K E E P I T S A F E

April 2024

Welcome to the April 2024 edition of Keep It Safe

15th Annual BFFF H&S Conference - We have just returned after delivering our 15th annual Health & Safety Conference where we achieved a full house of over 80 attendees The day was packed with insight from our speakers who were all very engaging, we have received some excellent feedback.

For those that attended they were able to increase their knowledge and update their CPD on various topics such as: Presenting with impact, claims defensibility, legislation, an OSH professionals true potential, OSH leadership/tools, simplifying, digitising and automating (HSMS), HSE MSD Tools and body and Defibrillators

Thanks to the delegates who continue to support us by attending and thanks to our exhibitors: Solo Protect, Protex AI, Flexi-tog and Defib Plus A special thank you to the BFFF team who worked tirelessly behind the scenes to make this a success Charley Price, Siobhan O’Callaghan, Emma Cranidge and Sarah Collison

Read about:

BFFF Initiatives

Primary Authority News and Events

Enforcement

Well-Being

Guidance

SimonBrentnall CMIOSHPIEMAAIFSM HeadofHealth&Safety BFFF

Fire Safety

Transport Hub

O N T E N T S

BFFF INITIATIVES

Further BFFF guidance for those employees working in cold stores from hotter climate

BFFF/WMDC Nomination for APSE Awards 2024 – Best Public/Private Partnership Working Initiative

Workplace Transport Safety Day 31st July 2024

The BFFF Health & Safety Group Meet at Bidfood Birmingham Depot

BFFF Recognises Global Asbestos Awareness Week 1st – 7th April 2024

FIRE SAFETY

Compartmentation & Fire stopping

PRIMARY AUTHORITY

BFFF help the Department for Business, Energy & Industrial Strategy (BEIS) develop and digitise the current Primary Authority Scheme!

ENFORCEMENT

Bakery company fined £400,000 after employee has left leg amputated

Important machinery basics overlooked resulting in £800,000 fine

Pizza maker fined £800,000 after two workers caught up in machinery

Company fined over £70,000 as worker has leg amputated

Asbestos: health effects, incident management and toxicology

Tackling stress in the workplace with five steps in five weeks

Maintenance of Machinery & Work Equipment – BS14200

Target areas for the enforcing authorities in 2024/25

TRANSPORT HUB

Automated Vehicles Bill: call for evidence

Smarter regulation: proposed changes to legislation for electrically assisted pedal cycles

LEGISLATION

BFFF Members need to be aware of new changes for RIDDOR

C

GUIDANCE Prime Minister launches retail crime crackdown Homeworking Guidance 2 3 3 3 4 6 7 8 8 11 11 12 12 13 14 15 16 16 18

Reporting Primary Authority 19 20 22 22 24 24 25 26 26 27

B F F F I N I T I A T I V E S

We are now pursuing our next industry changing objectives, this follows a civil claim received by one of our member companies when a worker was allegedly found unable to tolerate the lower temperatures of the Cold Store environment It was said that the employee was finding it difficult to go into cold areas, suffering from nose bleeds and unable to drink cold water The employee recovered without any long term problems, however a claim was settled based on the production of a military forces report.

In summary, this report states those from hotter climates are more susceptible to cold temperatures Some controls that have now been implemented by the BFFF member company include further scrutiny of medical questionnaires, informing HR departments, creating awareness with first line management and personal risk assessment, reporting symptoms such as nose bleeds and extra monitoring especially in first six months of employment We are working with our primary authority and the HSE with an aim to formalise assured guidance and will keep you updated

In this awards application, The British Frozen Food Federation and Wakefield Council’s Primary Authority partnership showcases the benefits and impact of the Primary Authority scheme. This partnership has transformed the supply of cold insulative footwear, reaching over 300 national retailers and suppliers of the frozen food industry and protecting thousands of employees and employers in the process

This collaboration with BFFF members (including Arco, Sysco, apetito and ABP), regulatory partners and the internationally recognised Shoe & Allied Trades Research Association (SATRA) has resulted in improved footwear safety standards across the sector Hopefully we look to celebrate this award very soon, fingers crossed!

. 3 F U R T H E R B F F F G U I D A N C E F O R T H O S E E M P L O Y E E S W O R K I N G I N C O L D S T O R E S F R O M H O T T E R C L I M A T E S

B F F F / W M D C N O M I N A T I O N F O R A P S E A W A R D S 2 0 2 4 –B E S T P U B L I C / P R I V A T E P A R T N E R S H I P W O R K I N G I N I T I A T I V E -

B F F F I N I T I A T I V E S 4

B F F F I N I T I A T I V E S 5

B

Thanks to Bidfood UK - Clare Flanagan, Simon Stretch & Dennis Keegan for hosting the British Frozen Food Federation Health & Safety Group meeting recently Bidfood UK were the perfect hosts which included a tour of their Birmingham facility.

The British Frozen Food Federation Health & Safety Group meets 3 times per year to discuss industry topics Subjects aired at this meeting included: Asbestos, Workplace Transport, EV Charging Points, Drugs & Alcohol, Composite

Insulated Panels, Planned Preventative Maintenance Cold Store Workers, Stress, Slips/Falls from Vehicle Tail-lifts and Aggression & Violence

We achieved record number of attendees (pictured above) This is a great example of sharing best practice and OSH collaboration at its best!

Thanks to the support of all attendees:Fiona Gordon-Smith - Unilever, Jemma Wiles - ABP Rupert Ashby – BFFF, Dennis Keegan – Bidfood, Millicent Holdsworth - Holdsworth Foods, Clare Flanagan – Bidfood, Scott Irwin –Greggs, Michael Cox – Sysco, Paul Duncalf - Sysco, Leanne Broome –Dalziel, Rosannah Hines – Dalziel, Kerry Broadhead – StoreLogs, Chris Humphries – Iceland, Ovidijus Barkauskas – Cook, Mark Lovett - apetito

To get involved and find out more about the Health & Safety group, simply e-mail: simonbrentnall@bfff.co.uk

I T I A T I V E S . 6 T H E B F F F H E A L T H & S A F E T Y G R O U P M E E T A T B I D F O O D B I R M I N G H A M D E P O T

F F F I N

The British Frozen Food Federation has recently recognised Global Asbestos Awareness Week 2024 which is held annually between 1st - 7th April to raise awareness of the risks of asbestos exposure and the need for prevention measures.

During Global Asbestos Awareness Week, organisations, trade associations, support groups, medical professionals, and individuals unite to inform others about the risks associated with asbestos exposure, share information about asbestos-related diseases, and promote measures to prevent exposure The BFFF recently raised the profile to members through its Health & Safety Group and presented on this subject

Asbestos was banned in the UK on the 24th November 1999, and there is a concern that the new generation of workers or not fully aware of the dangers We need to make everyone understand this these risks are real with Six million tons of asbestos still present and spread across 1.5 million buildings in the UK. Please make your businesses aware of the following statistics:

There are 26,000 mesothelioma deaths a year worldwide with a total of 107,000 deaths a year worldwide, The UK has 2,500 mesothelioma deaths a year with a total of 5,000 deaths a year in the UK, Blue asbestos is 500 times more dangerous, Brown asbestos 100 times more toxic than White, Asbestos will have claimed the lives of 10 million people worldwide before its fully controlled, Risk to workers is particularly high when work is being carried out at your premises through installation of new equipment, removal of old, maintenance work and construction /alteration work as asbestos fibres can be released if asbestos is disturbed or damaged

The HSE is currently running two asbestos campaigns:

Asbestos and You: highlights the risk of asbestos to tradespeople. It urges tradespeople to stay aware of hidden asbestos and protect themselves and others from exposure to asbestos fibres during their work, Asbestos – Your Duty: aims to raise awareness of the legal duty to manage asbestos in buildings aims to reach those responsible for maintenance and repair of nondomestic buildings built before the year 2000. More information on asbestos can be found on the HSE website here: https://www hse gov uk/asbestos/duty/ind ex htm

B

F F

N I T I A T I V E S . 7 B F F F R E C O G N I S E S G L O B A L A S B E S T O S A W A R E N E S S W E E K 1 S T – 7 T H A P R I L 2 0 2 4

F

I

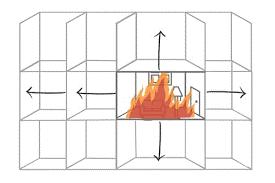

F I R E S A F E T Y

Author – Jonathan Dixson – Primary Authority Manager – Essex County Fire and Rescue Service

Author – Jonathan Dixson – Primary Authority Manager – Essex County Fire and Rescue Service

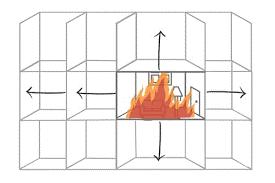

Requirements for ensuring that the elements of compartmentation, as well as fire stopping, in your buildings are installed to a reasonable standard is an essential defence against risk to life, assets and business continuity and should be assessed at an early opportunity.

The ‘passive’ fire safety elements installed within a building, generally go unnoticed but are an absolute essential part of a package of fire protection measures in place without which would have a detrimental effect should fire start and begin to spread

Most of the passive fire resisting elements are installed as part of the fabric of the building which restrict both the growth and spread of fire and smoke The passive elements are there to control the flammability of walls, ceilings and help to divide the building into fire resistant compartments, boxes, which give protection to the means of escape throughout the building, the building structure and ultimately prevent premature collapse.

The various elements ‘passive fire protection’ (PFP) include:

Fire doors

Fire resisting walls & ceilings

Fire resisting ducts and dampers.

Fire-stopping of service breaches

Requirements for the provision of such elements can be found within Building Regulations Approved Document B (ADB) as well as the requirement to prevent fire spread under the Regulatory Reform (Fire Safety) Order 2005, ‘The FSO’

In addition to the common construction materials used in buildings sandwich panels, which carry their own particular risks, are also commonplace in the food industry and are likely to be found in buildings occupied by the Bfff membership businesses. There are additional safeguards which should be considered where these types of building elements are present along with strict management around areas where these are placed. Helpful advice relating to safety around composite sandwich panels can be found within the ASFP guidance in Section 6 4

During the lifespan of a building there are often numerous changes that take place which can include structural changes to the internal layout and the extensive installation of ‘services’ such as communications cabling, ducting for air control systems and electrical wiring and through efficient fire safety management, should be safeguarded against the need for future remediation and retrospective repairs

Often the mismanagement of contractors, as well as a lack of awareness of the

. 8 C O M P A R T M E N T A T I O N & F I R E S T O P P I N G

F I R E S A F E T Y

impact of inefficient fire stopping where works resulting in compartment breaches can often be overlooked resulting in the need to retrospectively bring them up to a safe standard whilst leaving the building, and its occupants, vulnerable until the breaches have been identified

Implications for ignoring this part of fire safety include building damage and loss of assets, compromising of the escape route tenability and ultimately the potential for loss of life. It is also likely that insurances would not cover such an event if proved to be due to lack of fire safety management

When ‘works’ are carried out, which result in structural alterations, these are covered by the consultation process under Building Regulations, this process includes a series of check points including Building Control, Local Fire Service Fire Protection Departments and final sign off surveys

Contractors will also provide the necessary documentary evidence to show where their works are assured and meet the relevant standards

For smaller works including installation of services and minor works it will be down to the ‘Responsible Person’ to manage these ‘locally’. This is usually via a ‘permit to work’ system and fire risk assessment or FRA review

Where ‘permits to work’ are used effectively any damage to the building fabric during the fitting of services should be identified and a plan made to ensure these are adequately remediated following the works. This should be agreed with contractor’s prior the start of the work and checked post installation

There is value in reviewing your current system of ‘permits’ to ensure that they elicit the correct responses to safeguard against ‘lack of ownership’ of these responsibilities Permits were traditionally known as ‘hot works permits’ which traditionally covered plumbing type work, but the range of works that can be commissioned over a buildings lifespan vary vastly These can include decorating and refurbishments, electrical works, layout changes, communications, fire door installations and installation of other services which can affect your buildings fire compartments whilst taking place

The modern permit should ask questions about the impact any work might have on fire safety whilst taking place, how this will be mitigated in the interim whilst works are ongoing and an assurance that any fire precautions in the building being affected will be restored to their original state and in working order.

From the fire risk assessment perspective, you should check that your appointed assessor has made the relevant comments and given advice on the ‘passive elements’ of fire safety within the building The assessment would typically consider the condition of fire doors, the protection of escape routes, comment of any service penetrations and voids such as roof spaces or service risers and areas that are easily accessible whilst completing a type 1 assessment, for example a PAS79 fire risk assessment.

Beyond the type 1 assessment, where there may be doubt as to the adequacy of the compartmentation, a further type 4 assessment can be completed. This is a much more invasive survey and usually includes areas of the premises which are much more difficult to assess

9

F I R E S A F E T Y

These are more common where sleeping accommodation is present but can be carried out for assurance in other work environments where life and asset risk are relevant

Amongst other things the fire risk assessor should consider the type of occupancy, occupancy levels, size of building, risk posed by the processes taking place and extent of escape routes As noted above, generally a ‘waking occupancy’ is considered at less risk than building where sleeping accommodation is present, however, where the business operations are dependant personnel or where there is food contamination risk it becomes more important to consider where and how a fire may spread

Final Thought:

Further guidance can be found in the documents listed below and it is advised that fire risk assessments are checked to ensure that consideration has been made of the elements of compartmentation Since the introduction of Section 156 of the BSA risk assessors should be more aware of their responsibilities to include quality information within assessments to assist the responsible person in understanding the efforts to mitigate against compartmentation risks.

References:

ASFP: Guide to inspecting passive fire protection for risk assessors (Section 1.6) BS9999: for reduction in fire resistance for compensatory measures / mitigation Building Regulations: Approved Document B

1 0

P R I M A R Y A U T

H O R I T Y

BFFF help the Department for Business, Energy & Industrial Strategy (BEIS) develop and digitise the current Primary Authority Scheme!

Back in 2014, BFFF were the first trade association to take on the primary authority scheme, today, we still continue to protect our members from unwanted legal challenges and deliver crucial benefits through the scheme More recently, as a respected and well established primary authority provider, BFFF was approached by the Department for Business, Energy & Industrial Strategy (BEIS) to take part in a government initiative to further develop and digitalise the scheme. It was a privilege to be involved in this review, however, this did come with a caveat as Simon Brentnall BFFF’s Head of Health & Safety explains;

In the meeting, we did stress the importance of digitalisation, we do need to bridge the generation gap and innovate, this could translate into the development of a Primary Authority app More importantly, we also made it clear what a good primary authority partnership really looks like We raised the point that BFFF’s success with the scheme was not down to digitalisation but down to developing relationships through conversation, by simply picking up the phone and having regular discussions

The one piece of advice I would give to any company looking to take on primary authority would be to find a partner which is amenable, someone you can have regular open and honest dialogue with and experience in your industry

Over the years we have been lucky enough in finding the ideal partner who excel in this criteria We use Wakefield Metropolitan District Council for Health & Safety, they are amenable and nothing is too much trouble with the added benefit of having knowledge of our industry In summary, let’s develop, let’s innovate but most importantly, let’s keep talking

To find out more about the primary authority scheme, contact: simonbrentnall@bfff co uk

1 1

N F O R C E M E N T

Bakery company fined £400,000 after employee has left leg amputated

A food manufacturing company on the Wirral has been fined £400,000 after one of its employees had to have her leg amputated. Sharon Bramhall lost a leg following a serious incident at Baker and Baker Products, which is based in Bromborough The 58-year-old had to have her left leg amputated below the knee following the incident at the company’s premises on Stadium Road Mrs Bramhall had been supervising four other members of staff as they completed high-level cleaning tasks during a night shift on 22 April 2022 She had been acting as ‘a banksman’ for an employee who was controlling a mobile elevating work platform (MEWP) As the MEWP turned through 90 degrees into the warehouse it struck Sharon, crushing her left leg The incident was captured on CCTV.

The HSE’s investigation revealed a series of failings by Baker and Baker Products UK Limited The company failed to:

Have in place a suitable and sufficient safe system of work when escorting MEWP’s from a parked position to point of use

Provide information, instruction and training for the movement of the MEWP and use of banksman

Adhere to their normal practice and company policy to ensure a trained MEWP operator acted as banskman

The HSE has commented that had these been implemented, the incident could have been prevented Baker and Baker Products UK Limited, of Stadium Road, Bromborough, Wirral, pleaded guilty to breaching section 2(1) and 33(1) of the Health and Safety at Work etc. Act 1974. The company was fined £400,000 and was ordered to pay costs of £7,266 costs

This HSE prosecution was brought by HSE enforcement lawyers Karen Park and Matt Reynolds and paralegal officer Louisa Shaw. In a statement provided to the court, Mrs Bramhall said she felt ‘lucky’ it wasn’t worse “I know I could have died,” she said “Sometimes I wake up and just wish I’d booked that night off work for some reason and none of this would have happened ”She was hospitalised for three months and has had a total of nine operations including several skin grafts “I have a huge scar on my stomach from where the surgeons took a piece of it to use as a flap over my stump My left leg above my stump is really badly scarred and damaged It was trapped under the cherry picker The recovery afterwards was awful “It is difficult to put into words just how much the accident has impacted me. I have had to uproot and move my family I am struggling with blistering on my stump, even now, rendering me wheelchair dependent I am not able to leave the house on my own. I am fearful about what the future holds for me.

”After the hearing, HSE inspector Ian Betley said: “Sharon Bramhall suffered terrible injuries that will affect her for the rest of her life due to the failings of her employer. “Vehicles continue to be a major cause of serious injuries in the workplace, and the first principle of any employer should be to keep people and vehicles apart “The risk assessment decided that someone was needed to escort the MEWP, thus a safe system of work needed to be devised Employees should have been given appropriate banksman training, including how to effectively communicate with the driver.“Had these been in place, Sharon’s injuries could have been avoided ”

E

1 2

Important machinery basics overlooked resulting in £800,000 fine

A company that specialises in making pork pies has been fined £800,000 after two young workers lost fingers in incidents at two different Nottingham bakeries

Pork Farms Ltd, which makes other savoury goods such as quiches, at several sites across England, was given the fine after both workers were injured just weeks apart at the end of 2022

The first incident took place on 16 November when a 22-year-old worker had his hand trapped while trying to clear a blockage on a conveyor at the firm’s Tottle Bakery on Dunsil Drive He had to have a finger amputated after his hand was trapped between a chain and sprocket on a conveyor at the site.

Just weeks later, on Christmas Eve, Mahamad Hassan, who was just 19, suffered similar injuries at Pork Farms Limited’s Riverside Bakery. The teen also had a finger amputated as a result of coming into contact with a rotating shaft on a conveyor

Nottingham Magistrates’ Court was told that the company had failed to ensure that the conveyors involved in both incidents were adequately guarded

Unguarded

Investigating, the HSE found that dangerous parts of both conveyors were accessible at the time of each incident At the Tottle Bakery, an unsuitable interlock was used on a hinged guard over a chain conveyor system and an inadequate inspection and maintenance regime led to this interlock failing. The chain conveyor automatically moved as he tried to adjust the position of the chain following a blockage in the area

At the Riverside Bakery, a section of the driveshaft of a lineshaft style conveyor was unguarded and spacing of the rollers was sufficient for a persons arm to pass through and reach the driveshaft below Mr Hassan was injured when his arm went between the rollers and his gloved hand became entangled in the rotating driveshaft. In addition to physical guarding issues, there was no warning system to give notice that the conveyor was about to start working and emergency stop controls were not readily accessible.

Pork Farms Limited, of Queens Drive, Nottingham, pleaded guilty to breaching Sections 2(1) and 3(1) of the Health and Safety at Work etc. Act 1974. The company was fined £600,000 for the incident at the Tottle Bakery and £200,000 for the incident at the Riverside Bakery The company was also ordered to pay costs of £6,482

Speaking after the hearing, HSE inspector Tim Nicholson said: “Both of these incidents were completely preventable They left two young men with injuries that they will carry with them for the rest of their lives

“Companies shouldn’t overlook important machinery safety basics, including provision and maintenance of adequate guards and protection devices, to ensure that access to dangerous parts of machinery is prevented.”

E

1 3

N F O R C E M E N T

N F O R C E M E N T

Pizza maker fined £800,000 after two workers caught up in machinery

One of the nation’s largest producers of supermarket pizzas has been fined £800,000 after two workers suffered serious injuries at its factory in Bolton Stateside Foods Limited produces millions of pizzas each year, supplied to major UK supermarkets The company was fined after the employees were caught up in machinery at the Westhoughton site in two separate incidents during 2020

Bolton Crown Court heard how one man had his arm drawn into an inadequately guarded conveyor belt at the Lancaster Way factory, on 8 January 2020 The injury to his arm resulted in the removal of muscle and required a skin graft He has not returned to work since the injury and has been diagnosed with hypersensitivity in the affected arm.

Following on from this, on a night shift just nine months later, father of two Andrew Holloway had part of his middle figure severed after his hand was drawn between a roller and a conveyor belt on 14 October 2020 The acting team leader had been told of an issue on the production line and gone to investigate when the horrific incident happened

Although Mr Holloway returned to work after a six-month absence he left after just a couple of days – which resulted in him starting his career again

The HSE’s investigation found the company: Did not adequately guard their machinery Did not provide suitable and sufficient checks to ensure that their protective measures were working effectively.

Allowed the disabling of guarding systems and access to dangerous parts of machinery.

Stateside Foods Limited of Lancaster Way, Westhoughton, Bolton, pleaded guilty to breaching Section 2 (1) and 3 (1) of the Health and Safety at Work etc Act. The company was fined £800,000 and was ordered to pay £5,340 costs

The prosecution was brought by HSE enforcement lawyers Sam Crockett and supported by senior paralegal officer Stephen Parkinson

After the hearing, HSE inspector Leanne Ratcliffe said: “This is one of the country’s major food companies. The injuries sustained by both of these workers has been truly life changing

“This case should send a message to industry about how important it is understand the risks of bypassing guarding arrangements, and to re-evaluate their own guarding arrangements and procedures to eliminate any access to dangerous parts of machinery

“We will always be prepared to take action when companies fall short of their duties and responsibilities to protect their staff ” HSE Enforcement Lawyer Kate Harney presented the case at Bolton Crown Court.

E

1 4

E N F O R C E M E N T

Company fined over £70,000 as worker has leg amputated

A company that grows mushrooms has been fined after an employee’s leg became trapped in a machine and was later amputated

Luka Ilic’s right leg was caught by the rotating blades of a mushroom filling machine and became stuck in the device’s moving parts on 16 October 2019

He was part of a team of three at Howden Enterprises Ltd, trading under the name Hughes Mushrooms, that were cleaning the machine at the firm’s premises in Holme-onSpalding-Moor, East Yorkshire

The then 29-year-old climbed onto the machine, which is used to prepare and fill compost in growing trays, to remove the last remaining parts of the compost The machine was then turned on, leading to Mr Ilic’s leg being caught by the rotating blades in the mixing axle and becoming trapped

Investigating the incident, the HSE found Howden Enterprises Ltd had failed to adequately assess the operation of the filling machine, in particular the cleaning of the machine The firm failed to ensure there was robust isolation and safe operating procedures in place and followed

Howden Enterprises Ltd, of Trew Mount Road, Dungannon, County Tyrone, Northern Ireland, pleaded guilty to breaching Section 2(1) of the Health and Safety at Work etc. Act 1974. The company was fined £73,333.00 and ordered to pay £7,522 60 in costs

HSE inspector Louise Redgrove said: “The importance of a suitable and sufficient risk assessment which reflects all actual practical activities cannot be underestimated It is vital to ensure there are effective systems of work and physical controls which are implemented, supervised and used by all those involved This incident could have easily been avoided with a robust isolation procedure and padlock for each worker involved ”

This prosecution was brought by HSE enforcement lawyer Iain Jordan and supported by HSE paralegal officer Rebecca Whithell.

1 5

G U I D A N C E

Assaulting a retail worker is to be made a standalone criminal offence, the Home Office has announced.

Serial or abusive shoplifters will face tougher punishments under the new action announced by the Prime Minister last week to crack down on retail crime and protect UK highstreets.

Perpetrators could be sent to prison for up to six months, receive an unlimited fine and be banned from going back to the shop where they committed their crimes, with Criminal Behaviour Orders barring them visiting specific premises Breaching an order is also a criminal offence and carries a five-year maximum prison sentence For the most serious cases of assault, such as causing grievous bodily harm with intent, offenders could face a life sentence

The move to create the new offence follows longstanding campaigning on this issue from Matt Vickers MP, and some of the biggest retailers, calling for more action to better protect their staff

The government is also stepping up action to clamp down on offenders who repeatedly target the country’s high streets, with serial offenders forced to wear tags to track their movements

These tags will be a constant and physical reminder to offenders that the Probation Service can find out where they have been and when, and that they risk being sent to prison if they refuse to obey the rules. Under an amendment to the Criminal Justice Bill, if an offender is found guilty of assaulting staff three times, or is sentenced for shoplifting on three separate occasions, they should be made to wear a tag as part of any community order

Ahead of this legislation coming in, the government says it will partner with a police force to pilot a bespoke package of community sentencing measures which can be used by judges to tackle high levels of shoplifting, sending a clear message that repeat criminality will not be tolerated

The government is also ramping up the use of facial recognition technology to help catch perpetrators and prevent shoplifting in the first place Backed by a £55 5m investment over the next four years, the police will be able to further roll this new state of the art technology.

This will include £4m for bespoke mobile units that can be deployed to high streets across the country with live facial recognition used in crowded areas to identify people wanted by the police – including repeat shoplifters

The mobile units will take live footage of crowds in towns and on highstreets, comparing images to specific people wanted by the police or banned from that location. Police in the area will then be alerted so they can track down these offenders

1 6 P R I M E M I N I S T E R L A U N C H E S R E T A I L C R I M E C R A C K D O W N

G U I D A N C E

Prime Minister Rishi Sunak said: “Since 2010, violent and neighbourhood crime in England and Wales has fallen dramatically, showing our plan to keep our streets safe is working Yet shoplifting and violence and abuse towards retail workers continues to rise

“I am sending a message to those criminalswhether they are serious organised criminal gangs, repeat offenders or opportunistic thieves – who think they can get away with stealing from these local businesses or abusing shopworkers, enough is enough

Home Secretary James Cleverly said: “There is quite simply no excuse for threatening behaviour or stealing – which can run other people’s livelihoods into the ground, while being traumatic for workers

“To turn a blind eye to retail crime shakes the foundations of law and order which protect our society and that is unacceptable We are enhancing our plan and doubling down on the zero-tolerance approach needed to fight back

“The number of offenders being charged for these crimes is increasing and while I want to see more people face consequences for their actions, our plan is designed to help put a stop to these crimes happening in the first place ”

The government has driven forward significant efforts to tackle retail crime in the past year, bringing together policing and business to commit to smarter, more joined up working to reduce criminal behaviour and rebuild public confidence in the police response when it does occur

Crime and Policing Minister Chris Philp said: “Sadly if you speak to anyone working in retail, they will tell you of the verbal abuse and sometimes violent assaults they’ve been victims of, simply for

trying to do their job

“In no other workplace would this be accepted I have been driving forward action to improve the police response to retail crime since I became Policing Minister, because nothing less than a zero-tolerance approach will do

“That’s why we’re sending a clear message to criminals that enough is enough bringing forward further measures to protect retail workers and crack down on those who continuously disregard the law ”

A specialist new police team set up last year is building intelligence on organised retail crime gangs funded through ‘Pegasus’, a first-of-itskind business and policing partnership backed by 14 of the UK’s biggest retailers, National Business Crime Solutions and the Home Office, launched to radically improve the way retailers are able to share intelligence with police to identify more offenders The unit forms part of Opal, the national police intelligence unit for serious organised acquisitive crime

Where CCTV or other digital images are secured, police are committed to running this through the Police National Database, as standard, to aid efforts to identify prolific offenders or potentially dangerous individuals. This builds on the pledge by police forces across England and Wales that they will follow up on all lines of enquiry, where there is a reasonable chance it could lead them to catching a perpetrator and solving a crime. All police forces across England and Wales made another significant commitment last year to prioritise police attendance at the scene of a retail crime incident where violence has been used towards shop staff, where an offender has been detained by store security, or where evidence needs to be secured and can only be done by police personnel

1 7

G U I D A N C E

Published by the British Safety Council, this guidance sets out some general advice on how to manage and support the health, safety and wellbeing of home and hybrid workers

The number of people working from home, or splitting their working hours between their home and their employer’s workplace, has risen sharply in recent years, particularly since the COVID-19 pandemic According to the HSE, most of the time, the health and safety risks to home workers will be low and the actions employers will need to take to protect them will be straightforward However, home and hybrid working can nevertheless pose a number of risks to workers’ health, safety and wellbeing For example, if home workers do not get adequate support from their managers and colleagues, they may suffer work-related stress, which can have a negative impact on their mental health

Although the number of people carrying out office-type work at home has been increasing in recent years, the COVID-19 pandemic led to surge in the number of staff working from home And although a significant proportion of people have

returned fulltime to their fixed workplace, such as the office, recent years have also witnessed a major growth in hybrid working This is defined as when an employee splits their time between their workplace and remote working This could mean working at home or from other locations (such as a local coworking space) part of the time; or working from home but using it as a part-time base to travel to customers or different premises – for example, to provide a service

When employees are away from managers and colleagues as a result of home working, it can be more difficult for managers to provide good support – which can have a negative impact on a home worker’s work-related stress levels and their mental health

This guide notes the following statistics:

£53-56bn: estimated total annual cost of poor mental health to UK employers in 2020-21

£5 30: average return on investment for employers for every £1 spent on supporting employees’ mental.

6 6m: working days lost due to workrelated musculoskeletal disorders in Britain in 2022/23 (HSE/LFS)

17 1m: working days lost due to workrelated stress, depression or anxiety in Great Britain in 2022/23

Employers have the same responsibility for ensuring the health and safety of employees working at home as for any other employees –like those working at a fixed workplace, like a company office

Under the Management of Health and Safety Regulations 1999, employers must assess all significant risks to the health

1 8 H O M E W O R K I N G G U I D A N C E

G U I D A N C E

and safety of their employees and put appropriate measures in place to eliminate or control any risks they find The Management Regulations also place other important duties on employers, – such as ensuring that all workers are provided with adequate health and safety information and training when they first start work or are exposed to new risks. In addition, the Health and Safety at Work Act 1974 places a general duty on employers to take appropriate and suitable steps to ensure – so far as is reasonably practicable – the health and

safety of their employees and others who could be affected by their work activities, including during office-based and homebased working

The guidance goes on to cover:

Risk assessment.

Display Screen Equipment (DSE) work.

DSE: reducing the risks

Mobile working and laptops

Supporting the mental health of home and hybrid workers.

These documents provide information on the health effects of exposure, the chemical’s toxicity and material for responding to a chemical incident

Asbestos is a general name given to several naturally occurring fibrous minerals that have crystallised to form fibres. Asbestos fibres do not dissolve in water or evaporate, they are resistant to heat, fire, chemical and biological degradation and are mechanically strong Asbestos is generally divided into two subgroups; serpentine and amphiboles. Serpentine asbestos (chrysotile or white

white asbestos) was the most commonly used type of asbestos.

Chrysotile asbestos fibres are soft, flexible and curved and far less hazardous than the amphibole type Amphibole fibres (crocidoliteblue asbestos, amosite-brown asbestos, tremolite, actinolite and anthophyllite) are brittle fibres and are often rod- or needle-like in appearance It is this form that is more hazardous to health Crocidolite was the most commonly used amphibole asbestos in the past.

The information covers the following:

General:

Uses of asbestos.

How asbestos gets into the environment. Exposure to asbestos

How exposure to asbestos could affect your health

What to do if you are exposed to asbestos.

1 9

A S B E S T O S : H E A L T H E F F E C T S , I N C I D E N T M A N A G E M E N T A N D T O X I C O L O G Y

G U I D A N C E

Incident management:

Hazard identification.

Physicochemical properties

Reported effect levels from authoritative sources

Published emergency response guidelines.

Exposure standards, guidelines or regulations

Health effects

Decontamination at the scene

Clinical decontamination and first aid, and related information.

This April, the HSE is inviting Britain’s bosses to follow five simple steps to prevent and reduce stress in their workplace

The HSE’s Working Minds campaign has called on employers to support workers mental health during Stress Awareness Month

Liz Goodwill, head of the work-related stress and mental health policy team at HSE, said:

“We are inviting business owners, employers and managers to join others across Britain to make a difference

Toxicological overview:

Kinetics and metabolism.

Sources and route of human exposure

Health effects of acute or single exposure

Health effects following chronic or repeated exposure

For more information, please go to: https://www gov uk/government/publications/a sbestos-properties-incident-management-andtoxicology

during Stress Awareness Month in five steps ”

Over the course of the month, employers are encouraged to focus on one of the campaign’s five Rs for each of the five weeks. They are to:

Reach out and have conversations

Recognise the signs and causes of stress

Respond to any risks identified

Reflect on actions agreed and taken

Make it Routine.

Preventing work-related stress isn’t just the right thing to do by workers, it’s the law All employers are required to prevent work related stress to support good mental health in the workplace.

The Working Minds campaign brings together a range of tools and support to help businesses and workers including free online learning, Talking Toolkits, risk assessment templates and examples

2 0

T A C K L I N G S T R E S S I N T H E W O R K P L A C E W I T H F I V E S T E P S I N F I V E W E E K S

Liz added: “Failing to manage work-related stress can cost employers in reduced productivity, sickness absence costs, or even losing a valued member of the team Employers are required to assess the risk of work-related stress impacting their workers, and act on the risks identified.

“As well as guiding you step by step, we provide all the practical templates, tools and resources you need to get started or, you can use it as an opportunity to review what you already do A huge part of this is making it part of your everyday working life, not just a oneoff tick box that gets forgotten about ”

The CIPD, the professional body for HR and people development, and The National Examination Board in Occupational Safety and Health (NEBOSH) are the latest organisations to join as campaign partners, taking the total supporters to more than 30.

Rachel Suff, senior policy advisor, employee relations at the CIPD, says: “Many organisations are reactive and tend to put more emphasis on providing support when people become ill rather than on prevention, including for mental ill health and stress We need both! We want to see every organisation taking a

proactive approach to employee wellbeing. We’re supporting the Working Minds campaign to help employers to create the working conditions and environment that prevents stress and supports good mental health. That also means designing jobs with realistic workloads and targets, and encouraging people to have a healthy worklife balance ”

There are six main areas that can lead to work-related stress if they are not managed properly These are: demands control support relationships role change

Factors like skills and experience, age, or disability may all affect someone’s ability to cope

Matt Powell-Howard, Head of Product Development at NEBOSH, said: “I’m really pleased that NEBOSH is supporting the Working Minds campaign as we are committed to promoting good mental health and preventing work-related stress We were delighted to have also collaborated with HSE on the development of the NEBOSH HSE Certificate in Managing Stress at Work qualification, which is designed to help business meet their legal obligations in this area ”

D A N C E 2 1

G U I

G U I D A N C E

With the new British Standard BS 14200 for the maintenance of machinery and planned preventative maintenance (PPM) being target area for local authority intervention in 2024/2025, we have found the below Local Authority webinar from the HSE, this sets a benchmark for the maintenance of machinery

LA webinar - Maintenance of Machinery and work equipment - April 2024 on Vimeo

Hazard

Asbestos

Respirable Silica Dust

Cooling Towers in Build up Areas

All Sectors

Duty to manage In premises likely to contain asbestos (i e built before 2000) LA health and safety regulators should draw duty holders’ attention to their duty to manage and the relevant HSE guidance

Exposure to respirable crystalline silica (Retail outlets cutting/shaping their own stone or high silica content ‘manufactured stone’

Earlier this year there was a significant (around 20 cases) Legionnaires’ disease outbreak associated with a cooling tower on the roof of a 5-star hotel Cooling towers can have the potential to spread aerosol several hundred metres from the source, which in a built-up area

Work Related Stress (WRS)

Planned Preventative Maintenance (PPM)

Explosion caused by leaking LPG

Raising awareness of the need to prevent injury to members of the public from accessing large commercial waste and recycling bins

This year the national priority covers 2 aspects of linked work, the continued awareness raising of the work related stress and mental health campaign ‘Working Minds’ with businesses and a new angle of intelligence gathering Awareness raising Work related stress and poor mental health in the workplace has a direct impact on the nation’s workers, businesses, and the economy The numbers of workers suffering from work-related stress, anxiety and depression continues to be high and as co-regulators LA EHOs should continue raising awareness to employers and their workers

PPM of work equipment is essential to the reduction of serious injuries and fatalities in the workplace Maintenance ensures that plant and equipment continues to operate safely and also that it continues to be reliable and productive. Newly published British Standard BS 14200 entitled “Maintenance of machinery” is a “User Standard” which is one intended to inform those who use machinery in how to comply with good practice

Catering establishments Unsafe gas appliance installation/maintenance and unsafe use and storage of LPG cylinders and cartridges

There have been numerous cases where members of the public have gained access to commercial bins for shelter and then been injured or killed when those bins were emptied into collection and compaction vehicles HSE’s Waste & Recycling sector supports the strategic industry initiative to prevent people being injured or killed after entering large commercial bins (typically 660 litres capacity and above)

2 2 M A I N T E N A N C E O F M A C H I N E R Y & W O R K E Q U I P M E N T – B S 1 4 2 0 0

T A R G E T A R E A S F O R T H E E N F O R C I N G A U T H O R I T I E S I N 2 0 2 4 / 2 5 A R E O U T L I N E D A S B E L O W :

Hazard

G U I D A N C E

Occupational deafness

Industrial diseases / occupational lung disease (silicosis)

Industrial diseases / occupational lung disease (cancer)

Industry Sector

Industrial retail/wholesale premises Exposure to excessive noise

Industrial retail/wholesale premises Exposure to respirable crystalline silica

(Retail outlets cutting/shaping their own stone or high silica content ‘manufactured stone’

Industrial retail/wholesale premises Exposure to all welding fume regardless of type or duration may cause cancer. Exposure to be controlled with LEV and or appropriate RPE

Occupational lung disease (asthma)

Manual Handling

Explosion caused by leaking LPG

In-store bakeries and retail craft bakeries where loose flour is used and inhalation exposure to flour dust is likely to frequently occur Tasks where inhalation exposure to flour dust and/or associated enzymes may occur e g tipping ingredients into mixers, bag disposal, weighing and dispensing, mixing, dusting with flour by hand or using a sieve, using flour on dough brakes and roll machines, maintenance activities or workplace cleaning

Warehousing/Distribution Lack of effective management of manual handling risks

Catering establishments Unsafe gas appliance installation/maintenance and unsafe use and storage of LPG cylinders and cartridges

Premises with vulnerable working conditions and where intelligence indicates that risks are not being effectively managed Lack of suitable security measures/procedures Operating where police/licensing authorities advise there are local factors increasing the risk of violence at work e g located in a high crime area, or similar local establishments have been recently targeted as part of a criminal campaign

Fatalities/injuries resulting from being struck by vehicles

Industrial retail/wholesale premises Poorly managed workplace transport/ work at height/cutting machinery /lifting equipment

Work at height in Warehousing/Distribution

Violence at work

Falls from height

2 3

T R A N S P O R T H U B

The House of Commons Public Bill Committee is calling for those with relevant expertise and experience or a special interest in the Automated Vehicles Bill [HL], which is currently passing through Parliament, to submit written evidence

The Public Bill Committee will scrutinise the Bill line by line The first sitting of the Public Bill Committee is expected to be on 19 March and the Committee is scheduled to report by 18 April 2024

About the Bill

The Bill was announced in the 2023 King’s Speech The announcement said that the Bill would enable the safe deployment of selfdriving vehicles and by doing so “unlock a transport revolution” by providing certainty and confidence and attracting investment to the UK motor industry The accompanying notes to the speech said the Bill would:

Set the threshold for self-driving vehicles in law

Hold companies firmly accountable once vehicles are on roads

Investigate and learn from incidents.

Digitalise Traffic Regulation Orders (TROs) to create a central digital map of all roads

Create new organisations responsible for self-driving

Protect users from being unfairly held accountable

Clamp down on misleading marketing of ‘self-driving’ vehicles

The Bill has 100 clauses divided into seven parts, and six schedules.

The Bill generally extends and applies to England, Wales and Scotland, with the exception of Clause 54(2) and Clause 93 which do not extend to Scotland

Clause 54(2) creates a new offence of causing danger to road-users resulting in an automated vehicle killing or seriously injuring someone This clause would extend and apply in England and Wales

Clause 93, which requires local authorities to submit information on TROs, extends to England and Wales, but because local government is a devolved matter it would only have practical application in England

The Bill also makes two consequential amendments extending to Northern Ireland, but otherwise does not extend beyond Great Britain

Part 7 of the Bill would come into force on the day the Bill is passed. This part deals with general matters such as application, extent and the making of regulations The rest of the Bill would come into force upon the Secretary of State for Transport making regulations by statutory instrument.

Anyone wanting to submit written evidence is advised to do so as soon as possible Submissions should be sent to scrutiny@parliament.uk.

2 4 A u t o m a t e d V e h i c l e s B i l l : c a l l f o r e v i d e n c e

T R A N S P O R T H U B

This consultation is seeking views on proposed changes to the regulations on electrically assisted pedal cycles (EAPCs or ecycles) The government is proposing two changes to the regulations:

To amend the legal definition of EAPCs, so that the maximum continuous power output of the electric motor is 500 watts instead of 250 watts

To allow ‘twist and go’ EAPCs to have throttle assistance up to 15.5mph (25km/h) without the need for type approval.

The Electrically Assisted Pedal Cycles Regulations 1983 (as amended in 2015) set out the requirements an EAPC has to meet so as to fall outside the definition of motor vehicle contained within the Road Traffic Acts and to be treated as a cycle The requirements are that the:

Cycle must be fitted with pedals that are capable of propelling it.

Maximum continuous rated power of the electric motor must not exceed 250 watts

Electrical assistance must cut off when the vehicle reaches 15.5mph (25km/h).

An EAPC that complies with the above is not considered to be a motor vehicle within the meaning of the Road Traffic Regulation Act 1984 and the Road Traffic Act 1988.

EAPCs, therefore, are not required to be registered or subject to vehicle excise duty (road tax) and do not have to be insured as a motor vehicle.

The Road Traffic Act 1988, however, sets out that EAPCs must not be ridden by anyone under the age of 14 years

EAPCs are treated the same as pedal cycles in terms of what infrastructure they may use and can, therefore, use cycle lanes, tracks and other cycle facilities

The current regulations apply to Great Britain.

The consultation asks:

For views on the proposed changes About any benefits or risks the changes may present.

The consultation period ends on 25 April 2024

2 5 S M A R T E R R E G U L A T I O N : P R O P O S E D C H A N G E S T O L E G I S L A T I O N F O R E L E C T R I C A L L Y A S S I S T E D P E D A L C Y C L E S

L E G I S L A T I O N

HSE has updated its guidance for responsible persons on when and how to report incidents under RIDDOR (the Reporting of Injuries, Diseases and Dangerous Occurrences Regulations) This is important change for our members as additional data will be required when carrying out an investigation as all sections need to be completed on the RIDDOR site There are no changes to legal requirements, but the guidance will help you understand how and when you should submit a report under RIDDOR

The improvements are based on feedback gathered from our members and other stakeholders who felt the guidance was unclear in some places, particularly around reporting occupational diseases and dangerous occurrences. Stakeholders also felt the online reporting forms were hard to follow and would benefit from improved guidance

Main changes to the guidance include: More direct links to guidance on the various types of reportable incidents to help you decide whether a report is required, improved guidance on who should and should not report under RIDDOR · improved guidance on what is meant by a ‘work-related’ accident, information on when an occupational disease is not reportable, increased clarity on when an ‘over-7-day’ absence should be reported.

Main changes to the online forms include: The questions have been reordered to bring questions about the ‘severity of injuries’ to the beginning This will help you quickly decide if your incident is reportable, pop-up messages will now redirect you if the incident is not reportable, guidance has been improved throughout the forms to make them easier to use, injured or affected people now have an increased number of options when completing the gender field.

To further determine if RIDDOR is reportable please also refer to the BFFF assured guidance on our website

https://bfff.co.uk/wpcontent/uploads/2023/01/R IDDOR-Version-2 pdf

2 6 B F F F M E M B E R S N E E D T O B E A W A R E O F N E W C H A N G E S F O R R I D D O R R E P O R T I N G

BFFF were the first trade association to join the original Home Authority Scheme in 2004. We are also members of a Primary Authority user group, led by the Government Department for Business, Energy & Industrial Strategy (BEIS). This is to increase member engagement in the Primary Authority Scheme that is available to all BFFF members.

Primary Authority is a means for businesses to receive assured and tailored advice on meeting regulations such as environmental health, trading standards or fire safety through a single point of contact. This ensures start-ups get it right at the outset and enables all businesses to invest with confidence in products, practices and procedures, knowing that the resources they devote to compliance are well spent.

Primary Authority is based on legal partnerships between businesses and individual local authorities and / or fire and rescue authorities. Businesses can set up their own partnership or join through BFFF as part of our existing partnership.

What is Primary Authority?

Primary Authority is a government-run scheme that helps protect businesses from unnecessary legal challenges It helps to ensure businesses operating in the food sector are doing so safely and legally.

Once you have Primary Authority advice signed off within a registered partnership, if you are following the assured advice issued by the PA, and it covers the issue arising, your operating practices can’t be challenged by any other enforcement authority

Direct partnerships:

A direct partnership with a Primary Authority can look at your specific policies or operating procedures on site and assure themselves that you are operating within the law. In effect they endorse your operations and policies. Given their legal status as a Primary Authority partner this advice then has legal backing for your business. Under a direct partnership you pay an annual fee for 8 hours of support. (Extra hours can of course be purchased)

Co-ordinated partnerships: BFFF operates a co-ordinated Primary Authority scheme, and we have an expanding range of sector-wide advice. This partnership operates in the same way as the direct partnership but you don’t need to deal with the Primary Authority directly, BFFF does that for you. You can also rely on this advice as it also has the legal backing for your business This partnership is free of charge, however, advice is industry level and not specific to your organisation, however, this does not reduce the validity of the advice issued

Any BFFF member can benefit from advice, whether it is tailored to your business or sectoral advice put in place by BFFF.

If you would like more information about joining the scheme, please contact simonbrentnall@bfff.co.uk

E

2 7

N

W S A N D E V E N

P R I M A R Y A U T H O R I T Y

KEEP IT SAFE British Frozen Food Federation Warwick House, Unit 7 Long Bennington Business Park Main Road, Long Bennington NEWARK, Nottinghamshire NG23 5JR Tel: 01400 283090 www bfff co uk

Author – Jonathan Dixson – Primary Authority Manager – Essex County Fire and Rescue Service

Author – Jonathan Dixson – Primary Authority Manager – Essex County Fire and Rescue Service