www.kitech-uk.com

Email: sales@kitech-uk.com

Tel :+44 (0) 7515300974

Web : www.kitech-uk.com

KITECH

Email:

KITECH

sales@kitech-uk.com

:+44 (0) 7515300974

: www.kitech-uk.com

Tel

Web

> > > > >

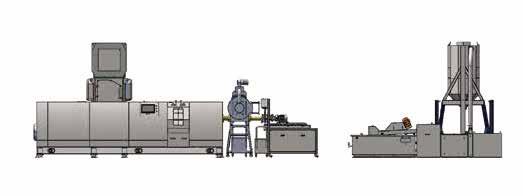

KSS85 Shredding Pelletizing System

KSS85 Shredding Pelletizing System

KSS85 shredding pelletizing system is a shredder integrated recy-

KSS85 shredding pelletizing system is a shredder integrated recy -

APPLICABLE MATERIALS >

e

Jumbo

Lumps LDPE

APPLICABLE MATERIALS >

Bottles/ Hard Plastics Non-woven Fabric Film Roll / Scraps

Bags

/ HDPE Bags

Sle fc leaningLaser Filter

-

Film

LDPE

Bottles/ Hard Plastics Non-woven Fabric

Roll /

Scraps

Jumbo Bags Lumps

/ HDPE Bags

ShredderShredder

ShredderShredder

INTERNAL STRUCTURE >

INTERNAL STRUCTURE >

Self-cleaning Laser Filter

Scraper Disc Mesh

Die Face Plate Cutting Blades

Underwater Pelletizing

Self-cleaning Laser Filter

Scraper Disc Mesh

Die Face Plate Cutting Blades

Underwater Pelletizing

Self-cleaning Laser Filter

Scraper Disc Mesh

Die Face Plate Cutting Blades

Underwater Pelletizing

Self-cleaning Laser Filter

Scraper Disc Mesh

Die Face Plate Cutting Blades

Underwater Pelletizing

Energy

Shredder Extruder

Self-cleaning

Downstream (options)

Rotor length (mm)

Motor power (kW)

Screw diameter (mm) L/D

Motor power (kW)

Disc mesh (um/mesh)

Disc diameter (mm)

Underwater pelletizer

Automatic strand pelletizer

Water ring pelletizer

Email: sales@kitech-uk.com

Tel :+44 (0) 7515300974

Web : www.kitech-uk.com

(kg/h)

SPECIFICATION > Type Capacity

consumption

(kWh/kg)

200-300 0.3-0.4 800 55 44 90 100-800/20-150 365×2 standard alternative KSS85 7248mm 3347mm 3372mm 13758mm KITECH

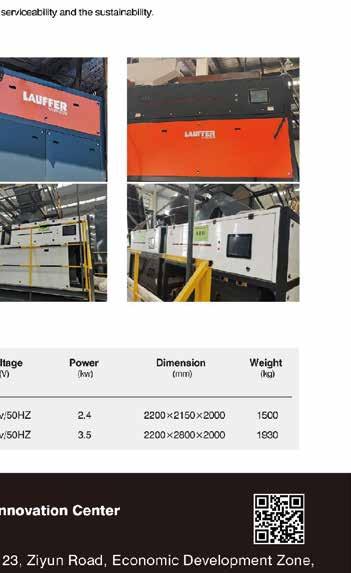

KCP series compacting pelletizing system is a three in one recycling machine designed for low density plastic articles. It could

KCP series compacting pelletizing system is a three in one recycling machine designed for low density plastic articles. It could

KCP series compacting pelletizing system is a three in one recycling machine designed for low density plastic articles. It could

system is a three in one recydensity plastic articles. It couldseries pelletizing system has system is a three in one recydensity plastic articles. It couldseries pelletizing system has compacting pelletizing system is a three in one recydesigned for low density plastic articles. It could

KCP series compacting pelletizing system is a three in one recycling machine designed for low density plastic articles. It could

KCP series compacting pelletizing system is a three in one recy cling machine designed for low density plastic articles. It could

KCP series compacting pelletizing system is a three in one recy cling machine designed for low density plastic articles. It could

duction factory and washing line. KCP series pelletizing system has

duction factory and washing line. KCP series pelletizing system has

duction factory and washing line. KCP series pelletizing system has

and washing line. KCP series pelletizing system has compacting pelletizing system is a three in one recydesigned for low density plastic articles. It could

duction factory and washing line. KCP series pelletizing system has

duction factory and washing line. KCP series pelletizing system

and washing line. KCP series pelletizing system has

duction factory and washing line. KCP series pelletizing system has

-

-

-

-

-

-

KITECH

KITECH

Email: sales@kitech-uk.com

Tel :+44 (0) 7515300974

Web : www.kitech-uk.com KITECH

Email: sales@kitech-uk.com

Email: sales@kitech-uk.com

Email: sales@kitech-uk.com

Email: sales@kitech-uk.com

Email: sales@kitech-uk.com

Tel :+44 (0) 7515300974

Email: sales@kitech-uk.com

Email: sales@kitech-uk.com

Tel (0) 7515300974

Tel :+44 (0) 7515300974

Tel :+44 (0) 7515300974

Tel :+44 (0) 7515300974

Tel :+44 (0) 7515300974

Web : www.kitech-uk.com KITECH

Tel :+44 (0) 7515300974

Web : www.kitech-uk.com KITECH

Web : www.kitech-uk.com KITECH

Web : www.kitech-uk.com KITECH

Web : www.kitech-uk.com

Email: sales@kitech-uk.com :+44 (0) 7515300974 www.kitech-uk.com KITECH

Web www.kitech-uk.com KITECH

Web : www.kitech-uk.com

KCP series compacting pelletizing system is a three in one recy cling machine designed for low density plastic articles. It could

KCP series compacting pelletizing system is a three in one recy cling machine designed for low density plastic articles. It could

duction factory and washing line. KCP series pelletizing system has

duction factory and washing line. KCP series pelletizing system has

Type Capacity (kg/h)

Capacity

Capacity (kg/h)

Capacity (kg/h)

Energy consumption ( kWh/kg )

Energy

Energy consumption ( kWh/kg )

Energy consumption ( kWh/kg )

A/Length(mm)

A/Length(mm)

A/Length(mm)

A/Length(mm)

A/Length(mm)

A/Length(mm)

A/Length(mm)

A/Length(mm)

B/Width(mm)

B/Width(mm)

B/Width(mm)

B/Width(mm)

B/Width(mm)

B/Width(mm)

B/Width(mm)

B/Width(mm)

C/Height(mm)

C/Height(mm)

C/Height(mm)

C/Height(mm)

C/Height(mm)

C/Height(mm)

C/Height(mm)

Compactor

Compactor

Compactor

Compactor

Compactor

Compactor

Compactor

Compactor

Extruder

(mm)

Extruder

Extruder

Extruder

(options)

Motor power (kW)

Two position plate type

Two position plate type

Filter (options)

Extruder Filter (options)

Filter (options)

2nd

Filter (options) 2nd

2nd Extruder (Optional)

2nd Extruder (Optional)

2nd Extruder (Optional)

Downstream (options)

Two position plate type

Two position plate type

Two position plate type

Two position plate type

Two position plate type

Two position plate type

Two position piston type

Two position piston type

Two position piston type

Two position piston type

Two position piston type

Two position piston type

Two position piston type

Two position piston type

Automatic self-cleaning type

Automatic self-cleaning type

Automatic self-cleaning type

Automatic self-cleaning type

Automatic self-cleaning type

Automatic self-cleaning type

Automatic self-cleaning type

Screw diameter (mm)

2nd Extruder (Optional) Downstream (options)

L/D

Downstream (options)

Screw diameter (mm) L/D

Screw diameter (mm) L/D

Screw diameter (mm) L/D

Screw diameter (mm) L/D

Screw diameter (mm)

Screw diameter (mm) L/D

Motor power (kW)

Motor power (kW)

Motor power (kW)

Motor power (kW)

Water ring pelletizer

Water ring pelletizer

Strand pelletizer

Strand pelletizer

Automatic strand pelletizer

Underwater pelletizer

Email: sales@kitech-uk.com

Tel :+44 (0) 7515300974

Web : www.kitech-uk.com

Extruder Filter (options) 2nd Extruder (Optional) Downstream (options) Volume (L) Motor power (kW) Screw diameter (mm) L/D Motor power (kW) Two position plate type Two position piston type Automatic self-cleaning type Screw diameter (mm) L/D Motor power (kW) Water ring pelletizer Strand pelletizer Automatic strand pelletizer Underwater pelletizer standard alternative KCP80 KCP100 KCP120 KCP140 KCP160 KCP180 150-250 0.3-0.4 11,570 5,900 3,000 650 45 36-42 55-75 12 30 12 37 12 45 12 55 12 75 12 90 250-450 0.3-0.4 12,800 6,200 3,100 650 55-75 36-42 110-132 400-550 0.3-0.4 13,800 7,460 3,900 1000 90-110 36-42 132-160 500-600 0.3-0.4 14,750 7,580 4,000 1000 132 36-42 200 700-1100 0.3-0.4 16,820 7,700 4,250 1400 160-185 36-42 250-315 950-1300 0.3-0.4 16,820 7,650 4,250 1400 200-250 36-42 355-400

Type

Extruder Filter

Volume (L) Motor power

diameter

L/D

(kW) Screw

standard alternative KCP80 KCP100 KCP120 KCP140 KCP160 KCP180 150-250 0.3-0.4 11,570 5,900 3,000 650 45 36-42 55-75 12 30 12 37 12 45 12 55 12 75 12 90 250-450 0.3-0.4 12,800 6,200 3,100 650 55-75 36-42 110-132 400-550 0.3-0.4 13,800 7,460 3,900 1000 90-110 36-42 132-160 500-600 0.3-0.4 14,750 7,580 4,000 1000 132 36-42 200 700-1100 0.3-0.4 16,820 7,700 4,250 1400 160-185 36-42 250-315 950-1300 0.3-0.4 16,820 7,650 4,250 1400 200-250 36-42 355-400 Type

(kg/h)

consumption ( kWh/kg )

Volume (L) Motor power (kW) Screw diameter (mm) L/D Motor power (kW)

Automatic strand pelletizer Underwater pelletizer standard alternative KCP80 KCP100 KCP120 KCP140 KCP160 KCP180 150-250 0.3-0.4 11,570 5,900 3,000 650 45 36-42 55-75 12 30 12 37 12 45 12 55 12 75 12 90 250-450 0.3-0.4 12,800 6,200 3,100 650 55-75 36-42 110-132 400-550 0.3-0.4 13,800 7,460 3,900 1000 90-110 36-42 132-160 500-600 0.3-0.4 14,750 7,580 4,000 1000 132 36-42 200 700-1100 0.3-0.4 16,820 7,700 4,250 1400 160-185 36-42 250-315 950-1300 0.3-0.4 16,820 7,650 4,250 1400 200-250 36-42 355-400 Type Capacity (kg/h)

consumption ( kWh/kg )

Energy

Filter (options)

Downstream

Volume (L) Motor power (kW) Screw diameter (mm) L/D Motor power (kW)

(options)

Motor power (kW) Water ring pelletizer Strand pelletizer Automatic strand pelletizer Underwater pelletizer standard alternative KCP80 KCP100 KCP120 KCP140 KCP160 KCP180 150-250 0.3-0.4 11,570 5,900 3,000 650 45 36-42 55-75 12 30 12 37 12 45 12 55 12 75 12 90 250-450 0.3-0.4 12,800 6,200 3,100 650 55-75 36-42 110-132 400-550 0.3-0.4 13,800 7,460 3,900 1000 90-110 36-42 132-160 500-600 0.3-0.4 14,750 7,580 4,000 1000 132 36-42 200 700-1100 0.3-0.4 16,820 7,700 4,250 1400 160-185 36-42 250-315 950-1300 0.3-0.4 16,820 7,650 4,250 1400 200-250 36-42 355-400 Type Capacity (kg/h) consumption ( kWh/kg )

Extruder Filter 2nd Extruder (Optional) Downstream Volume (L) Motor power (kW) Screw diameter (mm) L/D Motor power (kW)

C/Height(mm) Compactor

Motor power (kW) Water ring pelletizer Strand pelletizer Automatic strand pelletizer Underwater pelletizer standard alternative KCP80 KCP100 KCP120 KCP140 KCP160 KCP180 150-250 0.3-0.4 11,570 5,900 3,000 650 45 36-42 55-75 12 30 12 37 12 45 12 55 12 75 12 90 250-450 0.3-0.4 12,800 6,200 3,100 650 55-75 36-42 110-132 400-550 0.3-0.4 13,800 7,460 3,900 1000 90-110 36-42 132-160 500-600 0.3-0.4 14,750 7,580 4,000 1000 132 36-42 200 700-1100 0.3-0.4 16,820 7,700 4,250 1400 160-185 36-42 250-315 950-1300 0.3-0.4 16,820 7,650 4,250 1400 200-250 36-42 355-400 Type

Extruder Filter (options)

Extruder (Optional) Downstream (options) Volume (L) Motor power (kW) Screw diameter L/D Motor power

2nd

(kW)

Automatic self-cleaning

Screw diameter L/D Motor power (kW) Water ring pelletizer Strand pelletizer Automatic strand pelletizer Underwater pelletizer standard alternative KCP80 KCP100 KCP120 KCP160 KCP180 150-250 0.3-0.4 11,570 5,900 3,000 45 36-42 55-75 12 30 12 37 12 45 12 75 12 90 250-450 0.3-0.4 12,800 6,200 3,100 650 55-75 36-42 110-132 400-550 0.3-0.4 13,800 7,460 3,900 1000 90-110 36-42 132-160 1000 132 200 0.3-0.4 16,820 7,700 4,250 1400 160-185 36-42 250-315 950-1300 0.3-0.4 16,820 7,650 4,250 1400 200-250 36-42 355-400 Type Capacity (kg/h) Energy consumption ( kWh/kg )

type

Volume (L) Motor power (kW) Screw diameter (mm) L/D Motor power (kW)

Extruder (Optional) Downstream (options)

Water ring pelletizer Strand pelletizer Automatic strand pelletizer Underwater pelletizer standard alternative KCP80 KCP100 KCP120 KCP140 KCP160 KCP180 150-250 0.3-0.4 11,570 5,900 3,000 650 45 36-42 55-75 12 30 12 37 12 45 12 55 12 75 250-450 0.3-0.4 12,800 6,200 3,100 650 55-75 36-42 110-132 400-550 0.3-0.4 13,800 7,460 3,900 1000 90-110 36-42 132-160 500-600 0.3-0.4 14,750 7,580 4,000 1000 132 36-42 200 700-1100 0.3-0.4 16,820 7,700 4,250 1400 160-185 36-42 250-315 950-1300 0.3-0.4 16,820 1400 Type Capacity (kg/h) Energy consumption ( kWh/kg )

Extruder (Optional) Downstream (options) Volume (L) Motor power (kW) Screw diameter (mm) L/D Motor power (kW)

Water ring pelletizer Strand pelletizer Automatic strand pelletizer Underwater pelletizer standard alternative KCP80 KCP100 KCP120 KCP140 KCP160 KCP180 150-250 0.3-0.4 11,570 5,900 3,000 650 45 36-42 55-75 12 30 12 37 12 45 12 55 12 75 12 90 250-450 0.3-0.4 12,800 6,200 3,100 650 55-75 36-42 110-132 400-550 0.3-0.4 13,800 90-110 132-160 500-600 0.3-0.4 14,750 7,580 4,000 1000 132 36-42 200 700-1100 0.3-0.4 16,820 7,700 4,250 1400 160-185 36-42 250-315 950-1300 0.3-0.4 16,820 7,650 4,250 1400 200-250 36-42 355-400 Type Capacity (kg/h) Energy consumption ( kWh/kg )

Volume (L) Motor power (kW) Screw diameter (mm) L/D Motor power

(kW)

L/D Motor power (kW) Water ring pelletizer Strand pelletizer Automatic strand pelletizer Underwater pelletizer standard alternative KCP80 KCP100 KCP120 KCP140 KCP160 KCP180 150-250 0.3-0.4 11,570 5,900 3,000 650 45 36-42 55-75 12 30 12 37 12 45 12 55 12 75 12 90 250-450 0.3-0.4 12,800 6,200 3,100 650 55-75 36-42 110-132 400-550 0.3-0.4 13,800 7,460 3,900 1000 90-110 36-42 132-160 500-600 0.3-0.4 14,750 7,580 4,000 1000 132 36-42 200 700-1100 0.3-0.4 16,820 7,700 4,250 1400 160-185 36-42 250-315 950-1300 0.3-0.4 16,820 7,650 4,250 1400 200-250 36-42 355-400 KITECH

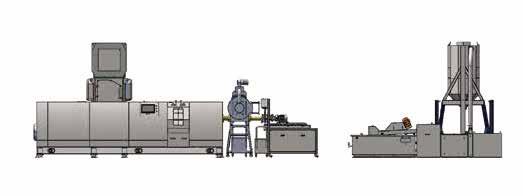

KSP series single screw extrusion and pelletizing system

KSP series single screw extrusion and pelletizing system combines quantitative feeding, high efficiency extruder,different types of filter and different types of pelletizer by modular design. It provides best solution for PE, PP, PS, ABS, PET, PA and many other rigid plastic regrind recycling.

feeder unit

feeder unit

onveyor are optiona ent material form. Ferrous and nonferrous metal separating at tion of the whole line.

conveyor are ent material form. Ferrous and nonferrous metal separating at tion of the whole line.

bel t c onve y or or screw loading device according form. nonferrous metal separating at tion

screw cording at tion ler,

bel t c onveyor or screw as loading device according form. nonferrous metal separating at tion

Dosing feeder with PLC intelligent controller, which ensures the extruder run steady.

Dosing feeder with PLC intelligent controller, which ensures the extruder run steady.

times service life of normal one Force double vacuum degassing system to get rid of the make sure high quality output pellets

times service life of normal one Force double vacuum degassing system to get rid of the make sure high quality output pellets

times service life of normal one Force double vacuum degassing system to get rid of the make sure high quality output pellets

times service life of normal one Force double vacuum degassing system to get rid of the make sure high quality output pellets

content s in m ateria l and yo u r habit

c ontent s in m ateria l and yo u r habit

Multi-vacuum degassing system and double stage extrusion system help you solve the problem of recycling heavy contaminated polymer

operate which mainly used for regular thermoplastic

intelligent controller, extruder run steady.

PLC intelligent controller, extruder run steady.

continuous thermal insulation, more than 30% energy consumption can be saved than normal heater.

continuous thermal insulation, more than 30% energy consumption can be saved than normal heater.

continuous thermal insulation, more than 30% energy consumption can be saved than normal heater.

continuous thermal insulation, more than 30% energy consumption can be saved than normal heater.

content s in m ateria l and yo u r habit which mainly for regular thermopla

operate which mainly used for regular thermoplastic Water

c ontent s in m ateria l and yo u r habit operate which mainly used for regular thermoplas

Email: sales@kitech-uk.com Tel :+44 (0) 7515300974

Email: sales@kitech-uk.com

Email: sales@kitech-uk.com

Email: sales@kitech-uk.com

(0) 7515300974

sales@kitech-uk.com Tel :+44 (0) 7515300974

Email: sales@kitech-uk.com Tel

(0) 7515300974

Email: sales@kitech-uk.com Tel :+44 (0) 7515300974

(0) 7515300974

(0) 7515300974

(0) 7515300974

www.kitech-uk.com

Tel :+44 (0) 7515300974 Web : www.kitech-uk.com

www.kitech-uk.com

Web : www.kitech-uk.com

www.kitech-uk.com

Multi-vacuum degassing system and double stage extrusion system help you solve the problem of recycling heavy contaminated polymer

www.kitech-uk.com

www.kitech-uk.com

Multi-vacuum degassing system and double stage extrusion system help you solve the problem of recycling heavy contaminated polymer

Multi-vacuum degassing system and double stage extrusion system help you solve the problem of recycling heavy contaminated polymer

Multi-vacuum degassing system and double stage extrusion system help you solve the problem of recycling heavy contaminated polymer

operate which mainly used for regular thermoplas operate which mainly used for regular thermopla operate which mainly used for regular thermoplas operate which mainly used for regular thermopla Water a u to m pe l let pe l let s ol u tion Wa t er a u tomatic pe l le t s . pe l le t s s o l ution Thanks and proprie supplying t e produc le KSP u plemen con abor owe crea KITECH

Tel :+44

Web :

ank proprie pp ly tem prod u le ts KSP imp abor st owes crea KITECH

Tel :+44

Web :

an and proprietary supplyin em produ pelle S co m onsu abor os owes rea KITECH

www.kitech-uk.com

Email: sales@kitech-uk.com

Tel

Web :

Thank s proprietar y ing m u ctivi s pelletizing could plemen su labor sts t KITECH

ks proprie upplyin em c t ts pelle ld e u labor sts st KITECH

:+44

www.kitech-uk.com

Email:

Web :

Web :

ank s proprie upplyin em uc s plemen cons st owe crea KITECH

Web

ank and proprietary st e prod u l e imple s labor lowes rea KITECH

:

Thank proprie pp l ying em prod u t s pelletizin d s abor. ts owes KITECH

Web :

Thank pp em e KSP ou p consu abor s owe crea sales@kitech-uk.com Tel :+44

:+44

KSP

screw extrusion and pelletizing system

series single

c ontent s in m ateria l and yo u r habit operate which mainly used for regular times service life of normal one Force double vacuum degassing system to get rid of the make sure high quality output pellets continuous thermal insulation, more than 30% energy consumption can be saved than normal heater

you solve the problem of recycling

polymer KSP series single screw extrusion and pelletizing system

Multi-vacuum degassing system and double stage extrusion system help

heavy contaminated

content s in m ateria l and yo u r habit operate which mainly used for regular thermopla times service life of normal one Force double vacuum degassing system to get rid of the make sure high quality output pellets

continuous thermal insulation, more than 30% energy consumption can be saved than normal heater

a u to m pe let pe let s ol u tion

Wa t a u tomatic pe l le t pe l le t s o l ution

Dosing feeder unit

Dosing feeder unit

Frequen cy c ontro l bel t c onve y or or screw conveyor are optional as loading device according ent material form.

Frequen c y c on t ro l bel t c onveyor or screw conveyor are optional as loading device according ent material form.

Ferrous and nonferrous metal separating at tion of the whole line.

Ferrous and nonferrous metal separating at tion of the whole line.

Dosing feeder with PLC intelligent controller, which ensures the extruder run steady.

Dosing feeder with PLC intelligent controller, which ensures the extruder run steady.

elletizing elletizing elletizing elletizing elletizing elletizing elletizing elletizing elletizing

a u tomatic s trand pelletizer and u nder water

a u to m a t i c s trand pel l etizer and u nder water

machine

which is easy to operate and save man power.

machine which is easy to operate and save man power. PLC in t elligen t con t rol sys tem available for re m ote diagno s i s , c ontrol and m onitoring to

P L C intelligen t c ontrol s y st em available f or re m ote diagno s i s, c on t rol and monitoring to

oplastic

hermoplastic

pe l le t s

pe l let s

Water rin g pe l letizer , s trand t ype pelletizer , m a t i c s trand pel l etizer and u nder water

Wa t er rin g pel l etizer, s trand t y pe pel l etizer, a u tomatic s trand pelletizer and u nder water

Water rin g pe l letizer , s trand t ype pelletizer , a u to m a t i c s trand pel l etizer and u nder water

oplastic

hermoplastic

rin g pel l etizer, s trand t y pe pel l etizer, tomatic s trand pelletizer and u nder water . can be en s ured for eit h er pelleziting ution

pe l le t s can be en s ured for eit h er pelleziting s o l ution

pe l let s c an be en su red for either pellezitin g s ol u tion

pe l le t s .

pe l let s .

s . s c an be en su red for either pellezitin g tion

Thanks to Siemens PLC and HMI, KCP series machine provides high intelligent operation system which is easy to operate and save man power.

Thanks to Siemens PLC and HMI, KCP series machine provides high intelligent operation system which is easy to operate and save man power. P L C intelligen t c ontrol s y st em available f or re m ote diagno s i s, c on t rol and monitoring to and m aintained and operated for a long ter m

pe l le t s can be en s ured for eit h er pelleziting s o l ution

and m ain t ained and operated f or a lon g ter m

and m aintained and operated for a long ter m

Wei g hing and m etering sys te m helps you m onitor the o u tp u t and energ y c on s u m ption of

Wei g hin g and meterin g s y s tem h e l p s yo u m onitor the o u tpu t and energy c ons um ption of

Thanks to Siemens PLC and HMI, KCP series machine provides high intelligent operation system which is easy to operate and save man power.

Thanks to Siemens PLC and HMI, KCP series machine provides high intelligent operation system which is easy to operate and save man power.

PLC in t elligen t con t rol sys tem available for re m ote diagno s i s , c ontrol and m onitoring to and m ain t ained and operated f or a lon g ter m

can be conne c ted to E R P s ys te m for q u antit a -

tive a ss e s sment

c an be c onne c ted to E R P s y st e m for q u antit ative a ss e s s m ent

pe l let s c an be en su red for either pellezitin g s ol u tion

P L C intelligen t c ontrol s y st em available f or re m ote diagno s i s, c on t rol and monitoring to and m aintained and operated for a long ter m

Wei g hing and m etering sys te m helps you m onitor the o u tp u t and energ y c on s u m ption of

Wei g hin g and meterin g s y s tem h e l p s yo u m onitor the o u tpu t and energy c ons um ption of

Wei g hin g and meterin g s y s tem h e l p s yo u m onitor the o u tpu t and energy c ons um ption of

PLC in t elligen t con t rol sys tem available for re m ote diagno s i s , c ontrol and m onitoring to and m ain t ained and operated f or a lon g ter m Wei g hing and m etering sys te m helps you m onitor the o u tp u t and energ y c on s u m ption of

can be conne c ted to E R P s ys te m for q u antit ative a ss e s sment

c an be c onne c ted to E R P s y st e m for q u antit ative a ss e s s m ent

can be conne c ted to E R P s ys te m for q u antit ative a ss e s sment

c an be c onne c ted to E R P s y st e m for q u antit ative a ss e s s m ent

Filter (options)

Filter (options)

Filter (options)

Filter (options)

2nd Extruder (optional)

(optional)

Two position plate type

Two position plate type

Downstream (options)

Downstream (options)

Two position plate type

Two position plate type

Two position plate type

Two

Two position plate type

Two position piston type

Two position piston type

Two position piston type

Two position piston type

Two position piston type

Two

Two position piston type

Back flush piston

Back flush piston type Automatic

Back flush piston type

Back flush piston type

Back flush piston type

Back flush piston type Automatic self-cleaning

Automatic self-cleaning type

Automatic self-cleaning type

Automatic self-cleaning type

2nd Extruder (optional)

Water ring pelletizer

Water ring

Downstream (options)

Water ring pelletizer

Water ring pelletizer

Water ring pelletizer

Water ring pelletizer

Strand pelletizer

Strand pelletizer

Strand pelletizer

Strand pelletizer

Automatic strand pelletizer

Automatic strand pelletizer

Automatic strand pelletizer

Automatic strand pelletizer

Underwater pelletizer

Underwater pelletizer

Underwater pelletizer

Underwater pelletizer

Dosing feeder unit

Dosing feeder unit

Dosing

Frequen c y conveyor are ent

Frequen cy c ontro l bel t c onve y or or conveyor are optional as loading device accordin ent material form.

Frequen c y c on t ro l bel t c onveyor conveyor are optional as loading device ent material form.

Ferrous and nonferrous metal separating of the whole line.

Ferrous and nonferrous metal separating of the whole line.

Dosing feeder with PLC intelligent which ensures the extruder run steady.

Ferrous and nonferrous of the whole line. Dosing feeder which ensures

Ferrous and of the whole Dosing feeder which ensures Dosing Frequen cy c ontro conveyor are optiona ent material

Dosing feeder with PLC intelligent control which ensures the extruder run steady.

C Type KSP80 KSP100 KSP120 KSP150 KSP180 Capacity (kg/h) 200-300 300-500 500-600 700-900 1000-1500 Energy consumption (kWh/kg) 0.3-0.4 0.3-0.4 0.3-0.4 0.3-0.4 0.3-0.4 A / Length (mm) 12,890 13,780 14,570 15,530 16,540 B / Width (mm) 2,820 2,960 2,670 2,910 3,260 C / Height (mm) 3,370 3,530 3,530 3,690 4,000 Extruder Screw Diameter (mm) L/D 32-36 32-36 32-36 32-36 32-36 Motor power (kW) 55-75 110-132 160 250 315-400 Filter (options)

position plate type

position piston type

flush piston type Automatic self-cleaning type 2nd Extruder (optional) Screw Diameter (mm) L/D 12 12 12 12 12 Motor power (kW) 30 37 55 75 90 Downstream (options) Water ring pelletizer Strand pelletizer Automatic strand pelletizer Underwater pelletizer C Type KSP80 KSP100 KSP120 KSP150 KSP180 Capacity (kg/h) 200-300 300-500 500-600 700-900 1000-1500 Energy consumption (kWh/kg) 0.3-0.4 0.3-0.4 0.3-0.4 0.3-0.4 0.3-0.4 A / Length (mm) 12,890 13,780 14,570 15,530 16,540 B / Width (mm) 2,820 2,960 2,670 2,910 3,260 C / Height (mm) 3,370 3,530 3,530 3,690 4,000 Extruder Screw Diameter (mm) L/D 32-36 32-36 32-36 32-36 32-36 Motor power (kW) 55-75 110-132 160 250 315-400

Back

type Automatic self-cleaning type 2nd Extruder (optional) Screw Diameter (mm) L/D 12 12 12 12 12 Motor power (kW) 30 37 55 75 90

A C

Type KSP80 KSP100 KSP120 KSP150 KSP180 Capacity (kg/h) 200-300 300-500 500-600 700-900 1000-1500 Energy consumption (kWh/kg) 0.3-0.4 0.3-0.4 0.3-0.4 0.3-0.4 0.3-0.4 / Length (mm) 12,890 13,780 14,570 15,530 16,540 / Width (mm) 2,820 2,960 2,670 2,910 3,260 / Height (mm) 3,370 3,530 3,530 3,690 4,000 Screw Diameter (mm) L/D 32-36 32-36 32-36 32-36 32-36 Motor power (kW) 55-75 110-132 160 250 315-400 (options)

B

Two position plate type

Automatic self-cleaning type 2nd Extruder (optional) Screw Diameter (mm) L/D 12 12 12 12 12 Motor power (kW) 30 37 55 75 90 (options)

Two position piston type Back flush piston type

Strand

Automatic strand pelletizer Underwater pelletizer A C

Type KSP80 KSP100 KSP120 KSP150 KSP180 Capacity (kg/h) 200-300 300-500 500-600 700-900 1000-1500 Energy consumption (kWh/kg) 0.3-0.4 0.3-0.4 0.3-0.4 0.3-0.4 0.3-0.4 A / Length (mm) 12,890 13,780 14,570 15,530 16,540 B / Width (mm) 2,820 2,960 2,670 2,910 3,260 C / Height (mm) 3,370 3,530 3,530 3,690 4,000 Extruder Screw Diameter (mm) L/D 32-36 32-36 32-36 32-36 32-36 Motor power (kW) 55-75 110-132 160 250 315-400 Filter (options)

pelletizer

B

Screw Diameter (mm) L/D 12 12 12 12 12 Motor power (kW) 30 37 55 75 90 Downstream (options) Water ring pelletizer Strand pelletizer Automatic strand pelletizer Underwater pelletizer A C

Type KSP80 KSP100 KSP120 KSP150 KSP180 Capacity (kg/h) 200-300 300-500 500-600 700-900 1000-1500 Energy consumption (kWh/kg) 0.3-0.4 0.3-0.4 0.3-0.4 0.3-0.4 0.3-0.4 A / Length (mm) 12,890 13,780 14,570 15,530 16,540 B / Width (mm) 2,820 2,960 2,670 2,910 3,260 C / Height (mm) 3,370 3,530 3,530 3,690 4,000 Extruder Screw Diameter (mm) L/D 32-36 32-36 32-36 32-36 32-36 Motor power (kW) 55-75 110-132 160 250 315-400

B

self-cleaning type 2nd Extruder (optional) Screw Diameter (mm) L/D 12 12 12 12 12 Motor power (kW) 30 37 55 75 90

Downstream (options)

C

Type KSP80 KSP100 KSP120 KSP150 KSP180 Capacity 200-300 300-500 500-600 700-900 1000-1500 Energy consumption (kWh/kg) 0.3-0.4 0.3-0.4 0.3-0.4 0.3-0.4 0.3-0.4 A / Length (mm) 12,890 13,780 14,570 15,530 16,540 B / Width (mm) 2,820 2,960 2,670 2,910 3,260 C Height (mm) 3,370 3,530 3,530 3,690 4,000 Extruder Screw Diameter (mm) L/D 32-36 32-36 32-36 32-36 32-36 Motor power (kW) 55-75 110-132 160 250 315-400 Filter (options)

A

B

type

Two position plate

type

flush piston type Automatic self-cleaning type 2nd Extruder (optional) Screw Diameter (mm) L/D 12 12 12 12 12 Motor power (kW) 30 37 55 75 90

Two position piston

Back

Automatic strand pelletizer Underwater pelletizer A

Type KSP80 KSP100 KSP120 KSP150 KSP180 Capacity (kg/h) 200-300 300-500 500-600 700-900 1000-1500 Energy consumption (kWh/kg) 0.3-0.4 0.3-0.4 0.3-0.4 0.3-0.4 0.3-0.4 A / Length (mm) 12,890 13,780 14,570 15,530 16,540 B / Width (mm) 2,820 2,960 2,670 2,910 3,260 C / Height (mm) 3,370 3,530 3,530 3,690 4,000 Extruder Screw Diameter (mm) L/D 32-36 32-36 32-36 32-36 32-36 Motor power (kW) 55-75 110-132 160 250 315-400

(options)

pelletizer Strand pelletizer

B

Filter

Screw Diameter (mm) L/D 12 12 12 12 12 Motor power (kW) 30 37 55 75 90 Downstream (options) Water ring pelletizer Strand pelletizer Automatic strand pelletizer Underwater pelletizer C B Type KSP80 KSP100 KSP120 KSP150 KSP180 Capacity (kg/h) 200-300 300-500 500-600 700-900 1000-1500 Energy consumption (kWh/kg) 0.3-0.4 0.3-0.4 0.3-0.4 0.3-0.4 0.3-0.4 A / Length (mm) 12,890 13,780 14,570 15,530 16,540 B / Width (mm) 2,820 2,960 2,670 2,910 3,260 C / Height (mm) 3,370 3,530 3,530 3,690 4,000 Extruder Screw Diameter (mm) L/D 32-36 32-36 32-36 32-36 32-36 Motor power (kW) 55-75 110-132 160 250 315-400

type 2nd Extruder (optional) Screw Diameter (mm) L/D 12 12 12 12 12 Motor power (kW) 30 37 55 75 90

Downstream (options)

A

Type KSP80 KSP100 KSP120 KSP150 KSP180 (kg/h) 200-300 300-500 500-600 700-900 consumption (kWh/kg) 0.3-0.4 0.3-0.4 0.3-0.4 0.3-0.4 / Length (mm) 12,890 13,780 14,570 15,530 16,540 / Width (mm) 2,820 2,960 2,670 2,910 3,260 / Height (mm) 3,370 3,530 3,530 3,690 4,000 Extruder Screw Diameter (mm) L/D 32-36 32-36 32-36 32-36 Motor power (kW) 55-75 110-132 160 250 315-400

B

Screw Diameter (mm) L/D 12 12 12 12 Motor power (kW) 30 37 55 75

Extruder

1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8

y

Dosing feeder unit

Dosing feeder unit

c on t ro l bel are optional as loading device material form. and nonferrous metal separating at whole line.

feeder with PLC intelligent control ensures the extruder run steady.

onveyor or screw device separating at control steady. or screw according separating at control steady.

ontro l bel t optional as loading device material form. nonferrous metal separating at line. with PLC intelligent control ensures the extruder run steady.

B KSP180 1000-1500 0.3-0.4 A / Length (mm) 12,89 15,53 16,540 Screw Diameter Motor power (kW) 315-400 Filter (options) Two position plate type Two position piston type Back flush piston type 12 90 B KSP180 1000-1500 0.3-0.4 A / Length (mm) 12,89 16,540 Screw Diameter (kW) 315-400 Filter (options) Two position plate type Two position piston type Back flush piston type 12 90 B KSP180 1000-1500 0.3-0.4 / (mm) 12,89 16,540 Screw Diameter (kW) 315-400 (options) Two position plate type Two position piston type Back flush piston type 12 90 B KSP180 1000-1500 0.3-0.4 A / Length (mm) 12,89 16,540 Screw Diameter (kW) Filter (options) Two position plate type Two position piston type Back flush piston type 12 12 30 90 C B KSP180 1000-1500 0.3-0.4 A / Length (mm) 12,89 16,540 (mm) (kW) Filter (options) Two position plate type Two position piston type Back flush piston type 2nd Extruder (optional) 12 12 30 90 Downstream (options) B KSP180 1000-1500 0.3-0.4 A / (mm) 12,89 16,540 (mm) (kW) Filter (options) Two position plate type Two position piston type Back flush piston type Extruder 12 12 30 90 (options) B KSP180 1000-1500 0.3-0.4 A / Length (mm) 12,89 15,53 16,540 3,260 4,000 Screw Diameter 32-36 Motor power 315-400 Filter (options) Two position plate type Two position piston type Back flush piston type 12 90 B KSP180 1000-1500 0.3-0.4 A / Length (mm) 12,89 16,540 Screw Diameter (kW) 315-400 Filter (options) Two position plate type Two position piston type Back flush piston type 12 90 B 1000-1500 0.3-0.4 / Length (mm) 12,89 15,53 Screw Diameter (kW) Filter Two position plate type Two position piston type Back flush piston type 12 90 1 2 3 4 5 6 7 8

Washing Washingmodular modularmodular modular Size reduction modular Size reduction modular Pre-processing modula Size reduction modular Pre-processing modula Size reduction modular Pre-processing modula Size reduction modular Pre-processing modula Size reduction modular Squeezer-hydraulic Press Type Squeezer-hydraulic Press Type Steam consumption (kg/h) Chemical consumption (kg/h) Energy consumption (kWh) 395 Installation power (kWh) 530 0-2 120 195 3 180 290 3 280 446 4 4 90x15x6 0-600 0-12 490 760 4 RPW5000 4000-5000 120x20x6 0-10 175 198 306 Installation power (kWh) 210 330 498 630 810 Man power (persons/shift) 3-5 3-8 3-10 3-12 3-12 Type WES1000 WES2000 Capacity (kg/h) 1700-200 90x15x6 0-5 Energy consumption (kWh) 170 280 Man power (persons/shift) 3-6 Steam consumption (kg/h) Chemical consumption (kg/h) Energy consumption (kWh) 395 Installation power (kWh) 530 120 195 3 180 290 3 280 446 4 4 90x15x6 0-600 0-12 490 760 4 RPW5000 4000-5000 120x20x6 0-600 0-10 175 198 306 Installation power (kWh) 210 330 498 630 810 Man power (persons/shift) 3-5 3-8 3-10 3-12 3-12 Type WES1000 WES2000 Capacity (kg/h) 1700-200 90x15x6 Steam consumption (kg/h) Energy consumption (kWh) Man power (persons/shift) Steam consumption (kg/h) Chemical consumption (kg/h) Energy consumption (kWh) 395 Installation power (kWh) 530 0-2 120 195 3 180 290 3 280 446 4 4 90x15x6 0-600 0-12 490 760 4 RPW5000 4000-5000 120x20x6 0-10 175 198 306 Installation power (kWh) 210 330 498 630 810 Man power (persons/shift) 3-5 3-8 3-10 3-12 3-12 Type WES1000 WES2000 Capacity (kg/h) 1700-200 90x15x6 170 280 Man power (persons/shift) 1 5 5 5 9 9 9 10 11 12 2 6 6 6 3 3 7 7 8 8 1 1 1 5 5 5 9 9 9 10 11 12 2 2 2 6 6 6 3 3 3 7 7 7 4 4 4 8 8 8 Pre-processing modular Size reduction modular Washing modular Drying modular Pre-processing modular Size reduction modular Washing modular Drying modular Pre-processing modular Size reduction modular Washing modular Drying Pre-processing modular Size reduction modular Washing modular Drying

Self-cleaning Laser Filter

Scraper Disc Mesh

Die Face Plate Cutting Blades

Underwater Pelletizing

Self-cleaning Laser Filter

Scraper Disc Mesh

Die Face Plate Cutting Blades

Underwater Pelletizing

Self-cleaning Laser Filter

Scraper Disc Mesh

Die Face Plate Cutting Blades

Underwater Pelletizing

Self-cleaning Laser Filter

Scraper Disc Mesh

Die Face Plate Cutting Blades

Underwater Pelletizing