Biogas Magazine | Edition 23 | 4 CONTENTS 12 16 22 26 29 32 36 In Conversation with Sh. Dinesh Dayanand Jagdale Upstream supply chain in biogas plants A Croatian perspective TTV Thöni Continuous High Solids Anaerobic Digestion Biogas from bagasse: An alternative to conventional combustion Applications of black salt in biogas Production and effects on biogas impurities Experts in feedstock quality control and process optimization in biogas production The hype about hydrogen – wonderful or insane? 16 32 36 29 22 INTERNATIONAL CORNER NATIONAL CORNER

“Dear Reader, Greetings!

The Indian government has recently shown incremental support for the bioenergy sector, particularly the biogas field, by taking several important steps. A few of the noteworthy initiatives are, laying the roadmap to reduce carbon intensity by 45% by 2030, allocating INR 10,000 crores to build 200 biogas plants across the country, moving towards mandating natural gas marketing companies to add 5% CBG, and exemption of the central excise duty levied on onward sale of Compressed biogas (CBG) blended with Compressed natural gas (CNG). In addition, the amendment to the Energy Conservation Bill 2022 focusing on the carbon credit market, resumption of the MNRE subsidy programme, and the introduction of the BIS standards on 'design, construction, and operation of biogas plants', will potentially contribute to the rapid expansion of the sector. More particularly, the adoption of BIS standards happens to be a watershed moment for the industry as it creates a level-playing field for promoting sustainable development and the application of biogas as an alternative energy source in India.

In this edition, the publication offers informative articles about various topics related to bioenergy. Some of the special highlights are insights from Sh. D. Jagdale, JS, MNRE; the use of black salt in biogas production and its effects on biogas impurities; an expert's interview providing a fresh perspective on feedstock quality control and process optimisation for biogas plants; a study on the utilisation of bagasse to generate biogas; a technical article on TTV technology for anaerobic digestion of dry organic waste; and an article on the upstream supply chain in biogas plants and its management from a Croatian perspective.

I'd also like to inform readers that from October 4 to 6, 2023, a bigger version of the Bio-Energy Pavilion will be at the REI Expo in Greater Noida. For more information, please visit https://biogas-india.com/ bio-energy-pavilion-2023/.

As always, we try to keep our readers up-to-date on what's going on in the field. Please let us know if there is a particular topic you would like us to investigate. Please share your thoughts with us at info@ biogas-india.com

Editors

Savita Boral

Prashansa Gupta

Designer

Komal Raghav

Administrator

Vishal Kanchan

Production Co-ordinator

Kavita Tanwar

Kavita Tanwar

About

The “Indian Biogas Association” (IBA) is the first nationwide and professional biogas association for operators, manufacturers and planners of biogas plants, and representatives from public policy, science and research in India.

The association was established in 2011 and revamped in 2015 to promote a greener future through biogas. The motto of the association is “propagating biogas in a sustainable way”.

/biogasindia

/indianBiogasAssociation

Abhijeet Mukherjee Program Director Indian Biogas Association

/indian-biogas -association

Biogas Magazine | Edition 23 | 5

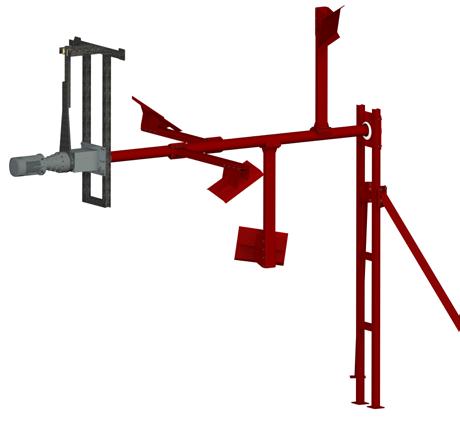

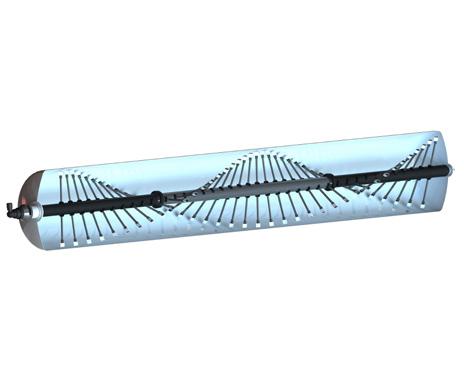

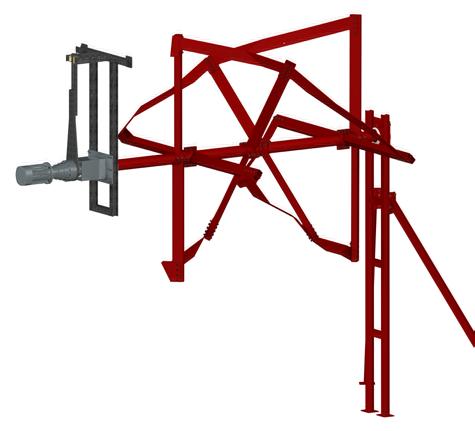

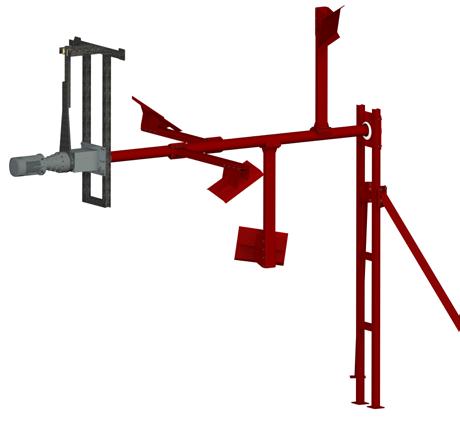

Steverding Agitator Technology

Steverding Agitator Technology is an expert in agitators. High technology is expected today at all levels of power generation. Steverding Agitator Technology can boast more than 20 years of experience in the manufacture of agitators. The continuous optimization and analysis of our products together with constant technical innovation show best results. Today, we are partners and system component suppliers of leading biomass facility manufactures in Germany, France, United Kingdom, Lithuania and many other countries.

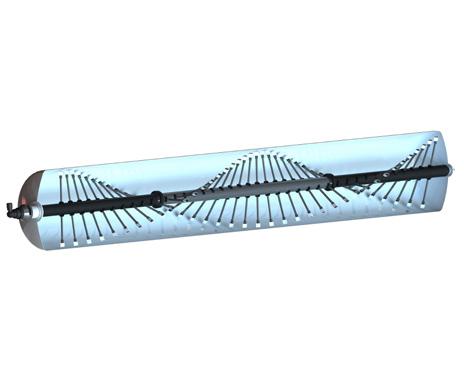

This is our current range of agitators from Steverding Agitator Technology:

Hydromixer

Schwanko

Impressions:

Steverding Agitator Technology • Gerhart-Hauptmann-Str. 41 • 48703 Stadtlohn • Germany

Spiralo®

Long shaft agitators

Vertical agitators

Plug-flow agitators

@ Gerhart-Hauptmann-Str. 41, 48703 Stadtlohn, Germany info@rt-st.com +49 2563 - 2088820 www.rt-st.com Contact person India Jörg Grondke Tel.: +49 17664751630 Mail: joerg.grondke@hrgsolutions.de

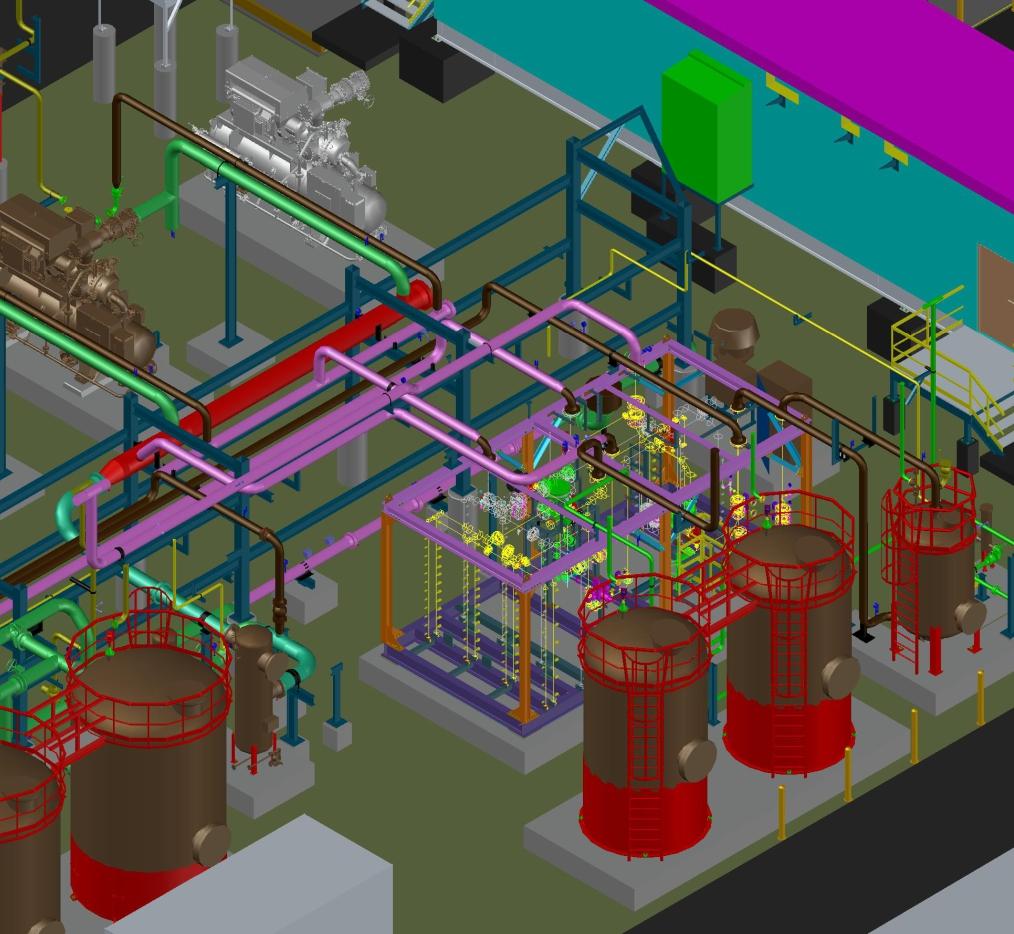

Biogas to Power and Biogas Upgrading Systems

Biogas to Power

Disposal and treatment of biological waste represent a major challenge for the waste industry. For a wide range of organic substances from agriculture, foodstuff of feed industries, anaerobic digestion is a superior alternative to composting. Biogas – a mixture of both methane and carbon dioxide – is created during anaerobic digestion and serves as a high-energy renewable fuel that can be used as a substitute for fossil fuels. Biogas-fuelled gas engines improve waste management while maximising the use of an economical energy supply.

Biogas Upgrading (Membrane gas separation technology)

Biogas upgrading is the process of the separation of methane from the carbon dioxide and other gases from biogas.

The concentrated biogas – close to 100% methane is called ‘biomethane’ or ‘renewable natural gas’ (RNG). This gas can be used as a vehicle fuel or injected into the gas distribution network. Biogas upgrading can be used in parallel to gas engines where power and heat are required on site.

Why Clarke Energy for biogas to power and biogas upgrading solutions?

+ Local long-established presence and footprint in India

+ Local team of field service engineers

+ Unparalleled international biogas experience on varying applications and process technologies

+ Proven, best-in-class technology

+ Quality engineering

+ Combination of biogas CHP and biogas upgrading support

Biogas Magazine | Edition 23 | 7

Find out more | Contact Clarke Energy India Private Limited Shivkiran, Plot No. 160, CTS No. 632, Lane No. 4, Dahanukar Colony, Kothrud, Pune 411038, India Tel. 020-30241777 Email. india@clarke-energy.com www.clarke-energy.com

IBA’s commitment towards leapfrogging the prospect in the biogas/bio-CNG industry

- Period: January- March, 2023

Webinar on Biogas & CBG: Understanding the subtleties of financing

On February 15, 2023, the Indian Biogas Association (IBA) organized a webinar titled "Biogas & CBG: Understanding the subtleties of financing" for the Biogas industry. The event was attended by prominent speakers from various organizations, including the Ministry of New & Renewable Energy (MNRE), GAIL India Ltd, Small Industries Development Bank of India (SIDBI), Indian Renewable Energy Development Agency Limited (IREDA), and

SouthPole.

The webinar aimed to educate industry professionals on the intricacies of financing biogas projects and Compressed Biogas (CBG) plants. The discussion covered topics such as project financing, subsidies, risk assessment, and business models for biogas and CBG projects.

The webinar was well received by attendees, who expressed their appreciation for the insights provided by the experts. Many participants noted that financing

can be a significant challenge for biogas and CBG projects, and the webinar helped to clarify the various financing options available.

Industry experts believe that the development of biogas and CBG projects is critical to India's renewable energy goals, as they offer a sustainable alternative to fossil fuels. The webinar provided valuable information and insights into how biogas and CBG projects can be financed, which is essential for their successful implementation.

Biogas Magazine | Edition 23 | 8

Overall, the webinar was a significant step forward in promoting the development of the biogas industry in India, and attendees left with a better understanding of how financing can be used to support this important sector.

Budget 2023-24: Due importance given to Biogas sector

The recently announced Indian Budget for 2023 has been lauded for its sharp focus on green growth, which is expected to provide a much-needed boost to the biogas and bioenergy sector in the country. The budget has allocated significant funds for various renewable energy initiatives, which is expected to accelerate the growth of the bioenergy sector.

In particular, the following measures were announced for biogas:

“The country's compressed biogas (CBG) market will grow as the budget announces plans for new plants as well as the intention to require natural gas marketers to sell biogas. The budget has also emphasized that "in due course, a 5% CBG mandate would be established for all businesses marketing natural and biogas." India imports over half of its natural gas consumption and hopes to replace some of it with indigenous biogas.

The budget also announced a central excise duty exemption for CBG when blended with natural gas. In the erstwhile era, CBG was subject to the goods and services tax (GST), but enterprises were also paying central excise duty when they blended biogas with compressed natural gas (CNG) for onward sale because natural gas is under excise/VAT regime. This used to result in double taxes, which the budget has sought to eliminate.

The budget has also been well proposed, with several measures aimed at promoting the development of biogas and bioenergy, including the establishment of a National Bio-energy Mission and the provision of financial support for biogas projects. The government has also announced plans to create a network of biogas plants across the country, which will generate renewable energy from agricultural waste. ”

Industry experts have welcomed the budget's initiatives for the biogas and bioenergy sector, noting that they will provide a much-needed boost to the industry. The increased investment in renewable energy is expected to create new jobs, promote sustainable development, and help India achieve its ambitious renewable energy targets.

Overall, the budget's sharp focus on green growth is expected to have a positive impact on the biogas and bioenergy sector in India, providing much-needed support for the sector's growth and development.

BIS standards for the Biogas Plants

The standards committee was headed by Dr. A. R. Shukla, President of the Indian Biogas Association, and supported by other members from prestigious organizations like MNRE, NIBE, and the Renewable Energy Sources Sectional Committees from BIS.

The main focus of the standards is to ensure the quality of different sizes of biogas plants that will be introduced in the country. The standards are expected to play a crucial role in promoting the growth of the biogas industry in India by ensuring that the plants are of the highest quality and operate efficiently. This will not only improve the performance of the biogas plants but also help maintain safety standards for the environment and the public.

The standard IS 9478 : 2023 is now available publicly. A webinar dated 22nd March 2023 was organized to acknowledge the public launch and contributions from all the

Biogas Magazine | Edition 23 | 9

committee members involved in the formulation of the standards. Overall, the standards published by BIS is a step towards promoting sustainable development and promoting the use of Biogas as an alternative source of energy in India.

Biogas Magazine | Edition 23 | 10

Vishal Kanchan BDM Indian Biogas Association

Biogas Magazine | Edition 23 | 11

In Conversation with Sh. Dinesh Dayanand Jagdale

The energy transition journey in India is fast evolving. May of large Indian Corporates have announced massive investments in the renewable energy sector as they envision a low-carbon sustainable future. The country has been at the forefront of adopting innovative approaches and solutions to boost the prospects of its RE sector, spanning deployment of projects, procurement mechanisms, and electricity market platforms. As a result, India has more than 175 GW of non-fossil based electric in-

stalled capacity in its electricity mix, which forms ~42% of its total installed electricity capacity. We have already deployed more than 12 GW of new Renewable Energy Capacities during the current financial year. The Government of India has set an ambitious target to achieve 500 GW of non-fossil based electric installed capacity by 2030.

India is set on the path to become one of the world’s largest economies. At this juncture, three critical objectives emerge — jobs, growth, and sustainability. For accomplishing these objectives, development solutions must be decentralised, inclusive, people-oriented, and environ-

ment-friendly. There are many existing and emerging RE technologies which can help meet these requirements. Diversifying our mix with these technologies would not only offer flexibility and resilience to our power system, but also deliver the desired socio-economic benefits.

Large bioenergy feed-stocks are available in the country in the form of organic wastes. Energy recovery from these wastes can be a feasible solution for effective waste management, building a circular economy, and providing valuable fuel to meet the ever-increasing energy requirements of the country, especially for industries, transport, and do-

Biogas Magazine | Edition 23 | 12

1. What is your viewpoint of the evolving energy sector from a sustainability perspective, including Biogas/CBG?

Sh. Dinesh Dayanand Jagdale

Joint Secretary, Ministry of New and Renewable Energy, Government Of India

Sh. Dinesh Jagdale is the Joint Secretary at the Ministry of New and Renewable Energy at the moment. He has a rich experience spanning more than two decades. He has worked as a director and chief executive officer at Panama Renewable Energy Group for over 8 years and has also worked for Enercon India Limited and Crompton Greaves Limited for over 15 years.

mestic end-use such as cooking. From a sustainability perspective, Compressed Biogas Projects (CBG) have significant benefits in terms of environmental sustainability, energy security, and reducing dependence on fossil fuels. Emissions reductions from preventing methane emissions due to unmanaged decomposition of organic wastes are additional benefits. India has a potential of around 62 million metric tonnes of CBG. This implies that substantial percentage of India’s natural gas imports could be replaced by domestically produced CBG, ensuring India’s energy security and protecting against volatility in international energy markets.

2. The welcoming news of the CFA revival is bringing fresh motivation to the entire Biogas fraternity, what are your thoughts on that?

The biogas/CBG sector in India is on the cusp of a large-scale transformation. The enabling environment is rapidly evolving, with financiers, supply chain actors, end-users, and entrepreneurs all realising the massive potential of the sector and the benefits of replacing natural gas with CBG becoming increasingly significant. Large-scale CBG projects with mature supply chains are emerging. There is a renewed focus on biogas, as put forth in the recent Union budget as well. The Ministry’s National Bioenergy Programme provides investors and project developers with long-term policy stability and highlights the government's commitment to support the sector. With a budgetary outlay of Rs. 858 crore under the National Bioenergy Programme under Phase-1, the CFA will provide

crucial support to the sector to achieve the CBG targets. The CFA, coupled with the 5% mandate for CBG consumption for all OMCs and natural gas organisations should provide the right set of push and pull incentives to boost the deployment of CBG plants across the country. The processes for availing the CFA have also been simplified, further increasing the ease of availing the government support for project developers.

3. What specific, big changes need to be made in the renewable energy sector for India to reach its net zero goals by 2070?

As India pursues a net-zero emissions pathway, integration of RE with the grid would be crucial. Hybrid RE projects, diversified technology mix, new power market offerings and strategies to make grid-scale storage technologies affordable could help. Resources such as pumped hydro storage could serve as a crucial grid balancer in coming years. Efforts must be made to account for the costs and benefits of increasing RE shares, and to allocate them efficiently between the stakeholders. Innovation in tariff structures and optimising power procurement portfolios of distribution companies would be key. Finding new sources of capital and opening up the domestic bond markets to finance RE projects could be taken up immediately.

As we maximise and harness green growth opportunities, policies must pre-empt risks and support transition to a market-driven sector. Procurement methods must transform. The share of short and medium-term

procurement by buyers under open access must increase. PPA structures must evolve. New financial models must enable investment in projects that are able to participate in flexible and market-based procurement.

Focus on institution building and bringing alignment, coordination, cooperation, and engagement between actors must enhance. Individuals and institutions across the value chain need to be trained for both technical and non-technical skills necessary for speeding up deployment, integration, and domestic manufacturing. We will need to take lead in forming multilateral collaborations on education and training, and partnerships between leading universities to build the workforces equipped with the desired hard and soft skills.

4. How can we reconcile net zero with the many other sustainability challenges? For example, how do we make circular thinking central to the net zero agenda?

India’s mission LiFE (Lifestyle for Environment) stands out in utilising the collective wisdom and power to solve challenges that our planet faces today. It motivates the world to act and live in a way that is consistent with sustainable development. This goal is naturally aligned with the development of a circular economy, which also leads to robust and resilient supply chains for clean energy.

Taking inspiration from the Mission LiFE and keeping India’s commitment to clean energy transition in mind, it is imperative that we build domestic

Biogas Magazine | Edition 23 | 13

manufacturing capacity, diversify supply chains for critical components, and identifies alternate technologies and processes based on locally available raw materials. Introducing circularity in supply chains is one of the solutions to mitigate the risks associated with mineral criticality and supply chain vulnerability. Reduced mineral intensity, increased component and product utilisation, material recovery from waste, recycling, and reusing are some possibilities. Urban mining, a concept that recovers minerals from discarded devices, can also aid in supplying the world's mineral needs in the future. We will need to showcase our leadership in building a circular economy in renewables, efforts should be directed towards initiating an advanced research development and demonstration (RD&D) programme. The purpose of this programme must be to create and test alternative input materials, appropriate technologies, and models for effective collection, extraction, recycling, and utilisation of high-value materials and minerals.

5. In 2047, India will celebrate 100 years of independence, so as a measure towards attaining Atmanirbhar Bharat, what are your suggestions/opinion on making the CBG sector more robust?

CBG is an important sector in achieving India’s decarbonisation and sustainability goals. It is thus necessary to increase the productive utilisation of various biomass residues to achieve the SATAT target. Demand creation for bioenergy products will be vital in increasing the utilisation of surplus waste and increasing

the use of CBG in power and thermal applications. It is also acknowledged that CBG projects will require financial support to become viable and scale-up in the coming years. Some measures that can be instrumental in scaling up CBG sector include:

● Advanced procurement pipelines: Oil marketing companies (OMCs) are already off-taking bio-CNG under the SATAT scheme. The industrial sector could be similarly targeted for large-scale offtake of bio-CNG and replace the current use of natural gas, while bio-CNG projects could be made eligible for city gas distribution (CGD) networks. Additionally, bio-fertiliser obligations and distribution networks can support assured additional revenue streams for bio-CNG project developers. The sale of organic fertilisers can strengthen the project viability, and their use can aid soil nutrition.

● Strengthening biomass supply chains through the efficient collection, aggregation, transportation, and storage of biomass residue is an essential requirement for scaling up bioenergy in India. New business models will be required to emerge to raise awareness about the social, economic, and environmental benefits of participating in the bioenergy supply chain. Identification, benchmarking, and successful business models in the supply chain can also help attract more players.

● Facilitating the development of waste management plans by ULBs and large RWAs. Model projects/ technologies could be demonstrated to showcase

commercial applications in this segment. ULBs can be encouraged to identify such projects in large communities/ establishments that may self-manage their waste and become the off-taker of the gas produced. ULBs, horticulture departments, RWAs and managers of commercial spaces/ complexes may be required to procure bio-manure for maintaining urban green spaces/ gardens/parks etc.

● To prepare the necessary workforce required for bio-CNG plants in the country, it is imperative to develop the knowledge base, training capacity, and skilling infrastructure for the workforce. Expanding the ambit of BDTCs to include upto-date and novel technologies for bio-CNG in their curriculum can be an effective channel to create the necessary workforce. The Skill Council for Green Jobs (SCGJ) can provide additional support and critical infrastructure through a national skilling programme focused on the bioCNG supply chain.

● Benchmarking of best practices and efficiency improvements must be implemented right from the beginning in the bio-CNG sector. This can also help optimize resource allocation on a national scale and identify areas for improvement. Robust performance monitoring through real-time data and reporting, regular updates to a central repository, and environmental performance reporting, the industry can achieve high efficiencies seen in other industrial and energy sectors.

Biogas Magazine | Edition 23 | 14

Biogas Magazine | Edition 23 | SAVECO

for Livestock Effluent & Biogas Digestate Treatment!

Equipments

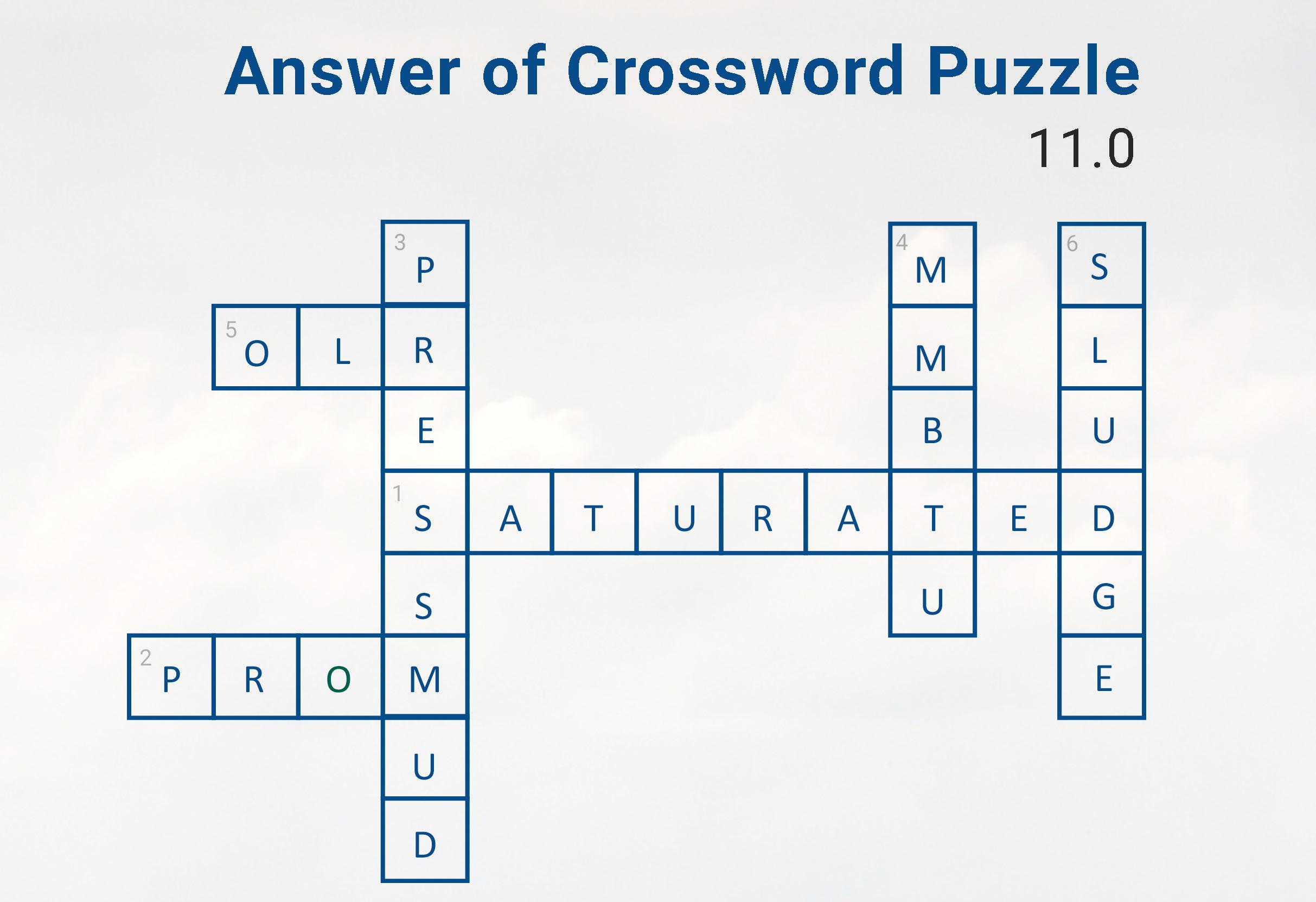

Upstream supply chain in biogas plants: A Croatian perspective

Introduction and function of the biogas plant

The suppliers of input raw materials will primarily be local farmers, whose fields are located in the immediate vicinity of the power plant. Input raw materials will be corn silage, molasses from sugar production, straw, chicken droppings, and cattle manure. Bovine slurry (cow dung) and chicken excrement will be used as additional liquid input raw material, which will be brought from farms in the surrounding area.

The raw material that comes in is processed, fermented in a biogas plant (with a reten-

tion time of more than 60 days), and then stored in the final warehouse until it can be taken to the fields. Fermented organic manure will be given to the farmers who initially signed a contract to take manure. Farmers take the fermented liquid manure from the final storage facilities with tank trucks and bring the useful fertilizer to their agricultural fields and areas.

The biogas produced after anaerobic digestion gas is stored in gas membranes above the fermenter and is then converted into electrical and thermal energy via a biogas cogeneration unit with a generator. The electricity that is

made will be sent to or sold to the local electricity distributor's network.

The thermal energy of the cogeneration unit is used as process heat for fermentation and for heating the premises of the facility for management and supervision (< 20% of the total thermal energy is used for heating the fermenter and the facility for management).

In the case of non-use of heat energy, the heat energy is drained via the forced cooler.

Suppliers of input raw materials

The power plant operator produces raw materials in

Biogas Magazine | Edition 23 | 16

their fields.

For one part of the raw materials, they will sign a delivery contract with local and nearby farmers. The farmers will agree to hand over or bring to the plant the required amount of corn silage that is grown in the field each year. In the same contract, the offtake of the digestate or fermented organic manure will be promised to the individual

farmers. Through the addition of slurry from cattle manure, the quantity of raw materials increases (compared to corn silage), this means that the farmer receives 30% more fermented slurry than the supplied amount of corn silage (1:1.30).

Farmers use the final femented organic manure (quality fertilizer), which is returned to their fields and meadows.

Substrates and energy yield

Quantities and composition of incoming raw materials

The delivery and purchase of raw materials corn silage, sugarcane, and cattle manure is planned, and the following annual quantities of raw materials, which will be used in the biogas plant, have been calculated:

Biogas Magazine | Edition 23 | 17

Part in [%TS] Quantity / year Name Dry matter content Dry matter content Org. dry matter content Org. dry matter cont. N P K Spec. Methane content Biogas yield Power (brutto) [t/a] [t/a] [%] [t/a] [% TS] [t/a] [kg/tFM] [%] [m³/h] [kW/h] 3% 750 Chicken litter 28.6 215 80 172 4.5 8 8 55 11 25 3% 750 Cow dung 27.8 209 80 167 4 3.2 8.8 50 8 19 44% 9980 Maize silage 35 3493 96 3353 3.3 1.9 7.8 52 224 502 8% 2750 Sorghum silaze 22.5 619 91 563 2.3 0 0 51 39 88 29% 2500 Mais strawshort 90 2250 92 2070 3.7 1.6 10.3 51 83 186 7% 750 Melasse 1 78.8 591 87 514 12 2.4 0 70 44 99 6% 750 Melasse 2 68 510 87 444 12 2.4 0 70 36 80 1% 10000 Waterrecirculate 0.5 50 0 0 0 0 0 0 0 0 100% 28230 Substrate mixture 28 7886 92 7283 - - - 55.0 445 999

However, the possibility of using other raw materials cannot be ruled out, such as:

• Expired food products (if they are hygienically safe)

• Spoiled, layered seed

• Sugar noodles, sugar beet, beet leaf, molasses

• Fruit pulp, residues from vegetable and fruit processing

• Seeds, peels, fallen fruit

• Remains of uneaten food

• Remains from the brewery

• Residues from milk and cheese production

• Residues from oil production (if they are free of extraction agents)

Storage, dosing and delivery of incoming raw materials

Corn silage will be brought to the plant once a year during harvest (August and September). Its weight will be measured on a scale, and then the silage will be stored in a trench silo. The operator will provide the necessary compaction of the silage in the mobile silo with a heavy-duty dosing vehicle. All of the raw materials that are brought in will be weighed, and the amount of substrate brought in will be written down in a book about the supply of raw materials.

The substrate mixture consists of liquid from the separation, recirculate from the fermenter, corn silage, molasses

and slurry of cattle manure. This mixture of liquid and solid raw materials will be pumped through PE plastic pipes using pumps, and during the day, in a certain quantitative ratio, will be dosed into the biogas plant.

During the flow time of the mixed raw materials, through mesophilic fermentation of the organic part of the dry matter, biogas is produced in the fermenters. The raw material gradually flows through a natural overflow from the fermenter to the post-fermenter. The level in the fermenters is recorded by a pressure measuring device (level measurement) and regulated with the pumping process.

From the post-fermenter, the liquid raw material is pumped to the separator, which will separate the rest of the solid part and the fermented liquid. The liquid residue from the separation is collected in the separator pit, which is located near the separation device and serves effectively as a recirculate in the dosing pit for mixing the new substrate or is pumped through a local pumping shaft to the final lagoon.

The final substrate will be pumped from the final lagoon

into the tank of the vehicle via the docking station. The pumped quantities, which are removed from the warehouse, will also be registered and entered in the raw materials book.

Through the processing and fermentation of raw materials, the organic dry fraction of approximately 50%. Due to the closed system, the constituent parts of the materials (N, P, and K) remain equal at 1:1. Only nitrogen (N) will change into a more favorable form of intake for plants, but its quantity will not change. Manure from the biogas plant is considered, due to its various positive properties, as a valuable fertilizer for plants.

Positive features:

• Good homogeneity

• Low odor load

• Good hygienic properties

• Easier availability of fertilizer to plants due to the effect of liquid dilution

• It can be quickly filtered into the soil

• There is no effect from corroding plants, etc.

Biogas Magazine | Edition 23 | 18

Igor Popović, Croatia Founder and CEO Total Bau d.o.o.

How the biogas industry is going to be a game changer for sustainable farming

Increasing concerns about soil degradation, depleting water resources, and falling crop yields have emphasized the importance of sustainable farming like never before. It is estimated that India’s population will be 166.8 crores by 2050, and we will need to increase our farm productivity manifold to feed the people.

The potential of the biogas sector to make agriculture sustainable is indisputable and can be a gamechanger in promoting sustainable farming in India. Putting biogas plants on sustainable farms helps the farmers, the environment, and the community as a whole in many ways.

Biogas plants help with waste management, reduce energy costs, improve soil fertility, and help optimising crop rotation. Catch crops, which are unused for food purposes and not costly, can be used as substrates for biogas plants. This improves crop rotation and also enhances biodiversity. Biogas plants can also incentivize growing cover crops. Cover crops, which are generally mulched into the ground, can also be harvested and used as feedstock for biogas digesters.

The waste generated from any crop cultivation and farm animals can be used as the substrate for biogas digest-

ers. The animal manure and other organic waste from the farm can be converted into bio-slurry that is odourless and does not attract pests and flies. Moreover, the bio-slurry from the biogas digesters provides higher nitrogen content to the soil in comparison to raw manure and controls methane emissions.

Agricultural biogas plants can make farmers self-sufficient in energy generation. Biogas generated from these plants can be used to generate energy for cooking and heating purposes, electricity for daily activities on the farm and fuel for tractors and other vehicles. Excess energy can be

Biogas Magazine | Edition 23 | 19

sold to earn additional revenue.

The digestate generated from the biogas plant can be further processed and used as an organic fertilizer and pesticide on the farm. The most significant benefit of installing a biogas plant is the increase in crop yield due to the use of organic fertilizer, which promotes soil health and improves fertility. The humic acid in the biogas digestate conditions the soil and improves its quality.

Biogas plants can benefit local communities by generating employment opportunities and improving the livelihoods of marginalized sections. The biogas sector has a huge potential for employment generation in both skilled and unskilled sectors. The additional jobs created can provide sustainable livelihoods and reduce the dependence on agriculture for livelihoods. Moreover, proper waste management on farms leads to less dumping of waste in landfills and water bodies, which improves the living conditions and health of the community.

Agricultural biogas plants can also have a positive effect on the environment. A study conducted in Europe demonstrated that substituting biogas for fossil fuels helps in the large-scale reduction of carbon emissions as burning biogas for energy generates fewer greenhouse gases in

comparison to fossil fuels. The reduced usage of fossil fuels for chemical fertilizers and pesticides and energy requirements can reduce pollution and help in reducing carbon emissions. Using organic fertilizers also prevents chemicals from leaching into the groundwater and surface water bodies and helps conserve water. Proper sorting and management of waste can make it easier on landfills and stop harmful gases from getting into the air.

However, biogas production poses some technological and economic challenges. Biogas plants are technology-intensive and many operators report recurring technical failures, especially when the fibrous and solid feedstock is used in the digesters. Operating a biogas plant can be expensive when the biomass has to be procured from outside. The environmental benefits of biogas are negated when the biomass has to be transported over long distances. However, these challenges can be addressed through a more robust use of technology and proper planning. Small farms with biogas plants can have trouble making money, but this can be fixed by putting in community

biogas plants where everyone can share the costs and profits.

Though biogas can have a huge positive impact on sustainable farming, most farmers are unaware of its benefits and fear financial constraints. Knowledge sharing and information dissemination can help to educate farmers about biogas and its importance in sustainable farming. Governments, professional associations, local authorities, and farmer’s cooperatives must come forward to inform, educate, and demonstrate the potential of biogas plants to convince the farmers. Technologically sound small biogas plants that can be easily integrated into the farm’s biomass cycles have to be developed for use on small farms. The government must create essential frameworks for greater cohesion among agricultural, environmental, and energy policies. Biogas plants can be a big part of sustainable farming if the government helps pay for and subsidise the installation of these plants.

Biogas Magazine | Edition 23 | 20

Dr. A. R. Shukla President Indian Biogas Association

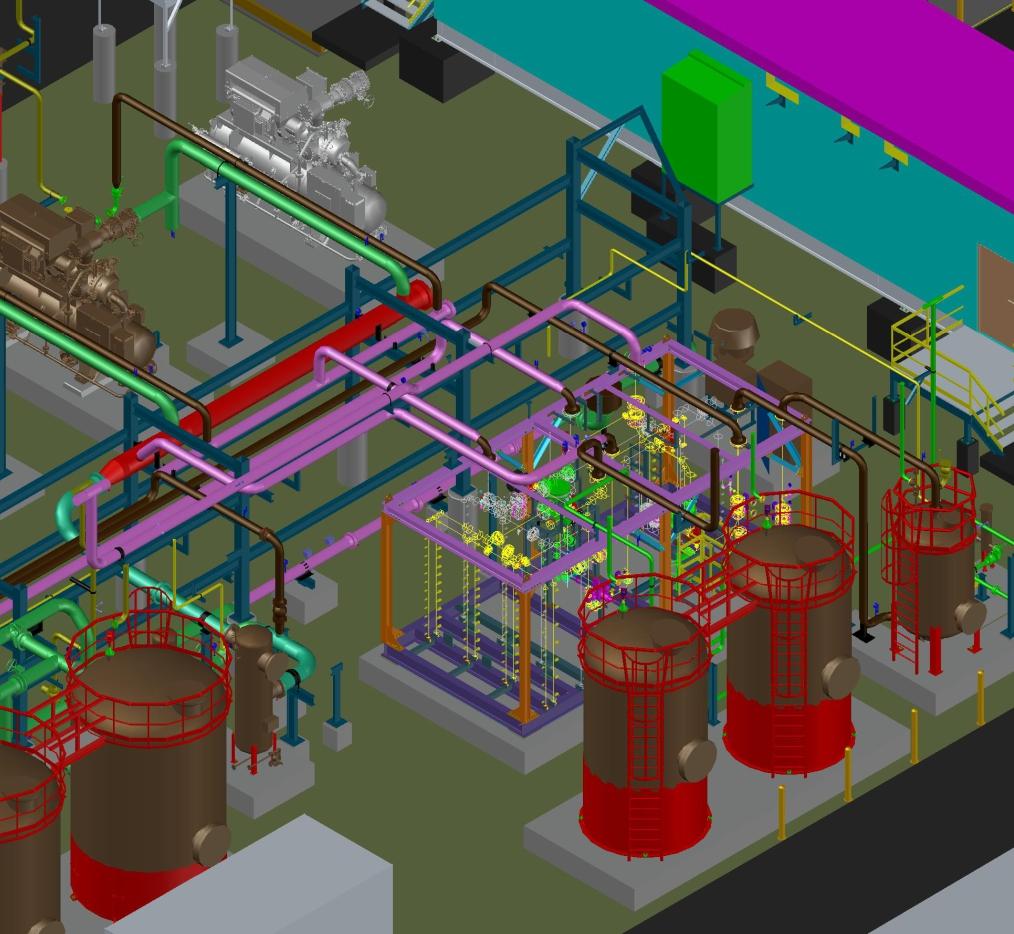

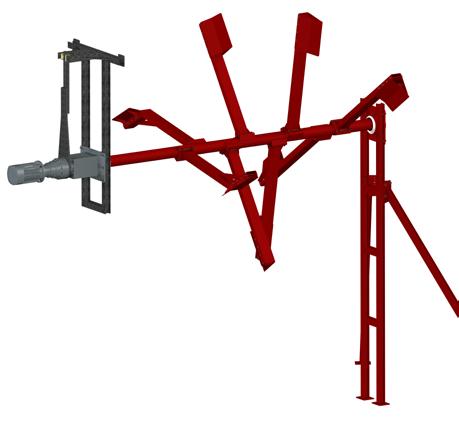

TTV Thöni Continuous High Solids Anaerobic Digestion

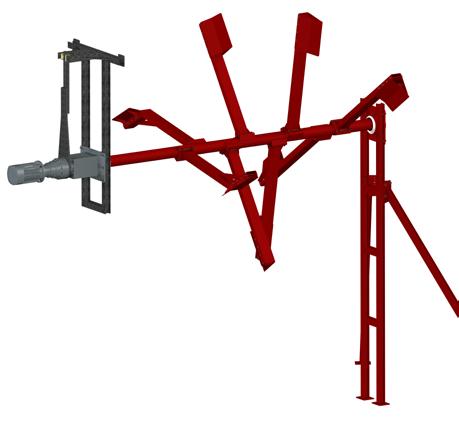

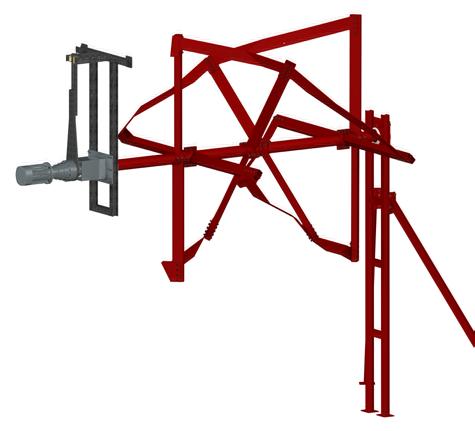

The TTV technology is distinguished by a high level of operational reliability and an exceptional biogas yield. The plug flow digester designed by us are for 'dry' organic waste, particularly when impurities are high. Key components such as the accessible, heated digester floor and the robust and powerful paddle-shaft are proven and patented, making them unique to us. Due to the special construction of the TTV digester, sediments and contaminants are continuously discharged. And so a continuous, safe operation of the digester is guaranteed.

TTV technology is developed, designed, manufactured, assembled, and commissioned by us; all core components come from a single source. This results in a high-quality standard as well as continuous system development and support.

Conditioning of the input (biowaste)

Incoming organic waste is shredded, followed by separation into fine and coarse fractions using a linked star screen (> 80mm). The fine fraction (less than 80 mm) is then passed through a mag-

netic separator. For intermediate storage of the pre-treated substrate, there are several solutions available, e.g., automated TBM bunker modules, crane bunker systems, etc. When necessary, structural lignin material is used to achieve an optimal C/N ratio and an ideal input composition for subsequent process steps.

Digestion

The TTV digester is continuously fed via an intermediate storage bunker, either via a twin-shaft mixer and hydraulic piston pump or directly via

Biogas Magazine | Edition 23 | 22

The digestion process inside the digester is based on an anaerobic, thermophilic, and completely biological process, classed as continuous High Solids Anaerobic Digestion (cHSAD or less commonly, so-called Dry AD). The process temperature inside the digester equals approximately 35–55 °C, and the input has an average dry substance content of 20-35%. The residence time is approximately 14-21 days, depending on specific project requirements. The controlled residence time of the material in the digester guarantees in-digester hygienization when running the digester thermophilic at 55°C and therefore process regulatory compliance.

The temperature and level in the digester, the quantity of gas produced, and the gas pressure are monitored continuously. The controlled end-to-end migration of the material through the digester, referred to as the plug flow

process, means that the digestion process is biologically and mechanically easy to supervise. It is also extremely reliable in operation, providing a high and consistent yield of biogas.

TTV agitators are known for being able to handle hard materials and make sure that different substrates are broken down evenly and continuously. The dimensions of the paddles and shaft guarantees high stirring efficiency and a virtually unlimited service life—even under the highest loads. This is achieved by the unique and patented shape of the paddle head, which is made of highly wear-resistant steel. The special combination of paddle design and configuration prevents sedimentation by up to 100% and continuously transports potential sediment to the digester outlet while simultaneously counteracting the formation of floating layers. In this way, the digester needs minimal maintenance in the long-term, even if the input

material contains significant and relatively heavy impurities. Due to the dimensioning of the agitator shaft and the special construction of the bearing, no mechanical support of the shaft is required inside the digester. The bearing and seal are accessible from the outside and can be serviced, if necessary, at any fill level of the digester.

The patented steel floor of the digester "hangs" between the two side walls made of concrete and can be reached through an inspection passage. The curved base of the digester and the patented agitator makes it impossible for sediments or other impurities to settle in the digester. Externally accessible heating elements are attached to the floor, through which the digester is heated. The floor panel has no direct connection with the concrete floor slab underneath, allowing checking of the digester base easily at any time.

TTV digesters are available in modular designs: single, double, and triple digesters. In multiple configurations, two or three digesters are struc-

Biogas Magazine | Edition 23 | 23

a plug screw.

TTV Thöni Paddle Agitator

TTV Digester bottom

turally linked but operated independently. The digesters are made from reinforced concrete, including a preshaped curved steel bottom; optionally, the single digester module can also be made entirely of steel. Standard sizes (nominal digester capacity) are: 1,050 m³ to 3,850m³.

Conditioning of the digestate (separation) and products of digestion

At the end of the digestion process, the digestate is pumped to the Thöni screw presses (TSP), where it is dewatered. Some liquids are recirculated in the digestion process and used for humidifying the fresh input material. The remaining liquids are stored in tanks and used as fertilizer in agriculture.

The solid part undergoes a further aerobic composting process in special composting units. On the basis of its experience, we can even provide solutions for liquid-free operation. These use innovative technologies for part stream digestion or technical digestate treatment options, tailor-made to customer requirements.

Biogas can either be turned into electricity on-site using a combined heat and power (CHP) station and fed into the public grid, or it can be turned into biomethane using a gas upgrading system and fed into the public gas network.

Biomethane can be used to make energy at certain places, like hospitals, schools, etc. By means of cogeneration, or it is used at filling stations as compressed natural gas (CNG) for vehicles. Overall, digestion plants with TTV technology integrate closed-loop material-recycling with energy by producing quality compost and fertilizer that can be declared with RAL quality assurance.

Biogas Magazine | Edition 23 | 24

Peter Scherl Global Sales Director Thöni Industriebetriebe GmbH

Biogas from bagasse: An alternative to conventional combustion

Biogas plants primarily produce biogas from organic matter. This is accomplished through anaerobic digestion, a process in which bacteria break down organic matter in the absence of oxygen. The amount of biogas produced and the substrates used are critical success factors for biogas plants.

Plant residues from the industrial processing of sugarcane, such as lignin-containing plant fibers like bagasse, are a potentially lucrative substrate for biogas production.

Bagasse is rich in cellulose and hemicellulose, which are easily digestible by anaerobic bacteria, and has a high dry substrate content, making it

an attractive option for biogas production. In addition to generating thermal energy and electrical power for sugar production, using sugarcane plant residues for biogas production can provide a sustainable source of energy and reduce greenhouse gas emissions from waste disposal.

Could bagasse be effectively fermented into biogas using anaerobic digestion? Could this offer an alternative to combustion, which emits CO2 and particulate matter?

Yes, bagasse can be effectively fermented into biogas using anaerobic digestion. This offers an alternative to combustion, which emits par-

ticulate matter. The potential analysis in the laboratory, as described in Figure 001_Fermentation_test_Bagassere_ Syrup, shows that bagasse can be effectively fermented to produce biogas. The yield of biogas from bagasse was tested in comparison to sugar syrup using a continuous fermentation test based on Standard 4630 of the Association of German Engineers (VDI), Fermentation of Organic Substances—Substrate Characterisation, Sampling, Material Data Collection, and Fermentation Tests.

We have performed a laboratory fermentation test where we used a mixture of 4.5 litres of fermented material from

Biogas Magazine | Edition 23 | 26

renewable resources and ten grams of organic solid matter from bagasse in a 6-litre fermentation container. The mixture was then fermented for 45 days at a temperature of 39 degrees Celsius.

The test results show that the fermentation process leveled off at an average of 180 Nl/kg oDM (organic dry matter) after growing exponentially for 12 days at 39 degrees Celsius. One tonne of bagasse with 45.5% oDM content yields 85.5 Nm3 of biogas, which can be considerably increased if the material is shredded before fermentation. Therefore, bagasse can be a viable feedstock for anaerobic digestion, and the resulting biogas can be used as a renewable energy source with lower green

house gas emissions than traditional combustion methods.

The lab tests show that the amount of biogas that can be made from bagasse is comparable to the amount that can be made from good cattle manure. Both can make a lot of biogas when they are put through anaerobic digestion. Additionally, the use of fermentation residues as organic fertilizers for agricultural land has several benefits, such as improving the water-binding capacity of the soil, contributing to the bioactivity of the soil, and reducing the need for mineral fertilizers.

Furthermore, biogas production from bagasse can be a more sustainable and envi-

ronmentally friendly alternative to combustion, as it can substitute the emission of greenhouse gases. The savings from reduced greenhouse gas emissions can be traded in the form of CO2 certificates in the EU and in countries like India with the cap-and-trade system. This can provide an additional economic incentive for the implementation of biogas plants using bagasse as a substrate. Overall, the use of biogas plants for energy production offers several advantages over combustion, including reducing greenhouse gas emissions, producing organic fertilizers, and earning CO2 certificates through emissions trading.

According to the results of Figure

Biogas Magazine | Edition 23 | 27

001_Fermentation_test_Bagassere_Syrup

the fermentation test, around 180 kWh of electricity can be generated per tonne of bagasse. Furthermore, the methane content in the biogas produced from bagasse is approximately 50%, which can be processed into biomethane too. Given that one tonne of sugar cane yields approximately 280 kilograms of ba- gasse, this byproduct could be a valuable resource for biogas plants. There is significant potential for utilizing ba- gasse as a substrate for biogas production in India, where sugar cane cultivation is significant, with a volume of 355 million tonnes per year as of 2020-2021.

Bagasse is utilised solely for its thermal properties between 150 and 270 days per year, during the harvesting

and production phases of sugarcane production. Biogas plants, on the other hand, can be supplied with organic substrates all year. Bagasse stored in silos is an excellent choice for this application. because it has the potential to supply the plant with substrate for an entire year.

But, in addition to agricultural, industrial, and administrative waste, various types of organic residues can be employed as substrates for fermentation. The flexible biogas has the potential to be directly turned into electricity and heat, both of which can then

be sold on the energy market. Alternatively, it can be purified and processed using PSA or membrane technologies in order to concentrate the biogas into biomethane. This would accomplish the same goal. It serves both as a storage medium and a feedstock for the production of bio-CNG or green hydrogen, which in turn contributes to a reduction in the amount of carbon dioxide that is released into the atmosphere.

Biogas Magazine | Edition 23 | 28

Dr. Annette Sander Team leader PlanET Biogastechnik GmbH

Applications of black salt in biogas production and effects on biogas impurities

The goal of the research is to spread information about how black salt can be used to make biogas. Black salt helps to improve anaerobic digestion and reduce hydrogen sulphide in the biogas. It needs to be

added as an additive. There are several chemical compositions in the black salts that help to improve the quality of raw biogas. It will not only reduce the concentration of hydrogen sulphide in raw biogas but also reduce ammonia.

The rate of production of biogas is dependent on the type of organic waste and variable temperatures.

The typical composition of biogas is depicted below.

Biogas Magazine | Edition 23 | 29

Constituents Composition Methane 50-75% Carbon dioxide 24-45% Nitrogen <2% Water vapour (moisture) 2-7% Hydrogen sulphide 20-20 000 ppm Oxygen <2%

ICL IS YOUR RIGHT PARTNER ! 80 Years Of Years Of Years Of Excellence! Excellence! Excellence! Air & Water Cooled Versions "Mini - lubricated" design for lowest oil contamination 275 bar, 2000 Designed in Italy H i g h P r e s s u r e B i o - C N G C o m p r e s s o r s Non - Lubricated Design For 24*7 continuous Process Duty Handles Raw Biogas L o W P r e s s u r e C o m p r e s s o r s Over 1800 Natural Gas/CNG Compressors Working Across India Dedicated Service Network in Every Indian City Serving All major CGD & Biogas Companies I N D I A N C O M P R E S S O R S L T D Sales@Didwania.com | www.Didwania.com Sm3/h BIOGAS COMPRESSORS

Methane is the useful gas in biogas. It is the only combustible gas in biogas, which is also clean in nature. The smell of rotten eggs comes from biogas; it is due to the presence of hydrogen sulphide in biogas. Hydrogen sulphide is poisonous and harmful for metallic parts.

Black salt: It consists of primarily sodium chloride and trace impurities of sodium sulfate, sodium bisulfate, sodium bisulfite, sodium sulfide, iron (I, II) sulfide, and hydrogen sulfide.

• Iron (I, II) sulfide helps to reduce the concentration of hydrogen sulfide by following reaction:

FeS + H2S→ FeS2 +2H

• Sodium bisulfate is used primarily to lower pH. This can be used to reduce the pH in a biogas digester. Generally, 6.5-7.5 is the ideal pH range required for biogas produc-

tion.

In the poultry industry, sodium bisulfate is used a lot to reduce the amount of ammonia and bacteria in the litter.

• Sodium bisulfite is a common reducing agent; it readily reacts with dissolved oxygen.

2NaHSO3+

O2→ 2NaHSO4

Sodium sulfide is a desulfurising and dechlorinating agent.

Also, black salt can be used to help digestion and improve the anaerobic process. In other words, adding black salts to digestive slurries aids in the production of high-quality raw biogas with low levels of hydrogen sulphide and oxygen, as well as in the acceleration of the digestion process.

How

In India, people use kala namak for medicinal purposes, like for digestion problems; ‘Hajmola’ is the most common digestive tablet widely used in India. It also contains black salt. In our body, when digestion is not proper, it releases smelly gases; that’s the smell of hydrogen sulphide. In our body, aerobic digestion (the presence of oxygen) takes place because we breathe oxygen.

Biogas Magazine | Edition 23 | 31

Ankit Anil Patil Senior research fellow IIT- Roorkee

can we click on this idea that black salt can reduce hydrogen sulphide and improve anaerobic digestion?

Experts in feedstock quality control and process Optimization in biogas production

In this issue of the Indian Biogas Association magazine, we speak to Dr. Jing Liu, CEO of BPC Instruments from Sweden, about his team’s work in the realm of biogas for feedstock quality control and process optimization.

BPC Instruments, which used to be called Bioprocess Control, and was started in 2006, and has quickly become the market leader in providing precise instruments to customers in the biogas and environmental biotechnology fields. Over the past 18 years, BPC Instruments has invested in the innovation and development of analytical instruments for both biogas research and commercial full-scale production units. Dr. Jing Liu, the CEO and Co-founder of BPC instruments, states the company has become a pioneer

in its field and currently holds an estimated 90 percent share of the global market for feedstock quality analysis in biogas production.

IBA: It’s impressive to see the global reach and impact of BPC Instruments in the biogas sector. With clients in 69 countries and over a thousand organizations in both the academic and industrial sectors, BPC Instruments seems to have a strong presence in the market. It’s also noteworthy that there are more than 1000 scientific publication references of experimental

studies conducted using your analytical instruments, as given in a statistical analysis of the scientific database www. sciencedirect.com. This is a testament to the scientific community’s recognition of the quality and reliability of their instruments. How do you see the importance of your work?

BPC instruments: In the most recent year, the need to scale up biogas and biomethane production is more urgent than ever, following the need to reduce dependency on natural gas imports and address

Biogas Magazine | Edition 23 | 32

high energy prices, while simultaneously addressing the climate crisis. In order to meet the increasing demand for biogas production, a significant effort is required to identify and collect suitable feedstock to feed more biogas production installations in the coming years. In the past, fermentation tests for feedstock quality control and process optimization had proven problematic, providing highly variable, unreliable results, but BPC’s precision instruments have changed this, providing robust, dependable results that are measured, calculated, and presented in a standardised form. Significant data improvement enables businesses to work more efficiently and make better evidence-based decisions.

As Dr. Liu explains, “For biogas plants, feedstock quality control and analysis are critically important for ensuring stable and efficient biogas production. AMPTS® (Automatic Methane Potential Test System) is currently the top choice of industrial biogas plants, service providers, research institutes, and universities worldwide for optimizing biogas production processes and ensuring stable and efficient plant operation by selecting and controlling the quality of receiving biomass feedstock.”

By using AMPTS®, users can

perform frequent and accurate analyses, including biochemical methane potential (BMP), biogas potential, specific methanogenic activity (SMA), and residual gas potential (RGP), with significantly reduced workload. With this tool, users can evaluate feedstock's true energy potential and biodegradation, and a deeper understanding of the biological behaviour of biogas production processes – allowing for a scientific and evidence-based decision for more efficient plant operations.

AMPTS® is a user-friendly system which allows for remote access, so the highly accurate data is at hand whenever it is needed, while the standardised measurement procedures, data interpretation, and reports provide meaningful data which is easily comparable and upon which sound business decisions can be made.

In addition, BPC’s involve-

ment in Task Force 3 ("Sustainable potentials for innovative biomass sources") of the European Biomethane Industrial Partnership (BIP) is a testament to their commitment to sustainability and innovation in the European biogas industry. By exploring the potential of innovative biomass sources for biogas/ biomethane production and promoting circular agriculture through the utilization of digestate as biogenic fertilizer, BPC is making a valuable contribution towards a more sustainable future.

Biogas and biomethane have the potential to become significant sources of renewable energy in the future, particularly in countries like India with abundant biomass resources and a high demand for clean energy for economic growth with little or no negative impact on the environment. Dr. Liu highlights the importance and increasing demand for feedstock analysis and process optimization

Biogas Magazine | Edition 23 | 33

for stable and cost-efficient biogas production, where advanced analytical instruments like AMPTS® can play a crucial role.

Speaking of the service BPC provides for its customers, Dr. Liu observes: "We provide more than analytical tools; we transfer know-how too, and with the value we add through our expertise and process-related analysis, we can play a critical role in planning and operating biogas plants with stability and efficiency."

"Our technical products are underpinned by our expert team, who are friendly, approachable, and have a genuine desire to help. Their

and direct involvement with the products mean they can always address customers’ inquiries; their commitment and expertise go far beyond a typical business exchange."

"BPC Instruments has an international team that is committed to delivering quality products and services. Our team provides technical support covering product enquiries, questions, maintenance, and product applications."

"It is our ambition to make sure that the instruments can be your tools for more effi-

cient, reliable, and high-quality analysis, leading to significant reductions in time and labour and more efficient utilization of manpower resources. India biogas industry is in the beginning of an exciting expansion phase." said Dr. Liu.

Biogas Magazine | Edition 23 | 34

Dr. Jing Liu CEO

BPC Instruments AB

Comprehensive Range of Biogas, Biomethane, Offgas & Landfill Gas Analysers

Continuous Online Analyzer

SWG 100 Biogas

TECHMARK OPTIMA Biogas

Up to 10 sites sample gas switching & monitoring on time sharing basis

NDIR sensor for CH4, CO2 and electrochemical for H2S & O2

Integrated Dew Point measurement

Calculated GCV / NCV values

Programmable Auto calibration for data validation

Real Time Monitoring with Remote Access & Data transfer facility.

Actuation of solenoid valve for closure, as per user settable limits

Alarm Generation on deviation from standard composition with message to concerned personnel / control room

Tamper Proof Password protection

Ex Proof Models also available

Handheld Analyzer

Biogas measurement : CH4, CO2, H2S, O2

Gas Leak detection probe for CH4 (LEL)

Light weight : 700gms

Simultaneous measurement of flow rate & biogas

Built-in condensate separator & dust for extra protection

Internal data storage for about 20,000 readings

SD card, Mini-USB & Bluetooth for data transfer to Smartphone, Tablet or PC

Long-life rechargeable battery with standard

USB charger

CONTACT US FOR DEMONSTRATION

TECHMARK ENGINEERS & CONSULTANTS

1020, Ansal Tower, 38 Nehru Place, New Delhi - 110019

Tel 011 46570392 - 94 Mobile : 7011389878

sales@techmark.co.in www.techmark.co.in

German technology with proven performance

Over 2000 anlaysers sold worldwide

Preferred choice of Indian OEMs, Project developers & owners

All India Service & Calibration support by trained team

Experience of over 26 years in handling gas analysers

The hype about hydrogen –wonderful or insane?

The following article is the continuation of Edition 22.

Strong demand likely from the steel and chemical industries

There may well be doubts that the resulting patchwork with methane “islands” of 100% and 80% is also ideal from an economic and technical viewpoint. Some actors want a separate infrastructure for pure hydrogen right away, like the Federal Association of Offshore Wind Farm Operators, which wishes to “preserve the value of green hydrogen”. The greatest demand for hydrogen is likely to soon come from energy-intensive industry: Both the German steel and chemical industries want to contribute to greenhouse gas neutrality

through hydrogen by 2050.

Germany currently consumes 1.8 million tonnes (t) of hydrogen (60 TWh) per year, with the chemical industry accounting for around 1 million tonnes. Refinery processes for cracking hydrocarbon chains, ammonia production and methanol synthesis are the biggest sectors with a demand for H2 that is covered with grey hydrogen. In the chemical industry the first step is to decarbonise existing processes with green hydrogen and then use it as an energy carrier.

Hydrogen as a reducing agent

For the steel industry, the key to decarbonisation lies in direct reduction, which is

intended to replace the traditional blast furnace process. Coke is used as a reducing agent for producing crude steel in the blast furnace. Here CO2 emissions are 1,800 kg per tonne of crude steel. With direct reduction on the other hand, natural gas and/ or hydrogen is used to reduce iron ore to sponge iron, which is processed further in an electric arc furnace. In contrast to the blast furnace, liquid pig iron is no longer produced. CO2 emissions can be reduced to as little 100 kg/t.

With the Salzgitter Low CO₂

Steelmaking project, Salzgitter AG wants to develop a purely hydrogen-based direct reduction process replace as much fossil fuel as possible with green hydrogen. For this purpose, the company is in-

Biogas Magazine | Edition 23 | 36

The hydrogen story: Research! Promotion! Yield?

Following the oil crisis in the 1970s, alternative energies were feverishly sought everywhere and hydrogen was discovered. In the 1980s the solar hydrogen project was set up in Neunburg vorm Wald/Bavaria with a photovoltaic system, three electrolysers, compressed gas storage and two fuel cells. The Euro-Quebec Hydro-Hydrogen Pilot Project ran from 1989 to 1998 in Canada, Germany, Italy and Belgium. The hydrogen was produced in the east of Canada using hydropower from a large storage reservoir. Buses with different H2 drive technologies ran on the roads in several cities. Emissions tests and studies were carried out. As the money quickly ran out, the project was scaled down in 1991.

The German government and industry had already invested several billion Deutschmarks in research into the hydrogen economy before the world's first public hydrogen filling station opened at Munich Airport in 1999. MAN tested fuel cell buses, and BMW developed its first hydrogen car. After two years however, the filling station was demolished, and the two vehicle manufacturers ultimately abandoned their hydrogen tests (2009). By then BMW had built a hundred of its Hydrogen 7 vehicles, which were able to run on hydrogen and petrol as a hybrid, and the cars were leased by celebrities and politicians.

It is still unclear whether the fuel cell for transport is superior to the use of hydrogen in conventional combustion engines, which are simple to adapt, as in the case of the Hydrogen 7. Only Toyota, Hyundai and Honda sell fuel cell cars. The sales figures are however negligible. Mercedes-Benz has discontinued its GLC fuel cell model because battery technology is superior in the passenger car sector. The company is concentrating on developing fuel cell technology in buses and trucks. VW also sees no future for the fuel cell in passenger cars. Some manufacturers are working full steam on developing hydrogen trucks. So far, there is only one liquid H2 truck with a fuel cell from Hyundai. 50 of them are already on the roads in Switzerland.

Nonetheless, operating conditions for the fuel cell in traffic are far more difficult than stationary operation in a boiler room. From 2008 to 2016, the German government funded the development of power-generating fuel cell heating appliances to the tune of over 50 million euros under the “Callux” programme. The result is lousy. Thanks to generous broad-based funding, there has been an uptick in recent years, but most of the units sold rely on Japanese fuel cells. Three manufacturers offer fuel cells developed in Germany but they are solid oxide fuel cells (SOFC) that directly utilise natural or liquid gas in place of hydrogen.

Biogas Magazine | Edition 23 | 37

tending to produce its own H2 from wind power. Following the experimental injection of hydrogen as a reducing agent in blast furnaces, Thyssenkrupp plans to connect them to the hydrogen network operated by Air Liquide in the Ruhr area. The first large-scale direct reduction plant is to be built in 2024 and from 2030 onwards, three million tonnes of climate-neutral steel will be produced per year.

The plans for green steel in Sweden are even more audacious: The start-up H2 Green Steel wants to build a brand-new steelwork for climate-neutral steel on a greenfield site in the northern Swedish region of Norrbotten. An electrolysis plant for hydrogen production is

incorporated in the 2.5 billion euro project. The region not only has hydro and wind power but also high-quality iron ore and the port of Lulea. Large-scale steel production is scheduled to begin as early as 2024. From 2030 Sweden wants to produce 5 million tonnes of green steel per year.

H2 Green Steel is the first showcase project of the European Green Hydrogen Acceleration Center, which aims to develop a green hydrogen economy with annual sales of 100 billion euros by 2025. While it is under the leadership of EIT InnoEnergy, a

European Union body, financial support comes from the cleantech fund Breakthrough Energy. The investors and the board of Breakthrough Energy include entrepreneurs such as Bill Gates, Jeff Bezos (amazon), Richard Branson (Virgin Group), Jack Ma (Alibaba, the Chinese counterpart to amazon) or Michael Bloomberg, media tycoon and ex-mayor of New York. When the richest men in the world are working together for hydrogen, nothing can really stand in the way of a breakthrough.

Biogas Magazine | Edition 23 | 38

Christian Dany Freelance Journalist

See you soon! BIO-ENERGY PAVILION 2023 By Indian Biogas Association Facts & Figures (2023) KEY FEATURES Networking Business Meetings Pitching with Investment Agencies Conference Sessions Discussion with Industry Experts Social Evening BOOK YOUR SPACE To avail Early Bird Discount! #bioindia2023 India Expo Centre, Greater Noida For more information, please feel free to reach us Mr. Vishal Kanchan, M: +91–7838 447 489, Email: vishal@biogas-india.com 40,000+ Trade Visitors Exhibitors Physical Conferences 700+ 40+ 04 05 06 October ’23

Biogas Magazine | Edition 23 | 40 HARVESTING

Specialization CBG CBG CBG Biogas Engineering India Pv t. Ltd. is a subsidiar y company of Biogas E n g i n e e r i n g I n c . U S A , w h i c h i s a n e n g i n e e r i n g , p ro c u re m e n t a n d c o n s t r u c t i o n ( E P C ) c o m p a n y . W e a r e a n e x p e r t i n u p g r a d i n g Biogas/Land fill gas to Compressed BioGas (CBG), utilize gas for Heat & Power Generation and waste gas for Carbon Capture.

YOUR RENEWABLES

Kavita Tanwar

Kavita Tanwar