www.philippine-resources.com

PENARROYO: ROCK WHISPERERS AND HYDROGEN HUNTERS: THE NEW EXPLORERS

BUNYE:

WOMEN IN MINING AND STEM EDUCATION

THE RACE FOR CRITICAL MINERALS: WILL THE PHILIPPINES BE LEFT BEHIND?

www.philippine-resources.com

PENARROYO: ROCK WHISPERERS AND HYDROGEN HUNTERS: THE NEW EXPLORERS

BUNYE:

WOMEN IN MINING AND STEM EDUCATION

THE RACE FOR CRITICAL MINERALS: WILL THE PHILIPPINES BE LEFT BEHIND?

Genluiching Mining Corporation (GMC) is a Philippine mining company registered with the Securities and Exchange Commission (SEC) and the Mines and Geosciences Bureau (MGB). It is licensed and authorized to engage in the exploration, quarrying, processing, and trading of iron ore, one of the Philippines’ high-value mineral products for export, as its principal business mission.

GMC partners with heavy construction equipment lessors, land transport and shipping companies, and petroleum suppliers for its exploring, drilling, excavating, hauling, transport, and shipment activities for greater financial fluidity and operational leverage. Its partners in this supply chain include Monark Equipment Corporation, Maxima Steel Mills Corporation, Phil lua Shipping Lines, Caltex Philippines, and Shell Philippines.

GMC’s concession area in Mati City, Davao Oriental yields iron ore and other minerals that include copper ore, gold ore, manganese ore, limestone, and silica.

GMC’s concession area in Ayungon, Negros mining site yields silica.

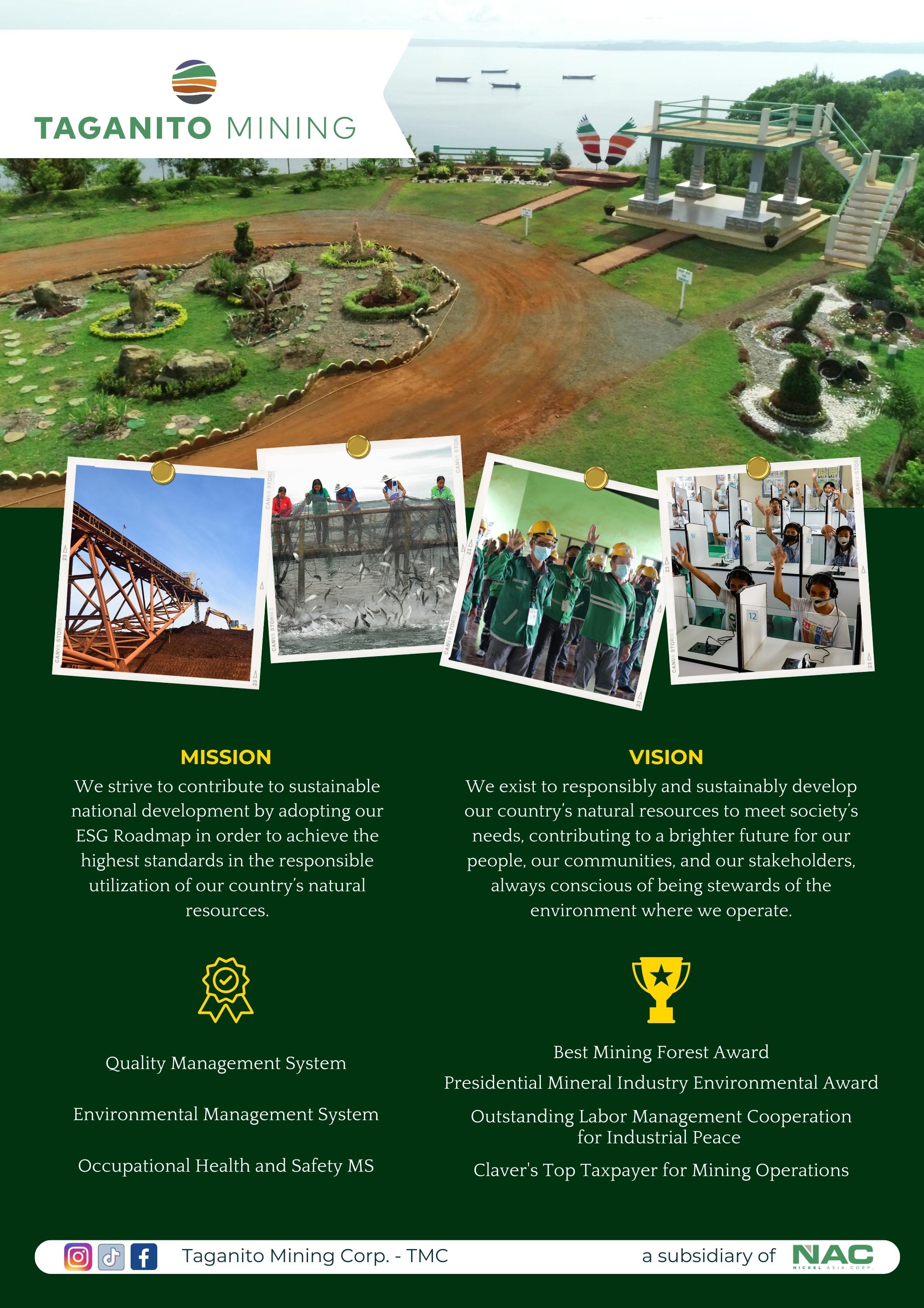

TAGANITO MINING CORPORATION

Supplies the limonite Ore (Mine waste), which contains 1.5%

Nickel and 0 10% Cobalt

Produces Mixed Sulfide, comprised of 57% Nickel and 5% Cobalt using the High Pressure Acid Leaching Technology

TAGANITO HPAL NICKEL CORPORATION NICKEL AND COBALT (MIXED SULFIDE)

METAL MINING CO., a Nickel Refinery

Conducts the final process and converts the Mixed Sulfide to 99.99% Nickel and 99.99% Cobalt.

Use as a prime component to produce Lithium batteries, electric vehicle batteries, mobile phones, steel products for largest skyscrapers, and many more.

A rare element utilized in lighting applications, aerospace, sports equipment, robust alloys and many other uses.

Utilized in the manufacturing of stainless steel, chrome plating, the production of corrosion-resistant superalloys, nichrome, and various types of paint

Rock Whisperers and Hydrogen Hunters: The New Explorers

Bridging the Jobs-Skills Mismatch in PH: Women in Mining and STEM Education

The PH Mining Industry Over The Last 15 Years: Dynamic Yet Often Turbulent

Making Mining’s SDG Pivot Work

The Race for Critical Minerals: Will the Philippines Be Left Behind?

PH Rises to Top 16 Rank in Fraser Institute’s Annual Mining Survey

PMEA Industry Updates, GRX 25 in Brisbane, and Courtesy Visits

Interview with Orica’s Newest Area Business Manager for Philippines

Marcos Signs New Fiscal Regime for Large-Scale Mining

Mining Rebound: Policy Shifts, Economic Impact, and the Role of Geotechnical Risk Management in the Philippines

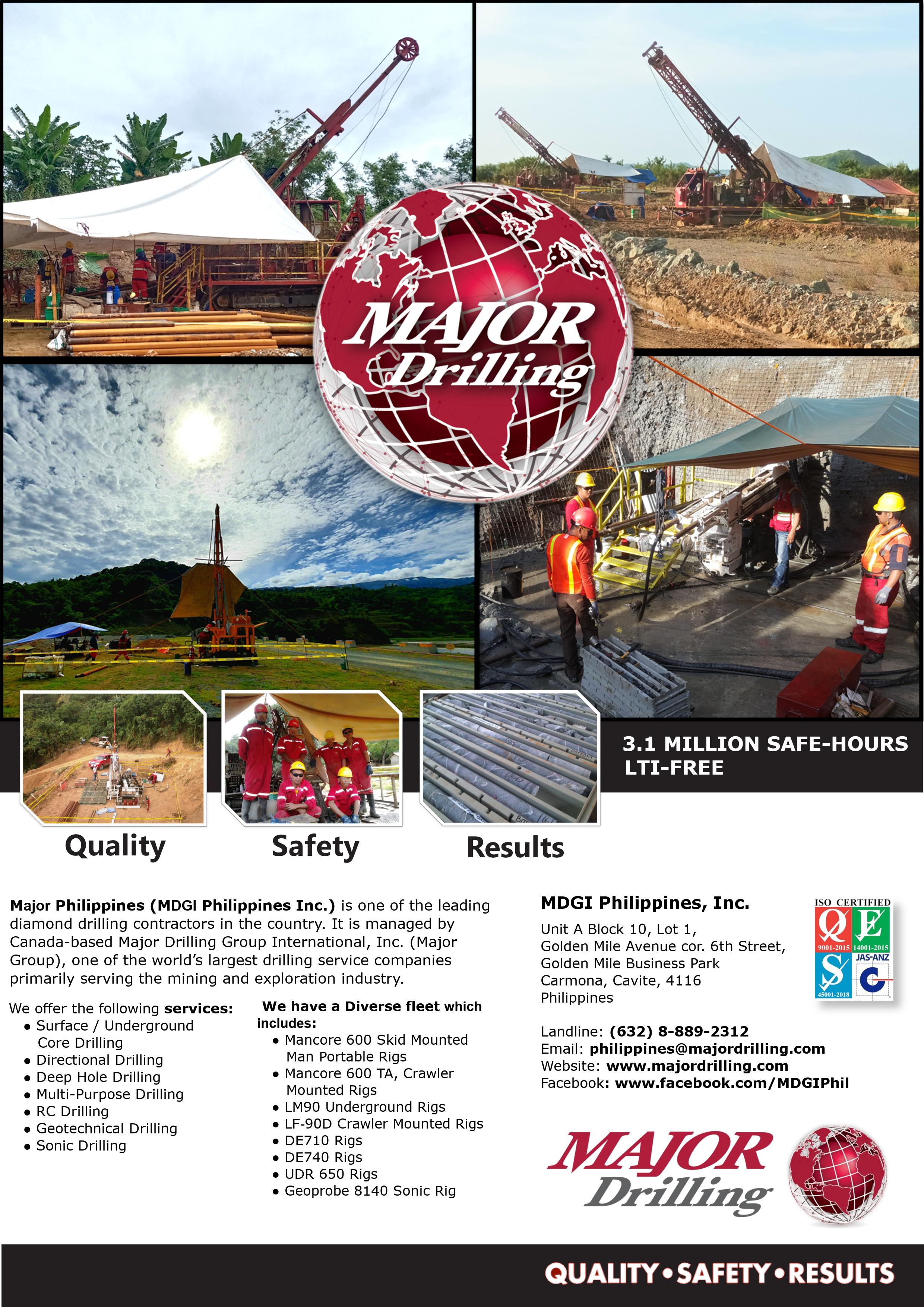

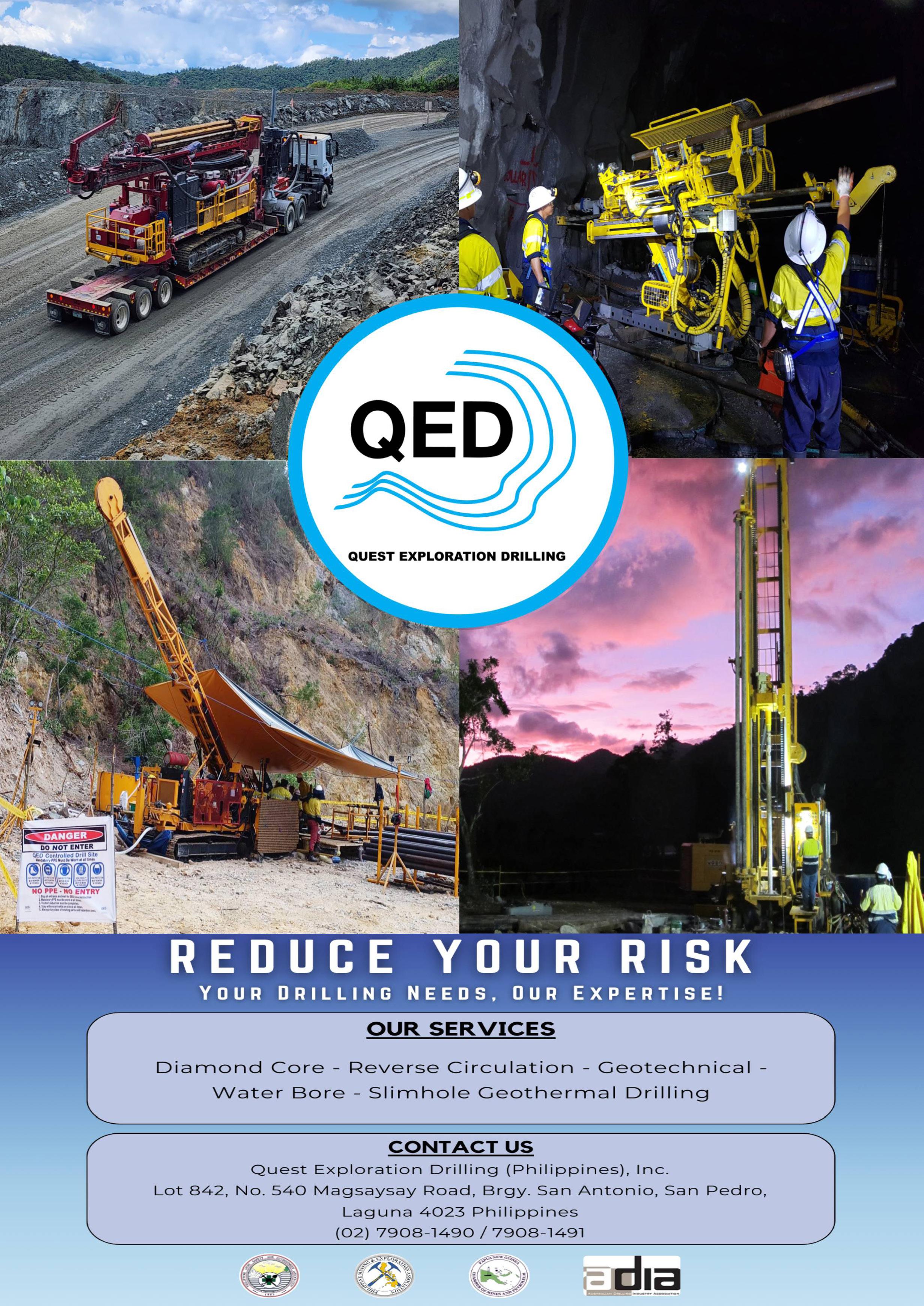

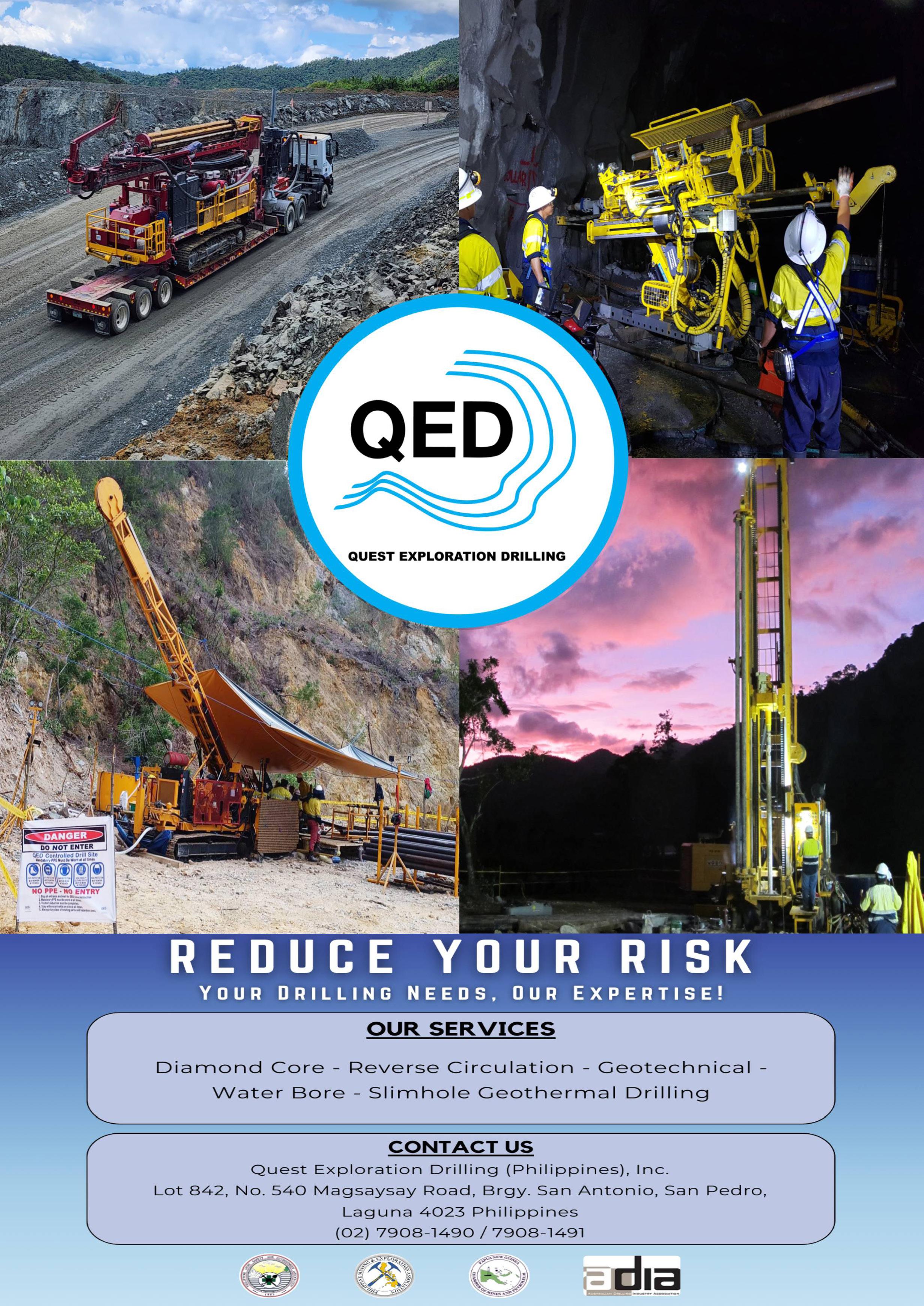

Successful Collaboration: Epiroc Philippines Delivers Technical and Product Training to Quest Exploration Drilling

Tramp Metal Protection in a Smaller Footprint

Advancing Mining Operations with Safer Devices in the Field

Rethinking

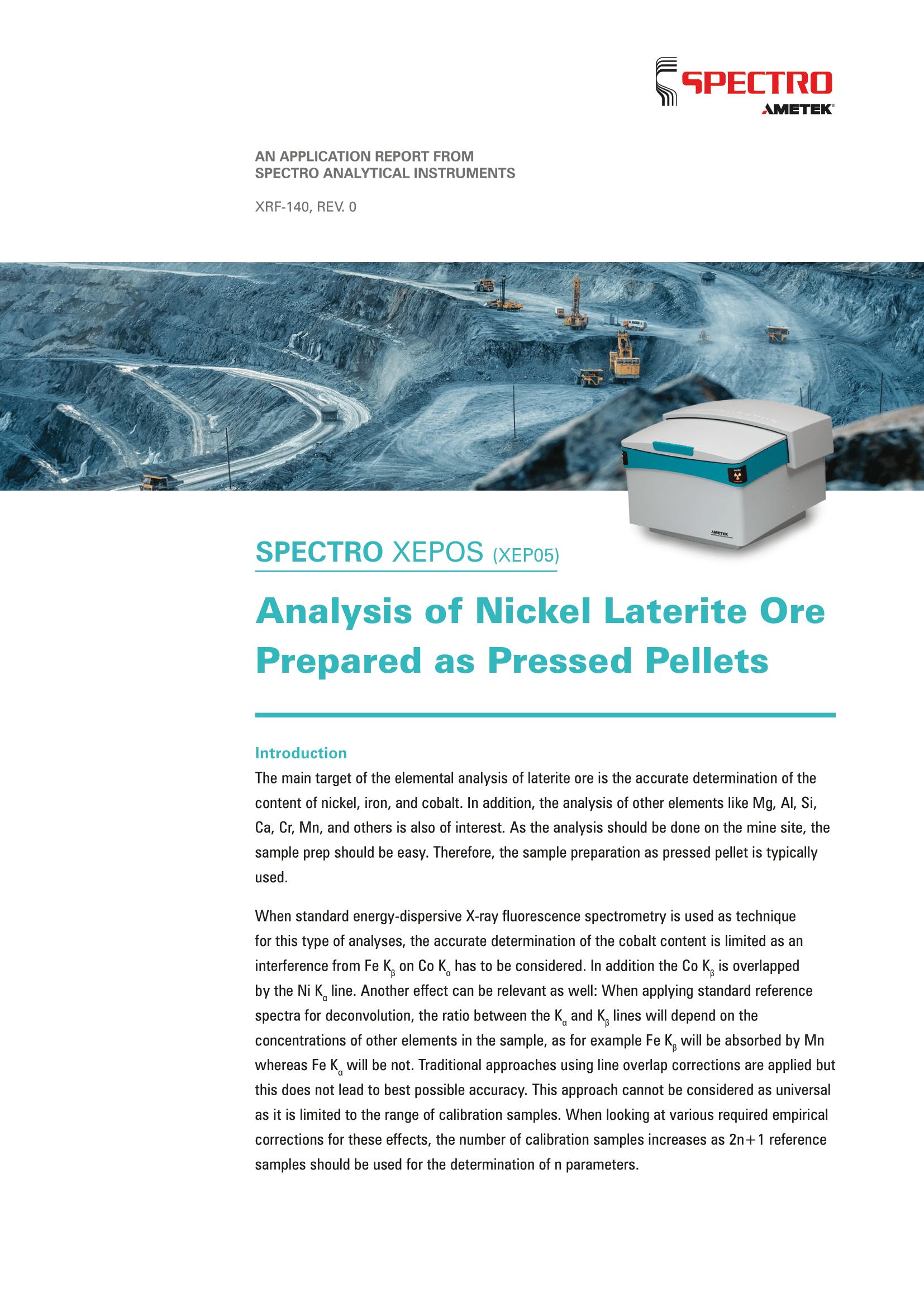

QES: Why Over 90% of PH Nickel Ore Mining Labs Trust the Spectro Xepos ED-XRF

36 Scholars Complete TMC-Led Heavy Equipment Operation Training

Beyond Compliance: TVIRD Group Exceeds TSHES Audit

Extending Asset Life in Mining and Quarrying with Belzona Solutions

OceanaGold Pioneers New Mine Rehabilitation Approach, Cutting Costs Per Hectare from PHP3.5M to PHP1.3M or 63%

DPWH, JICA Celebrate Successful Connection of Southbound Tunnel in Davao Bypass

President Marcos Jr. Highlights Infrastructure Gains, Vows Continuity in 4th SONA

EEI Corp. Bags P15.7-B Deal to Build Southeast Asia’s Largest MICE Hub in Pasay

Empowering the Philippines’ Construction & Mining with DANAOS ProjectVIEW ERP: Localized Compliance, Global Excellence

Powering PH Mining with Confidence

From Telematics to Cold Chain Intelligence: Safeguarding Resources in PH

Why Sinopulse Chooses German High-Speed Hose Braiding Machines

THPAL Boosts Communities with Education Support, Livelihood Opportunities in the PH

Maximize Tire Life, Minimize Costs Insights from Higantis and Maxam Tire

Powering Progress: An Australian-Philippine Alliance

TMC Showcases Local Products at Flagship ‘Tabo sa Minahan’

A Trusted Name in Rubber and FRP Manufacturing

TVIRD Stages Arbor Day 2025 in Balabag

The Expert in Drilling Consumables

VBL: Built for the Toughest Jobs, Trusted Worldwide

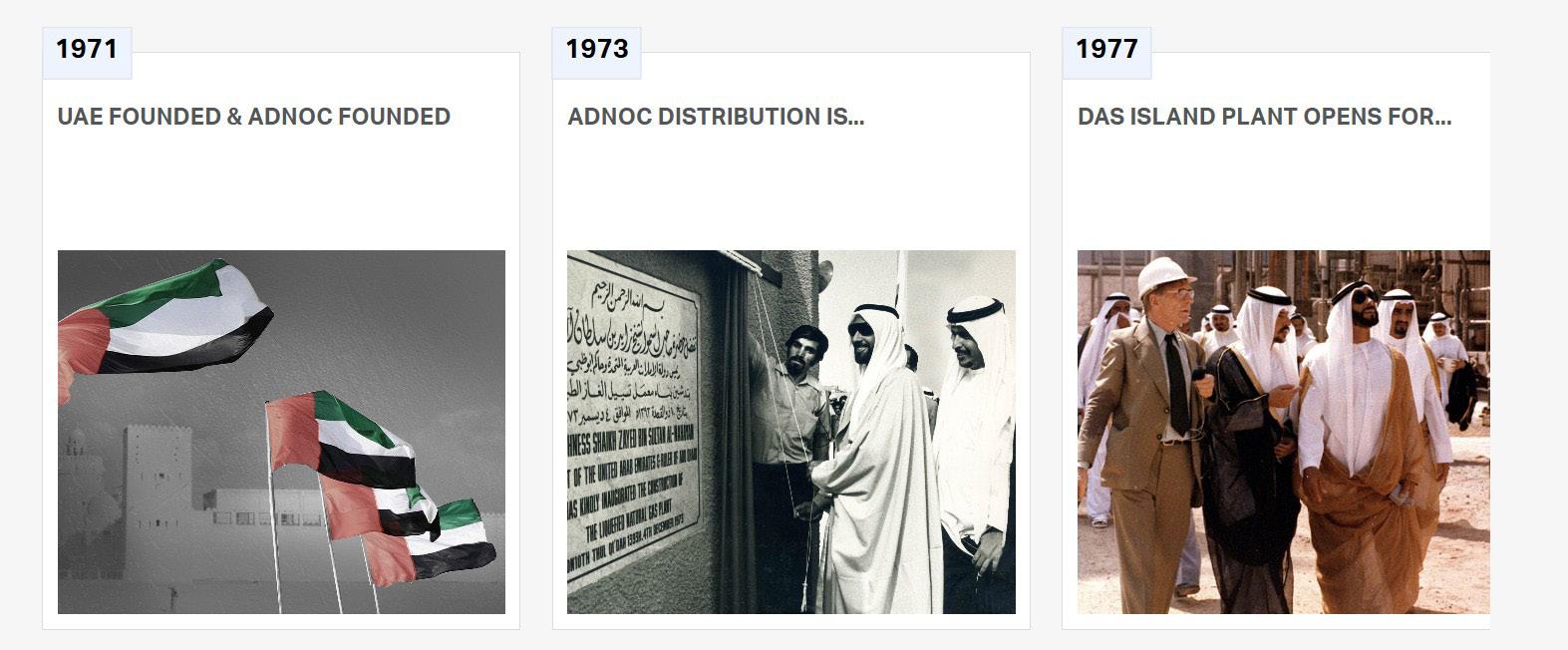

ADNOC Debuts in PH Through Partnership with PhilChamp

Connect, Collaborate, Innovate: Australia’s Mining Mission Calls on PH Companies

GPCCI, German Embassy Host Green Jobs Forum

Prime Energy CEO Highlights Malampaya’s Role in Powering Filipino Communities

PSEM Caraga Chapter Holds First-Ever Mining Symposium

Every Purchase of 1 x DX800 Comes with Exclusive Discounts & Freebies

Worth Up to USD 30,000!

Why Choose the DX800?

The Ranger DX800 is engineered for high-performance surface drilling in the most demanding environments. With unmatched reliability, productivity, and efficiency, it ensures a smart investment for various operations.

Sandvik offers a bundle deal for every DX800 purchase including:

10% OFF Preventive Maintenance Kits & Labor

15% OFF Rocktools Consumables

2x FREE Field Service Dispatches per PMS Kit purchase (up to 12 total)

FREE Initial Rocktools Consumables during commissioning Labor at Cost for included services

Commissioning Support with on-site technical assistance

Estimated Savings: Up to 22% or nearly USD 30,000

Ready to Drill Into Value?

Contact your Sandvik representative today to secure your DX800 bundle deal and elevate your operations with unmatched support and savings S can the QR code now!

Marof his myriad inflation and against economic from the hard put consumer public a tight result declincosts further dollar fuel for materials more for debt the proand the Government facilienergy utiliAmong recovery are conflict weaker about by intercountry. businessmoney and and serespecially economic globally. groups, the mining sustainable refrom the pandemic and slowdown. investments for underscored Secreassured the commitment to environment Diokno also expects adhere to practices. He strike environand supsocioeconomic Marcos ecomedium-term fissucceed mining

By Fernando Penarroyo

Iwritten by: FERNANDO PENARROYO

Fernando “Ronnie” S. Penarroyo specializes in Energy and Resources Law, Project Finance and Business Development. He is also currently the Chair of the Professional Regulatory Board of Geology; the government agency mandated under law to regulate and develop the geology profession. He may be contacted at fspenarroyo@penpalaw.com for any matters or inquiries in relation to the Philippine resources industry and suggested topics for commentaries. Atty. Penarroyo’s commentaries are also archived at his professional blogsite at www.penarroyo.com

Philippine Resources is published independently for executives in Philippine mining, construction, resources, and associated business sectors.

Publisher Elizabeth Galura

Consulting Publisher Greg Brimble

Editor James Galvez

Consulting Editor Jimbo Gulle

industry would have to perform well. During the Philippine Economic Briefing in New York where President Marcos delivered a keynote message to American investors, Diokno emphasized the administration’s commitment to help maximize the mining sector’s potential in attracting more foreign investments.

n our ever-evolving world, the demand for minerals and energy is growing faster than ever. From the smartphones in our pockets to the electricity powering our homes, these natural resources play a vital role in our everyday lives. But finding them—hidden deep underground or beneath the ocean floor—is no easy task.

The mining industry considered the Duterte administration as another wasted era for realizing the full economic potential of the sector. The Marcos government inherited a mining industry reeling from the anti-mining stance of the previous administration with the appointment of the late Regina Paz Lopez, a staunch anti-mining advocate, to head the Department of Environment and Natural Resources (DENR). The appointment was bitterly opposed by the industry resulting in Lopez’s rejection by the powerful bicameral Commission on Appointments.

cutting-edge research, practical implementations, and industry shifts. We’ll explore some of the latest techniques scientists and engineers are using to discover new sources of minerals and energy. Don’t worry—no geology degree is required! This article will break it down in simple, easy-to-understand language so we can understand just how incredible and important these discoveries really are.

accurately. This technology saves millions of dollars and years of guessing because there are fewer random diggings and smarter decisions .

Sales and Marketing Manager

Matt Brimble +63 927 721 6622 Matthew@philippine-resources.com

Account Manager

Merianjay Fallan +63 992 371 7060 merian@philippine-resources.com

Administration

Cecilia Pamular +63 917 308 1971 cecille@philippine-resources.com

During her term, Lopez ordered the closure of mining operations and initiated a national mine audit conducted on behalf of the Mining Industry Coordinating Council. Mining stakeholders described the three years of closure of these companies as “arbitrary” and claim that at that time, the industry practically “gasped for breath.”

Fortunately, science and technology are giving us powerful new tools to make searching easier, safer, and more accurate. Understanding new mineral and energy exploration techniques is important because the relatively easy-to-find resources—like oil, gold, and copper—are already being used up, and the world needs cleaner and smarter ways to discover what’s left. Old methods of exploration, like drilling everywhere or clearing forests, are expensive, slow, and often harmful to the environment.

With COVID-19 bringing down the economy on its knees and a worsening economic fallout becoming inevitable, Duterte issued Executive Order No. 130 in April 2021, lifting the nine-year moratorium on the granting of new mining permits. Finally in December 2021, the Duterte administration succumbing to economic pressure, lifted the ban on open-pit mining.

New technologies, like using satellites, artificial intelligence (AI), and sensors that “listen” to the ground, help scientists find resources faster, cheaper, and with less damage to nature. By learning how these new techniques work, we can support energy sources that are cleaner, protect the planet, and ensure we still have the minerals needed for things like electric cars, solar panels, and everyday gadgets in the future.

Recent research introduces workflows using AI to model copper prospectivity and refine targets. Presently, roughly more than 70% of mineral exploration projects leverage AI-powered data analysis for site selection and resource estimation. Machine learning applied to remote sensing like integrating satellite, airborne, and geological data, has enhanced mapping of lithology, alteration zones, and pathfinder mineral signatures.

It is well to note that at the height of the pandemic in 2021, the mining sector’s contribution to the gross domestic product

Page 8 >

Graphic Designer Bogtong Wangga

Journalists

Marcelle P. Villegas

Contributors

Patricia A.O. Bunye Fernando Penarroyo

Manila Publishing Office Suite 6, 2nd Floor Corinthian Plaza Building 121 Paseo de Roxas

Here is an overview of the latest technological trends in mineral and energy exploration—combining

Imagine you’re looking for buried treasure, but instead of digging randomly, you have a super-smart computer that can look at maps, satellite images, rock samples, and even underground sound waves to tell you exactly where to dig. That’s what AI is doing for mining, helping experts find metals like copper, lithium, and gold faster and more

Today, scientists are using advanced hyperspectral satellite cameras that can see more than just colors; they can detect the unique “light fingerprints” that different minerals reflect. This helps spot what’s in the ground just by looking from space. Some high-tech companies are going even further. They’re launching small satellites, placing sensors on the ground, and using AI to collect and analyze data.

Legaspi Village

Makati City, Philippines 1226 Phone +632 8251 5599

Digital Online Edition www.Philippine-Resources.com

On the Cover: Photos courtesy of RDCL

New Leopard DI650i down-the-hole surface drill rig offers long-term productivity and superior stability with robust and reliable main components – seamlessly integrated with state-of-the-art technical solutions. Scalable automation, easy maintenance and outstanding movability are the features that make Leopard DI650i a premium product, which is an honor to own.

Leave your paw print and enjoy the smooth, efficient ride.

Explore the new Leopard DI650i: ROCKTECHNOLOGY.SANDVIK/DI650 i

Satellites in space and drones flying overhead are now like “robot eyes” scanning the Earth for clues about what’s underground. Satellites can see patterns in rocks that the human eye can’t. Drones fly low over the ground with special cameras and sensors that “sniff

out” changes in rocks or soil. This technology allows explorers to scan vast areas quickly, especially in places that are hard to walk on like dense forests or deserts, useful even in difficult terrain and across larger areas.

Imagine a drone that can take off and hover like a helicopter but then fly forward like an airplane. That’s what a hybrid multirotor unmanned aerial vehicle (UAV) does. It gives you the best of both worlds: the flexibility of hovering and the long-range power of flight. Hybrid multirotor UAVs with optimized sensors extend airborne operations up to six times longer than traditional drones, improving precision data collection while minimizing costs and environmental impact. By placing special sensors on the surface, explorers are also listening to tiny natural vibrations in the Earth —like a super-sensitive stethoscope — to create detailed 3D maps of what lies underground, even as deep as 2.5 kilometers without digging. Instead of drilling hundreds of holes to “see” underground, scientists now listen to tiny vibrations called ambient noise tomography. All of this helps explorers find mineral-rich areas more accurately and safely, while cutting down on the need for risky and expensive drilling.

When geologists collect rock samples, they used to wait days or weeks to analyze them in labs. Now, geologists can carry handheld devices—about the size of a power drill—that can scan rocks right on the spot. These tools use techniques like X-ray fluorescence (XRF) or laser-based scanning to instantly reveal the chemical makeup of the rock. In just a few seconds to a few minutes, the device tells you exactly what minerals or metals are inside— whether it’s copper, gold, lithium,

or something else. It’s like a superadvanced metal detector that gives instant X-ray results.

Think of these machines as a super-smart barcode scanner, but for rocks. Just like a grocery store scanner instantly tells you the price and details of a product, these scanners reveal what elements are inside the rock. This means faster decisions, less wasted drilling, and more precise resource estimates.

Old mines and heaps of mining waste were once considered useless. Now, with new technology, companies can go back and recover valuable metals left in old mine tailings. Exploration is increasingly seeking value in waste and tailings, repurposing old mines to extract critical metals like tellurium, bismuth, zinc, and manganese. It’s like rummaging through old electronics and finding out that old circuit boards are filled with precious metals or finding gold in an old junkyard - eco-friendly and cheaper than starting a new mine.

At the bottom of the ocean, there are “potato-sized” lumps called polymetallic nodules that contain nickel, cobalt, and other valuable metals. New technology is being developed to allow controlled

collection of these nodules without digging or destroying the seafloor. It’s like using robotic vacuum cleaners to gently pick up scattered coins from your carpet, without ripping the carpet up.

This could be a game-changer for supplying metals for electric cars and renewable energy tech, but it’s being done cautiously to protect ocean ecosystems.

Deep-sea mining is now under active development globally, with regulatory frameworks expected to be in place by 2025. Think of it like careful underwater treasure hunting with environmental guards in place.

The Earth’s inside is super-hot. By drilling wells, we can tap into this heat to produce clean electricity called geothermal energy. But here’s the bonus - some of these underground hot waters carry dissolved minerals like lithium. New projects are combining the two: get clean energy and extract minerals from the hot water. It’s like getting two gifts from the Earth at the same time - energy and minerals, like boiling pasta and realizing you can also make soup from the water at the same time.

Geothermal energy is expanding rapidly. Major tech companies and energy firms are investing in subsurface heat projects, but serious skill gaps

exist in geoscience expertise, driving demand for trained exploration professionals. Filipino geologists who are renowned for their expertise in geothermal energy, can skillfully harness the Earth’s natural heat to power communities with precision and sustainability. Their deep understanding of volcanic and tectonic systems, combined with decades of hands-on experience, has positioned the Philippines as a global leader in geothermal exploration and development.

The mining sector is undergoing a digital revolution; automation, and integrated data analytics are being deployed broadly to enhance safety, productivity, and sustainability. Modern mines are starting to use robots, self-driving trucks, and smart sensors that monitor everything. All this information is sent to a control room where a small team watches everything like in a high-tech video game command center. This makes mining safer for workers and cuts down on mistakes and accidents. Real-time predictive maintenance, remote operations control, and cross-team data sharing are boosting operational effectiveness by a 20–30% reduction in exploration timelines and cost improvements.

10 >

Space is at a premium at the bottom of the pit. WebGen™ 200 Surface eliminates traditional scheduling constraints.

WebGen™ 200 Surface reduces exposure to geological hazards by minimizing the need for revisiting blastholes. With wireless detonation, all explosives are isolated within the blasthole, eliminating the risk of vehicle interactions with explosive components. Making it safe to transform a loaded blast into a productive haul road. orica.com/wireless

GET MORE FROM YOUR BLASTING WITH WIRELESS TECHNOLOGY

Lightning risk reduction Firing on demand Reduced exposure to geological hazards

Industry is responding with technology-integrated, sustainable, and data-first approaches. From satellite mapping to automated analytics, these capabilities shorten discovery cycles, cut environmental impact, and strengthen resilience. There is less guesswork as technology tells you where to dig; greener, exploration is becoming cleaner and less harmful to forests, rivers, and wildlife; smarter as mining is done in ways that protect the environment; sustainable as old waste becomes valuable again through recycling; faster as years of trial-and-error digging are minimized; and cheaper as there is less wasted money on bad drilling spots.

Hydrogen is the lightest and most abundant element in the universe. It is found in water, natural gas, and even in plants and animals. But here’s the catch: hydrogen gas doesn’t float around freely on Earth. It’s usually stuck to other elements, like oxygen in water. We need hydrogen to power cars, factories, and power plants without polluting the air. Planes and large ships could run on hydrogen in the future. Companies are working on hydrogen-powered engines or using hydrogen to make cleaner fuels for heavy industries. Hydrogen is a clean fuel. When you burn it, it only produces water vapor - no smoke, no CO₂ pollution.

Exploring natural hydrogen could give us a cheaper and greener source of energy that’s available 24/7, unlike solar or wind which depend on weather. Scientists have discovered that pure hydrogen gas is naturally produced deep underground. This hydrogen can slowly seep up through cracks in the Earth, kind of like natural gas or oil.

When certain types of rocks that are rich in iron deep in the Earth react with water, they produce hydrogen gas. This process happens in places like ancient volcanic areas, underneath old ocean floors, and tectonic

plate boundaries. Like a treasure hunt under the earth, scientists use several clues to look for it.

In some places, hydrogen gas seeps up naturally through the soil, kind of like tiny invisible “fountains.” Scientists use portable gas sniffers or take soil gas samples to detect these hydrogen leaks. Finding a seep can be a clue that a larger hydrogen pocket is hiding underground. Hydrogen often forms where certain types of ironrich rocks called ophiolites react with underground water. Scientists study maps, satellite images, and rock samples to locate areas with these special rocks.

Scientists use tools that send sound waves, electric currents, or magnetic signals into the ground. By seeing how these signals bounce back, they can “see” underground structures and guess where hydrogen might be trapped. If the clues are strong, companies drill small test wells to check if there’s enough hydrogen to be worth collecting. This is like how we explore oil or natural gas, but the wells for hydrogen are usually smaller and simpler.

The Philippines is now at the early but exciting stage of exploring natural underground hydrogen resources, after a significant discovery in Zambales. In this area, scientists found a natural seep where hydrogen gas is leaking from beneath the ground at a remarkable rate—about 808 tons per year, which is considered one of the largest natural hydrogen flows ever recorded worldwide. This seep is found in an area rich with ophiolite rocks, which the country has plenty of because of its geological features. This discovery has put the Philippines on the global map as a potential key player in the emerging hydrogen energy sector.

Recognizing this opportunity, the Department of Energy (DOE) has opened specific areas for hydrogen exploration in Zambales and Pangasinan, where similar rock formations exist. Several companies have submitted bids to explore these zones, and the DOE has been actively conducting preliminary surveys to assess the environment and geology. These early-stage activities include soil

gas sampling, mapping seep sites, and preparing technical guidelines for future exploratory drilling.

The DOE is also initiating training programs to equip Filipino scientists and engineers with the skills needed for hydrogen exploration, signaling a serious commitment to develop local expertise in this new field.

While no large-scale hydrogen production is happening yet, the Philippines is moving swiftly to build a foundation for it. The next steps involve granting exploration permits, performing test drilling, and confirming whether larger underground reservoirs of hydrogen exist beneath the surface. If successful, this could lead to pilot projects that produce clean hydrogen for local energy use, particularly in off-grid rural areas.

The exploration efforts in Zambales and Pangasinan are also seen as “test cases” that could open other ophiolite-rich regions in the Philippines, potentially making the country a pioneer in natural hydrogen energy development in Southeast Asia. Thanks to years of digging into ancient ophiolites, Filipino scientists may have just found the rocks that burp out clean hydrogen turning old ocean crust into tomorrow’s energy goldmine.

As the world races towards cleaner and more sustainable energy solutions, understanding and adopting new mineral and energy exploration techniques has never been more crucial. Innovations like AI-driven mineral mapping, drones that “see” underground, instant rock analyzers, and natural hydrogen exploration are revolutionizing how we discover and harness Earth’s resources.

The Philippines has rugged terrain and extensive forest cover. AI-driven satellite imaging and drone-based surveys are increasingly useful for identifying mineralized zones without heavy ground disturbance. This helps reduce the environmental footprint of early-stage exploration.

By adopting smarter targeting, Philippine mining firms can reduce the high risk and costs of

exploration, making projects more attractive to investors, reducing the need for large-scale ground clearing during exploration, and helping address community and environmental opposition. This is important in a country where mining often sparks social resistance, as it could accelerate the development of critical mineral supply chains while improving the sector’s social acceptability. Who knew that listening to rocks and chasing steam could turn geologists into the hottest hunters of the 21st century?

References

Barker, Miranda, Innovation can disrupt the mining industry. These sustainable start-ups are leading the way, World Economic Forum, 29 Nov 2024, https://www. weforum.org/stories/2024/11/13innovations-making-the-miningand-metals-industry-moresustainable/ Bishop, Sophie, 7 Technological Innovations Transforming the Mining Industry, USC Consulting Group, 12 February 2024, https:// usccg.com/blog/7-technologicalinnovations-transforming-themining-industry/ Leonida, Carly, Welcome to the age of smart mineral exploration, The Intelligent Miner, 06 June 2024, https://theintelligentminer. com/2024/06/06/welcome-to-theage-of-smart-mineral-exploration/ Peachey, Caroline, How is technology shaping minerals exploration? Mining Technology, 17 April 2025, https://www. mining-technology.com/features/ how-is-technology-shapingminerals-exploration/

Fernando “Ronnie” S. Penarroyo specializes in Energy and Resources Law, Project Finance and Business Development. He is also currently the Chair of the Professional Regulatory Board of Geology, the government agency mandated under law to regulate and develop the geology profession. For any matters or inquiries in relation to the Philippine resources industry and suggested topics for commentaries, he may be contacted at fspenarroyo@penpalaw.com. Atty. Penarroyo’s commentaries are also archived at his professional blogsite at www.penarroyo.com

Ichallenge: the mismatch between graduates’ skills and the available jobs.

At this event, attended by the Secretary of Education, the Director General of the Technical Education and Skills Development Authority (TESDA), the Chair of the Commission on Higher Education (CHED), industry leaders and heads of educational institutions discussed the need to reshape how education is delivered and ensure that Filipino graduates are job-ready.

In his keynote address, Dr. Cielito Habito, former Secretary of the National Economic and Development Authority (NEDA, recently renamed the Department of Economy, Planning, and Development or DEPDev under Republic Act No. 12145), delivered some disturbing statistics, including that college graduates now account for the single largest segment of the unemployed at 38.2%. He emphasized the need for integrated education and workforce development planning, closer coordination in curriculum design, and better anticipation of future skills demand.

written by: PATRICIA A. O. BUNYE

Patricia A. O. Bunye is the Managing Partner of Cruz Marcelo & Tenefrancia where she heads its Mining & Natural Resources Department and Energy practice group. She is also the Founding President of Diwata-Women in Resource Development, Inc., a non-government organization advocating the responsible development of the Philippines’ wealth in resources, principally through industries such as mining, oil and gas, quarrying, and other mineral resources from the earth for processing.

Equally, if not more disturbing was the recurring observation that the concerned agencies, namely the Department of Education, TESDA and CHED, have not been properly coordinating.

Simply put, until recently, they were not talking to each other. Fortunately, these agencies have come to the realization that closer inter-agency collaboration is required to achieve stronger industry alignment and policies that improve graduate employability.

UniEd, for its part, is batting for industry certifications,

microcredentialing [i.e., earning short, modular certifications for specific, in-demand skills, enabling workers to upskill, reskill, gain formal recognition for competencies, and advance in their careers without completing an entire degree or lengthy course], apprenticeship and on-thejob training, senior high school immersion, and skillsbased continuing professional development courses to specifically address the jobs–skills mismatch.

An Ernst & Young paper entitled “Can ASEAN move forward if women are left

behind?” observes that, with 40% of global employers today reporting talent shortage, education systems need to prepare graduates with relevant skills.

In ASEAN, the skills gap is largely marked by a shortage of technical knowledge. Science, Technology, Engineering and Mathematics (STEM) education is therefore particularly relevant given rapid technological shifts and the rise of industry automation, alongside the emphasis on infrastructure development in many

emerging ASEAN economies.

In the Philippines, the skills gap is very much pronounced with the country having the lowest gender parity in the region. It records the widest STEM workforce gender gap in AsiaPacific, with women in just 36.3% of STEM roles, compared to nearly 59% in non-STEM fields.

Although around 41% of STEM graduates are women, only 36.6% enter the STEM workforce within a year from graduation.

The decline continues as careers progress. Employers cite that women are less prepared due to fewer internships or technical opportunities. Many midcareer women opt out due to caregiving demands or biased perceptions.

Mining is one industry that would benefit from a closer

look at how STEM Education may help close the jobs-skills mismatch, especially for women.

The convergence of mining and STEM offers unique opportunities to counteract gendered mismatches:

• Empowerment via technical training: Tailored STEM education programs could equip women miners with essential competencies to open pathways to formal, technical roles.

• From informality to formal inclusion: Launching bridging programs that connect women in small-scale mining to technical certification and STEM jobs can reduce informal vulnerabilities and prepare them for emerging green technologies in mining.

• Visibility and leadership: Mentorship programs and

representation are required to boost women in the workforce. Highlighting female engineers, geologists, and other female leaders can inspire younger women to pursue both STEM and mining careers.

In the aforementioned Ernst & Young paper, Ambassador Delia Domingo Albert, Chairman of Diwata-Women in Resource Development, Inc., noted that “(T)here are horizontal gaps that consist of development gaps between and among the member countries, as well as gender equality gaps. There are also the vertical gaps between women who are well-educated and have better access to leadership roles and those who have fewer possibilities and are stymied by economic and social circumstances. These gaps hinder the possibilities for leadership roles.”

STEM Education may help

close this vertical gap through, among others, better designed curricula to anticipate both current and future skills demands; targeted technical training; and more vibrant academe-industry exchanges [with teachers immersing themselves by working in firms to improve their own skills and ‘real world’ application of what is being taught].

STEM education is also the backbone of a responsible, sustainable, and competitive mining industry in the Philippines. It ensures that local talent can fill technical roles, reducing reliance on foreign experts, and also fosters innovation in exploration, extraction, safety, and sustainability.

With these institutional shifts, and reimagined narratives, we can create pathways where women not only participate, but thrive, in the mining and STEM sectors.

Recognized as one of the leading construction and engineering firms in the Philippines with more than 90 years of experience and a proven track record, EEI Corporation offers excellent and quality engineering and construction services. Backed by top industry ratings and certifications, we are a trusted construction partner and have established strong brand equity in the construction services sector, where we currently serve and compete in four primary industry verticals - buildings, infrastructure, heavy, and light industry.

Truflo Pumps partners with Power Systems Inc.

Dewatering Pumpsets

Repairs and Servicing OEM Parts

written by: JIMBO GULLE

Over the past decade and a half, the Philippine mining industry has experienced a dynamic and often turbulent journey shaped by evolving government policies, environmental activism, shifts in global commodity markets, and new technological and economic priorities.

From 2010 to 2025, the sector has witnessed sweeping regulatory reforms, the rise and fall of major mining projects, highly publicized environmental controversies, and a renewed focus on mining’s role in the green energy transition.

Your Philippine Resources Journal has witnessed and chronicled these events over the last 15 years, and as we celebrate our anniversary in this issue, this narrative hopes to unpack the key events, policies, and trends that have defined the PH mining landscape during this pivotal period.

The start of the 2010s saw heightened optimism within the Philippine mining sector. Policymakers promoted mining as a pillar of national industrialization, encouraging value chain development and community-based mining initiatives. The spotlight fell on projects like Xstrata’s Tampakan copper-gold development, which promised to catapult the country into the ranks of leading mineral exporters. However, these ambitions quickly ran into strong headwinds. Environmental groups and local communities

intensified their campaigns against large-scale mining, culminating in South Cotabato’s enforcement of a provincial open-pit mining ban in 2011, which effectively stalled the high-profile Tampakan project (now under Sagittarius Mines Inc. or SMI).

National debates over mining’s true social and environmental costs gained traction, with the Senate holding hearings and grassroots campaigns like “No to Mining in Palawan” galvanizing public opinion.

In 2012, President Benigno Aquino III issued Executive Order 79 (EO 79), a landmark policy that imposed a moratorium on new mining agreements while calling for stricter environmental regulations and the rationalization of the sector.

EO 79 signaled a major policy pivot, prioritizing responsible mining practices and environmental safeguards over unfettered industry

expansion. The moratorium brought new investments to a halt, and by 2013, the industry’s contribution to GDP had declined, with mining companies facing mounting criticism for pollution, deforestation, and community displacement. Despite these headwinds, the sector maintained a degree of resilience. By 2014, metallic mineral production reached 138.6 billion, with nickel emerging as the country’s leading export mineral. The mining

Don’t spend more on tailings than you have to.

Weir’s unmatched technology and expertise means you can find a solution that’s built to your operational and site requirements. We’ve reduced customer energy consumption by 51%, average water usage by 76% and lowered TCO all while safely improving the stability of tailings and reducing the tailings footprint. Plus, we can even help re-purpose waste into useful materials for dam wall construction and backfill that saves valuable resources and increases efficiency.

Now it’s your turn to re-think tailings with a Weir tailored solution. www.global.weir/rethink_tailings

< Page 18

industry paid 21.4 billion in taxes that year and began expanding environmental and social development programs in response to growing scrutiny.

In 2015, investments rebounded to nearly US$1 billion, and operations at Didipio (under OceanaGold), Toledo (Carmen Copper), and Coral Bay (Rio Tuba) highlighted the sector’s ongoing economic relevance.

The Philippines also became a candidate member of the Extractive Industries Transparency Initiative (EITI), reflecting a new emphasis on accountability and global best practices.

A dramatic turning point arrived with the appointment of Gina Lopez as Secretary of the Department of Environment and Natural Resources (DENR) under the Duterte administration in 2016.

Lopez launched an unprecedented nationwide audit of mining operations, prioritizing ecological integrity and community welfare above industry profitability. Dozens of mines were suspended or ordered closed for failing environmental standards, and a national ban on openpit mining was imposed.

The reforms, while applauded by environmentalists and many local communities, sowed uncertainty throughout the industry and triggered a wave of legal and political challenges. By 2017, Lopez’s tenure had resulted in the suspension of five major operations and the closure of 23 others.

While the value of metallic production remained stable due to global price increases,

the industry grappled with regulatory unpredictability and the prospect of further interventions. The DENR also mandated full EITI participation, reinforcing the administration’s commitment to transparency.

However, Lopez lasted only one year in the post -and died in 2019 from brain cancer. She was succeeded at the DENR by former military general Roy Cimatu, who continued the Duterte government’s holding pattern on mining.

With Lopez’s departure, the regulatory climate gradually stabilized. Year 2018 saw a rebound in mining production, as the sector deepened its commitments to environmental, social, and governance (ESG) standards in response to both domestic activism and international investor expectations. However, opposition to largescale mining remained potent, with ongoing protests and calls for stricter oversight.

By 2019, the moratorium from EO 79 was still in effect, and exploration budgets stayed low. Major projects like Tampakan and Silangan (under Philex) continued to languish in regulatory limbo. The arrival

of the COVID-19 pandemic in 2020 dealt another blow, disrupting operations and supply chains.

Page 24 >

In a market flooded with GOEMs and mass-market products, here’s how to spot the difference:

In a market flooded with GOEMs and mass-market products, here’s how to spot the difference:

• Onan green color

• Onan green color

• “Cummins Power Generation” logo

• “Cummins Power Generation” logo

• Certified Stamford alternators with anti-counterfeit features

• Certified Stamford alternators with anti-counterfeit features

• One Cummins - unified sales support, warranty and service through Cummins’ global network

• One Cummins - unified sales support, warranty and service through Cummins’ global network

Contact us today!

Contact us today!

Cummins Sales and Service Philippines, Inc.

Cummins Sales and Service Philippines, Inc.

Tel: +63 2 7717 8165

Tel: +63 2 7717 8165

Email: csspi@cummins.com

Email: csspi@cummins.com

www.cummins.com

www.cummins.com

< Page 22

Nevertheless, mining still contributed 102.3 billion to the national GDP, with nickel maintaining its status as the top export mineral. Notably, Social Development and Management Program (SDMP) funds were redirected to support pandemic relief efforts in mining communities.

A watershed moment came in 2021, when Executive Order 130 (EO 130) lifted the nine-year moratorium on new mineral agreements, signaling a more investmentfriendly posture while retaining environmental safeguards.

This policy reversal was driven in part by the growing global demand for so-called “green metals” such as nickel and copper, essential for electric vehicles (EVs) and renewable energy technologies. Gold and nickel production surged, and the industry began to recover from years of stagnation.

In 2022, the government lifted the open-pit mining ban, further encouraging investment. The DENR promoted exploration for critical minerals, and exports soared to US$7.53 billion.

By 2023, the value of metallic production reached 249.7 billion, with 59 operating metallic mines and a strong focus on ESG. The DENR committed 387.95 billion to environmental programs, reflecting the sector’s newfound emphasis on sustainability and social responsibility.

As President Ferdinand Marcos Jr. took office, mining was explicitly prioritized as a key component of economic recovery and the national energy transition. Policymakers emphasized downstream mineral processing, seeking to capture greater value domestically rather than exporting raw ore.

The Mines and Geosciences Bureau (MGB)

under the DENR projected a strong outlook for the sector, buoyed by international demand for minerals critical to decarbonization. By 2025, mining was recognized as essential to the Philippines’ green technology ambitions. Nickel demand soared in response to the global EV boom, and draft fiscal reforms proposed tiered royalty schemes to balance government revenue with investor appeal.

The long-stalled Tampakan copper project was once again under consideration for launch in 2026, symbolizing the sector’s renewed confidence and strategic importance in a rapidly changing world.

Throughout this period, several overarching trends defined the local mining sector. Policy volatility— marked by alternating waves of restriction and liberalization—had profound impacts on investor sentiment and project viability.

Environmental scrutiny

intensified, with audits, suspensions, and ESG compliance becoming central to mining operations, especially from 2016 onward. The industry’s role in the global green transition brought renewed focus on nickel and copper, transforming them into strategic assets.

Finally, post-2021 reforms and global market dynamics triggered a revival in investment and exploration, as the Philippines positioned itself to supply critical minerals for a decarbonizing world.

The trajectory of the PH mining industry over the last 15 years illustrates a complex interplay between resource development, environmental stewardship, social accountability, and economic opportunity.

As the sector looks ahead, its continued evolution will depend on the delicate balancing of these priorities in the face of both domestic challenges and global shifts – and your Philippine Resources Journal will be here, ready to chronicle these changes.

On July 4, 2025, I sat in a crowded forum in Quezon City as the Mines and Geosciences Bureau (MGB) hosted the Department of Environment and Natural Resources’ (DENR) policy direction. The atmosphere was subdued. No questions, no applause lines. Yet the rollout deserves a closer look, not for its promises, but for what it might enable.

Signed in February by former Secretary Ma. Antonia Yulo - Loyzaga, DENR Administrative Order No. 2025-10 requires all Social Development and Management Programs (SDMPs) of mining firms to align with the United Nations Sustainable Development Goals (SDGs). SDMP is a unique legal requirement under the 1995 Mining Act and its implementing rules that compels mining firms to allocate 1.5% of their operating costs to community programs. For decades, this budget has been channeled into community projects— livelihood support here, a classroom repair there—often valuable, but not necessarily transformative. What DAO 2025-10 does is tether those pesos to something more coherent. From receipts to results.

The 2030 Agenda for Sustainable Development, adopted by 193 UN member

written by: NOEL B. LAZARO

Noel B. Lazaro is General Counsel of Global Ferronickel Holdings, Inc. He was named among the Top 5 In-House Counsel of the Year at the 2024 Asian Legal Business (ALB) Philippine Law Awards and has led his team to multiple national and regional honors. He teaches special proceedings and evidence in law schools and authors pieces for major media outlets.

states in 2015, sets 17 goals and 169 targets—from ending poverty to protecting biodiversity. Yet the UN warns of slow progress. In the Philippines, the MGB acknowledges gains in key areas but gaps in food security, climate action, and sustainability persist. Paragraph 45 of the Agenda calls on governments to work closely with local authorities.

DAO 2025-10 operationalizes that principle. It channels the SDMP budget toward tangible outcomes like access to clean water (SDG 6), better incomes (SDG 1), inclusive education (SDG 4), biodiversity protection (SDG 15), and decent jobs (SDG 8). The UN Development Programme (UNDP) urged similar reforms in its 2016 SDG-mining atlas while the Intergovernmental Forum on Mining, Minerals, Metals and Sustainable Development (IGF) has long supported this pivot.

On paper, we are catching up. But policies don’t succeed on paper alone.

In 2023, nickel miners reported spending 4.3 billion on SDMPs. They reforested 9,500 hectares, planted 4.3 million trees, and funded education and health projects. Between 2002 and 2027, nearly 28 billion in SDMP spending is projected. But impact isn’t just about inputs. Civil society

monitors—like Bantay Kita and local Multistakeholder Monitoring Teams— flag weak community involvement, poor tracking of results, and almost zero public transparency.

To make this reform real, four imperatives must guide implementation.

First, targets must be measurable. “Eradicating poverty” or “protecting forests” can’t just be slogans. The DENR must set clear indicators. How many pesos in income raised? How many hectares rehabilitated? Metrics are meaning.

Second, communities must be co-authors, not mere recipients. The 2030 Agenda says people are at the center of sustainable development. That means participatory planning, stronger local monitoring teams, and respect for Indigenous Peoples’ rights.

Third, SDMPs must be audited independently and disclosed publicly. In 2021, The Asia Foundation—a global nonprofit focused on governance in Asia—underscored how transparency builds public trust. A portion of SDMP budgets should be set aside for third-party audits. Results must be published online, accessible to everyone. SDG 16.6 calls for effective, transparent institutions.

Finally, noncompliance

must have consequences. DAO 2025-10 is a regulation, not a wish list. Failure to comply should lead to real sanctions. Without teeth, all we have are good manners. At the core of this shift is a recurring question: Will the mining governance framework finally serve the common good? In their celebrated book Why Nations Fail, 2024 Nobel laureates Daron Acemoglu and James Robinson argue that longterm prosperity depends on the nature of institutions. Inclusive institutions share power. Extractive ones hoard it. Mining, for all its potential, is often seen under extractive logics—not only in the physical sense, but in how decisions are made, and for whom.

DAO 2025-10 can change that. Not by spending more, but by spending better—linking community projects to real outcomes, and to a global development framework.

But good rules aren’t enough. It takes leadership to embed accountability into the system. And that falls on the shoulders of DENR Secretary Raphael Lotilla, who is known for his technocratic rigor and institutional calm. He doesn’t need to invent new tools. He just needs to make sure the ones we already have are tried, tracked, and trusted.

In the intensifying global race for critical minerals— crucial components in electric vehicles (EVs), renewable energy (RE) technologies, advanced electronics, and other strategic industries—the Philippines stands at a pivotal juncture in this global energy transition. With abundant reserves of nickel, cobalt, copper, and rare earth elements, the country holds in its soil the keys to the 21st-century economy. Yet, without a strategic critical minerals policy, it risks squandering this opportunity, remaining a mere supplier of raw materials rather than ascending the value chain.

A mineral is considered ‘critical’ if it is vital to a country’s strategically important economic sectors. Many governments have clear lists and strategies to safeguard these resources. An alternative to the term ‘critical minerals’ is ‘transitional minerals’ which may be strategic minerals, but not critical in terms of security and the economy. Unfortunately, the Philippines has to define which minerals are considered critical or transitional, let alone a policy that would protect its own resources and ensure a stable and sustainable supply of those minerals.

written by: REENO E. FEBRERO

Reeno E. Febrero is a senior legal officer at Global Ferronickel Holdings, Inc. He is currently pursuing his Master of Laws at the University of the Philippines, with a thesis focused on sustainable mining. He was named among the Top 8 finalists for Young Lawyer of the Year (In-House) at the 2025 Asian Legal Business (ALB) Philippine Law Awards. He also teaches taxation law and regularly contributes op-eds to major media outlets.

Nations worldwide are aggressively securing their critical mineral supply chains. A 2025 White & Case survey shows that geopolitics and economic interests—more than climate concerns—is the driving force shaping mining and metals. For instance, China’s state-backed financial institutions have poured over $57 billion in the past two decades into resource-rich countries to tighten Beijing’s grip on critical minerals. Key examples include copper and cobalt from the Democratic Republic of Congo and Peru, nickel from Indonesia, and lithium from Argentina. It now controls roughly 61% of rare earth production and more than 90% of processing capacity, according to the International Energy Agency— power that Beijing has wielded to squeeze its rivals, imposing export controls on a range of critical rare earth minerals, rattling its rival the United States.

Washington has scrambled to respond, imposing tariffs on Chinese EVs and batteries, solar panels, semiconductors, and other products. It has also diversified its supply chains by forging deals far and wide— from securing a mineral deal in war-battered Ukraine to even exploring the purchase

of Greenland, to brokering a peace deal between Rwanda and the DRC that could unlock lucrative mineral access to some of the world’s richest deposits of rare earths.

To diversify away from reliance on China and Russia, Canada and Germany signed an accord to deepen cooperation in securing critical mineral supply chains, increase collaboration on research and development, and co-fund new critical mineral projects that support a range of industries—from electric vehicle manufacturing to defense and aerospace.

Other nations are also acting decisively. The European Union’s Critical Raw Materials Act aims to shore up supply chains. In 2024, the EU signed a major agreement with Australia— home to some of the planet’s recoverable critical mineral deposits—to build sustainable and ethical critical mineral supply chains. Australia’s Critical Minerals Production Tax Incentive sweetens the deal for investors with generous tax incentives for domestic processing.

Meanwhile, Canada has committed $3.8 billion to its Critical Minerals Strategy, emphasizing sustainability and Indigenous partnerships.

The United Kingdom’s own strategy intends to position itself at the forefront of the green industrial revolution, while Brazil’s National Strategic Pro-Minerals Policy has helped it become one of the top lithium exporters. Closer to home, Malaysia even rolled out its National Advanced Materials Technology Roadmap 20212030 emphasizing the need to expand the downstream rare earth industry with the goal of creating a new source of wealth.

The Philippines, with its vast mineral wealth, is well-positioned to become a key player in this global landscape. Recent talks about joining the U.S.-Japan critical minerals agreement shows a clear willingness to engage more strategically. A free trade agreement with Canada focusing on critical minerals is in the works, and just this May, the Philippines signed a strategic pact with South Korea on critical minerals and EV development. And then, the EU, in partnership with the Department of Environment and Natural Resources (DENR), has announced the conduct of a scoping study to

< Page 28

identify potential sources of critical raw materials in the Philippines. The study aims to establish a “normative framework” that integrates the best practices of both the Philippines and the EU in promoting sustainable mining and attracting European investment.

However, to truly capitalize on its resources, the Philippines must develop a comprehensive critical minerals policy that addresses supply reliability and resiliency, sustainable and responsible practices, favorable investment climate, and stable regulatory environment.

Indonesia offers a lesson the Philippines cannot afford to ignore. Jakarta’s massive nickel production caused global nickel prices to plummet. For the Philippines, that should be a cautionary tale—highlighting the need to employ price stability mechanisms when striking future trade and investment deals.

If the Philippines wants to entice serious mineral processing investors, it must do more than showcase its mineral wealth—it must build the physical and regulatory infrastructure to move projects from vision to reality. The government has already proven it can cut red tape with the Energy Virtual One-Stop Shop (EVOSS) for energy projects. A similar mechanism could clear the bottlenecks that have long frustrated investors and stalled development.

Beyond economics, critical minerals have become a matter of geopolitics. The U.S., the EU, Japan, and other major economies are racing to secure reliable supply chains that are not dependent on China. This creates a rare window of opportunity for the Philippines to position itself as a trusted and strategic partner in the global transition

to clean energy and advanced technologies.

But to truly maximize its potential, the Philippines must move beyond the traditional extractive model. Exporting raw ore captures only a fraction of the value; the real gains lie in downstream industries such as refining, processing, and even component manufacturing for EVs, RE technologies, and electronics. A critical minerals policy that fosters domestic value addition will create jobs, strengthen industries, and insulate the economy from global price shocks.

While the DENR’s issuance of a DAO earlier this year outlining the guidelines for integrating the UN SDGs into the implementation of mining companies’ Social Development and Management Programs is commendable, a critical minerals policy should likewise prioritize sustainable mining practices. Such a policy must craft its own framework that adheres to—and ideally surpasses— international standards on sustainable development in mining, with the twin goals of protecting communities and safeguarding ecosystems.

The effectiveness of any policy will, in large part, depend on the level of trust it is able to build among stakeholders. Investors value regulatory clarity, while communities seek accountability and tangible benefits. Incorporating appropriate safeguards and participatory mechanisms would support the sustainability of the Philippines’ critical minerals policy.

At this pivotal moment, the Philippines cannot afford to remain without a clear roadmap. For the Philippines to claim its rightful place in the global critical minerals supply chain, the time to act—decisively and strategically—is now.

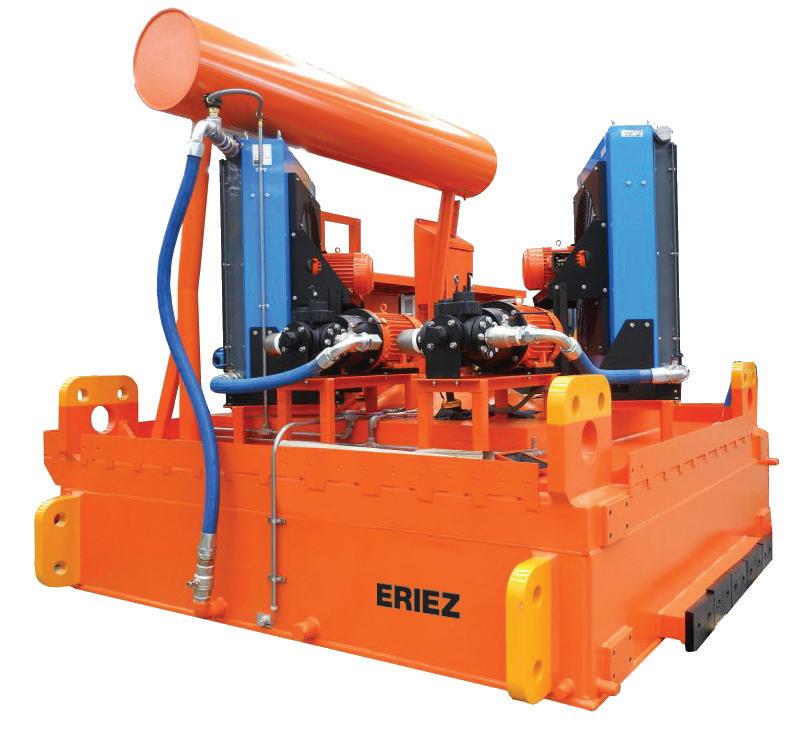

Eriez Compact Force-Cooled Suspended Electromagnets deliver powerful protection from tramp metal in a compact design, handling wet, dry, fine, or coarse applications at any burden depth. Eriez. Always the Right Choice.

Protect downstream equipment from stray ferrous metals while saving space, cutting costs, and matching the strength of larger magnets.

written by: MARCELLE P. VILLEGAS

The Philippines has surged to 16th place in the Fraser Institute’s 2024 Annual Survey of Mining Companies, a dramatic leap from 72nd out of 86 jurisdictions in 2023 in the Investment Attractiveness Index.

In the Policy Perception Index, the country also climbed to 25th out of 82 jurisdictions, improving significantly from 79th place the previous year. For the Best Practices Mineral Potential Index, the Philippines now ranks 9th out of 58, up from 41st in 2023.

The Chamber of Mines of the Philippines (COMP) hailed this performance as a major achievement, citing significant governance and policy reforms that contributed to the leap in rankings.

The Fraser Survey is a global benchmark that measures how attractive jurisdictions are for mining investment, based on perceptions of policy, governance, and mineral potential. It is widely used by investors and companies to guide exploration and investment decisions.

“The Philippines just surged to 16th place in the latest Fraser Institute Annual Survey of Mining Companies, a massive leap from 72nd out of 86 jurisdictions just last year. This dramatic improvement in our investment attractiveness ranking shows that steady reforms under the Marcos administration are paying off, especially in creating greater policy stability and making it easier to do business (EODB) for responsible miners,” COMP said.

This approach involves the cooperation of the Anti-Red Tape Authority, Department of Finance, Department of Trade and Industry, Department of Environment and Natural Resources, Mines and Geosciences Bureau, National Commission on Indigenous Peoples and the Office of the Special Assistant to the President for Investment and Economic Affairs.

“Even better, the forthcoming Mining Fiscal Regime Bill promises to lock in even more predictability and strengthen the Philippines’ reputation as a reliable destination for long-term mineral investments,” it said.

President Ferdinand R. Marcos Jr.

has consistently promoted responsible mining as a catalyst for rural development and the clean energy transition.

In a further update, COMP Chairman Atty. Mike Toledo welcomed the passage of the Mining Fiscal Regime Bill through the Bicameral Conference Committee, calling it a landmark step toward modernizing mineral taxation and improving regulatory clarity.

“The mining sector moves forward. The Bicameral Conference Committee has approved the new Mining Fiscal Regime Bill, a landmark development that modernizes how we tax and regulate one of the Philippines’ most critical industries,” Toledo said.

“As chairman of the Chamber of Mines of the Philippines and COO of Silangan Mindanao Mining Company Inc., I welcome this long-overdue breakthrough. After years of deliberation, we now have a fiscal regime that is forward-looking, investment-friendly, and aligned with global standards.”

Toledo added that the provision imposing an ore export ban was removed — a move that affirms the value of engagement between policymakers and industry in crafting pragmatic and growth-enabling

legislation.

The consolidated bill was submitted to the Presidential Legislative Liaison Office, Office of the President (PLLO-OP) on July 31, 2025.

The Fraser Institute’s Annual Survey of Mining Companies is a globally recognized standard that assesses how political and policy factors affect mining investment attractiveness across jurisdictions.

The 2024 survey was sent to 2,289 exploration, development, and mining companies worldwide and conducted from August 7 to December 15, 2024. Results were based on industry responses and evaluated how public policy factors — such as taxation, permitting, and land access — either encourage or deter mining investment.

The Fraser Institute, based in Canada, is an independent public policy think tank conducting research and advocacy on economic and policy issues globally.

Photo credit:

Photo by Tom Fisk: https://www. pexels.com/photo/yellow-excavator-2101137/

The Fluke 1551A/1552A Stik Thermometers offer intrinsically safe performance and accurate temperature logging for mining environments. Ideal for explosive zones and underground sites, they ensure compliance and traceable data without compromising safety or reliability.

Enable mining workers to perform various calibration tasks with a single device, reducing the need to carry multiple pieces of instruments. This rugged, reliable integrated communicating calibrator is ideal for calibrating, maintaining, and troubleshooting HART smart transmitters and other instrumentation.

www.fluke.com/en-ph

The Fluke 729 Pro is ideal for mining applications such as maintenance of compressed air systems, verification of hydraulic pressure sensors, and compliance checks for environmental monitoring stations—ensuring reliable performance and regulatory accuracy in demanding field conditions.

written by: MARCELLE P. VILLEGAS

PMEA President, Joey Nelson

Ayson, provided mining industry updates during the Philippine Mining & Exploration Association (PMEA) Monthly Membership Meeting for August 2025.

As of July 31, 2025, PMEA has 17 regular members, 57 associate, 29 Individual, and 17 honorary members.

He announced that on Nov. 18, 2025, PMEA will host the 8th PMEA Forum in Baguio City as part of the 71st ANMSEC. The forum’s theme is “Overcoming Challenges with Innovative Solutions”.

The Philippine mining sector, represented by PMEA and industry leaders, paid a courtesy call to DENR Secretary Raphael Lotilla to reaffirm its commitment to sustainable and responsible mining practices.

Atty. Fernando Penarroyo PRJ Columnist described the visit in his social media post, “Full circle moment. From being my constitutional law professor in law school to now leading the country’s natural resources agenda, DENR Secretary Raphael Lotilla and I reconnected and exchanged ideas on how law and policy can drive sustainable development.

I am grateful for his insights and inspired by his continued commitment to public service.”

DENR-MGB UPDATES

DMO (Department Memorandum Order) 2025-01 – Updated EIA Guidelines / Amending Provisions of DMO 2023-01 and 2023-04

- BMB (Biodiversity Management Bureau) clearance no longer required for ECC (Environmental Compliance Certificate) applications

- OSEC (Office of the Secretary) clearance downloaded to EMB (Environmental Management Bureau) Director or concerned EMB RD (Regional Director)

EO (Executive Order) 88 –Strengthening the National Task Force Diwalwal

- DENR as Chair

- Task Force oversees all mining activities in the reservation (to address

illegal operations, environmental degradation, and rehabilitation)

RA (Republic Act) 12229 - San Francisco Protected Landscape

- Signed into law on July 23, 2025

- Covers 29.6 hectares in San Francisco, Quezon (the Mulanay Watershed Forest Reserve) Critical Minerals Policy

- Under final review and will be an Executive Order to be signed by the President MGB (Mines and Geosciences Bureau) / DENR

- Benigno Cesar Espejo (MGB CAR Chief Geologist) appointed as OIC RD for Negros Island Region (NIR)

- Charlie E. Fabre appointed as OIC

RED (Regional Executive Director) for Negros Island Region (NIR)

PROPOSED NATIONAL ACTION PLAN ON BUSINESS AND HUMAN RIGHTS

- To safeguard IP rights and cultural heritage amid expanding business activities

- NCIP to draft preliminary version SUMMARY OF 2024 ECONOMIC CONTRIBUTION OF MINING

- PhP 253B in mineral output

- PhP 33B in taxes, fees and royalties

- 291,672 direct jobs

- PhP 10B in SDMP

- PhP 807M for H&S

- PhP 4B in FMR funds

NCIP (National Commission on Indigenous Peoples)

- Comments from DOJ on revised FPIC (Free and Prior Informed Consent) guidelines received and being addressed

Filminera Resources Corporation in Uson, Masbate, received their EP approvals on July 18, 2025 with EXPA (Exploration Permit Application) No. EXPA-00067-V. Ocelot Mineral Corporation in Ayungon, Negros Oriental, received their EP renewal on July 3, 2025 with EP No. EP-000017-VII.

MPSA (Mineral Production Sharing Agreement) approvals last July 2025 were given to Majestic Earth Core Ventures, Inc. in Calbayog City, Western Samar; Berong Nickel Corporation in Sitio Long Point, Aborlan, Palawan; and Bohol Limestone Corporation in Garcia Hernandez, Bohol.

MPP renewal in July 2025 was given to Graymont (Philippines) Inc. in Bataraza, Palawan.

Didipio Mine (OGPI)

- Drilling at Napartan ongoing

- New VP for Exploration Greenfields named in Nick Fitzpatrick Metals Exploration / FCF Minerals / Yamang Minerals / Woogle Corporation

- Q2 production of 19,993 oz Au (92.1% recovery)

- Access negotiations ongoing in Abra with drilling expected to commence Q1 2026

- EP approval of Dupax Project Philsaga / X64 Limited

- Q2 2025 production: 9,468 oz Au (vs 12,094 oz Au in Q1 2025)

- Tigerway Decline now connected to Levels 9, 10, 11 and 12

- JORC Resource Co-o Mine (M+I):

Geotab offers the greatest possible flexibility for any kind of project. Our device can be attached easily to any vehicle—regardless of manufacturer—and send the data to the same platform. Installation is simple, giving you visibility over the whole project and enabling you to track fuel efficiency, fuel burn, RPM, battery oil, engine health, and other key indicators.

Furthermore, through the multi-streaming function, contractors can be granted access to a database for a fixed duration. When the contract ends, their visibility to the site will cease, and the contractor can reassign it to someone else.

Our devices are built to withstand tough conditions on work sites. They are ideal for heavy mining equipment, construction, utilities, powered assets and trucks. Also, selected models are IP68 and IP69K rated with impact, water and humidity-resistant housing.

Begin your journey with Geotab today and move into a future where every trip is safe, and every operation is efficient.

With our help, you can track your valuable assets, increase equipment uptime and lower your operating costs.

For more information, visit geotab.com/apac

1.5Mt @ 8.92 g/t Au (451K oz Au)

- JORC Resoirce TSF-1 (I): 510Kt @ 1.72 g/t Au (28K oz Au

Cordillera Exploration Company Inc. (CExCI)

- Completed 11 drillholes in 2025 at Cordon Project (Dallao, Quemaldero, Gawed, Villa and Maemban prospects)

- Geophysics to follow in some areas Filminera Resources (B2 Gold)

- World Gold Council site visit this week (Documentation of best practices)

- Regional winner for TESDA 2025 Kabalikat Award (Industry Partner) Apex Mining / ISRI

- DOLE XI regional winner for Outstanding Labor-Management Cooperation

- Partnership with University of Makati for student internship training

- Currently using geothermal energy as part of its power supply.

Sagittarius Mines (Tampakan)

- Construction of mine access road ongoing

- Power source and infrastructures still under final study

- Working on some permits and approval

Carmen Copper Corporation

- Net loss of PhP 635M for H1 2025 (vs PhP 2.07B net income in H1 2024)

- H1 2025 production of 28.3Mlbs Cu metal and 7,751 oz Au

- Recently commissioned a 3ha floating solar facility producing 4.99 MW (10% of its needs)

- A 3-year redevelopment program to be completed in mid-2026 and will access higher grade ore at depths. Global Ferronickel Holdings Inc. (GFNI)

- Best Adopt-an-Estero/Waterbody Program award at the Water Summit 2025 (Reg. 13)

- PMRC resource (M+I) for the CAGA deposits as of June 30, 2025: 112.1 WMT @ 1.1% Ni, 29.2% Fe, 0.1% Co

- July 2025 shipment: PGMC - 670K WMT; Ipilan – 57K WMT (off season)

Techiron Resources

- 2025: Shipped 2 vessels of chromite concentrate (42-44% Cr) and 20 vessels of lateritic iron HFO (47-48% Fe) Makilala Mining / Celsius Resources

- Maharlika Fund planning to acquire a stake in Makilala with the deal expected to close in H2 2025

- Drilling ongoing (Drillcorp)

CTPCMC

- Completed 86th vessels loaded

- 4,721,482 WMT total; Limonite (0.82% Ni and 48.35% Fe); Saprolite (1.36% Ni and 23.42% Fe)

PASAR (Philippine Associated Smelting and Refining Corporation)

- On care and maintenance since February 2025

- Reported sale by Glencore to the Villar group

New Mining Fiscal Regime

- Consolidated bill transmitted by House to PLLO OP last July 31, 2025 for enrollment

- President can now act on it once enrolled / lapses into a law after 30 days if not acted on

- Proposed ore export ban dropped

- Progressive royalty regime based on operating profit margins and windfall earning

The sponsor for the evening was SANY ZWM Philippines (Zhongwang Machineries Phils. Inc.) with Hi-Lite speakers Jesette David, Business Development Manager and Abraham dela Cruz, Senior Sales Account Manager. Their topic was “Sany’s Role in the Mining Industry”.

The keynote speaker was Mr. Carlo Ascaño, Project Geologist of Crescent Mining and Development Corp./Blackstone Minerals with his presentation “The Geology, Mineralization and Resource of the Guinaoang Orebody, Mankayan Project”.

For the PMEA Monthly Member Meeting in July, the keynote speaker was Engr. Michael V. Cabalda, Assistant Secretary for Mining Concerns and Concurrent MGB Director. He gave a detailed report on key developments from the Department of Environment and Natural Resources (DENR).

On June 26, the Sustainable Forest Land Management Agreement (SFLMA) was launched, which opens 1.2 million hectares of forest land for sustainable investment in forestry plantations, agroforestry, pastureland, eco-tourism and renewable energy.

From the Mines and Geosciences Bureau, Al Emil Berador, formerly chief geologist, was named Officer in Charge

Regional Director of MGB 7, following the retirement of RD Armando Malicse.

The sponsor for the meeting last July was Veolia Water Technologies & Solution with speakers Mr. Handrey Decapia (Business Development Engineer) and Mr. Ariel Cruz (Business Development Manager). Their report is titled “Veolia Water Treatment in Mining Industries”.

From May 20 to 22, the Austrade Manila team facilitated a Philippine delegation to the Global Resources Innovation Expo (GRX) held at Brisbane Convention & Exhibition Centre, Australia.

At the Expo, 25 delegates from 12 Philippine companies attended. This is a collaboration between Austmine and AusIMM, aiming to showcase innovation and collaboration in the global resources industry. The event also included a conference, exhibition, and networking opportunities.

It showcased innovative mining technologies that reflect the dynamic changes shaping the global resources industry. The mission underscored the positive development in Philippine mining, specifically the strategic framework to build a strong minerals industry that balances profile, people and the planet.

A series of business matching activities and speed-networking sessions were also held at the Australia-Southeast Business Exchange Innovation, participated by 100 Australian METS and 30 delegates from the Philippines and Vietnam.

The Australian Philippine Business Council likewise hosted a Mining Resource Forum, which provided a tailored platform to discuss the Philippines’ mining policies, opportunities, and challenges. This forum aimed to foster a transparent, investment-friendly environment conducive to sustainable growth and community support in mining operations.

“Such dialogues are critical in aligning our shared aspirations for a mining sector that is both economically viable and socially responsible,” Austrade said in a statement.

Thank you to Ms. Tata Corpuz of Austrade Manila and Sir Joey Nelson Ayson of PMEA.

In GHD, we seamlessly integrate our services to achieve significant and lasting benefits to the mining business of our clients.

Tailings storage facility design

Geotechnical investigation

Geology and geophysics

Hydrogeology and hydrology study

Civil infrastructure design

Environmental and social impacts assessment

Environmental monitoring

Mine closure and rehabilitation

Construction management and supervision

Renewable energy system design

Structural design

Asset management systems and digital twins

ESG and strategic sustainability

written by: MARCELLE P. VILLEGAS

Orica is one of the world’s leading providers of mining and infrastructure solutions. From manufacturing explosives and blasting systems to supplying specialty chemicals, geotechnical monitoring tools, and advanced digital technologies, the company supports the sustainable mobilization of the earth’s resources.

Philippine Resources Journal presents this exclusive interview with Gulshan Sadhwani, Orica’s newly appointed Area Business Manager for Philippines, who shares his insights on the company’s role and future in the Philippines.

PRJ: As the newly appointed area business manager, what is your perspective on the current state and future prospects of the Philippine mining industry?

GS: The Philippines is one of the world’s most mineral-rich countries, ranking fifth globally in mineral endowment with significant deposits of copper, gold and nickel. The outlook is very strong, driven by global demand— particularly for copper and nickel, which are critical to the clean energy transition.

The government’s focus on responsible mining, increased investment and positioning the sector as a pillar of economic growth is creating a supportive environment. We’re also seeing a healthy pipeline of exploration projects, both greenfield and brownfield, expected to come online in the coming years.

Overall, the industry is on a growth trajectory. With the right balance of sustainability, innovation and operational excellence, the Philippines can

become a major contributor to both the national economy and the global minerals supply chain.

PRJ: What are the primary challenges facing the sector, and how is Orica positioned to help address them?

GS: The Philippine mining sector operates in one of the most complex environments in the world. Located in the Pacific Ring of Fire, the country faces frequent earthquakes, typhoons and volcanic activity. As an archipelago, logistics can also be challenging, with mines often in remote areas accessible only through difficult terrain. These conditions raise costs, lengthen lead times and increase safety risks.

At Orica, we address these challenges through resilient infrastructure and advanced technology. We have multiple

Page 42 >

High accuracy and ultra low detection limits for critical trace elements

High precision analysis of minor and major element concentrations

For many applications delivers WD-XRF performance at

cost

Fast and non-destructive elemental analysis of solid powder, pressed pellets, fused beads, and liquid samples

strategically located facilities and distribution points near key mining operations, ensuring reliable supply even during disruptions. We complement this with digital and advanced blasting solutions such as Orica Digital Solutions, underground bulk systems and wireless blasting. These technologies improve efficiency, precision and fragmentation, while reducing environmental impact. Our innovations help customers:

• Optimize productivity by reducing downtime.

• Improve flexibility by converting WebGen™-loaded blasts into haul roads.

• Enhance safety and strengthen community relations.

• Lower costs through more efficient use of explosives and reduced rework.

PRJ: Orica has been operating in the Philippines for more than five decades. What have been some of the company’s key contributions to the industry?

GS: Orica’s journey began in 1968 with the establishment of Philippines Explosives Corp., later rebranded as Orica Philippines in 1998. For over 50 years, we’ve partnered with the mining industry, bringing global expertise and local commitment. Our contributions stand out in five areas:

• Safety and sustainability: From pioneering next-generation bulk products and electronic blasting systems to delivering the country’s first wireless blast, we’ve consistently raised safety standards. Our Limay plant also leads in waste and energy efficiency, aligned with Orica’s net-zero goals.

• Technological innovation: Through advanced explosives, underground solutions and platforms such as BlastIQ™, we’ve helped customers improve productivity, manage costs and reduce environmental impact.

• People and communities: We invest in Filipino talent through scholarships and graduate programs and are proud to see more diversity in leadership

across our teams.

• Local presence with global expertise: With a strong footprint nationwide and the backing of Orica’s global network, we ensure reliable supply and tailored solutions for local mines.