QUARTERLY

FOCUS TOPIC: BIOFUNCTIONALIZATION

INNOVATION IS THE KEY.

SUSTAINABILITY LEADS THE WAY.

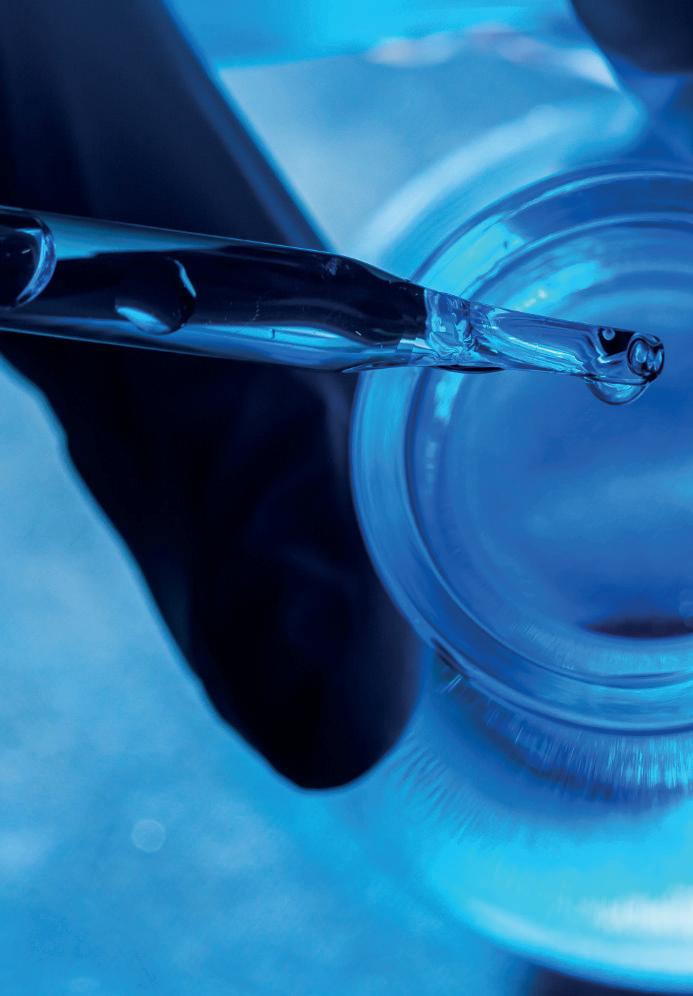

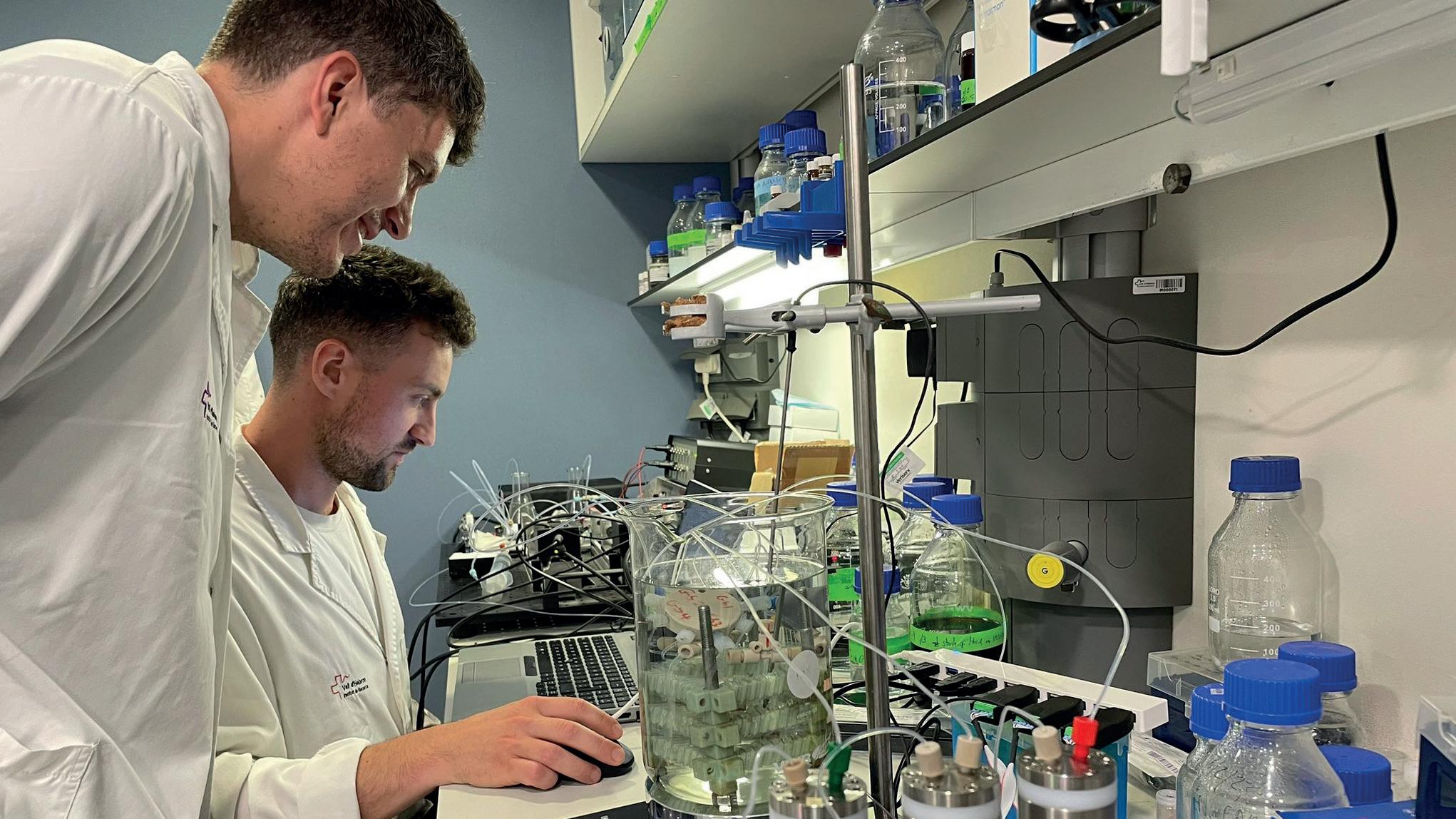

Cover: On-off-switch for Enzymes

© Attila Primus, BNN

WWW.BNN.AT

FOCUS TOPIC: BIOFUNCTIONALIZATION

INNOVATION IS THE KEY.

SUSTAINABILITY LEADS THE WAY.

Cover: On-off-switch for Enzymes

© Attila Primus, BNN

WWW.BNN.AT

This edition of the BNN QUARTERLY closes out an exhilarating month for the BioNanoNet Association and its members. No sooner were we “back to school” than we were heading from every corner of Austria and all across Europe to meet in Vienna for the BioNanoNet Annual Forum and Networking Event. The energy at TUtheSky, overlooking the beautiful skyline, was dynamic as we welcomed returning and new members and listened to experts from our community speak on the topic of biofunctionalization.

To build on the expertise presented in Vienna, this QUARTERLY highlights further research outcomes in biofunctionalization from our members and project partners, showing the range of applications from biomedical to therapeutic to technological. We are proud to have members with such wide-ranging but deep knowledge of this fast-faced field.

After with our Annual Forum, BNN also hosted the PRIME consortium and guests to the H2020 project’s final dissemination event, Microfluidics in their PRIME. Read more about this cutting-edge project, creating a lightactuated microfluidic printing platform, in our projects section.

Back in Graz it is just as exciting: we are happy to announce our newest colleague in graphic design, web design and CGI, a welcome addition to our busy Scientific Communication team. You can read more about his background, and then about the experiences of our summer chemistry intern.

We would love to hear from more of our members, with contributions to the QUARTERLY or with visits to our regular events. Mark your calendars for the SusChem-AT-Focusday (6 Nov 2023), ANTHOS 2024 (4-7 March 2024) and the TechForum Millstatt (3-7 June 2024). In addition, look out for our member survey, which should reach you in October. We hope you’ll take the time to provide us feedback!

Wishing you an energizing Autumn,

Andreas Falk CEO

We are happy to welcome our new BioNanoNet member:

INCDTIM

Extraordinary Member

The activity of the group focuses on the micro- and nanostructuring of polymers and liquid crystals in the search of novel functional polymeric systems of interest in different application fields such as Biomedicine, Photonics and Soft Robotics.

Extraordinary Member

The Polymer Chemistry & Biomaterials Group at Ghent University has been active over the last 15 years in the development of polymers for mainly biomedical applications (a.o. orthopaedic, ocular, lipofilling and cardiovascular applications).

View all members

We are happy to welcome our new BNN team member:

Attila Primus

Greetings, everyone!

Allow me to introduce myself – I am Attila Primus, originating from the beautiful city of Graz, Austria. My journey in the world of creativity and design has been an exciting one, and I’m thrilled to share it with you.

I earned both my BA and MA in Information and Media Design from FH JOANNEUM in Graz. During these formative years, my childhood passion for drawing and illustrating took a leap into the realm of 3D Animation and Visualization. Exploring the possibilities of visual expression became a driving force in my life, and I’ve been fortunate enough to see my dedication rewarded with the Austrian State Prize of Design.

Being an out-of-the-box thinker has always been my forte, and I am passionate about visual aesthetics. After completing my studies, I embarked on an exciting freelance journey, collaborating with some of Europe’s foremost studios. These experiences enriched my skillset and allowed me to hone my expertise in producing captivating CGI videos.

Now, I’m honored to have the opportunity to step into Barbara Ebner’s shoes at BNN, where I’ll be taking over design and communications for BNN and their EU projects during her educational leave, then working alongside her focusing on video and

to dive deep into understanding the project objectives and target audiences to help shape their success.

My aspiration is to enhance the visual communication strategies at BNN, utilizing my expertise in CGI videos to benefit the organization and its members. I can’t wait to bring my passion and enthusiasm to the table, working alongside the talented team at BNN to make a meaningful impact. Together, we’ll create a visual language that resonates with our audiences.

Thank you for welcoming me aboard!

Best regards, Attila Primus

Contact: attila.primus@bnn.at

Salja is studying Chemistry at the Chemistry Academy Graz and was our summer intern, supporting our colleagues in the Design for Technology Development (DfTD) area. We caught up with her at the end of her internship to learn more about her experience at BNN.

Salja, we are so happy you chose BNN to do your summer internship. Can you tell us why you chose BNN?

Salja: When I encountered your website, I was particularly drawn to BNN’s role as a non-profit research organization committed to supporting safety, quality, and sustain-

ability aspects already during the development phases of new technologies.

In addition to your focus on sustainability, I was impressed by your commitment to equity and inclusion, emphasized in your Gender Equality Plan’ on the website. This not only spoke of a respectful working environment but also highlighted your maturity as an organization. Finally, your expertise in nanotechnologies and commitment to keeping members informed about nanomaterial regulations stood out as a learning opportunity for me.

Describe a typical day at the office for you.

Salja: A typical day at the office consisted of performing desk research. For example, to map the Austrian and international nanomedical community, I was researching specific organizations and identifying their key expertise. My task was to collect this information to foster new networking opportunities. I also spent time on miscellaneous research tasks, such as helping to write reports and delving into topics such as Safe-andSustainable-by-Design chemicals and materials. In addition, I attended meetings to grasp the discussions and dynamics within EU projects, and occasionally reviewed and commented on project reports. Learning played a significant role – I completed an online course on EU nanomaterials’ legislation and watched recorded and live webinars to further expand my knowledge.

far we still need to go concerning the health and safety aspects of nano-related issues. Additionally, I’ve understood the necessity of being continually updated with State-of-theArt research and regulatory requirements, especially when considering bringing new technologies to the market, given that regulations aren’t a standard part of most curriculums in schools/universities.

Your internship is coming to an end soon. What are your next steps?

Salja: Following the final exams at the Chemistry Academy Graz, I hope to find a position that allows me to apply and expand upon the skills and insights I’ve gained at BNN.

What was the most interesting task you did here?

Salja: I enjoyed the opportunity to constantly learn about new technologies. The dynamic nature of the work made it engaging. One of the standout tasks was delving into chemical regulations. After attending a course I summarized the subject, deepening my understanding on what I learned.

What have you learned from BNN that you will take with you along your career path?

Salja: Communication has stood out as a crucial element, and I realized that without it, progress in any aspect is hindered. Furthermore, it was enlightening to see how

IUPAC|CHAINS 2023: the World Chemistry Congress

The 49th World Chemistry Congress of the International Union of Pure and Applied Chemistry (IUPAC) together with the 11th CHAINS meeting, the annual chemistry congress of the Netherlands Research Council (NWO), was held in The Hague, the Netherlands, from 20 – 25 August, 2023. Approximately 2000 participants from more than 70 countries came together to foster knowledge exchange, create new collaborations, and engage in discussions about chemistry and sustainability.

This was a great opportunity to connect on sustainability matters with likeminded colleagues of a huge community in the chemical sector. The CHASE Center and BNN represented the national technology platform SusChem-AT. In the focus session “Sensing at the Frontiers: Perspectives from Chemistry and Digitization“, Karin Kloiber (CHASE) contributed an invited talk called “Pillars of Digitalization: The Chemical Process Industries“. She introduced bottom-up approaches to process digitalization, process intensification, circular process streams, and sustainability considerations.

In the session “Safe and Sustainable by Design in Chemistry”, Andreas Falk presented BNN’s SSbD work, specifically in the conceptualization of SSbD-implementation (i.e., DeDNAed, SIXTHSENSE, SABATLE) as well as experiences from the integration of SSbD into technical developments. Furthermore, he could spread the word about the IRISSproject, NanoSyn4-initiative as well as the EU NanoSafetyCluster.

We interviewed our member Silvia Schobesberger from the Technical University of Vienna, who gave a presentation entitled “Point-of-Need Diagnostics - Game Changer in Future Healthcare?” at the BioNanoNet Annual Forum on 13 September at the TUtheSky in Vienna.

Silvia, thank you for presenting at our event! You are working in Peter Ertl’s Cell Chip Group , working on microfluidics and lab-on-a-chip. Besides reducing animal testing, what are the benefits of lab-on-a-chip systems?

Lab-on-a-chip systems enable miniaturization of laboratory processes, requiring less reagents and a smaller sample volume. The devices are portable due to the small size and therefore tests can be carried out on-site with reduced analysis time and less equipment. However, one of the greatest benefits is the design flexibility. Depending on the requirements of the laboratory process that is mimicked, the design of the lab-on-a-chip system can be adapted. All these reasons lead to a broad application field since exhaustive analytical procedures can be performed outside of the laboratory, where they are actually needed.

What are the long- and short-term objectives of the Cell Chip Group?

In the long run we want to develop microfluidic systems either to answer questions that are not possible to answer with state-of-the-art technology or, when microfluidic systems are already established, to push the technology towards commercialization. Right now, a very important area in our group is the development of organ-on-a-chip models. Here, we aim to reduce animal testing and increase the availability

availability of disease models for studying new drug candidates. Another research domain is the development of diagnostic sensing applications, which we additionally want to combine with organ-on-a-chip for downstream analysis.

What are some application areas for microfluidics that we might not have thought about?

An interesting approach is the shipment of microfluidic devices to the International Space Station to study the effect of microgravity. In addition, the cultivation of microorganisms that need extreme living conditions in terms of pressure or temperature could be an interesting field that has not been fully explored yet.

For which diseases are point-of-need diagnostics particularly effective? Where can patients and healthcare workers see the greatest benefits?

The pandemic showed that they are of great value in viral outbreaks since rapid tests detect infections and consequently virus spread can be reduced. In general, since the tests are easy-to-use, no medical personnel or lab facility is needed and the result is received within a short time. So we need to speed up, and one way to speed up is to work together. There is this old saying that if you would like to get something done quickly, do it yourself. But if you would like to go far, do it together with others. And I think that's why we need to work together here.

From my perspective, the diagnostic field will continue to grow rapidly in the next 5 years, especially since the number of microfluidic diagnostic devices that are approved is increasing. In 10 years, I think we will see a diversification of these diagnostic devices, for example more devices for rare diseases.

Tell us what you enjoy most about this area of research.

What I enjoy most about this research area is that it is so diverse. During the last years I gained insight in organ-on-a-chip, biosensor development, microfluidic prototyping and the development of diagnostic systems. Even for diagnostics, although we are focused on the medical field, there are so many other application areas that arouse my interest such as lactate measurements in professional sports.

What will point-of-need diagnostics look like 5 years from now? 10?

CENTER FOR COOPERATIVE RESEARCH IN BIOMATERIALS (CIC BIOMAGUNE), BASQUE RESEARCH AND TECHNOLOGY ALLIANCE (BRTA)

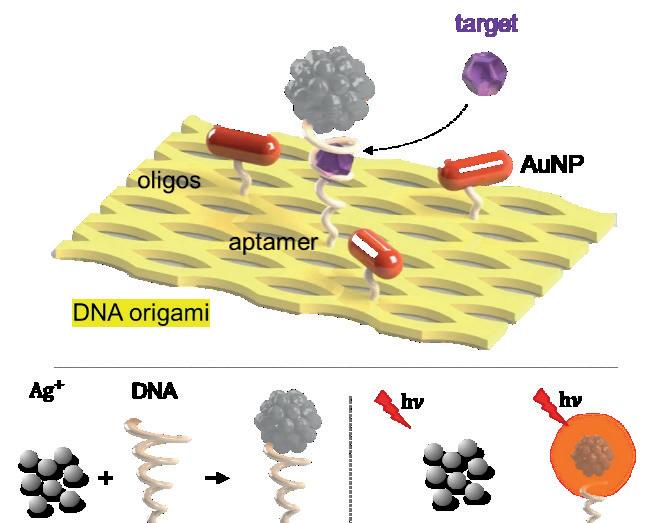

The DeDNAed project is developing a novel bioanalytical sensor-platform with advanced sensitivity and versatility, using SurfaceEnhanced Raman Spectroscopy (SERS) as an ultrafast optical analysis method. The novel sensor system enables the on-site detection of relevant biomarkers and carcinogens, such as aflatoxin B1 or Interleukin-6 for costefficient quality assurance in agriculture or to counteract emerging side effects in cancer therapy at an early stage [1].

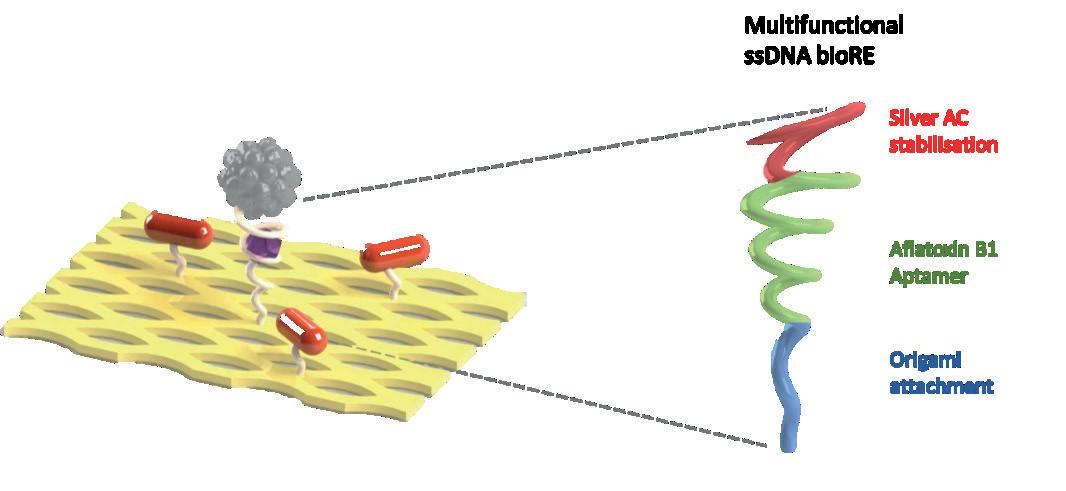

For the development of this novel biosensor with improved performance, the incorporation and combination of various nanotechnologies is critical, including the achievement of plasmonic nanoparticles (NPs) with specific bio-recognition elements (bioREs) such as DNA aptamers or antibodies. Additionally, DNA origami scaffolds are used as "nanobreadboards" to precisely control the nanoscale positioning of bioREs with respect to the plasmonic hotspots of NPs [2, 3].

To combine these technologies while ensuring high spatial precision we use biomolecules, in particular short DNA oligonucleotide sequences, a well-established method for attaching NPs and active bioREs to the DNA origami [4]. As shown in Figure 1, our concept incorporates metallic atomic clusters (ACs) integrated within the bioRE, providing enhanced fluorescence properties compared to other NP-based systems, while their synthesis is based on novel methods that ensure the recognition activity of the bioRE [5].

To fully exploit the DNA origami’s precise arrangement capabilities, it is important to utilize highly monodisperse plasmonic nanoparticles. Therefore, a surfactant based seeded-growth method is employed for synthesizing mono-crystalline gold nanospheres [6]. The resulting NPs are then biofunctionalized with thiolated singlestrand-ed(ss) DNA oligonucleotides complementary to the ssDNA strands displayed at the DNA origami. Appropriate DNA sequences, selected to avoid interference with the DNA origami folding process, the aptamer, and oligonucleotide sequences and their functionalities, are designed for NP functionalization, and synthesized in-house at CIC biomaGUNE.

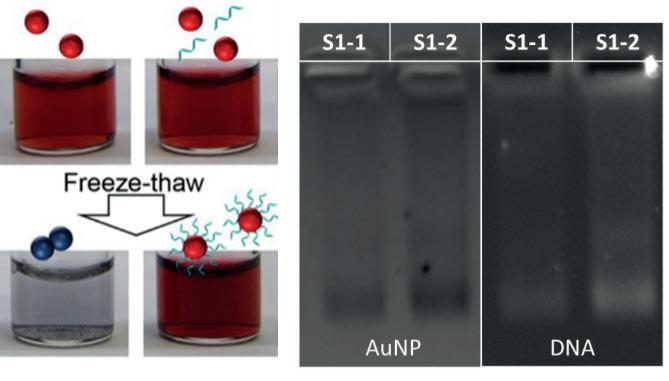

To attach the thiolated oligos to the AuNPs, different approaches have been optimized: a salt-aging and a freeze-thaw method [7, 8].

The salt-aging method uses the stepwise addition of NaCl to reduce the electrostatic repulsion of the negatively charged AuNPs and oligos. By adjusting the respective concentrations of the oligos and the salt as well as the reaction time, it is possible to achieve a high level of control over the loading ratio of oligos bound per NP. In the freeze-thaw method, the NP-oligo-mixture is instead shock-frosted in liquid nitrogen. Upon thawing, the NPs are functionalized with a near-maximum loading ratio of oligos. This method utilizes the shrinking liquid water volume available to the NPs and oligos upon the formation of ice crystals, forcing them to overcome their electrostatic repulsion. When instead NPs with no free oligos (or too few) are frozen, and thus brought into direct contact, they form stable aggregates which cannot be dispersed upon thawing, thus providing a quick initial qualitative check for the success of the NP functionalization (see Figure 2).

The bioRE is similarly conjugated to the DNA origami by the means of a complementary ssDNA sequence. In the case of an aptamer bioRE this means that the ssDNA aptamer sequence can simply be extended with an additional attachment sequence, while care must be taken that the different sequences do not show unintended cross-recognition. The bioRE is furthermore designed to additionally facilitate the coordinated synthesis of fluorescent atomic clusters (ACs). They are synthesized by a new enzymatic etching that does not denature the bioRE [9].

Thus, the bioRE is composed of three segments: one for DNA origami attachment, one for target-specific binding, and one for AC coordination (see Figure 3). The three segments have been independently and in combination analyzed and optimized, demonstrating their combined functionality.

5. L. Saa, M. Coronado-Puchau, V. Pavlov, L.M. Liz-Marzán Nanoscale 6 2014, 6, 7405–7409.

6. C. Hanske et al., Journal of Physical Chemistry C 2017, 121, 10899–10906

7. F. N. Gür, F. W. Schwarz, J. Ye, S. Diez, and T. L. Schmidt; ACS Nano 2016, 10, 5374–5382

8. B. Liu and J. Liu,; J Am Chem Soc 2017, 139, 9471–9474

9. L. Saa, et al., Nanoscale 2014, 6, 7405

1. V.V. Thacker, L.O. Herrmann, D.O. Sigle, T. Zhang, T. Liedl, J.J. Baumberg, U.F. Keyser Nat. Comm. 2014, 5:1, 1-7.

2. Wang, P.; Meyer, T.A.; Pan, V.; Dutta, P.K.; Ke, Y. Chem. 2017, 2, 359-382.

3. G. Lammel; R. Dorsch; T. Giesselmann; J. Goldeck; J. Hahn; N.N. Hasan; J. ; K. Gandhi Smart Systems Integration (SSI) 2021, 1 – 4.

4. J. Zessin, F. Fischer, A. Heerwig, A. Kick, S. Boye, M. Stamm, A. Kiriy, M. Mertig. Nano Lett. 2017, 17:8, 51635170.

CONTRIBUTION FROM JOANNEUM RESEARCH

If there is one experience that has united us since COVID-19 entered our lives, it might be the unending cycle of rapid testing. Without exaggeration, most of us now know how to run an antigen test and interpret the results like a pro: that’s because these tests are meant to be so foolproof and efficient that it takes little effort to carry them out. If you have taken a deeper look into diagnostics products that were rolled out in the market during the peak of the COVID-19 pandemic, perhaps you noticed that a great number of them possess the following hallmarks: easy-

to-use, quick, and highly accessible, to permit testing at the point of care. But have you ever wondered how these tests are manufactured? What makes up their inner workings? And how can we run a diagnostic test on a seemingly unassuming strip of paper or plastic? Wait no longer because we are going to delve together into how researchers at JOANNEUM RESEARCH are leveraging a cutting-edge tool that breathes life into modern diagnostics.

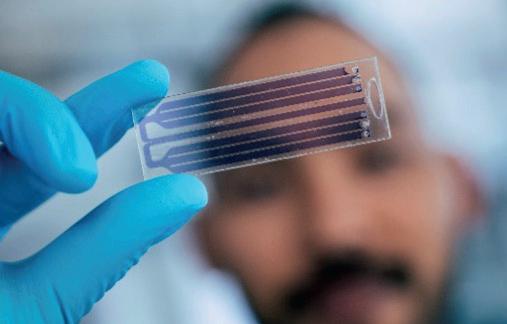

When we observe the trend of how point-ofcare diagnostic or any biological tests were designed and made into consumer products

over the past decades, we will clearly see how they are becoming smaller like computing microchips found inside smartphones and computers. In diagnostics, this downsizing gets its own official term: miniaturization. When the tests shrink in size, they not only become more portable, i.e., freeing themselves from the confines of conventional hospital labs to decentralized testing points like a doctor’s office or patient’s bedside, but they also are packed with a greater variety of assay options, driving the cost of production and eventually that of testing down to a more affordable level for all.

unleashes surface biofunctionalization from the bottleneck of batch operations to by making it compatible with roll-to-roll production that has already been implemented for the scaled production of microfluidic chips.

The microarray spotter has a pivotal role in nearly all demo cases in the NextGenMicro-fluidics (NGM) H2020 project and other initiatives where biofunctionalization in the specific compartments of microfluidic devices is necessary. In partnership with GENSPEED Biotech, which developed and pioneered an automated micro-ELISA point-ofcare platform for various clinical applications, we are adapting their existing products, such as the COVID-19 IgG xPOC antibody test and others in the developmental pipeline, to foilbased chips. The lesson we learned in the last few years is that each assay transferring faces its own challenges because switching to a new material microenvironment demands us to think critically about the biocompatibility of the probes with the particular surface and figure out the best way to anchor them without compromising their activities. As NGM is continues, we have gained significant momentum and promising outcomes; it will not be too long before one may come across the fruits of our collaborative research that

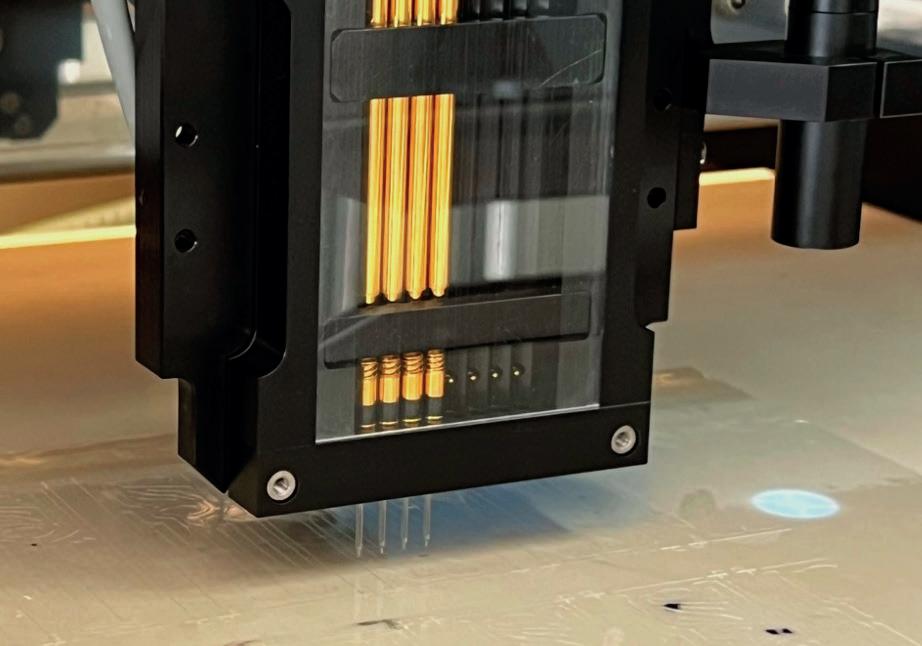

A close-up look at the printing manifold housing 4 glass nozzles working simultaneously

JOANNEUM

One of the tools that galvanizes the advent of assay miniaturization and truly realizes the vision for a lot of new portable tests discussed above is the non-contact piezoelectric microarray spotter. As fancy as it sounds, this device works just like any office inkjet printer that dispenses small droplets of biological probes, whether that being DNA or proteins, on the materials of interest in a very precise manner through the process called surface biofunctionalization. This exact process renders an otherwise passive surface to be biologically responsive to the molecules that we want to detect from the test samples. As diagnostic chips are getting smaller, the microarray spotter serves as a vital tool that allows developers to squeeze in more individual assays on the surface to address the need for multiplexed testing.

RESEARCH - MATERIALS institute is currently home to two microarray spotters, one of which is a custom device developed by Scienion, our Berlin-based leading manufacturer in the field, which elevates such a process to a whole new level. Designed from the perspective of industrial manufacturing, this machine

have successfully turned into commercial products.

To further unlock the full potential of the microarray spotter and highlight its merit, we also employ it for a special application to locally modulate the surface properties in separate sections of the microfluidic chip with the goal of improving the flow behavior. As far as we know, this is the first use case of the microarray spotter for non-biological surface functionalization. We anticipate more similar cases to emerge in forthcoming projects. With a highly versatile tool at our disposal, we believe that it is truly up to our creativity to navigate and put a new spin on how we can utilize it in any applications geared towards miniaturization. If you are curious about how the microarray spotter can contribute to your research, don’t hesitate to reach out to us at Joanneum Research - MATERIALS to learn more about the current spotting applications that we are undertaking. Contact

JOANNEUM RESEARCH - MATERIALS

jan.hesse@joanneum.at

www.joanneum.at/materials

Using a newly developed method for the efficient and cost-effective production of biocompatible microfibres, the production of autologous skin and organs can be significantly accelerated.

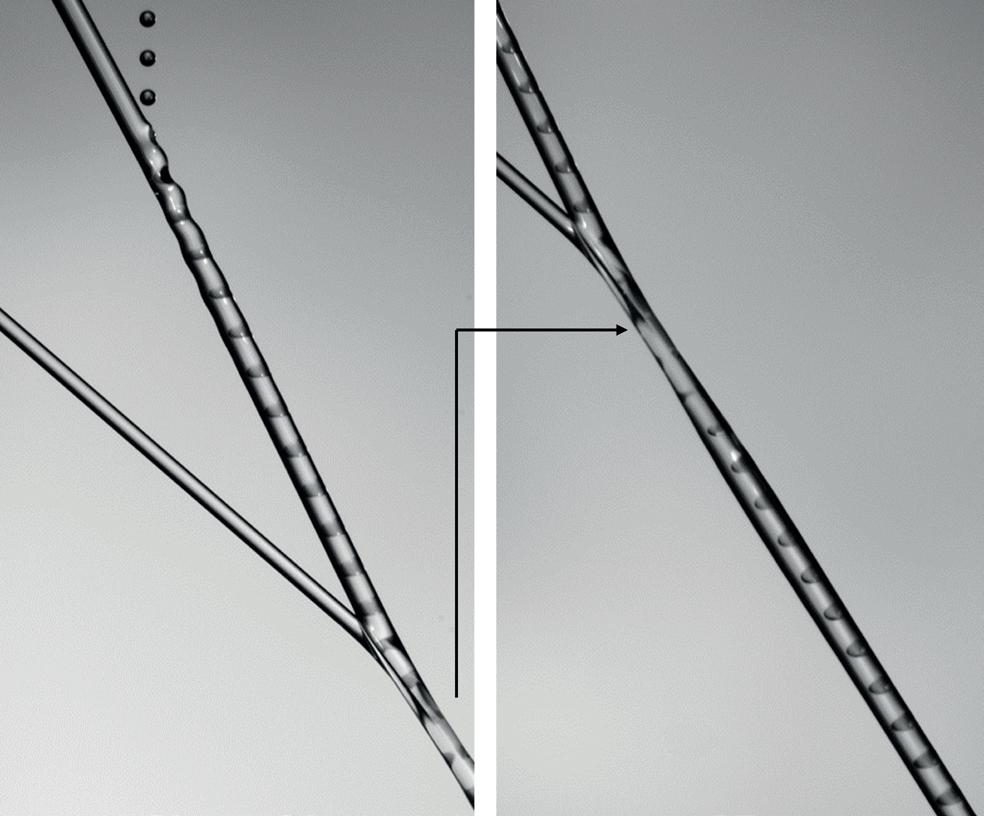

In biomedical technology, tissue engineering for the ex-vivo production of skin or organs is becoming increasingly important. This requires biocompatible microfibres with enclosed microcapsules of controlled size and shape, as the cells used for tissue engineering must be embedded in material that is as similar as possible to the natural arrangement in vivo. Until now, the production of such fibres at low output has been quite costly and timeconsuming. Researchers at Graz University of Technology (TU Graz) have now developed a new method for producing microfibres with the desired properties that can be used in pharmaceuticals and biomedicine, and which provides significantly higher yields than previous methods while requiring much less production effort.

In a paper published by the American Physical Society, Carole Planchette and her team from the Institute of Fluid Mechanics and

Heat Transfer at TU Graz explain how their development, funded by the Austrian Science Fund FWF and the Austria Wirtschaftsservice Gesellschaft aws, can produce several meters of this microfibre in seconds. (The current methods manage at most a few centimeters in the same period of time.) This acceleration has been made possible by moving away from the production of microfibres in a liquid environment using microfluidic chips to a production that is possible in sterile room air. As a result, the necessary process steps as well as the costs could be greatly reduced and potential sources of errors and blockages minimized.

Droplets are at first being hit by a liquid jet of aqueous alginic acid solution and this stream then gets hit by a jet of calcium cations. Image Source: David Baumgartner, Francesco Marangon - TU Graz

In the method now presented, a regular stream of droplets containing cells or active substances is combined with a liquid jet of aqueous alginic acid solution. The alginic acid obtained from brown algae forms upon contact with calcium cations an elastic hydrogel called alginate – similarly to the process commonly used in the molecular cuisine to form caviar pearls. This hydrogel is on the one hand fully biocompatible and on the other hand prevents the embedded droplets from coalescing together. Therefore, to cure the alginic acid solution stream, a second stream with calcium cations is jetted continuously on top. The resulting fibre, which can be grown at up to 5 meters per second, can then simply be collected on a turntable. All these steps take place in the air and not in liquid microfluidic production as before.

In a couple of years, it should be possible to produce a fiber assembly mimicking the skin from human cells using the new method. This integration of cells into the microfiber is the next step for Carole Planchette and her team. The expected result could be, for example, a great help for burn victims, as new and personalized skin for transplantation could be produced from their own intact skin cells in a very short time. In this perspective, researchers at TU Graz are working together with the Medical University of Graz on research into the production of artificial skin. Looking much further into the future, certainly more than ten years, one day it may also be possible to produce artificial organs using this microfibre.

In addition to tissue engineering, the new and faster production method opens up other areas of application for the biocompatible microfibre, such as cell screening. In the near future, it will be possible to test new molecules for medical agents much more extensively on cells to determine whether or at what point they are toxic. Due to the available fibre length, different temperatures or concentrations could be tested in a single run. For such tests on a large scale, animal experiments have been used up to now, and this could be largely avoided.

"For me, it is particularly interesting when I can use fundamental aspects of fluid mechanics to find new and innovative solutions to previously unsolved problems," explains Carole Planchette. "This allows us to discover pathways to new applications and our

manufacturing method of biocompatible microfibres with regular inclusions at high output and low cost demonstrates this. The possibilities for cell screening, tissue construction and eventually organ production that this opens up can be of great benefit to many disciplines. For me, this is also a clear sign of how important the role of basic and multidisciplinary research is, thereby creating the foundation for ground-breaking applications."

Contact

Carole PLANCHETTE

TU Graz | Institute of Fluid Mechanics and Heat Transfer

carole.planchette@tugraz.at

www.tugraz.at

CONTRIBUTION FROM GRAZ UNIVERSITY OF TECHNOLOGY

Researchers at TU Graz have gained new insights into the functioning of a protein found in bacteria, whose enzymatic activity is activated by blue light.

Light affects living organisms in many different ways: plants, for example, orient their growth direction towards the sun, while circadian rhythms in humans are controlled by daylight. These processes always involve photoreceptors, which are proteins that can sense different colors and intensities of light.

10,000-fold increase in enzymatic activity

Now, researchers at Graz University of Technology (TU Graz) have deciphered the function of a highly efficient photoreceptor. Their findings have been published in the journal Science Advances. The research team studied a diguanylate cyclase protein that is found in many bacteria. Its enzymatic function regulates the production of a central messenger substance that controls the way bacteria live. In darkness, the protein is almost completely inactive, but as soon as it is exposed to blue components of daylight, its enzymatic activity increases rapidly. “The protein’s enzymatic activity is about 10,000

times higher when it is exposed to light than it is in the dark," said Andreas Winkler, Head of the Photobiochemistry Working Group at TU Graz’s Institute of Biochemistry. In most photoreceptors, activity increases by a factor of between 5 and 50, resulting in more gradual changes in protein activity. “By contrast, the protein that we characterized reacts very strongly, so it actually works like an on-off switch,” Winkler explained. An efficient protein switch like this could be used in future to enhance and optimize optogenetic tools. actually works like an on-off switch,” Winkler explained. An efficient protein switch like this could be used in future to enhance and optimize optogenetic tools.

“I’m really excited that our research has generated valuable insights into the mechanism of this fascinating protein," commented Uršula Vide, first author of the study and a PhD student at the TU Graz Institute of Biochemistry. “Understanding the mechanism behind this light-activated enzyme switch opens the door to possible applications in a range of different disciplines.” One of these is in optogenetic treatment methods used in medicine. Drugs linked to a lightregulated protein switch could take effect at a precise time and only in a very limited area of the body, which would reduce potential side effects. A light-induced protein switch would also deliver benefits for research into cell

The researchers have now unlocked the architecture and function of the protein switch. The protein consists of two functional parts: one is responsible for the perception of blue light, and the other for the actual enzymatic activity, serving as the catalyst for a chemical reaction. If it is exposed to blue light, the protein changes its structure. When it is inactive, the whole protein is in a compact form, but when it comes into contact with light, the protein stretches, connecting the previously separated enzymatic parts. Then, the protein produces specific messenger molecules which signal to the bacterium that environmental conditions are changing. If possible, the bacterium adapts to these new conditions. “An example of this is the formation of aggregates, known as biofilms, which make

biology, as this would enable targeted triggering of specific changes at the molecular level that could then be analyzed more effectively. “We are still a long way away from such practical applications of this particular switch,” Winkler pointed out. However, he believes that his team’s research has produced some important, fundamental insights.

For their experiments, the researchers did not isolate the protein from the original bacteria, but instead produced it in the laboratory with the help of genetic engineering. They used X-ray diffraction to analyze the molecular structure, which formed the basis for a three-dimensional model. Combined with supplementary experiments, this model allowed the researchers to draw inferences about the changes in the protein’s structure upon exposure to blue light, which translated into specific conclusions about the molecular function of the biological switch.

Contact

Andreas WINKLERTU Graz | Institute for Biochemistry

andreas.winkler@tugraz.at

www.tugraz.at

The BioNanoNet Annual Forum, held on 13 September 2023 in the vibrant city of Vienna, Austria, was a remarkable gathering that opened its doors to the public. This event was made possible with the generous support of our national project NanoSyn4.

The central theme of this year's Annual Forum was "Biofunctionalization." However, it was not limited to this topic alone. The BioNanoNet Association members and collaboration partners shared their diverse competencies, making it a truly enriching experience.

One of the highlights of the Annual Forum was the dedicated session "Excellent Science and Collaboration Opportunities." Here, participants had the unique chance to engage in "Pitch & Match for Upcoming Calls." The Horizon Europe program of Cluster 4, as well as opportunities from Clusters 1, 5, and 6, took center stage. The national contact point provided insights into these calls, and participants seized the opportunity to present their project ideas and seek potential collaboration partners.

"The speakers from Ghent University, CSIC, TU Wien, FFG, INCDTIM, MUG, University of Vienna" provided us with their presentation

slides. Feel free to download them and enjoy reading:

The BioNanoNet Annual Forum 2023 brought together a multitude of speakers and members, fostering an atmosphere of collaboration and knowledge-sharing. As we reflect on this successful event, we eagerly anticipate the promising collaborations and breakthroughs that will emerge from this gathering.

In conclusion, the BioNanoNet Annual Forum 2023 in Vienna was a resounding success, showcasing the cutting-edge advancements in biofunctionalization and providing a platform for scientists, researchers, and industry experts to collaborate and shape the future of science and technology.

We are looking forward to the next BioNanoNet Annual Forum & BNN Networking Session in September 2024!

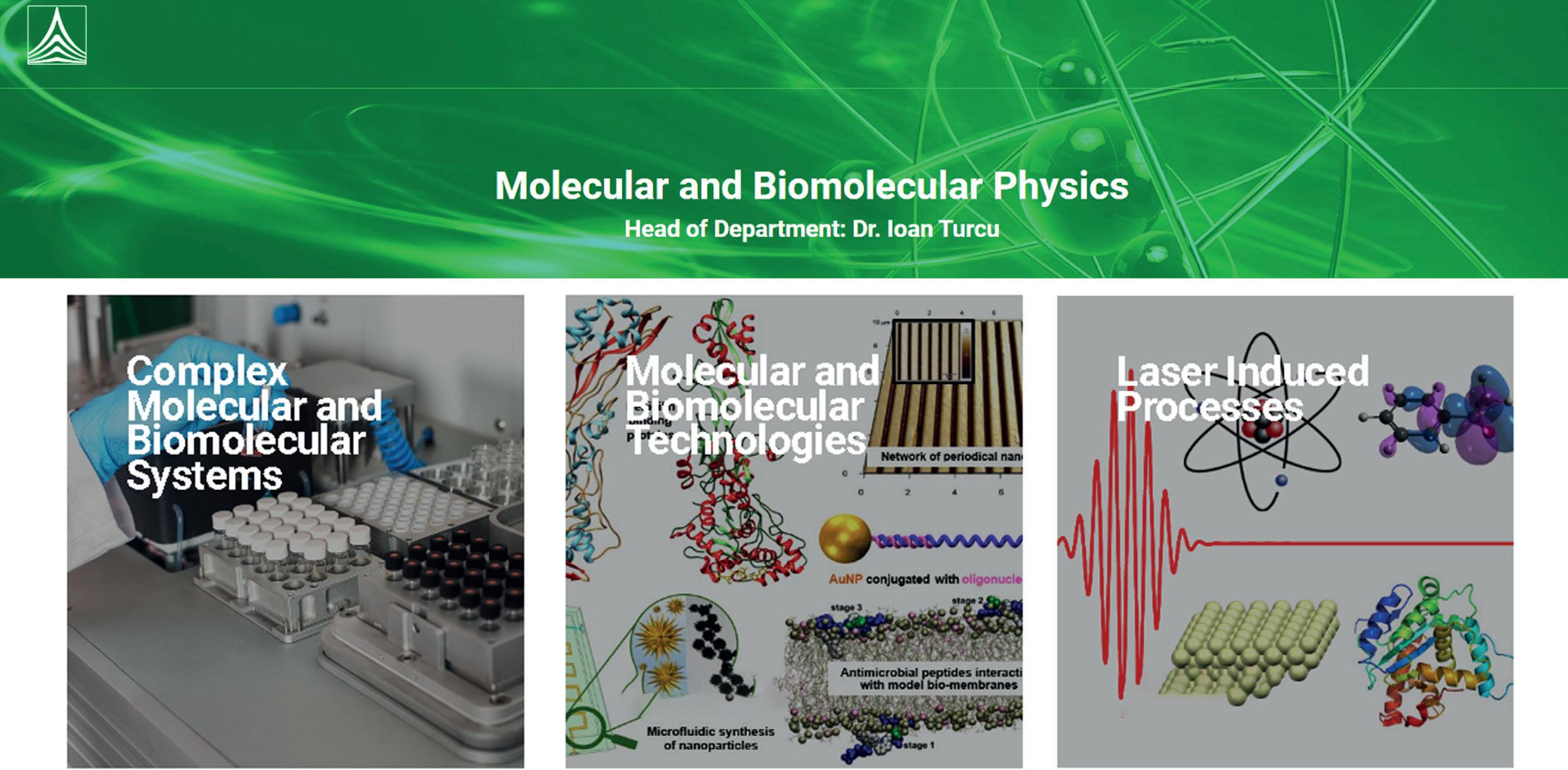

Head of Department: Dr. Ioan Turcu

The Molecular and Biomolecular Physics Department is a multidisciplinary scientific research entity (fundamental and applicative) in the field of physics and molecular and biomolecular systems’ technology. The department has some of the most modern and performant RDI equipment and highly trained research personnel. The mission of the department targets RDI activities aiming to achieve sustainable economic growth, development of novel molecular technologies with applications in medicine, bioeconomy, eco-technologies and emerging bionanotechnologies. The three research teams active within the department are the following:

“Molecular and Biomolecular Physics Department, National Institute for Research and Development of Isotopic and Molecular Technologies”

Complex Molecular and Biomolecular Systems – Team leader: Dr. Claudiu FILIP

Complex Molecular and Biomolecular Systems research team is developing its own R&D&I topics and, through collaboration with other groups, provides support for the synthesis / characterization of systems / materials of interest in areas like: health, pharmaceutical and nutraceutical industries, advanced materials, biotechnology, structural biology, biomimetics.

Molecular and Biomolecular Technologies –Team leader: Dr. Ioan TURCU

The Molecular and Biomolecular Technologies team is involved in advanced research that explores and develops novel micro/nanostructured systems targeting emerging technologies, theranostic biomedical applications, biomimetics, molecular and biomolecular sensors, molecular electronics, etc.

Laser Induced Processes – Team leader: Dr. Cosmin FARCĂU

The Laser Induced Processes research group develops theoretical and experimental research related to physico-chemical processes induced by coherent electromagnetic radiation in interaction with atomic, molecular and biological systems.

FROM THE MOLECULAR AND BIOMOLECULAR PHYSICS DEPARTMENT, NATIONAL INSTITUTE FOR RESEARCH

AND DEVELOPMENT OF ISOTOPIC AND MOLECULAR TECHNOLOGIES

Dr. Sanda BOCA-FARCAU is Scientific Researcher at the Molecular and Biomolecular Physics Department (DFMB), National Institute for Research and Development of Isotopic and Molecular Technologies, Cluj-Napoca, Romania and DFMB assigned person within the BNN.

Why did you decide to become a BioNanoNet member and what do you expect from the membership?What are the long- and shortterm objectives of the Cell Chip Group?

We are confident that as a member we can benefit from the BioNanoNet competences and long-standing expertise to assist us in becoming part of larger research partnerships, thus allowing us to improve our visibility and share our expertise.

Sustainability is a core value of BNN. What strategies have you implemented to improve your organization’s sustainability?

Sustainability is also one of our core values and a few strategies we approached for improving it are: i) Continuous Improvement and Innovation; ii) Prioritization of the gains for the community beyond self-oriented growth; iii) Transparency in Communication ; iv) Consistency in the long-term strategy.

Our Focus Topic of this issue is “Biofunctionalization”. Does your organization address this topic?

The expertise of the Molecular and Biomolecular Physics Department, National Institute for Research and Development of Isotopic and Molecular Technologies, Cluj-Napoca, Romania addresses the topic of Biofunctionalization, as confirmed by the published research results and ongoing projects http://en.itim-cj. ro/research/departments/molecular-and-biomolecular-physics/ .

What led you to your profession?

My interest for science and the attraction to the field of nanomedicine started to manifest during my doctoral studies. An important role had the postdoctoral training I’ve performed at the LIPhy - Université Grenoble Alpes, France.

What does your typical workday look like?

There is no doubt that the workday of a researcher is interactive and demanding. It starts from planning the research activity and continues with lab work and data analysis. Presentations, communication, and discussions are also integrated parts of the workday.

What’s the best aspect of your job?

Although it is often demanding and sometimes difficult and challenging, the research work will pay off in terms of results that might contribute to the scientific advancement and globally, to an increase of life quality.

What would you advise a young person considering working in your field?

My message to young scientists is to follow the path they are interested in, because if they are passionate about what they do, they already have a large percentage of what is necessary to succeed.

Who are people in your field that inspire you?

I don't have a particular model for a career in science. However, I think that in research, as in any other field, behind a model or models with professional success lies primarily a lot of work and determination. As for the notable discovery or discoveries of recent years, I find it fascinating the level of precision reached in the case of genomic editing, and the awarding of the Nobel Prize for Chemistry to researchers Emmanuelle Charpentier and Jennifer A. Doudna is a testimony.

What’s the best aspect of your job?

Although it is often demanding and sometimes difficult and challenging, the research work will pay off in terms of results that might contribute to the scientific advancement and globally, to an increase of life quality.

What would you advise a young person considering working in your field?

My message to young scientists is to follow the path they are interested in, because if they are passionate about what they do, they already have a large percentage of what is necessary to succeed.

What was your dream job when you were a kid?

Physician

If you could study anything (new) right now, what would it be?

Advanced Medicine & Pharmacy

Office, home office or hybrid?

Hybrid

Which book have you most enjoyed reading lately?

Nine Pints by Rose George

If you could make any activity an Olympic discipline, in which would you win a medal?

Research management and activity planning.

What is your motto?

Your only limit is the one you set for yourself.

Molecular and Biomolecular Physics Department, National Institute for Research and Development of Isotopic and Molecular Technologies, Cluj-Napoca, Romania

sanda.boca@itim-cj.ro

http://en.itim-cj.ro/portfolio/boca-farcausanda/

http://en.itim-cj.ro/research/departments/ molecular-and-biomolecular-physics/

With the growing amount of electronic waste generated by consumers, industry and other sectors, it is critical to address this specific environmental issue. Reducing the carbon footprint and promoting sustainability are therefore key to achieving climate goals and improving environmental protection. This is why Infineon Technologies AG (FSE: IFX / OTCQX: IFNNY) is taking another important step towards a greener future with the introduction of Soluboard®, a recyclable and biodegradable printed circuit board (PCB) substrate based on natural fibers and a halogen-free polymer. The product was developed by UK start-up Jiva Materials and helps to reduce the carbon footprint of the electronics industry.

READ MORE HERE

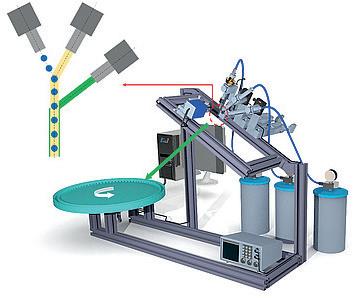

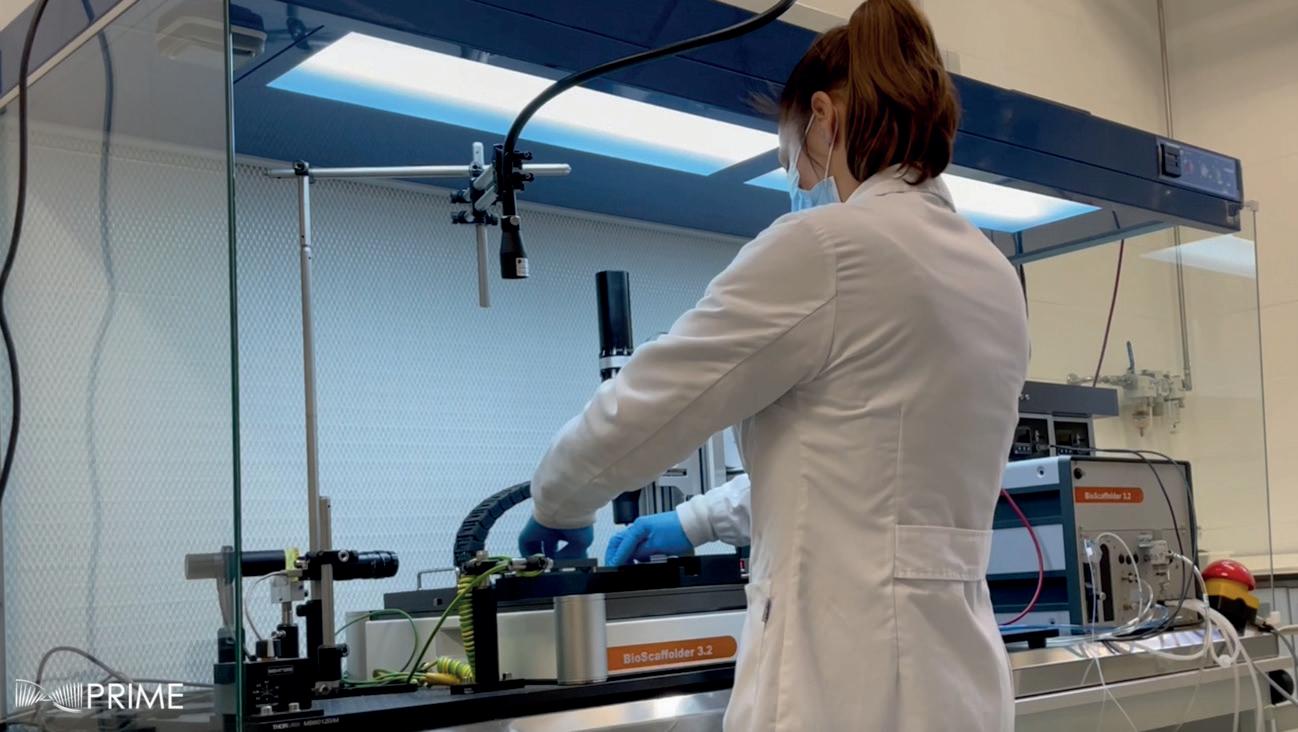

Microfluidics, through miniaturization, allows us to handle minimal amounts of fluid, perform complex assays with precious samples and, very importantly, reduce the assay time, becoming a key enabler in the fields of environmental, food and water assays, as well as in biomedicine. Microfluidics has also been embraced as a new advanced tool for biology, clinical research, and drug screening. As a result, microfluidics represents one of the most expanding markets. Despite this potential, existing technologies suffer limitations that impede its expansion, mainly the complexity and high prices of the required large-scale offchip equipment and its operational cost.

PRIME is a FET-OPEN project funded by the European Union focused on the development of a fabrication platform to create a new generation of active, tubeless and contactless microfluidic chips, effectively changing the currently established paradigm of passive microfluidic chips relying on the use of complex and expensive large-scale offchip equipment needed to control the fluidic functions and to perform analytical tasks. As a result, PRIME seeks to narrow the gap between Microfluidics and non-specialized labora-

tories and end-users, enabling the spread and penetration of the technology in diverse application fields as well as its geographical expansion to areas where large equipment is difficult to transport or resources are scarce. PRIME proposes the use of smart light-sensitive materials and additive manufacturing technologies to integrate light-actuated valves and ultra-sensitive and selective sensors in microfluidic devices.

The final device will be remotely addressed and read using simple photonic elements integrated in a portable operation & read device. In PRIME, CSIC, Eindhoven University of Technology, Max Planck Institute, Universidad de Zaragoza, BEOnChip and BNN have joined efforts to pursue this technology. During the project, PRIME has developed new light-responsive materials that can be processed through additive manufacturing technologies. These unprecedented types of materials, in combination with the use of advanced fabrication techniques, have enabled the preparation and integration, in a microfluidic chip, of smart valves addressed by light. Modelling of the mechanical response of the printed elements has facilitated the optimized design, in terms of geometry and material parameters, to ensure appropriate microfluidic function. PRIME has also produced new ultra-sensitive and selective sensors embedded in the chip and readable with light. The consortium is working on the effective integration of functional elements and progress towards the demonstration of the feasibility of the technology in real application cases such as in vitro diagnostic (IVD) and Organ-on-Chip (OoC). The aimed final chip is to be remotely addressed and read using simple photonic elements that can be integrated in compact, portable and cheap operation & read devices.

In the course of the project, the PRIME consortium has generated concrete results we aim to exploit towards the effective implementation of this active microfluidics technology—though exploitation in other application fields is also envisioned. In pursuit of the PRIME mission, we recognize the strategic significance of fostering

collaboration and establishing licensing agreements with key industry stakeholders. These strategic partnerships will help to accelerate the adoption of our innovations in the market.

4D printed light driven autonomous fluidic functions

PRIME developments have led to an unprecedented active valve technology based on liquid crystal elastomers that exhibit large deformations in response to light. This patented technology marks a significant leap in the realm of active microfluidics, introducing the revolutionary concept of 4D printing of responsive materials to embed the fluidic functions into the chip.

[1] In the pursuit of integrated active chip components, achieving substantial and rapid shape morphing capabilities is of paramount importance. PRIME innovations have meticulously developed new inks and printed actuators that demonstrate remarkable mechanical response. These advancements in material science and processing techniques are closely intertwined with cutting-edge modeling approaches, aimed at bridging the gap between the developed materials and the realization of functional active fluidic elements.

Within this context, the PRIME consortium has successfully engineered various geometries and integration strategies, culminating in the creation of microfluidic devices that embody the PRIME valve concept relying on smart materials. The laboratory experiments conducted by the PRIME consortium have demonstrated the viability of this valve concept, with microfluidic valves capable of stopping fluid flow under constant pressure conditions.

We continue working on improving the performance regarding pressure, flow and response times. PRIME's microfluidic valves can be integrated into the microfluidic cartridge, thereby converting this fluidic control component into a disposable entity. This integration approach facilitates the incorporation of multiple valves within the same microfluidic chip. The disposability of these valves mitigates the risk of crosscontamination that may arise with nonintegrable valve systems. Furthermore, the light-actuated nature of our valves eliminates the need for bulky equipment, facilitating their integration into portable devices.

In the domain of biomedical applications, our valve technology offers both societal and commercial advantages in applications such as point-of-care devices, in vitro diagnostics, and lab-on-a-chip platforms. Additionally, PRIME microfluidic valves are relevant in diverse domains, including environmental monitoring, biosafety, and biosecurity.

PRIME reaches significantly beyond the current state-of-the-art in nanoplasmonics and biosensing by proposing the development and elaboration of cholesteric-based thermal biosensors with a potential for application in fundamental science and healthcare. Based on our patented technology,[2] the sensing elements consist of a capture antibody crosslinked to the base floor of the microfluidic channel, and a detection antibody bioconjugated to the surface of a NIRabsorbing nanoparticle (NP). When the sample is loaded, the analyte, if present, interacts with the capture antibody and is retained in

the channel. Nanoparticles are subsequently retained by the detection antibody in the presence of the analyte, forming an antibodyanalyte-antibody sandwich. In a later step, the channels are irradiated with a NIR laser (1064 nm). This incoming light is transduced into heat thanks to the plasmonic properties of the nanoparticles. This heat generated can change a colorimetric thermal transducer (CTT) which is the optical detection element. So far, we have demonstrated the sensing concept for the detection of Carcinoembryonic Antigen (CEA), a common cancer marker, using a functional prototype. Within the framework of the project, we are making efforts to increase the sensitivity of detection in these systems. In addition, the operation and results obtained in the device can be executed and obtained by non-specialized users, since the particles are coupled to a thermoresponsive (thermographic) support. The use of these analytical devices is a novel concept and has been designed primarily to provide analytical capability at low cost in developing countries. The ambitious (high risk/high gain) plasmonic thermal sensing device proposed here will be prototyped by analyzing proteins. However, the underlying science involved is directly transferrable to a range of disciplines: from point-of-care clinical analysis, military and humanitarian aid field operations, to applications in art and conservation and many others where high throughput, low volumes of sample, low cost, and robustness are critical.

Over the past decade, a substantial amount of research has been devoted to fabricating stimuli-responsive polymers with large,

reversible deformations. The scientific fascination for nature’s responsive actuating systems has fueled the development of soft actuators that are readily applied in real-world applications, including artificial muscles, soft robotics, smart textiles, and devices exhibiting stimulitriggered deformations triggered by changes in humidity, temperature, and light, for example. Although these developments are promising, soft actuators are typically thermosets containing permanent crosslinks, thus virtually unrecyclable and not moldable. The work of PhD student Sean Lugger, developed within the PRIME project, focuses on developing thermoplastic shapechanging polymers to endow smart materials with recyclable and moldable features, affording sustainable soft actuators with a staggering variety of functionalities.

For this, melt-processable thermoplastic soft actuators are introduced, demonstrating immediate, reversible responses and weightlifting capabilities with large deformations upon exposure to light or temperature changes.

References:

[1] C. Sánchez-Somolinos, I. Ochoa, L. Fernández, M. Doblaré, Microfluidic valve, method for its manufacture, and uses thereof. WO 2021/260249.

[2] P. del Pino, B. Peláz, E. Polo, V. Grazú, J.M. de la Fuente, V. Parro, Biosensor comprising metal nanoparticles, WO2014/016465.

[3] S. J. D. Lugger, D. J. Mulder, A. P. H. J. Schenning, Method for the Preparation of a Thermoplastic Liquid Crystalline Polymer, WO/2023/059194.

María López Valdeolivas

Role of BNN in PRIME project: Communication & Dissemination activities

Contact Carlos Sanchez Somolinos Instituto de Ciencia de Materiales de Aragon (ICMA)

Consejo Superior de Investigaciones Científicas (CSIC)

pm-prime@csic.es

www.project-prime.eu

PRIME project has received funding from the European Union’s HORIZON 2020 research and innovation programme under grant agreement n° 829010.

As the project advances and the technologies are being developed in the different organisations, the technology transfer between universities/RTOs and industrial partners continues.

In July 2023, colleagues of the University of Leeds (UNIVLEEDS) in UK visited Applied NanoParticles (APPNPS) in Barcelona (Spain) with the main aim of coupling two essential modules of SABYDOMA’s Lead Demonstrator: the Silver Nanoparticles (AgNPs) flowthrough production line and the HISENTS

biomembrane screening module, that aims to reproduce the properties and interactions of a cell membrane. Both modules were previously successfully transferred at APPNPS facilities (read here for more details on HISENTS biomembrane module transfer).

Since the transfer, the HISENTS biomembrane has been operating very effectively, producing similar results to its sister setup system at UNIVLEEDS.

The AgNPs production line was also success-

fully transferred priorly but had developed some leaking issues. These were related with the malfunctioning of the mixing chamber unit, a Confined Impinging Jet (CIJ) mixer. A newly designed CIJ mixer was 3D-printed and sent to APPNPS in advance of Leeds visit.

The first day of the visit was devoted to fixing Lead Demonstrator AgNPs continuous flow production line by 1) replacing the damaged CIJ mixer, 2) coupling the UV-vis detector unit with the production line using a recently procured UV-vis OceanView Z-flowcell and 3) ensuring that the whole system worked properly performing some AgNPs synthesis tests.

The aim of these on-site tests was, firstly, to get the system to produce AgNPs with the same synthetic parameters (reagents concentrations and flows) as used at UNIVLEEDS. Once achieved, the next step was to improve the quality and output (amount of AgNPs) of the continuous flow AgNPs production line; this was done by (i) Decreasing up to 10x the concentration of Tannic Acid (used as strong co-reducer in the synthesis), (ii) Increasing up to 4x the concentration of Ag precursor (AgNO3, or silver nitrate), and (iii) Increasing the injection rates from the pumps, particularly crucial in the nucleation stage (first stage, where rate of injection/ is key for the size and monodispersity of the obtained silver seeds). With the introduction of these new synthetic parameters a high output of remarkably spherical and fairly monodisperse AgNPs were obtained (as checked later by TEM Imaging), largely improving the results obtained so far.

The following two days were focused on the coupling of the two technologies (the

AgNPs flow-through production line and the HISENTS biomembrane screening module). This was achieved via some changes in the fluidics design developed at UNIVLEEDS and the use of an ad hoc flow switching valve that were successfully also implemented in the APPNPS’ setup. Once that was achieved, the custom-made SABYDOMA control interface and routine algorithms for the coordinated operation of the coupled setup were further refined to adapt to APPNPS’ needs.

Summing up, the coupled systems forming the Lead Demonstrator of the SABYDOMA project, featuring membrane-activity-driven synthesis of AgNPs, are now fully operational at APPNPs. This achievement represents a notable milestone in the SABYDOMA project.

Role of BNN in SABYDOMA project:

Safety-by-Design, Graphic Design, Dissemination & Exploitation, Stakeholder engagement

Contact

BioNanoNet Forschungsgesellschaft mbH

b eatriz.alfaro@bnn.at

www.bnn.at

PRIME project has received funding from the European Union’s HORIZON 2020 research and innovation programme under grant agreement n° 862296.

www.sabydoma.eu

BNN @ European Researchers’ Night “Life is Science”

When? 29 September 2023

Where? Universalmuseum Joanneum, Graz, Austria

It’s time for Public Science again, and to give the public an insight into the world of research, the Austrian Center of Industrial Biotechnology (acib) is once again organising the Graz edition of European Researchers’ Night on 29th September 2023 – “Life is Science“.

This time the event will be located at the Universalmuseum Joanneum in Graz, where we can also expect exciting talks by Helmut Jungwirth (Science Buster and University of Graz), Christa Schleper (University of Vienna), Marlies Temper (FH St. Pölten), Matthias Slatner (acib) and Alexander Manhart (MedUni Graz). Other highlights include a pop-up planetarium by Ruth Grützbauch and a science slam with Bernhard Weingartner!

BNN will have a booth with information, games and activities regarding nanomaterials and nanotechnology– great for all ages! We hope you will stop by between 3 and 8 pm! For more information and a full programme, click HERE.

SusChem-AT-Focusday

When? 6 November 2023

Where? Vienna, Austria, TUtheSky

The topic “sustainable chemistry” is addressed by the actors of the national platform SusChem-AT in close cooperation with the European technology platform.

In order to support the developments on a national level in the best possible way, SusChem-AT is organizing the “Focus Day” on 6th of November 2023 from 10:0016:00, in Vienna, Austria (TUtheSky), which is dedicated to the topic “Green Chemical Engineering – Get it started!”

Lineup:

In the first part (10:00-12:00) the relevance of the topic will be discussed in keynote speeches and first developments and initiatives of the Austrian community will be shown.

The second part (13:30-15:30) will be dedicated to “Successful Applications of Green Chemical Engineering” and will include contributions on technology assessment, from the chemical and pharmaceutical industry, and concerning cross-sectoral industrial developments.

The event location is accessible and adapted with facilities for disabled people. We are continuously striving to improve the accessibility of our rooms. Should you have any questions or special requirements, our event team is at your disposal at veranstaltung@ gut.tuwien.ac.at.

Registration will be open & agenda will be available soon!

The event aims for certification according to the criteria of the Austrian Ecolabel for Green Events and Green Meetings.

Support us in implementation of sustainable events and take the opportunity for an environmentally conscious stay. Together, we are making a statement: Our commitment goes far beyond theory. Because every single active contribution matters!

REGISTER HERE

More information

Workshop „EU-Chemikalienstrategie für Nachhaltigkeit – Österreichische Roadmap zu Safe-and-Sustainable-by-Design“

When? 7 November 2023, 13:30-17:00 CET

Where? Vienna, Austria, Impact Hub

More information

Advanced (Nano)Materials and Technologies: Science, Research & Innovation for Safety and Sustainability

When? 4-7 March 2024

Where? Twelve (Hertha-Firnberg-Straße 8, 1100 Vienna, Austria)

The "Advanced (Nano)Materials and Technologies: science, research & innovation for safety and sustainability” Summit 2024 (ANTHOS 2024) promotes the advancements in technological innovation & research results on Safe-byDesign (SbD) for advanced (nano)

matererials and beyond. This summit serves as a platform for bringing together leading experts in Safe-by-Design (SbD) and Safe-and-Sustainable-by-Design (SSbD) from projects funded under the H2020 and Horizon Europe initiatives. Additionally, representatives of key

international stakeholder groups (European Commission, OECD, EFSA, ECHA, National Ministries, Industry…) as well as relevant associations and initiatives are invited to actively participate in the event.

Draft Agenda:

• Monday, 4th of March:

BioNanoNet General Assembly and BNN Networking Event

The event is open to research organizations, SMEs and large industries, consultancies, and other organizations active and interested in safety and sustainability of advanced materials, nanomaterials, and related products.

The event is organized by BNN, the EU NanoSafety Cluster, and the sister projects’ collaboration of the NMBP-15 projects ASINA, SAbyNA, SABYDOMA, SbD4Nano and NMBP-16 projects DIAGONAL, HARMLESS, SUNSHINE.

• Tuesday, 5th of March:

NMBP-15 Final Event – Demonstration of SbD tools, presentation of key results, and round table discussion

• Wednesday, 6th of March:

NMBP-16 Session – Latest developments on S(S)bD for advanced nanomaterials

• Thursday, 7th of March:

SABYDOMA’s 2nd SSbD Workshop / External Stakeholder Workshop

When? 3-7 June 2024

Where? Millstatt, Austria

More information

We hope you enjoyed reading the BNN QUARTERLY! Please don't hesitate to contact us if you have any suggestions or feedback.

Our next BNN QUARTERLY will be published in December 2023 and will focus on the topic " Innovation in Nanomedicine: Chances for strengthening the field” . BioNanoNet members are welcome to send their contributions regarding this focus topic as well as articles about their scientific research until 5th December 2023! Articles on other topics can be published anytime on the BNN website. Contact info@bnn.at

Impressum:

Owner and publisher: BioNanoNet Forschungsgesellschaft mbH

Kaiser-Josef-Platz 9, 8010 Graz, Austria

UID: ATU 63046279, FN 285326 y

Graphic Design & Layout: Barbara Ebner

All rights reserved. No part of this publication may be reproduced in any form without permission from the author or publisher. To request permission, contact info@bnn.at.