manufacturers of machines of paint brushes and rollers

Major Markets: International

Sustainability Initiatives: Recycling/use of solar energy etc.

By Alice Castle, Brush Expert Ltd | Photos by Brush Expert Ltd

Situated in the tranquil waters of the Tyrrhenian Sea, just a short distance from the vibrant southern Italian city of Naples, the island of Ischia represents one of Italy’s most cherished destinations. Renowned for its therapeutic thermal springs, dramatic landscapes and striking coastal panoramas, Ischia combines natural beauty with a rich history and culture. The vista that greeted attendees of the 65th Annual Congress of the European Brushware Federation (FEIBP), held from October 8-11, 2025, was nothing short of breathtaking.

Described as “an island within an island,” the elegant Hotel Continental welcomed guests to its fine establishment, nestled within lush Mediterranean gardens. With spacious rooms, excellent conference facilities, a spa and wellness center and no fewer than five thermal pools, it provided the perfect setting for a Congress whose theme — No Federation is an Island — could not have been more fitting.

After registration, the first night’s reception was held on the terrace of the hotel’s Olympic-sized pool. Under glittering warm lights, guests were served canapés, traditional Italian dishes and regional wines and aperitifs — the perfect start to the Congress, offering the chance to reconnect with colleagues and welcome new members of the association.

FEIBP President Alessandro Acquaderni formally opened the Congress, expressing his immense pleasure in welcoming delegates and their families to Ischia and thanking them for their attendance.

The 2025 meeting — the third and final chapter in the “island trilogy” following 2023’s No Man is an Island (Belfast) and 2024’s No Company is an Island (Ibiza) — marked a pivotal moment for the Federation. It was a time to transform the insights gained over the past two years into a foundation for the future, shaping the direction of both the Federation and the wider sector. Every participant was encouraged to contribute actively to this shared vision for progress.

As a testament to the strong alliance between the FEIBP and the American Brush Manufacturers Association (ABMA), ABMA President RJ Lindstrom attended the Congress and shared his greetings. Lindstrom expressed his pleasure in seeing many new attendees, describing it as a sign of FEIBP’s growth. Reflecting on the ABMA’s 2025 Convention in Austin, Texas, he noted that 150 members and partners gathered for three days of meetings, education, and networking — highlighting the association’s international reach.

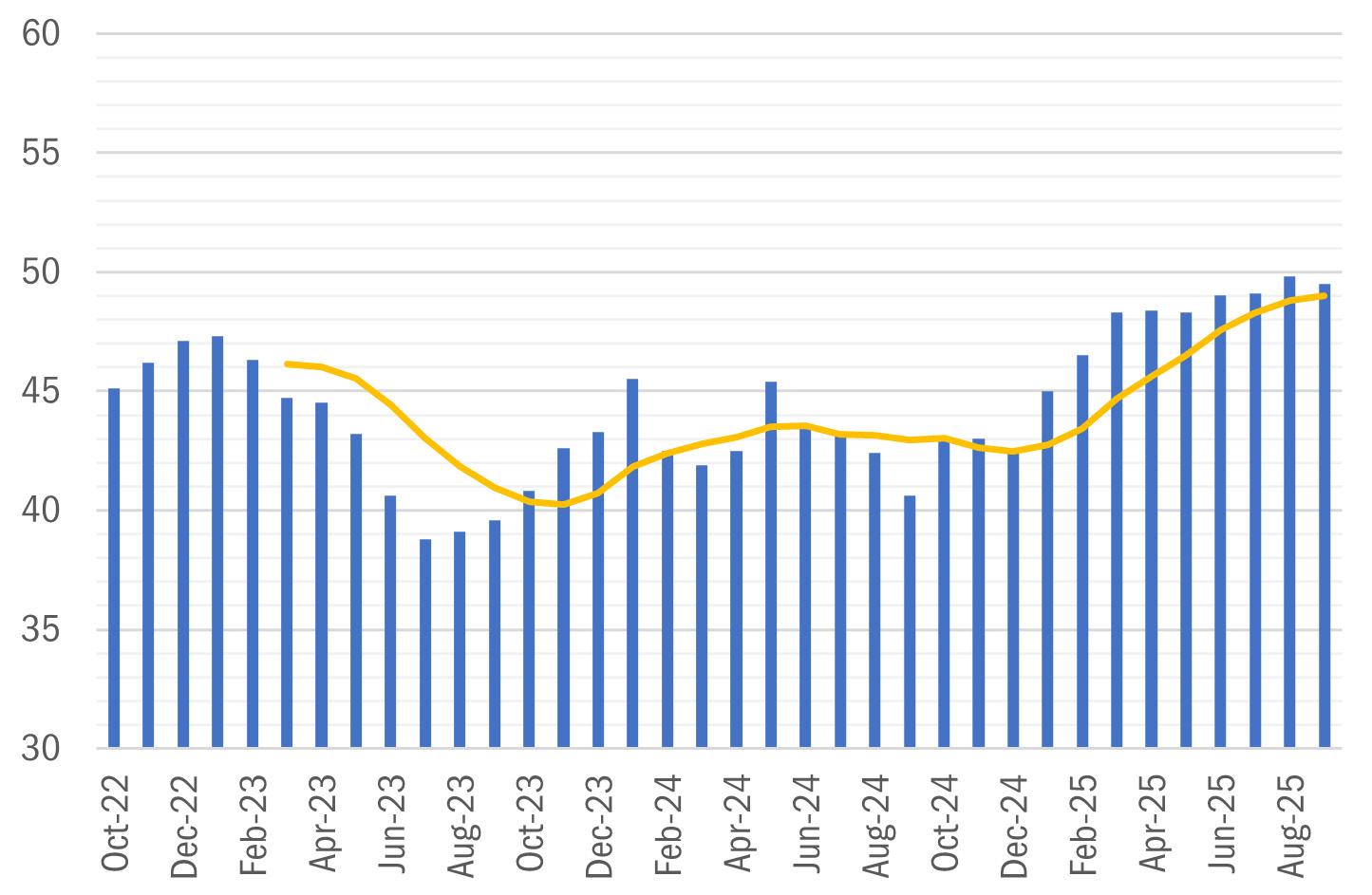

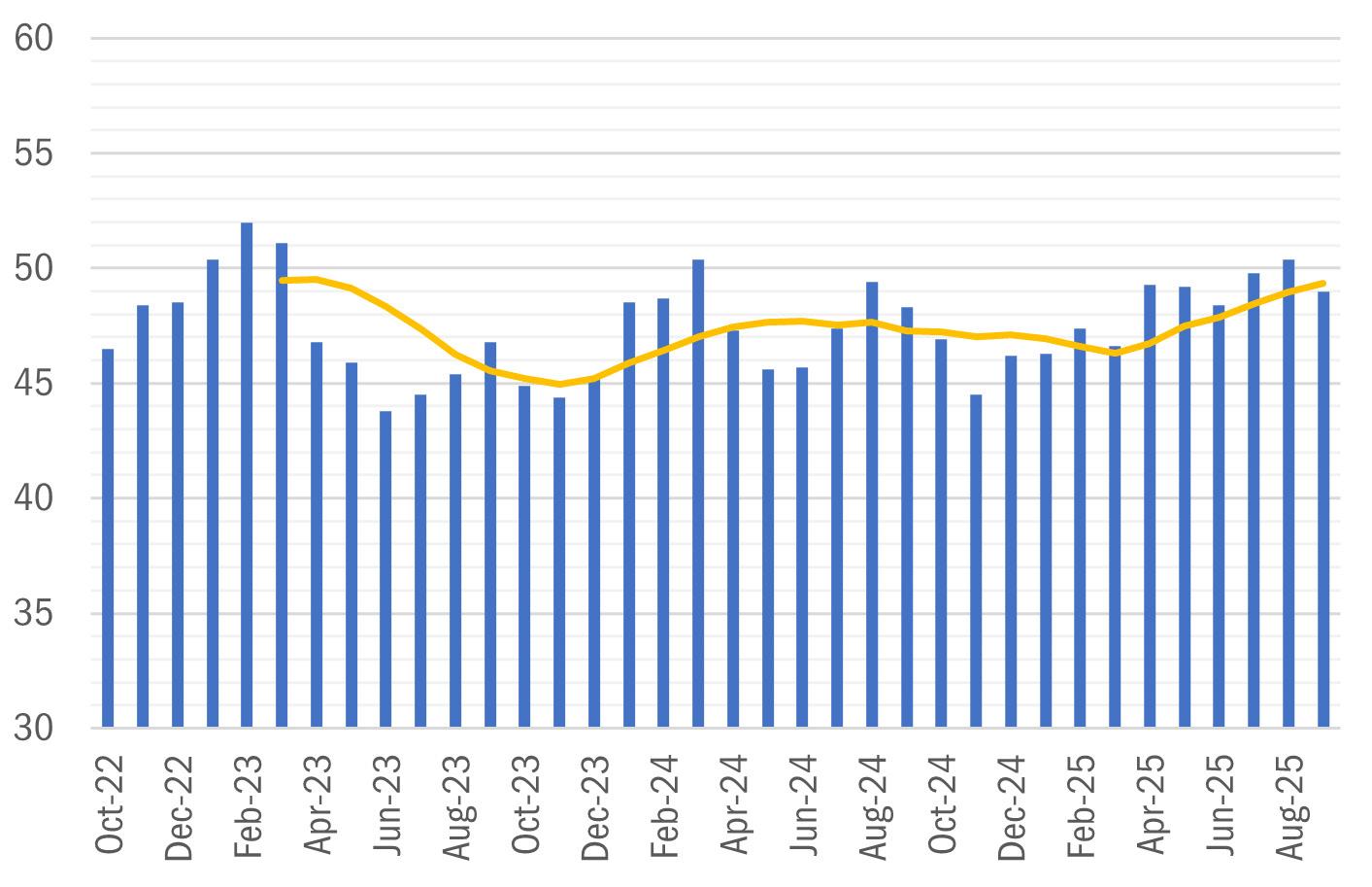

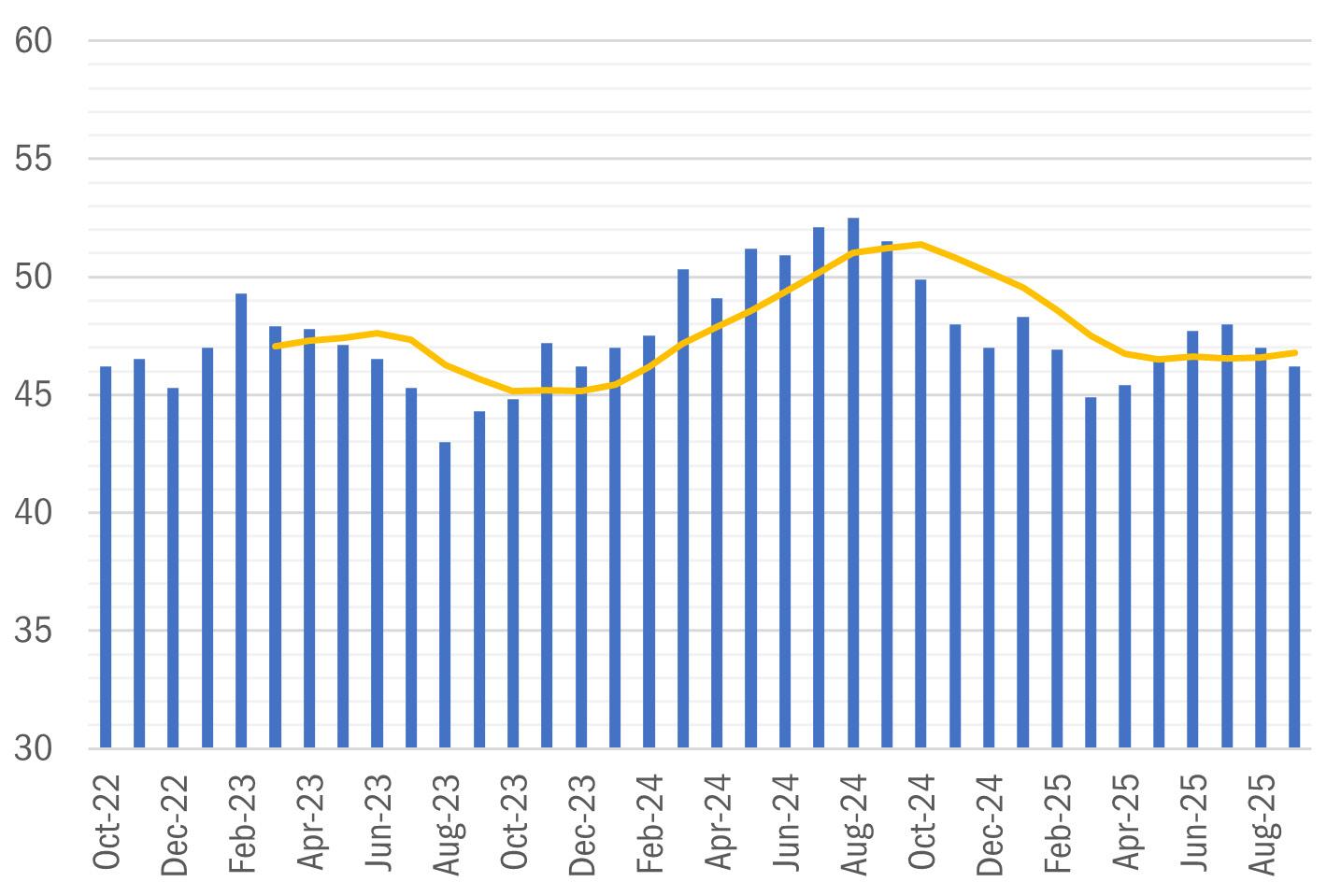

Looking ahead, he announced that the 109th ABMA Annual Convention will take place in Puerto Rico (March 24-27, 2026) and extended an open invitation to FEIBP members. He also commented on the impact of recent U.S. import tariffs and outlined the ABMA’s Monthly Economic Indicators Report, which tracks key market data to help members monitor trends.

65th FEIBP CONGRESS ISCHIA, ITALY | OCTOBER 8-11, 2025

Alessandro Acquaderni, FEIBP President

“Ischia offered the perfect setting for this third chapter of our journey — No Federation Is an Island. Over 120 participants from 14 nations across and beyond Europe brought energy, ideas, and that unmistakable volcanic spirit of renewal that only Ischia could inspire. The Congress marked a true milestone: the incorporation of FEIBP, the adoption of new statutes, and the transition from European to EMEA — opening our federation to a wider horizon. With 16 first-time attendees, a record number of Innovation Award candidates, and a full programme from LEGO Serious Play workshops to the Dolce Vita gala, the atmosphere was both creative and deeply human.”

R.J. Lindstrom (Zephyr Mfg), ABMA President

“My first FEIBP Congress as a representative from ABMA was a truly fantastic experience! The location was fantastic - it is easy to see why Ischia was voted one of the most beautiful islands in the world. Of course, the food in Italy is second to none, so we were treated to lots of great meals! As an American it was very helpful to get updates on the brush market from the European perspective. The strong relationship between ABMA and FEIBP will continue to benefit members of both organizations as we share information. The ABMA was lucky enough to be able to bring two additional representatives from the U.S., and we were all made to feel welcome and included in all conversations. I can’t wait to attend the FEIBP congress again in Lyon, France”

Acquaderni Family,

SITBRUSH-Societa Italiana Tecnospazzole

“At SIT, we have always believed in the power of coming together — meeting suppliers, customers, competitors, and above all, people. Because it is people who shape our industry. Our strong participation in the FEIBP Congress, and often in its organization, has always been viewed as an investment: an investment in knowledge, relationships, and the shared future of our sector. The Congress offers priceless insights, opportunities to meet customers and suppliers, and moments to strengthen personal relationships, all while contributing actively to the evolution and growth of our industry. We look forward to continuing this journey of collaboration and innovation. Count on SIT for the 66th FEIBP Congress in Lyon (France)!”

Caroline L. Schroth, Rothlaender & Co. GmbH

“When ideas meet action and teamwork meets trust, real impact follows. I am deeply grateful for the inspiring exchanges, the memorable sailing experience and the trust placed in me as Chair of the Paint Brush Working Group.”

In a gesture of friendship, Lindstrom presented Alessandro Acquaderni with two symbolic gifts: a hand-crafted compass representing guidance in global business, and a Kansas City BBQ apron, a nod to the city’s heritage and the Kansas City Chiefs. Acquaderni reaffirmed the value of the partnership, noting that the exchange of insights between the two associations remains truly invaluable.

This year’s Congress attracted a record 120 participants from 14 countries. First-time attendees introduced themselves and their companies, receiving a warm welcome from all. These included:

René Madsen – Stoddard Manufacturing Co Ltd

Jerome Polene – LTA Medical-Getinge Infection Control SAS

Herman Meyer – da Vinci Kunstlerpinselfabrik DEFET GmbH

Sören Homberg – Wöhler Brush Tech GmbH

Tamara Kenny – HATHO GmbH

Bas Wardeneaar – Sprenger en Brommer B.V. (Will also be President of the Dutch Brush Association from November 2025 and an FEIBP Board member.)

Matthew Piper – The Hill Brush Co Ltd

James Samuel – Mark Samuel Trading Ltd

Philippa Peat – Trades Tools Ltd

Luke Handley – Trades Tools Ltd

Bastien Fauvernier – Cardotech

Silena Fattori – Marcegalia Oskar Srl

Robin Haas – Gerhard Haas GmbH & Co. KG

Representing the FEIBP Secretariat, Feriel Saouli of SEC Newgate Group reflected on key achievements over the past 12 months:

Incorporation of the FEIBP: Now formally established under Belgian law, aligning its statutes with non-profit legislation to strengthen governance and clarify responsibilities.

Expanding Geographical Scope: Now encompassing the wider EMEA region, broadening reach and amplifying the Federation’s voice.

Transition of the Secretariat: The move to SEC Newgate Group marks a step toward a more professional and strategically focused organization.

World Brush Expo 2024: Delivered in partnership with the ABMA, achieving record participation, strong financial results and progress on sustainability initiatives.

Simon Lorillière, current Vice President and incoming President for 2026, announced that the 66th FEIBP Congress will be held in Lyon, France (September 23-24, 2026). Focusing on environmental transition and policy protection, the two-day mid-week format aims to encourage wider participation. Activities will include “Climate Fresk: All the Cards are in Your Hands” — a collaborative workshop designed to foster awareness and dialogue on climate issues. The Gala Dinner will take place at the Musée des Confluences, a museum exploring the relationship between humanity and the natural world — a setting that perfectly echoes the Congress theme.

Carlos Petzold, Borghi USA

Having participated in this year’s FEIBP Congress on the island of Ischia in Italy, I can say that I was very pleased to have attended. Why would an American attend the European Brushware annual Congress? It’s all about global networking, connecting to people in person, and sharing our challenges, views, and values between ABMA members and FEIBP members. If we don’t attend each other’s Congresses (conventions), it’s not as easy to understand each other and forge solutions to common problems and issues. Furthermore, as a past ABMA President as well as being an ABMA member for 41 years, I have seen a visit such as attending FEIBP, bring together like-minded brush manufacturers and suppliers that work in a spirit of fairtrade, open up business opportunities that pay for decades to come for trips to Europe. Time is precious, travel can be expensive, but networking and potential opportunities can be profitable. Hoping to see many of the FEIBP brush manufacturers at the ABMA convention in Puerto Rico March 24-26, 2026, for the same reasons I attended FEIBP. A special thank you to the Acquaderni family for their incredible hospitality!

Kris Geldof, GB Boucherie n.v.

“This year’s FEIBP Congress, which took place on the beautiful island of Ischia in the Bay of Naples, was a well-organized and interesting event. The work invested by the (now) past-President Alessandro Acquaderni is coming more and more to fruition, and the hands-on and professional secretariat made it all run like clockwork. This year again, the number of manufacturers present was higher than it was in a while, and the FEIBP is clearly dedicated to further improving the participation in the coming years. There are sectors of the brush industry that are still under-represented right now, so there is still room for growth once these branches of the industry realize what the FEIBP can do for them. With the enthusiasm and energy of the new president, Simon Lorrillière, which can be seen in the way he is approaching the members, we have very good hopes for a bright future. Up to the next one!”

Hermann Meyer, da Vinci Künstlerfabrik DEFET GmbH

“What a wonderful event! Beautiful surroundings, great organization and, above all, an invaluable opportunity to exchange feedback with partner companies from our industry and discuss ideas and strategies for a successful future in our complex business environment.”

Jürgen Lessmann, Lessmann GmbH

“The congress in Ishia was another great opportunity for us to exchange ideas with other manufacturers in the industry. One highlight for us was, of course, winning first place in the Innovation Award! This is fantastic confirmation of our work and shows that we made right decisions in selecting and developing our products.”

After the success of the inaugural event in 2024, preparations are underway for World Brush Expo 2028 in Ghent, Belgium (May 16-18). Klaus Van Cauwenberghe of i-One outlined ambitions for a sold-out exhibition exceeding 10,000 m², enhanced visitor engagement and a unified layout bringing all exhibitors together under one roof. A direct shuttle service from Brussels Airport (approx. 40 minutes) will provide convenient access for delegates.

Simon Lorillière presented findings from a survey of member companies, showing increased use of LinkedIn (+8 percent) and Instagram (+18 percent), while Facebook declined slightly (–4.6 percent). YouTube and Xing saw modest growth; Twitter and Pinterest continued to decrease.

The General Assembly followed the Opening Session, beginning with confirmation of the Board of Directors (2026-27). New members Bas Wardenaar and Caroline Schroth (Rothlaender) were welcomed, and outgoing members were thanked for their service. Caroline Schroth will chair the Paint Brushes Working Group and Karsten Skov (FBK) the PHB Working Group. With the Federation seeking candidates for Vice President, Alessandro Acquaderni stressed the importance of renewal and encouraged younger delegates to step into leadership roles.

Delegates received updates on key raw-material markets affecting the brush industry. Each report covered availability, pricing dynamics and supply developments across principal materials, offering insight into trends shaping procurement and manufacturing. The reports were:

• Steel Market Report 2025: Holger Kruse, Künne Gruppe

• Bristle Market Report 2025: Reinhold Hörz, DKSH

• Synthetic Filaments Market Report 2025: Andrew McIlroy, Perlon

• Vegetable Fibres Market Report 2025: Dr. Urte Rietdorf, Friedrich Platt

• Fine Hair Market Report 2025: Mark Samuel, Mark Samuel Trading

Feriel Saouli summarized the past year’s activities, highlighting the success of World Brush Expo 2024, the smooth transition of the Secretariat and the incorporation process. She noted that the Federation remains on a sound financial footing. The session closed with Alessandro Acquaderni thanking delegates for their collaboration before Working Groups convened for sector-specific discussions.

As in 2024, delegates attending the FEIBP 2025 Congress were invited to take part in one of two engaging team-building activities, each inspired by the island’s unique character and charm.

Pizza Making: With Ischia’s close proximity to Naples, the birthplace of the world-famous pizza, delegates choosing this option gathered in the hotel’s garden restaurant kitchen, guided by expert pizzaioli in crafting their own creations.

Participants learned the secrets of shaping traditional dough — from letting it overhang the work surface so gravity aids in forming the perfect base, to dusting with semola flour to prevent sticking. A wide selection of toppings and sauces allowed everyone to personalise their pizza before sliding it into the searing oven. Once baked to perfection, the tasting began — arguably the highlight of the experience!

Sailing: Taking advantage of the calm, crystalline waters surrounding Ischia, delegates and partners who opted for sailing set out under clear skies to take part in a lively regatta. Split into teams of four to six across six boats, each with an experienced skipper, participants took on different roles, working together to bring their craft across the finish line first. Described by many as an unforgettable experience, it proved a wonderful way to spend an afternoon on the water — combining teamwork, friendly competition the relaxed spirit of the island.

Dinner was hosted in the hotel’s elegant marquee-style Garden Restaurant, where guests enjoyed live music, appetizers and aperitifs outdoors before moving inside for a buffet of traditional Italian dishes. As the evening progressed, the “through the ages” disco playlist filled the dance floor — a lively finale to a wonderful day.

This year’s Brush Forum provided suppliers, machine manufacturers and Innovation Award nominees the opportunity to showcase their products in an engaging tabletop display format.

Thirteen companies — Fass, Borghi, HT Filaments/Woehler Bohemia/Woehler Brush Tech, Zahoransky, Künne Group, Rothlaender, Roth, Marcegaglia Oskar, Loewert, Pogliani, Perlon, Boucherie and the World Brush Expo Organiser — joined the four Innovation Award nominees (Ebnat, da Vinci, Lessmann, and Zahn Pinsel) and presented their innovations to delegates in what proved to be one of the most popular Forums to date — encouraging lively discussion and inspiration.

In a departure from the traditional “speaker slot,” this year’s programme introduced an engaging, hands-on workshop facilitated by LEGO Serious Play.

Participants were invited to form small groups with people they knew least, sparking fresh connections and new perspectives from the very start.

Armed with the colourful LEGO bricks we all know and love, the workshop encouraged everyone to:

Build connections: Through play and storytelling, LEGO Serious Play helped everyone connect, share experiences and spark meaningful conversations in an open and inclusive space.

Think outside the brick: By building with purpose and using metaphor, participants found new ways of thinking, tapping into fresh ideas and leaving old mindsets behind.

Tackle challenges together: LEGO offered a fun and practical way to test out ideas, experiment freely and cocreate imaginative solutions as a team.

Over the course of an hour, groups worked together to bring their ideas to life, building imaginative responses to questions such as what members can expect from the FEIBP, how to picture the “ideal FEIBP island” and how future congresses (both FEIBP and ABMA) can help shape this shared vision.

The workshop wrapped up with participants moving around the room, exploring and learning about each other’s LEGO® creations. The feedback was overwhelmingly positive— what began as a fun and unexpected activity turned out to be both thought-provoking and thoroughly enjoyable.

Replacing the traditional speaker slot, this interactive workshop used LEGO Serious Play to explore members’ ideas about the FEIBP’s role, the “ideal FEIBP island,” and the future of its Congresses. The session was imaginative, collaborative, and widely praised by participants.

On Friday afternoon, delegates explored the Aragonese Castle, one of Ischia’s most iconic landmarks. Built on a rocky islet and linked to the main island by a causeway, the fortress has stood for centuries as a symbol of resilience and unity. Walking through its ancient corridors and panoramic terraces offered delegates both historical insight and a moment to reflect on the enduring spirit of collaboration that defines the Federation.

To close the Congress, delegates gathered at Lisola Restaurant, perched above the shimmering bay of Forio, for the finale Gala Dinner. Timed perfectly with the sunset, guests enjoyed cocktails and canapés against a spectacular backdrop before moving indoors to savour the restaurant’s renowned Mediterranean-style cuisine.

During the evening, the FEIBP Innovation Award winner was announced — Lessmann’s Knotted Conical Brushes for Battery-Powered Brush Cutters — presented to Jürgen and Johannes Lessmann by Alessandro Acquaderni and Simon Lorillière.

As Acquaderni’s term as President concluded, he expressed gratitude to the Board and partners, including the ABMA, for their unwavering support, and extended best wishes to incoming President Simon Lorillière (Brosserie Brenet).

In a warm gesture, Lorillière, joined by Andrew McIlroy (Perlon GmbH), presented Acquaderni with gifts in recognition of his exemplary service and leadership.

With its relaxed atmosphere, warm hospitality and awe-inspiring views, the evening provided a fitting conclusion to an inspiring few days on Ischia.

On Saturday, the optional group tour visited Negombo Thermal Park, one of the island’s most iconic wellness destinations. Set in the beautiful Bay of San Montano, Negombo offers a full sensory experience: thermal baths, Mediterranean gardens, sea views and serenity.

“20 people attended the Negombo thermal park experience, enjoying a very relaxing and healthy break, as well as the very nice lunch at the Al Fugà Restaurant inside the park,” said Acquaderni. “We particularly enjoyed the carrot cake, shaped as a lemon, with lemon sorbet and crumble with sesame seeds – unforgettable! Many people toured almost all of the 20 different thermal pools, while others enjoyed the beach or simply relaxed after the enriching Congress we had, eventually indulging themselves with a face mask based on the unique park’s thermal waters.”

As the 65th Annual FEIBP Congress drew to a close, delegates departed Ischia with renewed energy, strengthened connections and shared optimism for the year ahead. The Federation’s commitment to collaboration, innovation and growth remains steadfast, proving once again that no federation is an island.

In line with the FEIBP’s commitment to progress, four companies earned nominations for this year’s Innovation Award. A representative from each company was invited to share details of their revolutionary products that have been developed over the last 12-month period. Each company was also allocated a display space within the Brush Forum, enabling delegates to find out more about each product or concept ahead of the ballot to find a winner. Once all votes were counted, the winner was announced during the Gala Dinner that was held on the last night of the Congress. We are pleased to reveal that the winner of the FEIBP Innovation Award for 2025 was Lessmann’s Knotted Conical Brushes for Battery-Powered Brush Cutters.

Wheel brushes and conical brushes on motorized and battery-powered brush cutters are ideal for removing weeds and wild plants from lawn pavers, curbs, paved areas, or other hard-to-reach places.

Lighter brush models are ideal for cordless brush cutters. These brushes have a smaller cup and fewer bristles, which means they can be operated effortlessly by battery-powered brush cutters and still achieve excellent cleaning results.

Lessmann brushes for batterypowered brush cutters are available with 12 or 22 knots. The high-quality steel wire works extremely effectively on many surfaces. Plastic bristles (PBT or PP) are ideal for working on sensitive surfaces. The special feature of Lessmann brushes for battery-powered brush cutters is that they have standard mounts. This means that the products fit all common battery-powered brush cutters that are designed for tool changes without the need for an additional adapter. This technical feature is unique and is protected by a utility model. www.brushexpert.com/news/product/article/FEIBP-Innovation-WinnerLessmann-brush-cutter

The NEW Nail Design Brush Configurator from Zahn Pinsel is the brand new, web-based configurator which allows the user to design their very individual nail design brush in just 4 steps. With over 300 possible combinations of head shape, hair quality, handle shape, ferrule colour and logo print options, this flexible, modular system offers maximum customization with a low minimum order quantity of 120 pieces. This allows you to successfully stand out from the market with unique brushes and boost your brand!

www.brushexpert.com/news/product/article/zahn-nail-design-brushconfigurator-feibp-2025-inn

The new “Paddle Brush” from da Vinci Künstlerpinselfabrik DEFET of Germany are distinguished by their elegant, innovative design featuring a specially shaped, extra-short handle that allows you to work directly from the wrist.

There are three different bristle types to choose from: the soft FIT variant, the extra-strong IMPASTO bristle configuration and the versatile SYNTHETIC BRISTLE version, which is suitable for various painting techniques.

All brushes are equipped with the DUROPLUS-System, which includes a specially moulded grip tooth that penetrates deeply into the adhesive layer, securing the bristles and ensuring a long brush life.

Wide brushes are exposed to particularly high stress, which is why the connection between the handle and brush head is designed to be especially sturdy. The brushes feature stainless steel ferrules and have a laser-cut grip zone that ensures a secure hold.

The wood used comes from sustainable European forestry, highlighting the environmentally friendly aspect of the brush production.

www.brushexpert.com/news/product/article/paddle-brush-da-vinci-defetFEIBP-innovation-2025

This elegant dishwashing brush impresses not only with its dynamic design but also with its numerous inner qualities. This brush has a real punch, despite, or perhaps precisely because of, its hollow construction.

The “Gap” is committed to sustainability from head to handle and still offers all the advantages of wet use: It is truly lightweight. Compared to a conventional dishwashing brush, material savings of 30% were achieved.

The already slim body is also made of 95% PCR-PP, and the bristles are made of 100% recycled plastic (PIR). Despite the minimal use of material, the ergonomic and voluminous handle with its soft-touch surface fits perfectly in the hand. Material was also saved in the hanging hole, as it is significantly larger. Fits all conventional hooks.

Durability also entails sustainability. For long-lasting hygiene, the brush can be cleaned in the dishwasher. www.brushexpert.com/news/product/article/ Dishwashing-brush-Gap-Ebnat-FEIBP-Innovation-2025

By Alice Castle, Brush Expert Ltd | Photos by Brush Expert Ltd

Delegates received updates on key raw material markets affecting the brush industry. Each report covered availability, pricing dynamics and supply developments across principal materials, offering insight into trends shaping procurement and manufacturing.

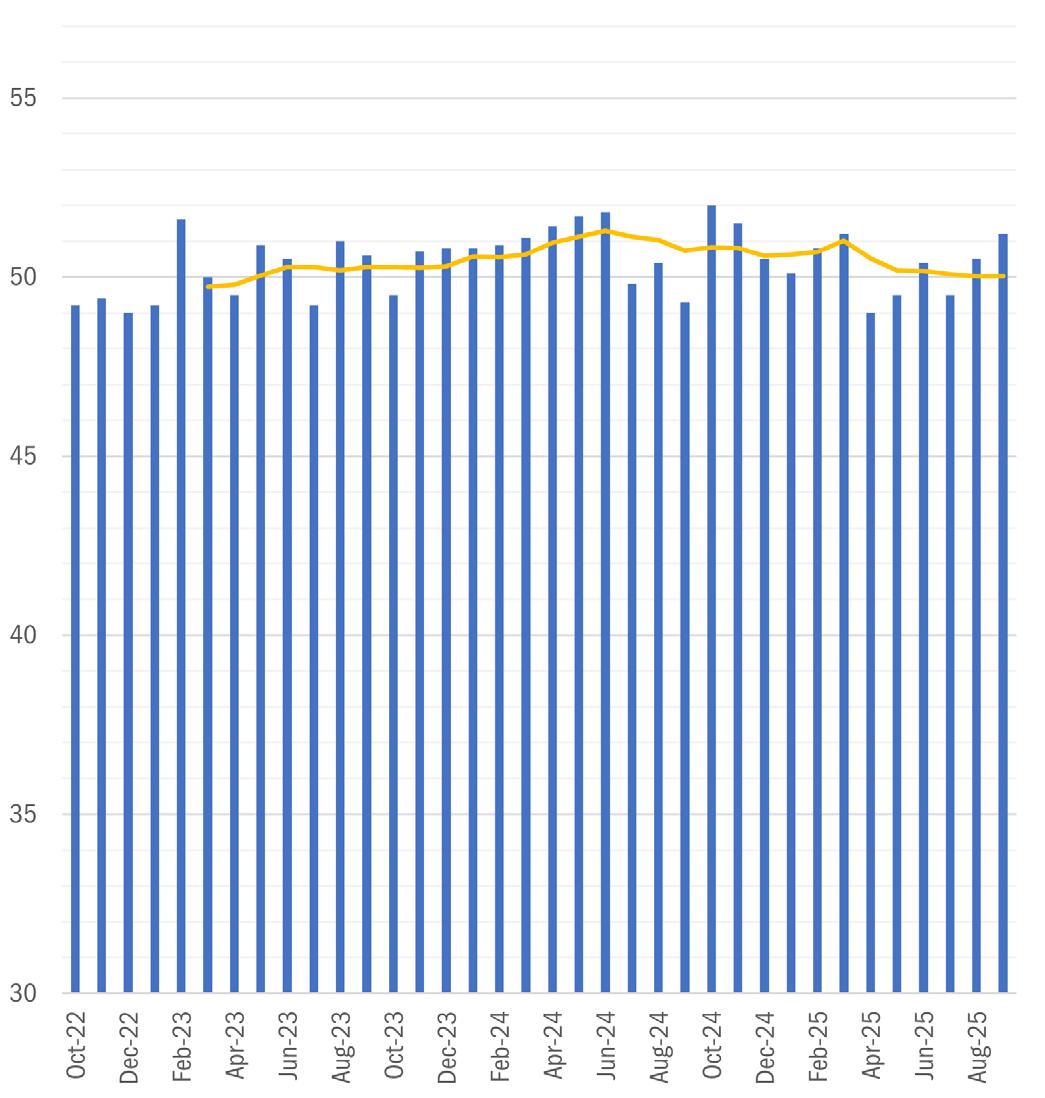

Andrew McIlroy of Perlon GmbH, leading German manufacturer of filaments from all the main polymer groups required for use in a wide variety of brush and tool applications, opened his report by remarking upon the stability in plastics pricing over the past 3 years. He had the following to say about factors affecting the end-pricing of synthetic filaments:

Oil

Oil prices have been subject to a decrease of around 8% in the past 12 months, although this has had a minimal effect as a feedstock for polyolefins.

The projected demand for oil for the coming months remains low and, despite interest rate cuts and a recent decision by the OPEC+ group to increase production, prices should remain stable, helping to keep the pricing for PP and LDPE stable at a low level

Electricity

Good news does seem to be on the horizon for larger industrial users of electricity. Despite an EU-wide plan to subsidise pricing until 2027 which will bring costs down to support manufacturing in the EU, no current plans for assistance are in place beyond this date. The current €90 MwH could half but would still leave prices higher than before the Ukraine war with no long-term plan for lower costs.

Polymer price development

For all the polymers used in the brush industry, the price development is almost identical, with very little change for almost 3 years now. Most raw materials are priced on a monthly basis, and although prices do go up and down in small increments, there has been no sustainable increases or decreases of note.

The reason for this remains the lack of overall demand globally – for oil and other feedstocks – which helps to keep pricing stable. We remain of the opinion, that the large chemical companies making raw materials are far from happy with the prices they are able to charge. There have been several rounds of plant closures and site consolidations over the past two years and the general consensus amongst European manufacturers is that local production is becoming unsustainable.

Whilst we can’t predict the future, common opinion is that this situation is likely to remain unchanged in the coming months.

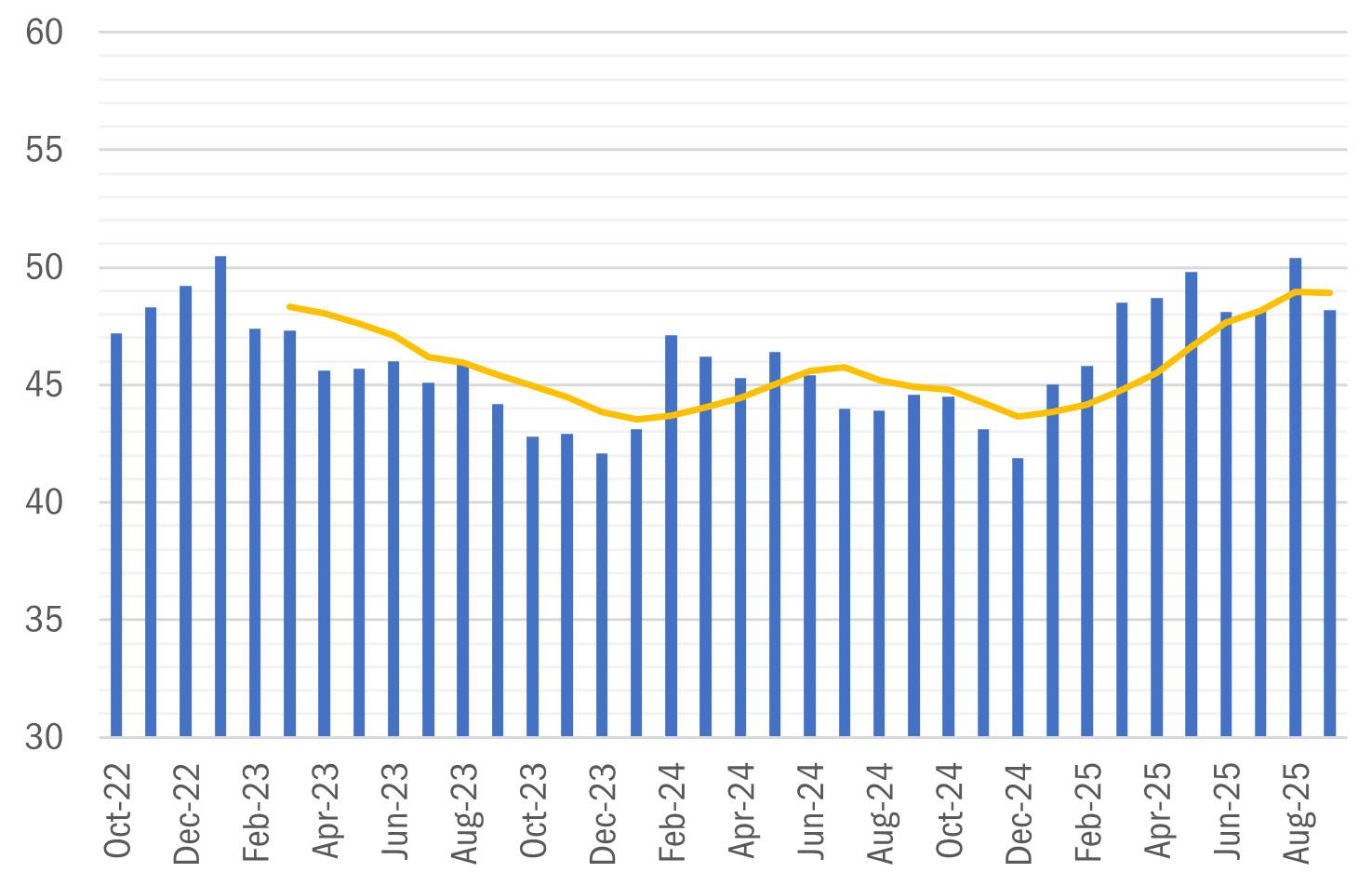

Urte Rietdorf, Friedrich Platt

Dr. Urte Rietdorf of Friedrich Platt GmbH, suppliers of filling materials for brooms and brushes, provided an update on the vegetable fiber market over the last 12 months.

Tampico

Whilst producers are doing their best to keep prices stable, they have been hampered by unpredictable economic situations, with shortages of raw fiber, inflation and transportation costs being the main difficulties. Drought is still affecting availability and quality of supply and harvest is inconsistent due to a lack of workforce, with the extraction of long fibers proving particularly challenging.

Bahia Piassava

Prices of Bahia Piassava are rising due to various economic pressures and a shrinking workforce. This leads to an increase in production costs and, consequently, raises prices.

Harvested in rural, deep-forest areas, extraction methods can be arduous and, whilst quality maintained constant levels, harvesting and processing times have become longer. Unpredictable weather has also hampered the drying process.

Sherbro

Prices remain at a very low level compared to other fibers and are only rising moderately at most, as production and transport costs are increasing. In the near future, only slight price adjustments are expected as the markets continue to be volatile.

The quality remains constant despite difficult circumstances and production remains at a low level, with restricted raw material supply and a generally uncertain economic situation.

Palmyra

Prices have largely remained stable and for the near future will presumably remain consistent. However, unpredictable, small price pressures on the raw fibers can lead to difficulties. Trade uncertainties, rising transport costs and increasing labour costs can affect the production costs at any time. Climate changes can also lead to price increases.

Experienced producers are able to keep the quality consistent and ensure a sufficient supply of high-grade materials. The availability of a skilled workforce is also essential and production and supply are now operating more efficiently and harvesting conditions have improved.

To eliminate varieties in fibers, investments in mechanical cleaning and grading are planned, however large-scale mechanization is improbable at present.

Precarious climatic periods can affect fiber characteristics also.

In summary, the present situation is stable, with supply and demand balanced. However, demand is slowly rising and cultivation is increasing which could lead to challenges when demand outstrips the plants’ growth.

Coconut

For coconut, prices have been relatively stable, with 2024 demand reaching fairly high levels. There has been a significant increase in whole coconut market with continued growth potential. Supply

is steady and a shortage is not expected at a normal harvest level, although increased demand for other coconut products such as husk chips means less available material for coconut fiber production.

There are sufficient Arenga trees in terms of the whole of Indonesia. However, Java is the main processing region and, for harvest regions located too far away, the challenges are workforce recruitment and the high transportation costs to Java.

In addition, climatic conditions continue to be difficult. The fiber cannot be harvested during rainy periods and the drying is considerably slower as sunlight is needed for proper drying.

www.oskaritalia.it

Fast, flexible and built to spec, we turn your ideas into steel solutions.

Pricing is stable, but the current situation is critical. Exports in 20245 have been under pressure which has affected the Arenga price. The domestic Indonesian Arenga price has attained now nearly an equal level compared to export prices.

Mark Samuel of Mark Samuel Trading Ltd reported no significant change in terms of raw material prices over the last 3 years, as demand for most types of fine hair continues to remain weak.

The demand for high-value hairs, including kolinsky, weasel and squirrel has been low, despite a decline in prices since their peak 2 to 3 years ago. Prices were expected to fall further, but with low stock levels, there hasn’t been too much pressure to slash prices. This is further exacerbated by the fur industry, which, in general, has seen an overall decline in demand which impacts the availability of the tails from which the hair is sourced.

Chinese governmental restrictions on wild animal trade have enhanced trading difficulties, which has prevented prices for dropping even lower. Recent reports from Russia reflect a similar situation, with kolinsky prices remaining high and the supply of tails and skins limited. The price of red and black Kazan squirrel sourced from Siberia remains high with no foreseeable downward trend.

The price for both farmed and wild badger hair remains stable with a marginal downward trend as more manufacturers move towards the use of synthetic filaments. However, high-quality traditional shaving brushes are still sought after.

With the demand for goat and pony hair having seen a dramatic decline, it is difficult to determine prices; for stock items, it is certainly down, but for fresh goods, it is unclear due to the closure of many dressing factories.

Ox ear hair sourced from China has remained stable in price for the last 8 to 10 years and demand for the shorter 35 to 55mm sizes is constant. Longer sizes may see a fall in prices as its traditional market of varnish brush manufacturers in the US moves increasingly towards the use of synthetic alternatives.

Reinhold Hörz of DKSH, suppliers of top-quality bristles to the brush industry, reported on the trend towards the industrialisation of pig production in China, which continues to have a major impact on sourcing. It has become obvious that the traditional source of stiff-haired, mountain-reared Meishan pig is now in short supply, with prices for such hair rising. Market tendencies towards a readyprepared bundle of natural bristle have forced suppliers to blend with “slaughterhouse quality” bristle to prevent prohibitive pricing.

Taking into consideration the above-mentioned point, the raw hair market prices should rise, but in a rather competitive environment, it’s impossible to increase. As a consequence, prices are stable for black bristle between 51mm and 57mm, whilst prices are rising for 89mm and upwards. Middle sizes are rather under pressure due to a declining demand.

For white bristle of 51-70 mm, prices are stable, whereas 76mm and up are under pressure.

Demand vs Availability

Black:

38 to 44mm - Strong demand from Inland China

51 to 64mm - Strong demand from Europe and the US vs. lack of raw material

64 to 83mm - Rather under pressure