BREAKING GROUND: PHILIPPINES’ FIRST WIRELESS BLAST AT MASBATE WITH ORICA’S WEBGEN

MINING AND DATA PRIVACY: PROTECTING BOTH NATURAL AND DIGITAL RESOURCES

HAS THE PHILIPPINES’ MINING RENAISSANCE FINALLY BEGUN?

BREAKING GROUND: PHILIPPINES’ FIRST WIRELESS BLAST AT MASBATE WITH ORICA’S WEBGEN

MINING AND DATA PRIVACY: PROTECTING BOTH NATURAL AND DIGITAL RESOURCES

HAS THE PHILIPPINES’ MINING RENAISSANCE FINALLY BEGUN?

Genluiching Mining Corporation (GMC) is a Philippine mining company registered with the Securities and Exchange Commission (SEC) and the Mines and Geosciences Bureau (MGB). It is licensed and authorized to engage in the exploration, quarrying, processing, and trading of iron ore, one of the Philippines’ high-value mineral products for export, as its principal business mission.

GMC partners with heavy construction equipment lessors, land transport and shipping companies, and petroleum suppliers for its exploring, drilling, excavating, hauling, transport, and shipment activities for greater financial fluidity and operational leverage. Its partners in this supply chain include Monark Equipment Corporation, Maxima Steel Mills Corporation, Phil lua Shipping Lines, Caltex Philippines, and Shell Philippines.

GMC’s concession area in Mati City, Davao Oriental yields iron ore and other minerals that include copper ore, gold ore, manganese ore, limestone, and silica.

GMC’s concession area in Ayungon, Negros mining site yields silica.

TAGANITO MINING CORPORATION

Supplies the limonite Ore (Mine waste), which contains 1.5%

Nickel and 0 10% Cobalt

Produces Mixed Sulfide, comprised of 57% Nickel and 5% Cobalt using the High Pressure Acid Leaching Technology

TAGANITO HPAL NICKEL CORPORATION NICKEL AND COBALT (MIXED SULFIDE)

METAL MINING CO., a Nickel Refinery

Conducts the final process and converts the Mixed Sulfide to 99.99% Nickel and 99.99% Cobalt.

Use as a prime component to produce Lithium batteries, electric vehicle batteries, mobile phones, steel products for largest skyscrapers, and many more.

A rare element utilized in lighting applications, aerospace, sports equipment, robust alloys and many other uses.

Utilized in the manufacturing of stainless steel, chrome plating, the production of corrosion-resistant superalloys, nichrome, and various types of paint

Protecting Both Natural and Digital

Has the Philippines’ Mining Renaissance Finally Begun?

Irresponsible Mining Has No Place in Our Nation, Marcos Declares

PMEA’s President is PH Representative for AUSIMM A

Philex Mining Secures Pangasinan Exploration Permit to Expand Resource Base

OceanaGold Philippines Announces New Board Chair in Brian Martin

PH Companies Shine at 4th ASEAN Mineral Awards

How Dinapigue Mining Corp. is Building a Greener Future with Eco-Bricks

Precision Drilling with Sandvik at Masbate Gold Project

for

Cutting Costs and Reducing Risks The Digital Road to Operational Excellence (Part 2)

Agata Renews Commitment to the IP Communities

TVIRD’s Novel Reforestation Follows Nature’s Rhythm Through Progressive Rehab

Charting the Future in the 5th Roads, Bridges, and Tunnels Summit

ProjectVIEW ERP: The Leading Construction ERP in PH for Real-Time Cost Control, Project Success

PECAFORM: Building Smarter, Greener, and Faster for the Philippine Construction Industry

Megawide, Megaworld Seal Residential Megadeal

Driving Smarter: How

Antrak Philippines Rebrands to FLS Group for Strategic Partnership

Eriez DVMF Removes Fine Iron-Bearing Contaminants

Drive Smarter, Work Safer: Tips to Boost Mining Productivity

HMC–TNP Takes Action for Cleaner Seas During ICC 2025

Comparison of Filter Packs in Well Design: Gravel vs. Glass Beads

CHC Navigation: Integrated Geospatial Systems for Enhanced Efficiency, Risk Mitigation in Modern Mining Operations

Beyond Borders: The Strength of a Connected RDCL Across Australasia

Taganito Mining Celebrates Environment Month 2025

Umahan sa Minahan: From Mined-Out Land to Sustainable Farm

Truflo Pumps: Powering PH Mining Operations

Robit: Top Hammer Business

Precision Meets Power: VBL V81VX & V81VX CE Teeth

Discover Belzona Solutions

From Waste to Wealth: How the Philippines Can Turn Tailings into Valuable Resources

Narrow carrier, wide possibilities. Advanced technology for narrow vein mining applications.

Marof his myriad inflation and against economic from the hard put consumer public a tight result declincosts further dollar fuel for materials more for debt the proand the Government facilienergy utiliAmong recovery are conflict weaker about by intercountry. businessmoney and and serespecially economic globally. groups, the mining sustainable refrom the pandemic and slowdown. investments for underscored Secreassured the commitment to environment Diokno also expects adhere to practices. He strike environand supsocioeconomic Marcos ecomedium-term fissucceed mining

By Fernando Penarroyo

Twritten by: FERNANDO PENARROYO

Fernando “Ronnie” S. Penarroyo specializes in Energy and Resources Law, Project Finance and Business Development. He is also currently the Chair of the Professional Regulatory Board of Geology; the government agency mandated under law to regulate and develop the geology profession. He may be contacted at fspenarroyo@penpalaw.com for any matters or inquiries in relation to the Philippine resources industry and suggested topics for commentaries. Atty. Penarroyo’s commentaries are also archived at his professional blogsite at www.penarroyo.com

Philippine Resources is published independently for executives in Philippine mining, construction, resources, and associated business sectors.

Publisher Elizabeth Galura

Consulting

Publisher Greg Brimble

Editor Jimbo Gulle

Sales and Marketing Manager

Matt Brimble +63 927 721 6622

Matthew@philippine-resources.com

Account Manager

he Philippines has long been recognized as one of the world’s most mineral-rich countries. With deposits of nickel, copper, and gold, it plays a vital role in global supply chains, especially at a time when electric cars, batteries, and renewable energy systems are driving demand for these resources.

industry would have to perform well. Dur ing the Philippine Economic Briefing in New York where President Marcos delivered a keynote message to American investors, Diokno emphasized the administration’s commitment to help maximize the mining sector’s potential in attracting more foreign investments.

Even though mining can create jobs, bring in muchneeded revenue, and connect the Philippines to international markets, there is still the lingering perception that it can harm the environment and displace communities.

The mining industry considered the Duterte administration as another wasted era for realizing the full economic potential of the sector. The Marcos government in herited a mining industry reeling from the anti-mining stance of the previous administration with the appointment of the late Regina Paz Lopez, a staunch anti-mining advocate, to head the Department of Environment and Natural Resources (DENR). The appointment was bitterly opposed by the industry resulting in Lopez’s rejection by the powerful bicameral Commission on Appointments.

Now, another kind of resource is taking center stage alongside minerals—data. Mining in the twenty-first century is not only about extracting ores from the earth; it is also about gathering information.

During her term, Lopez ordered the closure of mining operations and initiated a national mine audit conducted on behalf of the Mining Industry Coordinating Council. Mining stakeholders described the three years of closure of these companies as “arbitrary” and claim that at that time, the industry practically “gasped for breath.”

form of extraction can create serious risks for privacy, fairness, and sovereignty. But handled well, it can be turned into an opportunity to strengthen communities, improve governance, and protect national interests.

safety conditions. These tools generate huge amounts of data that can be used to comply with environmental rules, improve productivity, and reduce accidents.

Merianjay Fallan +63 992 371 7060 merian@philippine-resources.com

Administration

Cecilia Pamular +63 917 308 1971 cecille@philippine-resources.com

Graphic Designer Bogtong Wangga

Journalists

Marcelle P. Villegas

Contributors

Patricia A.O. Bunye Fernando Penarroyo

Manila Publishing Office

Suite 6, 2nd Floor

Corinthian Plaza Building 121 Paseo de Roxas

Legaspi Village

Makati City, Philippines 1226 Phone +632 8251 5599

Digital Online Edition www.Philippine-Resources.com

While mining companies use drones to map terrain, satellites to track environmental changes, and sensors to monitor everything from air quality to worker safety, they also collect information from host communities and indigenous peoples.

The Philippines has the chance to set an example by treating both minerals and data as shared resources that must be managed responsibly for the benefit of Filipinos.

With COVID-19 bringing down the economy on its knees and a worsening economic fallout becoming inevitable, Duterte issued Executive Order No. 130 in April 2021, lifting the nine-year moratorium on the granting of new mining permits. Finally in December 2021, the Duterte administration succumbing to economic pressure, lifted the ban on open-pit mining.

It is well to note that at the height of the pandemic in 2021, the mining sector’s contribution to the gross domestic product

Through surveys on health, demographics, and community sentiment, mining companies are no longer just extracting resources from the ground, they also “extracting” information from people and the environment.

Handled poorly, this new

Page 8 >

Mining today is highly digitized. Advanced technologies have transformed operations, making it possible for companies to work more efficiently and safely. Drones are used to create detailed maps of landscapes, satellites help track changes in forests and water bodies, and sensors provide constant updates on machinery and

Beyond technology, mining firms also collect information directly from communities. Environmental and social impact assessments often involve surveys about health and livelihoods, while corporate social responsibility programs may gather data on education and living standards. In some cases, companies or their contractors even monitor social media to see how people feel about mining projects.

New Leopard DI650i down-the-hole surface drill rig offers long-term productivity and superior stability with robust and reliable main components – seamlessly integrated with state-of-the-art technical solutions. Scalable automation, easy maintenance and outstanding movability are the features that make Leopard DI650i a premium product, which is an honor to own.

Leave your paw print and enjoy the smooth, efficient ride.

Explore the new Leopard DI650i: ROCKTECHNOLOGY.SANDVIK/DI650

When collected and shared responsibly, this kind of information can be valuable. It can help companies respond more quickly to community concerns, give government agencies evidence to enforce

Truflo Pumps’ dewatering systems have proven themselves around the world. Whether it’s underground or an open pit, we have the best water management solutions for your mining operation.

HEAD OFFICE AUSTRALIA

Truflo Pumping Systems Pty Ltd

Ph +61 2 6333 4500

10 Irving Place, Bathurst NSW 2795 Australia paul.power@truflopumps.com.au

PHILIPPINE DISTRIBUTOR

Power Systems Inc., DEUTZ DIVISION Ph +63 2687 9275

2/F Topy’s Place Building, Cnr Calle Industria & Economia Rd. Bagumbayan, Quezon City, 1110 | absalvador@psi-deutz.com

rules, and provide communities with the data they need to push for better services.

For example, if surveys show an increase in health issues near a mining site, this could become the basis for improved health care in the area. If water quality tests reveal pollution, communities could use this data to demand cleaner practices or compensation. In this way, data has the potential to balance power between corporations, the state, and its citizens.

However, risks arise when data collection is done without fairness or transparency. One of the biggest concerns is that communities may not give informed consent for how their data is used.

Under the Indigenous Peoples’ Rights Act, indigenous groups must give their free, prior, and informed consent (FPIC) before mineral exploration and mining operations begin on their land.

Yet FPIC usually does not extend to data collection. This means a community might allow a project to operate but not realize their personal information and opinions, or household details are being stored and possibly shared with third parties.

Another issue is information imbalance. Often, companies collect data and share it with investors or government agencies but not with the very people from whom the information was generated and most affected by the operations.

A mining company may test river water quality and submit a report to regulators saying conditions are safe, but families who depend on that water for farming or drinking may never see the full results. This creates an unfair situation where those who face the risks have the least access to the knowledge that could help them.

There is also the potential for misuse. In areas where opposition to mining is strong, information about community leaders or activists could be used to monitor

them. Even if this is not the intention, the risk remains that data collected for one purpose could later be applied in ways that put individuals at risk.

Despite these challenges, data can be seen as an opportunity if it is treated as a resource in its own right. Just as minerals are considered part of national patrimony, there is a strong case for viewing mining-related data as a national asset.

Companies see it as part of their business operations, but governments recognize its value for planning, monitoring, and security, while communities see it as essential for protecting their health and livelihoods. Balancing these interests is key.

This debate mirrors the general struggle over mineral sovereignty. For decades, Filipinos have insisted that the benefits of mining flow to the nation before being repatriated abroad. The same logic can apply to information.

The Philippines supplies large amounts of nickel and copper, which are critical for the global shift to clean energy. Investors often require access to operational data before they commit funds. If the Philippines asserts sovereignty over this information, it can make sure it is shared under terms that benefit the country, not just outside players.

The strategic value of mining-

related data goes beyond economics. Geological surveys, environmental records, and infrastructure maps have national security implications. If such information is stored abroad or left in foreign hands, the Philippines could lose control over knowledge about its own resources.

This is especially important in a world where powerful nations like the United States and China are competing for control of supply chains for clean energy. In this context, protecting mining data is not only about fairness for host communities but also about protecting sovereignty at the national level.

Handled wisely, mining data can enhance the Philippines’ negotiating position. A country that demonstrates strong data governance signals to investors and partners that it values not only economic efficiency but also sovereignty and rights. This can attract responsible investment, increase trust, and prevent exploitative practices.

Critics of mining often use the term “extractivism” to describe the large-scale removal of resources that benefits outsiders more than locals. Increasingly, some fear that the same thing is happening with information. Data is being “extracted” from people without giving them anything in return.

Yet the Philippines has an opportunity to change this

narrative. Instead of allowing extractivism to dominate, the country can practice shared stewardship. This means treating minerals and data not as things to be taken but as resources to be managed responsibly, with benefits fairly distributed.

Imagine if every community near a mine automatically received the results of environmental and health studies in plain, easy-tounderstand language.

Imagine if mining companies used the data they collect not just to meet legal requirements but also to invest in cleaner water, stronger health systems, and better local infrastructure.

Imagine if the government stored mining data locally and used it to guide national plans for disaster preparedness and climate resilience.

This is the vision of stewardship: turning data into a tool for empowerment.

The Data Privacy Act of 2012 (Republic Act No. 10173) provides a foundation for this. The law protects individual personal information in both government and private sectors by regulating the collection, processing, and storage of personal data.

It created the National Privacy Commission to implement regulations, protect data subjects’ rights, and ensure the country’s data protection measures are in line with international standards.

The law emphasizes transparency, legitimate purpose, and proportionality, meaning that data must be collected openly, only for clear reasons, and in amounts that are necessary. For mining companies, this means employee records, health surveys, and community data must all be handled responsibly.

In practice, enforcement is still uneven. Many communities are not fully aware of their rights under the law, and the National Privacy Commission has limited resources to enforce such rights.

Environmental regulators rarely coordinate with privacy regulators, leaving gaps in oversight. But these challenges can be addressed. With stronger cooperation, more training, and better resources, the Data Privacy Act can become a powerful tool for protecting and empowering both people and the nation.

Artificial intelligence (AI) is now integral to modern mining operations, optimizing exploration, production, logistics, and sustainability. However, this integration brings complex dataprivacy challenges.

AI systems in mining collect vast amounts of information ranging from worker biometrics to operational performance data, which may contain personally identifiable or sensitive industrial details.

These systems often aggregate and analyze data across departments, leading to privacy risks such as surveillance concerns, unintentional reidentification, and exposure through third-party vendors or cross-border data transfers.

The growing use of AI also introduces risks tied to the difficulty of explaining or contesting automated decisions affecting individuals.

As AI systems become more involved in making or supporting decisions, it becomes harder for people and sometimes even for the companies using them to understand how or why those

decisions were made. The Data Privacy Act demand stronger governance, emphasizing employee consent, data minimization, and transparency.

Meanwhile, regulatory trends such as data localization are reshaping how global mining firms handle information.

Data localization prohibits or restricts the transfer of certain types of data (especially personal, environmental, or strategic industrial data) to servers or cloud platforms located outside the country. The goal is to protect national sovereignty, privacy, and security by keeping sensitive data under Philippine jurisdiction.

Beyond compliance, these measures have strategic implications. As AI turns data into a valuable asset, privacy management becomes central to maintaining corporate reputation and social license to operate. Breaches or unethical use of data could harm community trust and investor confidence.

Ultimately, while AI enhances efficiency and sustainability, it also demands rigorous, transparent, and ethical data governance to ensure that innovation aligns with human rights and privacy standards.

Several steps can help move toward this vision. Extending

social license and community consent to cover digital data would give communities control over how their information is collected and used. Guaranteeing that communities have access to health and environmental data would ensure transparency.

Requiring that sensitive mining information be stored properly would protect sovereignty. Including data practices in environmental impact assessments would mandate companies to explain not only how they treat land and water but also how they handle digital information.

Strengthening the capacity of regulators and encouraging public-private partnerships could further build systems where digital data is shared responsibly. Each of these pathways transforms digital information from a potential liability into a tool for empowerment and development.

Mining in the Philippines has never been just about minerals. It has always been about who benefits, who bears the costs, and who gets to decide.

In the digital age, this struggle now extends to data. Communities that once fought for land rights must now also claim their informational rights, while the state must balance local needs with global pressures. This is not only a challenge but also an opportunity.

By protecting both natural and digital resources, the Philippines can move beyond extractivism and build a model of stewardship that is inclusive, sustainable, and sovereign.

If mining is left unchecked, it could continue to drain both natural wealth and informational resources without fairly benefiting the country. But if managed wisely, the Philippines can turn mining into a force for justice and sustainability.

Protecting both land and information ensures that communities are empowered, companies are accountable, and the nation secures its place in a competitive world. Mining responsibly and governing data fairly are not separate goals. They are part of the same fight for dignity, sovereignty, and the future of the Filipino people.

Fernando “Ronnie” S. Penarroyo specializes in Energy and Resources Law, Project Finance and Business Development. He is also currently the Chair of the Professional Regulatory Board of Geology, the government agency mandated under law to regulate and develop the geology profession. For any matters or inquiries in relation to the Philippine resources industry and suggested topics for commentaries, contact him at fspenarroyo@penpalaw.com. Atty. Penarroyo’s commentaries are also archived at his professional blogsite www.penarroyo.com

Hard-wearing and long-lasting polymeric solutions withstand the toughest mining conditions

The mining and quarrying industry poses significant challenges to machinery and equipment due to a combination of abrasion, corrosion, wear, impact, and chemical exposure.

Reliable and cost-effective, Belzona’s cold-curing repair composites and protective coatings can extend equipment life, reduce downtime and ensure operational integrity - even in the extreme operating conditions found in mining and quarrying environments.

unlocking its full mining potential. For decades, red tape, policy uncertainty, and public distrust have kept investors away, even as the country sat atop the proverbial pot of gold.

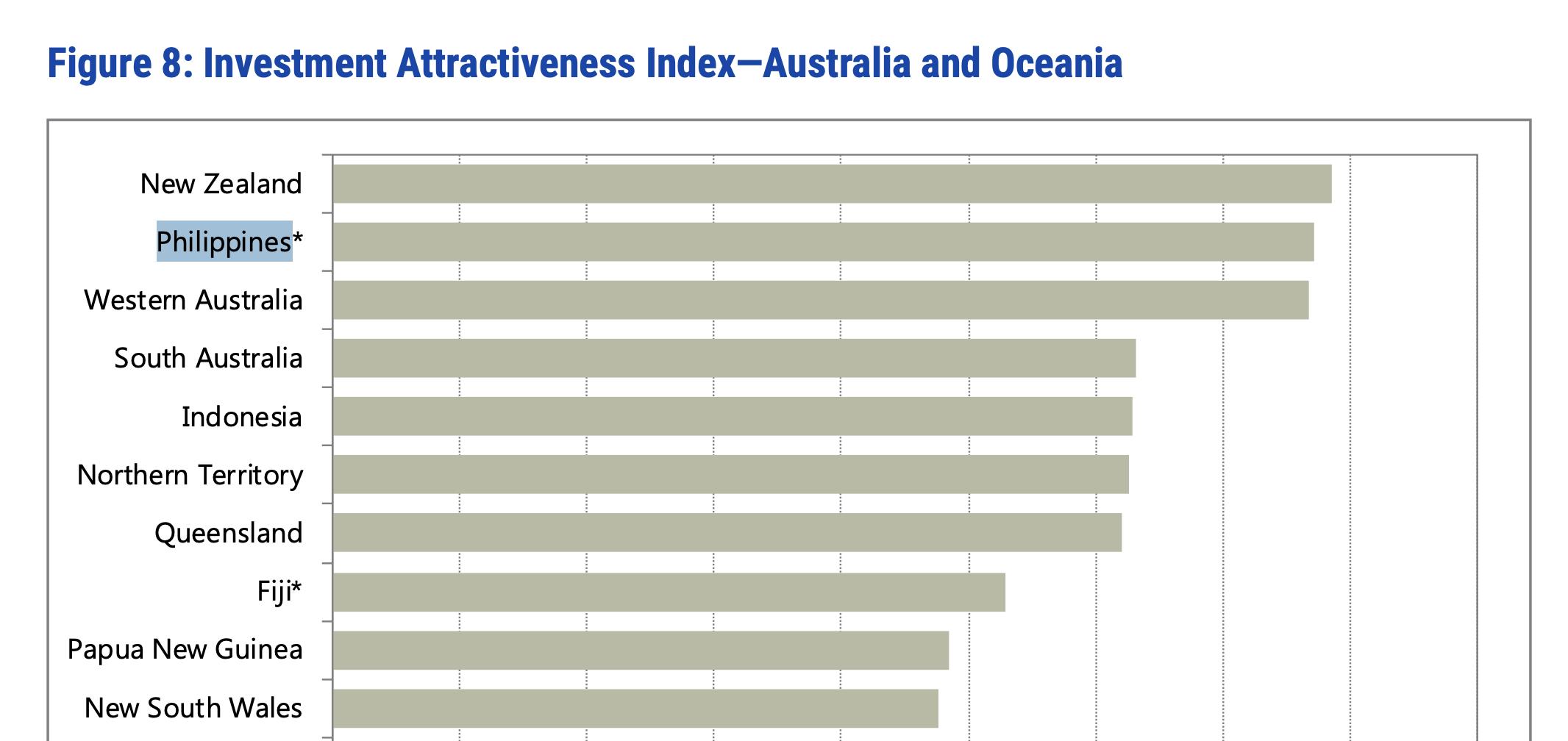

However, this year’s leap in the 2024 Fraser Institute’s Investment Attractiveness Index, from 72nd to 16th place among 82 countries, tells a new story: the Philippines is finally reclaiming its place in the global mining map.

This turnaround did not happen by chance. It is the result of deliberate policy reforms, sustained regulatory improvement, and a changing mindset within both government and industry.

The Department of Environment and Natural Resources (DENR) and the Mines and Geosciences Bureau (MGB) have, over the past few years, pursued a vision that balances growth with governance, an approach long overdue in a sector often viewed with suspicion.

According to the Fraser Institute’s 2024 Annual Survey of Mining Companies, the Philippines’ score nearly doubled: from 36.89 in 2023 to 77.11 in 2024. This surge reflects two critical shifts: a stronger

written by: PATRICIA A. O. BUNYE

Patricia A. O. Bunye is the Managing Partner of Cruz Marcelo & Tenefrancia where she heads its Mining & Natural Resources Department and Energy practice group. She is also the Founding President of Diwata-Women in Resource Development, Inc., a non-government organization advocating the responsible development of the Philippines’ wealth in resources, principally through industries such as mining, oil and gas, quarrying, and other mineral resources from the earth for processing.

geological attractiveness ranking, now 9th globally, and a dramatic improvement in policy perception, from 79th to 25th. Simply put, the country’s potential is finally matched by a more predictable and

courtesy of the Fraser Institute’s Annual Survey of Mining Companies 2024.

transparent policy environment. This progress may be traced to the reforms initiated by former DENR Secretary Maria Antonia Yulo Loyzaga, including streamlined permitting and digital

transparency measures, and which are being continued by the current Secretary, Raphael Lotilla. While the aforementioned reforms

16 >

DANAOS

are largely procedural, they nevertheless translate into predictability and clarity which investors value.

The numbers tell their own story. In 2024 alone, the mining sector generated ₱253 billion in production value, contributed ₱33 billion in taxes and royalties, and provided nearly 292,000 direct jobs.

Beyond economics, companies invested billions more in environmental protection, community development, and rehabilitation efforts, proof that responsible mining, once dismissed as an oxymoron, can indeed take root.

Other signs point to a resurgence in the mining industry. Aside from the sharp improvement in investment-attractiveness rankings, regulatory, fiscal, and policy reforms have likewise contributed to investor confidence.

The recent passage of the Enhanced Fiscal Regime for

Large-Scale Metallic Mining Act (Republic Act 12253) introduces tiered royalty rates, windfall profit taxes, projectbased ring-fencing, and other provisions that aim for fairness, environmental protection, and better revenue sharing.

Another factor is the rise in production values and asset valuation. Metallic mineral output value has increased mainly due to the “re-entry of projects” [following the lifting of the ban on new mineral agreements in 2021 via Executive Order 130, which allows for new mining projects to proceed] and strong commodity prices. The total value of mineral assets rose by 4.6% in 2024 (from ₱460.16 billion in 2023 to ₱481.45 billion) based on Philippine Statistics Authority data.

The increased global demand, especially for nickel, copper and other “critical minerals,” both from foreign investors and governments (e.g. U.S., China, EU) looking to secure supply chains for technologies like EV

batteries, is also a major factor in the renewed attractiveness of the Philippine mining industry. Since much of the Philippines’ mineral wealth lies untapped, there is a wealth of opportunity for the next wave of responsible mining investment.

But not everything is rosy. Despite these positive outlook, many challenges remain. Regulatory enforcement, infrastructure gaps, and interagency coordination still need work. Reforms must therefore be sustained to turn optimism into long-term confidence.

The Philippines has the potential to become a leading supplier of critical minerals which are essential for the world’s shift to clean energy, but the government and private sector must continue working together.

The message from the Fraser Index is clear: investors are noticing. The Philippines is no longer seen as a high-risk frontier but as a credible, emerging hub for mineral development in the Asia-Pacific.

This is a far cry from 20172021 when the Philippines ranked much lower in the Policy Perception Index (PPI), often among the bottom 10 jurisdictions. For example, in the 2021 survey, the Philippines was listed among the worst jurisdictions in the PPI.

Beyond rankings and reports lies a deeper question: what kind of mining future do we want? A future where resources uplift communities and where the wealth beneath our soil powers not just global supply chains but, more importantly, local progress. If the government can sustain reform and accountability, this renaissance will not just be statistical: it will be structural and sustainable.

The Philippines has taken a major step forward in mining: the real test is to remain sure-footed in sustaining that momentum.

Graphs courtesy of the Fraser Institute’s Annual Survey of Mining Companies 2024.

written by: JAMES GALVEZ AND MARCELLE P. VILLEGAS

President Ferdinand R. Marcos, Jr. became the first sitting Philippine president in decades to attend the Mining Philippines International Conference and Exhibition, underscoring his administration’s resolve to revitalize the minerals industry through responsible and sustainable practices.

Speaking before an audience of industry leaders, diplomats, engineers and local government executives at the Grand Hyatt Manila on October 22, the President delivered a keynote address that many described as a defining moment for the sector.

“Irresponsible mining has no place in our nation,” Marcos declared to sustained applause. His statement, delivered with clarity and conviction, set the tone for the three-day conference organized by the Chamber of Mines of the Philippines (COMP). The event focused on a shared goal: developing a world-class mining industry that upholds environmental integrity, transparency and equitable community benefit.

“Mining has long been a great part of our nation’s story,” Marcos said. “From the gold veins of Baguio to the copper deposits of Cebu to the nickel belts in Mindanao—these resources have provided livelihoods and shaped communities throughout the years.”

The President emphasized that the industry must now redefine its role in light of global environmental challenges. “To be given this much potential is both a blessing and a responsibility,” he continued. “We are offered the chance to help power the global green transition and ensure that this progress uplifts every Filipino, especially those who live closest to the mines themselves.”

Marcos stressed that the nation’s vast mineral wealth must be harnessed to drive sustainable development, particularly as demand for critical minerals such as nickel, copper and cobalt increases to support renewable energy technologies.

The President described responsible mining as essential to the country’s long-term growth strategy. “Here we ask the vital questions,” he told delegates. “How can the Philippines become a reliable source of critical minerals for a greener future? How can mining fuel regional industrialization and create decent, lasting jobs? And how can we open doors to responsible investment without compromising our planet or our people?”

The conference provided a platform for government, industry and civil society to explore how the Philippines can position itself as a trusted global supplier of “green metals” while ensuring environmental protection and community inclusion.

Marcos commended the Chamber of Mines for championing the Towards Sustainable Mining (TSM) initiative, an internationally recognized framework for environmental, social and governance (ESG) performance originally developed in Canada.

“The Philippines stands proud as the first in Asia to implement this program,” the President said, noting that the country now joins resource-rich nations such as Canada and Australia

in promoting ethical and transparent mining practices.

He also reaffirmed the government’s commitment to the Extractive Industries Transparency Initiative (EITI), saying it ensures that revenues from mining are “managed wisely and used for the good of the people.”

“This is the kind of partnership that turns resource generation into human progress,” Marcos said.

“Mining should build communities, not burden them.”

The President detailed a series of legislative and administrative measures forming the backbone of his administration’s mining policy:

• Enhanced Fiscal Regime for LargeScale Metallic Mining Act — now enacted into law, providing a fair, consistent and transparent taxation framework to promote investor confidence and public accountability.

• Philippine Ecosystem and Natural Capital Accounting System Act — ensuring that the value of forests, minerals and ecosystems is integrated into national economic planning.

• Alignment of Social Development and Management Programs (SD -

In GHD, we seamlessly integrate our services to achieve significant and lasting benefits to the mining business of our clients.

Tailings storage facility design

Geotechnical investigation

Geology and geophysics

Hydrogeology and hydrology study

Civil infrastructure design

Environmental and social impacts assessment

Environmental monitoring

Mine closure and rehabilitation

Construction management and supervision

Renewable energy system design

Structural design

Asset management systems and digital twins

ESG and strategic sustainability

MPs) with the United Nations Sustainable Development Goals (SDGs) — requiring mining firms’ community programs to contribute directly to education, health and gender equality.

• Streamlined permitting procedures — reducing bureaucratic delays while tightening environmental compliance.

Marcos said these reforms are designed to cultivate a “responsible, inclusive and climate-resilient” minerals sector that attracts investors who “respect our laws, our people and our environment.”

The President reiterated that mining revenues must directly benefit communities. “The wealth from our soil should translate into schools for our children, hospitals for families and roads that link people with opportunities,” he said.

He also warned against environmental violations. “We will enforce the laws against practices that destroy forests, that poison rivers, that endanger lives,” Marcos stated.

Sustainability, he said, is the truest measure of national progress. “Sustainability is measured by how many lives we uplift and how faithfully we guard the blessings of our land for generations to come.”

COMP Chairman and President Michael T. Toledo welcomed the President’s participation as a “historic moment” for the mining industry.

“In just the past few years, we’ve seen real progress—the lifting of the moratorium on new projects,

the removal of the open-pit ban, the simplification of permitting, and most recently, the passage of the new fiscal regime signed into law by our most distinguished guest this morning,” Toledo said.

“These are not small steps; they mark a genuine turning point,” he added. “For years, we’ve said that responsible mining can be a partner in nation-building. Today, that belief is finally reflected in government policy and in growing public understanding.”

Toledo cited the Philippines’ dramatic rise in the Fraser Institute’s 2024 Annual Survey of Mining Companies, where the country climbed from 72nd to 16th in Investment Attractiveness and from 79th to 25th in Policy Perception. “These figures show how steady reforms are paying off,” he said.

Environment Secretary Raphael Lotilla reaffirmed the Department of Environment and Natural Resources’ (DENR) commitment to a modern fiscal and investment framework that supports responsible mining.

He said the new fiscal regime answers a “decades-old call for a fair, transparent and efficient system,” while ensuring that local governments receive their rightful share of national wealth.

Lotilla also revealed that the DENR is adopting a climate and ecosystem-based lens in evaluating mining projects. “We are recognizing that every intervention on the landscape affects water, biodiversity and communities,” he said. “This approach is strengthened by our national geospatial database, our

Natural Capital Accounting System and the creation of the Water Resources Management Office to align mining operations with watershed protection.”

He further announced that the Mines and Geosciences Bureau (MGB) is streamlining permitting, launching a national mineral inventory by 2026 and strengthening indigenous people’s participation in benefit-sharing mechanisms.

“These reforms signal a new phase for Philippine mining,” Lotilla said. “Minerals are no longer viewed merely as commodities to extract, but as strategic assets for a clean-energy future and inclusive progress.”

For decades, the Philippine mining industry has been dogged by environmental controversies and public distrust. Yet as global demand grows for responsibly sourced critical minerals, the country now has the opportunity to redefine its narrative.

“The story of mining in our country,” Marcos said, “is the story of our people—of how we optimize what we have to create a better future for everyone.”

He urged industry leaders and investors to ensure that operations remain “underpinned by science, guided by sustainable goals and anchored on shared interests.”

“Together,” he concluded, “let us shape a mining industry that is a source of pride, a pillar of progress and a model of sustainability.”

Turning these commitments into tangible results will require coordination among government agencies, local authorities, indigenous communities and private investors. If sustained, the Philippines could position itself as a regional leader in ethical and climate-conscious mining, supplying the minerals that will power the world’s clean-energy future—without sacrificing its own natural heritage.

For now, the President’s message is clear: the era of unchecked extraction is over. What must follow, Marcos insists, is an era where prosperity, people and the planet advance together.

Photo credit: Marcelle P. Villegas

written by: MARCELLE P. VILLEGAS

AusIMM, the Australasian Institute of Mining and Metallurgy, has appointed Philippine Mining and Exploration Association (PMEA) President, Joey Nelson R. Ayson as International Representative in the Philippines in May 2025.

The International Representative is a voluntary, appointed position by AusIMM, which is the peak professional body for people in the global resources sector.. The role entails that a Representative must be a current financial member of AusIMM residing in the country outside of Australia or New Zealand.

The International Representative’s responsibilities include:

-- Be the main point of contact for AusIMM activities and members in that country.

-- Provide advice to AusIMM on local mining industry updates, regulations, projects, and news for inclusion in AusIMM newsletter and for AusIMM to meet its international strategic objectives.

-- Collaborate with AusIMM to deliver events and initiatives for local members.

-- Represent AusIMM at relevant local functions, events and meetings.

The AusIMM International Representative may wish to form and Chair a small supporting committee to assist with the above responsibilities. AusIMM is a professional organization representing professionals in the global resources sector, including mining, metallurgy, and geoscience.

For the last meeting of the year for the PMEA, Ayson reported the Industry Updates and PMEA Matters. This was held on October 6, 2025.

Engr. Jerome Magdato

(Environmental Scientist, GHD PTY LTD) was the hi-lite speaker with the topic “GHD Emission Estimation: Vegetation Clearing”.

Ma. Donna Del Moro (Acting Superintendent - Environment, Oceana Gold Philippines, Inc.) reported the topic “Harmony in Diversity (HiD) Effect in Mine Rehabilitation”.

Tata Corpuz (Business

Development Manager, Austrade) announced that the Australian Trade Commission (Austrade) will hold a trade mission entitled “Australian Innovation for Sustainable Mining in the Philippines” on November 17 to 20, 2025, with events in Manila and Baguio.

The Bar Sponsor for this PMEA Meeting was GHD PTY LTD.

Page 26 >

Ayson reported the following updates pertaining to mining laws, guidelines, and regulations.

-- RA 12253 Mining Fiscal Regime- Signed on September 04, 2025- IRR to be completed in 3 months by DOF- Each mining claim is a separate taxable entity

-- RA 12238 Panaon Island

Protected Seascape - Signed on August 29, 2025 - 61,204-hectare marine sanctuary covering the waters surrounding Panaon Island

-- RA 12237 Mt Sawtooth Protected Landscape - Located in the municipalities of Mayantoc and San Jose, Tarlac

-- RA 12252 – Amendment of Investors’ Lease Act - Allows foreign investors to lease land up to 99 years - Must have an approved investment project under the Foreign Investments Act of 1991

-- RA 12287 – Declaration of State of Imminent Disaster ActEmpowers the government to act before a calamity strikes - Based on a pre-disaster risk assessment, which must show highly probable catastrophic effects - At least 3 - 5 days of lead time for the government to prepare.

The Mines and Geosciences Bureau XII announced the designation of Engr. John Mikel P. Ansao as the new Officer-InCharge (OIC) Regional Director of MGB-XII, pursuant to DENR Special Order No. 2025-694,

issued by DENR Secretary Raphael P.M. Lotilla dated September 23, 2025.

Engr. Ansao will serve as OIC Regional Director in concurrent capacity as Chief of the Mine Safety, Environment and Social Development Division (MSESDD).

-- Northern Cement Corporation – Best Practices in Non-metallic Mineral Processing (Winner)

-- Hinatuan Mining Corporation

Tagana-an – Best Practices in Metallic Mineral Distribution (Winner)

-- Eagle Cement Corporation - Best Practices in Non-metallic Mineral

Mining (First Runner-Up)

-- FCF Minerals - Best Practices in Metallic Mineral Processing (Runner-Up)

-- Carrascal Nickel Corporation

– Best Practices in Metallic Mineral Mining (Runner-Up

2025 (FROM MGB)

-- PhP 135.6B (2025) vs PhP 117.8B (2024): 15.1% increase

-- Au (59%); Ni (29.4%); Cu (10.1%)

-- Drop in production for Cu, Ni, Cr

-- Excise tax collected – PhP 3.11B

-- Royalties from Mineral Reservations – PhP 940.24M

-- Additional Government Share

– PhP 466.86M (OGPI) & PhP 29.22 (HMC)

written by: MARCELLE P. VILLEGAS

The 80th Philippine Mining Club Luncheon in July featured two companies who underscored the importance of technology and expertise in achieving safety, sustainability, and environmental stewardship.

A pioneer in ISO certification in the Philippines and a global leader in lab testing, inspection, and verification, SGS Philippines Inc. takes the lead in helping mining companies comply with a new carbon accounting mandate.

Randall Evangelista, Business Manager, Industries & Environment – Health & Safety of SGS Philippines, Inc. was one of the guest speakers in Philippine Mining Club Luncheon on July 18, 2025. He is also a Greenhouse Gases Lead Auditor under GHG Protocol & ISO 14064-1:2018.

In his presentation titled “Sustainability: Facets of Carbon Accounting”, he urged mining firms to comply with the new carbon accounting directive.

As an environmental expert, Evangelista emphasized the importance of carbon accounting and greenhouse gas (GHG) reporting among Philippine industries, particularly the mining sector.

This is in reference to the DENR latest order, DAO 2025-10. The new regulation is in conformance with the United Nations Sustainable Development Goal (SDG) 13 on climate action.

More specifically, DENR Administrative Order 2021-43 requires companies to report their emissions. This order contains “Guidelines on the establishment of the carbon accounting, verification, and certification system (CAVCS) for forest carbon projects”.

It states, “Provides for establishing a carbon accounting, verification, and certification system for forest carbon projects to

encourage and support investments in activities that sequester carbon dioxide and avoid emissions from deforestation and forest degradation”.

Evangelista pointed out that GHG reporting is now a key expectation from investors, customers, and regulators as part of risk management and business accountability. While full implementation in the Philippines remains gradual, the practice is steadily expanding in various industries, from mining to food production and infrastructure— where carbon emissions are being monitored and verified.

From his presentation, in Setting Operational Boundaries, it entails three steps, namely: identify emissions associated with operations, classify emissions as direct or indirect, and categorize the “scope” of emissions.

Carbon accounting and reporting in the Philippines follows international standards and methodologies, namely: -- ISO 14064-1 -- GHG Protocol, A Corporate Accounting & reporting Standards -- IPCC Guidelines for National Greenhouse Gas Inventory GHG Protocol http://www. ghgprotocol.org/ -- UK Government guidance “Guidance on how to measure and report your greenhouse gas emissions” [1] These guidelines cover both direct and indirect emissions under Scopes 1 and 2, with Scope 3 involving supply chain emissions. Mining companies were encouraged to begin measuring Scopes 1 and 2 to establish baseline data that can later guide reductions and sustainability strategies.

Mining firms have the opportunity to engage in carbon sequestration within their declared rehabilitation areas, primarily through the implementation of biomass or, more effectively, mangrove projects.

Through these initiatives, they can be converted into valuable carbon offsets and subsequently traded as carbon credits within established international frameworks, such as the VERRA protocol or the Verified Carbon Standard (VCS) Program. VCS is the world’s most widely used greenhouse gas (GHG) crediting program.

The potential of mangrove ecosystems was emphasized by Evangelista, that the total carbon sequestered by mangroves is 20 times that of a regular forested area. Such projects, described as “low-cost, high-impact” strategies, present a pathway for the industry to contribute significantly to environmental protection.

SGS Philippines, Inc. offers both consulting and third-party verification services and is an accredited auditor under VERRA. The company has been operating in the Philippines since 1949, and is currently the country’s top provider of certification, testing, verification, and inspection.

Their Philippine headquarters is in Makati City, with a network of offices and laboratories located in Subic, Mariveles, Navotas, Batangas, Albay, Nueva Vizcaya, Masbate, Leyte, Surigao City, Davao City, and Cebu City. SGS was founded in Rouen, France, in 1878. Its headquarters moved to Geneva, Switzerland, in 1915, and it was officially renamed Société Générale de Surveillance (SGS) in 1919.

The next speaker for the Mining Luncheon is Steve Gagnuss, Vice President, Southeast Asia, Industrial Service & Equipment for Konecranes. He has 39 years of experience in Konecranes. His presentation is titled “Safe, Productive and Sustainable Products and Services in the Mining Industry”.

Konecranes is a global leader in

material handling solutions, serving a broad range of customers across multiple industries. The company is known to consistently set the industry benchmark, from everyday improvements to the breakthroughs.

During his presentation, Gagnuss emphasized the company’s strong commitment to safety, sustainability, and digital innovation in lifting solutions.

Konecranes is a world-leading group of Lifting Businesses™, serving a broad range of customers, including manufacturing and process industries, shipyards, ports, and terminals.

He also highlighted the company’s global operations and technological advancements. Gagnuss noted that many specifications in the industry remain outdated, limiting opportunities to integrate modern safety and productivity features. He urged customers to adopt updated standards that would allow the use of advanced technologies designed to enhance operational efficiency and workplace safety.

The legacy of Konecranes dates back in 1910 in Helsinki, Finland as KONE Corporation, an electrical motor repair shop. Today, the company operates in 50 countries with over 16,700 employees, and continues to lead in safety management, requiring employees to document observations and improvements through a mobile app. This practice helps drive operational enhancements both within Konecranes and its client operations. With the acquisition of the Demag brand in 2017, Konecranes now holds a Gold rating in sustainability, placing it among the top 5% of global companies for responsible operations.

Konecranes currently has more than 17,000 connected equipment units worldwide, enabling realtime data monitoring through its Industrial Internet ecosystem. The company’s innovations, such as sway control technology that prevents load swing accidents, demonstrate its commitment to safety-driven engineering. Locally, Konecranes is set to deliver two large mobile harbor cranes to Cebu, showcasing its role in supporting port operations in the Philippines. With predictive maintenance tools, smart features, and digital transparency, Konecranes continues to redefine lifting as a safer, smarter, and more sustainable industry.

Reference: [1] You may get a copy of UK Government guidance – “Guidance on how to measure and report your greenhouse gas emissions” from this link: https://www.gov.uk/government/ publications/guidance-on-howto-measure-and-report-yourgreenhouse-gas-emissions

With more than 80 years of magnetic expertise behind them, Eriez Dry Vibrating Magnetic Filters (DVMF) dramatically reduces contamination in materials that require extremely high levels of purity. Eriez. Always the Right Choice.

The high intensity induced magnetic field provides exceptional separation efficiency removing ferrous debris and weakly magnetic contamination such as scale and chromites.

Philex Mining Corporation, one of the oldest and largest copper and gold producers in Southeast Asia, has been granted an Exploration Permit (EP) by the Mines and Geosciences Bureau (MGB) to conduct mineral exploration in Pangasinan.

The approval reinforces the government’s commitment to responsible mining and the company’s efforts to sustain long-term resource development in the country.

The permit was formally signed at the MGB Central Office in Quezon City.

Among those present were Victor Francisco, Philex Vice President for Environment and Community Relations; Noel Oliveros, Division Manager for Exploration; Eulalio Austin Jr., Philex President and CEO; Michael Cabalda, Department of Environment and Natural Resources Assistant Secretary for Mining Concerns and concurrent MGB OICDirector; Danilo Delena, MGB Mining Tenements Management Division Chief; and Francis Joseph Ballesteros Jr., Philex Corporate Affairs and Communications Head.

Under the Philippine Mining Act of 1995, an EP grants the right to explore for all types of minerals in a specified area, with the Mines and Geosciences Bureau retaining

authority to grant such permits to qualified applicants.

The document allows Philex to undertake technical and scientific studies to determine the potential for mineral development in Pangasinan, subject to strict environmental safeguards and consultations with host communities.

A legacy in Philippine mining

Founded in 1955, Philex Mining is regarded as a pioneer in the Philippine minerals industry. The company operates the Padcal Mine in Benguet, which began commercial operations in 1958 and remains the country’s first large-scale underground mining operation.

Padcal has been a major producer of copper, gold, and silver for more than six decades, contributing significantly to government revenues, community development, and employment in Northern Luzon.

Beyond Padcal, Philex has also advanced exploration and development projects aimed at ensuring its future growth.

Its Silangan Copper-Gold Project in Surigao del Norte is among the largest mining investments in the country, projected to produce billions worth of mineral output over its mine life.

Silangan is designed with advanced technologies and sustainability measures, positioning it as a next-generation model for responsible mining in the Philippines.

The Pangasinan EP provides Philex with an opportunity to diversify and strengthen its resource pipeline. Exploration activities will focus on identifying mineralized zones that may support future commercial operations, which in turn can generate local employment, infrastructure, and social programs for surrounding communities.

The new mining permit emphasized the company’s commitment to responsible mineral development, reinforcing partnerships with stakeholders and aligning with national goals for sustainable resource use.

With its track record of balancing production with environmental stewardship and community engagement, Philex is positioning itself to continue as a leading force in Philippine mining. The latest EP underscores both the government and the company’s determination to responsibly unlock the country’s mineral potential.

OceanaGold (Philippines), Inc. is pleased to announce the appointment of Mr. Brian Martin as Chair of the Board of Directors, effective September 24, 2025.

“It is an honor to be appointed Chair of OceanaGold Philippines. I look forward to working closely with the Board of Directors and the management team to continue delivering strong operational performance and value creation for our shareholders,” Martin said in a statement.

“With a high-quality asset in Didipio and an experienced and dedicated team, we are well-positioned to build on our success and contribute meaningfully to the Philippines and the communities we serve,” he added.

As an executive with two decades of experience in the metals and mining sector, Martin brings deep expertise in corporate strategy, investor engagement and business development.

He currently serves as Senior Vice President, Business Development and Investor Relations, at OceanaGold Corporation.

In this role, Martin leads OceanaGold’s investor relations program, advances strategic growth initiatives, and plays a central role in shaping and executing the company’s corporate strategy.

While meeting with key national stakeholders and regulators, Martin reiterated OceanaGold Philippines’ commitment to continuing to invest in the Philippines and to supporting local and national development.

He met with Deputy Governor Mamerto G. Tangonan of the Bangko Sentral ng Pilipinas (BSP) and underscored the agreement of OceanaGold Philippines to sell at least 25 percent of its annual gold doré production directly to the BSP, helping strengthen the country’s gold reserves and supporting the Philippine financial system.

Martin also paid a courtesy visit to Philippine Stock Exchange (PSE) Chief Operating Officer Atty. Roel Refran, where he emphasized OGP’s growth potential and commitment

to creating long-term value for its shareholders.

These engagements come at a time when OceanaGold Philippines continues to gain recognition in the Philippine market for its steady operational performance and exceptional returns for shareholders since its successful IPO in May 2024. In August 2025, the Company was added to the PSE MidCap Index.

“Our recent inclusion in the PSE MidCap Index is a strong endorsement of the trust investors and regulators place in us. It reflects our consistent performance, transparent governance, and commitment to

responsible mining,” Martin said.

With the Company’s strong leadership, OceanaGold Philippines continues to deepen its collaboration with governments, communities, and regulators as it strives to create a better future for all its stakeholders.

OceanaGold Philippines operates the Didipio gold-copper mine in Luzon under a Financial or Technical Assistance Agreement.

The company is committed to safely and responsibly maximizing the generation of free cash flow from its operations and delivering strong returns for its shareholders.

Philippine mineral companies emerged as top winners in five of the six categories of the 4th ASEAN Mineral Awards (AMA), held on October 2 in Vientiane, Lao PDR.

Eagle Cement Corporation won the Best Practices in Mineral Mining – Non-Metallic Minerals award, while Northern Cement Corporation took home the Best Practices in Mineral Processing –Non-Metallic Minerals award.

Hinatuan Mining Corporation received the Best Practices in Mineral Distribution – Metallic award.

Carrascal Nickel Corporation and FCF Minerals Corporation were named first runners-up in the Best Practices in Mineral Mining – Metallic and Best Practices in Mineral Processing – Metallic categories, respectively.

Ambassador Elizabeth T. Te congratulated the representatives of the Philippine companies who received the awards, highlighting the country’s strong regional standing in responsible and sustainable mining. The ASEAN Mineral Awards

recognise outstanding companies in the ASEAN region that demonstrate excellence in environmentally and socially responsible mining, processing, and mineral distribution practices.

The biennial awards aim to promote sustainable mineral development and encourage the sharing of best practices among ASEAN member states.

The awards were conferred during the Gala Dinner of the 10th ASEAN Ministerial Meeting on Minerals (AMMin) and its associated meetings and events, held from 29 September to 3 October 2025 in Vientiane.

Environment and Natural Resources Assistant Secretary for Mining Concerns Michael Cabalda, who also serves as Officer-in-Charge of the Mines and Geosciences Bureau (MGB), led the Philippine delegation to the 10th AMMin.

During the meeting, ASEAN ministers endorsed and adopted the ASEAN Minerals Development Vision (AMDV) and the ASEAN Minerals Cooperation Action Plan (AMCAP) IV 2026–2030.

This outlines the region’s collective strategy for advancing sustainable mineral resource management and regional cooperation.

Get all the testing and troubleshooting power you need inside or outside ATEX zones 1 or 2 with Fluke 28 II Ex. It is MSHA-certified for the mining environment, ensuring safe operation in hazardous zone, reducing downtime, and keeping critical processes running smoothly even in the most demanding conditions.

Digging in the wrong place and hitting a utility line can lead to costly repairs and create hazardous safety situations. Avoid this disruption with the rugged and durable Amprobe UAT-600 Series, designed to accurately pinpoint underground utilities and buried services up to 100 feet deep with accurate depth measurement to 20 feet.

www.fluke.com/en-ph

With FieldSense™ technology, it now supports non-contact voltage measurement up to 1000 V ac and current up to 200 A ac, all through the open fork and without test lead contact to live voltage.

When checking continuity, the T6-1000 PRO screen automatically turns green while the beeper is on with Visual Continuity™. It is perfect for those times when it’s too loud to hear the beeper in the mining site.

In Dinapigue, Isabela, the story of mining is taking a creative turn. Where others see discarded glass and plastics, Dinapigue Mining Corporation (DMC) sees the building blocks of sustainability.

Inside its Material Recovery Facility (MRF), bottles and wrappers that would have likely ended up as waste are crushed, shredded, and given a second life as eco-bricks – a durable, low-cost, construction material now used to line pathways in the mine site and the local community.

So far, DMC has produced 48,000 eco-bricks, recycling 7 tons of glass bottles and 3 tons of plastics in the process.

“This is our way of showing that mining can transform and improve not just landscapes, but entire mindsets about waste,” said DMC Resident Mine Manager Engr. Edwin R. Casiano.

DMC also conducts information, education, and communication sessions with its host and neighboring communities to share its best solid waste management practices such as eco-bricks manufacturing to make environmental protection a shared effort.

The eco-bricks initiative is part of DMC’s broader approach to circular economy, ensuring that waste from daily operations finds new life.

Complementing the company’s reforestation efforts, the program reinforces DMC’s goal of leaving behind not just rehabilitated land, but blueprints for sustainable development.

As a subsidiary of listed natural resources development company Nickel Asia Corporation (NAC), DMC continues to prove that responsible mining can co-exist with sustainable innovation.

The company also maintains two on-site nurseries capable of hosting 300,000 seedlings, contributing

to 1,352.86 hectares of greenoffset plantations across Isabela, Cagayan, Quirino, and Nueva Vizcaya, equaling 1,099% more than its total disturbed area.

The company has also planted 731,896 seedlings both within and outside Dinapigue and has established 132.15 hectares of new plantations as part of its restoration and reforestation efforts.

Beyond its environmental milestones, DMC remains deeply invested in community development.

Through its Social Development and Management Program (SDMP), DMC has invested PHP 43.1 million since 2015 in initiatives that support education, health, infrastructure, and livelihood in its host and neighboring communities.

The company’s scholarship programs have also produced 27 graduates, some of whom now work with the company as professionals.

DMC is a two-time recipient of the Titanium Achievement Award under the Presidential Mineral Industry Environmental Award (PMIEA) in 2023 and 2024, recognizing its excellence in

environmental protection, safety, and social responsibility.

“In mining, people tend to look at what is taken from the ground,” said Casiano. “We want to show what can be given back.”

Through its consistent focus on safety, environmental stewardship, and community development, Dinapigue Mining Corporation continues to demonstrate that responsible mining can indeed go beyond the pit, creating a legacy that’s greener, stronger, and built to last.

Geotab offers the greatest possible flexibility for any kind of project. Our device can be attached easily to any vehicle—regardless of manufacturer—and send the data to the same platform. Installation is simple, giving you visibility over the whole project and enabling you to track fuel efficiency, fuel burn, RPM, battery oil, engine health, and other key indicators.

Furthermore, through the multi-streaming function, contractors can be granted access to a database for a fixed duration. When the contract ends, their visibility to the site will cease, and the contractor can reassign it to someone else.

Our devices are built to withstand tough conditions on work sites. They are ideal for heavy mining equipment, construction, utilities, powered assets and trucks. Also, selected models are IP68 and IP69K rated with impact, water and humidity-resistant housing.

Begin your journey with Geotab today and move into a future where every trip is safe, and every operation is efficient.

With our help, you can track your valuable assets, increase equipment uptime and lower your operating costs.

For more information, visit geotab.com/apac

Precision drilling and operational discipline are essential at the low-grade, high-tonnage Masbate Gold Project, one of the largest operating surface mines in the Philippines.

Every meter matters at the Masbate Gold Project. Located on a remote island 350 kilometers southeast of Manila, the mine has built a reputation for delivering gold safely, sustainably, and efficiently.

Filminera Resources Corporation (FRC) is responsible for mining the mature epithermal deposit while B2Gold Corporation subsidiary Phil. Gold Processing & Refining Corp. (PGPRC) handles processing.

PGPRC is projected to process around 8 million metric tons of ore during 2025, blending fresh and stockpiled ore in the flexible plant to produce between 170,000 and 190,000 gold ounces. The mine’s daily tonnage ranges between 90,000 and 105,000 tons, and with an average gold grade of 0.9 grams per ton, every ton counts.

“You can imagine it’s a lot of dirt,” said Patrick Mkonyi, Assistant Vice President Technical Services of FRC. “Our success hinges on mine-to-mill discipline. We need clean drilling and blasting, minimal dilution, reliable equipment and process stability to keep tons and recovery where they need to be. Our focus is sustained productivity on variable ore sources while maintaining safety excellence and cost discipline.”

Disciplined, efficient production is paramount. That starts with drilling precision and reliability.

“It’s foundational to our success,” Mkonyi said. “Good drilling underpins everything we measure daily. If we miss a bit on the drilling, then the downstream side will run dry just like a river. It dictates blast outcome, which determines fragmentation, diggability, crusher throughput and, ultimately, cost per ton. If drilling isn’t right, nothing else works.”

In 2012, FRC took delivery of its first four Pantera™ DP1500i surface drill rigs from Sandvik. The rigs impressed in Masbate’s demanding conditions, standing out for their balance of power, intelligence and serviceability.

Thereafter, in 2017, FRC decided to self-operate the mines, instead of relying on a service contractor, it again purchased four new Pantera™ DP1500i rigs to replace the original four.

“We matched bench geometry, hole size range and desired penetration rates against haul-road constraints and maintainability,” Mkonyi said. “Pantera™ DP1500i hit the sweet spot. Power-to-weight ratio, automation options and cost per meter all aligned perfectly for our benches and rock mass.”

Designed for a wide hole range of 89 to 152 millimeters, Pantera™ DP1500i is a versatile top-hammer rig suited to high-capacity production drilling. Intelligent control systems and automated rod handling streamline the drilling cycle.

“The operator-friendly cab layout, intuitive controls and fast setup meant quick learning curves and high early utilization,” Mkonyi said. “Over time, the rigs have continued to meet or exceed expectations for penetration, accuracy and availability.”

Masbate measures the drills’ performance in meters per shift, hole deviation, utilization and cost per meter. Across all those KPIs, the fleet of Pantera™ DP1500i rigs deliver.

“We’ve seen stable penetration rates, repeatable hole quality and steady availability that aligns with our production plan,” Mkonyi said.

Sandvik delivered FRC’s 15th and 16th Pantera™ DP1500i units in 2024, the final additions to the fleet before open-pit mining is scheduled to conclude.

“They’re performing really well,” said Nikko Vanell Dolino, FRC’s Chief Mining Engineer. “They’re very reliable and they have aligned with our goals, especially with cost savings and production targets.”

Sandvik’s local support team in the Philippines plays a key role in sustaining that performance. Through regular site visits, technical guidance and proactive parts logistics, Sandvik ensures the rigs stay

“Depth of local expertise is one of Sandvik’s greatest strengths,” Mkonyi said. “Their technicians are on the ground, helping with condition-based maintenance, operator coaching and parts management. That partnership gives us confidence to meet our targets every month.”

In Masbate’s tropical and logistically remote environment, equipment reliability is vital.

“Access to service points is good, planned maintenance windows are short and predictable and the Pantera™ DP1500i’s design makes daily inspections straightforward,” Mkonyi said. “With genuine Sandvik parts and consumables, we’ve extended component life and stabilized cost per meter.”

Over time, FRC’s fleet of Pantera™ DP1500i rigs has grown steadily, a clear vote of confidence in both the equipment and the partnership behind it.

“Uptime, hole quality and responsive local support are the reasons we’ve stayed with Sandvik,” Mkonyi said. “Their commitment to performance transparency and fast feedback loops matches our own culture.”

While FRC’s open-pit operations evolve in response to market conditions, its legacy is already defined as a safe, responsible operation that has sustained thousands of jobs and delivered consistent output. From the first four Pantera™ DP1500i rigs in 2012 to the latest deliveries in 2024, one thing has remained constant: consistent performance, locally supported — the hallmark of Sandvik’s relationship with the Masbate Gold Project operation.

Major capital expenditure is often investors’ main concern when deciding whether to start a mining operation.

Numerous financial considerations arise, including infrastructure needs such as road construction, fixed plant requirements, the number of haul trucks, or the installation of rail links to port. These upfront costs can be significant and are often a deciding factor in whether a project proceeds.

In situations where capital expenditure must be carefully managed—due to short mine lifespans, remote locations, or dispersed ore bodies—mobile mining equipment can offer a more suitable and flexible alternative to traditional fixed plant.

That’s where MMD’s mobile and semi-mobile Sizer stations come into their own.

Among the most innovative of these offerings is MMD’s trailer-mounted sizing station. Designed for quick deployment and mobility, this unit can be delivered to site by truck and made operational with minimal setup. It processes material at rates between 300 to 2,000 tonnes per hour—ideal for lower-tonnage operations or sites that require scalable, flexible solutions.

Despite its compact footprint, the trailer-mounted unit performs like a fixed plant. It can be equipped with a primary, secondary, or tertiary Sizer and tailored with a range of tooth designs to suit various ore types.

Hydraulic legs and a folding conveyor make transportation and relocation straightforward, while wireless or onboard control options ensure ease of use.

Another effective option is the FMS 500—a more robust rig that is either track- or skid-mounted and constructed modularly to meet a client’s specific needs.

With a low-cost setup and the ability to operate in remote or hardto-reach locations, the FMS 500 delivers increased durability while still minimizing environmental impact. The track-mounted variant, for example, can be deployed anywhere a shovel can operate.

Both solutions underscore MMD’s commitment to flexible, sustainable mining. These smaller Sizer stations require virtually no groundworks and use advanced motor technologies to reduce energy consumption—ideal for mining operations seeking a lower environmental footprint and reduced operating costs.

While the smaller rigs offer flexibility and fast ROI for specific use cases, MMD also provides larger fully mobile and semi-mobile sizing stations designed for high-throughput operations—up to 10,000 tonnes per hour.

These units are often the preferred choice when projects still seek mobility but need the performance to match long-term, large-scale output.

For mining enterprises that anticipate decades of production and want to reduce reliance on expensive haulage fleets, these high-capacity systems can be deployed at the face of the mine, moving as the operation develops.

The result is reduced truck usage, lower fuel costs, and fewer emissions— key advantages in today’s ESGconscious landscape.

Although they involve a more significant setup than the smaller rigs, these larger mobile and semi-mobile

stations still offer faster commissioning and lower capital outlay compared to traditional fixed plant infrastructure and long haulage.

They strike a balance between operational scale and cost-effectiveness, particularly for mines where flexibility is critical to long-term planning.

For decades, fixed plant was the default for large mining operations. When a mine’s lifespan extended over decades, it made sense to invest heavily upfront. But for many of today’s operations—especially those in remote areas, with uncertain lifespans, or with multiple ore bodies—this model no longer fits.

MMD’s mobile and semi-mobile Sizer stations deliver a compelling alternative. Material can be processed closer to where it’s extracted, and the equipment can be relocated as needed.

Whether it’s a compact trailermounted rig or a 10,000 TPH highcapacity system, these solutions reduce setup times, lower capital risk, and boost operational efficiency.

Backed by decades of expertise, MMD’s mobile strategy is built to meet the evolving demands of modern mining. From smaller start-ups to established operations expanding into new zones, the company’s sizing stations offer a smarter, leaner way to move forward.

Because in today’s mining world, success isn’t just about digging deeper— it’s about mining smarter.

Traditional tailings dams are water-intensive and carry long-term risks. Metso’s dry stacked tailings solution changes the game. By removing water through high-efficiency filtration and stacking tailings dry, we help you:

• Eliminate the need for dams

• Recover up to 90% of water for reuse

• Reduce effluents and environmental footprint

• Improve safety and community trust

With over 100 sustainable Metso Plus products and services, our end-to-end tailings solutions, from filtration to digital optimization, deliver more performance where it matters most.

Safer. Smarter. More sustainable. That’s the future of tailings with Metso.

written by: JAKE TAN, PRODUCT MANAGER, FLUKE SOUTH EAST ASIA PTE LTD

In the mining industry, every decision about safety carries weight. Beyond the visible risks of heavy machinery and unstable ground, electrical hazards remain one of the most underestimated threats.

A small anomaly such as an unusual reading, a flicker in performance, or a faint sign of resistance can seem trivial in the moment, yet it may be the precursor to fire, electrocution, or catastrophic equipment failure.

Raising awareness of electrical safety is more than simply a matter of compliance. It’s about embedding the mindset that vigilance, proper training, and the right tools can mean the difference between safe operations and irreversible loss.

THE HIDDEN RISK: GROUNDING AND ENVIRONMENTAL CHALLENGES

Remote mining sites, particularly

in regions prone to monsoons and typhoons such as the Philippines, faces unique electrical safety challenges. Flooding erodes soil, changing its resistance and compromising grounding systems. When grounding resistance changes, the fault current might not flow safely, creating conditions ripe for short circuits, fires, or fatal shocks.

Standards such as NETA (for insulation resistance testing) and IEC 60364 (for electrical installation) exist to safeguard both workers and assets. Yet many operators in the field remain unaware of these standards, or lack the tools to test against them.

This gap highlights why awareness and skills training are critical to ensure proper maintenance of the infrastructure.

Advances in electrical testing tools are helping bridge the gap between operational needs and

safety requirements. Non-contact technologies which are nonintrusive reduces risks for workers while making inspections faster and easier.

• Underground cable locators detect buried power utilities before excavation begins, preventing potential accidental strikes.

• Non-contact voltage detectors such as the Amprobe TIC 300 PRO, mounted on a pole, give visual and audio alerts when it detects energized high-voltage overhead lines.

• Thermal imaging cameras reveal overheating components invisible to the naked eye, flagging early defects before they escalate into fires or equipment breakdowns.

• Advanced clamp meters (such as the Fluke 378 or T6-1000 PRO) measure both current and voltage without direct contact, allowing safe testing from outside panel doors.

< Page 46

• Acoustic imagers such as the Fluke ii905 identify leaks during mineral refining processes from a distance, even in noisy environments.

These innovative tools are convenient and, more importantly, essential daily safeguards that turn invisible risks into visible warnings.

While tools are indispensable, knowledge remains the first line of defence. Many workers in remote mining environments “don’t know what they don’t know.” Without training, they may overlook small signs of abnormality or be unaware of safer, newer technologies available to them.

Recognizing this, companies like Fluke are investing not only in equipment but also in training and on-site education.

By bringing awareness programs directly to mining sites, they help operators and HSE departments understand how to integrate safety practices into daily routines, creating a stronger culture of prevention.

Service and maintenance can be challenging when sites are located far awayfrom immediate support.

Innovations from Fluke, such as the Fluke 283 FC multimeter with a built-in, self-check function, give operators confidence that their tools are functioning correctly even in the most remote conditions. This capability reduces downtime, ensures accurate testing, and provides reassurance for lean teams with limited resources.

Electrical safety goes beyond PPE and compliance checklists. It’s about creating systems where people, processes, and technology align to reduce risk. Early detection of hazards prevents costly downtime, extends equipment lifespan, and saves lives.

By combining international standards, advanced test tools,