With 100+ years in the packaging industry, 2,000+ packaging professionals and a global network of suppliers and warehouses, we provide amazing packaging to customers just like you.

Our Agenda:

• Introduction to Berlin Packaging

• Quality Partnerships

• RFP Supply Plan Overview

• Demand Planning

• Next Steps

• Seamless Transition Plan

• Billions of packaging components sold annually

• 50,000+ available SKU’s available

• 1,700 suppliers worldwide

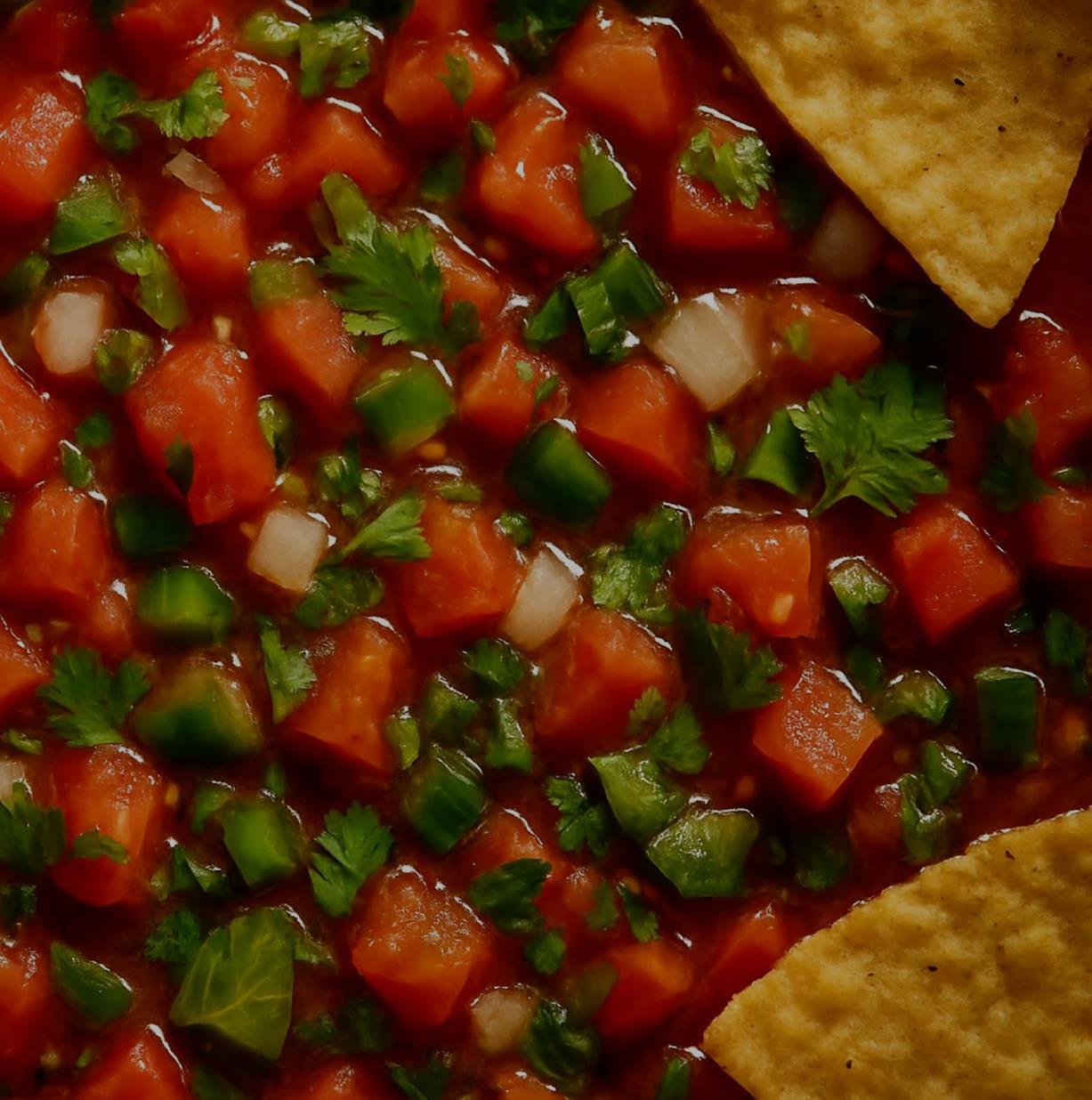

• We supply packaging of all types and are experts across all markets

Our mission is to improve our customers’ net income through packaging products and services.

We strive to have a positive impact on your business. Over the last 3 years, our customers’ net income increased $200+ million as a direct result of working with Berlin Packaging.

We provide the packaging you need, when you need it. We serve:

• Start-ups

• Emerging brands

• Fortune 500 companies

• 150+ sales and warehouse locations

• 2,000+ staff members globally

• 1,700+ suppliers worldwide

• Design & innovation centers throughout North America and Europe

Best Elements Of Manufacturers

Value-Added Specialty Services Distribution & Logistics

• We have the best elements of a manufacturer.

• We perform distribution and logistics services.

• We boost your income with our value-added specialty services.

• Strategic design & innovation

• Proactive quality management

• Sustainability solutions

• Global sourcing

• Warehousing & logistics

• Logility & demand planning

• Customer portal growth

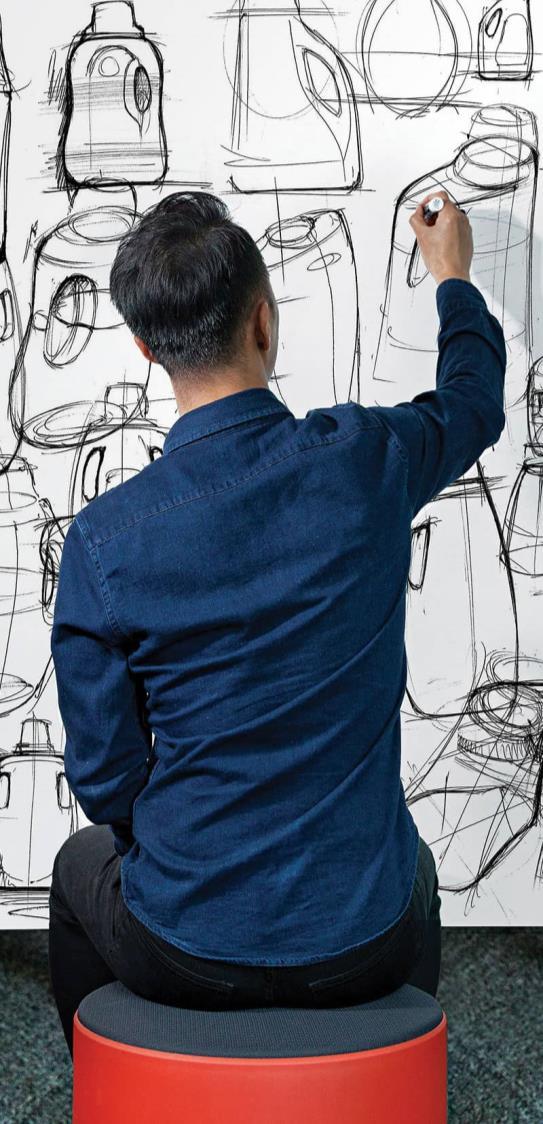

Our Studio One Eleven design division provides world-class package and product design:

• Market research and consumer insights

• Brand strategy and visual branding design

• Structural packaging design and development

• Engineering and design-formanufacturing (DFM)

• Custom tooling and manufacturing integration

Market-level Data Analyses

Competitive Landscape Evaluation

User Ethnographic Studies

Account Line Reviews

Regulatory Reviews & Guidance

SKU Rationalization

Sustainability Planning

Intellectual Property Guidance

Brand Naming Strategy

Logotypes & Identities

Communication Structures

User Ethnographic Studies

Production Artwork

Rapid Visualizations

Rapid Prototyping

Mechanical Engineering

3D Modeling

Rapid Visualizations

Rapid Prototyping

Planagram Simulations

Low-Volume Production

Design forManufacturing

Filling Plant/ Equipment Audit

Product Lifecycle Planning

Pallet / Shipping Optimization

Complex Program Management

PlantQualification & Selection

Risk Mitigation Planning

ISO-Certified Processes

FirstArticle Inspections

Amazon APASS Reviews Full Spectrum

Proactive Quality Programming

• Packaging Expertise across all substrates

• End-to-End Project Management from start to finish

• Dedicated Quality Team providing technical support, customer training, and manufacturer management

• Warehouse ownership

• Best-in-Class Demand and Supply Planning

• True Partnerships with continuous focus on improving customers’ bottom line

• Transitional Experts

• A dedicated Quality team with more than 100 years of combined experience

• ISO certified, clearly defined proactive and reactive quality processes

• Multiple on-site laboratories with diverse testing capabilities such as microscoping, stability testing, drop testing, out of round testing, vacuum leak testing, and much more

Focused on their P&L Manufacturer approach

Focused on your P&L

Brand Owner approach

Focused on your P&L

What

•Over 120+ years of Quality Management experience in North America.

•Standalone Quality division that’s 100% focused on quality.

•Hands-on industry knowledge.

•Networked with manufacturers.

•Your advocate.

• 24 Trained Quality Managers / Technicians in Europe and Asia

• Social / Ethical / cGMP / QMS Audits completed at initial setup

• Periodic Auditing for continued Compliance

• For Cause Visits / Audits when required for issues

• Standard Inspection Protocols / Quality Plans for every Plastic or Glass item

•Factory Inspections

•Social Accountability

•Sourcing

•Project Management

•On-Site Quality Assurance

Technical Support

Specification Review.

Documentation and Sampling.

Line Evaluation.

Regulatory Coaching.

Customer Training

Overall Quality Program.

Inspecting and Sampling Plans.

Manufacturing Process Advice.

Manufacturer Management

Certifications and Inspections.

cGMP Auditing.

Performance Scorecards.

We evaluate all our manufacturer partners monthly.

✓Product quality.

✓On-time delivery.

✓Service levels.

On-Site Laboratory

Video Microscope Metrology. Leak Testing. Accelerated Aging. ISTA Drop Testing.

Container Vibration Testing.

Induction-Seal Evaluation.

Customer Bulletins

Relevant News You Can Use.

White Papers

Business Insights on Quality.

Within

Within

Within

ISO 9001:2015 Certification

Customer-advocate Quality Policy and Objectives

• 24-48 Hour Lead Times

• Near Site Warehousing at both Hormel locations

• The ability to Ship Mixed Truckloads

• 60-Day Payment Terms

• Local Quality and Technical Support

• Demand & Supply Planning Partnership

Inventory occupies a lot of cash and costs a lot to maintain. A more efficient supply chain will minimize your inventory investment. With 130+ warehousing locations and 6 million+ square feet of warehouse space, we’re in the inventory business so you don’t have to be.

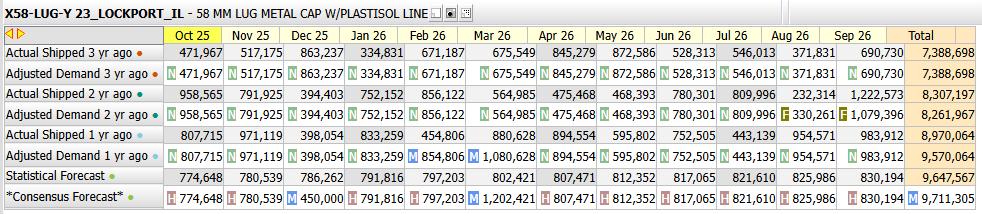

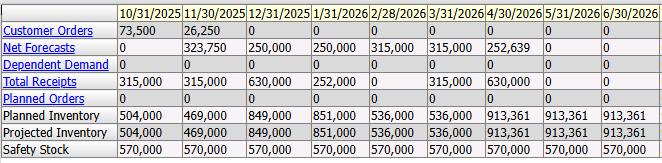

• Best-in-class forecasting coupled with monthly collaboration for mutually agreed-upon plans

• Dynamic safety stock levels to support your growth strategies

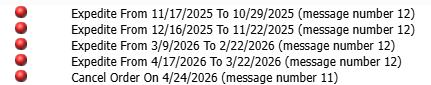

• Proactive + Responsive planning -> fewer stockouts & less aged ware for all

Takes Aligned Demand Forecast Passes through Inventory “Rules” Generates Buy Signals & Alerts to Manage Inventory

Berlin & customers collaborate (at least) monthly - Bringing statistical data & business intel - Leaving with aligned plans to support the customer’s growth strategies

Plannedendofyear slowdownand holidayweek shutdown. BerlintoadjustDec forecastandhold incominginventorywith supplier.

Daily updated plans assess incoming inventory vs…

• Agreed-Upon Consensus Forecast

• MTD Released Shipments

• Vendor lead times and MOQs

• Dynamic Safety Stock Targets

• Agreement that a move to a forecast -based stocking plan makes sense for your business.

• Alignment on which items should be a part of a stocking plan.

• Collaborate on forward-looking demand forecasts for identified items.

• Agree on safety stock levels.

• Set up a meeting cadence to review your demand plans.

• Kick Off Meeting to align on project goals and timelines

• Verify Details of current products and manufacturing requirements

• Berlin Technical Support visit to Hormel’s manufacturing facilities.

• Begin Line Trials assisted by Berlin’s technical support team

• Work with demand planning to Ramp Up Inventory for production.