Taganito Special Economic Zone

Taganito Special Economic Zone

e effect positive change in the lives of many people.

We empower communities to be self-reliant and selfsufficient.

We promote the spirit of cooperation and collaborative partnership.

We share responsibility in enhancing economic prosperity and the general welfare.

We leave a legacy to the present and the future generations.

Answers Industry’s Queries

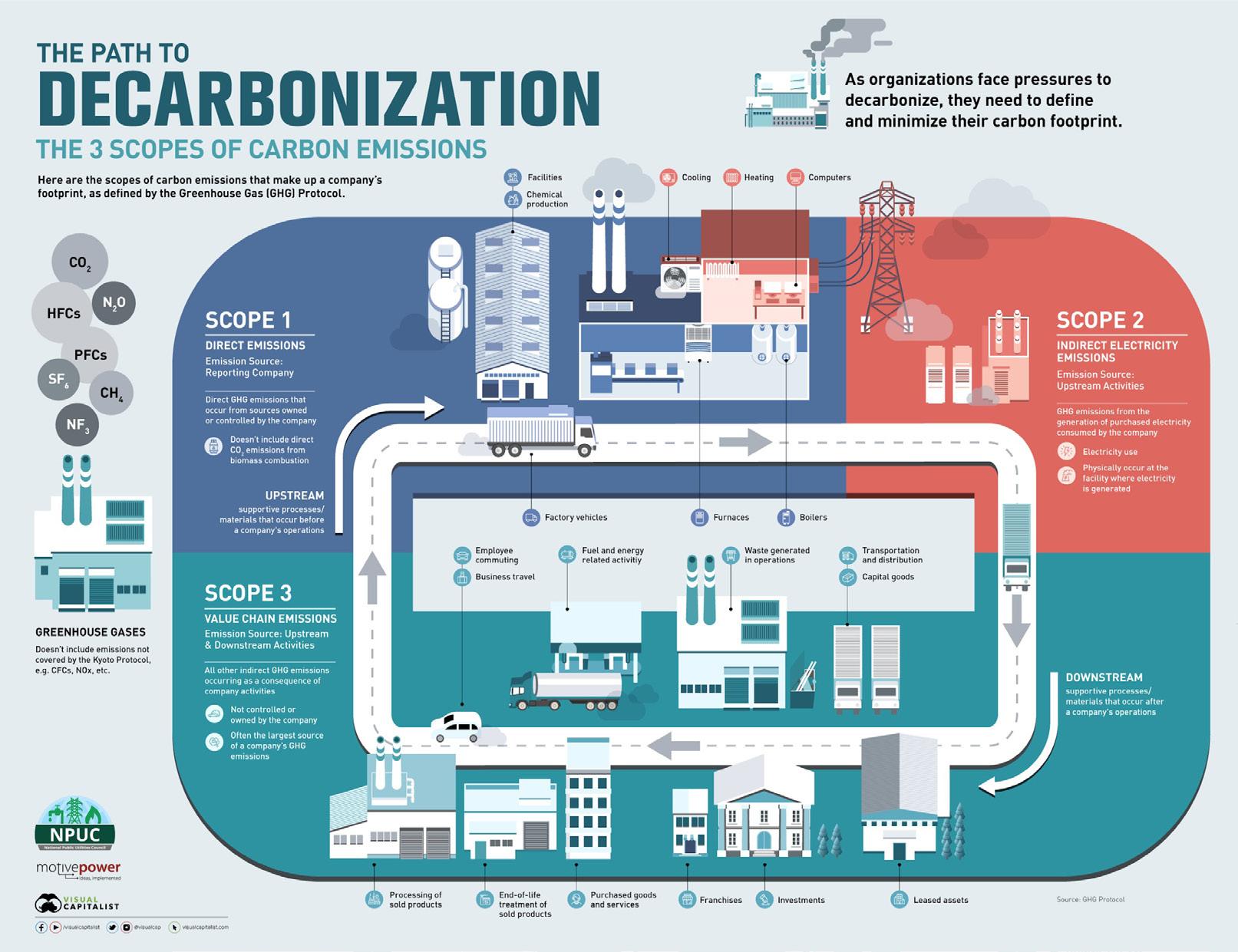

Mining Decarb: E-mission Impossible?

QES Technology Philippines, Inc.

Chamber of Mines Pushes for Policy Reforms

PMEA welcomes new MGB Director Cabalda

Expected Rebound for Nickel Industry Growth in 2025

Industry Updates from PMEA President

Addressing Bottlenecks and Drafting a Mining Royalty Cap

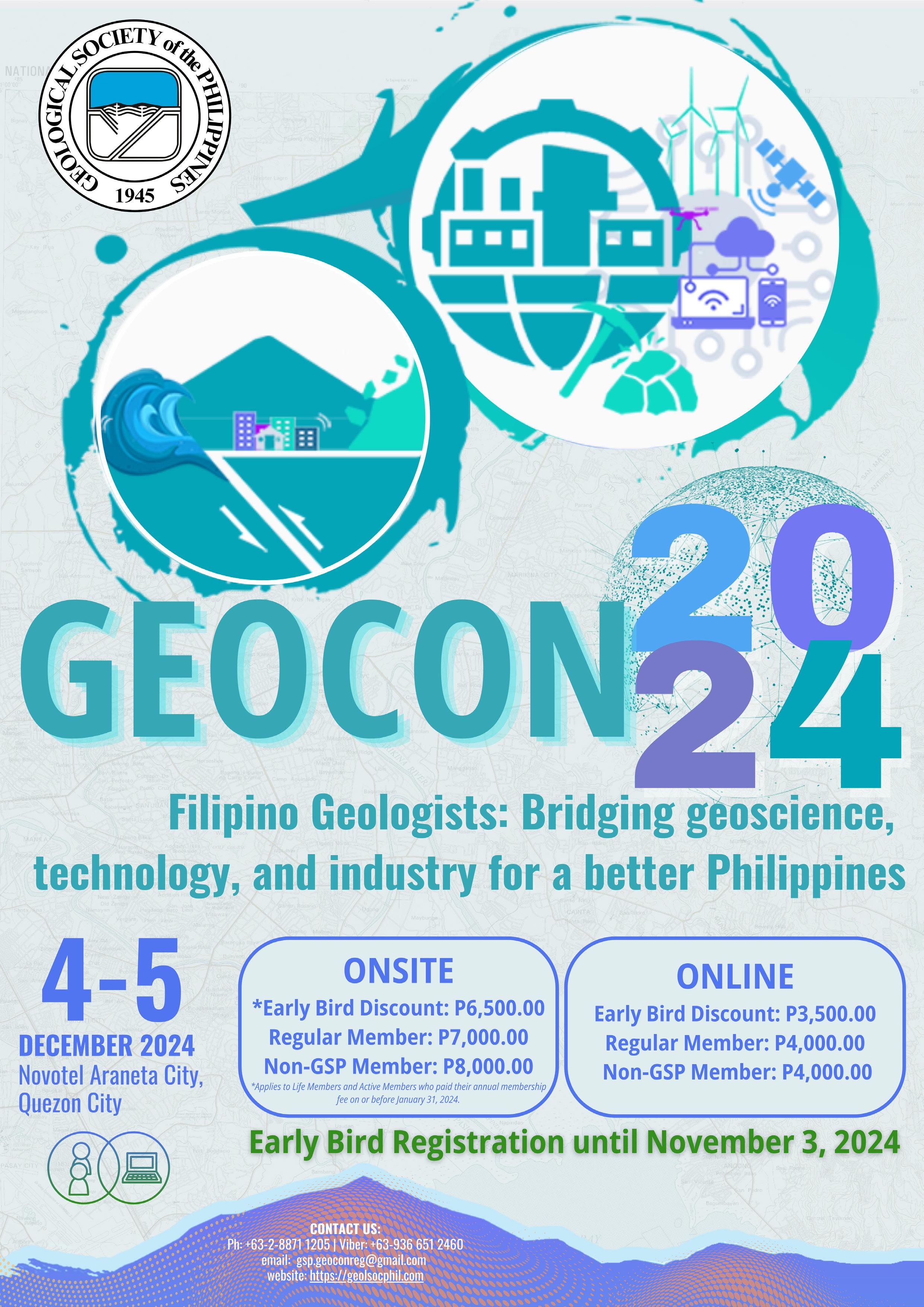

Geological Society of the Philippines Launches GEOCON 2024

Leading Voices Illuminate Future of Mining at PH Mining Club Luncheon

Go Home Safe

Johnson Screens Solutions Unlock Highest Efficiency in Water Wells for Mining Applications

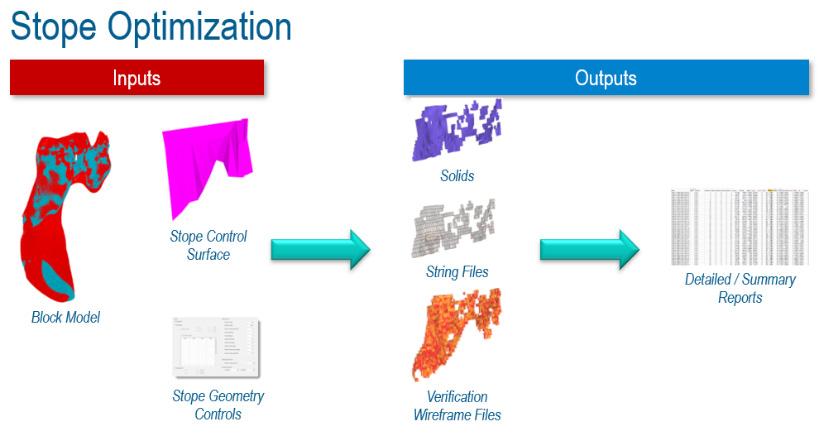

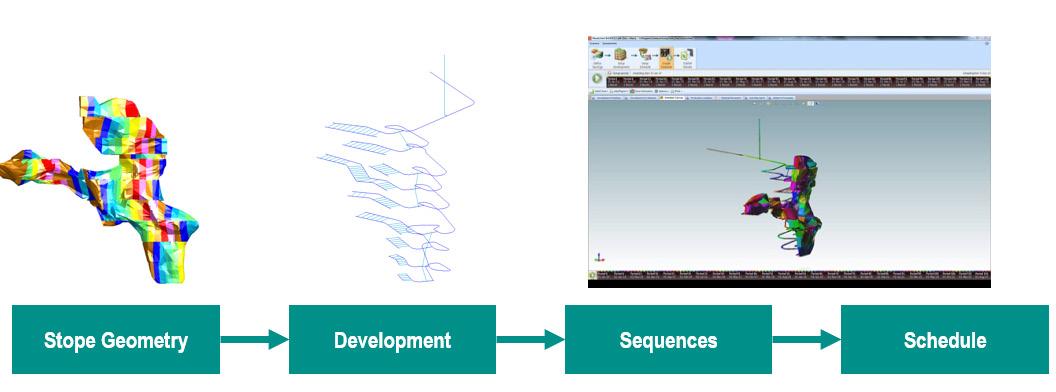

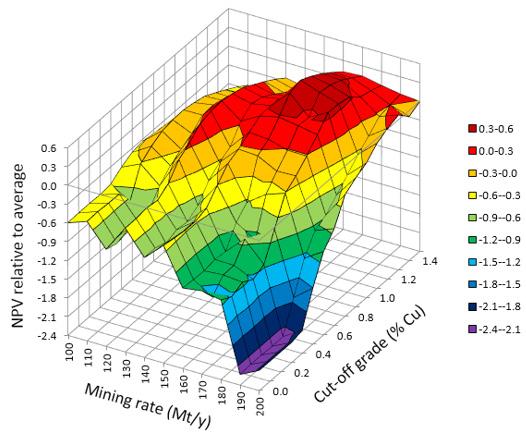

Underground Mine Value Through Stope

Intertek Minerals: Offering Mineral

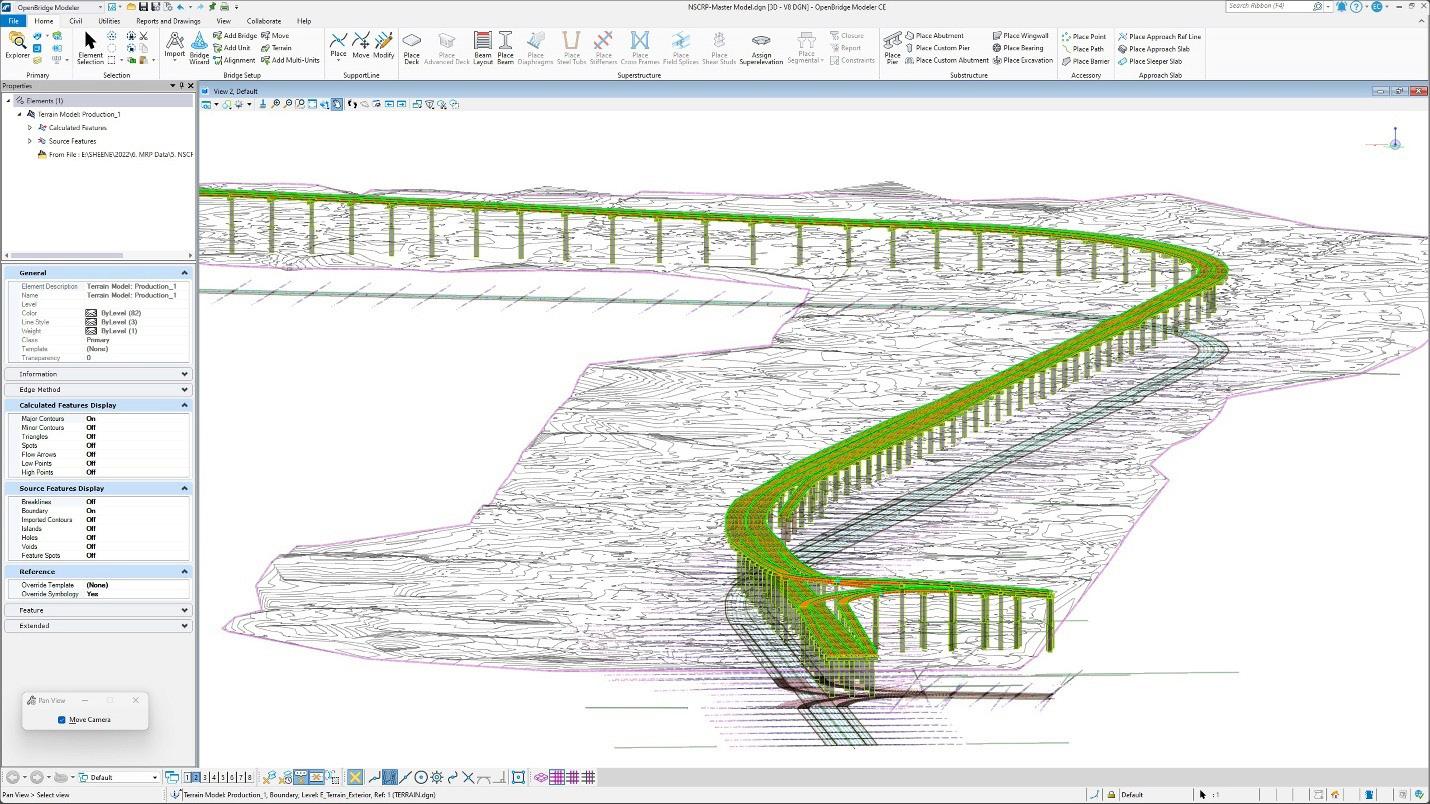

Transforming PH Infrastructure with Mixed Reality Solutions

Cement Makers’ Group Ready to Meet Growing Housing Demand

Prices of Construction Materials Remain Stable, Says PSA

DBM: August Infrastructure Spending Drops 11%

DTI-CIAP inks MOU with SCLP to Boost PH Construction’s Economic Potential

Successful Technical Summit Navigates Future of PH Infrastructure

RDCL: The Power of Geophysics in Modern Engineering

THPAL Celebrates International Day

Sandvik’s Centrevo Unifies Enhanced Rock Tools Digital Solutions Suite

Brings Spectro Scientific’s FieldLab 58C to the Mining Industry: Revolutionizing On-Site Oil Analysis

Customized Solutions for Efficient Material Handling: Chief Industrial Conveyor Systems

Robit: Serving Global Customers with Drilling Consumables

Higantis’ On-Site Tire Management: How We Help You Save Costs and Boost Efficiency

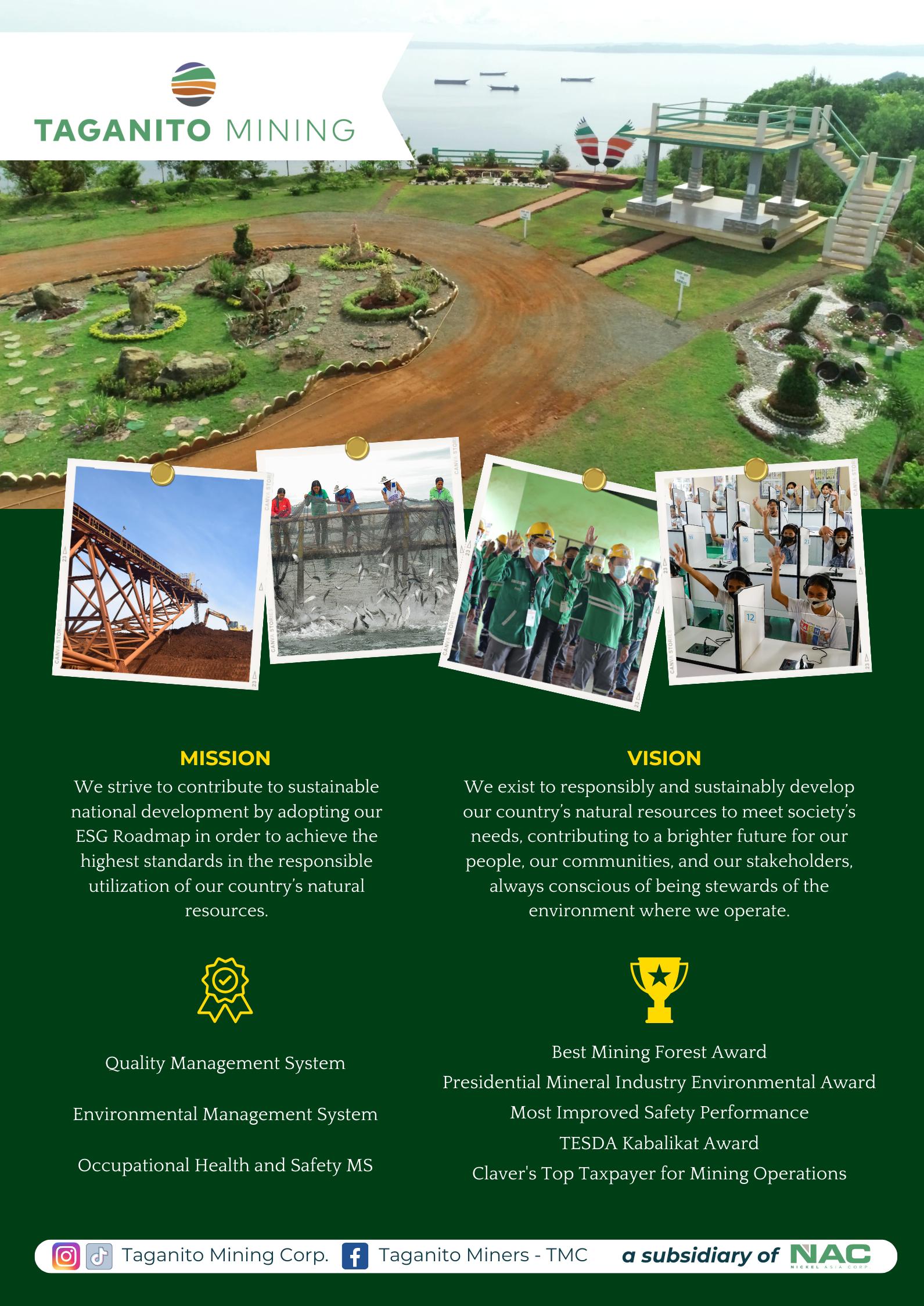

Taganito Mining Corp. Hailed as Overall Top Taxpayer in Claver for 2023

Manitowoc Crane Group, Inc. Unveils New Office Relocation to Enhance Customer Support and Service Capabilities

International Coastal Cleanup 2024: HMC-TNP Makes a Difference

Community Outreach Program with APEX at Your Service

Uniroc—The Innovative Path of the ‘Small Cross-Section Roadway Development Expert’

Leading Innovation and Community Engagement

Epiroc Unveils Diesel-Electric Minetruck MT66 S eDrive

TVIRD’s Balabag and Siana Gold Projects Gain Regional Gawad Kaligtasan at Kalusugan Award

Narrow carrier, wide possibilities. Advanced technology for narrow vein mining applications.

Marof his myriad inflation and against economic from the hard put consumer public a tight result declincosts further dollar fuel for materials more for debt the proand the Government facilienergy utiliAmong recovery are conflict weaker about by intercountry. businessmoney and and serespecially economic globally.

groups, the mining sustainable refrom the pandemic and slowdown. investments for underscored Secreassured the commitment to environment Diokno also expects adhere to practices. He strike environand supsocioeconomic Marcos ecomedium-term fissucceed mining

written by: FERNANDO PENARROYO

By Fernando Penarroyo

IFernando “Ronnie” S. Penarroyo specializes in Energy and Resources Law, Project Finance and Business Development. He is also currently the Chair of the Professional Regulatory Board of Geology; the government agency mandated under law to regulate and develop the geology profession. He may be contacted at fspenarroyo@penpalaw.com for any matters or inquiries in relation to the Philippine resources industry and suggested topics for commentaries. Atty. Penarroyo’s commentaries are also archived at his professional blogsite at www.penarroyo.com

Philippine Resources is published independently for executives in Philippine mining, construction, resources, and associated business sectors.

Publisher Elizabeth Galura

Consulting

Publisher Greg Brimble

Editor Jimbo Owen Gulle

Sales and Marketing Manager

industry would have to perform well. Dur ing the Philippine Economic Briefing in New York where President Marcos delivered a keynote message to American investors, Diokno emphasized the administration’s commitment to help maximize the mining sector’s potential in attracting more foreign investments.

t has been almost four decades since I have worked in the resources and energy industry. My career history can be set against the backdrop of the ups and downs of the industry starting from the time I began working as a government petroleum geologist up to the present where I am both a government regulator and a private law practitioner.

The mining industry considered the Duterte administration as another wasted era for realizing the full economic potential of the sector. The Marcos government in herited a mining industry reeling from the anti-mining stance of the previous admin istration with the appointment of the late Regina Paz Lopez, a staunch anti-mining advocate, to head the Department of En vironment and Natural Resources (DENR). The appointment was bitterly opposed by the industry resulting in Lopez’s rejection by the powerful bicameral Commission on Appointments.

During her term, Lopez ordered the clo sure of mining operations and initiated a national mine audit conducted on behalf of the Mining Industry Coordinating Council. Mining stakeholders described the three years of closure of these companies as “arbitrary” and claim that at that time, the industry practically “gasped for breath.”

I witnessed the paradigm shift in the industry when environmental protection became the norm in the 80s and indigenous peoples’ rights were given legal recognition in the 90s. The millennium saw how green energy transition and digital transformation drove companies to adhere to the ESG framework extending sustainability beyond environmental issues to encompass climate change, human rights, monitored revenues, and strict adherence to laws.

Trondheim, Norway, 1988

Matt Brimble +63 927 721 6622

Matthew@philippine-resources.com

Account Manager

Merian Jay Fallan +63 955 738 0266

merian@philippine-resources.com

Administration

Cecilia Pamular +63 917 308 1971

cecille@philippine-resources.com

Graphic Designer Bogtong Wangga

Journalists

Marcelle P. Villegas

Engr. Edison Mating

Contributors

Patricia A.O. Bunye Fernando Penarroyo

Manila Publishing Office

Suite 6, 2nd Floor

Corinthian Plaza Building 121 Paseo de Roxas

Legaspi Village Makati City, Philippines 1226

Phone +632 8251 5599

Digital Online Edition www.Philippine-Resources.com

With COVID-19 bringing down the economy on its knees and a worsening economic fallout becoming inevitable, Duterte issued Executive Order No. 130 in April 2021, lifting the nine-year moratorium on the granting of new mining permits. Finally in December 2021, the Duterte administration succumbing to economic pressure, lifted the ban on open-pit mining.

It is well to note that at the height of the pandemic in 2021, the mining sector’s contribution to the gross domestic product

I embarked on a geology course upon the persuasion of my parents who wanted me to have a stable and relatively high-paying job. A relative was gainfully employed as a structural geologist in a government corporation and my parents believed that the profession offered numerous opportunities for career advancement.

So, there I was, a wideeyed high school graduate from a small parochial school, enrolled in UP in a freshman block composed of 15 geology

Page 8 >

and 15 engineering majors. The group was a merry mix-up of kids from both exclusive and public schools, and uber-smart guys from Xavier School and Philippine Science High School who ate advanced calculus for breakfast. Our block president became active in university politics and was elected as University Student Council Chair, a prelude to his eventual rise as senator of the republic. Many in our freshmen block pursued their PhDs in geology while surprisingly, a good number became lawyers like me.

On the Cover: Photos is courtesy of

New Leopard DI650i down-the-hole surface drill rig offers long-term productivity and superior stability with robust and reliable main components – seamlessly integrated with state-of-the-art technical solutions. Scalable automation, easy maintenance and outstanding movability are the features that make Leopard DI650i a premium product, which is an honor to own.

Leave your paw print and enjoy the smooth, efficient ride.

Explore the new Leopard DI650i: ROCKTECHNOLOGY.SANDVIK/DI650 i

Amidst the political turbulence and economic chaos brought about by the

assassination of Benigno “Ninoy” Aquino, I obtained my geology degree. Little did I realize that graduation from the university was just the beginning of the real challenge. Employment in the geoscience field depended highly on the price of commodities, particularly metals and oil. We entered the job market when metal and oil prices in the eighties were depressed. Qualifying for a geoscience job in the resources industry was difficult. The options were either being employed as a contractual worker in government or staying in the

university as a research assistant while pursuing graduate studies. Private companies were not hiring and in fact retrenching their technical people.

In the 1970s, copper prices trended upward and peaked. The country’s copper production continued and boomed until 1980 when output recorded its highest production. Meanwhile, the 1973 energy crisis, also known as the Oil Shock of 1973–74, was a period of skyrocketing energy prices and fuel shortages resulting from an embargo by Arab oil-producing nations in response to U.S. support for Israel during the Yom Kippur War. These periods saw the initial boom and increase in demand for geologists.

However, in 1986, Saudi Arabia grew tired of attempts to stabilize the oil glut in the market by curbing its output and increasing oil production from two to five million barrels of crude oil per day. Between August 1985 and August 1986, crude oil prices plummeted from $28 per barrel to $8 per barrel before stabilizing at $18 per barrel.

During the oil price decline, copper prices also recorded low prices brought about a decline in demand for the metal. The world recession in 1982 – 1984 also pulled down copper prices further dampening demand, which fell more steeply than crude oil.

In the 1980s, the Philippine mining sector started its decline with the closure of several mining companies due to the financial crisis and the occurrence of several mining accidents. Inflation brought about by the debt moratorium crisis in 1983 and unstable political environment, devalued the Philippine peso effecting an increase in the costs of mining production, materials and equipment. Aggravating the situation were the economic crisis and political unrest in the Philippines in the mid-eighties. There were basically limited employment opportunities for

new geology graduates at that time.

As a twenty-year-old and fresh from the university, I was practically forced to accept any technical job offered to me. My family was concerned that I would just be bumming around the house after graduation, so I accepted a job as a contractual cartographer at the Bureau of Energy Development (BED) under the then Ministry of Energy. Friends and classmates chided me as overqualified for the job and described my work as nothing but a glorified draftsman.

Beggars can’t be choosers because there were no permanent positions for new geology graduates who have not even hurdled the board examinations. Thankfully, BED management gave us, the new graduates, leeway to review for the board exams. The senior geologists also provided us with a collection of review materials and past examinations for our guidance. However, human resources cautioned us that we would lose our jobs if we fail the board exams. So, we used our allocated time in the afternoon to study and attended review classes in the evening.

In August of that year, a few months after graduating and getting employed in April, I took the board exams. After passing the licensure exams and

becoming a registered geologist, I was regularized and became a permanent government employee with the title junior science research specialist.

Fortunately, when I entered the BED, there was an existing World Bank-funded project called “Petroleum Exploration Promotion Project”. The Project aimed to rekindle the interest of petroleum companies in exploring for oil and gas in the Philippines by undertaking a nationwide evaluation of the petroleum potential of the country’s fifteen (15) onshore and offshore sedimentary basins. Aeromagnetic and offshore seismic surveys were undertaken and the information generated was integrated with comprehensive regional basin evaluation studies. The more prospective Northwest Palawan and Reed (Recto) Bank areas in the West Philippine Sea were subsequently included in the study. Complementing the Project was a grant from Petro-Canada International Assistance Corporation, which acquired additional seismic data in selected offshore areas.

The Project also aimed to strengthen the exploration knowhow and technical capabilities of the government implementing entities - the BED and the Philippine National Oil Company Exploration Corporation (PNOC-EC). It

was an effective mechanism of training the Filipino technical staff involved in the Project and I was a beneficiary of the knowledge transfer. My colleagues and I were mostly young geologists and geophysicists with very little exploration experience when we joined the BED.

It was in the Project where I initially learned the ropes of petroleum exploration. I was exposed to several aspects of exploration from seismic data acquisition, processing, and interpretation when I was assigned to the geophysics section. It was an effective on the job training for me as I was under the supervision of World Bank foreign consultants and Filipino senior geoscience professionals seconded to the BED from PNOC-EC.

During the marine seismic survey conducted by PetroCanada, I was sent aboard the research vessel to familiarize myself with the seismic data acquisition process. Marine data acquisition was conducted by using seismic vessels outfitted with sources and streamers that are towed behind the ship. I was seasick for the first few days and was advised to stay in the cabin. When I recovered from motion sickness, my job was to assist in the lay-out and design of the

Page 12 >

survey lines. I also helped in the quality control of the initial data generated.

It was a spectacular feeling of being out in the open sea. The rhythm of the waves and the wind can help clear the mind and make one feel more connected with nature. I also experienced the sight of so many marine life like dolphins, sharks, flying fish, box jellyfish, and sea birds.

The raw seismic data were then sent to the data processing center. The recorded seismic signals were analyzed to filter unwarranted noise to create an image of the subsurface and enable geological interpretation and identify structures for petroleum accumulation. Under the Project, PNOC-EC set up their own seismic processing center funded by their own loan from the World Bank. Part of my training as a geophysicist was my assignment to PNOCEC’s Data Processing Center to understand how seismic data are prepared for analysis and interpretation. Seismic data were stored in magnetic tapes and once processed were printed on paper sections.

Seismic interpretation was the last stage in seismic exploration and used to infer the geology at certain depths from the ocean bottom. In the 1980s, data were first reproduced from sepia films using ammonia-based blue printing machines. Seismic interpretation was still done manually on paper sections of two-dimension data using colored pencils. At that time, we pressed our face sideways against the paper seismic sections spread across a long table. By looking sideways, we were able to trace subsurface horizons and large structural traps that could hold oil and gas deposits. We also encoded data and made structural contour maps manually without the aid of modern computer workstations and basin modeling software. The structural maps generated are then incorporated with other geoscience data to create drilling prospects. The

exploration geologist would then have to convince higher management that the mapped prospects contained petroleum in commercial quantities.

In addition to mentoring us in the basics in seismic exploration, BED management also allowed us to attend short in-house advanced training courses organized by the World Bank. Foreign experts were engaged and flown to the Philippines to conduct these one-week training courses. The classroom seminars and workshops allowed us to fully understand the theoretical and analytical concepts behind petroleum exploration.

With the change of government after February 1986, and the marked improvement and stabilization of oil prices towards the end of the year, things began to pick up for the upstream petroleum industry. The results of the assessment of the petroleum prospects were assembled in the form of a promotional package contained in 70 sets of a 12-volume report which consisted of a project summary, six volumes of texts and appendices, four atlas volumes and one supplement. The promotion of the Project was finally implemented in 1987 with roadshows conducted by senior government energy officials in major cities in the world to entice foreign oil companies to explore in the Philippines.

Following the conclusion of the World Bank project, management decided to send me abroad to attend a graduate diploma course on petroleum exploration and production. I was sent to Europe for further technical studies at the Norwegian Institute of Technology located in the university city of Trondheim, north of Oslo. Norway is a major petroleum producing and exporting country tapping the vast marine wealth of the North Sea, one of the busiest but treacherous bodies of water. It has an international assistance program for developing countries like the Philippines, which funded the studies and training of young professionals in different

technical fields.

Norway also boasts to have the world’s largest sovereign wealth fund, a government-run investment fund that invests in assets such as stocks, real estate, and bonds. The aim of the fund is to ensure a long-term management of revenue from its oil and gas resources, so that this wealth benefits both current and future generations. Investments are spread across most markets, countries, industries, and currencies to achieve a broad exposure to global growth and value creation and ensure good risk diversification.

Selected geologists from around the world were provided scholarships to study specialized subjects in petroleum exploration and production by the Norwegian aid agency. For ten months I was back at the university, imbibing highly technical subjects together with other international students. I studied with inquisitive mainland Chinese whose country was then starting to liberalize their economy and super competitive Indians who have to pass a battery of government examinations to win the scholarship. There were also other Asians, Africans, South Americans, and Europeans with different levels of experience.

A small Filipino community

existed in Trondheim composed of nurses and their families, and Filipinas who were married to Norwegians. They took good care of Pinoy scholars, and certainly made life bearable in a far and cold country. At that time, the world was not that globalized yet and Norwegians in a small town have very limited encounters with Asians. Except for a few Vietnamese “boat people” refugees who sought political asylum in Norway from their communist government, Norwegians have but a few interactions with young, darkhaired East Asians like me. On several occasions inside the public bus and train, I noticed blonde, blue-eyed descendants of Norsemen staring and smiling at me. Perhaps my “exotic” looks back then were the precursor of the present K-pop phenomena. If you dare to ask me whether I have had a Scandinavian girlfriend, that is best left narrated in another article.

When I returned to the Philippines after my scholarship, it was the time when the Philippines began to reap the fruits of the success of the World Bank Project. During the late eighties to early nineties, the country was on the radar of large petroleum exploration companies

Page 14 >

like Exxon, Shell, British Petroleum, Chevron, Atlantic Richfield, Occidental, and other majors. The release of the Report coincided with the discovery of the Camago-Malampaya natural gas field by Occidental and Shell, and the start of oil production from the West Linapacan by Alcorn Petroleum.

It was a bullish era for the upstream petroleum industry. The BED now renamed as the Office of Energy Affairs, following the reorganization and downgrade of the Ministry of Energy by President Corazon Aquino, was busy managing petroleum service contracts and applications. It was then the opportune time to harness my newly acquired technical knowledge. But the irony in government service is that the moment one begins to climb the career ladder, more administrative work is assigned to the individual. In my case, I was charged with more compliance review work

addressing the technical and financial qualifications of applicants for production sharing agreements and service contracts.

They say that if you want to see the world, then be a geologist. While there are certainly numerous opportunities for graduate studies and employment abroad for geologists, the profession also has inherent occupational and personal security risks. Field geologists often work in remote, harsh, and unpredictable environments, where they may encounter natural hazards, wildlife, accidents, or even violence. They explore frontier areas rampant in banditry, insurgency, and lawlessness.

My best friend in college who entered the BED with me at the same time, met a tragic accident off the waters of Tablas Island in Romblon province during fieldwork. He was a good swimmer, but he lost his young life trying to save another friend and colleague from drowning when

their speedboat capsized in choppy waters. Both died in the accident, and it was such a terrible reminder to the office not to take safety precautions lightly. It was truly heart breaking on my part to inform his parents about his death. A sad day indeed when I was also tasked by the office to retrieve his remains from Romblon and bring him home through a chartered eight-seater plane arranged by the government. Another blockmate from UP who has a PhD also perished in a helicopter crash together with a nationally renowned volcanologist while doing aerial survey work in the Sierra Madre for the Philippine Institute of Volcanology and Seismology. Geology is indeed a fascinating and rewarding field of study, but it also comes with many risks and challenges. Geologists also face pressures, such as long hours, deadlines, and numerous travel which take them away from their family and friends.

Why did I pursue a career in law?

(To be continued)

Fernando “Ronnie” S. Penarroyo specializes in Energy and Resources Law, Project Finance and Business Development. He is also currently the Chair of the Professional Regulatory Board of Geology, the government agency mandated under law to regulate and develop the geology profession. Atty. Penarroyo was recently awarded the 2024 Distinguished Alumnus Award for Geosciences by the UP Alumni Association. For any matters or inquiries in relation to the Philippine resources industry and suggested topics for commentaries, he may be contacted at fspenarroyo@penpalaw.com. Atty. Penarroyo’s commentaries are also archived at his professional blogsite at www.penarroyo.com

The World Bank, Report No. 8891 “Project Completion Report: Philippines Petroleum Exploration Promotion Project (Loan 2201-PHL)”, 29 June 1990, https://documents1. worldbank.org/curated/ en/422601468333040235/pdf/ multi-page.pdf

DMT is a leading mining consultancy and engineering group. Through its network of local offices, it serves clients all over the world. DMT is a major subsidiary of the German based TÜV NORD GROUP which employs more than 10,000 people. DMT’s mining consultancy offices are located in Bahrain, Canada, Germany, India, Indonesia, Kazakhstan, Peru, Russia, South Africa, Turkey and the UK

written by: PATRICIA A. O. BUNYE

the keynote of newly appointed Department of Environment and Natural Resources (DENR) Assistant Secretary (ASec.) for Mining Concerns and concurrent OIC Director of the Mines & Geosciences Bureau (MGB) Michael Cabalda.

In his prepared speech, ASec. Cabalda highlighted a number of initiatives including: (1) pushing a proposed Department Administrative (DAO) order articulating a policy framework that would allow the country to gain from our mineral wealth; (2) streamlining the permitting process to reduce the time to 11 months or shorter; and (3) reviewing the Small Scale Mining Act to formalize small scale miners and increase their contributions. These initiatives envision a mining industry that is not only an ore supplier but a critical player in mineral processing and downstream manufacturing.

The more spirited portion of the program was the Q&A where it was apparent that the audience was keen to hear directly from Assistant Secretary Cabalda in his first engagement with industry since his appointment.

Asked how soon the MGB will be able to implement the above policy changes, particularly the reduction of the processing

Patricia A. O. Bunye is a Senior Partner at Cruz Marcelo & Tenefrancia where she heads its Mining & Natural Resources Department and Energy practice group. She is also the Founding President of Diwata-Women in Resource Development, Inc., a non-government organization advocating the responsible development of the Philippines’ wealth in resources, principally through industries such as mining, oil and gas, quarrying, and other mineral resources from the earth for processing.

period for permits, Assistant Secretary Cabalda credited DENR Secretary Maria Antonia Yulo Loyzaga for leading these initiatives, foremost of which is giving the MGB Director the authority to sign documents that previously needed to be cleared. He also spoke about a more active MGB with respect to the pricing of nickel, statistics on safety and environment, among others.

Most encouraging was his assurance “Help me out and I’ll try to deliver and give you what you need.” He added that the “MGB is your partner. We will be with you when you do your work.” His warning “and we will punish you when you don’t” drew laughter from the crowd.

A recurring theme was the need for communication between the government and the private sector and institutionalizing a mechanism for government to address problems raised by industry. A suggestion to hold regular dialogs with industry was well received.

In addition, Asec. Cabalda expressed the need to touch base with his ‘council of elders’ or the MGB old-timers who possess the institutional knowledge and experience to be applied to (not-so-new) issues. This is expected to promote consistency in the MGB’s interpretation and application of issuances across the different regional offices. He likewise reiterated that he intends to build on what MGB,

Assistant Secretary/ MGB OIC Director Michael Cabalda and his predecessor Danilo Uykieng.

and the regional directors have done.

Another key strategy is to digitize all records and information to eliminate the current antiquated paper-based system. With information being available online and available in real time, there will be greater transparency, as well as identification of where the bottlenecks are.

As Asec. Cabalda discussed the need for coordination with other government agencies, particularly the National Commission on Indigenous Peoples and the Department of Interior and Local Government, I recalled his comments (prior to his appointment) during the May 2024 “Mining Summit” where he said that there is no need to reinvent the wheel as there is an existing and comprehensive Minerals Action Plan prepared by the Minerals Development Council back in 2004, with specific and detailed

items to address the identified challenges. Even 19 years later, it is replete with implementable action items.

It bodes well that our new MGB Director is approaching his role with openness and candor. The industry can do no less by responding in kind. ***

Postscript: Due to family commitments, I missed the Chamber of Mines’ “Digging Deeper” Policy Forum and will also miss, for the first time in recent years, PMSEA’s Annual National Mine Safety and Environment Conference (ANMSEC).

The ANMSEC has always been an opportunity for DiwataWomen in Resource Development to contribute to the discussion of important mining issues, as well inviting the participation of the ambassadors of countries which are developed mining jurisdictions.

One particularly memorable event for me was our 2012 forum featuring the Deputy Mineral Resources Minister of South Africa, Godfrey Oliphant. He was a fiery and outspoken advocate for mining, despite his once being a member of South Africa’s Communist Party. His story of how he came to realize the important role that mining played in South Africa’s economy was the perfect counterpoint to the student activists who had met him in UP Baguio.

(PART ONE OF TWO)

written by: NOEL B. LAZARO, EVEART GRACE P. CLARO, JUDD YONDER L. REYES, AND MARIELLE D. MARBELLA

In the foothills of Brooke’s Point, Palawan, the air is thick with purpose as workers press seedlings into the earth, each one a small promise for a greener future. Two years into its operation, the Ipilan Nickel Project has planted nearly three million seedlings. Yet, while the commitment to reforestation is clear, the challenge lies not in the availability of seedlings or the manpower to plant them, but in securing suitable land for these young trees to thrive within the municipality’s 85,064.90 hectares.

Afforestation of previously scorched mountainsides and agroforestry initiatives are underway.

By May 2024, mining companies had planted over 55 million seedlings in more than 50,000 mined-out areas, expecting a survival rate near 90 percent. Tree planting can help local communities, but it is not a complete answer.

Mining drives the world’s economy, providing raw materials vital for industries. The World Economic Forum notes that half of global GDP relies on natural resources. But mining comes with heavy costs. A 2020 McKinsey report estimates that mining produces 1.9 to 5.1 gigatons of carbon emissions yearly, largely from coal-bed methane and energy use. In 2022, the Deloitte Economics

Noel B. Lazaro is a director and general counsel at Global Ferronickel Holdings, Inc. His practice spans diverse fields, including environmental litigation. He was an associate at SyCip Salazar Hernandez & Gatmaitan and a partner at Siguion Reyna, Montecillo & Ongsiako. A UP College of Law graduate, he teaches evidence, special proceedings, and special writs at law schools.

Eveart Grace Pomarin-Claro is the Corporate Secretary of Global Ferronickel Holdings, Inc. and the Executive Legal Officer at Platinum Group Metals Corporation. A University of St. La Salle College of Law graduate, she specializes in securities and capital markets, taxation, project finance, and mergers and acquisitions.

Judd Yonder L. Reyes is a research associate and paralegal at Platinum Group Metals Corporation. A Bachelor of Arts in Communication graduate (Magna Cum Laude) from Pamantasan ng Lungsod ng Maynila, she is a completer of the 29th Foundation Course of the Paralegal Training Program of the University of the Philippines - Law Center.

Marielle Marbella is a research associate and paralegal at Platinum Group Metals Corporation. A Bachelor of Science in Life Sciences-Communication Track graduate (Magna Cum Laude) from Ateneo de Manila University, she has a background in journalism and supports the group’s sustainability programs.

Source: Visual Capitalist (https://www. visualcapitalist.com/)

Institute warned that climate change could lead to global losses of $178 trillion from 2021 to 2070. In the Philippines, the Nationally Determined Contributions (NDC) indicates that the mineral industry will continue to be a major greenhouse gas (GHG) emitter through 2030. This article examines the challenges and opportunities for decarbonization in the Philippine mining sector.

Decarbonization is essential for mitigating climate change by reducing or eliminating carbon dioxide (CO2) and other GHGs. It involves transitioning to cleaner energy sources and adopting sustainable practices to lower pollution. The ultimate goal is achieving “net-zero” emissions, where the amount of GHG released is balanced by the amount removed. Emission control can be achieved through natural methods like tree planting or watershed restoration,

and the costlier technological solutions such as direct air capture and storage. As the global community grapples with the urgent need for sustainable practices under the 2015 Paris Agreement, the Department of Environment and Natural Resources (DENR) has launched a “green transition” initiative. Secretary Maria Antonia Yulo-Loyzaga frames the transition as a “whole-of-so -

ciety” effort, advocating for science and technology investments alongside social and ecological considerations. Her emphasis on promoting biodiversity, carbon footprint reduction, and effective waste management practices is a step in the right direction.

At the Nordic-Philippine Climate Executive Dialogue held on June 18, she advocated for “nature-based solutions” for carbon reduction, suggesting a preference for simpler, less costly strategies over more complex carbon capture technologies. However, nature-based solutions, while essential, must be part of a broader strategy that includes robust carbon and efficient regulatory frameworks and tech advancements to genuinely meet the country’s pledge to reduce GHG emissions by 75 percent by 2030.

The secretary highlighted the Philippine Ecosystem and Natural Capital Accounting System (PENCAS), which aims to quantify the value of natural resources, including minerals, to socio-economic development and includes addressing the impacts on ecosystems by adopting the mitigation hierarchy in mining operations, which follows the steps of avoidance, minimization, restoration, and offsetting compensation for affected communities. On the other hand, the DENR’s recent release of the Implementing Rules and Regulations for the Extended Producer Responsibility Act of 2022, which mandates large companies to manage plastic waste, is a positive development.

The drive for modern infrastructure—encompassing electrification, renewable energy, automated systems, and AI-powered monitoring—represents a critical yet challenging evolution. In this context, electric vehicles (EVs) offer cleaner alternatives that reduce reliance on diesel machinery, which, according to a 2023 Mining Technology report, emits high levels of nitrogen oxides (NOx) and sulfur dioxide (SO₂). EVs are

also safer and quieter, contributing to lower fire risks.

However, such transformations often require substantial investments that can be prohibitively high. Thus, the call for effective incentives is crucial, but details remain vague. For Atty. Dante R. Bravo, president of Global Ferronickel Holdings, Inc. (FNI) and Philippine Nickel Industry Association, Inc. (PNIA), the industry “needs clarity in terms of incentives for mineral processing” and “competitiveness given the size of investments required.”

The dialogue around margin-based royalties and windfall profit taxes is envisioned to help build a more equitable arrangement.

The Chamber of Mines of the Philippines (COMP) has made a significant stride by launching the first phase of its Towards Sustainable Mining (TSM) initiative among its 19 members. This global standard for environmental, social, and governance (ESG) performance provides mining companies with essential tools to manage risks responsibly and adopt best practices. As the only ASEAN nation to adopt TSM, the Philippines sets a noteworthy precedent in the region.

The initiative focuses on vital areas such as health and safety, outreach to Indigenous Peoples, crisis management, tailings and water management, biodiversity conservation, and climate change. During the “Mining Philippines: Digging Deeper 2024” conference on October 17, four of eight randomly selected companies received the highest ratings across five key TSM protocols.

However, concerns remain regarding the scalability of these practices across the 56 largescale metallic and 59 non-metallic mines, along with over 3,000 small quarries in operation. The voluntary nature of TSM and its reliance on self-assessment raise doubts about its effectiveness. Inconsistent adherence, particular -

ly among non-members, could diminish the initiative’s overall impact.

This situation underscores the need for a more structured approach that transcends self-regulation. Regulators and legislators should take cues from TSM to develop a governance framework beyond existing mining laws and ISO benchmarks, potentially incorporating training and resource access.

TSM raises the compliance bar, but its success depends on overcoming limitations and fostering inclusivity.

Investing in carbon rights is touted to be a more ingenious approach to offset carbon emissions. Generating a new source of income helps to meet financial objectives while also advancing global carbon reduction goals.

The proposed Low Carbon Economy Investment Act (House Bill 7705) aims to advance the Philippines’ transition to a low-carbon economy. This legislation requires major GHG emitters to formulate decarbonization plans limiting global temperature increases to below 2°C. It also introduces a carbon pricing mechanism that imposes costs on emissions exceeding set thresholds, thereby creating a decarbonization fund. This fund is intended to be reinvested in sustainable, low-carbon initiatives, offering considerable opportunities for businesses and investors committed to sustainable development.

Concurrently, the Carbon Rights Act (House Bill 10635) is envisioned to overcome obstacles to investing in carbon forestry and related projects. This legislation clarifies ownership of carbon rights and establishes processes for their transfer, thus enabling better integration into global carbon markets. For investors, particularly those focused on nature-based solutions, this act opens new avenues for investment in essential carbon projects intended to achieve global emission reduction goals.

Carbon trading involves the exchange of emission rights and credits that permit organizations to emit specific volumes of CO2. Companies can purchase credits to increase emissions or sell them to reduce emissions. This system allows mining companies to support biodiversity and restore ecosystems while generating revenue.

Atty. Analiza Rebuelta-Teh, DENR Undersecretary for Finance, Information Systems and Climate Change, recently disclosed that the Department of Finance is creating a framework for carbon finance while the DENR is working on the rules for carbon credits.

These legislative initiatives signify notable progress, yet substantial challenges loom. The effectiveness of the Low Carbon Economy Investment Act hinges on precise baseline emissions data, rigorous enforcement, and vigilant monitoring; without these, companies may underreport emissions or sidestep decarbonization commitments. In addition, the viability of the carbon pricing mechanism depends on businesses’ capacity to adapt, requiring time to develop essential infrastructure and mitigate oversupply issues that have plagued other markets. Public backing for carbon pricing presents difficulties, particularly if it results in higher consumer costs; thus, clear communication of its benefits is essential.

Furthermore, while the Carbon Rights Act aims to attract investment into carbon projects, potential investors may confront legal ambiguities, bureaucratic hurdles, and a lack of transparency. Ultimately, the Philippines must compete with other nations for carbon project investments, necessitating demonstrable benefits, a stable regulatory framework, and proactive policies to avoid the pitfalls faced by early carbon markets in the European Union.

Addressing these hurdles will be crucial for their successful implementation and maximizing the benefits of a transition to sustainable practices.

(To be continued…)

written by: MARCELLE P. VILLEGAS

[Oct. 17, 2024] The Westin Manila -- Digging Deeper: A Mining Philippines Policy Forum is a oneday conference that tackles the most pressing legal and regulatory issues of the mining industry today.

On his Welcome Address, Atty. Michael T. Toledo, Chairman at Chamber of Mines of the Philippines, emphasized the need to address key challenges in the country’s mining sector. Toledo outlined the obstacles hindering the country’s mineral processing industry and called for immediate reforms to boost investor confidence and secure the industry’s long-term future.

He mentioned that these challenges have driven mining investors away from the Philippines and must be resolved to realize the common goal of the Marcos administration and the mining sector.

These are: (1) long-term policy consistency, (2) the long and complex approval process for exploration permits and mineral agreement applications, (3) business continuity risks from LGUs and communities, and (4) tax uncertainties and lack of adequate benefits to invest.

He pointed out that recommendations were already submitted to the President during a meeting in Malacañang recently. The recommendations are:

“First, assure long-term policy consistency via the drafting of a robust mining policy that would, among other things, clarify the role of national and local government units and specify the approach to Indigenous community management,” he said.

“Second: Simplify and expedite approval processes for mineral agreements by reducing application steps, eliminating redundancies, and imposing clear-cut timelines, in close coordination with government agencies with which our industry interacts. We also recommended the implementation of an online register of pending applications.”

“Third: Minimize business continuity risks from local ordinances

the status of mining companies as government contractors and exporters to be consistent across national and local laws; (2) rationalizing LGU power to issue ordinances that prohibit mining or specific mining methods within their jurisdictions; and (3) requesting ARTA to identify and fix redundancies between national laws and local ordinances, and empowering it to suspend the implementation of those inconsistent with the Ease of Doing Business Act and the LGU Citizen’s Charter.”

Finally, he stated, “Our fourth recommendation is: Address uncertainties in tax policy and investment incentives

Establishing a stable and predictable mining fiscal regime (2) Including a ‘financial stability clause’ in all mineral agreements to guarantee continuity of mining operations and to assure the sanctity of contracts, regardless of material adverse change in government policies that would prevent mining contractors from performing their obligations

Enhance your safety and prevent downtime with the new Fluke acoustic technology. It allows user to see compressed air leaks, detect dangerous partial discharges, and detects potential mechanical problems at mine site.

Get your equipment’s and cables’ insulation resistances in check to keep you safe. You can combine a digital insulation tester with a full-featured, true-rms digital multimeter in a single unit to enhance your productivity for both troubleshooting and preventive maintenance.

www.fluke.com/en-ph

When is the last time you have done a earth ground test inside your facilities, power pylons, or buildings? Poor grounding not only contributes to unnecessary downtime, but exposes you to the risk of electric shock. Test your electrical grounding or bonding condition today.

aims to reduce the approval time for mining permits from the current 7 years to just 2 years.

“When you start to evaluate applications, there are always technical and legal aspects and it depends on the person evaluating that. We want to track where these tracks are getting stalled,” he said.

David said that like the ECCs, the application always starts in the Regional Offices. He noted that the system is still imperfect, so there’s a need to iron out some kinks.

However, he gave assurance that the digital application process prevents some indiscretions that causes delays in the mining applications.

The DENR also introduced a parallel processing system, where permit approvals can be initiated without waiting for other regulatory bodies, such as local government units (LGUs) or the National Commission on Indigenous People (NCIP), to finalize their own approvals.

In a separate discussion during the forum, COMP announced that four of its operating members have achieved performance levels on par with global best mining practices, as measured by the Towards Sustainable Mining (TSM) standard.

Filminera Resources Corp.’s Masbate Gold Project received the highest verified ratings of AAA in TSM’s Biodiversity Conservation Management across all of this Protocol’s 3 Indicators. Philex Mining Co.’s Padcal Project received a rate of AAA in all 6 Indicators under Tailings Management.

TVI Resource Development Phils., Inc. was rated AAA in 3 of the 4 Indicators under Water Stewardship. Taganito Mining Co. received the highest scores in 4 of the 5 Indicators under Safety & Health, as well as in all 5 Indicators under the IP and Community Outreach and Social Development Management.

Toledo said, “TSM provides us a roadmap with which to measure our performance on important areas that our stakeholders, especially our host

communities, care about. We now know how to achieve global mining best practices, and our members will constantly strive to reach the highest ratings towards better ESG performance, and consequently, improved relationships and bottom line.”

The 4 companies were among the 8 COMP operating members that were randomly selected this year to undergo external verification of their self-ratings for their 2023 TSM performance. The other 4 companies that were subjected to verification are Platinum Group Metals Corp. Surigao Project, Carmen Copper Corp., FCF Minerals Runruno Project, and Cagdianao Mining Co.

All of COMP’s 19 members with active mine sites submitted their TSM self-assessment results earlier this year. The 11 other self-rated mines will be verified in 2025 for their 2024 performance.

Most of the verified mines showed good assessments in IP Community Outreach & Social Development Management, as well as Safety & Health. However, there is a need to improve in the Water Stewardship and Climate Change Protocols.

TSM was established by the Mining Association of Canada in 2004 and adopted by COMP in 2017.

From the media release of COMP, TSM is defined as a set of tools and indicators to drive performance and ensure that key mining risks are managed responsibly, and best practices are used at members’ facilities. It is currently being implemented in 15 mining jurisdictions worldwide.

This year marks the first year of COMP’s full implementation of the program. The association of the Philippines’ biggest large-scale metallic mining firms had been preparing for TSM since 2018. Their preparation also entails the Filipinization of TSM Protocols and Indicators, the formation of a multi-sector advisory panel, the accreditation of external verifiers, and the development of the TSM online submission app.

The external verification reports for the 8 mines can be found in the COMP website.

Acknowledgement:

Thank you to the Chamber of Mines in the Philippines.

Thank you to Mr. Rocky Dimaculangan, Vice President for Communications & National Coordinator for Towards Sustainable Mining

written by: MARCELLE P. VILLEGAS

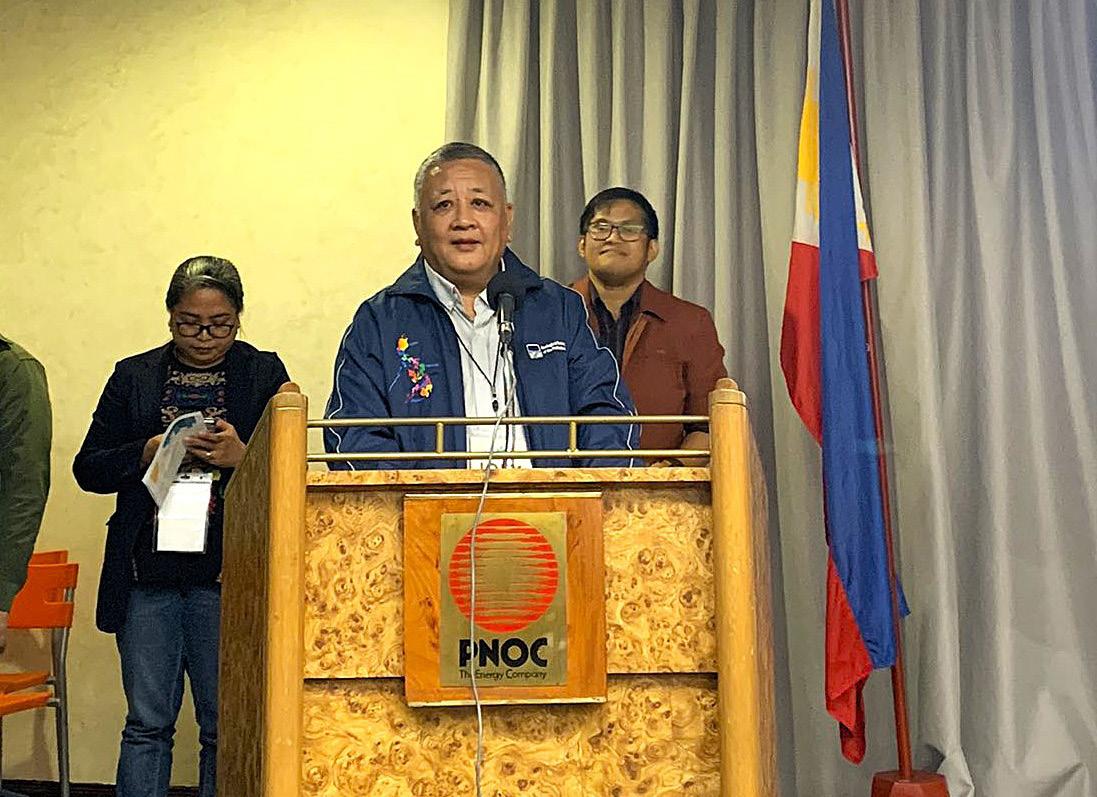

Last Oct. 7th, the Philippine Mining and Exploration Association’s (PMEA) Monthly Membership Meeting had a full house as members were eager to meet and welcome the newest, concurrent OIC Director of MGB, Engr. Michael V. Cabalda. He is also the Assistant Secretary for Mining Concerns, Mines and Geosciences Bureau, DENR.

Mr. Joey Nelson Ayson, PMEA President, reported the PMEA Matters and Industry Updates. This was followed by Mr. Cabalda’s keynote speech.

The open forum had a lively exchange of questions, ideas, and forecast on what to expect in the near future in terms of MGB’s plans and actions in supporting the mining industry.

Present during the meeting were Atty. Danilo Uykieng (OIC Director, MGB), Mr. Rufino Bomasang (former Undersecretary of Dept. of Energy), Mr. Joel Muyco (former MGB Director), Ms. Tata Corpuz (The Australian Trade Commission or Austrade), Mr. Rocky Dimaculangan (Towards Sustainable Mining, Chamber of Mines of the Philippines), and more.

In his address to PMEA Members, titled “Challenges and Opportunities of the Philippine Mining Industry”, Mr. Cabalda highlighted the vital role of the mining industry in driving the Philippines’ economic recovery and transitioning toward sustainable practices. He also expressed the current administration’s commitment to revitalizing the mining sector amid increasing global demand for critical minerals.

“…The current administration is placing significant emphasis on revitalizing the mining sector. This is not only because of its immense potential, but also due to its key role in driving the country’s economic recovery.”

“This strategic move comes at a pivotal time as the whole world embarks on the journey towards net zero carbon emissions and a clean energy future. The increasing global demand for critical minerals places significant responsibility on the mining industry beyond ensuring the delivery of the useful programs and services.”

“MGB remains steadfast in its commitment to promoting sustainable and responsible mining practices.”

“Central to this is the Bureau’s ongoing efforts to establish a policy framework that would allow the country to gain more from our mineral wealth. This would include streamlining of the permitting process.”

He pointed out that MBG aims to accelerate the permitting process, thus reducing approval time from 8 to 11 years to as little as 11 months.

“We are working to ensure that our policies reflect the needs of the current administration and the realities of the industry,” he stated.

Additionally, he acknowledged the need for a thorough review of the “long overdue” Department Administrative Order (DAO)

and improvements in People’s Small Scale Mining Act to foster inclusivity and economic contribution from local miners.

He urged stakeholders to embrace innovation and sustainability, stressing that the future of the mining industry lies not just in resource extraction but in advancing mineral processing and downstream manufacturing.

Mr. Cabalda concluded by calling for collaboration in building a resilient mining sector that supports both economic growth and environmental stewardship.

“Together, we can navigate the complexities ahead and establish a mining industry that is a cornerstone of our nation’s progress.”

“As we move forward, the challenge is not merely to extract resources, but to harness them in ways that elevate both our economy and our communities.

The path ahead may be complex, but with our shared commitment to innovation, sustainability, and responsible mining, we can navigate these challenges successfully.”

[Makati City] Oct. 7, 2024 –PMEA

In GHD, we seamlessly integrate our services to achieve significant and lasting benefits to the mining business of our clients.

Tailings storage facility design

Geology and geophysics

Hydrogeology study

Geotechnical investigation

Hydrology study

Civil infrastructure design

Renewable energy system design

Structural design

Environmental impact assessment and monitoring

Mine closure planning

Construction management and supervision

Digital twin

ESG and strategic sustainability initiatives development

Asset management framework development

In closing, he said, “Let us continue to work together to build a mining industry that serves as a cornerstone that the nation’s progress conflicting at all the economic recovery, but to a cleaner and more prosperous future.”

Later in the meeting, there was an open forum and Q&A session where many participated in sharing their thoughts and questions to the guest speaker.

One of the participants in the discussion was Mr. Rufino Bomasang who is the Chairman of Upgrade Energy Philippines, Inc. Given his background as former Undersecretary of Department of Energy, Mr. Bomasang gave an informative talk about the mining industry’s role in the global energy transition. He read an excerpt of his speech during the Powertrends 2024 International Exhibition and Conference, held last Oct. 3-4, at New World Makati Hotel.

He read, “The transition is now well underway and according to the International Renewable Energy Agency, RE accounted for two thirds of new power generating capacity in 2020 and countries around the world are setting ambitious targets for RE deployment.”

“However, major constraints remain, one of which is the shortage of minerals (e.g. nickel, cobalt, lithium, copper and rare earth elements, etc.) needed for batteries and expanded electricity infrastructure. They are essential components in modern technology, RE systems, electric vehicles (EV, and high-tech manufacturing.”

“In a recent interview with Sherry Duhe, CEO of Newcrest, Australia said ‘The mining industry needs to bring online the equivalent of 17 more Escondidas (the world’s biggest copper mine) just to meet global demand for copper under the energy transition.’”

Moreover, Mr. Bomasang noted, “The Philippines, with its vast untapped resources of nickel and copper, is potentially in a position to help facilitate the implementation of the global energy transition by expanding

its production of said minerals to help address the shortage of critical minerals, which, if not addressed, could delay achievement of the UN’s ultimate objective of net zero emissions by 2050.”

“For the Philippines, the said expansion of critical minerals creates tremendous economic and strategic opportunities and benefits while further enhancing its energy security, provided it can effectively address key challenges and constraints to said expansion.”

He mentioned that among the regulatory and governance issues, some of the major issues are corruption, inconsistent regulations, inadequate enforcement of environmental and labor standards, and uncontrolled illegal mining.

“Can the Philippines actually address the various challenges and constraints and thereby realize the tremendous economic and strategic opportunities, while enhancing national energy security? I am optimistic the Philippines can with the current supportive policies of the Marcos administration government, which hopefully will be sustained under succeeding administrations.”

He clarified that this optimism is due to the fact that there has been a growing new paradigm of responsible mining in the Philippine mining industry since the promulgation of the Mining Act of 1995.

“We in the Professional Regulatory Board of Mining Engineering have actually witnessed said new paradigm

in our recent mine visits. We have witnessed progressive rehabilitation in surface mining operations, particularly in nickel mines, modern more tailings disposal systems in copper mines, upliftment of the lives of surrounding communities, including those of indigenous communities, and extensive reforestation being conducted by the mining companies.”

“I particularly saw Semirara Coal Mine propagating marine life through a hatchery. Not surprisingly therefore the last ASEAN awards for best mining practice and best mineral processing practice were won by Rio Tuba in Palawan and Oceana Gold in Nueva Vizcaya, respectively.”

“All of these bode well for the future of the Philippine mining industry, the realization of the economic and strategic opportunities and benefits for the entire country, and enhanced energy security from the expansion of its nickel and copper production,” said Mr. Bomasang.

written by: MARCELLE P. VILLEGAS

During a mid-year mining event by the Philippine Mining Club, guest speaker, Dante R. Bravo, discussed the Philippine mining industry’s growth, particularly nickel, amidst global trends on green technologies. Bravo is a member of the Board of Trustee of the Chamber of Mines of the Philippines and President of the Philippine Nickel Industry Association, Inc. (PNIA). He is also the President of Global Ferronickel Holdings, Inc.

Despite a 28% drop in nickel prices from July 2023 to July 2024, with forecasts ranging from $16,954 to $18,635 per pound for fiscal year 2024, long-term demand is projected to rise due to electric vehicles and clean energy technologies. The industry is adapting ESG principles and standardizing practices to attract foreign investments, with

potential partnerships from countries like Canada, Australia, and USA. Challenges include regulatory hurdles, but the Philippines aims to enhance its global competitiveness through policy reforms and strategic collaborations.

Bravo discussed the increasing demand for critical minerals caused by the shift towards green technologies and digitalization.

“As the world transitions towards green technologies and digitalization, the demand for critical minerals like lithium, cobalt, and nickel, is increasing rapidly. These minerals are essential for the production of electric vehicles and renewable energy technologies,” he said.

“Despite the rising demand, the global mineral market is experiencing significant fluctuations due to various macroeconomic and geopolitical factors. Recently, we have observed a general decrease in metal prices globally. This could be attributed to a number of factors.”

Emphasis on the importance of sustainable mining practices, with mining companies adopting ESG principles to reduce environmental impacts and ensure transparency.

On his keynote speech, he said that China currently dominates the market for critical minerals, with advanced technology and public finance.

The Philippine government’s efforts to open up the mining indus

Intertek Minerals is proud to be the largest in-country provider of mineral testing services in the Philippines.

As the Philippines continues to experience growth in its mining industry, access to reliable, efficient, and comprehensive mineral testing services is more critical than ever.

Intertek is a leading Total Quality Assurance provider to industries worldwide.

+1000 locations

+100 countries

try for foreign investments are seen as a positive development.

The rise of net zero goals in major economies creates opportunities for the Philippines to widen its market for critical mineral exports.

Bravo reported that nickel prices have dropped significantly by 28% from July 23 to July 2024, with a forecasted range for fiscal year 2024 between $16,954 and $18,635 per pound.

The decline in nickel prices is attributed to increased supply from countries like Indonesia, the ban on Russian and UK metals, and trade tariffs.

Despite the current price drop, long-term demand for nickel is expected to increase due to the growing demand for electric vehicles and stainless steel.

Bravo projects a potential nickel deficit by 2030, driven by the increasing demand for clean energy technologies.

Bravo emphasizes the importance of ESG principles in the mining industry, highlighting the need for environmental stewardship and social responsibility.

He stated, “There is a heightened focus on sustainable mining practices. Mining companies globally are increasingly adapting environmental social and governance, or ESG, principles, to mitigate environmental impacts, improve social outcomes and ensure confidence transparency. This shift towards sustainability is crucial for maintaining the social license to operate and for the long-term viability of the mining sector.”

“But mainly right now, if you want to have a good investment, you have to comply with the ESG standards. So, I believe that the industry is truly passionate about ESG, and I look forward to friendly competition among us players on how best we can meaningfully contribute to our communities and enhance our environment.”

He noted that the integration of ESG practices is seen as a strategic imperative, not just a regulatory requirement. Mining companies in the Philippines are actively implementing ESG principles, including the Sustainable Development Goals (SDGs) and ISO 14001 management systems.

The extractive industries transparency initiative mandated by the Department of Finance ensures transparency at the multilateral level.

Bravo presented the findings of the Fraser Institute’s 2023 mining survey, which ranks the Philippines 72nd out of 86 mining jurisdictions. The low ranking is attributed to historical challenges, including the constitutionality of the mining law, the global financial crisis, and a moratorium on mineral agreements.

Despite these challenges, the development of the local mining industry is critical for both the national and global economies.

Further in his address, Bravo emphasized the importance of positioning the Philippine nickel industry for long-term success and sustainability.

“Despite our industry’s current standing against our foreign neighbors, the future remains bright for local mining industry, major countries globally have reached out to our local industry in the hopes of rooting sustainable and significant trade relationships.”

He noted that appointing a champion for the nickel industry, such as Secretary Frederick D. Go, is crucial for advocating for the industry and influencing regulators. He stated that the Philippines must remain persistent in its efforts to attract more investments and position itself as a key player in the global market.

Sustained collaboration and political will are essential to translate signals into firm commitments that will make the mining industry truly competitive.

Bravo said, “There is a grow -

ing interest in the Philippines, particularly because this administration has opened up the mining industry for more foreign investments. Now, with the continuous support of the government in our local communities, we continue to ramp up production to meet our foreseen increase in demand brought about by increased productivity in China and the net zero goals.”

Last October 17 at Digging Deeper 2024: A Mining Policy Forum, Bravo said a rebound will be felt next year with La Niña or prolonged wet season finally ending. This year, nickel production is expected to fall short of expected targets primarily because some companies stopped production due to inclement weather. He said a spike in demand is expected in 2025 due to the global demand for transition metals, buoyed by the boom in e-vehicle production, including batteries.

Mines and Geosciences Bureau (DENR-MGB) reported the value of production metal reached P249.05 billion in 2023, up by 4.8% from P237.66 billion in 2022 with gold accounting for nearly half of the total production value or P106.64 billion, a 17% increase from P91.05 billion in 2022.

Nickel ore was valued at P65.84 billion, up by 7% from a year ago. Nickel ore and other nickel byproducts were valued at P113.37 billion, accounting for 45.52% of the total production value, while copper was valued at P25.41 billion (10.2%), and the combined output of silver, chromite, and iron at P3.63 billion (1.46%).

Metals production declined 6.7% in value during the first half amid soft nickel prices, according to the MGB.

The Philippine government, under the Marcos Jr. administration, is counting on mining to play a crucial role in the country’s post-pandemic economic recovery. The mining industry contributed 249.05 billion to the national economy in 2023, with nickel, gold, and copper production as the leading minerals. As the industry looks to the future, addressing policy and operational bottlenecks will be key to unlocking its full potential.

Versatility and optimal lifting performance

For almost a century, Manitowoc Cranes has been a premier crane manufacturer. We pride ourselves in providing the most complete range of lifting solutions and services to our customers. Manitowoc Cranes off the most innovative and highest quality products in the market, with the best dealer and service network to support them.

Manitowoc Cranes product line up:

• Grove all-terrain cranes

• Grove rough-terrain cranes

• Grove truck-mounted cranes

Support Services:

• Parts & Services

• Maintenance

• Manitowoc lattice-boom crawler cranes

• Potain tower cranes

written by: MARCELLE P. VILLEGAS

On October 7th, Philippine Mining and Exploration Association (PMEA) President, Joey Nelson R. Ayson, reported PMEA Matters and Industry Updates during the association’s Monthly Membership Meeting in Makati.

He mentioned that according to DENR-MGB, the metallic production on the first half of 2024 is Php114.77B. In contrast, last year’s metallic production is Php123.01B (H1 2023). This is due to lower gold and nickel production and lower nickel prices. The estimated royalties within mineral reservations are Php81.33M, from 20 nickel mines and 1 chromium mine. The estimated excise tax is at Php2.84B. (Au mines - Php1.14B or 40.07%, Cu mines - Php0.99B or 35.17%, Ni mines - Php0.65B or 22.82%, and Cr/Fe mines - Php0.05B or 2.22%)

On the first half of 2024, the top producers in gold are PGPRC (2933 kg), OGPI (1536 kg), APEC Maco (1340 kg), FCF (1312 kg), MMPRC Co-O (741 kg), and BSP Purchases (3883 kg -- excludes purchases from Benguet, OGPI, Hexat). Total gold produced is 14,187 kg.

For copper, the top three producer are CCC (92,555 DMT), OGPI (26,468 DMT), and Philex Padcal (23,027 DMT). Total copper production is 142,050 DMT.

For nickel direct-shipping ore (DSO), the top producers are Rio Tuba (3,053,599 DMT), Taganito (1,783,398 DMT), Nickelace/Verum Terra (987,224 DMT), Carrascal Nickel/CTPCMC (961,359 DMT), and CTPCMC Adlay & Dahican (826,851 DMT). Total nickel production is 13,372,483 DMT.

For silver, the top producers are TVI Balabag (10,446 kg), APEX Maco (4919 kg), PGPRC (2888 kg), and OGPI (2168 kg). Total silver production is 23,268 kg.

For chromite, the top producers are Taganito HPAL (37,887 DMT) and Techiron (35,125 DMT). Total chromite production is 73,013 DMT.

For iron, the top producer is Ore

Asia Mining (31,798 DMT). Total iron production is 31,798 DMT.

Finally, for mixed nickel-cobalt sulfide, the top producers are Taganito HPAL (25,823 DMT) and Coral Bay HPAL (13,636 DMT). Total production for mixed nickel-cobalt sulfide is 39,459 DMT.

DENR-MGB UPDATES

Staff Movement

-- Engr. Mike Cabalda was appointed as DENR Assistant Secretary (co-terminus) on August 27, 2024.

-- DENR SO 2024-568 assigning Mike Cabalda as ASEC for Mining Concerns and Concurrent OIC MGB Director

-- DENR SO 2024-567 assigning Engr Ted Sandoval as OIC Asst. MGB Director

Draft Policy Enhancement for the EIA Process of Mining Projects (Proposed DAO)

-- Canada TAP EDM Project

-- Consultations held at DENR on Sept. 26-27, 2024

-- PMEA has sent its comments, but proposed DAO intends to:

1. Require ECC during exploration

2. Involvement of EMB in the SDMP/

CDP with experts to do reviews (costs charged to??)

3. Increasing buffer zone from 20m to 30m

4. Requiring IP consent before issuing EP

5. Estimate GHG emissions and mitigating measures for >25,000 mt CO2

6. Gender and Human Rights to be included

7. Strategic Environmental Assessment for mining projects within biodiversity zones

8. Assessment of mine closure plans by experts if there are residual structures/post closure monitoring

MGB MIMAROPA New Office

Their new office is located at Basic Petroleum Building, 104 Carlos Palanca Street, Legaspi Village, Makati City.

Exploration for Critical Minerals (LGSD)

-- Ni, Cu, Co, Cr, Fe, Au, REE, PGMs

-- Establishment of new mineral reservations

-- Ongoing geological assessments; environmental resource mapping and conduct of public hearing to follow

-- REE Exploration (Phase 1: 20172025)

< Page 36

Extraction of Critical Minerals (MTD)

-- Pilot-Scale Production of Nickel Pig Iron from Low Grade Laterite Ores

-- Significant amount of Sc in the slag

Critical Minerals in Seabed (MGSD)

-- Deep sea (2,500-4,000m depth) –manganese nodules and crust

-- Shallow marine (40-100m depth) –magnetite sand, placer metals and quarry sand materials

-- Draft Guidebook for offshore mining applications, evaluation and operations monitoring

Towards Sustainable Mining (TSM)

-- 19 companies submitted self ratings with 8 companies undergoing external verification

-- Verified results were discussed in detail in October 17, 2024 at Digging Deeper – A Mining Philippines Policy Forum.

National Unified IEC Program (NUIECP)

-- Survey of participating organizations show overall satisfaction with campaign management and impact

-- Generated a total PR value equivalent to almost PhP 1B – nearly 2,000% of target

Presidential Mineral Industry Environment Awards (PMIEA)

-- 42 entries have been received by MGB Regional Offices

-- Results of initial screening (for field validation) (Quarry – 11 of 16; Surface Mining – 13 of 17; Mineral Processing – 3 of 8; Underground Operations – 0 of 0; Exploration – 0 of 1)

PwC Audit

-- Phase 1 on organizational set-up completed

-- Phase 2 on processes completed and final report to be prepared

Senate Bill 2826 (Enhanced Fiscal Regime for Large Scale Metallic Mining Act)

-- Introduced by Sen JV Ejercito- Royalty of 5% of gross output within mineral reservations and 5-tier margin-based for those outside

-- 5-tier windfall profit tax- 40% share of LGU to be remitted directly to concerned LGU

-- Local business tax shall not exceed 50% of 1% of total gross output

-- Ring fencing – contractor treated as a separate taxable entity with respect to each tenement

Proposed Amendments to RA 7076

-- Revision of HB 6408 as proposed by National Coalition of SSM in the Phil, ALU-TUCP, ILO, MGB

-- Establishing a “Minahang Bayan”,

limited validity of mining contracts, definition of SSM

BSP Gold Sale

-- 24.95 tons Au sold in H1 2024; reducing total Au reserves to 134.06 tons

-- Average Au reserves from 20002024 is 187.99 tons

Anti-Red Tape Authority

-- Included responsible mining in 2024 as among its focus sectors for re-engineering and streamlining

-- Discussions with MGB, NCIP, LGU have identified the challenges and corresponding initiatives for streamlining the permitting process and service requirements including permits issued by LGUs

-- Invitation extended to Private Sector Advisory Council (PSAC) for the conduct of Whole of Government Re-engineering and Process Streamlining Workshop for the Mining Sector (Oct. 08, 2024)

-- Discussions to focus on: 1. Mining’s contribution to national economy

2. Fostering a stable and conducive environment for domestic and foreign investments 3. Regulatory frameworks, challenges and best practices in mining

Reference: [1] Ayson, Joey Nelson (Oct. 7, 2024).

PMEA Monthly Membership Meeting – PMEA Matters and Industry Updates.

An Executive Order (E.O.) that will define and establish a policy on mining royalty is being drafted by the Department of Environment and Natural Resources (DENR), to be passed for approval by Malacañang.

At a recent Mining Philippines event, Digging Deeper: A Mining Policy Forum, Prof. Carlos Primo David, DENR Undersecretary for Integrated Sciences, spoke on behalf of DENR Secretary Maria Antonia Yulo-Loyzaga. The event was organized by the Chamber of Mines of the Philippines with an objective to discuss current policy issues affecting the minerals development sector.

David is an expert in environmental science and is a licensed geologist.

During an ambush interview, he mentioned to journalists that the mining E.O. would be presented before the Office of the President to address some of the conflicting provisions in the National Commission on Indigenous Peoples (NCIP), Local Government Code.

He also pointed out the issue of

conflicting interpretations of the law on mining royalty which needs to be addressed through the E.O.

He clarified that such conflicting interpretations of the mining royalty, and complexities with LGUs and Indigenous Peoples and Indigenous Cultural Communities often cause mining investors to be on a “waitand-see” attitude.

He also noted that the E.O. is still a draft.

“For any royalty, you will have to put a ceiling. Because if there is no ceiling, it can be 1%, 2%, 10%, or up to 100%. That is something that we have to address,” he said.

He mentioned that what the law specifies right now is the minimum.

The E.O. is not intended to replace any legislation.

“Any legislation needs another legislation, but the E.O. should correct some of the issues such as conflict with the I.R.R. and other provisions of the law, such as in the NCIP.”

For this matter, the DENR, the Office of the Secretary, and the Department of Finance (DOF) are

collaborating on the drafting of the E.O.

David added that eventually, when a fiscal regime is passed by Congress, the E.O. is set aside.

Additionally, during the Mining Philippines event, he stated that the DENR’s initiative to launch digital application processing in 3 mining regions will reduce the waiting time for the approval of mining permits from 6 to 7 years to at least 2 years. The digital application will include the CARAGA region and Davao.

The introduction of the digital application process will also help the DENR monitor the workflow and track the bottlenecks in the mining permit applications in various DENR Regional Offices. Managing the process digitally will, in the long run, propel the mining operations.

Reference: [1] (Oct. 17, 2024). Media release from Digging Deeper: A Mining Policy Forum. Chamber of Mines of the Philippines.

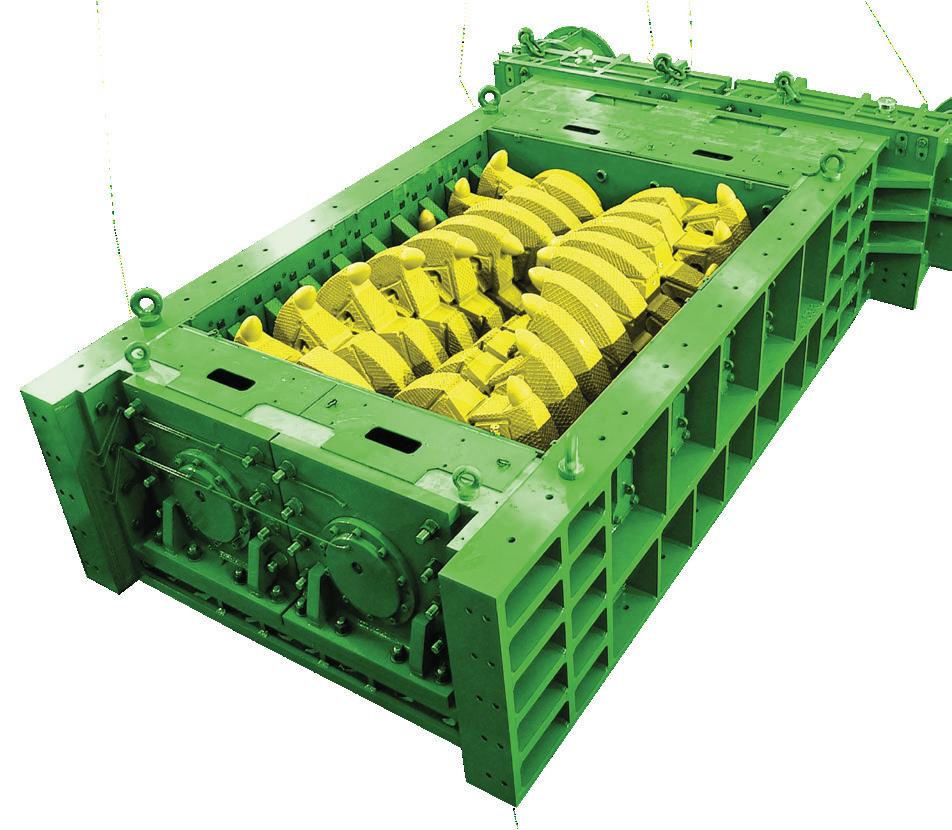

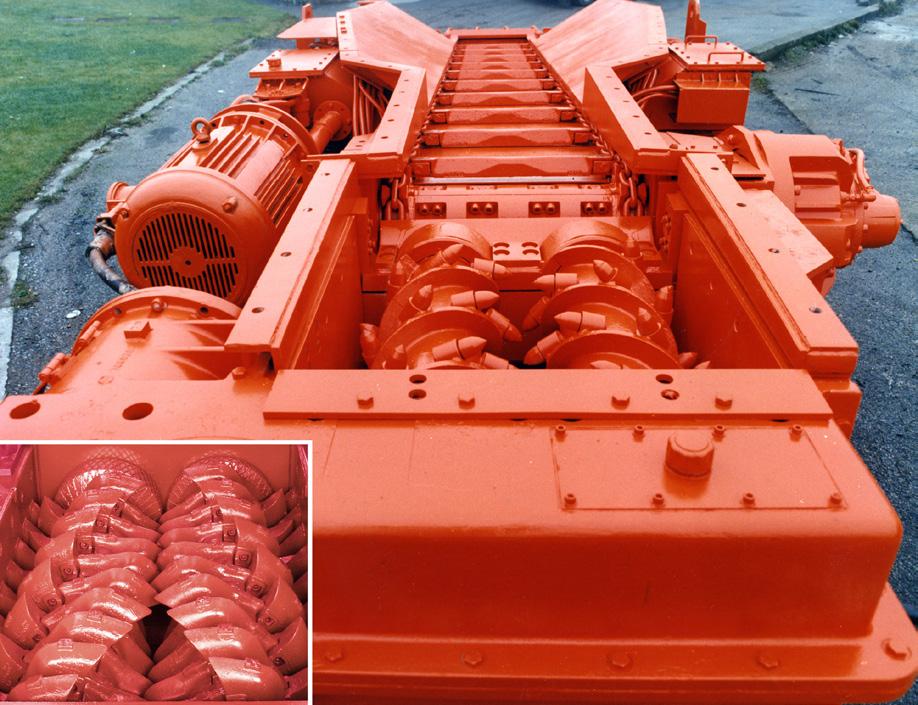

For over 45 years, we have successfully provided pioneering Sizer technology to many industries worldwide. Our tailored mobile, semi-mobile and fixed Sizer stations as well as our latest in-pit innovations, are reliable and efficient answers to reduce the complexity of today’s modern mining challenges.

As a turnkey provider, we have the specialist knowledge and equipment to offer comprehensive services and support. From conceptual planning and design through to manufacture, installation and aftersales service. We are your partner throughout your sustainable journey.

Here’s something to look forward to this December.

The Geological Society of the Philippines (GSP) officially launched GEOCON 2024 at the PNOC Networking Hall. As the country’s leading geological conference, the launch provided an exclusive preview of the upcoming conference, set to take place on December 4 and 5, 2024.

GEOCON 2024, a landmark conference, aims to shape the future of the geosciences in the Philippines, with a focus on sustainable solutions. GEOCON 2024 is expected to serve as a critical platform for fostering innovation, collaboration, and dialogue among professionals in the industry.

The initial gathering was attended by approximately 60 prominent figures from the geological sector—including members of the GSP Board of Trustees, industry leaders, government representatives, academic experts, and representatives from the private sector.

This launch marked a significant moment for the geological community, with key stakeholders gathering to celebrate the advancements in the field of geosciences in the Philippines.

The highlight of the launch was the unveiling of the conference’s theme: “The Filipino Geologists – Bridging Geoscience, Technology, and Industry for a Better Philippines.” This theme reflects the essential role of Filipino geologists in addressing the nation’s environmental, economic, and societal challenges. Additionally, the theme shows importance of harnessing geoscientific knowledge and technological advancements to develop sustainable solutions that benefit both local communities and future generations.

In his opening remarks, GSP President, Mr. Joey Nelson R. Ayson, expressed optimism for the upcoming conference. “GEOCON 2024 is more than just a platform for sharing scientific ideas. It is a call to action for geologists to commit to sustainable practices that protect our planet. Our theme reflects this dedication to responsible environmental stewardship.”

Department of Energy

Undersecretary, Mr. Alessandro O. Sales, was also present at the launch. In his keynote speech, he who pointed out the importance of collaboration between the geological community, government agencies, and industry leaders.

Usec. Sales noted that such partnerships are crucial for tackling the country’s most pressing environmental issues and fostering a more resilient future.