KEEP

'EM

F LY I N G

The work continues... By Matt Parkhouse #13272 IT FEELS KIND OF STRANGE TO BE THINKING

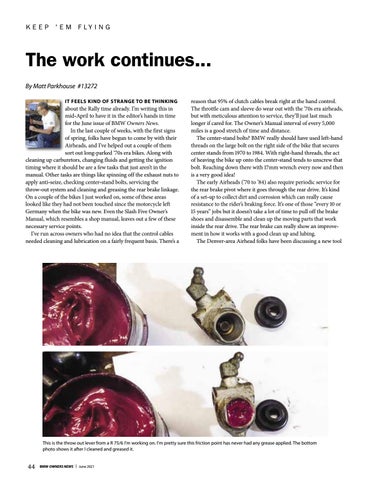

about the Rally time already. I’m writing this in mid-April to have it in the editor’s hands in time for the June issue of BMW Owners News. In the last couple of weeks, with the first signs of spring, folks have begun to come by with their Airheads, and I’ve helped out a couple of them sort out long-parked ‘70s era bikes. Along with cleaning up carburetors, changing fluids and getting the ignition timing where it should be are a few tasks that just aren’t in the manual. Other tasks are things like spinning off the exhaust nuts to apply anti-seize, checking center-stand bolts, servicing the throw-out system and cleaning and greasing the rear brake linkage. On a couple of the bikes I just worked on, some of these areas looked like they had not been touched since the motorcycle left Germany when the bike was new. Even the Slash Five Owner’s Manual, which resembles a shop manual, leaves out a few of these necessary service points. I’ve run across owners who had no idea that the control cables needed cleaning and lubrication on a fairly frequent basis. There’s a

reason that 95% of clutch cables break right at the hand control. The throttle cam and sleeve do wear out with the '70s era airheads, but with meticulous attention to service, they’ll just last much longer if cared for. The Owner’s Manual interval of every 5,000 miles is a good stretch of time and distance. The center-stand bolts? BMW really should have used left-hand threads on the large bolt on the right side of the bike that secures center stands from 1970 to 1984. With right-hand threads, the act of heaving the bike up onto the center-stand tends to unscrew that bolt. Reaching down there with 17mm wrench every now and then is a very good idea! The early Airheads (’70 to ’84) also require periodic service for the rear brake pivot where it goes through the rear drive. It’s kind of a set-up to collect dirt and corrosion which can really cause resistance to the rider’s braking force. It’s one of those “every 10 or 15 years” jobs but it doesn’t take a lot of time to pull off the brake shoes and disassemble and clean up the moving parts that work inside the rear drive. The rear brake can really show an improvement in how it works with a good clean up and lubing. The Denver-area Airhead folks have been discussing a new tool

This is the throw out lever from a R 75/6 I'm working on. I'm pretty sure this friction point has never had any grease applied. The bottom photo shows it after I cleaned and greased it.

44

BMW OWNERS NEWS | June 2021