GCC high-grade sanitaryware markets

BAM: Carbon tari s for Asian ceramic manufacture

Central Asia and Russia: Tough challenges ahead

STATE PROFILE: Uttar Pradesh

GCC high-grade sanitaryware markets

BAM: Carbon tari s for Asian ceramic manufacture

Central Asia and Russia: Tough challenges ahead

STATE PROFILE: Uttar Pradesh

he growth of Chinese investment and trade in Latin America, often referred to as 'expansionism', is primarily driven by economic factors. There are some analysts who argue that Latin American countries will benefit economically, while others have worries about increased dependency and geopolitical repercussions. State-owned companies in China are major investors in the energy, infrastructure, and space sectors in South America, and the country has surpassed the United States in terms of trade volume. There has also been an increase in Beijing's cultural, diplomatic, and military presence in the region. With its influence and reach, China has also impacted the ceramic sector in the region. Chinese companies are investing heavily in the ceramics sector in Latin America, considered the second-fastest-growing ceramics market, after Africa. It is bringing in new technologies and production methods. No doubt, while China's presence in the ceramics sector offers opportunities for technology transfer and market access, it also poses challenges for local industries, especially in terms of competition and potential price wars. Whichever way you view this argument, one thing is certain: the region is fast becoming a hub for Chinese influence and power. Taking a closer merica, Rohan Gunasekera examines the

EDITOR

Editor Isaac Hamza

Email: ihamza@asianceramics.com

ADVERTISING AND DESIGN

Advertising Sales

ienced strong growth in the Gulf tural gas and crude oil prices, ruction industry. Construction led to increased sanitaryware ome of these countries have high per ticularly high-end ones, on the rise. ies for manufacturers of these products h Malik, who provides an overview of

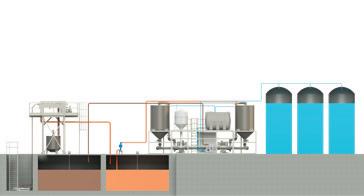

ts associated with complying with order Adjustment Mechanism (CBAM), loped markets. The EU CBAM is October 2023, with full implementation imposes import duties on carbon-intensive ium, fertilisers, hydrogen, and e future. Rohan Gunasekera recommends issions, including electrification and well as process-related emissions, such epared for this eventuality. Kyrgyzstan, Tajikistan, , continue to manufacture and es, especially maintaining free trade t geopolitical conditions. Increasing many challenges to Central Asian port manufacturing hub competing uture is bright, however, as Jahir Ahmed apped potential that this region possesses. PT Monokem Surya manufactures d ilmenite industries. With its headquarters strategically placed in Rengas Dengklok, nd director, Sardimin Sungkarto, ent activities and future plans.

Paul Russell

Email: prussell@asianceramics.com

Mobile/WhatsApp + 44 (0) 787 621 2193

Valerie Adamson

Email: vadamson@asianceramics.com

Mobile/WhatsApp: + 44 (0) 777 425 5051

Production and design

Tim Mitchell www.corpsvector.co.uk

Bangladesh

Jahir Ahmed jahir@asianceramics.com

India

Yogender Singh Malik yogender@asianceramics.com

Sri Lanka

Rohan Gunasekera rohan@asianceramics.com

RESEARCH

Research Manager

Andy Skillen

Email: askillen@bowheadmedia.com

HEAD OFFICE

27 Old Gloucester Street, London WC1N 3AX, UK.

Directors:

Valerie Adamson and Paul Russell.

KAJISEKI has built asystem capable of manufacturing tableware without the need for skilled engineers. Operation using an interactivedisplay not only allows you to manage the manufacturing process, but also gives you control over aspects of the production system such as production quantity and production errors.

Head Office : 2-2-1 Hachiman-cho, Takahama, Aichi 444-1302, Japan

URL : http://www.takahama-ind.co.jp

E-mail : info@takahama-ind.co.jp

TEL : +81-566-52-5181

A look at the high-grade sanitaryware market and major manufacturers in the Gulf Cooperation Council, home to many of the world's most prestigious and luxurious projects, by Yogender Singh Malik.

and

Matthew Grandage and Michelle Wang, Asian Ceramics' special correspondents for China, explore Foshan, known as the 'China Ceramic Capital' and a major zone for ceramic tile production.

In their quest to expand into foreign markets, Chinese ceramic manufacturers are becoming multinationals and venturing as far as Latin America, says Rohan Gunasekera.

As Asian ceramics exporters to the European Union comply with the EU’s Carbon Border Adjustment Mechanism, they will see higher costs. However, the tax could also contribute to decarbonisation, says Rohan Gunasekera.

Despite producing ceramics and exporting them, Central Asia Republic (CAR) countries face numerous challenges. However, Jahir Ahmed's report offers hope for the region with plenty of potential.

70

With 234 million inhabitants, Uttar Pradesh is India's most populous state and one of its most important ceramic markets.

Customer segments are served best by durable, functionally appropriate and aesthetically appealing tiled surfaces, not by the number of SKUs, says Dinesh Vyas, building material expert.

Surya, discusses his company's business and plans with Asian Ceramics.

open doors in the UK. According to Asian Ceramics special

Rahman, Thakur reinvent ceramics

In a breakthrough that blends ancient design with modern materials science, researchers at the University of Houston have developed a new class of ceramic structures that can bend under pressure – without breaking. Potential applications for this technology range from medical prosthetics to impact-resistant components in aerospace and robotics, where lightweight – but tough – materials are in high demand.

use in high-impact or adaptive applications. But that may soon change as a team of UH researchers, led by Maksud Rahman, assistant professor of mechanical and aerospace engineering and Md Shajedul Hoque Thakur, postdoctoral fellow, has shown that origami-inspired shapes with a soft polymer coating can

Their work was recently published in Advanced Composites and Hybrid Materials.

“Ceramics are incredibly useful – biocompatible, lightweight and durable in the right conditions – but they fail catastrophically,” says Rahman. “Our goal was to engineer that failure into something more graceful and safer.”

To do that, the team 3D printed a ceramic structure based on the Miura-ori origami pattern – which

stretchable, biocompatible polymer.

The resulting structures can handle stress in ways ordinary ceramics cannot. When compressed in different directions,

“The origami geometry gave us mechanical adaptability,” says Thakur. “And the polymer coating introduced just computer simulations. The coated versions consistently showed greater toughness – especially in directions where the original ceramic was weakest.

“Origami is more than an art – it is a powerful design tool that can reshape how we approach challenges in both functionalities in even the most fragile materials.”

A new era in impact-resistant component manufacturing could be born from this research. For aerospace applications, lightweight but robust ceramic structures can result in improvements to aircraft designs, resulting in improved fuel patient comfort. A technological advance such as this may greatly impact the lives of individuals who rely on these technologies to maintain their independence and mobility.

By Isaac Hamza

The UK and India agreed to a landmark trade deal on the 6th of May that will have a significant impact on both countries' core missions of growing the economy and improving living standards. For the UK, the agreement will result in a reduction of Indian tariffs on 90% of tariff lines, with 85% becoming tariff-free within a decade. Automobile tariffs, for instance, will go from over 100% to 10% under a quota.British shoppers could see cheaper prices and more choice on products including clothes, footwear, and food products as UK liberalises tariffs.

Indian businesses and consumers stand to gain an equal number of benefits as well. Aerospace, medical devices and electrical machinery are among the goods with reduced tariffs, which can open markets and reduce trade costs for India. The deal is expected to increase bilateral trade by £25.5 billion, UK GDP by £4.8 billion and wages by £2.2 billion each year in the long run. UK businesses are expected to gain a competitive edge over international competitors when entering India’s enormous market as it gets even bigger, forecasted to become the third largest global economy within three years.

British people and businesses."

Indian Prime Minister Narendra Modi says, "These landmark agreements will further deepen our comprehensive strategic partnership and will catalyse trade, investment, growth, job creation and innovation in both our economies."

The UK and India also have a deep and broad relationship, underpinned by a strong ‘living bridge’ of at least 1.9 million people with Indian heritage living in the UK. Even though the Indian market sits behind some of the world’s highest barriers to trade, it was the UK’s 12th largest trading partner in 2024 with total trade worth £43 billion.

Reynolds believes striking a new trade deal with the fastest-growing economy in the world makes both economic and emotional sense.

largest and most dynamic markets, and drive growth and innovation across the UK-India corridor,” he says. “We welcome this strong commitment to partnership and prosperity.”

Richard Heald, the UK-India Business Council chair, concurs with Winters. He says: “It matters when the fifthand sixth largest economies in the world reach a trade agreement.

“Such an agreement is illustrative of the positive momentum in the UK-India relationship, the commitment and ambition of both governments and the opportunities for greater trade, investment and collaboration between our countries.”

Benefits to the ceramic sector

The UK-India trade deal is expected to positively impact the ceramics sector, offering increased opportunities for businesses in both countries. Ceramics is one of many items made duty-free under the deal. India's reduced tariffs will increase UK ceramics' competitiveness, potentially increasing exports. It is anticipated that this development will also strengthen India's position as a global ceramic player.

The deal done In early May, Jonathan Reynolds, the UK's business and trade secretary, met with India's commerce minister Piyush Goyal to conclude negotiations that had been reopened only two months ago. Both sides have worked around the clock since February in order to achieve this deal, which is the largest and most important bilateral trade agreement the UK has done since its departure from the European Union, and the best trade deal India has ever signed.

According to Keir Starmer, Britain's Prime Minister, “Today, we have agreed a landmark deal with India, one of the fastest-growing economies in the world, which will grow the economy and deliver for

“In times of global uncertainty, a pragmatic approach to global trade that provides businesses and consumers with stability is more important than ever.

“At least 1.9 million people with Indian heritage call the UK their home and striking this deal will strengthen the vital partnership between our two democracies.The benefits for UK businesses and consumers under this deal are massive, with wins across an array of sectors.”

Bill Winters, as co-chair of the UK-India Financial Partnership and the group CEO of Standard Chartered, views this UK-India Free Trade Agreement (FTA) as an important achievement.

“It will create new opportunities for UK and Indian businesses, enable greater access to one of the world’s

Ceramic manufacturers in both countries have welcomed the move.

The UK has been a key destination for Indian ceramic exports over the last five years, with shipments reaching an estimated $119.38 million by 2024, according to Kamlesh Patel, chairman and managing director of Asian Granito India, quoted by The Hindu businessline.

“The FTA promises to be a gamechanger, offering Indian ceramic products duty-free access to the UK market. This strategic advantage is expected to unlock new growth opportunities and further strengthen India’s position as a global ceramic powerhouse,” says Patel.

Indeed, this deal is a win-win situation for both countries. It will strengthen the UK-India partnership, bringing down barriers to trade and granting stability to businesses inboth countries.

Explore new frontiers of ceramic decoration with Effecta, the machine that enriches your printing system by adding materiality and tactile finishes through post-drying effects such as shaper and water-repellent. Effecta transforms every surface into a sensorial experience thanks to multi-texture configurations and real-time integration with existing software and printers. Also available in water-based version and with a compact design, it combines innovation, sustainability and the Made in Italy reliability of Projecta, world leader in digital printing for ceramics and agglomerated quartz.

Research guides Bangladesh towards cleaner brick production • Research guides Bangladesh towards cleaner brick production in harsh environments • Moroccan Ceramic Industry Association elects new president • Minh Long marks its 55th anniversary tech sector with transition metals, & value-added products • BWI announces $15B strategic MoU with Saudi Arabia

BANGLADESH/UNITED STATES

A new study found that brick kiln owners were willing to implement energy-efficient operational changes after receivingtrainingandsupport. The social benefits of reduced carbon emissions from these changes outweighed costs by a factor of 65 to 1.

Brick manufacturing is a central component of the economy in South Asia, but also a major source of greenhousegasemissionsand air pollution, as the practice releases carbon dioxide (CO ), fine particulate matter (PM2.5), and other contaminants into the environment. This coalpowered industry poses a serious threat to human health, agriculture, and the environment in low- and middle-income countries that lack the capacity to monitor and regulate these largely informal operations.

As scientists continue to sound the alarm on the increasing dangers of fossil fuels, a new study by researchers at Boston University School of Public Health (BUSPH), Stanford University, icddr,b, Greentech Knowledge Solutions, and the Bangladesh University of Engineering and Technology has introduced an evidencebased strategy proven to increase energy efficiency and reduce emissions in the brick manufacturing industry by encouraging operational changes that prioritise practicality and profit.

Published in the journal Science, the study analyses the results of a randomised controlled trial (RCT) that showed that brick kiln owners in Bangladesh are willing and able to implement cleaner and more efficient business practices within their operations, without legal

enforcement, if they receive the proper training and support, and if those changes are aligned with their profit motives. The study is the first to rigorously demonstrate successful strategies to improve efficiency within the traditional brick kiln industry.

The RCT evaluated an intervention that provided educational resources, training, and technical support to kiln owners in Bangladesh during the 2022-2023 brick kiln seasonwith276brickkilns.The intervention aimed to motivate the owners to make energyefficient adjustments to their manufacturing process, such as streamlining brick stacking and using powered biomass fuel, both of which improve complete fuel combustion and reduce heat loss in the kilns.

The study found that 65% of the brick kiln owners adopted these changes, which led to a 23% reduction in energy use. The changes substantially improved air quality, contributing to 20% reductions in CO and PM2.5 emissions. This intervention also brought substantial savings in coal expenditures and higher-quality bricks. Notably, the researchers estimated that the social benefits due CO2 reductions from the intervention outweighed costs by a factor of 65 to 1 and that the CO2 reductions were achieved at the low cost of $2.85/tonne. When the team returned to participating brick kilns the next year, they found adoption of the improved practices had not only sustained but increased.

Study lead and corresponding authorNina Brooks, assistant professor of global health at BUSPH, said: “Brick manufacturing is central

to development, urbanisation, and construction in Bangladesh and across South Asia, but the industry has not experienced much innovation, leaving open the possibility for win-win solutions that target low efficiency.

“Our findings demonstrate that brick kiln owners are willing to embrace simple changes that protect human and environmental health when they have the knowledge and training, and those changes deliver tangible economic gain.”

These findings are promising, as previous efforts to regulate the brick kiln industry have been unsuccessful in Bangladesh, where workers produce27 billion bricksannually in harsh working conditions. This industryaccountsfor 17% of CO emissions and 11% of PM2.5 emissions each year. Existingregulations, such as fuel mandates that ban the use offirewood,orlawsthatrequire brick kilns to be distanced from schools, health facilities, and other establishments, are onlyminimally enforced; for example, the majority of brick kilns in Bangladesh are

located illegally nearschools.

In a 2024pilot studyfor this intervention, the researchers learned that zigzag brick kiln owners were unaware of proper zizgag kiln operation, which are alreadydesignedto be less polluting, or that these approaches could increase their profit. The owners were also sceptical to implement the intervention, for fear that the changes were too technologically advanced for their workers. Although the study included an experimental armthatexplainedthebusiness case for incentivising workers to adopt the new practices, these were not widely taken up. An important area for future research is identifying strategies to improve work conditions that are aligned with kiln owners’ profit motives and may be implemented within a weak regulatory state.

Co-senior author Stephen Luby, the Lucy Becker Professor of Medicine and senior fellow at the Stanford Woods Institute for the Environment, said: "The remarkable success of the intervention demonstrates the benefit of deep engagement with local stakeholders.”

production • Breakthrough coating technology enables Nd-Fe-B magnets to thrive anniversary at Vietnam headquarters • Vedanta commits to powering India’s Arabia • MKS breaks ground on Thailand chemical manufacturing centre ...

Since their discovery thousandsofyearsago,magnets have fascinated humankind with their unique properties. Even today, scientists are studying and finding new applications for these materials.

In 1984, the development of neodymium-ironboron (Nd-Fe-B) magnets revolutionized this field. Known for their unparalleled magnetic strength, these magnets have now become ubiquitous, serving as critical components in renewable energy systems and advanced electronics. However, their susceptibility to degradation under moisture, salt spray, and temperature fluctuations has, thus far, strongly limited their deployment in harsh environments. Traditional protective coatings such as NiCu-Ni, Zn, and epoxy resin often fail under prolonged exposure, leading to catastrophic magnet failure.

Toovercomethesechallenges, a team of researchers from the Institute of Advanced Magnetic Materials at Hangzhou Dianzi

University, led by Zhen Shi (first author) and Xuefeng Zhang (corresponding author), has developed a ‘slippery liquidinfused porous surface’ (SLIPS) coating for Nd-Fe-B magnets through a multi-dimensional design strategy. Their recent work has been published in the journal Small on 14 April 2025. Elaborating on their findings, Zhang says: “This technology could revolutionize motor applications, ranging from aerospace systems to deep-sea roboticsandpolarinfrastructure, by preventing saltwater, humidity, and temperature fluctuation-induced magnet degradation. Moreover, we can significantly extend motor lifespans while reducing the maintenance costs.”

In this study, the team chemically engineered silica nanoparticles to form a dense polymer network with enhanced interfacial adhesion and locked lubricant film. Consequently, the resultant coating enables Nd-Fe-B magnets to resist corrosion, humidity, mechanical stress,

and extreme temperatures with unprecedented durability. Through extensive experimentation, the researchers found that there was no corrosion detected even after 136-day immersion in 3.5 wt.% saltwater. Furthermore, the novel SLIPS coating delays ice formation with 10fold longer freezing time and reduces ice adhesion strength by 75% at -20°C, as well as repairs mechanical scratches autonomously and restores surface functionality.

Compared to commercial Ni-Cu-Ni, Zn, and epoxy resin coatings, SLIPS coating demonstrates super stable corrosionprotectionforNd-Fe-B magnets. In electrochemical experiments, the impedance modulus of SLIPS coating at 0.1 Hz can be maintained at 3.31×10 day immersion, far surpassing that of commercial coatings. Notably, the impedance modulus of all commercial coatings deteriorated within 14 days.

Shi briefly highlights the

technologicalimpactofthisnew coating. “Our multidimensional design bridges the gap between laboratory innovation and real-world applications. By addressing corrosion and icing simultaneously, we have transformed NdFe-B magnets into reliable components even for the most demanding environments.” Lastly, the research team further noted that the selfhealing capability of the SLIPS coating ensures longevity even after physical damage, a critical feature for missioncritical systems in remote or inaccessible locations. While initially tested for offshore wind turbines, the robustness of the proposed technology suggests transformative potential across various industries. Aerospace engineers could leverage these magnets for lightweight, high-efficiency motors in satellites, while polar research equipment and deepsea exploration tools utilizing this innovation could achieve unprecedented reliability.

The Moroccan Ceramic Industry Association (APIC) embarks on a new chapter of its development with the unanimous election of Omar Chaabi as its President. This collective decision by the industry’s stakeholders signals a shared ambition: to breathe new life into a strategic sector with high growth potential.

Vice president of YNNA Group since 2009, Chaabi is a well-known figure in the national industrial landscape. He also sits on the boards of several major companies, including SNEP and GPC

Papier et Carton. Within APIC, he represents Super Cerame, one of Morocco’s well-known ceramic manufacturers.

His appointment marks a turning point for the association at a time when the ceramic industry is called to transform in the face of competitiveness, sustainability, and industrial sovereignty challenges.

Chaabi said: “Our ambition is clear: to build a strong, resilient, and future-oriented Moroccan ceramic sector. Together with industry players, we will implement a pragmatic action plan aimed at driving

innovation, boosting local integration, and enhancing our international footprint.”

APIC has announced the preparation of an ambitious sectoral recovery plan, built on consultations with industry stakeholders and tailored to the market’s concrete needs. Key priorities include modernisation of production tools, promotion of Made in Morocco products, trade defence, and upskilling of the sector’s workforce.

APIC said Chaabi’s presidency continues the momentum initiated by

Mohammed Lacham, who laid the foundation for renewed governance before retiring and handing over the leadership.

VIETNAM

The global tableware manufacturer, Minh Long, celebrated its 55th anniversary on 12th January at its headquarters near Ho Chi Minh, Vietnam.

The company was established in1970tomanufactureporcelain products that meet quality standards for technology, aesthetics, and consumer friendliness. Today, it employs more than 3,000 people and produces over 50 million products annually. The Minh Long brand, which operates on the Vietnamese porcelain market, offers products with contemporary design and

cutting-edge technology.

In addition to its domestic market, the company exports to countries throughout the world, including the US, Germany, and France.

The event was an important milestone in Minh and his family's effort to build a brand known for its quality porcelain andtableware.Today,MinhLong has successfully expanded its brand beyond South East Asia and Vietnam.

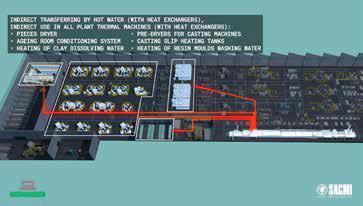

The event was also attended by the Sacmi Group, which has served as a key supplier to the Vietnamese firm for many years. It is noteworthy that

Minh Long has had a longstanding relationship with the Sacmi network of tableware companies, including Sama, which recently acquired Lippert, and Riedhammer.

“This anniversary represents not just a moment to celebrate our history and many successes, but also an opportunity to look towards the future. Our partnership with the Sacmi Group has been of fundamental importance in achieving excellence, which makes us stand out on the market today. We are proud to work with a partner who shares our values of quality

and continuous innovation,” Minh said, speaking about the company's long-standing relationship with Sacmi.

The celebration continued on the 13th of January with a visit to Minh Long's factories, during which the opening of a new porcelain museum was also held.

OnIndia’sNationalTechnology Day, celebrated on 11th May, Vedanta Limited, India’s leading producer of energy transition metals commits to powering India’s technology and engineering sector through its thrust on value-added and sophisticated range of metals. Vedanta is expanding its valueadded products for its zinc and aluminium products. The company has forayed into zinc alloys with a 30 KTPA plant while the aluminium business plans to significantly boost the share of value-added products in its portfolio to over 90% in the near-term.

For its aluminium capacity expansion, Vedanta's board had approved about $1.5 billion, including a smelter expansion (for additional aluminium production) and increased value-added product (VAP) capacity at its flagship aluminium plants.

Vedanta produces the four most widely used metals in the world – iron (for steel production), aluminium, copper and zinc. These are the four most important metals that makemodernlifepossible.From primary applications such as building&construction,defence, aerospace, power generation, automotive etc, these metals are now powering tomorrow’s new-

age tech such as renewable energy, energy storage, biotechnology, nanotechnology, space exploration, and hi-tech manufacturing. Simultaneously, the company is building its critical minerals footprint, exploring copper, nickel, cobalt, chromium, vanadium, tungsten and Platinum Grade Elements (PGEs) across states like Maharashtra, Rajasthan, Bihar, Arunachal Pradesh, Karnataka, and Chhattisgarh, supported by India’s policy push for mineral security.

Globally, there are about 3,000 technological applications of aluminium across various industries, whereas India has explored only about 300 so far.

Vedanta alone produces nearly 60% of India’s aluminium and finds its usage in developing advanced technologies owing to its exceptional properties of lightweight, high strengthto-weight ratio and infinite recyclability. The company is expanding its value-added aluminium products capacity in billets, primary foundry alloys (PFA), rolled products and wire rods. Aluminium billets are used in aerospace, defence and solar power sectors while aluminium rolled products are used in modern highspeed railways, electric vehicles,

pharmaceuticals and new-age battery enclosures.

As the world’s largest integrated zinc producer, Vedanta’s Hindustan Zinc is exploring uses beyond zinc galvanization of steel to protect it from rust, which currently accounts for over 60% of global zinc demand. Its latest range of value-added alloys, HZDA3 and HZDA-5 (Hindustan Zinc Die-Casting Alloys), have a wide range of uses across automobiles, defence, household appliances, sanitary-ware etc.

Emerging research identifies zinc-based batteries as safe, cost-effective, and recyclable alternatives to lithium-ion batteries. Zinc batteries offer high thermal stability, non-flammability, and high performance across extreme temperatures. This makes zinc a geopolitically secure and sustainable solution for India’s energy storage systems to store solar power. Advanced applications of zinc, such as in 3D printing, semiconductors, and solid-state energy systems are also rapidly increasing.

Vedanta Limited (“Vedanta”), a subsidiary of Vedanta Resources Limited, is one of the world’s leading natural resources companies spanning across India, South

Africa, Namibia, Liberia, UAE, Korea, Taiwan and Japan with significant operations in oil and gas, zinc, lead, silver, copper, iron ore, steel, nickel, aluminium, power and glass substrate and foraying into semiconductors and display glass. www.asianceramics.com

Burkhan World Investments (BWI), a United States-based global investment platform with hubs in Abu Dhabi and Miami, has announced the signing of three landmark Memoranda of Understanding (MoUs) with Saudi partners, totalling $15 billion in new investment commitments.

The MoUs were signed during the USA-Saudi Strategic Investment Forum in Riyadh, as part of President Donald Trump’s official delegation, reinforcing the deepening of economic and technological ties between the United States and the Kingdom of Saudi Arabia. These agreements span critical minerals, artificial intelligence, semiconductors, and dualpurpose defence technologies, marking a major advancement in transnational collaboration between two global allies. Each MoU was designed to align with the Kingdom’s Vision 2030, a bold national framework aimed at economic diversification, industrial capability building, and future-focused innovation.

The first Memorandum of Understanding, valued at $9 billion, was signed with Grand Mines Mining to launch a new Mining Investment and Operations Company headquartered in Saudi Arabia. This initiative will focus on the exploration, development, processing, and export of critical minerals, including lithium, cobalt, and rare earth elements, vital to advanced manufacturing, energy storage, and clean energy infrastructure in the United

States and allied nations.

The company will integrate cutting-edge technologies to enhance mineral extraction and refinement and will serve as a key supplier of processed critical minerals to US and global markets. In addition, the initiative is designed to catalyse local and international capital through Saudi Arabia’s capital markets, positioning the Kingdom as a regional and global hub for mineral wealth and strategic resource delivery.

The agreement directly supports Saudi Vision 2030 by unlocking the economic potential of the Kingdom’s untapped mineral reserves, creating skilled jobs, enhancing industrial capacity, and accelerating the shift toward a diversified and innovation-led economy.

The second Memorandum of Understanding was signed with Watad Digital, a Saudi privatesectorleaderinemerging technologies. This agreement launches a $1 billion AI and Semiconductor Investment Platform and Innovation Hub, aimed at developing and commercialising foundational technologies for artificial intelligence, chip design, and high-performance computing.

The hub will nurture local startups, support global R&D partnerships, and facilitate the manufacturing of nextgeneration semiconductor components within the Kingdom. This initiative aligns with Saudi Arabia’s Vision 2030 mandate to build a digital economy, accelerate

AI adoption, and establish the Kingdom as a center of technological excellence in the MENA region and beyond.

The third and largest MoU, signed with Advanced Aircraft Technology (AAT) and global private sector partners, will establish BWI Nexus, a $5 billion Dual-Purpose Defense Innovation Fund and Integrated Innovation Hub in the Kingdom. The Fund will co-invest with leading defence investors in areas such as AI-powered defence systems, autonomy, advanced sensors, cybersecurity, space technologies, and nextgeneration materials.

The accompanying Innovation Hub will support over 320 deep tech firms from both Saudi Arabia and abroad. These companies will benefit from physical infrastructure, operational support, and access to regional markets, enabling them to localise operations, commercialize innovations, and scale globally from Saudi Arabia.

The initiative supports Vision 2030’s ambition to build sovereign defence capabilities, stimulate private sector innovation, and reduce dependence on foreign military imports through the growth of a local dual-use technology ecosystem.

Shahal Khan, Founder and CEO of Burkhan World Investments, said: "Burkhan is honoured to contribute to the next chapter of Saudi-US economic cooperation.

"These memoranda are

more than investments — they are long-term platforms that support Saudi Arabia’s Vision 2030 while aligning US technological strength with regional growth priorities. We believe in building cross-border ecosystems that drive security, innovation, and prosperity for all stakeholders.”

Through these Memoranda of Understanding, Burkhan has reaffirmed its commitment to bridging global capital with strategic sectors, building partnerships that create economic impact, support industrial transformation, and contribute to geopolitical alignment between allied nations.

BWIis a global investment firm focused on high-impact opportunities in strategic sectors such as infrastructure, defence, AI, and critical minerals. Operating from Miami and Abu Dhabi, BWI partners with sovereign wealth funds, family offices, and institutional investors to deliver ‘Profit with Purpose’ investment strategies that combine financial return with national and global impact.

MKS Instruments (MKS), a global provider of enabling technologies, announced 7th May the groundbreaking of its cutting-edge Atotech chemical manufacturing and TechCenter facility at the Asia Industrial Estate Suvarnabhumi, located east of Bangkok, Thailand. This strategic investment

aligns with MKS’ commitment togrowalongsideitscustomers and deliver localised expertise to accelerate technological advancements across the region. The new facility also underscores MKS’ dedication to fostering Thailand’s growing role within the printed circuit board (PCB) industry.

John T C Lee, president and

CEO of MKS Instruments, said: “This facility represents a major milestone for MKS, as we expand our footprint in Southeast Asia.

“By bringing world-class manufacturing, cuttingedge technology, and specialised laboratory services to Thailand, we are reinforcing our ability to

support Southeast Asia’s fast growing PCB manufacturing and semiconductor advanced packaging sectors, as well as the region’s top specialty industrial manufacturers.

“This investment demonstrates our long-term visionforgrowthandinnovation in the global electronics and plating industries.”

LS Electric has partnered with the top domestic company for electric commercial vehicle charging solutions to expand its electric vehicle charging infrastructure business.

On the 9th, LS Electric announced that it signed a Memorandum of Understanding (MOU) with Pumpkin for cooperation in the electric vehicle charging solution business at LS Tower in Anyang, Gyeonggi Province.

The event was attended by Kim Dong-young, Head of K-Power Solution Division at LS Electric, and Choi Yong-gil, CEO of Pumpkin, along with executives from both companies. They discussed strategies for business collaboration and future plans in response to changes in the domestic electric vehicle charging solution market.

LS Electric and Pumpkin

have agreed to strengthen collaboration across the entire charging infrastructure sector. This includes developing specialized DC solutions like DC circuit breakers for commercial EV charging, expanding their application, ensuring charger quality, enhancing customer trust, and jointly exploring new markets.

Currently, the key components of domestic electric vehicle chargers, such as 'DC circuit breakers' and 'power modules,' rely heavily on Chinese products, with power modules accounting for over 90% of the market share from China.

In the public fast-charging market, Chinese products maintain high presence due to price competitiveness despite quality issues. Last year, the domestic EV charger market was valued at approximately 337.2 billion won.

Kim Dong-young, director, LS Electric, said: “We will strengthen our technological capabilities and ensure price competitiveness to localise core components of chargers, thus contributing to the growth of the electric vehicle charging infrastructure market, which faces challenges due to demand stagnation.”

Choi Yong-gil, CEO of PUMPKIN, said: “Collaborating with LS ELECTRIC will significantly enhance the reliability and performance of high-speed chargers, proving the excellence of domestic technology.

“We aim to continue enhancing the competitiveness of the Korean charging infrastructure by partnering with technologically adept domestic companies.”

Pumpkin is a fleet charging specialist company focused

on establishing charging infrastructure for electric buses and large commercial vehicles. It has set up numerous largescale charging stations at key depot locations and commercial vehicle hubs. Its proprietary pantograph-style high-speed, high-capacity charging technology and overhead bus chargers provide optimized solutions for large electric buses and commercial vehicles. Through technical cooperation with LS Electric, Pumpkin expects to supply an even more stable and advanced system.

QuantumScape Corporation, a US company that develops solid-state rechargeable lithium metal batteries for electric cars, and Murata Manufacturing Co, have entered into the first phase of an agreement to explore a collaboration for high-volume manufacturing of ceramic film for QS’s solid-state battery technology.

Murata Manufacturing is a Japanese company engaged in the design, manufacture and sale of ceramic-based passive electronic components and solutions, communication

modules and power supply modules.

Siva Sivaram, CEO, QS, said: “Murata’s deep expertise in high-precision ceramics manufacturing makes them an exceptional partner as we look to scale production of our proprietary ceramic separator.

“By combining our groundbreaking Cobra separator production process with Murata’s proven capabilities and global manufacturing strength, this agreement has the potential to create significant value.

“It brings together QS’s

advanced solid-state battery technology with Murata’s longstanding track record of delivering ceramic-based electronic components for some of the world’s most demanding applications.”

Building a global ecosystem is a cornerstone of QS’s capital-efficient business strategy: by leveraging a network of industry-leading partners, QS is accelerating the industrialisation of its solidstate battery technology while maintaining a strong focus on innovation and technological advancement. This ecosystem

On 13th May, Renesas Electronics Corporation, a premier supplier of advanced semiconductor solutions, announced its partnership with the Ministry of Electronics & Information Technology (MeitY), India, to support local startups and academic institutions in the field of VLSI and embedded

semiconductor systems.

Renesas also celebrated the expansion of its offices in Bengaluru and Noida to accommodate its growing research and development teams, with the inauguration ceremonies held on the same day. The strategic move is aimed at underscoring Renesas’

commitment to innovation and excellence in India and aims to drive continued growth in the region.

consists of leading equipment vendors, materials suppliers, auto OEM customers and contract manufacturers. By collaborating with experts in key areas, QS ensures a streamlined path to commercialisation while optimising resources for continued innovation.

QS’s next-generation solidstate lithium-metal battery technology is designed to enable greater energy density, faster charging and enhanced safety to support the transition away from legacy energy sources toward a lower carbon future.

Renesas and the Centre for Development of Advanced Computing (C-DAC), an autonomous scientific society of MeitY, signed two Memoranda of Understanding (MOUs) under the MeitY Chips to Startup (C2S) programme (Note).

These MOUs focus on supporting local startups by enabling them to drive technological advancement and promote local manufacturing in alignment with the Make in India initiative; and enhancing industry-academia collaboration by fostering an innovative, product-focused mindset among students.

EdgeCortix, a fabless semiconductor company specialising in energy-efficient edge Artificial Intelligence (AI), announced on 12th May that it has been awarded an Other Transaction (OT) agreement by the United States Defense Innovation Unit (DIU).

In winning the award, EdgeCortix became the first Japanese company and its USbased subsidiary to achieve such success.

The OT, awarded in February 2025, will enable the DIU to rapidly evaluate and ultimately deploy EdgeCortix's cuttingedge hardware and software solutions across a variety of DoD edge applications. These include areas involving AI-powered vision and generative AI.

Sakyasingha Dasgupta, CEO of EdgeCortix, said: “We are deeply honored to be the first

TAIWAN

Japanese company selected for a DIU contract, a testament to the innovative edge AI solutions our team has developed.

“This partnership not only validates our commitment to advancing energy-efficient AI technologies but also opens up transformative opportunities to contribute to critical global and national security challenges.

"We are thrilled to collaborate with the DIU team, whose seamless and easy-to-navigate process has made exploring the potential of our solutions across diverse domains, from space and aerial platforms to landbased systems, a rewarding experience. Together, we aim to redefine what’s possible in defence at the edge.”

As part of this initiative, EdgeCortix will demonstrate howitssolutionscansignificantly enhance mission capabilities for military personnel while

optimising platforms, systems, and components used across the DoD.

The collaboration aligns with DIU’s Resource Optimized Compute programme, which seeks to advance modern AI and machine learning systems capable of efficiently collecting, processing, and distributing mission-critical information at strategically decisive speeds.

This programme aims to ensure a strategic information advantage for national and global security operations across air, space, sea, ground, and cyber platforms. Key applications targeted include advanced AI analytics, real-time decision support systems, autonomous operations, and enhanced situational awareness.

Through a structured, multiphase process, EdgeCortix and DIU will collaborate

Taiwan Semiconductor Manufacturing Company (TSMC) unveiled its next cuttingedge logic process technology, A14, at the company’s North America Technology Symposium on 24th April.

Representing a significant advancement from TSMC’s industry-leading N2 process, A14 is designed to drive artificial intelligence (AI) transformation forward by delivering faster computing and greater power efficiency. It is also expected to enhance smartphones by improving their on-board AI capabilities, making them even smarter. Planned to enter production in 2028, the current A14 development is progressing smoothlywithyieldperformance ahead of schedule.

Compared with the N2 process, which is about to enter volume production later this year, A14 will offer up to 15% speed improvement at the same power, or up to 30% power reduction at the same speed, along with more than

20% increase in logic density.

Leveraging the company’s experience in designtechnology co-optimisation for nanosheet transistor, TSMC is alsoevolvingitsTSMCNanoFlex standard cell architecture to NanoFlex Pro, enabling greater performance, power efficiency and design flexibility.

CC Wei, TSMC chairman and CEO, said: “Our customers constantly look to the future, and TSMC’s technology leadership and manufacturing excellence provides them with a dependable roadmap for their innovations.

“TSMC’s cutting-edge logic technologies like A14 are part of a comprehensive suite of solutions that connect the physical and digital worlds to unleash our customers’ innovation for advancing the AI future.”

In addition to A14, TSMC also debuted new logic, specialty, advanced packaging and 3D chipstackingtechnologies,each contributingtobroadtechnology

platforms in high performance computing (HPC), smartphone, automotive, and Internet of Things (IoT). These offerings are designed to equip customers with a comprehensive suite of interconnected technologies to drive their product innovations.

TSMC confirmed it continues to advance its Chip on Wafer on Substrate (CoWoS) technology to address AI’s need for more logic and high-bandwidth memory (HBM). The company plans to bring 9.5 reticle size CoWoS to volume production in 2027, enabling integration of 12 HBM stacks or more in a package together with TSMC’s leading-edge logic technology.

The company is supporting AI on edge devices and its need for high-speed, low-latency wireless connectivity to move massive data with N4C RF, the latest generation of TSMC’s radio frequency technology. It is scheduled to enter risk production in first quarter of 2026.

TSMC is meeting customers’

with various DoD agencies, leading US defence, aerospace companies and NASA to leverage EdgeCortix technology.

This collaboration underscores EdgeCortix’s milestone achievement as the first Japanese company to receive DIU funding, significantly advancing edge AI solutions for national and global security.

EdgeCortix is a fabless semiconductor company that specialises in energy-efficient AI processing of Generative AI workloads at the edge. The company was founded in 2019 with its research and development headquarters in Tokyo, Japan. It offers a software-first approach with its patented 'hardware and softwareco-exploration'system to design a reconfigurable AI accelerator from the ground up.

needs with the most advanced N3A process going through the final stage of AEC-Q100 Grade-1 qualification, and continuousdefectimprovement to meet Automotive defective parts per million (DPPM) requirements. N3A is entering production for automotive applications, joining a full suite of technologies for future software-defined vehicles. As everyday electronics and appliances adopt AI functionality,IoTapplicationsare taking on greater computational tasks while remaining on a slim budget for battery power. With TSMC’s previously announced ultra-low power N6e process now in production, the company is targeting N4e to continue pushing the envelope of power efficiency for future edge AIs.

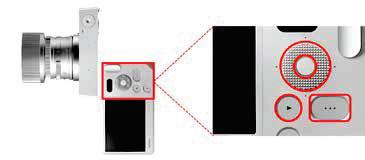

Kyocera Corporation announced that Haptivity, its proprietary tactile technology that replicates realistic touch sensations, has been integrated into the Sigma BF, a full-size mirrorless camera which was released in April. This is the first application of Haptivity in a mirrorless camera.

Haptivity is a groundbreaking technology that harnesses Kyocera’s piezoelectric ceramic vibrating elements to create truly immersive tactile sensations. Biomechanically engineered vibration waveforms provide tactile feedback by stimulating neural receptors in the user’s fingertip, providing physical verification when a button is depressedandreleased,oreven simulating the feel of a physical button where none exists.

Kyocera’sHaptivitytechnology integrates seamlessly into Sigma BF’s three recessed rear buttons (Function Dial, Options, and Playback, including the dial’s up, down, left, and right

touchpoints), for accurate, comfortable, intuitive operation. Haptic feedback ensures reliable performance by enhancing user confidence and avoiding duplicate commands.

Kyocera envisions a future where Haptivity becomes a ubiquitous, high-performance tactile technology.

“With its piezoelectric ceramic vibrating elements, Haptivity has the potential to revolutionise consumer and automotive applications as an essential component of the next-generation human-machine interface,” the company said. “It can improve the user experience for any device having physical buttons, or having screens and panels designed to provide tactile feedback.”

According to Kyocera, Haptivity features include excellent vibration response, realistic tactile feeling, tactile confirmation improving operationandrecessedbuttons

saving space and increasing design freedom.

Haptivity uses a piezoelectric ceramic vibrating element with excellent touch-response, delivering physical feedback that instantly confirms user input and eliminates duplicate commands.

A mechanical button delivers twosensationsnamelyonpress, and on release. Conventional tactile technology generates a single sensation (when pressed), which differs from the tactile feeling of a button. In contrast, Haptivity generates an initial vibration when pressed,

and a second vibration when released, providing a more realistic button sensation.

“Immediate tactile feedback confirms user input instantly, ensuring reliable operation and eliminating ambiguity. This makes Haptivity ideal for demanding applications, includingmobility,telemedicine, and industrial equipment,” the company said.

“Haptivity facilitates compact, thin, flat designs, allowing recessed buttons that promote space-saving and greater freedom of design,” Kyocera added in its statement.

An exhibition featuring over 80 pieces of China's renowned Dehua white porcelain was held at the Museum of Kyoto in Japan from 27th -30th March.

The artworks, crafted in Dehua County, Quanzhou City in southeast China's Fujian Province, were divided into categories such as classical cultural recreations, artisanal porcelain, everyday porcelain, and export porcelain. These works that blend practicality with artistic beauty drew enthusiastic responses from Japanese audiences, noted Xu Jianyong, executive vice president of Fujian Ceramics Industry Association.

Dehua porcelain has gained worldwide fame as ‘Blanc de Chine’ (White from China) for its milky-white hue and jade-like finish. Different from this simple elegance, Japanese ceramics emphasize rich colours and

decorations. The two cultural stylescanhaveanextraordinary encounter with each other through such exhibitions, said Wang Jiaming, who is in charge of the art department of Seki Shikyo Art Lab, the exhibition curator.

The event facilitated cultural exchanges between Fujian's master artisans and Japanese ceramic enthusiasts.

Zhang Minggui, executive secretary general of Dehua ceramic art masters alliance, said both China and Japan boast long history of porcelain production. This exhibition transcended art display and became a cultural dialogue allowing Japanese audiences to experience the charming traditional Chinese culture.

During the Sui and Tang dynasties (581-907), a large number of Chinese ceramics were exported to Japan,

exerting significant influence on Japanese ceramics.

During the Song and Yuan dynasties (960-1368) when Quanzhou's overseas trade boomed, Dehua porcelain wares became cornerstone exports on the Maritime Silk Road.

Dehua saw its annual ceramic output value grow 15% year on year to reach 66.3 billion yuan (about $9.1 billion) in 2024, with over60%ofitsproductsshipped to more than 190 countries and regions.

The county has taken moves to expand overseas markets in recent years, including establishing seven white porcelain promotion and exhibition centres in places like Singapore, Kuala Lumpur, and Malacca, and organizing international showcases in Malaysia, Germany, and the United States among others.

Lucid Group, maker of advanced electric vehicles, and King Abdullah University of Science and Technology (KAUST), an academic and research institution focused on science and technology innovation with regional and global impact, announced on 5th May a strategic partnership designed to shape the future of EV technology. Leveraging the growing resources in the Kingdom of Saudi Arabia, Lucid aims to further advance the company's technology leadership.

Marc Winterhoff, interim CEO at Lucid, said: "KAUST's worldclass research infrastructure and talent has the potential to further boost our technology leadership in many dimensions incl. our ADAS and AD roadmap, bringingcutting-edgeinnovation from the lab to the road.

"This collaboration also strengthens our global research and development footprint

bringing additional resources to bear in our efforts to continue as a leader in EV powertrain, battery systems, advanced materials, and software-defined vehicle platforms.

“As this partnership demonstrates, we continue to strengthen our collaboration with the Kingdom and are fully committed to working together to help achieve their vision to become a global centre for mobility innovation."

As part of this cooperation, LucidwillhaveaccesstoKAUST's supercomputing capabilities.

Edward Byrne AC, president of KAUST, said: "KAUST is proud to partner with Lucid to join our research capabilities with their real-world EV expertise while contributing to the Kingdom's strategic goals.

"This collaboration underscores our joint commitment to pioneering innovative solutions in electric vehicle technology."

Eric Bach, SVP of product and chief engineer at Lucid, said: "Access to high-performance computing at this level is truly transformative.

"It dramatically enhances our ability to develop advanced fluids, materials and alloys, simulate real-world physics for crash safety and structural optimisation, model fluid dynamics and thermal transfer, analyse electromagnetic flux, and accelerate AI training for digital twin technology, autonomous systems, and large language models.

“We are deeply grateful for this opportunity and excited about the breakthroughs it will drive across our engineering and AI initiatives."

Joint efforts will also focus on the design and prototyping of next-generation components and systems, integrating disciplines such as mechanical, electrical, thermal, and chemical engineering.

Advancements in materials science will play a pivotal role, with research dedicated to high-performance metallic and polymer-based composites, heat-reflective glass coatings, innovative laminates, and alternative non-conventional materials, each aimed at optimising vehicle efficiency and durability.

Thecollaborativeresearchand development activities will be hosted at KAUST's advanced laboratories in King Abdullah Economic City.

i2Cool, a pioneering company in electricity-free cooling technology, has announced a global strategic partnership with Marubeni, one of Japan's largest general trading companies. This collaboration aims to expand the global adoption of electricityfree cooling technology, with a particular focus on jointly developingelectricity-freecooling marine coatings and exploring innovative solutions within the shipping industry.

The signing ceremony was attendedbyMartinZhu,CEOand co-founder of i2Cool, along with Yasuhiro Arai, assistant general managerofMarubeni'schemicals department, and Yasuke Nagai, president of Marubeni Hong Kong & South China Limited. Zhusaid:"TheJapanesemarket, with its high level of technological acceptance and strong demand for environmental sustainability, offers a vast potential for the application of electricity-free cooling technology. This collaboration will facilitate

breakthroughs in localised production, adaptation to Japanese building and industrial standards, and cooperative promotion models."

With the rise of extreme temperature weather globally, the potential for applying electricityfree cooling technology is becoming increasingly prominent. This technology offers efficient and innovative energy-saving cooling solutions for various scenarios, including green buildings, industrial applications, and everyday protection. It has already been implemented in over 200 projects worldwide, covering more than 300,000 square meters.

i2Cool's flagship product, i2Coating,isanidealsustainable cooling solution for buildings and outdoor equipment, achieving surface temperature

cutting air conditioning energy costs by 10% to 40%. i2Coating hasbeensuccessfullyappliedto global architectural landmarks,

like the Dubai Mall and the Hong Kong Coliseum.

Marubeni representatives praised the coating's simplicity and immediate effectiveness, expressing confidence in its future market growth.

Under the agreement, both partieswillcollaboratetopromote the global implementation of electricity-free cooling technology, with a particular emphasis on expanding into the Japanese market. The partnership will also develop next-generation marine coatings to improve solar reflection and infrared radiation on ships, reducing cabin temperatures and air conditioning energy use.

Marubeni Corporation and its consolidated subsidiaries’ operations span various sectors, including lifestyle, information technology solutions, food, agribusiness, forest products, chemicals, metals and mineral resources, energy, power, infrastructureprojects,aerospace and shipping, finance, leasing

and real estate, construction, industrialmachineryandmobility, next-generation business and corporate development.

i2Cool is a green and energyefficient technology pioneer specialising in passive radiative cooling. Established by leading professors and young scientists from the School of Energy and EnvironmentatCity Universityof Hong Kong, i2Cool transforms cutting-edge research, featured in top journals such as Science, into innovative commercial solutions.

The company's core products are electricity-free cooling coatings and window films, along with a diverse range of other products such as textiles, membranes, automotive solutions, and ceramics. By leveraging proprietary nanomaterials, i2Cool achieves high solar reflectivity and mid-infrared emissivity, enabling zero-energy cooling with temperature reductions of up to 42°C.

Working people are expected to benefit from1,000jobsata new state-of-theartgigafactoryinSunderlandina £1 billion auto deal to accelerate the transition to electric vehicles andboostgrowth.

According to the government, this investment will be another boost for the British car industry a er UK’s landmark economic dealwiththeUnitedStatessaved thousands of jobs by slashing tari sonBritishexports.

The new AESC gigafactory will manufacture batteries for electric vehicles, powering up to 100,000EVseachyear,asix-fold increase on the country’s current capacity, making the UK globally competitive selling more British EVs at home and abroad and helping to achieve the country's netzerotarget.

In the landmark transaction, the National Wealth Fund and UK Export Finance will provide financial guarantees which unlock £680 million in financing from banks including Standard Chartered, HSBC, SMBC Group, Societe Generale and BBVA.

This will cover construction and operation of the new plant. The remaining £320 million has been securedthroughprivatefinancing inadditiontonewequityprovided byAESC.

In addition to this £1 billion investment, the government’s automotive transformation fund is also investing £150 million in grantfunding.

It is the government's Plan for Change which is being implemented in order for the country to become more competitive on the global stage, therebyhelpingthenationachieve itsgoalofbecomingasuperpower in clean energy by increasing innovation in the automobile sector, resulting in economic growth that results in higherskilled jobs and more money in people'spockets.

Chancellor Rachel Reeves said: “This investment in Sunderland will not only further innovation andaccelerateourmovetomore sustainable transport, but it will also deliver much-needed high quality, well-paid jobs to the NorthEast,puttingmoremoneyin people’spockets.”

Business and trade secretary, Jonathan Reynolds, said: “We arebackingourworld-classcar industry, and this investment is yet another vote of confidence intheNorthEast’sthrivingauto manufacturing hub which will secure a thousand well-paid jobsandboostprosperityacross theregion.

“Our modern industrial strategy will drive this growth even further, powering our highpotential sectors like advanced manufacturing so we can deliver jobs and investment in every corner of the UK and make our PlanforChangeareality.”

The Chancellor visited AESC in Sunderland on 9th May where shemetsta andlocalleadersto discuss how the investment will bring jobs and prosperity to the NorthEast,andhowthelandmark economic deal secured with the US will secure the industry for yearstocome.

Thedealslashescarexporttari s from27.5%to10%andwillapply to a quota of 100,000 UK cars –almostthetotalexportedlastyear.

This will save some car companies hundreds of millions

of pounds, making high skilled jobs in industrial heartlands like Sunderlandmoresecure.

Shoichi Matsumoto, CEO of Japanese headquartered AESC, said: “This investment marks a key milestone in AESC’s ongoing e orts to support the UK’s path towards decarbonisation and the expansionofitsEVmarket.

“Through close collaboration with strategic partners, we strive to accelerate this transition while creating high-quality local jobs and building resilient, sustainable supplychain.

“We are honoured to contribute to the development oflow-carboneconomywithour advancedbatterytechnologies.”

UKEFCEO,TimReid,said:“This hugelyexcitingprojectisaprime exampleofhowexportfinancing is a powerful tool for unlocking growth opportunities for British exporters and strengthening localeconomies.

“We are proud to join forces with partners to back this pioneering gigafactory that will helpcementtheUK’sprowessas an EV battery-making force for yearstocome.”

The Federal Institute for Materials Research and Testing (BAM), the Helmholtz-Zentrum Berlin (HZB), and Humboldt University of Berlin (HU) have signed a memorandum of understanding(MoU)toestablish the Berlin Battery Lab (BBL). The laboratory will pool the expertiseofthethreeinstitutions to advance the development of sustainablebatterytechnologies. The joint research infrastructure will also be open to industry for pioneeringprojectsinthisfield. Berlinhasestablisheditselfasan important location for research into sodium-ion batteries and lithium-sulphur batteries. The cityo ersconcentratedexpertise in these areas, supported by numerous research projects and high-profileresearchgroups.

The BBL will combine

the strengths of the three partner institutions: BAM has internationally recognised expertise in battery safety and electrochemicalenergymaterials.

HUBerlinisaleaderinGermany inacademicresearchonsodiumion batteries. HZB is particularly active in research on lithiumsulphurbatteries.

The laboratory aims to acceleratethetransferofmaterial developments into marketable products. In the field of basic research, material development ties in with the battery activities of the HZB large-scale research facilityBESSY-II.

The BBL activities culminate in the production of demonstrator cells and thus form an interface with safety and application tests. The collaboration between basic research, applied research, and certification enables a

faster transition from research to industrial application. This is particularly important in an increasingly protectionist trading world, where the availability of sustainable raw materials and thus the secure production of batteriesarecrucial,evenintimes ofcrisis.

The BBL is open to industry partners from all over Germany and Europe and serves to promote the development and production of locally manufactured sustainable batteries. Existing partnerships, suchaswithBASF,willbefurther expanded. In addition, physical laboratories are planned in Berlin to support research and developmentonsite.

BAM president Ulrich Panne said:“The planned establishment of the Berlin Battery Lab is a significant step for sustainable

batteryresearchinGermany.

“Through close cooperation with the Helmholtz Center Berlin andHumboldtUniversity,weare poolingourexpertiseandcreating auniqueresearchinfrastructure.

“This will enable us to bring innovative and sustainable battery technologies to market more quickly and thus make an important contribution to the energy transition. We look forward to working with our partners and industry to realise groundbreaking projects and further strengthen Berlin as a leading location for batteryresearch.”

Christoph Schneider, vice president for research at HU, said:“With the Berlin Battery Lab, we are building a bridge between excellent basic research and marketable, innovativetechnologies.

In March, the European Specialist Printing Manufacturers Association (ESMA) successfully completed its annual General Assembly in Milan, bringing industry leaders together for insightfuldiscussions,networking opportunities,andtheelectionof a new Board of Directors. In this year's assembly, Tracey Brown fromMeteorInkjetwasappointed thenewChairofESMA.

Theeventbeganontheevening of 20th March with two keynote presentations. Enrico Barboglio of Stratego Group presented an overview of the Italian printing sector, followed by Stefania Bolla of IXLA who presented cuttingedge technologies for security documentprinting.

During the assembly, Elaine Campling, a long-term Chair of ESMA's Health, Safety, and

Environmental Protection Committee, was awarded the honourableambassadorawardfor hercontribution.

Camplingsaid:“Iamprivilegedto havebeenpartofthecommittee forover20years.Itisdi cultto put into words how proud I am to have been named the ESMA Honourable Ambassador. This awardmeansalottome,coming from an organisation with great standing, which continues to evolve and remains strongly focused on providing value to itsmembership.”

Speaking on her new role, Brown said: “I have been an enthusiastic supporter of ESMA since 2018 and it has been a privilege to work with such a pivotal organisation. I am incredibly proud of what we o er our members, from expert technicalguidancetoinvaluable

networkingopportunities.

“With the launch of the new Screen Print Innovations (SPI) exhibition and the undeniable impact of the Industrial Print Integration (IPI) conference, the only event of its kind in the world, ESMA continues to thrive.Ilookforwardtoworking closely with the Board, the Management Team and the widerESMAcommunitytobuild on our successes and continue delivering tangible value to ourmembers.”

ESMAhasservedtheindustrial printing sector since 1990. The Europeanassociationforprinting manufacturers in screen and digital printing has grown into an organisation representing industrial, functional and speciality print. Over the years, ESMA has developed the Knowledge Hub concept, which

now provides cross-technology expertisetoalmost70European manufacturer members and Technology Partners. ESMA members have access to advantageous terms at major trade shows and ESMA's own conferences. Among the other benefits is the opportunity to attend technical seminars and committee meetings. Members and partners receive assistance and advice regarding health, safety, and environmental legislation as well as participate insettingindustrystandards.

In2024,wienerbergerachieved the third-best result in its history,despiteachallenging market environment, particularlyinthenewbuildsector.

The company increased total revenues by 6% to €4.5billion whilemaintainingarobustgrouplevel operating EBITDA margin of 17%. These results are based on disciplined cost management and operational e ciency and also confirm the resilience of wienerberger’s long-term valuecreatinggrowthstrategywithits targetedacquisitions.

wienerbergersaidinastatement that strategic acquisitions strengtheneditsmarketposition.

“Most construction markets globallydidnotrecoverasquickly as anticipated in 2024. Interest rates went down slower than expected, construction costs remained high and political uncertainties further decreased investment,” it said. “However, in 2024wienerbergeradheredtoits value-creating growth strategy andremainedfocusedonorganic growth through innovation and an increasing share of system solutionsinitsportfolioaswellas

growth through selected valueaccretivecorporateacquisitions.”

As a result, wienerberger profited from rising demand in certain markets that recovered faster than others. Especially the integration of Terreal, which advanced ahead of schedule, deliveredapositivecontributionto overallprofitabilityasitexpanded wienerberger’s activities in the growing renovation sector. The company also gained further market share in the sector of piping for water and energy management thanks to targeted investments in plant expansions andnewsystemsolutions.

Inaddition,strategicacquisitions, including Slatek OY in Finland, TekkenASinNorway(smartwater solutions) and GrainPlastics in the Netherlands (drainage and cable protection solutions), have expandedthecompany'sportfolio, optimised the supply chain and positionedwienerbergerforlongterm,sustainablegrowth.

Sustainability remains an integral part of its strategy, wienerberger emphasised. In 2024, the company continued to follow its ambitious 2026 goals

for decarbonisation, biodiversity and the circular economy by developing new solutions for ecologicalconstruction.

“One key achievement was the opening of wienerberger’s modernised nearly CO ₂ -neutral brick plant in Uttendorf, Austria, where the company installed the world’s largest electric industrial kiln and now operates Europe’s most sustainable brick productionfacility.Withtheseand other innovations, wienerberger continues to lead the green transformation of the entire constructionsector.”

Heimo Scheuch, CEO, Wienerberger, said: “Today, wienerberger is more resilient, innovative,ande cientthanever.

As part of our strategy, we are committedtodrivingthetransition towards climate neutrality –creating long-term opportunities forfuturegenerations.

“Sustainability and innovation go hand in hand and form the core of wienerberger. We will keep developing new solutions for ecological and innovative construction as well as smart water and energy

management solutions and lead the transformation of the entire constructionsector.”

According to Wienerberger, the company generates 33% of its revenue from innovative products, with a goal of reaching35%by2026.Pointing to the launch of Wioniq, it said it was one major step in bringing together four innovative companies, namely Inter Act, I-Real, Wideco, and Slatek, and creating a new platform for smart water and energy management solutions, which o ers significant growthpotential.

“By further increasing its innovationstrength,wienerberger willcontinuetofindnewwaysto reduce emissions, save natural resourcesandimprovethequality of life for current and coming generations,”itsaid.

In a crucial move to address unprecedented challenges facing the UK ceramics industry, Ceramics UK held a vital summit on 14th March, bringing together key stakeholders to finalise ‘The UK CeramicsIndustryRescuePlan’.

Hosted at the Sta ordshire Chamber of Commerce, the eventunitedapowerfulcollective of voices, including members of parliament from Stoke-onTrent and the Amber Valley in Derbyshire, regions with deeprootedceramicheritage,alongside trade union representatives, local government leaders, and prominent figures from the UK ceramicssector.

The summit facilitated open

dialogue and collaboration, enabling participants to identify key priorities and actionable strategiestosafeguardthefuture of this vital foundation industry from unprecedented threats, including soaring energy costs, cheap imports, forgery, and the costofdecarbonisation.

On 18th March, policymakers were presented with the rescue plan, which outlined key challenges and calls for decisive Government action to ensure the UK ceramics sector's long-term sustainabilityandgrowth.

Ceramics UK CEO Rob Flello stressed the critical urgency, stating: “The UK ceramics industry, a vital economic contributor, urgently needs

Governmentsupport.Thisrescue plan is essential for the UK Labour government to support this critical sector and its skilled workforce.”

InJanuarythisyear,asuccessful parliamentary event hosted by MrGarethSnell,MPonbehalfof Ceramics UK, provided members from across all areas of the organisation’sfoundationindustry with a valuable opportunity to discuss critical issues with governmentrepresentatives.

Over two hours, attendees spoke directly with the industry minister, as well as numerous MPs, including the business secretary’s parliamentary privatesecretary.

Key topics included the impact

of energy prices, carbon costs under the UK Emissions Trading Scheme, the Carbon Border Adjustment Mechanism, the risk ofo shoring,unfairimports,and theAutumnBudget.

Speakingatthetime,Flellosaid: “TheMinisterwasclearlylistening carefully but also already aware of the needs of our industry. We will continue to engage with her on possible solutions to the challengesweface.”

The collaboration between Reply, Marazzi and ACPV Architects Antonio Citterio Patricia Viel redefines a new connection between technological innovation and environmental sustainabilitythrough the productionofinnovativeceramics whose design is also generated through artificial intelligence (AI)algorithms.

A concrete step forward in the adoptionofinnovativesustainable technologies in industrial production where the integration of generative algorithms, inspired by principles of biomimesis, has made it possible to create patternsthatcombinetheorganic uniqueness of the natural world with the algorithmic precision of thedigitalone.

The project, which started in 2023 as an interdisciplinary experimentationbetweenthethree realities,nowseestherealisationof a special production ofgenerated

marbles, large stoneware slabs intendedtoconfiguresomespaces of Reply's new headquarters in Turin, at the former Caserma De Sonnaz, designed by Reply and ACPVArchitects.

Tatiana Rizzante, CEO of Reply, said: “The synergy between our team specialised in AI and machine learning with those of Marazzi and ACPV Architects has madepossiblethecreationofnew ceramic surfaces that reinterpret naturalmarbles.”

PatriciaViel,CEOandco-founder of ACPV Architects, said: "This project is an example of how AI, nurtured and guided by the architectural vision, can amplify human creativity and redefine productionprocesses.

“The ceramic surfaces resulting from this collaboration are not simply coverings, but unprecedented marbles, where technology and design sensibility cometogether.”

Oneofthemainchallengesfaced

by the team ofMachine Learning Reply, Reply Group company specialising in AI, andACPV Architectswas to reproduce marbles on a large scale, without creating an optical hallucination e ect and maintaining realistic e ectiveness applicable on large architectural surfaces, up to 3.2 metresinheight.

Theadoptionofthese‘generated marbles’ is part of a path that opensupnewcreativepossibilities and, at the same time, allows for the optimisation of key steps in the production process, such as materialprocurementandlogistics.

Marazzi, a major player in the industry, applies these algorithms to develop high-performance surfaces, integrating the technologyintomoree cientand resource-consciousproduction.

Mauro Vandini, CEO of Marazzi and president Mohawk Global Ceramic, said: "This project demonstrates how generative AI can transform ceramic design,

Cerabyte, a ceramicbased data storage solutions provider, announced 12th May a strategic investment fromWestern Digital Corp, a developer and manufacturer of storage solutions, including

hard disk drives. The partnership will accelerate the development of Cerabyte’s ground-breaking ceramic data storage technology, designed to meet the growing demand for permanent accessible longterm data storage in existing

andnewusecases.

Next-generation active archives will combine multiple storage technologies optimizing permanent data retention and accessibilityforthedigitalageas the industry is heading towards the Yottabyte era. Ceramic data

creating surfaces that not only respecttheenvironment,butalso elevatetheaestheticandfunctional standardsoftheindustry."

Asanetworkofhighlyspecialised companies, Reply specialises in the design and implementation of solutions based on new communication channels and digitalmedia.

Marazzi, present in more than 140 countries, is a producer of ceramics for floors and walls. It was founded in 1935 in the Sassuolo(Modena)district,which is well known for ceramic tile production.MarazziGroupispart ofMohawkIndustries,theworld's largest manufacturer in the flooring industry, a multinational group listed on the New York StockExchange.

ACPVArchitectsAntonioCitterio Patricia Vielis an international collectivewiththeaimofnurturing shared well-being through unique, high-profile architectural solutionsworldwide.

storage has the potential to enablenewusecaseswithbetter total cost of ownership (TCO) thancurrentcold-tiersolutions.

ShantnuSharma,chiefstrategy and corporate development o cer,WesternDigital,said:“We are looking forward to working with Cerabyte to formulate a technology partnership for the commercialisation of thistechnology.“

THE INNOVATIVE PRESS WITHOUT MOULD FOR BIG SLABS AND TRADITIONAL TILES

Very high productivity: up to 29.500 sqm/day